Southbend SGS-60, SGS-48E, SGS-60E, SGS-24E, SGS-36 User Manual

...

OPERATOR’S MANUAL

Counter Griddle

Model Numbers

SGS-24 SGS-24E

SGS-36 SGS-36E

SGS-48 SGS-48E

SGS-60 SGS-60E

MANUAL 1182629 REV 2

$9.00

COUNTER GRIDDLE

MANUAL SECTION BR

COUNTER GRIDDLE

SAFETY PRECAUTIONS

Before installing a nd opera ting this equipm ent, be sure e ver yone invol ved in its operat ion is f ully tr ained and

aware of precautions. Accidents and problems can be caused b y failure to follow fundamental rules and

precautions.

The following s ymbols, found throug hout this manual, alert you to potentially dangerous conditions to the

operator, service personnel, or to the equipment.

! DANGER

! WARNING

! CAUTION

NOTICE

This symbol warns of immediate hazards that will result in severe injury or

death.

This symbol refers to a potential hazard or unsafe practice that could result in

injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in

injury, product damage, or property damage.

This symbol refers to information that needs special attention or must be fully

understood, even though not dangerous.

! WARNING

FIRE HAZARD

FOR YOUR SAFETY

Do not store or use ga soline or other flamm able vapors and l iquids in the vicinit y of this or an y other

appliance.

Keep area around appliances free and clear of combustibles.

Purchaser of equipment m ust post in a prom inent location, detailed instruct ions to be follo wed in the

event the operator smells gas. Obtain the instructions from the local gas supplier.

! WARNING

Asphyxiation can result from improper ventilation. Do not obstruct the flow of combustion and

ventilation air to and from your cooking equipment.

NOTICE

Be sure this Operator’s Man ual and important papers ar e given to the proper authorit y to retain for

future reference.

NOTICE

This product is intended for commercial use only. NOT FOR HOUSEHOLD USE.

PAGE 2OPERATOR’S MANUAL 1182629 REV 2

COUNTER GRIDDLE TABLE OF CONTENTS

Congratulations! You have purchased one of the finest pieces of commercial cooking equipment on the

market.

You will find that your new equipm ent, like all Southbend equipment, has been desig ned and m anufactured

to meet the toughest standards in t he industr y. Each piece of Southbend e quipment is carefull y engineered

and designs are verified through laboratory tests and field installations. With proper care and field

maintenance, you will experience years of reliable, trouble-free operation. For best results, read this

manual carefully.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Table of Contents

Specifications..........................................................................................................................4

Installation...............................................................................................................................7

Operation ..............................................................................................................................19

Cleaning................................................................................................................................21

Adjustments ..........................................................................................................................22

Troubleshooting ....................................................................................................................26

Parts......................................................................................................................................27

Read these instructions carefully before attempting installation. Installation and initial startup should be

performed by a qualified installer. Unless the installation instructions for this product are followed by a

qualified service tech nician (a person experienced in and knowledge able with the insta llation of comm ercial

gas an/or electric cooking equipm ent) then the terms and conditi ons on the Ma nufactur er’s Lim ited W arranty

will be rendered void and no warranty of any kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, write to:

