Southbend Range FF-21-36 Service Manual

IMPORTANT

$8.00

southbend

A MIDDLEBY COMPANY

FOR FUTURE REFERENCE

Please complete this

information and retain this

manual for the life of the

equipment.

MODEL #__________________

SERIAL #__________________

DATE PURCHASED__________

OWNER'S MANUAL

INSTALLATION

USER'S GUIDE

SERVICE

PARTS

DEEP FAT FRYER MANUAL SUPPLEMENT

for

FRYER FILTER SYSTEM

MODEL FF-21-36, FF-21-42

These instructions should be read thoroughly before attempting installation. Set up, Installation

and Performance Check should be performed by a qualified service technician. The

Manufacturer, Southbend (1100 Old Honeycutt Rd., Fuquay-Varina, North Carolina 27526),

informs you that unless the installation instructions for the above described Southbend product

are followed and performed by a qualified service technician, (a person experienced in and

knowledgeable concerning the installation of commercial gas and/or electrical cooking

equipment) then the terms and conditions of the Manufacturer's Limited Warranty will be

rendered void and no warranty of any kind shall apply.

If the equipment has been changed, altered, modified or repaired by other than a qualified

service technician during or after the 12-month limited warranty period, then the

manufacturer shall not be liable for any incidental or consequential damages to any person

or to any property which may result from the use of the equipment thereafter. Some States

do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion thereto may not apply to you.

In the event you have any questions concerning the installation, use, care, or service of the

product, write Customer Service Department, Southbend, 1100 Old Honeycutt Rd., Fuquay Varina, North Carolina 27526.

FRYER FILTER SYSTEM

DEEP FAT FRYER

(Manual Section SR)

Congratulations! You have just purchased one of the finest pieces of heavy-duty, commercial

SECTION

ONE

- INSTALLATION

Specifications..............................................................................................

...........................1

Installation...........................................................................

........................

...........................1

Performance Check.....................................................................................

...........................2

Warranty...................

...................................................................................

See Fryer Manual

Operation.....................................................................................................

Adjustments/Service....................................................................................

...........................1

Parts List........................................................

..............................................

...........................1

southbend

1100

Old Honeycutt Road

cooking equipment on the market today.

You will find that your new equipment, like all Southbend equipment, has been designed and

manufactured to some of the toughest standards in the industry — those of Southbend Corporation.

Each piece of Southbend equipment has been carefully engineered and designs have been verified

through laboratory tests and field installations in some of the more strenuous commercial cooking

applications. With proper care and field maintenance, you will experience years of reliable, troublefree operation from your Southbend equipment. To get the best results, it's important that you read

this manual carefully.

TABLE OF CONTENTS:

SECTION TWO - USER'S GUIDE

...........................1

SECTION THREE - SERVICE

SECTION FOUR - PARTS

NOTE: CONSULT DEEP FAT FRYER MANUAL - PT# 1161609 FOR ALL FRYER

INFORMATION

CAUTION: POST IN PROMINENT LOCATION INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION SHALL BE

OBTAINED FROM LOCAL GAS SUPPLIER

Retain this manual for future reference.

INTENDED FOR COMMERCIAL USE ONLY.

NOT FOR HOUSEHOLD USE.

WARNING - WARRANTY WILL BE VOID IF

A. SERVICE WORK IS PERFORMED BY OTHER THAN QUALIFIED

TECHNICIAN.

B. OTHER THAN GENUINE SOUTHBEND REPLACEMENT PARTS ARE

INSTALLED.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF HIS OR ANY OTHER APPLIANCE.

KEEP AREA AROUND APPLIANCES FREE AND CLEAR FROM COMBUSTIBLES.

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN EQUIPMENT AT

THE MAINSHUT OFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR

GAS SUPPLIER FOR SERVICE.

