Page 1

INSTALLATION AND OPERATION

MANUAL

GAS TILTING KETTLES

MODELS: KSLT-20

KELT-30

KGLT-40

KGLT-60

PRINTED IN CANADA

Page 2

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

FOR

YOUR

SAFETY

00

NOT STORE OR USE GASOLINE

FLAMMABLE VAPOURS AND LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THAT THE

THIS APPLIANCE SMELLS GAS MUST BE POSTED IN A PROMINENT

LOCATION. THIS INFORMATION SHALL BE OBTAINED BY CONSULTING

THE LOCAL GAS SUPPLIER.

DO NOT ATTEMPT TO OPERATE THIS UNIT IN THE EVENT OF POWER

FAILURE.

ADEQUATE CLEARANCES MUST BE MA

INTAINED FOR SAFE AND

OPERATION.

THE APPLIANCE AREA MUST BE KEPT FREE AND CLEAR OF

COMBUSTIBLES. DO NOT OBSTRUCT THE FLOW OF COMBUSTION

VENTILATION AIR.

MAINTENANCE CAN CAU

SE PROPERTY DAMAGE, INJURY OR DEATH.

THE INSTAUATTON, OPERATING AND MAINTENANCE INSTRUCTIONS

WARNING

IMPORTANT

WARNING

IMPROPER INSTALLATION. ADJUSTMENT, ALTERATION, SERVICE-OR

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

CONTACT THE FACTORY. THE FACTORY REPRESENTATIVE OR A

LOCAL SERVICE COMPANY TO PERFORM MAINTENANCE AND THE

REPAIRS SHOULD APPLIANCE MALFUNCTTON. REFER TO

WARRANTY TERMS.

Page 3

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

WARNING:

IM THE EVENT OF POWER FAILURE. NO ATTEMPT SHOULD BE MADE

TO OPERATE THE APPLIANCE DURING POWER FAILURE-

WARNING:

IN THE EVENT OF MAIN BURNER IGNITION FAILURE, A 5 MINUTE PURGE

PERIOD MUST BE OBSERVED PRIOR TO RE-ESTABLISHING IGNITION

SOURCE

MARKING:

IN THE EVENT A GAS ODOR IS DETECTED. SHUT DOWN EQUIPMENT AT THE

MAIN SHUTOFF2 VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

WARNING

DISCONNECT UNIT FROM POWER SUPPLY BEFORE CLEANING OR SERVICING

APPLIANCE-

Page 4

INSTALLATION AND OPERATION

It is recommended that this manual be read thoroughly and that all instructions be

followed carefully. This manual should be retained for future reference.