Technical Service Department

Southbend

1100 Old Honeycutt Road

Fuquay-Varina, North Carolina 27526 USA

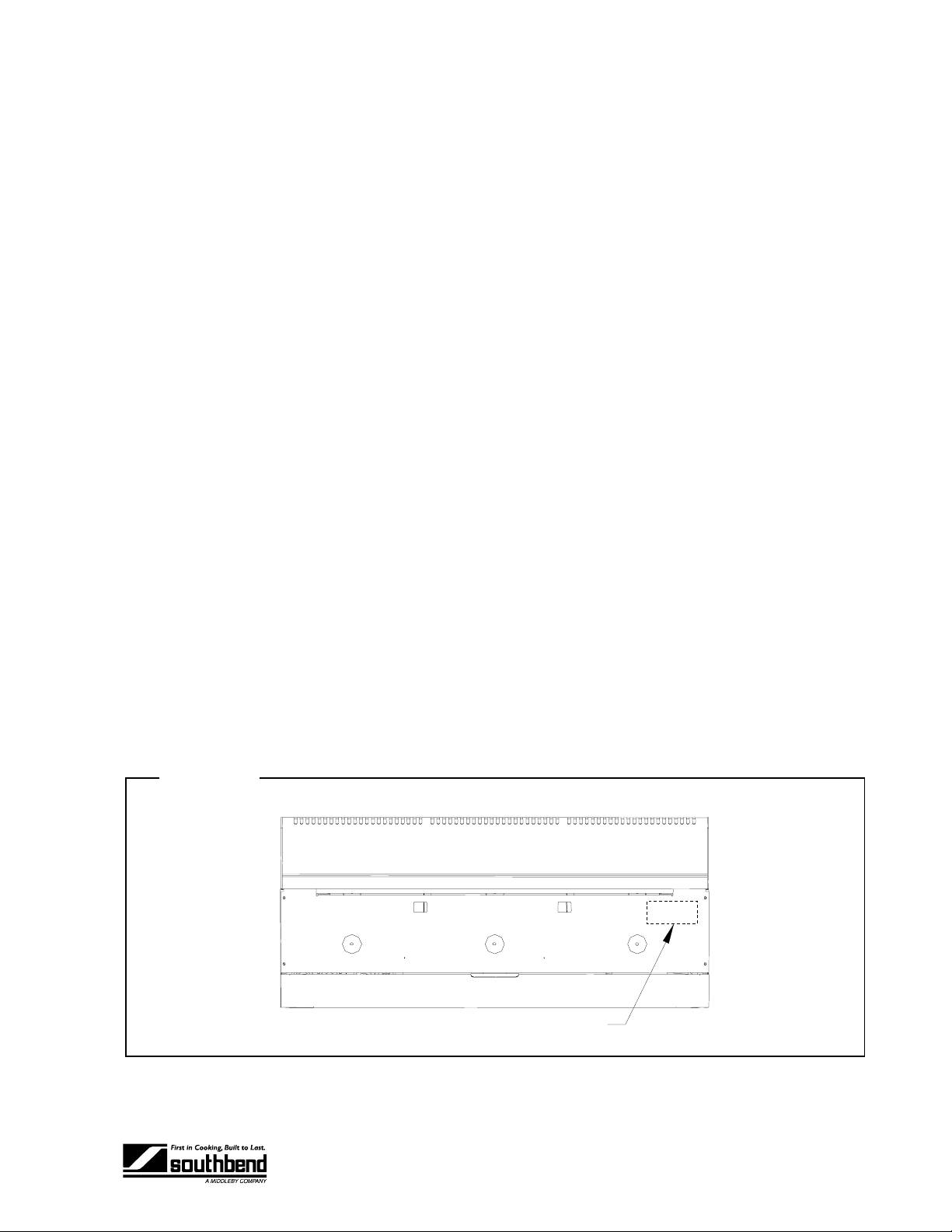

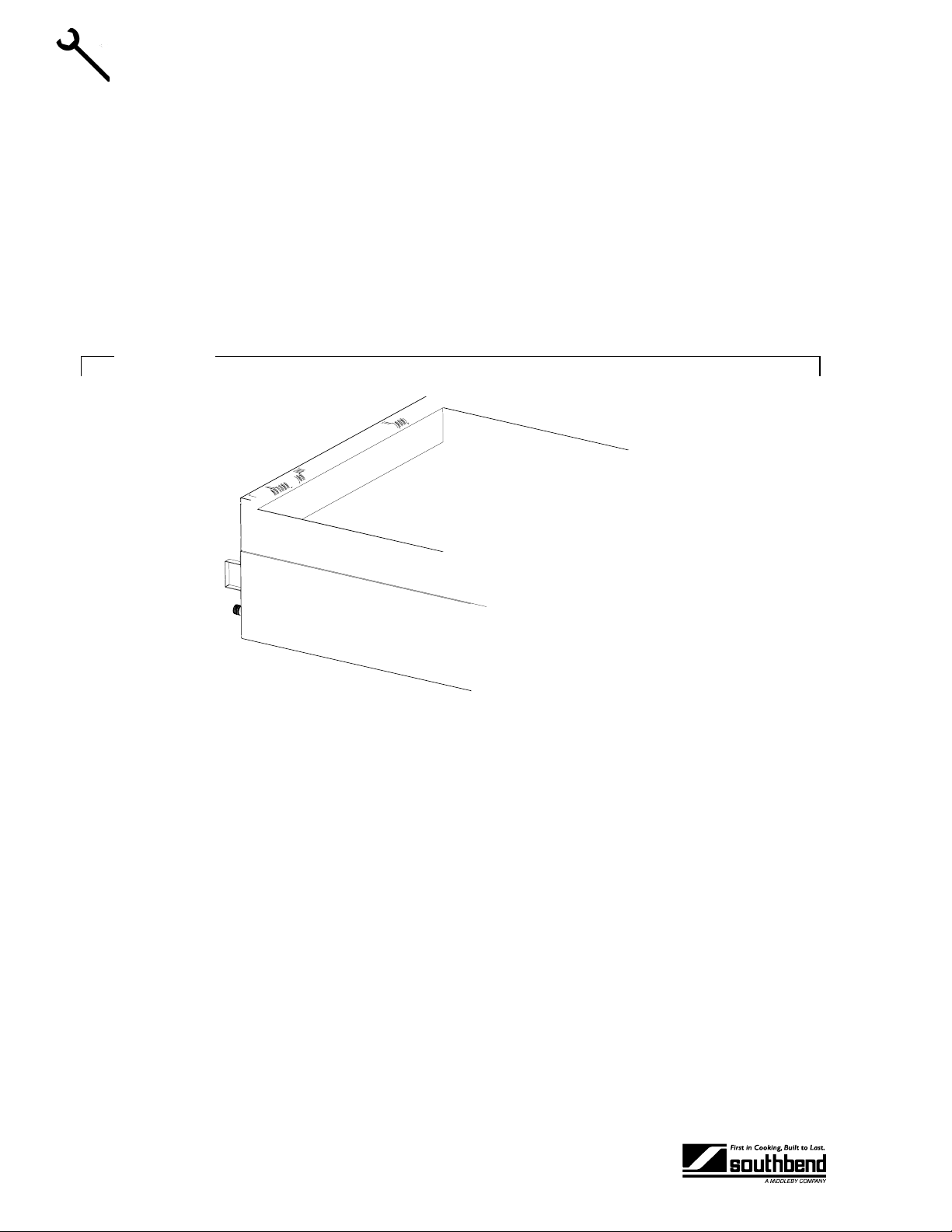

The serial plate is located on the interior side of the upper front panel, as shown below:

Figure 1

Serial plate is located on the inside of this panel.

OPERATOR’S MANUAL 1182629 REV 2PAGE 3

Model SGS-36 Shown

SPECIFICATIONS COUNTER GRIDDLE

SPECIFICATIONS

SPECIFICATIONS

NOTICE

Installation must comply with National Fuel Gas Code, ANSI Z223.1, Natura l Gas Installation Code,

CAN/CGA-B149.1, or the Propane Installation Code, CAN/CGA-B149.2, as applicable.

Local codes regarding install ati on vary greatly from one area to another. The Nat ion al F ir e Protec t ion

Association, Inc. states in its NFPA 96 latest edition that local codes are the “authority having

jurisdiction” when it com es to insta llation req uirem ents for equ ipment. T herefore, install ations s hould

comply with all local codes.

Southbend reserves the right to change specifications and product design without notice. Such

revisions do not e ntitle the bu yer to c orres pondi ng cha nges, add it ions, or rep lacem ents f or previo usl y

purchased equipment.

This product is intended for commercial use only, not for household use.

GAS SUPPLY

The Serial Plate is located on the int erior side of the upper f ront panel ( see Figur e 1 on p age 3). It indicates

the type of gas (propane or natural gas) the griddle is equipped to burn. All Southbend equipment is

adjusted at the factory. Check type of gas on serial plate.