A MIDDLEBY COMPANY

Fuquay-Varina, NC 27526

(919) 552-9161

FAX (919) 552-9796

(800)348-2556

FRYER FILTER SYSTEM

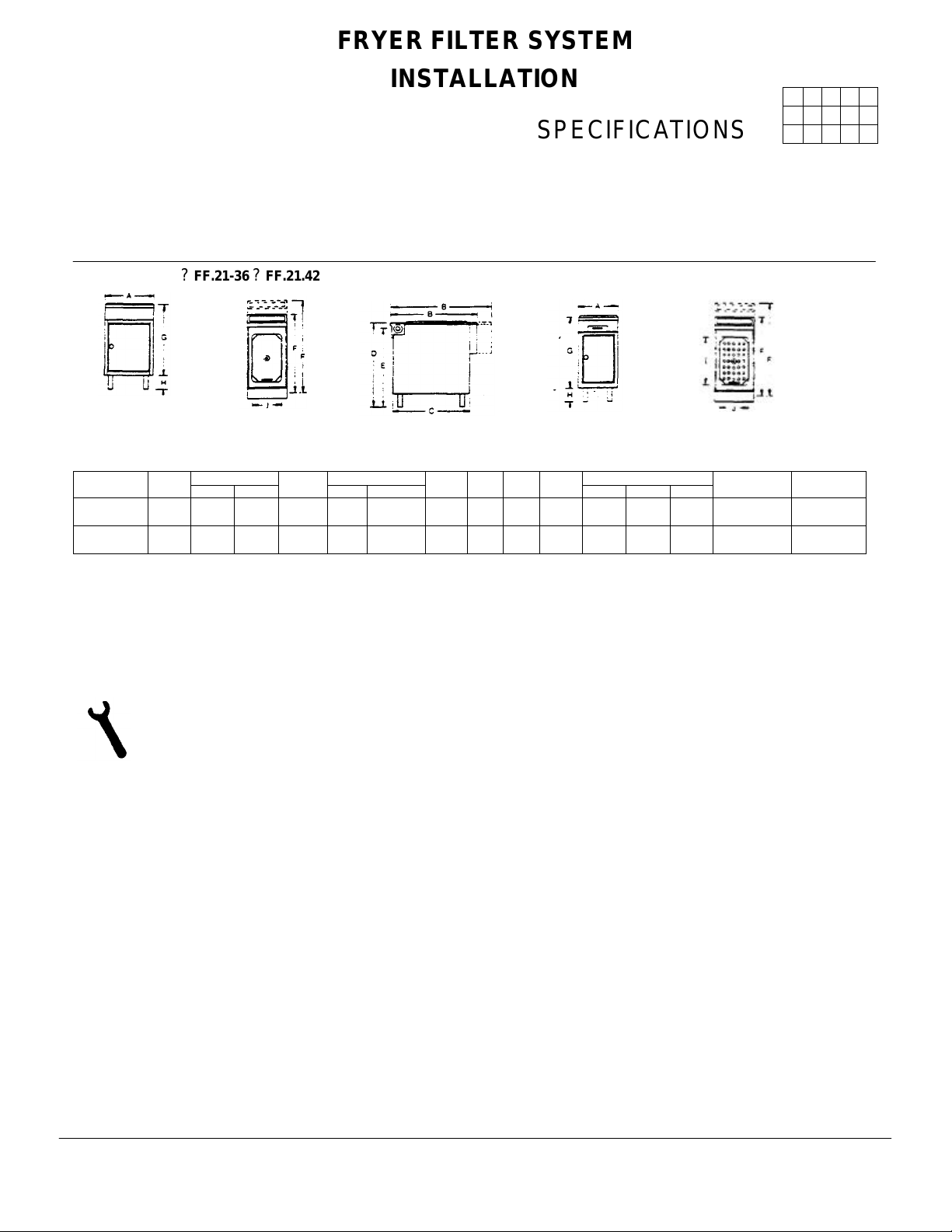

FRYER FILTER ? FF.21-36 ? FF.21.42

DEPTH

1 ¼” GAS CONN.

CRATE SIZE

Width

B C

E F

Width D

epth Height

Cubic

Crated

(533)

(914)

(854)

(762)

.65 cu.ft.

90.0 kg.

(1067)

(854)

(1003)

(762)

(152)

(572)

(1092)

(1041)

.65 cu.ft.

90.0 kg.

