Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this

manual for the life of the equi pment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

OPERATOR’S MANUAL

Medium Duty Counterline

Griddle Models MDG-24, MDG-36

(shown), and MDG-48

Thermostatic Griddle Models

MDGT-24, MDGT-36, and MDGT-48

Charbroiler Models MDC-24,

MDC-36, and MDG-48

Lava-Rock Models MDCL-24,

MDCL-36 (shown), and MDCL-48

Open Top Models MDO-12,

MDO-24, and MDO-36 (shown)

! WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

(800) 348-2558 or (919) 552-9161 • FAX (800) 348-2558 or (919) 552-9798

MANUAL 1178822 REV 3

$18.00

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

MEDIUM DUTY COUNTERLINE

MANUAL SECTION MD

Page 2

MEDIUM DUTY COUNTERLINE

SAFETY PRECAUTIONS

Before installing a nd opera ting this equipm ent, be sure e ver yone invo lved in its operat ion is full y trained and

aware of precautions. Accidents and problems can be caused by failure to follow fundamental rules and

precautions.

The following s ymbols, found throughout this manual, alert you to potent ially dangerous conditions to the

operator, service personnel, or to the equipment.

! DANGER

! WARNING

! CAUTION

NOTICE

This symbol warns of immediate hazards that will result in severe injury or

death.

This symbol refers to a potential hazard or unsafe practic e that could result in

injury or death.

This symbol refers to a potential hazard or unsafe practic e that could result in

injury, product damage, or property damage.

This symbol refers to information that needs special attention or must be fully

understood, even though not dangerous.

! WARNING

FIRE HAZARD

FOR YOUR SAFETY

Do not store or use gas oline or other flamm able vapors and liq uids in the vicinity of this or an y other

appliance.

Keep area around appliances free and clear of combustibles.

Purchaser of equipment m ust post in a prom inent location, detailed instructi ons to be follo wed in the

event the operator smells gas. Obtain the instructions from the local gas supplier.

! WARNING

Asphyxiation can result from improper ventilation. Do not obstruct the flow of combustion and

ventilation air to and from your cooking equipment.

NOTICE

Be sure this Operator’s Man ual and important papers ar e given to the proper authorit y to retain for

future reference.

PAGE 2OPERATOR’S MANUAL 1178822 REV 3

Page 3

MEDIUM DUTY COUNTERLINE TABLE OF CONTENTS

Congratulations! You have purchased one of the finest pieces of commercial cooking equipment on the

market.

You will find that your new equipm ent, like all South bend equipment, has been desig ned and m anufactured

to meet the toughest standards in the indust ry. Each piece of So uthbend equipm ent is carefully engine ered

and designs are verified through laboratory tests and field installations. With proper care and field

maintenance, you will experience years of reliable, trouble-free operation. For best results, read this

manual carefully.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Table of Contents

Specifications..........................................................................................................................4

Installation...............................................................................................................................9

Operation ..............................................................................................................................12

Cleaning................................................................................................................................14

Adjustments ..........................................................................................................................16

Troubleshooting ....................................................................................................................18

Parts......................................................................................................................................21

Read these instructions carefully before attempting installation. Installation and initial startup should be

performed by a qualified installer. Unless the installation instructions for this product are followed by a

qualified service technic ian (a person experienced in and knowledgeab le with the installati on of commer cial

gas an/or electric cooking equipm ent) then the terms and conditions on the Ma nufacturer ’s Lim ited W arranty

will be rendered void and no warranty of any kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, write to:

Technical Service Department

Southbend

1100 Old Honeycutt Road

Fuquay-Varina, North Carolina 27526 USA

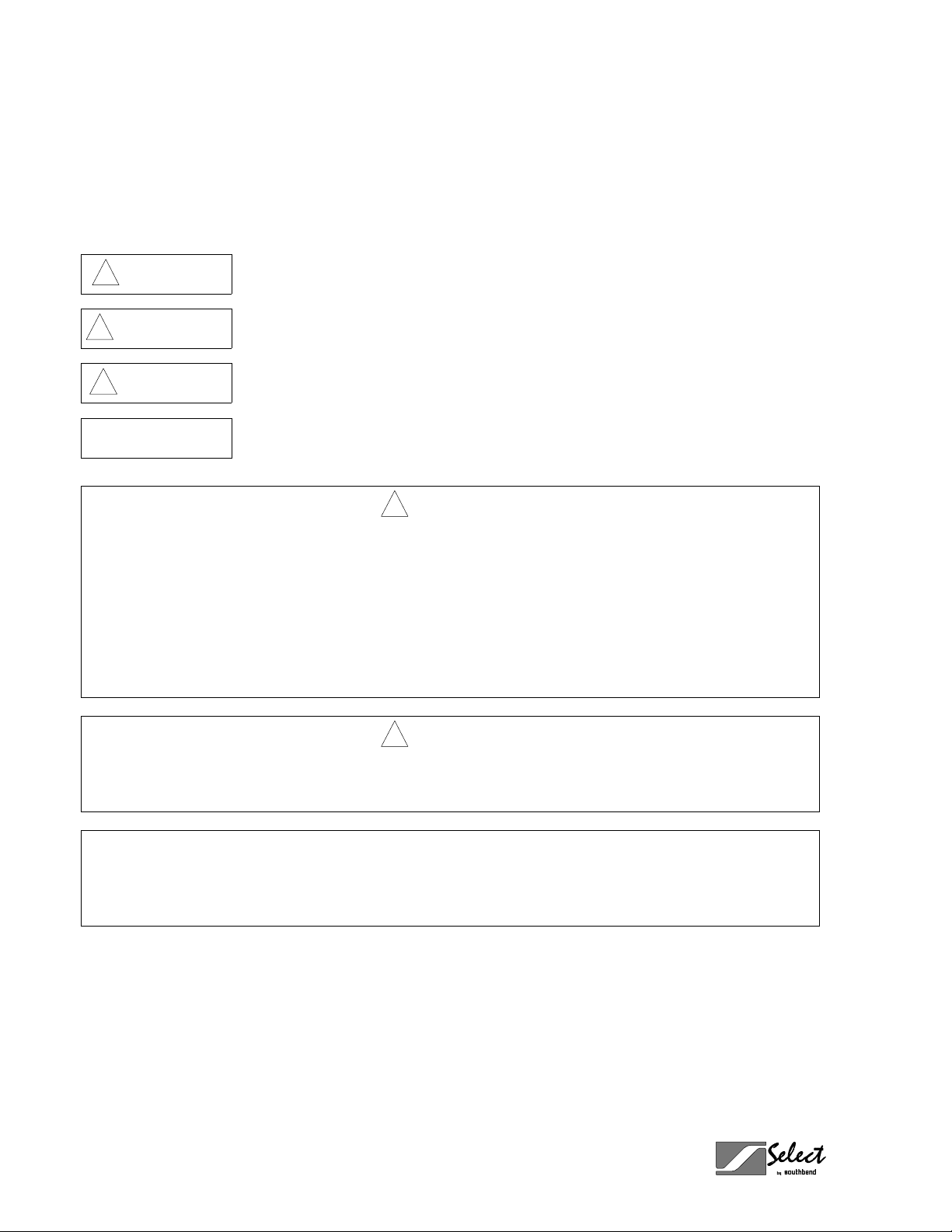

The serial plate is located on the interior side of the valve panel, as shown below:

Figure 1

Serial plate is located behind this panel.

