Page 1

CONVECTION STEAM

ELECTRIC BOIL

(Manual Section CS

OWNER'S MANUAL

INSTALLATION

USER'S GUIDE

SERVICE

PARTS

CONVECTION STEAMER

ELECTRIC BOILER

MODELS: ECX-2S

These instructions should be read thoroughly before attempting installation. Set up, installation

and Performance Check should be performed by a qualified service technician. The Manufacturer,

Southbend (1100 Old Honeycutt Rd., Fuquay-Varina, North Carolina 27526), informs you that

unless the installation instructions for the above described Southbend product are followed and

performed by a qualified service technician, (a person experienced in and knowledgeable

concerning the installation of commercial gas and/or electrical cooking equipment) then the terms

and conditions of the Manufacturer's Limited Warranty will be rendered void and no warranty of

any kind shall apply.

If the equipment has been changed, altered, modified or repaired by other than a qualified service

technician during or after the 12-month limited warranty period, then the manufacturer shall not be

liable for any incidental or consequential damages to any person or to any property which may

result from the use of the equipment thereafter. Some States do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion thereto may

not apply to you.

In the event you have any question concerning the installation, use, care, or service of the

product, write Customer Service Department, Southbend Corporation, 1100 Old Honeycutt Rd.,

Fuquay-Varina, North Carolina 27526.

southbend

A MIDDLEBY COMPANY

Page 2

Congratulations! You have just purchased one of the finest pieces of heavy-duty, commercial cooking equipment on the

manufactured to some of

those of Southbend Corporation. Each piece of Southbend equipment has been

carefully engineered and designs have been verified through laboratory tests and field installations in some of the more

ng applications. With proper care and field maintenance, you will experience years of

TABLE OF CONTENTS:

Warranty

1

Dimensions

2

SECTION TWO

— STEAM FUNCTION

6

SECTION FOUR

— OPERATION

SECTION FIVE

— COOKING SCHE

DULES

SECTION SIX

— SERVICE

SECTION SEVEN

— PARTS

SECTION EIGHT

— WIRING

market today.

You will find that your new equipment, like all Southbend equipment has been designed and

the toughest standards in the industry -

strenuous commercial cooki

reliable trouble-free operation from your Southbend equipment. To get the best results, it's important that

you read this manual carefully.

SECTION ONE — INSTALLATION

Service Connections 2

Functioning Mode 5

SECTION THREE — MAINTENANCE

Instructions and Cleaning 12

Pan Selection 13

Service Information 16

Parts List 20

Wiring Diagrams 33

CAUTION: WATER QUALITY IS THE MAJOR FACTOR AFFECTING THE PERFORMANCE OF

Retain this manual for future reference.

YOUR APPLIANCE. INCOMING WATER HARDNESS SHOULD NOT EXCEED 2.0 PPM GRAINS AND THE

pH SHOULD NOT EXCEED 7.5. IF YOU ARE UNSURE OF WATER CONDITIONS. HAVE IT ANALYZED.

CONSULT YOUR LOCAL WATER DEPARTMENT OR A COMPETENT WATER CONDITIONER AGENCY.

FAILURE OR MALFUNCTION OF THIS APPLIANCE DUE TO POOR QUALITY OF WATER IS NOT

COVERED UNDER THE WARRANTY.

WARNING — WARRANTY WILL BE VOID IF

A. SERVICE WORK IS PERFORMED BY OTHER THAN A QUALIFIED TECHNICIAN.

B. OTHER THAN GENUINE SOUTHBEND REPLACEMENT PARTS ARE INSTALLED.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

KEEP AREA AROUND APPLIANCES FREE AND CLEAR FROM COMBUSTIBLES.

Page 3

CONVECTION STEAMER

SERVICE WORK. THE AUTHORIZED SERVICE AGENCY MAY AT HIS OPTION REQUIRE PR

OOF OF PURCHASE DATE.

In all cases the closest Southbend Authorized Agency mus

t be used.

Sight Glasses

, Cathodic, Descalers or Anodes .........................................................................................

90

days material and labor.

ELECTRIC BOILER

USER'S GUIDE

LIMITED WARRANTY

Southbend warrants that the equipment, as supplied by the factory to the original purchasers, is free from defects in materials and

workmanship. Should any part thereof become defective as a result of normal use within the period and limits defined below, then

at the option of Southbend such parts will be repaired or replaced by Southbend or its Authorized Service Agency. This warranty is

subject to the following conditions:

If upon inspection by Southbend or its Authorized Service Agency it is determined that this equipment has not been used in an

appropriate manner, has been modified, has not been properly maintained, or has been subject to misuse or misapplication.

neglect, abuse, accident, damage during transit or delivery, fire. flood, riot or Act of God, then this warranty shall be void.

Specifically excluded under this warranty are claims relating to installation; examples are improper utility connections and improper

utilities supply. Claims relating to normal care and maintenance are also excluded; examples are calibration of controls, and

adjustments to pilots and burners.

Equipment failure caused by inadequate water quality is not covered under the warranty. WATER QUALITY must not exceed the

following limits; Total Dissolved Solids (TDS) - 60 PPM (Pans Per Million), Hardness - 2 Grains or 35 PPM, PH Factor - 7.0 to 7.5.

Water pressure 30 PSI minimum, 60 PSI Maximum. Boiler maintenance is the responsibility of the owner and is not covered by

warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial application.

Repairs under this warranty are to be performed only by a Southbend Authorized Service Agency. Southbend can not be

responsible for charges incurred from other than Authorized Southbend Agencies.

THIS WARRANTY MUST BE SHOWN TO AN AUTHORIZED SERVICE AGENCY WHEN REQUESTING IN-WARRANTY

This warranty does not cover services performed at overtime or premium labor rates nor does Southbend assume any liability for

extended delays in replacing or repairing any items in the equipment beyond the control of Southbend. "Southbend shall not be

liable for consequential or special damages of any nature that may arise in connection with such product or part." Should service be

required at times which normally involve overtime or premium labor rates, the owner shall be charged for the difference between

normal service rates and such premium rates.

In all circumstances, a maximum of one hundred miles in travel and two and one half hours (2.5) travel time shall be allowable.

The actual warranty time periods and exceptions are as follows:

This warranty only covers product shipped into the 48 Contiguous United States and Hawaii, one year labor, one year parts

effective from the date of original purchase. There will be no labor coverage for equipment located on any island not connected by

roadway to the mainland.

Exceptions to standard warranty, effective within above limitations:

Glass Windows, Door Gaskets, Rubber Seals. Light Bulbs, Ceramic Bricks,

Stainless Steel Fry Pot ......................................................................... 4 years extended material warranty on fry pot only - No labor.

Stainless Steel Open Top Burners .................................................... 4 years extended material warranty on burners only - No labor.

Pressure Steam Boiler Shell ........................................................ Prorated 4 years extended warranty on boiler shell only - No labor.

(Boiler shells which have not been property maintained will not be covered by warranty.)

In all cases parts covered by a five year warranty will be shipped FOB the factory after the first year.

Our warranty on all replacement parts which are replaced in the field by our Authorized Service Agencies will be limited to three

months on labor, six months on materials (parts) effective from the date of installation. See LIMITED WARRANTY - REPLACE-

MENT PARTS for conditions and limitations.

If the equipment has been changed, altered, modified, or repaired by other than a qualified service technician during or after the

one year limited warranty period, then the manufacturer shall not be liable for any damages to any person or to any property which

may result from the use of the equipment thereafter.

“THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS, AND CONSTITUTES THE ENTIRE LIABILITY OF

SOUTHBEND. IN NO EVENT DOES THE LIMITED WARRANTY EXTEND BEYOND THE DURATION OF ONE YEAR FROM THE

EFFECTIVE DATE OF SAID WARRANTY."