This appliance should be connected ONLY to the type of gas for which it is configured.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas

required for satisf ac tor y perf ormance. Fluctuations of more than 25% on natural gas or 10% on pr opa ne gas

will create problems and affect burner operating characteristics. A 1/8” pressure tap is located on the

manifold to measure the manifold pressure.

No segment of the gas supply line to the griddle should be smaller than the inside diameter of the inlet

connector of the griddle (3/4" NPT).

Purge the supply line to clean out dust, dirt, or other foreign matter before connecting the line to the griddle.

All pipe joints and connections must be tested t horoughl y for gas le aks. Use only soap y water for tes ting on

all gases. NEVER use an open flame to c heck for gas leaks. All con nections must be checked f or leaks

after the griddle has been put into operation. Test pressure should not exceed 14” W.C.

! CAUTION

THIS APPLIANCE AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE DISCONNECTED FROM

THE GAS SUPPLY PIPING SYST EM DURING ANY PRESSURE TESTING OF THAT SYSTEM AT

TEST PRESSURES IN EXCESS OF 1/2 PSIG (3.45 kPa).

THIS APPLIANCE MUST BE ISOLATED FRO M THE GAS SUPP LY PI PING SYST EM BY C LOSING

ITS INDIVIDUAL MANUAL SHUTOFF V ALVE DURING ANY PRESSURE TESTING OF THE GAS

SUPPLY PIPING SYSTEM AT TEST PRESSURES EQUAL TO OR LESS THAN 1/2 PSIG (3.45

kPa).

PAGE 4OPERATOR’S MANUAL 1182629 REV 2

COUNTER GRIDDLE SPECIFICATIONS

CLEARANCES

!

WARNING

There must be adequate clearance between griddles and adjacent construction. Clearance in the

front must also be provided for servicing and for operation.

Minimum clearances from COMBUSTIBLE construction are 12" on sides, 8" on rear, and 4" on

bottom (order the countertop legs or floor stand).

Minimum clearances from NON-COMBUST IBLE construction is 0" on sides, 2" on rear ( the 2" deep

stand-offs on the rear may be against a wall), and 0" on the bottom.

VENTILATION

!

WARNING

Improper ventilati on can result in person al injur y or death. Vent ilation whic h fails to pr operly re move

flue products can cause headaches, drowsiness, nausea, or could result in death.

All griddles m ust be install ed in such a m anner that the f low of combustion and ve nt ilation air ar e not

obstructed. Provisions for adequate air supply must be provided. Do not obstruct the rear of the

griddle at as combustion air enters through this area.

SPECIFICATIONS

NOTICE

Proper ventilation is the owner ’s responsibility. Any problem due to improper ventilatio n will not be

covered by the warranty.

Air for combustion enters the rear of the griddle. The exhaust flue runs along the top rear edge.

Southbend recommends that a ventil ati on ca nopy extend 6" past the edg es of the griddle and be loc a ted 6'6 "

above the floor.

If a wall exhaust fan is installed in t he wall behind t he griddle , it should be a t least two f eet above the t op of

the flue opening along the back edge of the griddle.

To avoid a negative pressure condit ion, return air must be br ought into the room to reple nish the air being

removed by the ventilation exhaust fan. RETURN-AIR FANS MUST NOT BLOW DOWN INTO THE

GRIDDLE FLUE (ALONG THE TOP REAR EDGE OF THE GRIDDLE), NOR DIRECTLY ONTO THE

GRIDDLE SURFACE.

Ventilation filters should be i nstalled at an an gle of 45° or mor e from the horizontal. T his prevents dripp ing

grease and facilitates collecting the run-off grease in a drip pan, usually installed with a filter.

Be sure to inspect and clean the ventilation system according to the ventilation equipment manufacturer ’s

instructions.

In case of unsatisf actor y perf orm ance on an y appli ance, ch eck the app liance with the vent ilatio n ex haus t f an

in the “OFF” position. D o th is on l y long eno ugh to check equipment performanc e. T hen tur n the f an bac k on

and let it run to remove any exhaust that may have accumulated during the test.

