Southbend Range KSLG-20E Service Manual

southbend

KSLG

-

20, KSLG

-

20E

A MIDDLEBY COMPANY

OWNER'S MANUAL

INSTALLATION

USER'S GUIDE

SERVICE

PARTS

STATIONARY

GAS — SELF CONTAINED

STEAM KETTLES

MODELS:

KSLG-40, KSLG-40E

KSLG-60, KSLG-60E

These instructions should be read thoroughly before attempting installation. Set up,

installation and Performance Check should be performed by a qualified service

technician. The Manufacturer, Southbend (1100 Old Honeycutt Rd., Fuquay-Varina,

North Carolina 27526), informs you that unless the installation instructions for the above

described Southbend product are followed and performed by a qualified service

technician, (a person experienced in and knowledgeable concerning the installation of

commercial gas and/or electrical cooking equipment) then the terms and conditions of

the Manufacturer's Limited Warranty will be rendered void and no warranty of any kind

shall apply.

If the equipment has been changed, altered, modified or repaired by other than a

qualified service technician during or after the 12-month limited warranty period, then

the manufacturer shall not be liable for any incidental or consequential damages to any

person or to any property which may result from the use of the equipment thereafter.

Some States do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion thereto may not apply to you.

In the event you have any question concerning the installation, use, care, or service of

the product, write Customer Service Department, Southbend Corporation, 1100 Old

Honeycutt Rd., Fuquay-Varina, North Carolina 27526.

STATIONARY GAS

SELF CONTAINED STEAM KETTLE

(Manual Section SK)

Congratulations! You have just purchased one of the finest pieces of heavy-

duty, commercial cooking equipment on

has been carefully engineered and designs have been verified through laboratory tests and field installations in some

Adjustments

1 Service

3

Trouble Shooting

4

A MIDDLEBY COMPANY

the market today.

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to some

of the toughest standards in the industry — those of Southbend Corporation. Each piece of Southbend equipment

of the more strenuous commercial cooking applications. With proper care and field maintenance, you will

experience years of reliable, trouble-free operation from your Southbend equipment. To get the best results, it's

important that you read this manual carefully.

TABLE OF CONTENTS:

SECTION ONE - INSTALLATION

Specifications 1

Installation 2

Performance Check 4

SECTION TWO - USER'S GUIDE

Warranty 1

Operation 2

This manual applies to Stationary Gas Kettles with a standing pilot or electronic ignition. You can determine if your unit is equipped with

electronic ignition by examining the Model No. on the serial plate. The serial plate is located on the lower right side of the unit. An "E" suffix at

the end of the Model No. indicates the unit is equipped with electronic ignition.

Maintenance. 6

SECTION THREE – SERVICE

Schematic Drawings 6

SECTION FOUR – PARTS

Parts List 1

CAUTION: POST IN PROMINENT LOCATION INSTRUCTIONS TO BE FOLLOWED

Retain this manual for future reference.

INTENDED FOR COMMERCIAL USE ONLY. NOT FOR HOUSEHOLD USE.

IN THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION SHALL BE OBTAINED FROM LOCAL

GAS SUPPLIER.

WARNING - WARRANTY WILL BE VOID IF

A. SERVICE WORK IS PERFORMED BY OTHER THAN A QUALIFIED TECHNICIAN.

B. OTHER THAN GENUINE SOUTHBEND REPLACEMENT PARTS ARE INSTALLED.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

KEEP AREA AROUND APPLIANCES FREE AND CLEAR FROM COMBUSTIBLES.