SOUTHBEND - Effective February 1. 1990

Page 4

SECTION 1

2

FIG. 1

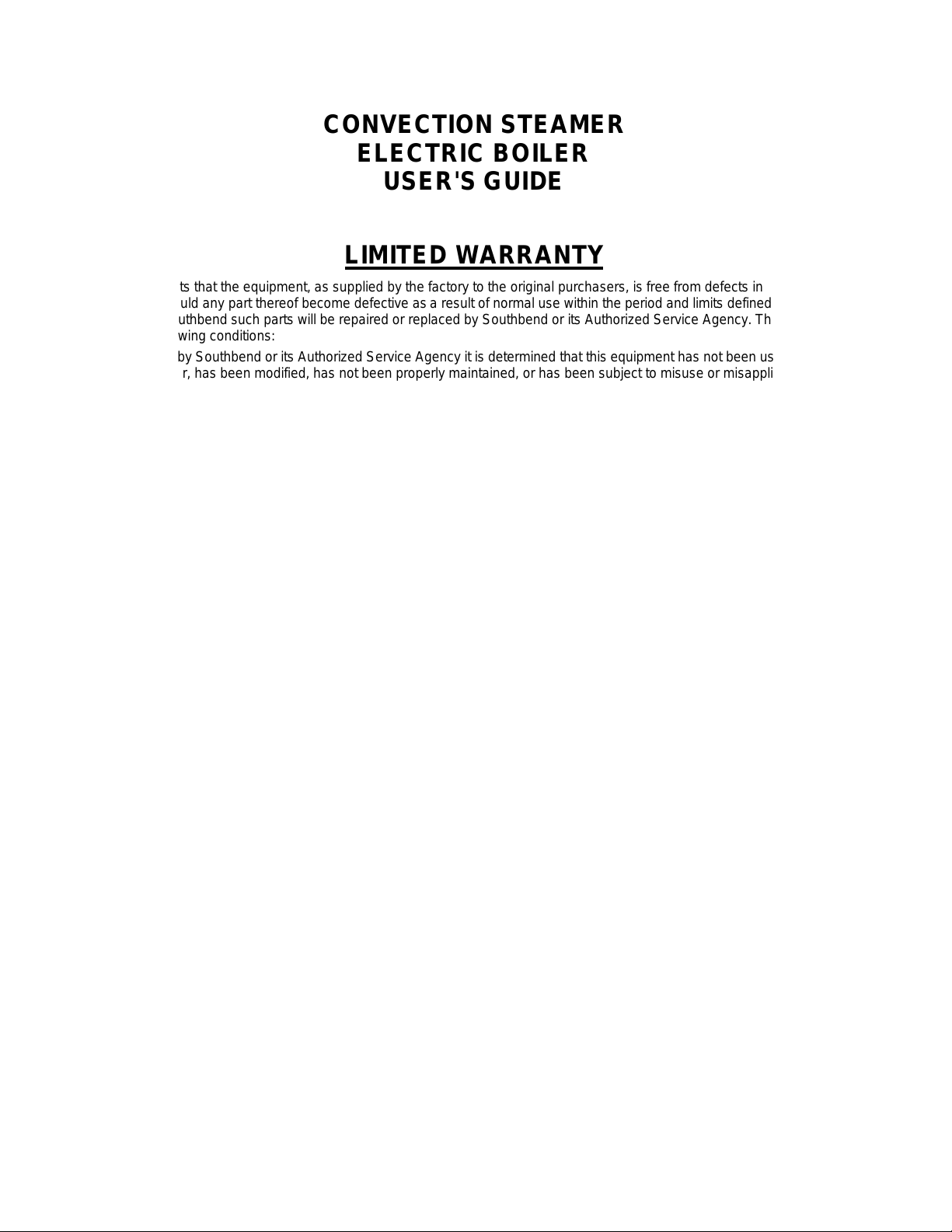

DIMENSIONS & SERVICE CONNECTIONS

STEAM-EX MODEL ECX-

FLOOR MOUNTED CONVECTION STEAMER

A B C D E F G H J K L M N O

inches 15 7 5-1/2 21 4-1/2 193s 9 6-1/2 13 11 1-1/2 3 4-1/2 4

mm 381 178 140 533 108 495 229 165 330 279 38 76 114 102

LEGEND

EC

Field Wiring Electrical Connection to be as specified on Electrical Rating Label which is according to

Customer's Order.

DR

Appliance drain is 2" pipe size. Provide Open air gap type drain.

CW

Cold Water supply. Provide 3/8" copper tube.

HW

Hot Water supply to Boiler. Provide 3/8" copper tube. A Backflow Prevention Device acceptable to BOCA

Code or equivalent must be installed in this line.

ST

Steam take-off locations to supply steam to adjacent units if desired

2

Page 5

INSTALLATION & SERVICE CONNECTIONS

2

STEAM-EX MODEL ECX-

SECTION 1:

FLOOR MOUNTED CONVECTION STEAMER

INSTALLATION INSTRUCTIONS

Ideally an Exhaust System should be provided directly above the Steam-Ex in order to exhaust steam and heat

generated by the appliance.

Set Steam-Ex in place and level appliance using spirit level.

Ascertain that a floor drain (open gap) is convenient to the appliance drain.

Mark hole locations on floor through anchoring holes provided in flanged adjustable feet.

Remove appliance and drill holes into locations marked on floor and insert proper anchoring devices.

Set Steam-Ex back in proper position and relevel.

Bolt and anchor appliance securely to the floor.

Seal bolts and flanged feet with Silastic or equivalent compound.

Make service connections as indicated in LEGEND (Fig. 1) and test that appliance operates properly.

3

Page 6

START UP & TESTING PROCEDURES

2

STEAM-EX MODEL: ECX-

SECTION 1:

TESTING PROCEDURES

Floor Mounted Convection Steamer

Once the unit Is installed and proper service connections have been made, your Steam-Ex should be

thoroughly tested before operation.

If the appliance is equipped with a manual Blowdown Valve, close it.

Open left cabinet door and turn ON Power Switch. Pilot light will come on (green) and water will begin to

enter Boiler and required water level will be reached in about 3 minutes. Observe water gauge glass to

verify. Steam generation will now commence and be completed in about 15 minutes. Observe that Boiler

Pressure Gauge indicates steam pressure in a range of 9 to 12 psi. On Cooker Digital Control Panel both

COOK TIME-MINUTES 'Windows' will display "00" and both READY (green) lights will be on indicating that

Steam-Ex is now ready for the cooking cycle. Open both compartment doors and observe that no steam

has entered cooking compartments. Close doors.

Touch number 8 twice on both Digital Controls. Observe that all segments of "88" in both display windows

light up. As well. touch all other numbers and observe that they function. On both Digital Controls touch

CANCEL and display windows will show "00".

Touch number 2 on both Digital Controls and "02" will be displayed.

Touch START on both Digital Controls. READY lights will go off and COOK (red) lights will come on and

steam will be heard entering cooking compartments.

After one minute when display windows show "01", open each door and observe for a couple of minutes

that steam has ceased to enter each compartment, but COOK lights and cooking times at "01" are

maintained.

WARNING: THE COOKING COMPARTMENTS CONTAIN LIVE STEAM AND

TO AVOID SCALDING AND/OR BURNS STAY CLEAR WHEN

OPENING EACH DOOR.

Shut doors. Steam generation and cook time will resume. Observe Appliance Drain that live steam from

compartments is being cooled by cold water from Cold Hater Solenoid Valve (thermostatically controlled).

When each 'Window' shows "00" each buzzer will come on, steam generation will cease, COOK lights will

go off and READY lights will go on. To silence buzzers, open and close each compartment door.