OPERATOR’S MANUAL 1178822 REV 3PAGE 3

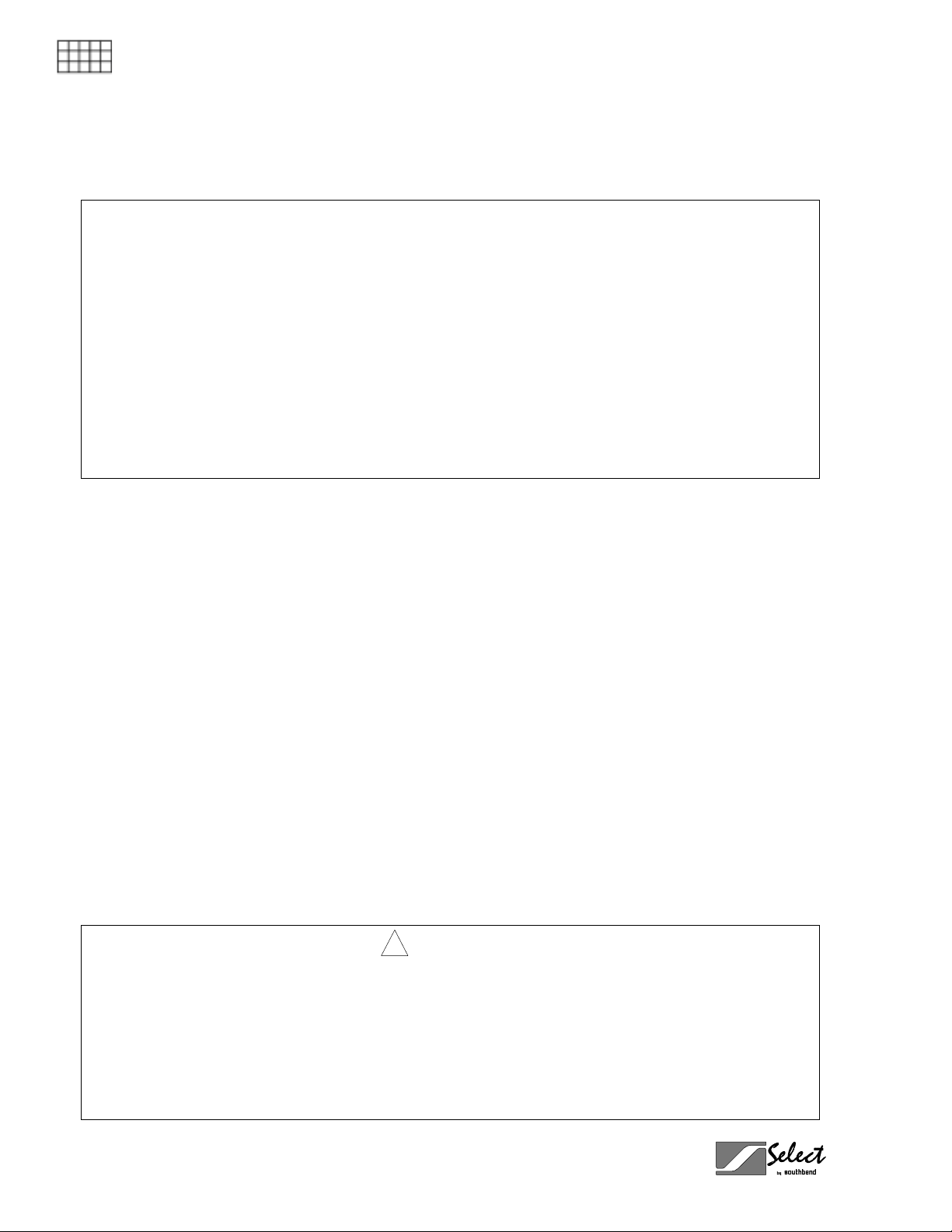

Page 4

SPECIFICATIONS MEDIUM DUTY COUNTERLINE

SPECIFICATIONS

SPECIFICATIONS

NOTICE

Installation must comply with National Fuel Gas Code, ANSI Z223.1, Natura l Gas Installation Code,

CAN/CGA-B149.1, or the Propane Installation Code, CAN/CGA-B149.2, as applicable.

Local codes regarding install ation var y greatly from one ar ea to anoth er. The Nat ional Fir e Protect ion

Association, Inc. states in its NFPA 96 latest edition that local codes are the “authority having

jurisdiction” when it com es to installation req uirements for equ ipment. Theref ore, installations shou ld

comply with all local codes.

Southbend reserves the right to change specifications and product design without notice. Such

revisions do not e ntitle the bu yer to c orres ponding c hanges , add itions , or r eplacements for previo usl y

purchased equipment.

This product is intended for commercial use only, not for household use.

GAS SUPPLY

The Serial Plate is located on the inter ior side of the valve pa nel (see Figure 1 on page 3) . It indicates the

type of gas the unit is equipped to burn. All South bend equipment is adjus ted at the factory. Chec k type of

gas on serial plate.

These models are design-cer tified for operat ion on natural or propan e gases. The un it is shipp ed configured

for natural gas. A k it for c onversion to using pro pane gas is inclu ded (see i nstructions in k it or page 9 of this

manual).

This appliance should be connected ONLY to the type of gas for which it is configured.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas

required for satisf actor y perform anc e. Fluctua tions of m ore than 25% on nat ural gas or 10% on propa ne g as

will create problems and affect burner operating characteristics. A 1/8" pressure tap is located on the

manifold to measure the manifold pressure.

An adequate gas supply li ne to the unit should be no smaller than the inside diameter of the p ipe from the

unit to which it is connected.

Purge the supply line to clean out dust, dirt, or other foreign matter before connecting the line to the unit.

All pipe joints and c onnections must be tested t horoughl y for gas leak s. Use only soap y water for testing on

all gases. NEVER use an open flame to check f or gas leaks . All c onnec tions m us t be chec ked f or leak s af ter

the unit has been put into operation. Test pressure should not exceed 14" W.C.

! CAUTION

THIS APPLIANCE AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE DISCONNECTED FROM

THE GAS SUPPLY PIPING SYST EM DURING ANY PRESSURE TESTING OF THAT SYSTEM AT

TEST PRESSURES IN EXCESS OF 1/2 PSIG (3.45 kPa).

THIS APPLIANCE MUST BE ISOLATED FRO M THE GAS SU PPLY PI PING SYST EM BY C LOSING

ITS INDIVIDUAL MANUAL SHUTOFF V ALVE DURING ANY PRESSURE TESTING OF THE GA S

SUPPLY PIPING SYSTEM AT TEST PRESSURES EQUAL TO OR LESS THAN 1/2 PSIG (3.45

kPa).

PAGE 4OPERATOR’S MANUAL 1178822 REV 3

Page 5

MEDIUM DUTY COUNTERLINE SPECIFICATIONS

CLEARANCES

! WARNING

There must be adequ ate clear ance be twee n units and a djacent constr uction. C lear ance m ust als o be

provided for servicing and for operation.

Minimum Clearances from COMBUSTABLE construction:

Griddle Models Open Top Models

Sides 4" 4"

Back 4" 4"

Bottom 4" 4"

Minimum Clearances from NON-COMBUSTABLE construction:

Griddle Models Charbroiler Models Open Top Models

Sides 0" 0" 0"

Back 0" 0" 0"

Bottom 4" 4" 4"

SPECIFICATIONS

VENTILATION

! WARNING

Improper ventilation can result in personal injur y or death. Ventilation which f ails to properly rem ove

flue products can cause headaches, drowsiness, nausea, or could result in death.

All units must be installed in s uch a manner that the flow of com bustion and ventilation air are not

obstructed. Provis ions for adequ ate air suppl y must be pro vided. Do not obs truct the f ront of the unit

at the top by the control panel as combustion air enters through these areas.

NOTICE

Proper ventilation is t he owner’s responsibility. An y problem due to improper venti lation will not be

covered by the warranty.

All units must be installed in such a manner that the flow of combustion and ventilation air are not obstructed.

Provisions for an adequate air supply must be provided. Do not obstruct the front or rear of the unit, as

combustion air enters thro ugh th is area. Be sur e to i nspect a nd cl ean the vent ilation system accor ding to t he

ventilation equipment manufacturer’s instructions.

In case of unsatisf actory performance on an y appliance, check the applianc e with the hood exhaust fan in

the “OFF” position. Do th is only long enough to check equipment performance. T hen turn the fan back on

and let it run to remove any exhaust that may have accumulated during the test.