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN EQUIP-MENT AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

southbend

1100 Old Honeycutt Road

Fuquay-Varina. NC 27526

(919) 552-9161

FAX (919) 552-9798

(800) 348-2558

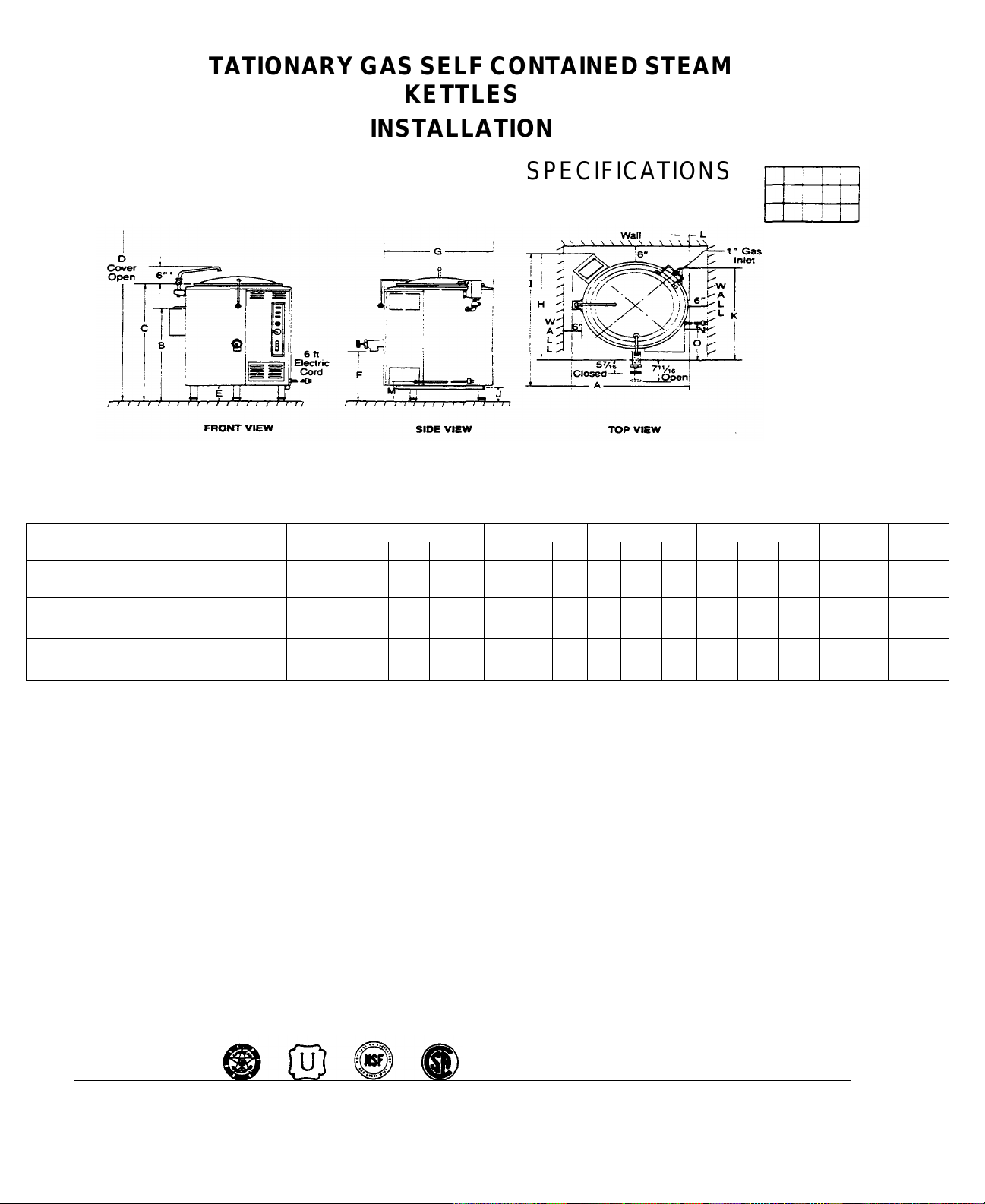

STATIONARY GAS SELF CONTAINED STEAM

?

ft. attitude and was not so specified on

l with proper orifice sizing may

APPROVALS:

KETTLES

INSTALLATION

SPECIFICATIONS

Not For Scale

For Dimensional Purposes Only

DIMENSIONS: ( ) = Millimeters

MODEL Width A

? KSLG-20 32" (813)

? KSLG-40

? KSLG-60

40"

(1016)

44"

(1118)

HEIGHT DEPTH GAS CONN. ELECTRIC CONN. CRATE SIZE

B C D

32"

40"

(1016)

43.5"

(1105)

49"

(1245)

63.3125"

(1610)

73.3125"

(1862)

82.3125"

(2091)

(813)

35"

(889)

39"

(991)

E F

6"

(152)

6"

(152)

8"

(203)

UTILITY INFORMATION:

GAS — KSLG-20 — Total 100,000 BTU. One 1" male connection (for location.

see drawing above). ?

Required operating pressure: Natural Gas 4" W.C.: Propane Gas 10" W.C.

GAS — KSLG-40 — Total 100,000 BTU. One 1" male connection (for location.

see drawing above).

Required operating pressure: Natural Gas 4" W.C.; Propane Gas 10" W.C.

GAS — KSLG-60 — Total 130,000 BTU. One 1" male connection (for location.

see drawing above).

Required operating pressure: Natural Gas 4" W.C.; Propane Gas 10" W.C.

ELECTRIC — KSLG-20, KSLG-40, KSLG-60

? STANDARD: 115/60/1 — furnished with 6-ft cord w/3-prong plug. Total maximum amps

2.0.

? OPTIONAL: 208/60/1 or for use on 3 (190 to 219 volts) — supply must be wired to unit —

see drawing above. Total maximum amps 1.0.

? OPTIONAL: 236/60/1 or for use on 3 (220 to 240 vote) — supply must be wired to unit —

see drawing above. Total maximum amps 1.0.

NOTE: If this equipment is being installed over 2.000

order, contact Southbend Service Department. Failure to instal

void the warranty.

G H I J K L M N O Width Depth Height

19"

(483)

19"

(483)

21"

(533)

26"

(660)

32"

(813)

36"

(914)

35.5"

43.1875"

(902)

(1097)

40.5"

48.1875"

(1029)

(1118)

(1224)

44"

51.6875"

(1313)

NATURAL ? PROPANE

? NATURAL

? NATURAL ? PROPANE

5.5"

(140)

5.5"

(140)

7.5"

(191)

28"

(711)

35"

(889)

35"

(889)

1.25"

8"

(32)

(203)

2.5"

8"

(64)

(203)

3.5"

10"

(89)

(254)

PROPANE

6"

(1524)

6.75"

(171)

7.5"

(184)

10"

(254)

11"

(279)

13.5"

(343)

37"

(940)

42"

(1067)

45"

(1143)

40"

(1016)

47"

(1194)

54"

(1372)

49"

(1244)

54"

(1372)

60"

(1524)

VOLUME

42 cu. ft. 1.26

61.7 cu. ft.

1.85 cu. m.

84.4 cu. ft.

2.53 cu. m.

CUBIC

cu. m.

CRATED

WEIGHT

55016s.

249.5 kg.

700 lbs.

317.5 kg.

850 lbs.

385.5kg.

STATIONARY GAS STEAM KETTLES

SECTION ONE — INSTALLATION

PAGE 1

INSTALLATION

GENERAL:

THE UNIT WHEN INSTALLED MUST CONFORM WITH LOCAL CODES, OR IN THE ABSENCE OF LOCAL

CODES, WITH THE NATIONAL FUEL GAS CODE ANSI 2223.1-1984.

THE UNIT WHEN INSTALLED MUST BE ELECTRICALLY GROUNDED AND COMPLY WITH LOCAL CODES, OR

IN THE ABSENCE OF LOCAL CODES, WITH THE NATIONAL ELECTRICAL CODE ANSI NFPA 70-1981.