During simulation of the cooking cycle, the Heater Elements will cycle on and off to maintain steam

pressure in the Boiler between 9 to 12 psi range.

Turn OFF power switch. If the appliance is equipped with an Automatic Blowdown Solenoid Valve, the

Boiler contents water and steam, will be blown out and exhausted through the appliance Drain. The Cold

Water Solenoid Valve will now be activated as well. If, however, the appliance is equipped with a manual

Blowdown Valve, open it.

4

Page 7

FUNCTIONING MODE

2

FLOOR MOUNTED CONVECTION

SECTION 2:

STEAM-EX MODEL ECX-

This Steam-Ex is intended for use in commercial establishments as an appliance utilizing steam in the pressureless

mode for cooking a variety of food products. It is floor supported and consists of two sections, the Cabinet and the

Cooker, both of which incorporate steel enclosures to contain live electrical parts.

The Cabinet is the lower foot supported section of the appliance with two front doors to provide internal access and

contains components which control the functioning of the Electric Boiler and hence is the steam supply source to the

Cooker. A switch located on the front face of the Generator Control Box, when turned on will provide power for the

entire appliance. Once switched ON, the Water Level Control will signal the Water Fill Solenoid Valve not only to

supply water to fill the Boiler to the required level and consequently immerse the heater Elements, but also to replenish

and maintain proper level as water is depleted through steam generation. With adequate water level, energizing of

Heater Elements is then permitted and steam generation commences. However, since the Electric Boiler is designed to

ASME Code and approved as a steam heating boiler restricted to operate at pressures not to exceed 15 psi, therefore

a Pressure Switch is utilized to regulate the cycling of the Heater Elements to maintain steam pressures at

approximately 9 psi minimum but not to exceed 13 psi since pressure approaching 15 psi will blow the Safety Relief

Valve.

The Cooker is the upper section of the appliance consisting of two compartments and a Digital Control Panel. Each

compartment is provided with its own door, Digital Control, Steam Solenoid Valve and Solid State Boards. Pans,

containing food properly portioned, are then placed unto guided compartment racks. With the Door closed and the

Digital Control timed for the correct COOK TIME in MINUTES and touching START, the Steam Solenoid Valve is

energized and opens allowing constant steam to enter the compartment through eight ports which provide thorough

steam coverage of the entire compartment. Since steam is allowed to exhaust through the compartment drain, the

chamber cannot ever become pressurized and hence pressureless steam is the cooking mode utilized. With this mode,

it should be noted particularly apparent on vegetables, that color, flavor and texture are retained as "fresh from the

garden". At the completion of the cooking cycle, the "Window" on the Digital Control will display "00" and an audible

buzzer will be set off and can only be silenced by opening the door and presumably the cooked food product removed.

Closing the door permits the Initiation of the next cooking cycle.

Refer to Periodic Maintenance, Section 3, for detailed version of components and controls.

5

Page 8

SECTION 3:

2

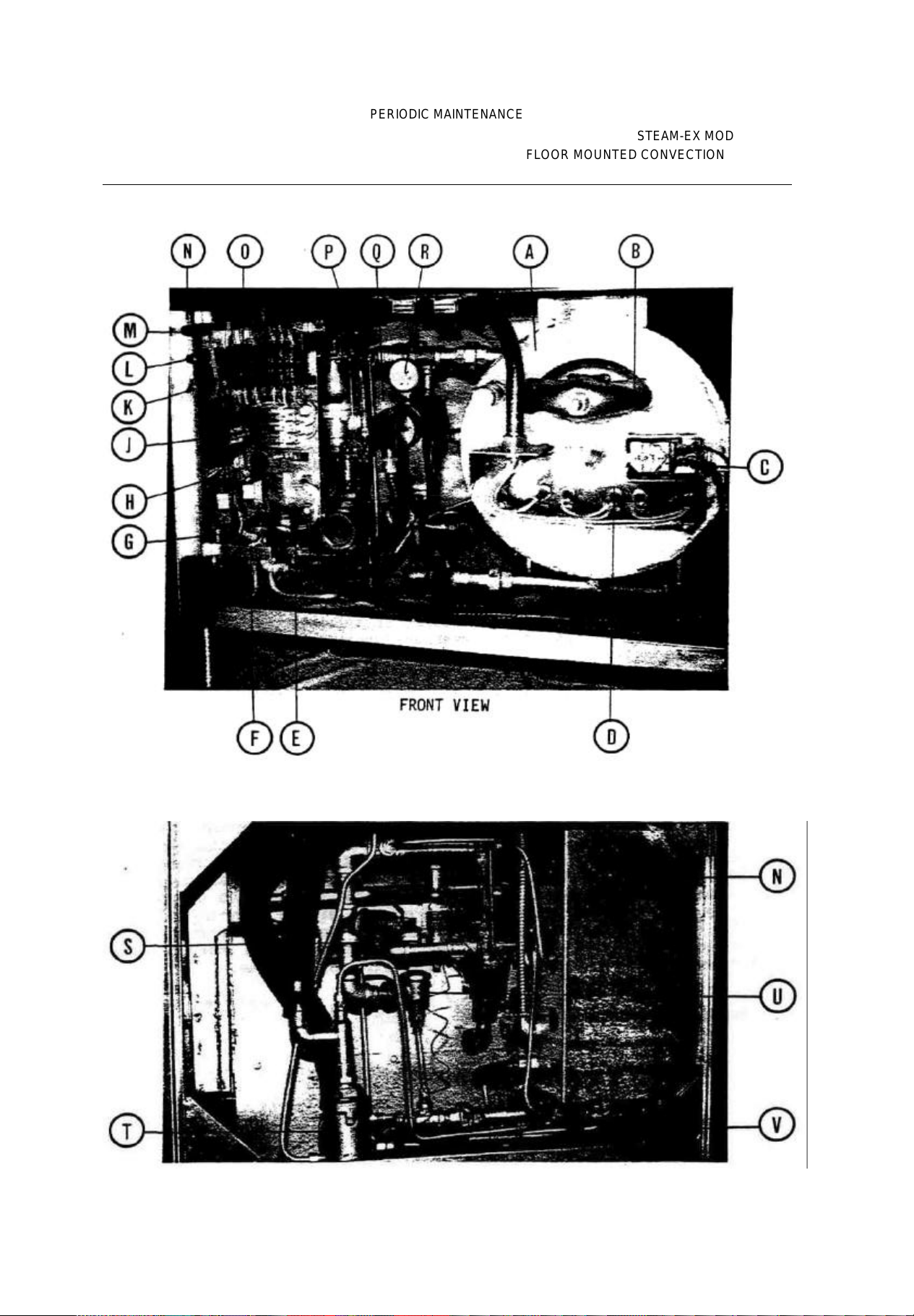

FIG. 2

PERIODIC MAINTENANCE

STEAM-EX MODEL ECX-

FLOOR MOUNTED CONVECTION STEAMER

SIDE VIEW

6

Page 9

PERIODIC MAINTENANCE

2

STEAM-EX MODEL ECX-

SECTION 3:

FLOOR MOUNTED CONVECTION STEAMER

The Steam-Ex is made of two sections, the Cabinet and the Cooker.

FIG. 2: The Cabinet is the lower section of the Steam-Ex and not only does it provide a base for the Cooker to be

positioned at a proper working height but also provides the enclosure for the Boiler and Controls.

FRONT VIEW

Item A: Electric Boiler weldment assembly.

Item B: Handhole Cover Assembly when unbolted and removed allows internal examination and cleaning of Boiler if

required.