OPERATOR’S MANUAL 1178822 REV 3PAGE 5

Page 6

SPECIFICATIONS MEDIUM DUTY COUNTERLINE

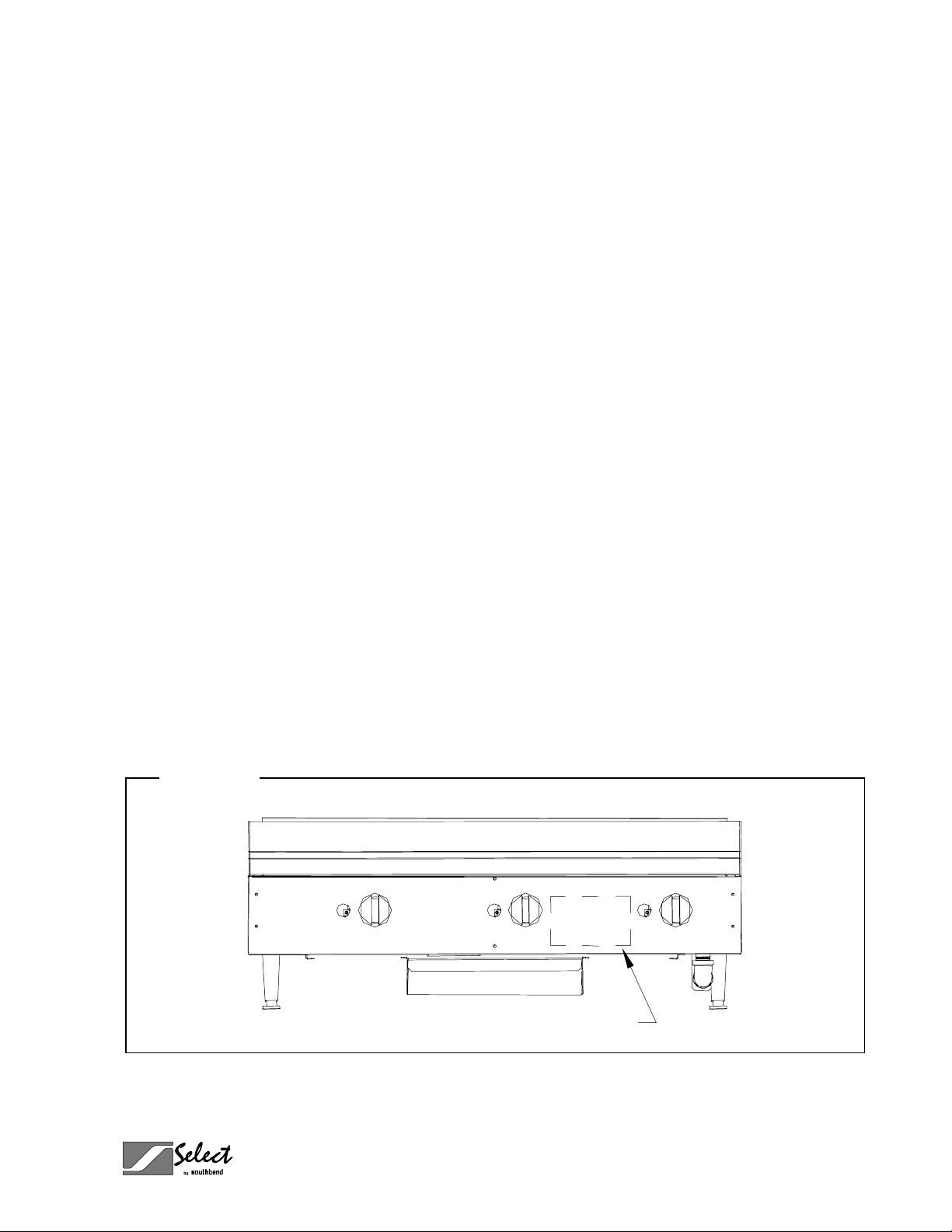

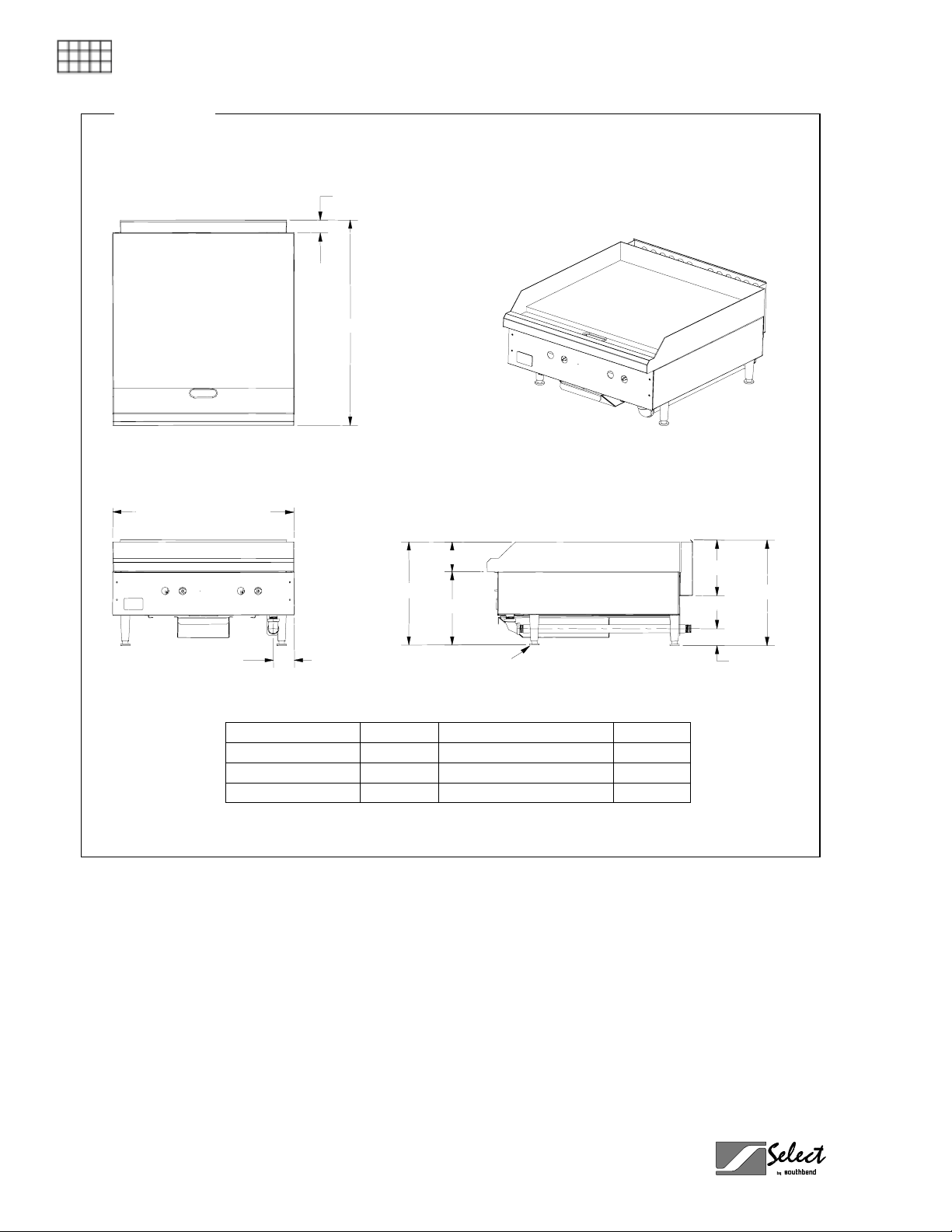

Figure 2

DIMENSIONS OF GRIDDLE & THERMOSTATIC-GRIDDLE MODELS

SPECIFICATIONS

1.7"

27.2"

TOP VIEW

Width (see table below)

3.9"

13.7"

9.8"

7.4"

14.0"

FRONT VIEW

2.8"

4" Adjustable Legs

SIDE VIEW

Model Width Number and Size of Burners Total BTU

MDG-24 & MDGT-24 24" 2 @ 20,000 40,000

MDG-36 & MDGT-36 36" 3 @ 20,000 60,000

MDG-48 & MDGT-48 48" 4 @ 20,000 80,000

2.2"