INDEX

DESCRIPTION PAGE

IMPORTANT NOTES 1

INDEX 3

INSTALLATION AND SERVICE CONNECTIONS 4

INSTALLATION INSTRUCTIONS 5

OPERATION INSTRUCTIONS 7

PERIODIC MAINTENANCE 8

PREVENTIVE MAINTENANCE 9

TROUBLE SHOOTING 10

Page 5

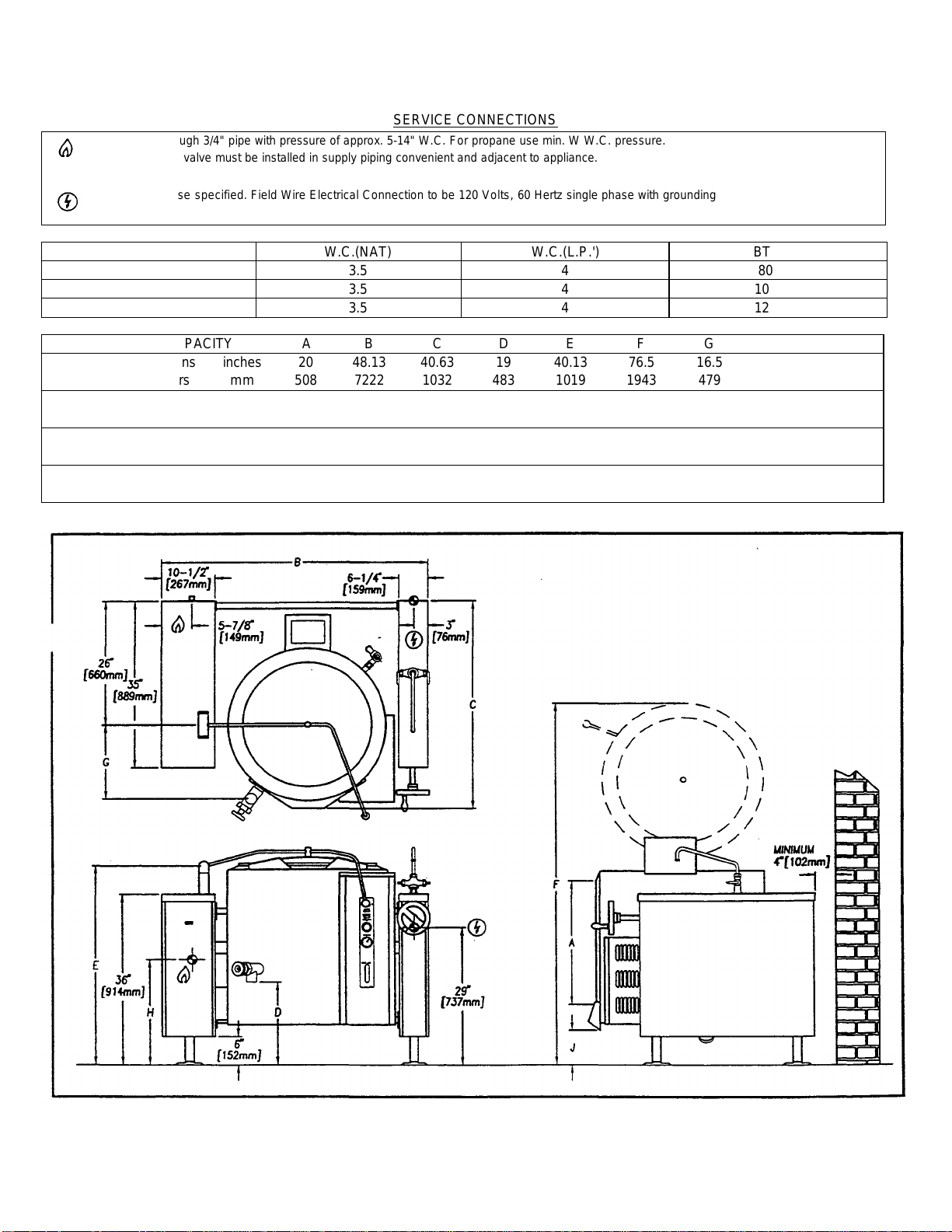

SERVICE CONNECTIONS

Supply gas through 3/4" pipe with pressure of approx. 5-14" W.C. For propane use min. W W.C. pressure.

A gas shut—off valve must be installed in supply piping convenient and adjacent to appliance.

Unless other wise specified. Field Wire Electrical Connection to be 120 Volts, 60 Hertz single phase with grounding

wire.

MODEL W.C.(NAT) W.C.(L.P.') BTU/HR

GLT-20 3.5 4 80.000

GLT-30/40 3.5 4 100,000

GLT-60 3.5 4 120.000

MODEL CAPACITY A B C D E F G H J

GL1—ZU

GLT-30

GLT-40

GLT-60

20 gallons inches 20 48.13 40.63 19 40.13 76.5 16.5 24 11

76 liters mm 508 7222 1032 483 1019 1943 479 670 279

50 gallons inches 26 54.25 43.63 16.5 37.25 73.75 15.5 22.25 7.5

114 liters mm 660 1378 1108 419 946 1873 J94 565 797

40 gallons inches 26 54.25 43.63 16.5 41.5 76 15.5 22.25 7.5

152 liters mm 660 1378 1108 419 1054 1930 394 565 797

60 gallons inches 50 58.13 45.63 17.88 45.5 82 19.5 22.25 5.5

227 liters mm 762 1476 1159 454 1156 2083 495 565 740

Page 6

INSTALLATION INSTRUCTIONS

Appliance location should have an exhaust system provided directly above the appliance to

exhaust combustion generated by the gas burner.