OPERATOR’S MANUAL 1182629 REV 2PAGE 5

SPECIFICATIONS COUNTER GRIDDLE

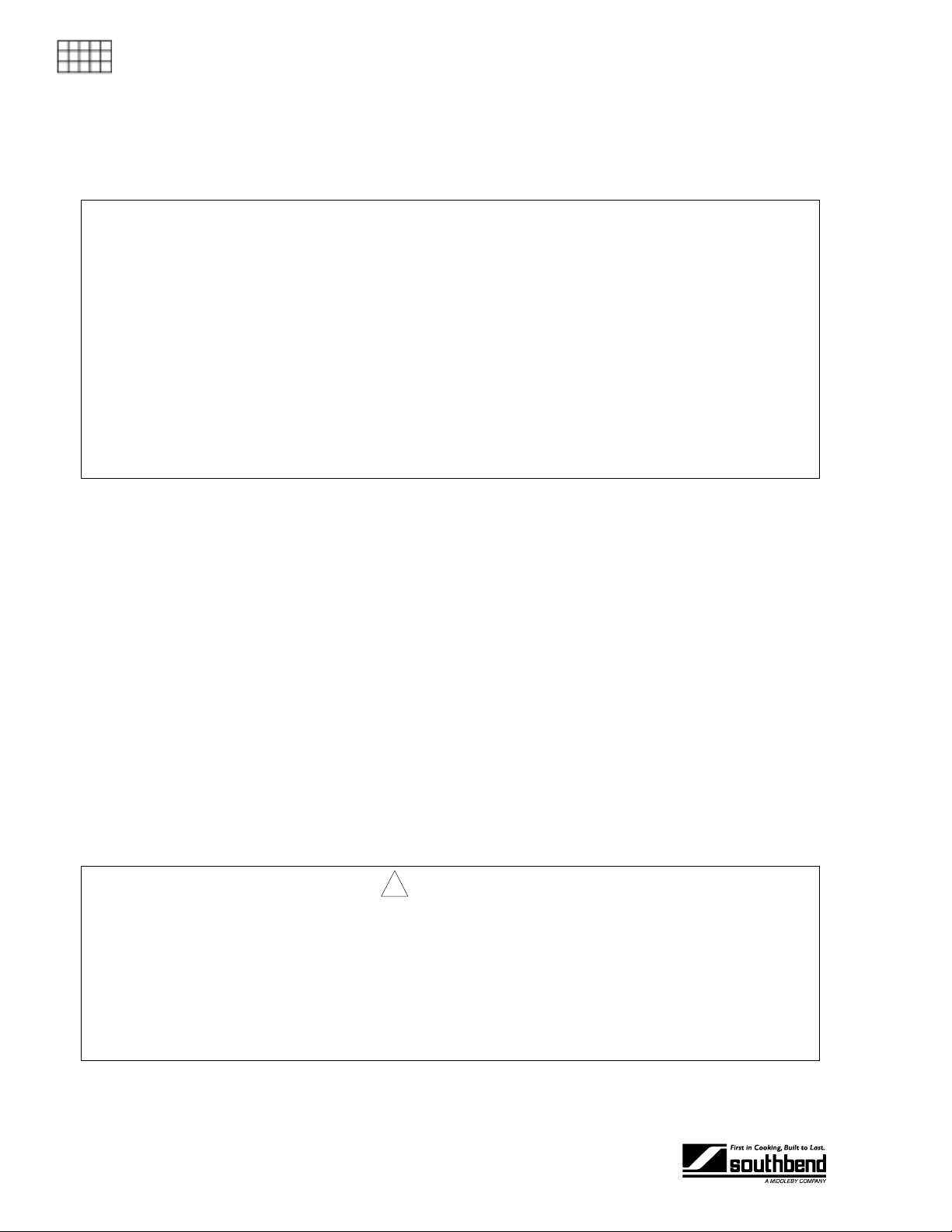

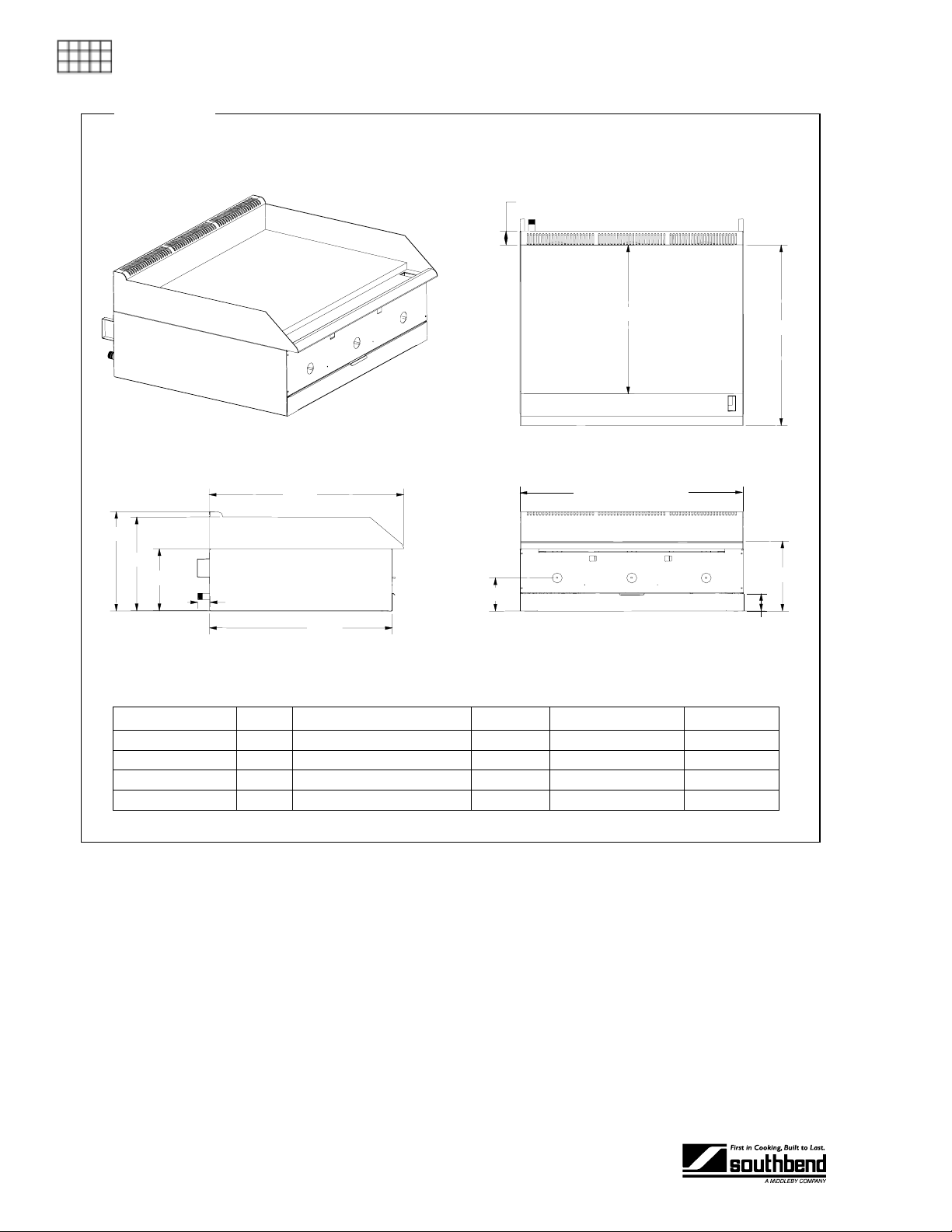

Figure 2

DIMENSIONS

SPECIFICATIONS

31.32"

16.00"

15.10"

9.96"

2.00"

29.42"

2.24"

24.00"

29.08"

Top View

Width (see table below)

11.24"

5.34"

2.78"

Front ViewSide View

Model Width Number and Size of Burners Total BTU Crate Size Crated Weight

SGS-24 & SGS-24E 24" 2 @ 30,000 60,000 31"W x 39"D x 24"H 305 lbs.