CANADIAN INSTALLATION MUST COMPLY WITH CAN1-B149 INSTALLATION CODE FOR GAS BURNING

APPLIANCES AND EQUIPMENT AND CSA STANDARD C22.1-CANADIAN ELECTRICAL CODE PART 1.

EXHAUST FANS AND CANOPIES: Canopies are set over ranges, ovens, kettles, etc., for ventilation purposes. It is

recommended that a canopy extend 6" past appliance and be located 6' 6" from the floor. Filters should be installed

at an angle of 45° or more with the horizontal. This position prevents dripping of grease and facilitates collecting the

run-off grease in a drip pan, usually installed with the filter. A strong exhaust fan tends to create a vacuum in the

room and may interfere with burner performance or may extinguish pilot flames. Makeup air openings approximately

equal to the fan area will relieve such vacuum. In case of unsatisfactory performance on any appliance, check with

the exhaust fan in the "OFF" position.

WALL EXHAUST FAN: The exhaust fan should be installed at least 2 feet above the vent opening at the top of the

unit.

CLEARANCES: Adequate clearance must be provided in aisle and at the side and back. Adequate clearances for air

openings into the combustion chamber must be provided, as well as for serviceability.

Minimum clearances from combustible construction:

SIDES - 6 INCHES BACK- 2 INCHES AT FLUE BOX FLOORS - 6 INCH LEGS

All units must be installed in such a manner that the flow of combustion and ventilation air are not obstructed.

Provisions for an adequate air supply must also be provided. Do not obstruct the lower front or right side of the unit,

as combustion air enters through these areas. The bottom of the control area must also remain unobstructed.

WARNING:

THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL OR WARRANTY

WILL BE VOIDED-

TO INSTALL:

1. Uncrate carefully. Report any hidden freight damage to the freight company immediately.

Set the unit in place. Be certain to maintain the following minimum clearances to combustible construction:

2.

To level the unit use a spirit level in all directions on the top of kettle (lid up).

3.

A. Units with legs — adjust the bottom foot on each leg to overcome an uneven floor.

B. Units with casters — loosen the locking nuts, turn casters in or out as required and tighten locking nuts.

4. Be certain to leave adequate clearances for cleaning, maintenance and service.

Sides — 6 inches

Back — 2 inches (at the flue box)

Floor — 6 inches

STATIONARY GAS STEAM KETTLES

SECTION ONE — INSTALLATION

PAGE 2

Litho in U.S.A.

5-88

INSTALLATION

5. The pressure relief valve is located at the right rear of the unit. This area should be kept clear and should not

be in an area where operators will normally stand. The elbow on the relief valve should be turned toward the

floor. A maximum 3 foot, 3/4" diameter pipe may be used to extend to the floor, but must not be piped directly

to a drain. It must vent to the atmosphere.

6. Check the pressure gauge on the front panel before operating. If the pressure gauge does not indicate 20 to 30

inches of mercury column vacuum, see "Re-establishing Vacuum" section under SERVICE, after completing

installation instructions.

GAS CONNECTION:

The A.G.A. serial plate on the lower right side of the unit indicates the type of gas your unit is equipped to burn. Do

Not connect to any other gas type.

A 1" NPT line is provided at the rear for the connection. Each unit is equipped with an internal pressure regulator

which is set for 4" W.C. manifold pressure for natural gas and 10" W.C. for propane gas. Use 1/8" pipe tap on the

burner manifold for checking pressure.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas required for

satisfactory performance. A steady supply pressure, between 7" W.C. and 8" W.C. for natural gas and 11" W.C. and

12" W.C. for propane gas, is recommended. With all units operating simultaneously, the manifold pressure on all

units should not show any appreciable drop. Fluctuations of more than 25% on natural gas, and 10% on propane

gas, will create pilot problems and affect burner operating characteristics. Contact your gas company for correct

supply line sizes.