For use on noncombustible Floors. Minimum clearance from combustible and

noncombustible constructions, sides "0" inches, back "4" inches at flue box.

Clearance must be adequate in aisle and at the side and back. Adequate clearances for air

openings into combustion chamber must be provided, as well as for serviceability.

All units must be installed in such a manner that the flow of combustion and ventilation

are not obstructed. Provisions for an adequate air supply must also be provided. Do not

obstruct the lower front or left side of the unit, as combustion air enters through these

areas.

Uncrate carefully. Report any hidden freight damage to the freight company immediately.

Set unit in place. Be certain to maintain the following minimum clearances to combustible

construction. Side 0 inches, back 4 inches (at flue box).

Level the unit using a spirit level in all directions on the top of kettle (lid up).

Adjust the bottom foot on each leg to overcome an uneven floor.

Be certain to leave adequate clearances for cleaning, maintenance and service.

If unit is also equipped with an optional water fill valve it too must be connected with a

flexible water supply tube, quick disconnect and strain relief.

Page 7

SERVICE CONNECTIONS

Make service connections as indicated .in Installation & Service Connections.

GAS INSTALLATION TO CONFORM TO LOCAL CODES OR IN THE ABSENCE OF LOCAL CODES TO NATIONAL FUEL GAS CODE

- ANSI Z223.1 - LATEST EDITION IN CANADA INSTALLATION IN ACCORDANCE WITH CAN/CGA-B149.1 OR .2 OR

CURRENT CODE.

1. The appliance and it's individual shut-off valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures in

excess of 1/2 psig (3.45 kPa).

2. The appliance must be isolated from the gas supply piping

system by closing it's individual manual shut-off valve during any pressure testing of

the gas supply piping system at test pressures equal to or less than 1/2 PSIG (3.45

kPa).

ELECTRICAL GROONDING MOST BE PROVIDED IN ACCORDANCE WITH LOCAL CODES, OR IN THE ABSENCE OF

LOCAL CODES, WITH THE NATIONAL ELECTRIC CODE, ANSI/NFPA 70 - LATEST EDITION IN CANADA

INSTALLATION IN ACCORDANCE WITH C.S.A. C22.1 CANADIAN ELECTRIC CODE, PART 1.

WARNING: ELECTRICAL GRODNDING INSTROCTIONS UNITS EQUIPPED WITH A THREE-PRONG

GROUNDING)PLDG FOR YOUR PROTECTION AGAINST SHOCK HAZARD AND SHOULD BE

PLUGGED DIRECTLY INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. DO NOT

CUT OR REMOVE THE GROUNDING PRONG FROM THIS PLUG. (120 VOLT UNITS ONLY).

UNITS: 208/236V 60 HZ Single and three phase OR

220V 50 HZ Single phase

Units with these electrical rating are factory equipped with a transformer. To connect

supply wire remove top right cover and route supply wires and ground wire through the hole

in the back of console with strain relief fitting supplied. Connect wires to terminal

block and ground lug. Replace cover.

Wiring diagram for unit is located in side panel of the left hand console facing the front

of the unit.

Page 8

OPERATION INSTRUCTIONS

NOTE: Unit is shipped with gas combination valve turned "ON".

1. Open manual gas shut off valve.

2. With thermostat set at OFF.

3. Turn power switch ON.

4. Set thermostat to maximum, initiating a 30 second pre-purge.

If after 36 seconds the burner fails to ignite or burner lights then goes out and system

goes into Safety Lockout; de-energize the system by setting the thermostat to OFF for 5

minutes and try again.

5. Set thermostat to desired temperature setting.

DAILY SHUTDOWN

1. Turn power switch "OFF".

2. Turn thermostat "OFF".

COMPLETE SHUT DOWN

1. Turn power switch OFF.

2. Turn thermostat "OFF".

3. Turn power supply to unit "OFF".

4. Remove front access panel on left side and turn dial on combination valve to

"OFF".