PAGE 6OPERATOR’S MANUAL 1178822 REV 3

Page 7

MEDIUM DUTY COUNTERLINE SPECIFICATIONS

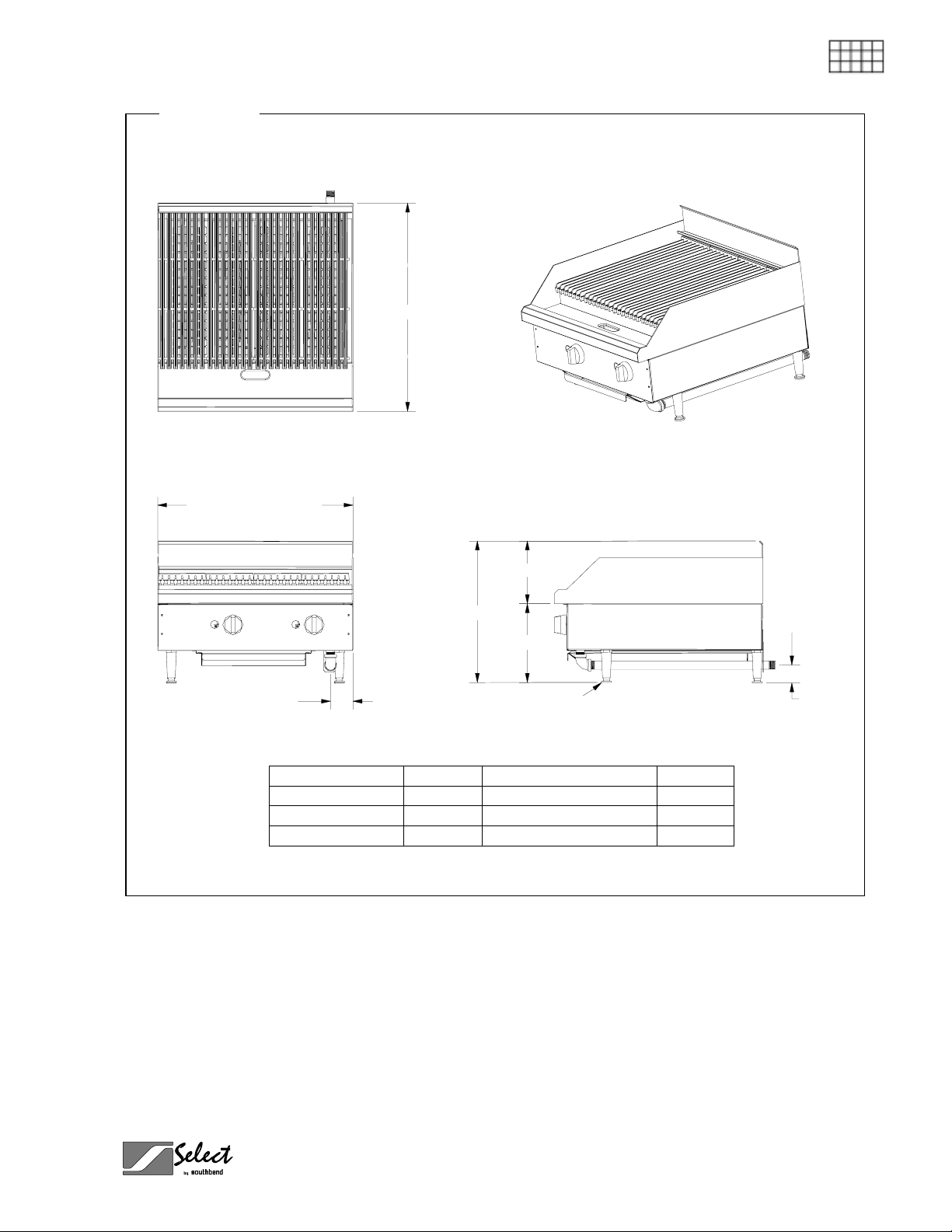

Figure 3

DIMENSIONS OF CHARBROILER MODELS

25.7"

TOP VIEW

Width (see table below)

SPECIFICATIONS

FRONT VIEW

7.8"

17.5"

9.7"

2.8"

4" Adjustable Legs

SIDE VIEW

Model Width Number and Size of Burners Total BTU

MDC-24 & MDCL-24 24" 2 @ 20,000 40,000

MDC-36 & MDCL-36 36" 3 @ 20,000 60,000

MDC-48 & MDCL-48 48" 4 @ 20,000 80,000

2.2"

OPERATOR’S MANUAL 1178822 REV 3PAGE 7

Page 8

SPECIFICATIONS MEDIUM DUTY COUNTERLINE

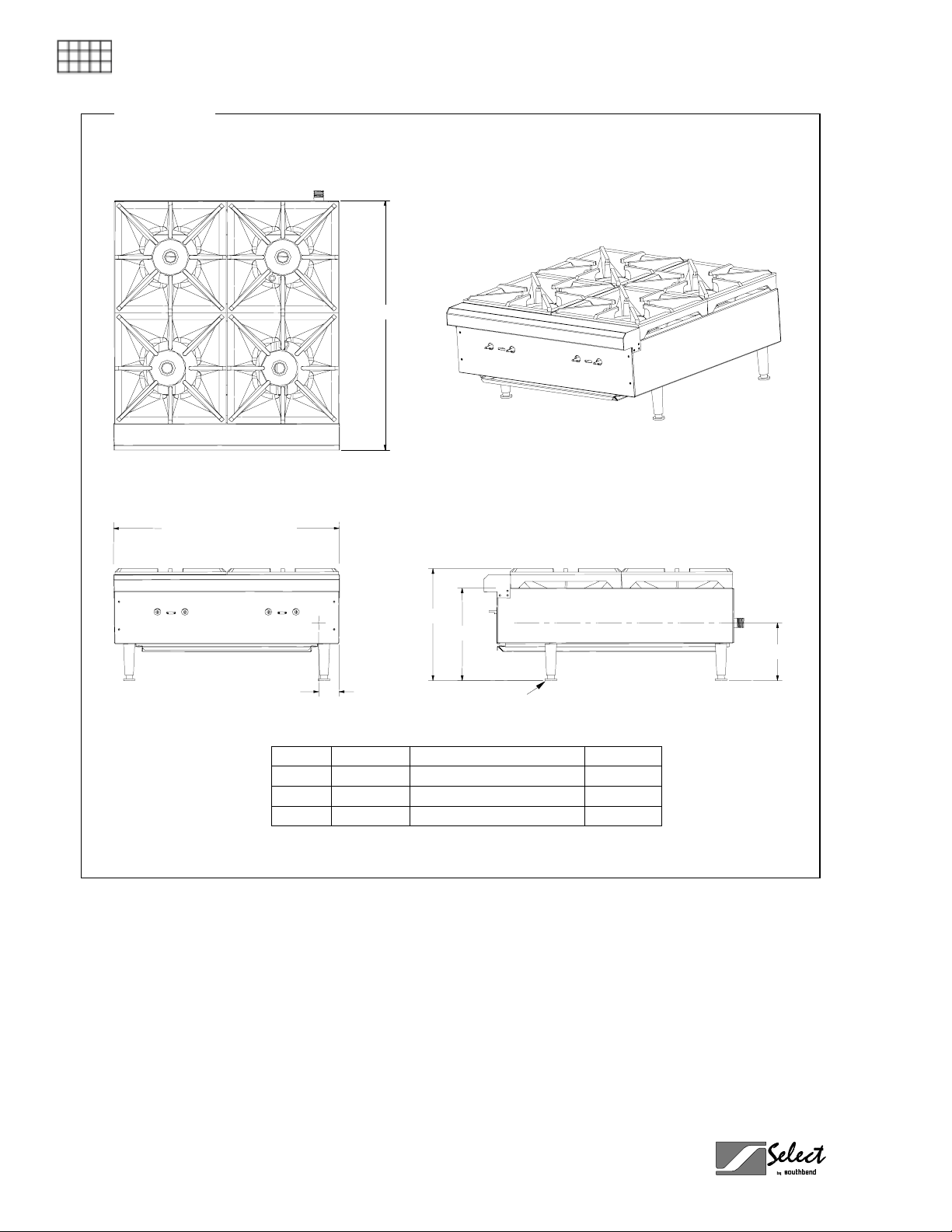

Figure 4

DIMENSIONS OF OPEN TOP MODELS

SPECIFICATIONS

27.3"

TOP VIEW

Width (see table below)

FRONT VIEW

MDO-12 12" 2 @ 20,000 40,000

MDO-24 24" 4 @ 20,000 80,000

MDO-36 36" 6 @ 20,000 120,000

12.2"

10.1"

2.2"

Model Width Number and Size of Burners Total BTU

4" Adjustable Legs

SIDE VIEW

6.3"

PAGE 8OPERATOR’S MANUAL 1178822 REV 3

Page 9

MEDIUM DUTY COUNTERLINE INSTALLATION

INSTALLATION

NOTICE

Installation must comply with National Fuel Gas Code, ANSI Z223.1, Natura l Gas Installation Code,

CAN/CGA-B149.1, or the Propane Installation Code, CAN/CGA-B149.2, as applicab le.

These installation procedures must be followed by qualified personnel or warranty will be void.

Local codes regarding install ation var y greatly from one ar ea to anoth er. The Nat ional F ire Protect ion

Association, Inc. states in its NFPA 96 latest edition that local codes are the “authority having

jurisdiction” when it com es to installation req uirements for equ ipment. Theref ore, installations shou ld

comply with all local codes.

Step 1: Unpack

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

INSTALLATION

All containers shou ld be examined for dam age before and during unlo ading. The freight car rier has

assumed responsibility for its safe transit and delivery. If damaged equipment is received, either

apparent or concealed, a claim must be made with the delivering carrier.

Apparent damage or l oss m us t be noted on the f reight b ill at the t im e of deliver y. T he f reight bi ll m ust

then be signed by the c arrier representative (Dr iver). If the bill is not s igned, the carrier may r efuse

the claim. The carrier can supply the necessary forms.

A request for insp ection must be m ade to the carrier within 15 da ys if there is concea led damage or

loss that is not apparent until after the equipment is uncrated. The carrier should arrange an

inspection. Be certain to hold all contents plus all packing material.

1. Uncrate carefully. Report any hidden damage to the freight carrier IMMEDIATELY.

2. Do not remove any tags or labels until unit is installed and working properly.

Step 2: Covert Unit to Use Propane Gas (if necessary)

Each unit is shipped equ ipped with fixed orifice hoods appropriate for use with natural gas. If propane gas

will be used, convert the unit for use with propane gas by the following procedure:

1. Remove the front panel by removing the knobs and screws on the front.

2. For charbroiler and open top m odels, rem ove the grates and bur ners to acces s the orifices fr om above.

For griddle models, slide t he burner toward the rear of the unit to access the orifices (see diagram on

page 22), OR remove the griddle plate to access the orifices by removing two nuts at the rear of the unit.