Purge the supply line to clean out any dust, dirt, or other foreign matter before connecting the line to the unit. It is

recommended that an individual manual shutoff valve be installed in the gas supply line to the unit. Use pipe joint

compound which is suitable for use with LP gas on all threaded connections. Test pipe connections thoroughly for

gas leaks. USE SOAPY WATER ONLY FOR TESTING ON ALL GASES. NEVER USE AN OPEN FLAME TO

CHECK FOR GAS LEAKS. ALL CONNECTIONS MUST BE CHECKED FOR LEAKS, AFTER THE UNIT HAS BEEN

PUT IN OPERATION.

CAUTION:

THIS APPLIANCE AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE DISCONNECTED FROM

THE GAS SUPPLY PIPING SYSTEM DURING ANY PRESSURE TESTING OF THAT SYSTEM

AT TEST PRESSURES IN EXCESS OF 1/2 PSIG (3.45 kPa) (13.84 IN. W.C.).

THIS APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY

CLOSING ITS INDIVIDUAL MANUAL SHUTOFF VALVE DURING ANY PRESSURE TESTING

OF THE GAS SUPPLY PIPING SYSTEM AT TEST PRESSURES EQUAL TO OR LESS THAN

112 PSIG (3.45 kPa) (13.84 IN. W.C.).

NOTE: If this equipment is being installed at over 2,000 feet altitude and was not so specified on order, contact

Southbend Service Department. Failure to install with proper orifice sizing may void the warranty.

WATER CONNECTION:

On units equipped with an optional water fill valve connect a water line (minimum 1/4") to the valve with a 1/4" NPT

female fitting. Units with dual (hot & cold) valves must have the hot water line connected to the side with the hot

water valve (Red) and cold water line to the cold water valve (Blue). Plastic or rubber hose is not recommended, as it

may melt against the hot kettle side.

WARNING:

FOR AN APPLIANCE EQUIPPED WITH CASTERS, THE INSTALLATION SHALL BE MADE

WITH A CONNECTOR THAT COMPLIES WITH THE STANDARD FOR CONNECTORS FOR

MOVABLE GAS APPLIANCES, ANSI Z21.69-1983. ADEQUATE MEANS MUST BE PROVIDED TO

LIMIT THE MOVEMENT OF THE APPLIANCE WITHOUT DEPENDING ON THE CONNECTOR

AND ANY QUICK-DISCONNECT DEVICE OR ITS ASSOCIATED PIPING TO LIMIT THE

APPLIANCE MOVEMENT.

STATIONARY GAS STEAM KETTLES

SECTION ONE — INSTALLATION

PAGE 3

INSTALLATION

Litho in U.S.A.

If the unit is also equipped with an optional water fill valve it too must be installed with a flexible water supply tube, a

quick disconnect and strain relief.

ELECTRICAL CONNECTION:

120 VAC - 60 Hz - Single Phase. I.

Units with this electrical rating are factory supplied with a three-wire cord and three-prong plug which fits any

standard 120V, three-prong grounded receptacle. A separate 15 amp supply is needed for each unit.

WARNING: ELECTRICAL GROUNDING INSTRUCTIONS

THIS APPLIANCE IS EQUIPPED WITH A THREE-PRONG (GROUNDING) PLUG FOR YOUR

PROTECTION AGAINST SHOCK HAZARD AND SHOULD BE PLUGGED DIRECTLY INTO A

PROPERLY GROUNDED THREE-PRONG RECEPTACLE. DO NOT CUT OR REMOVE THE

GROUNDING PRONG FROM THIS PLUG. (120V UNITS ONLY.)

208/236 VAC - 60 Hz - Single & Three Phase. II.

Units with this electrical rating are factory equipped with a transformer. To connect supply wires remove cover

from transformer box at right rear of unit. Route supply wires and ground wire through the hole in the cover with a

strain relief fitting. Connect wires to the primary transformer terminals as required by your power supply voltage.