5. Close manual gas shut off valve.

Page 9

PERIODIC MAINTENANCE

Notice: As a safety precaution, disconnect the power supply during cleaning or

servicing.

Cleaning: For easier cleaning add cold water to the kettle immediately after

removing contents and let soak.

Wash exposed cleanable areas daily. To remove normal dirt, grease or product residue

from stainless steel, use ordinary soap and water applied with a sponge or cloth. Dry

thoroughly with a clean cloth. Never use vinegar or any corrosion cleaner. Never use

ordinary steel wool, wire brush or steel scouring pads. Never use cleaning solvents with

a hydrocarbon base on control panel. Blower wheel inlet screen and motor air vent should

be cleansed if an accumulation of dust or lint is obvious.

At least twice a year the unit venting system should be examined and cleaned.

At least twice a year have an authorized Service Person clean and adjust the unit for

maximum performance.

Page 10

TROUBLESHOOTING

Motor will not run:

1. No current

2. Defective thermostat.

3. Defective motor.

4. Motor overload out.

5. Blown fuse.

Motor runs no spark:

1. Defective transformer.

2. Defective spark ignition.

3. Defective spark electrode (cracked insulator).

4. Defective high tension wire.

5. Defective centrifugal switch on motor.

Motor runs, spark present no gas ignition:

1. Manual main valve off.

2. Mislocated spark or ground rods.

3. Defective valve.

4. Defective primary safety control.

5. Air shutter open too far.

Flame burns only about 6 second and shuts off:

1. Flame rod or flame ground mislocated.

2. Defective flame rod wire.

3. Defective primary control.

Page 11

Short flame:

1. Wrong main orifice.

2. Low gas pressure.

3. Air shutter adjustment.

4. Main manual valve partially closed.

5. Inoperative step regulator portion of main valve.

Long hazy flame:

1. Wrong main orifice.

2. High gas pressure.

3. Dirty blower wheel.

4. Air shutter adjustments.

5. Main regulator adjustment.

Gas fails to shut off:

1. Dirt on valve seat.

2. Defective main valve.

Note: Loose, broken or grounded wiring may cause many of the symptoms listed.

Check all wiring and make sure it is intact.

Page 12

Low water lite comes on - Add water

1. Unit should be completely cold and off.

2. Lift handle of pressure relief valve to release vacuum in kettle.

3. Remove relief valve and attach a 3/4" NPT elbow pointing upward.

4. Using pure distilled water only, pour the water into the

open end of elbow ( a funnel will be helpful). Water will enter kettle slowly, as

air must escape through the same hole. Water should be added until water level at

the sight glass is half way between the minimum and maximum levels.

5. When sufficient water has been added, remove elbow and

replace pressure relief valve. Be sure to seal threads with a pipe joint compound

suitable for steam at 50 psi.

6. Vacuum must be re-established (Re-establishing Vacuum).

FOR REFERENCE: The total amount of distilled water contained in each kettle is

listed below:

GLT-20 - 6 gallons

GLT-30 & 40 - 9 gallons

GLT-60 - 12 gallons

Page 13

RE-ESTABLISHING VACUUM:

With the kettle completely cold a vacuum of 25 to 30 inches mercury column (M.C.) should

be maintained as indicated by the pressure gauge on the front control panel. If at any

time the vacuum is less than 25 inches M.C. the vacuum should be re-established.

With the kettle empty, turn the thermostat knob to the highest temperature. When the

pressure gauge reaches 20 psi turn thermostat off, open the pressure relief valve

until manometer reads 1 psi, then sharply release it. This should remove the air and any

loss in performance should return.

Should the kettle fail to maintain a vacuum after repeated attempts to establish it,

further checks should be made to see if the pressure relief valve is leaking or if there

are any leaks in the pressure relief valve piping, copper lines going to the pressure

switch, pressure gauge or thermostat fitting.

Page 14

FRONT PANEL CONTROLS

1. POWER SWITCH

This switch turns the main power to the unit on and off. It must be turned on to

heat the kettle.. It should be turned off when the kettle will not be in use for

long periods.

2. (RED) COOKING LIGHT

This light is on whenever the main burner gas is on.