Item C: Safety Thermostat, shown enclosed within Thermostat Cover Box, is a protective device which will shut off the

Heater Elements should the water level in the Boiler drop below a level sufficient to immerse and protect the Heater

Elements. The heat sensing Capilliary Bulb of the Thermostat enters the Boiler through the Boiler Head and is

attached to an upper leg of one of the Heater Elements and will remain inoperative while immersed in water.

Item D: Heater Elements located within the lower portion of the Boiler provide the heat required to generate steam in

the Boiler. During operation of the appliance, water level must be sufficient to immerse and protect the Elements.

Item E: Solenoid (Cold Water) Valve is fastened to the right rear bottom of Generator Control Box. This valve supplies

cold water to condense live steam before it exhausts into the drain and its functioning is controlled by a thermostat.

Item F: Solenoid (Hot Water) Valve is fastened to the bottom of Generator Control Box immediately in front of Item E.

This valve feeds hot water to the Boiler but its functioning is entirely dependent on the Water Level Control (Item Q).

Item G: Operating Pressure Switch is fastened to the inside bottom-front of the Generator Control Box and is plumbed

to sense the pressure in the Boiler and thence control the operating cycle of the Contractors (Item 0) through which

the Heater Elements must obtain power for steam generation. This switch is factory set to energize and close the

contacts (of the Contactors) to allow power to the Elements at 9 psi but to de-energize them and shut off power to the

elements at 12 psi thus maintaining a pressure range in the Boiler between 9 psi to approximately 13 psi (override

considered).

Item H: Hi-Limit, Switch, similar to and directly behind Operating Switch Item G. is a protective device intended to deenergize the Contactors and hence shut off power to the Heater Elements at approximately 14 psi and will only

function if the Operating Pressure Switch fails.

AT LEAST TWICE A YEAR. UNBOLT AND REMOVE HANDHOLE COVER ASSEMBLY INSPECT

INTERIOR OF BOILER FOR SCALANT AND LIME BUILD UP.

7

Page 10

PERIODIC MAINTENANCE

2

STEAM-EX MODEL ECX-

SECTION 3:

FLOOR MOUNTED CONVECTION STEAMER

Item J: Transformer. Primary Voltage as per Customer specifications. Secondary at 120V.

Item K: Power Switch is fastened to the front face of the Generator Control Box and when switched ON will

automatically begin the steam generating process in the Boiler.

Item L: Pilot light is located directly above the Power Switch and when lit (green) indicates power is ON.

Item M: Fuse is a protective device fastened to the front face of the Generator Control Box to prevent excessive power

to secondary circuit.

Item N: Generator Control Box is fastened permanently to. the left top portion of the Cabinet directly behind the left

cabinet door. It contains provisions for field wiring and a number of Boiler controls.

Item O: Contactors are fastened to the rear wall of the Generator Control Box. Refer to Item G on functioning mode.

Item P: The Water Gauge has a glass tube for visual verification that water level is being maintained in the Boiler during

operation. The manual valves at the top and the bottom of this assembly must be fully open and only closed if damage

should occur to the glass tube.

Item Q: Water Level Control is a mechanical switching device activated by the float contained within the chamber of this

control. When the float drops, as water is depleted in the Boiler by steam generation, it will trip the switch and energize

the Water Fill Solenoid Valve to replenish water to the proper level in the Boiler and consequently the control chamber.

Should the water in the Boiler drop to an unsafe level, this control will de-energize the Contactors and hence the Heater

Elements.

WARNING: TURN POKER OFF TO THIS APPLIANCE BEFORE REMOVING COVER PANEL OF

GENERATOR CONTROL BOX.

OBSERVE THAT THE WATER IS CLEAN AND CLEAR IN THE GLASS TUBE. THE APPEARANCE

OF EXTREME MURKINESS IN THE MATER INDICATES INADEQUATE MATER QUALITY AND

MILL CAUSE FAILURE OF CONTROLS AND THE APPLIANCE. WARRANTY DOES NOT COVER

MALFUNCTION DUE TO POOR MATER CONDITIONS.

Item R: The Pressure Gauge is directly above and threaded to the Water Level Control. It should read '0' during shut

down and function in a range of approximately 9 to 13 p.s.i. during operation of the appliance.

A MANUAL VALVE LOCATED DIRECTLY BELOW THE MATER LEVEL CONTROL CHAMBER

MUST BE OPENED BRIEFLY AT LEAST ONCE A MEEK TO BLOWDOWN SEDIMENT AND

SCALANT THAT HAY BE LODGED IN THE CHAMBER. FAILURE TO DO SO MAY CAUSE

EXCESSIVE ACCUMULATION AND SEIZURE OF THE FLOAT AND EVENTUAL MALFUNCTION

OF THE HATER LEVEL CONTROL.

8

Page 11

PERIODIC MAINTENANCE

2

STEAM-EX MODEL ECX-

SECTION 3:

FLOOR MOUNTED CONVECTION STEAMER

SIDE VIEW

Item S: Safety Valve is a protective device set at 15 psi. Malfunction or improper setting of controls may allow the

pressure to exceed 15 psi in the Boiler and will consequently set off this valve.

Item T: Drain for compartments and Boiler approximately 2" pipe size. Must be provided with open air gap type floor

drain.

Item U: A Thermostatic Steam Trap is plumbed to the steam supply piping from the Boiler and is a mechanical device

that closes on high temperatures and opens when the temperature drops. This Trap allows air and water formed from

condensed steam to exhaust into the appliance Drain but will retain steam being of a higher temperature.

Item V: Boiler Slowdown Valve is plumbed to the drain pipe of the Boiler and when specified as automatic will be

electrically operated solenoid valve which will close when energized in order to facilitate maintenance of proper water

level in the Boiler.

ONCE A WEEK THIS VALVE SHOULD BE TRIPPED DURING OPERATION TO ASSURE THAT IT

FUNCTIONS PROPERLY.

THE STEAM-EX SHOULD BE SWITCHED OFF AT LEAST ONCE DAILY WHICH WILL DEENERGIZE AND OPEN THE VALVE IN ORDER FOR THE BLOWDOWN PROCEDURE TO OCCUR

AND REMOVE SEDIMENTS, SCALANTS AND LIME BUILD-UP IN THE BOILER. IF THE

APPLIANCE IS SUPPLIED WITH A MANUAL VALVE, IT SHOULD BE OPENED DAILY WHEN THE

APPLIANCE IS SHUT DOWN.

9

Page 12

SECTION 3:

2

FIG. 3

PERIODIC MAINTENANCE

STEAM-EX MODEL ECX-

FLOOR MOUNTED CONVECTION STEAMER

10

Page 13

PERIODIC MAINTENANCE

2

STEAM-EX MODEL ECX-

SECTION 3:

FLOOR MOUNTED CONVECTION STEAMER

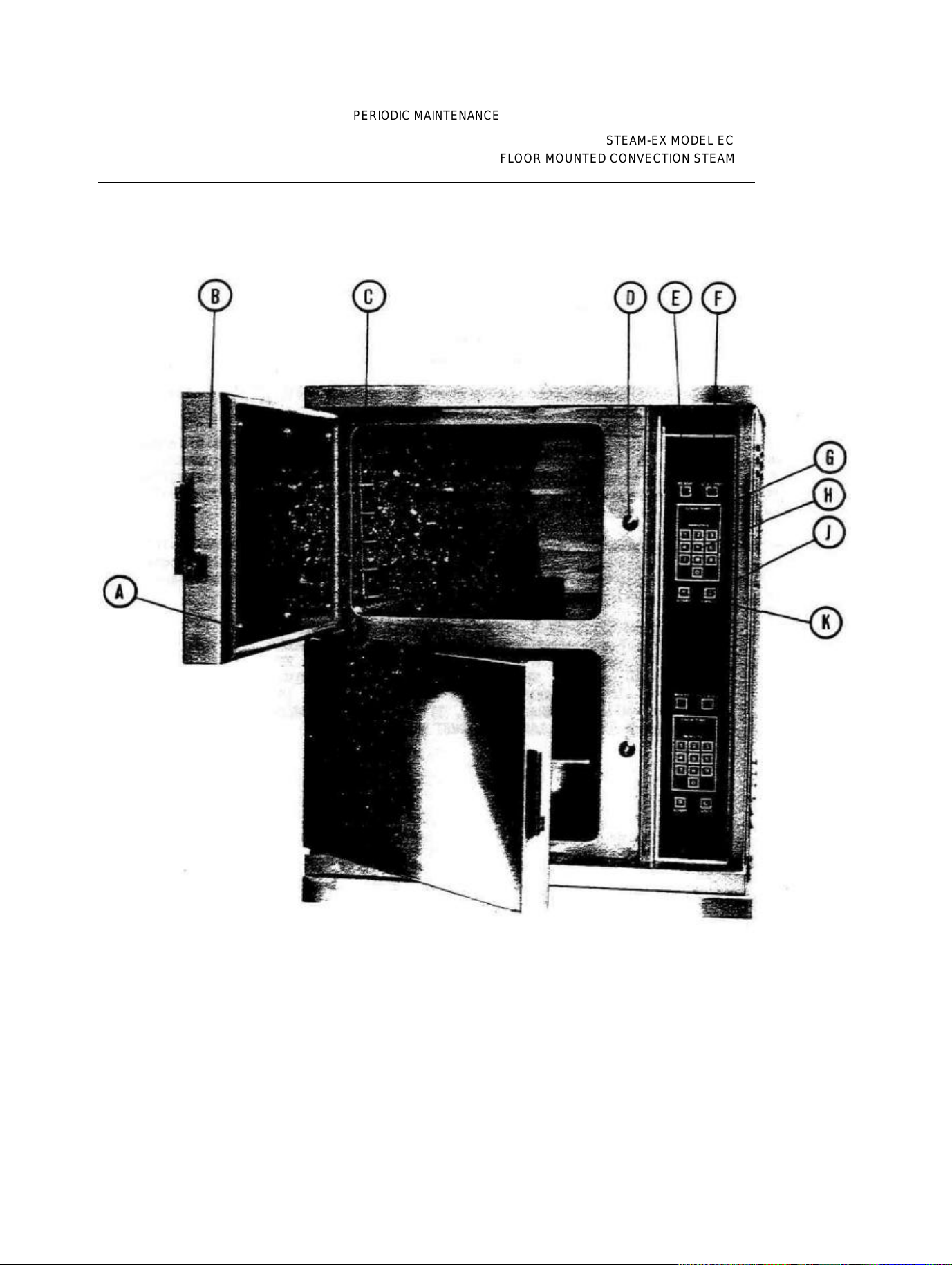

FIG. 3: The Cooker is the upper section of the steamer and is a two compartment appliance. Each compartment

functions independently with its own controls.

Item A: A Stainless Steel Screw on Gasket Plate immediately adjacent to each corner of Gasket allows adjustment of

Gasket if necessary. Refer to Section 6, Service Information.

Item B: A Door Gasket is provided on each compartment door and ensures proper sealing of the cooking

compartment.

Item C: Stainless Steel Pan Rack for guiding pans into compartment at properly spaced intervals.

Item D: Door Striker provides positive latching of door.

Item E: READY light when lit (green) indicates appliance is ready for the cooking cycle.

Item F: COOKING light when lit (red) indicates appliance is in the cooking phase.

Item G: 'Window' displays '00' during READY phase and when programmed will display in minutes the duration of the

cooking cycle when STARTed. Maximum programmable time is '99' minutes which is more than adequate for all

Cooking Schedules. Note that time displayed counts down and shows amount of time left to complete the cooking

cycle.

Item H: Numberical 'touch pad' for prograrmring required cooking time. Note that whatever is the final time programned

and displayed becomes the actual COOK TIME in MINUTES when START is activated.

Item J: CANCEL when touched will automatically cancel any programmed time and window will display '00'. Touching

CANCEL during the cooking cycle will also automatically cancel and end the cooking cycle and not only will the

'window' display '00' but the buzzer will come on and the Door must now be opened and closed to initiate a new

cooking cycle.

WASH THE GASKET SEALING SURFACE DAILY WITH MILD DETERGENT TO REMOVE

HARMFUL FOOD ACIDS. DAMAGE TO GASKET SEALING SURFACE SUCH AS NICKS OR CUTS

WILL CAUSE STEAM LEAKAGE.

AT THE END OF EACH COOKING DAY REMOVE PANS AND RACKS. WASH PANS, RACKS AND

COMPARTMENT INTERIORS TO REMOVE RESIDUE FOOD PARTICLES TO PREVENT

BACTERIAL GROWTH AND ODOURS.

Item K: START when touched initiates the cooking cycle.

11

Page 14

OPERATING AND CLEANING INSTRUCTIONS

2

STEAM-EX MODEL: ECX-

SECTION 4:

FLOOR MOUNTED CONVECTION STEAMER

OPERATION

a) If the appliance is equipped with a manual Blowdown Valve, close it. Open left cabinet door and turn ON Power

Switch. Pilot light will come on (green) and water will begin to enter Boiler until required water level is reached

(about 2 minutes). Immediately thereafter steam generation will commence and be completed in about 10

minutes. Observe that Boiler Pressure Gauge indicates steam pressure in a range of 9 to 12 psi. On Cooker

Digital Control panel both COOK TIME-MINUTES 'Windows' will display "00" and both READY (green) lights will

also have come on indicating that Steam-Ex is now ready for use.

b) When READY light (green) comes on, preheat cooking compartment for one minute by pressing number 1 on

digital panel and press START. READY light will go off and COOK light (red) will come on. Make sure door is

closed. This step is only required when cooking chamber is cold or when unit is to be first used for the day.

When buzzer sounds, open and close door to silence buzzer.

WARNING: THE COOKING COMPARTMENTS CONTAIN LIVE STEAM AND TO AVOID SCALDING

c) With compartment pre-heated and READY light on, Place pans of food into cooking compartment and shut door.

Refer to Cooking Schedules and press in desired cooking time on digital panel. Touch START for cooking cycle

to begin. Cooking cycle may be interrupted at any time by opening door and resumed again by closing door.

AND/OR BURNS STAY CLEAR WHEN OPENING EACH DOOR.

d) When the buzzer sounds, it indicates the end of the cooking cycle and no more steam in entering the cooking

compartment. Buzzer must be silenced by opening door and removing cooked food. The COOK light will go off

and the READY light will come one.

e) Touching CANCEL will automatically display "00" on "Window". Correct time may now be entered.

f) To shut down your Steam-Ex, turn OFF Power Switch. If the appliance is equipped with an Automatic Blowdown

Solenoid Valve, the Boiler contents water and steam, will be blown out and exhausted through the appliance

Drain. The Cold Water Solenoid Valve will now be activated as well. If, however, the appliance is equipped with

a manual Blowdown Valve, open it.

CLEANING

Turn Power Switch OFF. Remove Pans and Racks from compartment and wash in sink. Wash compartment interior

with clean water. Never use steel wool or abrasive scouring pads as they will scratch and ruin the general surface

appearance of your appliance. Use a clean damp cloth to wipe down exterior of your Steam-Ex.