See wiring diagram at the rear of the service section in this manual. Connect ground wire to ground lug. Replace

cover. Three-phase units are wired as above, using only two supply wires. The third supply wire is not connected

and must be properly terminated.

220 VAC - 50 Hz - Single Phase. III.

Units equipped with this voltage rating should be wired exactly as in (II.) above.

PERFORMANCE CHECK:

The following items should be checked before or within the first 30 days of operation by a qualified service technician.

1. Verify correct gas type.

2. Verify correct voltage, cycle and phase.

3. Gas pressure.

4. Internal gas connections.

5. Internal electrical connections.

6. Pilots — adjustment and ignition.

7. Burners — adjustment and ignition.

8. Thermostat — cycle for operation check.

9. Supply valve — check for operation.

10.

Check hinge and lid assembly.

11.

Draw-off valve — check operation.

12.

Advise user on cleaning procedures.

STATIONARY GAS STEAM KETTLES

SECTION ONE — INSTALLATION

PAGE 4

5-88

STATIONARY GAS SELF CONTAINED STEAM KETTLES

limited to three months on labor,

MENT PARTS for conditions and

USER'S GUIDE

LIMITED WARRANTY

Southbend warrants that the equipment, as supplied by the factory to the original purchasers, is free from defects in materials and workmanship.

Should any part thereof become defective as a result of normal use within the period and limits defined below. then at the option of Southbend

such parts will be repaired or replaced by Southbend or its Authorized Service Agency. This warranty is subject to the following conditions:

If upon inspection by Southbend or its Authorized Service Agency it is determined that this equipment has not been used in an appropriate

manner, has been modified, has not been properly maintained, or has been subject to misuse or misapplication. neglect, abuse, accident,

damage during transit or delivery, fire. flood, riot or Act of God. then this warranty shall be void.

Specifically excluded under this warranty are claims relating to installation; examples are improper utility connections and improper utilities supply.

Claims relating to normal care and maintenance are also excluded: examples are calibration of controls. and adjustments to pilots and burners.

Equipment failure caused by inadequate water quality is not covered under the warranty. WATER QUALITY must not exceed the following limits;

Total Dissolved Solids (TDS) - 60 PPM (Parts Per Million), Hardness - 2 Grains or 35 PPM. PH Factor - 7.0 to 7.5. Water pressure 30 PSI

minimum. 60 PSI Maximum. Boiler maintenance is the responsibility of the owner and is not covered by warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial application.

Repairs under this warranty are to be performed only by a Southbend Authorized Service Agency. Southbend can not be responsible for charges

incurred from other than Authorized Southbend Agencies.

THIS WARRANTY MUST BE SHOWN TO AN AUTHORIZED SERVICE AGENCY WHEN REQUESTING IN-WARRANTY SERVICE WORK.

THE AUTHORIZED SERVICE AGENCY MAY AT HIS OPTION REQUIRE PROOF OF PURCHASE DATE.

This warranty does not cover services performed at overtime or premium labor rates nor does Southbend assume any liability for extended delays

in replacing or repairing any items in the equipment beyond the control of Southbend. "Southbend shall not be liable for consequential or special

damages of any nature that may arise in connection with such product or part." Should service be required at times which normally involve

overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such premium rates.

In all circumstances, a maximum of one hundred miles in travel and two and one half hours (2.5) travel time shall be allowable. In all cases the

closest Southbend Authorized Agency must be used.

The actual warranty time periods and exceptions are as follows:

This warranty only covers product shipped into the 48 Contiguous United States and Hawaii, one year labor, one year parts effective from the

date of original purchase. There will be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Exceptions to standard warranty, effective within above limitations:

Glass Windows, Door Gaskets, Rubber Seals, Light Bulbs, Ceramic Bricks,

Sight Glasses, Catnodic Descalers or Anodes ................................................................................................................. 90 days material and labor.

Stainless Steel Fry Pot ................................................................................................ 4 years extended material warranty on fry pot only - No labor.