3. Remove the natural gas orifices and install the furnished propane orifices.

4. Re-install the burners.

5. Re-install the front panel.

6. Remove the hex- threade d p lug from the pr essur e regula tor. I nsid e is a rem ovabl e ins ert. Pull the ins ert

out, turn it around, an d put it back in so th at the end with the l etters “LP” is now fac ing you. Re-attach

the hex-threaded plug. The pressure regulator is now set for 10" (25.4 cm) water column.

7. Check the pressure.

OPERATOR’S MANUAL 1178822 REV 3PAGE 9

Page 10

INSTALLATION MEDIUM DUTY COUNTERLINE

Provided orific es are size #45 for natural gas and #55 for propane gas. For spec ial gas mixtures, and for

altitudes above 2,000 feet, consult factory for appropriate orifice sizes.

Step 3: Connect Gas Supply

All units are shipped from the factory equipped for use with natural gas. If the unit is to be used with propane

gas, the orifices must be replaced and the pressure regulator converted (see Step 2 on previous page).

If this equipment is being installed at over 2, 000 feet altitude and that inform ation was not specifie d when

ordered, contact the appropriate authorized Southbend Service Representative or the Southbend Service

Department. Failure to install with proper orifice sizing will result in poor performance and may void the

warranty.

The serial plate is located interior side of the valve panel (see Fi gure 1 on page 3). It indicates the type of

gas the unit is equipped to burn. All Southb end equipment is adjus ted at the factory. Check type of gas on

INSTALLATION

serial plate.

These models are desig n- cer tif ied f or operat ion on natural or propane gases. For nat ur al gas, the convertible

regulator is set to deliver a 4" W.C. pressure to the manifold. For propane gas, it is set to deliver 10" W.C.

If applicable, the ven t line from the gas appliance pressure regulator shall be installed to the outdoors in

accordance with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code, CAN/CGAB149.2, as applicable.

This appliance should be connected ONLY to the type of gas for which it is equipped.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas

required for satisf actor y perform anc e. Fluctua tions of m ore than 25% on nat ural gas or 10% on propa ne g as

will create problems and affect burner operating characteristics. A 1/8" pressure tap is located on the

manifold to measure pressure.

An adequate gas supp l y li ne t o the u nit s hou ld be n o s maller than the I.D. of the pipe from the unit to which it

is connected.

Purge the supply line to clean out dust, dirt, or other foreign matter before connecting the line to the unit.

Use pipe joint compound that is suitable for use with LP gas on all threaded connections.

! CAUTION

ALL PIPE JOINTS AND CONNECTIONS MUST BE TESTED THOROUGHLY FOR GAS LEAKS.

USE ONLY SOAPY W ATER FOR TESTING O N ALL GASES. NEVER USE AN O PEN FLAME T O

CHECK FOR GAS LEAK S. ALL CONNECTIONS MUST BE CHEC KED FOR LEAKS AFTER T HE

UNIT HAS BEEN PUT INTO OPERATION. TEST PRESSURE SHOULD NOT EXCEED 14" W.C.

Step 4: Position Unit for Operation

1. Check that the unit is level. The leng th of eac h l eg is adjus tab le b y scr e wing the bott om portion of the leg

in or out. The unit must be level for proper operation!

2. Check for adequate clearances around the unit (see page 5).

3. Check for adequate ventilation (see page 5).

PAGE 10 OPERATOR’S MANUAL 1178822 REV 3

Page 11

MEDIUM DUTY COUNTERLINE INSTALLATION

Step 5: Spread Out Lava-Rock Briquettes (Lava-Rock Charbroilers Only)

This step applies only to the insta llation of lav a-rock char broiler models. Such models are shippe d with the

lava-rock briquettes in bags located between the lava-rock grates and the top cooking grids.

1. Lift out the cooking grids to reach the bags of lava-rock briquettes.

2. For each section, open the b ag of lava-rock br iquettes and spread them eve nly on the lava-rock grate.

The briquettes must be spread evenly to avoid “hot spots.” Discard the empty bags.

3. Reposi tio n the cook ing gr ids abo ve the briq uettes.

Step 6: Adjust Air Shutters and Pilot Heights

All units are adjusted at the factory. However, burner air shutters and pilot heig hts should be checked at

installation and adjusted if necessary. On new installations, s tart with the burner of the u nit(s) furthest from

the gas input to the manifold. This will purge the system of air.

4. Turn main gas supply “ON.”

5. Follow the instructions on pages 12 to 13 light the pilots and burners.

6. If the burner f lame is strong but l ifting fr om the burner , loosen t he sc rew o n the air s hutter an d close the

shutter a little at a time until the flame settles back onto the burner.

INSTALLATION

Step 7: Condition Griddle Surface

For griddle and ther mostatic-griddle m odels , th e ne w gr idd le s urface should be c arefully temper ed an d c ared

for in order to avo id possib le damage. T o break in a new gr iddle, f irst wipe it clea n. Nex t, light all t he griddle

burners and turn them to low for one hour. T hen gradua lly bring each gr iddle up to f rying tem perature. Next ,

spread three or four o unces of be ef suet, or as a substi tute, bak ing soda, to s eason it. N ever al low water on

a hot griddle and never wash it with soap and water.

OPERATOR’S MANUAL 1178822 REV 3PAGE 11

Page 12

OPERATION MEDIUM DUTY COUNTERLINE

OPERATION

! DANGER

EXPLOSION HAZARD

Purchaser of equipment m ust post in a prom inent location, detailed instructi ons to be follo wed in the

event the operator smells gas. Obtain the instructions from the local gas supplier.

! CAUTION

To eliminate gas build up which could result in an explosion, in the event of main burner ignition

failure a five minute purge period must be observed prior to re-establishing ignition source.

OPERATION

! CAUTION

Top section pilots, when out, do not interrupt the f low of gas to the burners . Consequently, it is the

responsibilit y of the operator to c heck the ignitio n of the burn ers, imm ediately after burner va lue has

been turned “ON.” Should ignitio n fail after 10 sec onds, turn of f burners, wait 5 minutes, and then tr y

again.

LIGHTING AFTER GAS HAS BEEN SHUT OFF

When turning the main gas supply on after the gas supply has been shut off, do the following:

1. Make sure all of the control valves are in the “OFF” position.

2. Turn on the gas supply.

3. Light the pilots as described below.

GRIDDLE & THERMOSTATIC-GRIDDLE MODELS

Each 12"-wide gri ddle sectio n has a k nob on the f ront pane l that dir ectl y controls the f low of gas, a nd so t he

heat. Turn the knob clockwise to increase the heat; turn it counterclockwise to reduce the heat.

At the end of each day’s use, turn all knobs to the “ OFF ” position. Af ter each period of us e, allo w the gr idd le

surface to cool norm ally. Af ter the gridd le has c ooled, coat t he gridd le surface with a light f ilm of c ooking o il

to protect the surface from moisture.

To light the pilot of a griddle section, do the following:

1. Turn all control knobs to the “OFF” position.

2. Light the p ilot tu be locat ed n ext to eac h bur ner. T he pilot f lame c an be adj usted b y tur ning the scr ew o n

the end of the pilot fitting.

3. Turn burner knobs to “HI” position. The burners shou ld have a 1/2 " to 5/8" steady b lue flame. Adjus t if

necessary.

4. To turn burners off, turn knob to “OFF” position.

PAGE 12 OPERATOR’S MANUAL 1178822 REV 3

Page 13

MEDIUM DUTY COUNTERLINE OPERATION

CHARBROILER MODELS

Each 12"-wide charbr oiler s ection has a knob on the front pa nel that d irectl y controls th e flow of gas, and so

the heat. Turn the knob clockwise to increase the heat; turn it counterclockwise to reduce the heat.

At the end of each day’s use, turn all knobs to the “OFF” position.

To light the pilot of a charbroiler section, do the following:

1. Turn all control knobs to the “OFF” position.

2. Light the p ilot tu be locat ed n ext to eac h bur ner. T he pilot f lame c an be adj usted b y tur ning t he scre w o n

the end of the pilot fitting.

3. Turn burner knobs to “HI” position. The burners sho uld have a 1/2 " to 5/8" steady b lue flame. Adjus t if

necessary.

4. To turn burners off, turn knob to “OFF” position.

OPEN-TOP BURNER MODELS

Each 12"-wide open- top burner sec tion has t wo knobs on the f ront panel th at directl y control the flo w of gas

to the section’s two b urners, and so control the heat. T urn a knob clockwise to increase the heat; t urn it

counterclockwise to reduce the heat.