NEVER SPRAY HATER INTO ELECTRIC CONTROLS

12

Page 15

COOKING SCHEDULES

2

SECTION 5:

FLOOR MOUNTED CONVECTION STEAMER

THE FOLLOWING ITEMS MUST BE COOKED IN SOLID PANS:

STEAM-EX MODEL ECX-

ITEM

Eggs

-Scrambled 10 - 12 8 Dozen

Rice

-Long grain (Cover with 4 cups water/lb) 25 2 Pounds

Pasta

(Place perforated pan inside solid pan, cover pasta with cold water)

-Spaghetti - regular/vermicelli 12 - 15

-Macaroni - shells/elbows 15 - 18

-Noodles - 1/2" wide 12 - 15

-Lasagna noodles 15 - 18

Frozen casseroles, lasagna 35 Full pan

Meat Loaf

(3-5 lbs each) 40 15 Pounds

Beef

-Ground chuck 20 - 25 10 Pounds

-Sliced as purchased 35 - 40 10 Pounds

TIMER SETTING

IN MINUTES

WEIGHT

PER PAN

Shrimp, frozen

(10 shrimps per 1b) 5 4 Pounds

Beans

-Baked 9 10 Pound Can

-Retried 9 10 Pound Can

Canned vegetables 6 10 Pound Can

Prunes, dried 12 - 15

13

Page 16

COOKING SCHEDULES

2

-

Frozen

10 - 12 3

Dozen

-

Claws

4

2-1/2

Pounds

-

Hard

Cooked

15

4

Dozen

-

Soft Cooked

9-10 4

Dozen

-

Breasts

(2) 90 6-7

Pounds each

-

Frozen

10 - 12 3

Dozen

-

Green

- 2"

cut (frozen/fresh)

6

5

Pounds

-

Lima (frozen)

8

5

Pounds

-

Spears (frozen)

8

4

Pounds

-

Spears (fresh)

6

5

Pounds

-

Flowerettes (frozen)

6

5

Pounds

SECTION 5:

PERFORATED PANS RECOMMENDED FOR FOLLOWING ITEMS:

FLOOR MOUNTED CONVECTION STEAMER

STEAM-EX MODEL ECX-

ITEM

TIMER SETTING

IN MINUTES

WEIGHT

PER PAN

Clams

-Fresh, cherrystone 5-6 3 Dozen

King Crab (frozen)

-Legs 4-6 4-1/2 Pounds

Lobster tail (frozen) 6 10 Pounds

Lobster live (10"-12") 5 4 Per Pan

Salmon fillets (frozen - 8oz. ea.) 5 7-1/2 Pounds

Scallops (fresh) 4 3 Pounds

Scrod fillets (fresh) 3-5 4 Pounds

Eggs

-Soft yoke for Caesar Salad 6-8 4 Dozen

Chicken

-Breasts, legs, thighs 20 15 Pounds

Turkey (frozen)

-Cut lengthwise 55 20-25 Pounds

Corned Beef 40 - 75 6-8 Pounds

Hot dogs or wieners 3 80-100 Count

Asparagus spears

-Fresh 5 5 Pounds

Beans

-Baby lima (frozen) 5 5 Pounds

Broccoli

14

Page 17

COOKING SCHEDULES

2

-

Defrosted

5 6 Pounds

SECTION 5:

PERFORATED PANS RECOMMENDED FOR FOLLOWING ITEMS: - continued

FLOOR MOUNTED CONVECTION STEAMER

STEAM-EX MODEL ECX-

ITEM

Brussel sprouts (frozen) 6 5 Pounds

Cabbage (fresh) 1/6 cut 8 5 Pounds

Carrots

-Baby whole (frozen) 8 7 Pounds

-Crinkle cut (frozen) 7-8 4 Pounds

-Sliced (fresh) 11 9 Pounds

Cauliflower, flowerettes

-Frozen 6 4 Pounds

-Fresh 7-8 5 Pounds

Celery (1" diagonal cut) 7 5 Pounds

Corn

-Yellow whole kernel (frozen) 5 5 Pounds

8 27 Ears -Cobbettes (frozen)

16 - 18 80 Ears

-Corn-On-The-Cob (frozen) 10 - 12 18 Ears

Peas, green 6 5 Pounds

16 - 18 54 Ears

TIMER SETTING

IN MINUTES

WEIGHT

PER PAN

Potatoes, whole russett 55 10 Pounds

Spinach

-Chopped (frozen) 17 6 Pounds

-Fresh cut 3 2 Pounds

Squash-Acorn Halves 25 10 Halves

Zucchini, slices 8 10 Pounds

Frozen mixed vegetables 6-7 5 Pounds

Fruit-Blanch for peeling:

-Grapefruit 3

-Oranges

Pineapple - whole for cutting 4

15

Page 18

SERVICE INFORMATION

2

STEAM-EX MODEL ECX-

SECTION 6:

FLOOR MOUNTED CONVECTION STEAMER

COOKER PROBLEMS DOOR

GASKET LEAKS

If Gasket is nicked, cut or at end of useful life it must be replaced.

However, if leak occurs in one corner only and Gasket appears serviceable, then turn stainless steel screw on Gasket

Plate immediately adjacent to leaking corner one half turn counterclockwise. Do not attempt excessive turning of

screws since misalignment of Door is likely.

WATER ACCUMULATES ON BOTTOM OF COMPARTMENT

Water accumulation on bottom of cooking compartment is primarily condensed steam and failure to drain out quickly

and completely may be due to clogged debris on Compartment Drain Screen which must be pulled out, completely

removed and thoroughly cleaned and then replaced.

COOKING CYCLE CANNOT BE ACTIVATED

Although this appliance has been thoroughly tested, it is advisable to inspect that all wire terminations are positive and

secure before assuming any other malfunction.

When Power Switch on Generator Control Box of Cabinet is ON and both COOK TIME-MINUTES 'windows' do not

disply "00", then obviously power is not being supplied to Cooker components. Check that all wire terminations are

positively secured.

When Power Switch on Generator Control Box is ON, both COOK TIME-MINUTES 'windows' display "00" and after

about 15 minutes steam generation shows pressure of 8 psi minimum on Pressure Gauge and consequently both

Digital Controls indicate READY (both green pilot lights lit), then touch 2 on both Digital Controls and "02" will be

displayed. Then, with doors closed. touch START on both Digital Controls and READY lights should go off and COOK

lights (red) should come on and steam should now enter both cooking compartments. However, if on one compartment

touching START does not activate steam generation and consequently COOK light refuses to come on then remove

Cooker Side Enclosure Panel and 'jump' both terminals marked 'A' and 'B' on Printed Circuit Control Board and then

touch START again. If COOK light now comes on and steam enters compartment then the Magnetic Switch is either

defective or must be realigned properly. Remove jumper wire. The Magnetic Switch is located directly above the Striker

lodged in the panel pocket and must be slightly rotated so that the 'reeds' in the glass case are directly one behind the

other when facing front to back for proper magnetic action of door magnet. If however the Magnetic Switch is defective

it must be replaced. Remove by placing slotted screwdriver under spring retaining clip and wedge outwards and

remove switch from 'pocket'. Care must be exercised not to damage glass casing when inserting new switch. Assure

that 'reeds' are one behind the other when facing front to back of appliance.

16

Page 19

SERVICE INFORMATION

2

STEAM-EX MODEL ECX-

SECTION 6:

FLOOR MOUNTED CONVECTION STEAMER

CABINET CONTROL PROBLEMS SAFETY RELIEF VALVE BLOWS AND

RELEASES STEAM FREQUENTLY

The Safety Relief Valve, set at 15 psi, is a protective device intended to prevent pressure from exceeding 15 psi in the

Boiler. During the operating cycle observe the fluctuating pressure range as indicated on the Pressure Gauge located

directly on top of the Water Level Control. The fluctuating range should read approximately 9 to 12 psi during a normal

operating cycle and if the Safety Relief Valve blows prematurely then assume it must be defective and requires

replacement.