FRONT VIEW

TOP VIEW

FRONT VIEW

TOP VIEW

DIMENSIONS:

INSTALLATION

SPECIFICATIONS

SIDE VIEW

Scale 1/4" = 1 ft.

( ) = Millimeters

MODELS

?FF-21-36

?FF-21-42

A

21”

21"

(533)

36”

42'

31.75”

(805)

31.75”

(805)

Height

36”

(914)

36”

(914)

33.75

33.75

33.5”

(851)

33.5”

Q H I J

30”

8”

N/A N/A

(152)

30"

8”

N/A N/A

22.5”

(572)

2Zf

43”

(1092)

43"

41"

(1041)

41"

Volume

23.0cu.ft.

23.0cu.ft.

Weight

200 lbs.

200 lbs.

UTILITY INFORMATION

1/3 HP - 115 OR 230 VOLT

AMPS-115 VOLT-6.5

230 VOLT-2.6

INSTALLATION

GENERAL:

THE UNIT WHEN INSTALLED MUST CONFORM WITH LOCAL CODES, OR IN THE ABSENCE OF LOCAL

CODES, WITH THE NATIONAL FUEL GAS CODE ANSI Z223.1.1984.

The unit must be installed in such a manner that the flow of combustion and ventilation air are not obstructed.

Provisions for an adequate air supply must also be provided.

ASSEMBLY INSTRUCTIONS:

For battery installation of units consult SECTIONAL RANGE FRONT MANIFOLD - BATTERY TYPE OWNERS

MANUAL - Part # 1161610. Follow instructions as outlined in Section 1 - Installation - pages 4 thru 11.

Individual Assembly Instructions for internal piping of drain line to filter will be furnished with each individual

battery.

FRYER FILTER SYSTEM

SECTION 1 • INSTALLATION

PAGE 1

WARNING:

PAGE

2

THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL OR WARRANTY

WILL BE VOIDED.

LEGS OR OPTIONAL CASTERS:

1. A set of legs or casters are packed in the unit. A threaded receptacle is fastened to the base frame at each comer.

Each leg or caster has a similar mating thread.

2. Raise unit sufficiently to allow legs or casters to be screwed into the receptacles. For safety, "shore up" and

support the unit with an adequate blocking arrangement strong enough to support load.

3. Lower unit gently. Never drop or allow the unit to fall.

4. The legs or casters can be adjusted to overcome and uneven floor.

5. After the unit has been leveled, tighten the lock nuts.

WARNING:

FOR AN APPLIANCE EQUIPPED WITH CASTERS, THE INSTALLATION SHALL BE MADE

WITH A CONNECTOR THAT COMPLIES WITH THE STANDARD FOR CONNECTORS FOR

MOVABLE GAS APPLIANCES, ANSI Z2169-1979, AND ADDENDA Z21.69a.l983, AND A QUICKDISCONNECT DEVICE THAT COMPLIES WITH THE STANDARD FOR QUICK-DISCONNECT

DEVICES FOR USE WITH GAS FUEL, ANSI Z21.41-1978, AND ADDENDA Z21.41a.l9 81 AND

Z21.41b.l983. ADEQUATE MEANS MUST BE PROVIDED TO LIMIT THE MOVEMENT OF THE

APPLIANCE WITHOUT DEPENDING ON THE CONNECTOR AND THE QUICK.DISCONNECT

DEVICE OR ITS ASSOCIATED PIPING TO LIMIT THE APPLIANCE MOVEMENT.

WARNING:

IF DISCONNECTION OF THIS RESTRAINT IS NECESSARY TO REMOVE THE APPLIANCE FOR

CLEANING, ETC., RECONNECT IT WHEN THE APPLIANCE IS MOVED TO ITS ORIGINALLY

INSTALLED POSITION.

PERFORMANCE CHECK:

The following items should be checked before or within the first 30 days of operation by qualified service technician.