At the end of each day’s use, turn all knobs to the “OFF” position.

OPERATION

To light the pilots of an open-top burner section, do the following:

1. Turn all gas valves to the “OFF” position.

2. Check to make sure pilots are in the correct position.

3. Light the pilots.

4. Adjust the pilot flame as necessary.

5. Turn burner knobs to “HI” position. Each burner flame should be steady blue and impinge on the

underside of a pot placed on the support grate. Adjust if necessary.

6. To turn burners off, turn knob to “OFF” position.

OVERNIGHT SHUTDOWN

Turn knobs to the “OFF” position to turn the burners off.

EXTENDED-PERIOD SHUTDOWN OF THERMOSTATIC GRIDDLE

To shut down a therm os tatic gridd le for an exte nded per iod (or before dis connec ting the gas s upply), turn all

manual gas valves and pilots “OFF,” then turn the main gas supply valve to “OFF” (see Figure 5 below).

Figure 5

Main Gas Supply Valve

OPERATOR’S MANUAL 1178822 REV 3PAGE 13

Page 14

CLEANING MEDIUM DUTY COUNTERLINE

CLEANING

Southbend equipment is constructed with the best quality materials and is designed to provide durable

service when properl y maintained. To expect the b est performance, your equipment must be m aintained in

good condition and cleaned dail y. Naturally, the frequenc y and extent of cleaning depends on the amount

and degree of usage.

EXTERIOR AND TOP SECTIONS:

1. Keep exposed, cleanable areas of unit clean at all times.

Daily:

A. Remove, empty, and clean grease drawers and dirt trays.

B. Clean griddle drain chutes.

Monthly:

A. Clean around burner air mixers and orifices if lint has accumulated.

B. Visually assure proper pilot operation.

STAINLESS STEEL SURFACES

1. To remove normal dirt, grease and product residue from stainless steel that operates at LOW

temperature, use ordinar y soap and water (with or without deterg ent) applied with a spo nge or clot h. Dry

thoroughly with a clean cloth.

2. To remove grease and food s platter, or condensed vapors , that have BAKED on the equipment, apply

CLEANING

cleanser to a dam p cloth or sponge and r ub cleanser on th e metal in th e direction of the po lishing lines

on the metal. Rubbing cleanser, as gent ly as possible, in th e direction of the po lished lines wil l not mar

the finish of the stainless steel. NEVER RUB WITH A CIRCULAR MOTION. Soil and burnt deposits

which do not respond to the above procedure can usually be removed by rubbing the surface with

SCOTCH-BRITE scouring pads or STAINLESS scouring pads. DO NOT USE ORDINARY STEEL

WOOL, as any particles left on the surface will rust and further spoil the appearance of the finish.

NEVER USE A WIRE BRUSH, ST EEL SCOU R ING P AD S (EX C EPT STAINLESS), S CRA P ER, FIL E OR

OTHER STEEL TO OLS. Surfaces whic h are marred c ollect dirt more r apidly and becom e more diff icult

to clean. Marring also increases the possibility of corrosive attack. Refinishing may then be required.

3. To remove heat tint – Dark ened areas sometimes appear on stain less steel surfaces where the are a

has been subjected to excessive heat. Thes e dark ened areas ar e caused b y thick ening of the pr otective

surface of the stainless steel and ar e not harmful. Heat t int can normally be rem oved by the foregoin g,

but tint which does not r espond to this procedure calls for a vigorous scouring in the direction of the

polish lines, usin g SCOTCH-BRIT E scouring pads or a STAINLES S scouring pad in combinat ion with a

powered cleanser. Heat tint action m ay be lessened by not ap plying, or by reducing he at to equipment

during slack periods.

BURNERS – GENERAL

Little attention is needed, but if spi llage should occur, it ma y be necessary to clean around pi lot areas, air

mixer and under burners. Use a wire brush if necessary.

Periodically, burn ers (partic ularl y open top t ype) should be rem oved and clean ed. Allo w interior to drain. Dr y

thoroughly before replacing.

PAGE 14 OPERATOR’S MANUAL 1178822 REV 3

Page 15

MEDIUM DUTY COUNTERLINE CLEANING

CARE OF GRIDDLES

New griddles should be car efully tempered and car ed for in order to a void possible damage. T o break in a

new griddle, firs t wipe it clean. Next, light all the gr iddle burners and turn them to low for one hour. Then

gradually bring eac h gridd le up to fr ying tem perature. Nex t, sprea d thre e or f our ounc es of beef suet, or as a

substitute, baking soda , to season it. Never allo w water on a hot griddle and never wash it with soap and

water.

Use a Norton Alundum Griddle Brick to clean the griddle. Always remember to heat griddle slo wly because

quick heat may cause costly damage. Griddle plates cannot be guaranteed against damage due to

carelessness. Never place utensils on griddle. Do not overheat griddle above 550°F, as this will cause

warpage or breakage.

Do not use any type of s teel wool. Sm all particles m ay be left on the surfac e and get into f ood products. D o

not clean spatula by hitting the edge on the griddl e plate. Such action will only cut and pit t he griddle plate,

leaving it rough and hard to clean.

Do not waste gas or abuse equipment by leaving valves at “Full On” position or thermostat at a high

temperature if not required. During idle periods, set valves at “Low” position or thermostats to low

temperature settings to keep griddl e warm. Reset valves or thermostats, as r equired, for periods of heavy

load. Turn valves or thermostats to “OFF” at end of daily operation.

CLEANING

OPERATOR’S MANUAL 1178822 REV 3PAGE 15

Page 16

ADJUSTMENTS MEDIUM DUTY COUNTERLINE

ADJUSTMENTS

! WARNING

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

TECHNICIAN WHO IS EXP ERIENCED IN, AND KNOW LEDGEABLE WITH, THE O PERATION OF

COMMERCIAL COOKING EQUIPMENT. HOWEVER, TO ASSURE YOUR CONFIDENCE,

CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR RELIABLE SERVICE, DEPENDABLE

ADVICE OR OTHER ASSISTANCE, AND FOR GENUINE FACTORY PARTS.

In case of problem s in opera tion at i nitial i nstallat ion, check t ype of gas an d m anifold pr essure and com pare

with information listed on the serial plate.

GAS PRESSURE REGULATOR

The convertible press ure regu lator is f actory set at 4" W .C. for natur al gas. (To convert for use with prop ane

gas (10" W.C.), follow the procedure on page 9.) To check the manifold pressure:

1. Turn all burner valves to “OFF” position.

2. Turn main gas valve to entire unit off.

3. Remove front panel and locate 1/8" plug in manifold.

4. Remove plug and install a fitting appropriate to connect a manometer.

5. Turn on main gas to unit and light pilots.

6. Turn all burners and ovens to full “ON” position and read manometer.

7. If manometer does not r ead 4" W.C. for natural gas (or 10" W .C. for propane gas), check the incom ing

gas line for proper pressure.

8. Remove manometer fitting and replace plug in manifold.

9. Repeat step 5.

10. Replace front panel.

ADJUSTMENTS

TOP PILOTS: NON-AERATED (YELLOW-TIPPED FLAME) TYPE

Outage is often caus ed by an unsta ble flam e due to over-adj ustment to the po int where th e flame is leaving

its port, or “blowing off.”

Often, in an effort to improve ignition, the pilots are increased too much and result in this unstable condition.

These pilots are adjusted by inserting the b lade of a scre wdriver into the slot on the small valve, located on

the manifold. The m aximum flame size is appr oximately 3/4" with a s light yellow tip. T he first indicatio n of

over-adjustment is evident when the yellow tip begins to stream into black streaks and generate carbon.

Continued over-adjustment leads to the unstable lifting and blowing condition.

ALL TOP BURNERS

All burners have a primary air adjustment by means of an air shutter on the mixer face.

Loosen screw and rotate mixer cap until a clear, stable blue flame is obtained. The flame should not be

yellow tipped nor should it blow off the burner ports.

PAGE 16 OPERATOR’S MANUAL 1178822 REV 3

Page 17

MEDIUM DUTY COUNTERLINE ADJUSTMENTS

All orifice sizes and burner rate are properly set at the factory and should not be altered.

Over-rated burners cause poor burner and pilot performance, resulting in less heat, and wasted gas.

Over-gassed burners DO NOT heat griddles as efficiently as those that are properly adjusted. Such

conditions also cre ate “hot spots ” on griddles. F loating an d unstable burner and pilot flames will result when

solid tops are lowered into position beca use the rear ope nings of the burn er compartm ent are not adequate

to vent the enormous flue products gen erated b y over-gassed b urners. The “unb urned” gas will ignite at the

rear and burn in th is section and even up ins ide the backguard or shelf venting s ystem, causing str uctural

members in this area t o deteri orate. Als o, some of these hot f lue products will vent forwar d into t he m anifold

compartment resulting in problems with valves and thermostats due to overheating. AGAIN, over-rated

burners waste energy and cause service problems.