However, if the pressure reading, indicated on the Pressure Gauge approaches 15 psi then lower adjustments of the

Pressure Switches are required. Remove Cover from Generator Control box and locate both switches at bottom left

side on Control Box. When facing Pressure Switch in the upright position, the adjusting nut on the higher top point to

the back controls the high pressure setting of that switch and the adjusting nut on the lower top surface to the front of

the switch controls the low pressure setting of that switch. Both nuts when turned counter clockwise with a 1/4" wrench

will lower the pressure settings. Refer to Periodic Maintenance Section 4, for proper pressure settings. Each nut

should be turned slightly and the pressure reading on the Gauge observed before adjusting the next nut

unnecessarily.

WATER IS NOT BEING SUPPLIED TO BOILER

When the appliance is first turned ON, and assuming that water supply is definitely available to the appliance, and

after 20 minutes no water can be observed in the Water Gauge Assembly then either the Solenoid (Hot Water) Valve

is defective or is incapable of being energized by the Water Level Control. As mentioned previously, the float within

the chamber of the Water Level Control may be seized and remain stuck in the upper position by scalant therby falsely

indicating sufficient water is present in the Boiler. The Water Level Control Assembly must be detached, removed and

thoroughly cleansed to remove scalants and lime build up. Refer to Boiler on Removal of Scalants etc.. This

malfunction indicates extremely poor water quality being supplied to the appliance and must be attended to

immediately to avoid complete breakdown of the appliance.

Another possibility is that as quickly as water is fed to the Boiler it is being drained through an open Boiler Blowdown

Solenoid Valve which cannot close since it is not being energized either through defective wiring, a burnt out coil or

the inability of the valve to close completely. This valve contains a moveable blade and when de-energized the blade

reacts as a guillotine which should be free to move fully down into the valve pocket (projection at bottom of valve) so

that the pierced hole in the blade aligns perfectly with the body opening. If debris has accumulated in the bottom of the

valve pocket then blade obviously will be impeded from moving into pocket completely. Further, a burnt out valve coil

is likely. With valve removed from Cooker body remove retaining clip at top of solenoid. Grasp (green) cover and

housing intact with

(Continued)

17

Page 20

2

SERVICE INFORMATION

STEAM-EX MODEL ECX-

SECTION 6:

CABINET CONTROL PROBLEMS (Continued)

WATER IS NOT BEING SUPPLIED TO BOILER (Continued)

coil inside and slide off from valve. Unscrew projecting tube from top of valve body and remove internal mechanism

together with blade assembly. Next unscrew both assembly bolts and split brass body of valve removing loose internal

parts. Now flush and clean pocket thoroughly. Reassemble all parts in reverse order of disassembly. Energize valve

with 120V power and if valve fails to close replace coil. Reconnect all plumbing.

BOILER BLOWDOWN SOLENOID VALVE DOES NOT DRAIN

When the appliance is turned OFF the Boiler Blowdown Valve is de-energized and consequently opens and the water,

contained in the Boiler being under pressure, should be blown through this Valve and be noticable visible exhausting

out the appliance Drain. However if the blowdown operation appears to function rather sluggishly or not at all then

assume that considerable scalant may be lodged in the drain pipe and/or the Valve. Disconnect Valve from the drain

line and inspect both the Valve and the drain pipe fixed to the Boiler. If considerable scalant or lime build up is apparent

then not only the Valve but also the Boiler and Water Level Control must be thoroughly cleansed. Refer to preceding

paragraph on cleaning procedure of Valve and also Removal of Scalants from Boiler Procedure.

FLOOR MOUNTED CONVECTION STEAMER

BOILER ACHIEVES PRESSURE SLOWER THAN NORMAL

If the Boiler requires considerably more time than 15 minutes to achieve normal operating pressure (9 to 12 psi), then

assume that heavy build up of scalant has completely coated not only the interior of the Boiler but also the Heater

Elements and consequently heat transfer is hampered by the insulating effect of the scalant. Unbolt and remove the

Handhole Cover Plate and Gasket assembly. Examine interior of Boiler and if scalant and/or lime build up is apparent

follow Removal of Scalants from Boiler Procedure.

If considerable scalant is evident then both the Boiler Blowdown Solenoid Valve and the Water Level Control must also

be examined.

If the Boiler interior and the Heater elements appear relatively clean and free of scalants then examine and test for a

bum out Heater Element and replace if necessary.

REMOVAL OF SCALANTS FROM BOILER

Close Manual Blowdown Valve.

If the appliance has an Automatic blowdown Solenoid Valve, then turn OFF power supply to the appliance and remove

cover from Generator Control Box. Disconnect line splices and supply external 120V power to Blowdown Solenoid

Valve wire leads to energize and close this valve. Turn power supply back on to appliance.

18

Page 21

SERVICE INFORMATION

2

STEAM-EX MODEL ECX-

SECTION 6:

CABINET CONTROL PROBLEMS (Continued)

REMOVAL OF SCALANTS FROM BOILER (Continued)

Remove 3/4" pipe Plug from end of Steam Take-off located on front head of Boiler next to handhole.

Turn appliance Power Switch ON. Water will now enter and fill Boiler to required level and Heater Elements will come

on. Observe closely that as soon as initial flow of steam is readily apparent from the Steam Take-off (approximately 10

minutes), shut appliance Power Switch OFF in order to prevent excessive steam generation and consequently

pressure in the Boiler.

Insert appropriate hose or tube through Steam Take-off port and pour in ONE gallon (US) of a recommended Boiler

Descaling Solution (full strength).

Replace and screw Plug in securely to Steam Take-off port to prevent leakage.

Allow two hours for descaling and cleaning of Boiler and chamber of Water Level Control.

FLOOR MOUNTED CONVECTION STEAMER

Manually open both the Blowdown and Water Level Control Valves for complete drainage and then close both valves.

If the appliance has an Automatic Blowdown Solenoid Valve, turn OFF power supply to the appliance, disconnect

external 120V power to this valve and reconnect spliced line terminals. Screw Cover back on to Generator Control

Box. Open Water Level Control Valve. Turn power supply back on to appliance. After complete drainage close Water

Level Control Valve.

Turn appliance Power Switch ON. When water has entered and filled Boiler to required level ('approximately 2

minutes), turn OFF Power Switch and rinse water will drain out of Boiler. If the appliance has a manual Blowdown

Valve, open it until complete Boiler drainage has occured and then close it. Repeat this step again.

Turn appliance Power Switch ON allowing steam generation and consequently pressure to rise to normal operating

level and then turn OFF Power Switch for a final purging of Boiler and steam supply lines.

"Appliance is now ready for use.

19

Page 22

CONVECTION STEAMER

SERIAL NUMBER/RATING PLATE:

ELECTRIC BOILER

PARTS

WARNING:

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID THE WARRANTY ON THIS

EQUIPMENT.

The serial plate is located inside the left door of the cabinet base at the top of the panel.

Replacement parts may be ordered either through a Southbend Authorized Parts Distributor or a South-bend

Authorized Service Agency.

When ordering parts please supply the Model Number, Serial Number, Part Number, Description, plus Finish, and

Electrical Characteristics, as applicable.

For parts not listed consult a Southbend Authorized Parts Distributor or Southbend Authorized Service Agency. If

necessary, please consult Southbend Escan Parts Department for assistance.

Page 23

PARTS LIST

SECTION 7: CABINET

FIG. 4

ITEM NO. PART NO. DESCRIPTION QUANTITY

1 8-1400 Cabinet Assembly (Galv. Back) 1

8-1410 Cabinet Assembly (Stainless Back) 1

2 8-1305 Side Panel 2

3 8-1308 Flanged Adjustable Foot (Rear) 2

4 5-FS64 Adjustable Foot Insert (Front) 2

5 5-MC02 Magnetic Door Catch 2

1-11C2 Magnetic Door Catch Screws 8

6 8-1303 Right Hand Door (Shown) 1

8-1304 Left Hand Door 1

Note: Item No. 3, 'Flanged Adjustable Foot', may be specified

as an option on all four legs at time of order.