3. (AMBER) LOW WATER LIGHT

All kettles are supplied with sufficient distilled water in pressurized jacket. If

at any time the water level falls below that required for proper operation, the

kettle will not heat and this light will come on. See "Adding Water" section.

4. THERMOSTAT

The thermostat selects are desired internal kettle operating temperature.

CONTROL FUNCTIONS

5. PRESSURE GAOGE

The pressure gauge indicates the internal operating pressure of the kettle. When

cold, the gauge should indicate 25 to 30 inches mercury column vacuum. If it does

not, refer to "Re-establishing Vacuum" section. Under normal operation with the

kettle empty (thermostat set at 285 F) the pressure shall reach 38 psi. When loaded

the pressure may be considerably less.

6. SIGHT GLASS

The sight glass indicates the minimum and maximum water level within the kettle. IF

water level falls below minimum level more distilled water should be added. See

"Adding Water" section.

Page 15

7. PRESSURE RELIEF VALVE

The pressure relief valve is a safety device which prevents the internal kettle

pressure from ever exceeding 50 psi. It should never be tampered with.

Page 16

ADJUSTMENTS WARNING

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED TECHNICIAN WHO IS

EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE OPERATION OF COMMERCIAL GAS COOKING

EQUIPMENT. HOWEVER, TO ASSURE YOUR CONFIDENCE, CONTACT YOUR AUTHORIZED SERVICE

AGENCY FOR RELIABLE SERVICE, DEPENDABLE ADVICE OR OTHER ASSISTANCE, AND FOR GENUINE

FACTORY PARTS.

THERMOSTAT

The thermostat adjustment should not be changed. Check the following before changing

the thermostat.

1. With kettle cold, the pressure on the pressure gauge should read 25 to 30 inches

mercury column vacuum. If not, see "Re-establishing Vacuum" section.

2. The pressure switch is not set too high or too low and causing the out of

adjustment condition. A voltmeter should be used by a properly trained servicemen

to determine if the pressure switch or thermostat is actually cycling the burners.

If the pressure switch is found to be the problem, see "Pressure Switch" section.

PRESSURE SWITCH

The pressure switch should not be adjusted until it is determined to be the cause of an

operating pressure difficulty. See "Thermostat" section to determine if the source of

difficulty is the pressure switch or thermostat,

The major difficulties caused by pressure switch mis-adjustment are:

1. Pressure relief valve opening, especially on preheat from a cold start to 285°F

(pressure switch set too high).

2. Pressure in kettle is too low and burners are being shut down by pressure switch

(not thermostat).

Page 17

The pressure switch is preset for proper operation from the factory. It is adjusted to

the maximum pressure which will prevent the pressure relief valve from opening. This

setting will be slightly different on different kettles due to variations in the pressure

relief valves. During preheat to the maximum thermostat setting (285°F), from either a

cold condition or a lower temperature setting, the temperature may overshoot the

thermostat setting and be shut down by the pressure switch. This is normal, however,

after the kettle has cycled several times (empty) the thermostat will begin cycling the

unit.

TO ADJUST PRESSORE SWITCH:

1. With the kettle empty and completely cold, turn kettle on and set thermostat to

maximum setting (285°F).

2. Pressure in kettle (read pressure gauge on front panel) should reach a maximum

pressure of 40 psi and pressure relief valve should not open. Kettle pressure may

rise 3 or 4 psi even after burners shut down.

3. Relief valve should not open when kettle pressure is 40 psi;

pressure switch setting is satisfactory.

4. If relief valve opens, reduce setting on pressure switch, cool kettle completely by

running cold water through it and repeat this procedure.

5. If pressure in kettle is below 40 psi increase setting of

pressure switch, cool kettle completely by running cold water through it and repeat

this procedure.

6. To obtain access to the pressure switch the front panel must be removed. Remove

the screws on either side of the panel. Be sure to support the panel to avoid

excessive strain on the wiring.

7. To increase the pressure switch setting turn the white ribbed knob clockwise; to

decrease turn it counterclockwise. Use the center of the black ring as an

indicator.

Loading...

Loading...