SNAP-ACTION THERMOSTATIC VALVE

Thermostatic-griddle models have snap-action thermostatic valves that are adjusted at the factory. If the

griddle surface temperature is different from the thermostat dial setting, adjust the valve (see Figure 6

below).

Figure 6

Thermostat Calibration Screw

Calibrate the valve using the screw at the base of the stem. Turn the screw clockwise to

increase the temperature, or counterclockwise to decrease the temperature.

ADJUSTMENTS

OPERATOR’S MANUAL 1178822 REV 3PAGE 17

Page 18

TROUBLESHOOTING MEDIUM DUTY COUNTERLINE

TROUBLESHOOTING

Consult the following table and the flowchart that begins on the following page.

Problem Look for -

All burners and pilots in unit will not turn on – Main gas supply to unit is “OFF.”

All burners produce excessive carbon deposits – Incorrect gas type supplied to unit.

– Incorrect supply pressure.

Only some burners in a unit produce excessive carbon

deposits

Only some pilots produce excessive carbon deposits – Pilot gas not adjusted properly.

Top burner will not come on – Manual valve for top burner in “OFF” position.

Top section pilot will not stay ignited

Lava-rock charbroiler has “hot spots” – Stacked-up lava-rock briquettes. The briquettes should be

– Incorrect orifices.

– Primary air not adjusted properly.

– Incorrect pilot orifice.

– Pilot out.

– Pilot gas not adjusted properly.

– Clogged orifice.

– Draft condition.

– Improper ventilation system.

– Air in gas line.

spread out evenly.

TROUBLESHOOTING

PAGE 18 OPERATOR’S MANUAL 1178822 REV 3

Page 19

MEDIUM DUTY COUNTERLINE TROUBLESHOOTING

OPEN TOP BURNER

TROUBLESHOOTING.

Common checks for all top configurations.

Check that the burners are set

level in the support brackets.

Check that the burners are

clean and all ports are clear.

Remove each burner and

check that the venturi is clean

and free of buildup and debris.

With each burner removed

check that the orifice size is

correct and clean and free of

buildup and debris.

Remove the knobs and carefully

lower the top valve cover panel.

NOTE: Griddle Tops

NOTE: Griddles must be

raised and secured or

removed.

CAUTION! Before

raising or removing

Griddle Tops.

Remove the knobs and

carefully lower the top

valve cover panel.

Check that each burner valve and

orifice is in alignment with the burner.

Shut off the main gas supply.

Install a pressure tap in the main

gas line before the range pressure

regulator and install a manometer.

Turn on the main gas supply.

Re-light all pilots.

Light all burners on the range.

Observe the inlet pressur e.

Inlet pressures for gases are:

Natural = 5 to 7 in. water column.

Propane = 11 to 14 in. water column.

If the inlet pressure is low, all

equipment on the main gas line

should be lit and the pressure

adjusted.

Shut off the range burners

and main gas and remove

the pressure tap.

Continue on next page.

TROUBLESHOOTING

OPERATOR’S MANUAL 1178822 REV 3PAGE 19

Page 20

TROUBLESHOOTING MEDIUM DUTY COUNTERLINE

Continued from

Previous Page

With the gas supply shut off,

install a pressure tap on the

manifold in the plugged tap

provided.

Install a manometer on

the pressure tap.

Turn on the gas

supply to the range.

Re-light the pilots and

turn on all the burners.

Observe the manifold pressure.

Manifold pressures are:

Natural gas = 4 in. water column.

Propane gas = 10 in. water column.

If the pressure is low, check the

incoming line for obstructions.

Shut off the burners and

main gas and remove the

pressure tap.

Replace the pressure tap

plug in the manifold.

Re-light the pilots.

Test each burner.

Each burner should have

a steady blue flame on

each port of the burner.

Propane burners may have a

small amount of yellow

tipping. This is normal.

If the flame is rising up off

of the ports adjust the

burner shutter closed.

If the flame is long and

yellow adjust the burner

shutter open.

NOTE: Griddle burners may

be long and float when cold.

Allow the top to heat before

making burner adjustments.

Propane burners may

Install the grates or

griddle tops.

TROUBLESHOOTING

PAGE 20 OPERATOR’S MANUAL 1178822 REV 3

have a slight popping

noise when turned off.

This is normal.

Reinstall the front

panel and knobs.

Page 21

MEDIUM DUTY COUNTERLINE PARTS

PARTS

NOTICE

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID T HE WARRANTY

ON THIS EQUIPMENT.

The serial plate is located inside of the front panel (see Figure 1 on page 3).

Replacement parts may be ordered either thr ough a Southbend Auth orized Parts Dis tributor or a S outhbend

Authorized Service Agency.

When ordering parts, please supply the Model Number, Serial Number, Part Number, and Description.

For parts not listed, consult a Southbend Authorized Parts Distributor or Southbend Authorized Service

Agency. Consult the Southbend Authori zed Parts/Servic e Distributor list f or the Authorized P arts supplier in

your area. If this list is not available, call Southbend at 1-800-348-2558 to obtain this list.

Index of Parts Diagrams

Page Number Description

22 Parts for Griddle Models MDG-24, MDG-36, and MDG-48

24 Parts for Thermostatic-Griddle Models MDGT-24, MDGT-36, and MDGT-48

26 Parts for Charbroiler Models MDC-24, MDCL-24, MDC-36, MDCL-36, MDC-48, and MDCL-48

28 Parts for Open-Top Models MDO-12, MDO-24, and MDO-36

OPERATOR’S MANUAL 1178822 REV 3PAGE 21

PARTS

Page 22

PARTS MEDIUM DUTY COUNTERLINE

Medium Duty Counterline Griddle Parts

See drawing on following page.

Key Part Number Qty Description

1 1177704 ** Knob

2 1178840 1 Front panel, 24" (for Model MDG-24)

1178842 1 Front panel, 36" (for Model MDG-36)

1178843 1 Front panel, 48" (for Model MDG-48)

3 1178826 1 Tailpipe

4 1172857 4 Legs (set of four)

5 1178836 ** Burner

6 1178801 1 Griddle weld assembly, 24" (for Model MDG-24)

1178802 1 Griddle weld assembly, 36" (for Model MDG-36)

1178803 1 Griddle weld assembly, 48" (for Model MDG-48)

7 1178890 1 Flue riser, 24" (for Model MDG-24)

1178891 1 Flue riser, 36" (for Model MDG-36)

1178892 1 Flue riser, 48" (for Model MDG-48)

8 1038099 ** Pilot

9 1178816 ** Pilot extension

10 1178821 ** Pilot adjustment valve

11 1008745 ** Orifice, natural #45

1008755 ** Orifice, propane #55

12 1178202 ** Valve

13 1178845 1 Manifold weld assembly, 24 " (f or Model MDG-24)

1178895 1 Manifold weld assembly, 36" (for Model MDG-36)

1178896 1 Manifold weld assembly, 48" (for Model MDG-48)

14 1178886 1 Grease drawer, 12" (for Models MDG-36 and MDG-48)

1178923 1 Grease drawer, 6" (for Model MDG-24)

15 1178817 ** Pilot bracket

* 1178815 1 Pressure regulator, nat/LP

* 1181735 1 Poly panel, 24" (for Model MDG-24)

1181736 1 Poly panel, 36" (for Model MDG-36)

1181737 1 Poly panel, 48" (for Model MDG-48)

* Not shown on drawing.

** One per griddle section (total of two for a Model MDG-24, three for a Model MDG-36, or four for a Model MDG-48).

PARTS

PAGE 22 OPERATOR’S MANUAL 1178822 REV 3

Page 23

MEDIUM DUTY COUNTERLINE PARTS

Medium Duty Counterline Griddle Parts

See parts list on previous page. Model MDG-36 is shown.

9

10

12

2

1

8

7

11

6

5

15

13

4

3

14

OPERATOR’S MANUAL 1178822 REV 3PAGE 23

PARTS

Page 24

PARTS MEDIUM DUTY COUNTERLINE

Medium Duty Counterline Thermostatic-Griddle Parts

See drawing on following page.