Stainless Steel Open Top Burners ........................................................................... 4 years extended material warranty on burners only - No labor.

Pressure Steam Boiler Shell ............................................................................... Prorated 4 years extended warranty on boiler shell only - No labor.

(Boiler shells which have not been properly maintained will not be covered by warranty.)

In all cases parts covered by a five year warranty will be shipped FOB the factory after the first year.

Our warranty on all replacement parts which are replaced in the field by our Authorized Service Agencies will be

six months on materials (parts) effective from the date of installation. See LIMITED WARRANTY - REPLACE

limitations.

If the equipment has been changed, altered, modified, or repaired by other than a qualified service technician during or after the one year limited

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property which may result from the use of the

equipment thereafter.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS, AND CONSTITUTES THE ENTIRE LIABILITY OF SOUTHBEND. IN NO EVENT DOES

THE LIMITED WARRANTY EXTEND BEYOND THE DURATION OF ONE YEAR FROM THE EFFECTIVE DATE OF SAID WARRANTY."

SOUTHBEND - Effective February 1, 1990

STATIONARY GAS STEAM KETTLES

SECTION TWO — USER'S GUIDE

PAGE 1

OPERATION

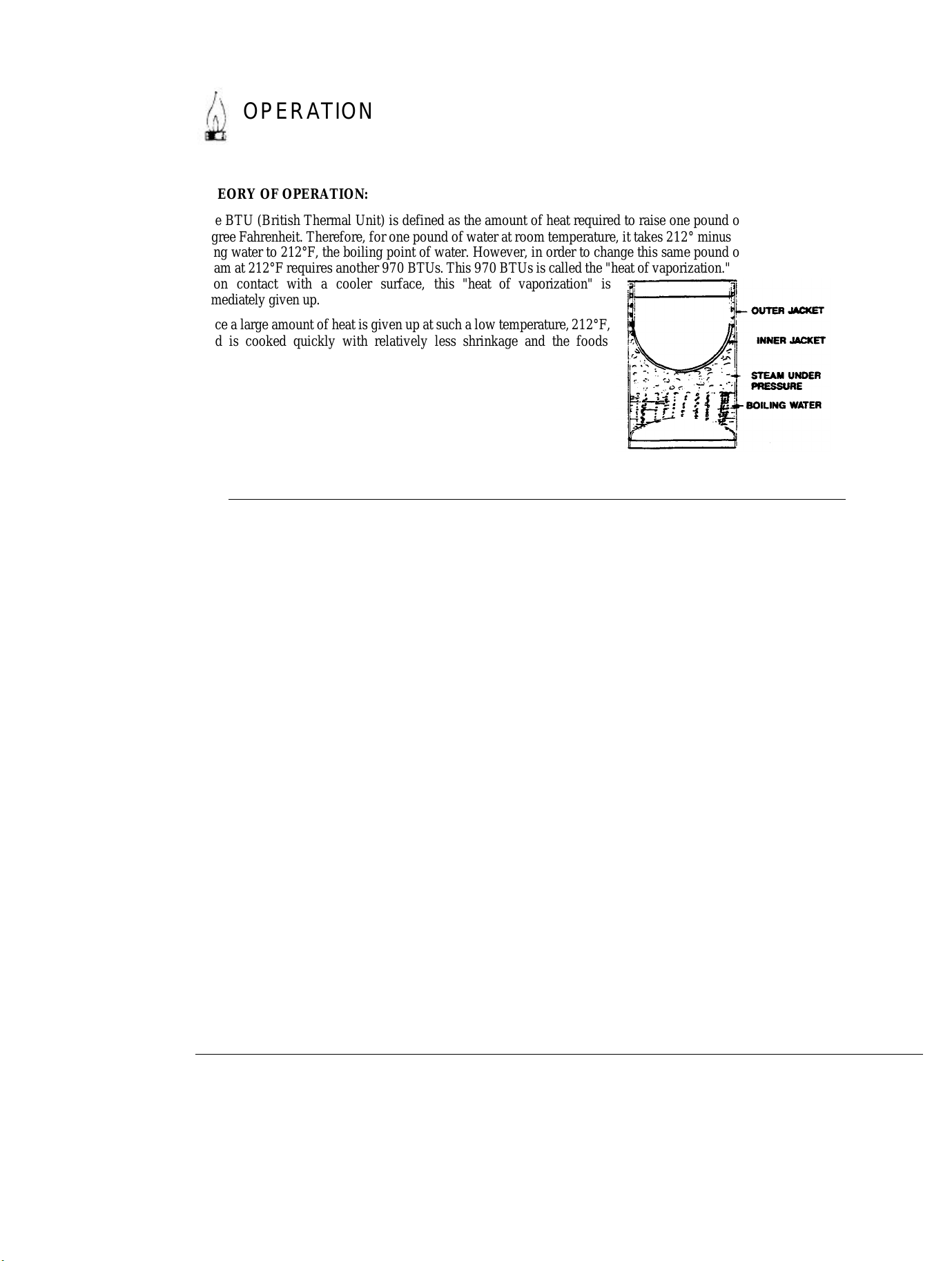

THEORY OF OPERATION:

One BTU (British Thermal Unit) is defined as the amount of heat required to raise one pound of water through one

degree Fahrenheit. Therefore, for one pound of water at room temperature, it takes 212° minus 70°, or 142 BTUs, to

bring water to 212°F, the boiling point of water. However, in order to change this same pound of water at 212 °F to

steam at 212°F requires another 970 BTUs. This 970 BTUs is called the "heat of vaporization."

Upon contact with a cooler surface, this "heat of vaporization" is

immediately given up.

Since a large amount of heat is given up at such a low temperature, 212°F,