SGS-36 & SGS-36E 36" 3 @ 30,000 90,000 55"W x 39"D x 24"H 445 lbs.

SGS-48 & SGS-48E 48" 4 @ 30,000 120,000 55"W x 39"D x 24"H 545 lbs.

SGS-60 & SGS-60E 60" 5 @ 30,000 150,000 67"W x 39"D x 24"H 705 lbs.

CONSTRUCTION

The front, sides, and 5 " riser are all s tainless steel. T he rear and bottom panels ar e aluminized steel. T he

reinforced double-wall sides are fully insulated.

The griddle surface is high-c arbon, 1" thick , polished s teel plat ed with tr ivalent chr omium . The c hrome plate

has an emissivity rating of approximately 0.08.

Each foot of griddle width is heated by a U-shaped burner controlled by a thermostatic gas valve for

independent temperature control. Each pilot is equipped with a flame failure safety device.

The base of a 60" griddle consists of the base of a 24" griddle and a 36" griddle connected together,

spanned by a 60" griddle surface with one greas e duct and one gr eas e dra wer.

PAGE 6OPERATOR’S MANUAL 1182629 REV 2

COUNTER GRIDDLE INSTALLATION

INSTALLATION

NOTICE

Installation must comply with National Fuel Gas Code, AN SI Z223.1, Na tural Gas Installation Code,

CAN/CGA-B149.1, or the Propane Installation Code, CAN/CGA-B149.2, as applicable.

These installation procedures must be followed by qualified personnel or warranty will be void.

Local codes regarding install ati on vary greatly from one area to another. The Nat ion al F ir e Protec t ion

Association, Inc. states in its NFPA 96 latest edition that local codes are the “authority having

jurisdiction” when it com es to insta llation req uirem ents for equ ipment. T herefore, install ations s hould

comply with all local codes.

Step 1: Unpack

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers shou ld be examined f or damage before an d during unloading. The freight carri er has

assumed responsibility for its safe transit and delivery. If damaged equipment is received, either

apparent or concealed, a claim must be made with the delivering carrier.

Apparent damage or l os s must be noted on the f reight b i ll at the time of deli ver y. T he f r eight bi ll must

then be signed by the c arrier representat ive (Driver). If the bill is not s igned, the car rier may ref use

the claim. The carrier can supply the necessary forms.

A request for insp ection must be m ade to the carrier within 15 da ys if there is concea led damage or

loss that is not apparent until after the equipment is uncrated. The carrier should arrange an

inspection. Be certain to hold all contents plus all packing material.

INSTALLATION

1. Uncrate carefully. Report any hidden damage to the freight carrier IMMEDIATELY.

2. Do not remove any tags or labels until griddle is installed and working properly.

Step 2: Attach Countertop Legs, Mount on Counter, or Mount on Stand

The counter griddle can be mounted in several ways:

To mount it on short, countertop legs, go to Step 2a on page 8.

To mount it directly on a countertop, go to Step 2b on page 9.

To mount it on an insulated base on a countertop, go to Step 2c on page 10.

To mount it on a stand that rests on the floor, go eit her to Step 2d on p age 11 (for 24", 36", and 48"

models) or to Step 2e on page 13 (for a 60" model).