Key Part Number Qty Description

1 1182586 ** Knob

2 1178988 1 Front panel, 24" (for Model MDGT-24)

1181400 1 Front panel, 36" (for Model MDGT-36)

1181408 1 Front panel, 48" (for Model MDGT-48)

3 1163506 1 Tailpipe

4 1172857 4 Legs (set of four)

5 1178836 ** Burner

6 1178982 1 Griddle weld assembly, 24" (for Model MDGT-24)

1178996 1 Griddle weld assembly, 36" (for Model MDGT-36)

1181404 1 Griddle weld assembly, 48" (for Model MDGT-48)

7 1178890 1 Flue riser, 24" (for Models MDG-24 & MDGT-24)

1178891 1 Flue riser, 36" (for Models MDG-36 & MDGT-36)

1178892 1 Flue riser, 48" (for Models MDG-48 & MDGT-48)

8 1038099 ** Pilot

9 1178816 ** Pilot extension

10 1178821 ** Pilot adjustment valve

11 1008745 ** Orifice, natural #45

1008755 ** Orifice, propane #55

12 1182553 ** Valve

13 1178986 1 Manifold weld assembly, 24 " (f or Model MDGT-24)

1178998 1 Manifold weld assembly, 36" (for Model MDGT-36)

1181406 1 Manifold weld assembly, 48" (for Model MDGT-48)

14 1178886 1 Grease drawer, 12" (for Models MDG-36, MDGT-36, MDG-48, and MDGT-48)

1178923 1 Grease drawer, 6" (for Models MDG-24 and MDGT-24)

15 1178817 ** Pilot bracket

16 1178991 *** D ivider, cavity

17 1181498 ** Probe support weld assembly

18 1178149 ** Clamp, probe

19 1179932 ** Spring

20 1180581 ** Probe support base weld assembly

21 1180582 ** Heat shield

22 1-5771 1 Manual gas supply on-off valve

* 1178815 1 Pressure regulator, nat/LP

* 1178990 1 Poly panel, 24" (for Model MDGT-24)

1181402 1 Poly panel, 36" (for Model MDGT-36)

1181410 1 Poly panel, 48" (for Model MDGT-48)

* Not shown on drawing.

** One per griddle section (total of two for a Model MDGT-24, three for a Model MDGT-36, or four for a Model MDGT-48).

*** One between each griddle section (one for a Model MDGT-24, two for a Model MDGT-36, or three for a Model MDGT-48).

PARTS

PAGE 24 OPERATOR’S MANUAL 1178822 REV 3

Page 25

MEDIUM DUTY COUNTERLINE PARTS

Medium Duty Counterline Thermostatic-Griddle Parts

See parts list on previous page. Model MDGT-36 is shown.

19

17

12

18

20

6

11

15

5

8

10

9

7

21

13

3

1

2

22

14

16

4

PARTS

OPERATOR’S MANUAL 1178822 REV 3PAGE 25

Page 26

PARTS MEDIUM DUTY COUNTERLINE

Medium Duty Counterline Charbroiler Parts

See drawing on following page.

Key Part Number Qty Description

1 1177704 ** Knob

2 1178840 1 Front panel, 24" (for Models MDC-24 and MDCL-24)

1178842 1 Front panel, 36" (for Models MDC-36 and MDCL-36)

1178843 1 Front panel, 48" (for Models MDC-48 and MDCL-48)

3 1178826 1 Tailpipe

4 1172857 4 Legs (set of four)

5 1178836 ** Burner

6 1178902 ** Charbroiler radiant

7 1182659 1 Charbroiler ass embly, 24" (for Models MDC-24 and MDCL-24)

1182676 1 Charbroiler assembly, 36" (for Models MDC-36 and MDCL-36)

1182677 1 Charbroiler assembly, 48" (for Models MDC-48 and MDCL-48)

8 1038099 ** Pilot

9 1178816 ** Pilot extension

10 1178821 ** Pilot adjustment valve

11 1008745 ** Orifice, natural #45

1008755 ** Orifice, propane #55

12 1178202 ** Valve

13 1178845 1 Manifold weld assembly, 24 " (f or Models MDC-24 and MDCL-24)

1178895 1 Manifold weld assembly, 36" (for Models MDC-36 and MDCL-36)

1178896 1 Manifold weld assembly, 48" (for Models MDC-48 and MDCL-48)

14 1178886 1 Grease drawer, 12" (for Models MDC-24 and MDCL-24)

1178841 1 Grease drawer, 26" (for Models MDC-36, MDCL-36, MDC-48, and MDC L-48 )

15 1178817 ** Pilot bracket

16 1172781 *** Grid, charbroiler

17 1182657 *** Grate, lava-rock (for MDCL models only)

* 1173193 ** Briquettes, bag (for MDCL models only)

* 1178815 1 Pressure regulator, nat/LP

* 1181735 1 Poly panel, 24" (for Models MDC-24 and MDCL-24)

1181736 1 Poly panel, 36" (for Models MDC-36 and MDCL-36)

1181737 1 Poly panel, 48" (for Models MDC-48 and MDCL-48)

* Not shown on drawing.

** One per charbroiler section (total of two for a Model MDC-24 or MDCL-24, three for a Model MDC-36 or MDCL-36, or four for a Model

MDC-48 or MDCL-48).

*** Two per charbroiler section (total of four for a Model MDC-24 or MDCL-24, six for a Model MDC-36 or MDCL-36, or eight for a Model

MDC-48 or MDCL-48).

PARTS

PAGE 26 OPERATOR’S MANUAL 1178822 REV 3

Page 27

MEDIUM DUTY COUNTERLINE PARTS

Medium Duty Counterline Charbroiler Parts

See parts list on previous page. Model MDCL-36 is shown.

9

10

8

11

12

2

1

13

16

17

7

6

5

15

3

4

14

OPERATOR’S MANUAL 1178822 REV 3PAGE 27

PARTS

Page 28

PARTS MEDIUM DUTY COUNTERLINE

Medium Duty Counterline Open Top Parts

See drawing on following page.

Key Part Number Qty Description

1 1177704 *** Knob

2 1178971 1 Front panel, 12" (for Model MDO-12)

1178969 1 Front panel, 24" (for Model MD0-24)

1178970 1 Front panel, 36" (for Model MD0-36)

3 1178944 1 Tailpipe

4 1172857 4 Legs (set of four)

5 1177439 ** Burner, rea r

6 1177111 ** Burner, front

7 1181100 *** Grate, counter top

8 1178942 ** Pilot, rear

9 1178941 ** Pilot, front

10 1166004 *** Pilot adjustment valve

11 1008745 *** Orifice, natural #45

1008755 *** Orifice, propane #55

12 1178202 *** Valve

13 1178960 1 Manifold weld assembly, 12 " (f or Model MDO-12)

1178936 1 Manifold weld assembly, 24" (for Model MDO-24)

1178959 1 Manifold weld assembly, 36" (for Model MDO-36)

14 1178966 1 Grease drawer, 12" (for Model MDO- 12)

1178973 1 Grease drawer, 24" (for Model MDO-24)

1178965 1 Grease drawer, 36" (for Model MD0-36)

15 1178940 ** Pilot brac ket

16 1178958 1 Front rail, 12" (for Model MDO-12)

1178934 1 Front rail, 24" (for Model MDO-24)

1178957 1 Front rail, 36" (for Model MDO-36)

* 1178815 1 Pressure regulator, nat/LP

* 1181738 1 Poly panel, 12" (for Model MDO-12)

1181739 1 Poly panel, 24" (for Model MDO-24)

1181740 1 Poly panel, 36" (for Model MDO-36)

* Not shown on drawing.

** One per open-top section (total of one for a Model MDO-12, two for a Model MDO-24, or three for a Model MDO-36).

*** Two per open-top section (total of two for a Model MDO-12, four for a Model MDO-24, or six for a Model MDO-36).

PARTS

PAGE 28 OPERATOR’S MANUAL 1178822 REV 3

Page 29

MEDIUM DUTY COUNTERLINE PARTS

Medium Duty Counterline Open Top Parts

See parts list on previous page. Model MDO-36 is shown.

6

9

8

5

7

12

10

11

2

1

16

13

3

15

4

14

OPERATOR’S MANUAL 1178822 REV 3PAGE 29

PARTS

Page 30

MEDIUM DUTY COUNTERLINE

PAGE 30 OPERATOR’S MANUAL 1178822 REV 3

Page 31

MEDIUM DUTY COUNTERLINE

OPERATOR’S MANUAL 1178822 REV 3PAGE 31

Page 32

MEDIUM DUTY COUNTERLINE

MEDIUM DUTY COUNTERLINE

A product with the So uthbend name incorp orates the best in dura bility and low m aintenance. We

all recognize, however, that replacement parts and occasional professional service may be

necessary to extend the useful life of this unit. When service is needed, contact a Southbend

Authorized Service Agenc y, or your dea ler. T o a void conf usion, alwa ys refer to the m odel number,

serial number, and type of your unit.

Southbend

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(800) 348-2558 or (919) 552-9161 • FAX (800) 348-2558 or (919) 552-9798

PAGE 32 OPERATOR’S MANUAL 1178822 REV 3

Loading...

Loading...