20

Page 24

PARTS LIST

2

SECTION 7:

STEAM-EX MODEL ECX-

GENERATOR ASSEMBLY

FIG. 5

21

Page 25

2

1

PARTS LIST

SECTION 7:

GENERATOR ASSEMBLY

MODEL ECX-

FROM FIG. 5

ITEM NO. PART NUMBER DESCRIPTION QUANTITY

1 8-1600 Electric Boiler (Specify KW) 1

2 4-WC67 Low Hater Cut-Off 1

3 3-PG30 Boiler Pressure Gauge 1

4 3-WG20 Water Gauge Assembly 1

5 3-SRV3 Boiler Safety Valve 1

6 3-TST1 Thermostatic Steam Trap 1

7 8-1320 Exhaust Drain Assembly 1

8 8-1321 Appliance Drain Assembly 1

9 3-S567 Blowdown Solenoid Valve 1

or

5-BVEO

Manual Valve

22

Page 26

PARTS LIST

2

SECTION 7:

MODEL ECX-

ELECTRIC BOILER ASSEMBLY

FIG. 6

23

Page 27

2

Cookers with Boiler Rating of 36KW Have Six 6000W Elements

Cookers with Boiler Rating of 42KN Have Six 7000W Elements

PARTS LIST

SECTION 7:

ELECTRIC BOILER ASSEMBLY

MODEL ECX-

FROM FIG. 6

Item No. Part Number Description Quantity

1 8-1415 Element (Specify KW & Voltage) 3 or 6*

2 8-1428 Element Fastening Nut (Specify KW) 6 or 12

3 8-1430 Element Enclosure Box (Specify KW) 1

4 2-75UO Fastening Nut 1

5 8-1410 Yoke 1

6 8-1409 Handhole Gasket 1

7 2-75U9 Fastening Bolt 1

8 8-1408 Handhole Cover Plate 1

9 4-TH46 Safety Thermostat 1

* Cookers with Boiler Rating of 24KW Have Three 8000W Elements

Cookers with Boiler Rating of 48KW Have Six 8000W Elements

24

Page 28

PARTS LIST

2

SECTION 7:

GENERATOR CONTROL

BOX COMPONENTS

STEAM-EX MODEL ECX-

FLOOR MOUNTED CONVECTION STEAMER

FIG. 7

25

Page 29

2

PARTS LIST

SECTION 7:

GENERATOR CONTROL BOX ASSEMBLY

STEAM-EX MODEL ECX-

FROM FIG. 7

ITEM NO.

PART

NUMBER

DESCRIPTION QUANTITY

1 3-PA26 Pressure Switch c/w 3-RD20 Transducer 2

2 4-FH03 Fuseholder 1

3 4-PL04 Pilot Light 1

4 4-S191 Power Switch 1

5 1-55C8 Pressure Switch Bolt 8

6 4-LQE7 Liquid Tite Elbow Assembly 3

4-LQE7 Liquid Tite Connector Assembly (to Element) 1

7 3-S252 Solenoid Valve 1

8 3-S162 Solenoid Valve 1

9 4-TxxH Transformer (Specify Voltage) 1

10 4-24T9 Terminal Block 1

11 4-22T8 Terminal Block 1

12 4-70EU Ground Terminal 1

13 4-CF50 Contactors 2

14 8-1244 Control Box Cover 1

26

Page 30

PARTS LIST

SECTION 7: COOKER ASSEMBLY

FIG. 8

27

Page 31

2

PARTS LIST

SECTION 7:

Item No. Part Number Description Quantity

1 8-5101 Hinge Rod 1

2 8-5078 Bronze Bushing 2

3 8-5076 Door Assembly 2

4 8-5023 Perforated Trough Channel 1

5 8-5081 Compartment Drain Screen 2

6 8-5005 Digital Control Panel 1

7 8-5080 Pan Rack 4

8 1-34S4 Stainless Steel Panel Screws 2

9 8-5102 Enclosure Panel 1

STEAM-EX MODEL ECX-

COOKER ASSEMBLY

10 1-90S0 Lock Washer 2

11

12 8-5022 Stainless Steel Washer 2

13 8-5021 Striker 2

14 8-5108 Top Panel (not shown) 1

1-99S0 Nut 2

28

Page 32

PARTS LIST

2

SECTION 7:

FIG. 9

STEAM-EX MODEL ECX-

DOOR ASSEMBLY

29

Page 33

2

PARTS LIST

SECTION 7:

FROM FIG. 9

STEAM-EX MODEL ECX-

COMPARTMENT DOOR PARTS

Item No. Part Number Description Quantity

1 8-5060 Door Panel 1

2 8-1101 Name Plate 1

3 8-5079 Bronze Bushing 3

4 8-5069 Latch Assembly Plate 1

5 1-CS77 Compression. Spring 1

6 8-5068 Locking Device 1

7 1-T658 Spring Tension Pin 1

8 8-5067 Latch Pin 1

9 8-5875 Magnet 1

10 8-5070 Enclosure Plate 1

11 1-XB33 Retaining Ring 1

12 1-34S8 Stainless Steel Screw 2

13 8-5066 Door Handle 1

14 1-T5S6 Spring Tension Pin 1

15 1-CS78 Compression Spring 4

16 8-5065 Mounting Plate 1

17 8-5063 Gasket 1

18 8-5064 Gasket Plate 1

19 2-0T0R "0" Ring 6

20 2-53S5 Stainless Steel Screw 6

MOTE: Parts are sequenced in order of assembly. For disassembly and reassembly. Door must be removed

from Cooker and placed face down on flat surface. When assembling Parts 15 to 20 inclusive, screw

in tow threaded 1/4-20 rods initially into Door Panel and insert Parts 15, 16, 17 and 18. Remove

threaded rods one at a time and replace with '0' Rings and Stainless Steel Screws.

30

Page 34

PARTS LIST

2

SECTION 7:

COOKER CONTROL COMPONENTS FIG. 10

FLOOR MOUNTED CONVECTION STEAMER

STEAM-EX MODEL ECX-

31

Page 35

2

PARTS LIST

SECTION 7:

COOKER CONTROL COMPONENTS

STEAM-EX MODEL ECX-

FROM FIG. 10

Item No. Part Number Description Quantity

1 8-5061 Door Switch 2

2 4-T199 Transformer 1

3 8-5003 Printed Circuit Board 2

4

5 8-5002 Printed Circuit Board 2

6 4-TH04 Drain Thermostat (Water Cooling) 1

7 3-S263 Steam Solenoid Valve 2

3-PA36 Pressure Switch 1

8 3-P615 Pressure Gauge 1

9 3-TSH Thermostatic Steam Trap 1

32

Page 36

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

33

Page 37

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

34

Page 38

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

35

Page 39

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

36

Page 40

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

37

Page 41

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

38

Page 42

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

39

Page 43

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

40

Page 44

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

41

Page 45

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

42

Page 46

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

43

Page 47

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

44

Page 48

WIRING DIAGRAM

SECTION 8: MODEL ECX-2

45

Page 49

CONVECTION STEAMER

ELECTRIC BOILER

A product with the Southbend name incorporates the best in durability and low

maintenance. We all recognize however, that replacement parts and occasional

professional service may be necessary to extend the useful life of this unit. When

service is needed, contact a Southbend Authorized Service Agency, or your dealer. To

avoid confusion, always refer to the model number, serial number, and type of your

unit.

PART NUMBER A44-00002 Printed in Canada

Loading...

Loading...