1. Verify correct electrical characteristics.

2. Internal drain piping drains properly.

3. Check gas supply connection on front manifold.

4. Internal electrical connections.

5. Pump operates properly.

6. Advise user on cleaning procedures.

PRYER FILTER SYSTEM

INSTALLATION

For Fil

ter Pan

braided hose from the filter pan to the fryer's oil return lines.

push upward on the wooden ring while inserting the

action will be reduced or eliminated if these latches are not

ADJUSTMENTS

SERVICE

WARNING:

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

TECHNICIAN WHO IS EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE OPERATION

OF COMMERCIAL GAS COOKING EQUIPMENT. HOWEVER, TO ASSURE YOUR

CONFIDENCE, CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR RELIABLE SERVICE,

DEPENDABLE ADVICE OR OTHER ASSISTANCE, AND FOR GENUINE FACTORY PARTS.

TROUBLE SHOOTING

DESCRIPTION FUNCTION

1. Quick Disconnect This Quick Disconnect fitting connects the stainless steel

#1174293 The stainless hose must be disconnected at this fitting

prior to sliding the filter pan outward for cleaning or

removal. The fitting is operated by pushing upward on the

wooden ring and exerting downward pressure on the

connecting end of the stainless hose. For reconnection,

stainless hose. Release the wooden ring when the hose

fitting is fully inserted to lock it in position. Refer to Page 4

2. Filter Pan The Filter Pan contains the filter paper which serves to

#1174289 removes breading and other impurities from the oil during

3. Filter Pan Hold-Down The Hold-Down Bracket is contained in the filter pan and

Bracket and Latches serves to insure that the fitter paper is held tightly in place

#1174288 by means of the four locking latches. The fryer's filtering

Item 4 for the location of this component.

the filtering procedure. Oil is drained into the filter pan

where the fryer's pumping action draws it thru the filter

paper and returns it to the cooking vessel by way of the

Filter Pan Hose.

4. Drain Valve Pulling this handle towards you allows shortening to drain

#1134799 from the frying vessel into the filter pan. WARNING: MAKE

5. Drain Line Piping Nipple This Pipe-Nipple attaches to the drain piping to minimize

FRYER FILTER SYSTEM

SECTION THREE-SERVICE

properly secured.

SURE THERMOSTAT IS IN "OFF POSITION. Open the

valve slowly to avoid burns from splashing of hot oil.

Always, make sure that the valve is closed prior to adding

shortening.

splashing of hot oil when the fry-kettle is filtered or drained.

The Pipe-Nipple must be removed before sliding the filter

pan out of the fryer.

PAGE 1

DESCRIPTION FUNCTION

6. Quick Disconnect

for Oil Discharge

Wand #1174293

This Quick-Disconnect Fitting is used in conjunction with the oil

discharge wand to remove oil from the Fryer that is to be discarded.

The Quick Disconnect is operated in the same manner as was

explained in Item 1 of this section.

OIL FILTRATION SYSTEM INOPERATIVE; PUMP DOES NOT RUN

1. If switch is in the "On" Position, use a multimeter to verify that the pump switch is functioning properly. If switch

is operative, refer to wiring diagram and locate the filter pump and motor assembly and use a multimeter to check

for proper voltage at the pump motor. If voltage is correct a defective pump motor is indicated. Remove and

replace the pump motor assembly. Otherwise refer to the wiring diagram at the rear of this manual and isolate the

defective wiring or wiring connection.

OIL FILTRATION SYSTEM PUMPS SLOWLY

1. Insure that filter paper is not clogged or torn.

2. Insure that hold-down frame in filter pan is latched at all four positions inside filter pan.

3. Insure that the 18" stainless steel flexible hose which leads from filter pan to quick-disconnect fitting is securely

locked inside quick-disconnect fitting. If hose will not lock in quick-disconnect, remove and replace quickdisconnect fitting.

4. Examine the 18" stainless steel flexible hose described above for signs of crimping or collapse. If crimping or

collapse is noted, remove and replace it.

5. If no defect is found in the 18" stainless steel flexible steel hose, disconnect pump from filter lines and insure that

no obstructions exist in the plumbing leading to the pump, if all lines are clear, remove and replace the filter pump

assembly.

FRYER FILTER SYSTEM

SERVICE

PAGE 2

Loading...

Loading...