food is cooked quickly with relatively less shrinkage and the foods

valuable nutrients are retained.

An additional advantage of this low temperature is that most foods won't

stick to the sides. This transmits into reduced labor costs since most foods

do not require constant stirring.

GAS CONTROL INSTRUCTIONS: (Non-Electronic Ignition Units Only)

Lighting

A.

1. Turn thermostat to lowest position and power switch to "off" position.

2. Open control panel access door.

3. Turn dial on combination control to "pilot" position. (NOTE: Any gas service valves exterior to the unit should be

open.)

Remove shield which fits over the burners for access to the pilot, which is located on the right side of the left burner,

4.

approximately 6" into the combustion chamber. Depress dial on the combination control while lighting pilot burner.

Hold dial for 30-45 seconds, until pilot remains lit when dial is released. A lit taper is recommended for easy access in

lighting the pilot burner.

On units recently installed, the pilot line will require "bleeding." Consequently, the pilot may not ignite immediately

and it may be necessary to keep the combination control dial depressed until sufficient gas reaches the pilot to keep it

burning. After "bleeding" wait 5 minutes before attempting ignition.

5. Turn combination control dial to "on" position.

Shut Down

B.

Standby 1.

a. Turn combination control to "pilot" position.

Complete

2.

a. Depress lightly and turn combination control dial to "off" position.

b. Turn thermostat to lowest position.

c. Turn power switch to "off."

d. Turn any gas service valves supplying gas to "off."

Relighting

C.

1. Shut off all gas (turn combination control to "off" position).

2. Wait 5 minutes.

3. Repeat "lighting" instructions in Section A.

CAUTION:

IF YOU SMELL GAS DURING THE LIGHTING PROCEDURE, IMMEDIATELY

SHUT OFF THE GAS SUPPLY UNTIL THE LEAK HAS BEEN CORRECTED.

STATIONARY GAS STEAM KETTLES

SECTION TWO - USER'S GUIDE

PAGE 2

Litho in U.S.A.

5-88

Loading...

Loading...