OPERATOR’S MANUAL 1182629 REV 2PAGE 7

INSTALLATION COUNTER GRIDDLE

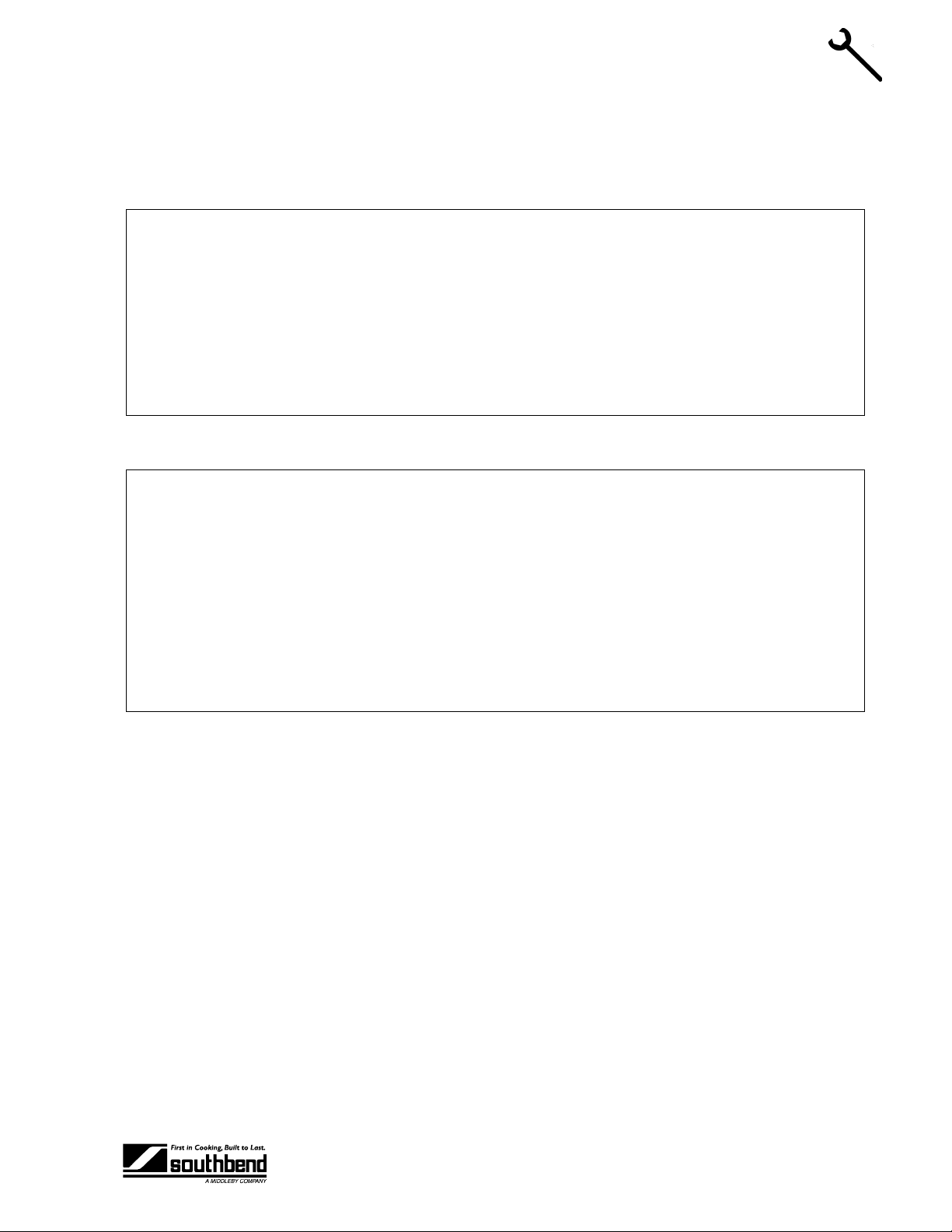

Step 2a: Installation on Countertop Legs

To install the griddle using countertop legs, do the following:

1. Locate the box of four legs shipped with the griddle (if countertop legs were ordered).

2. Raise the griddle about 6" so that th e legs can be screwed into the bottom near the corners. Lift the

griddle only from the ends, never from the middle! Support th e lifted gridd le so that it will not f all while

you are attaching the legs.

3. Screw the four le gs into the threaded holes loc ated on the bottom of the gr iddle near each corner ( as

shown in Figure 3 below).

4. Gently lower the griddle onto the counter. Level the gr iddle sur face b y screwin g one or m ore of the legs

INSTALLATION

in or out.

5. Go on to Step 4 on page 16.

Figure 3

PAGE 8OPERATOR’S MANUAL 1182629 REV 2

COUNTER GRIDDLE INSTALLATION

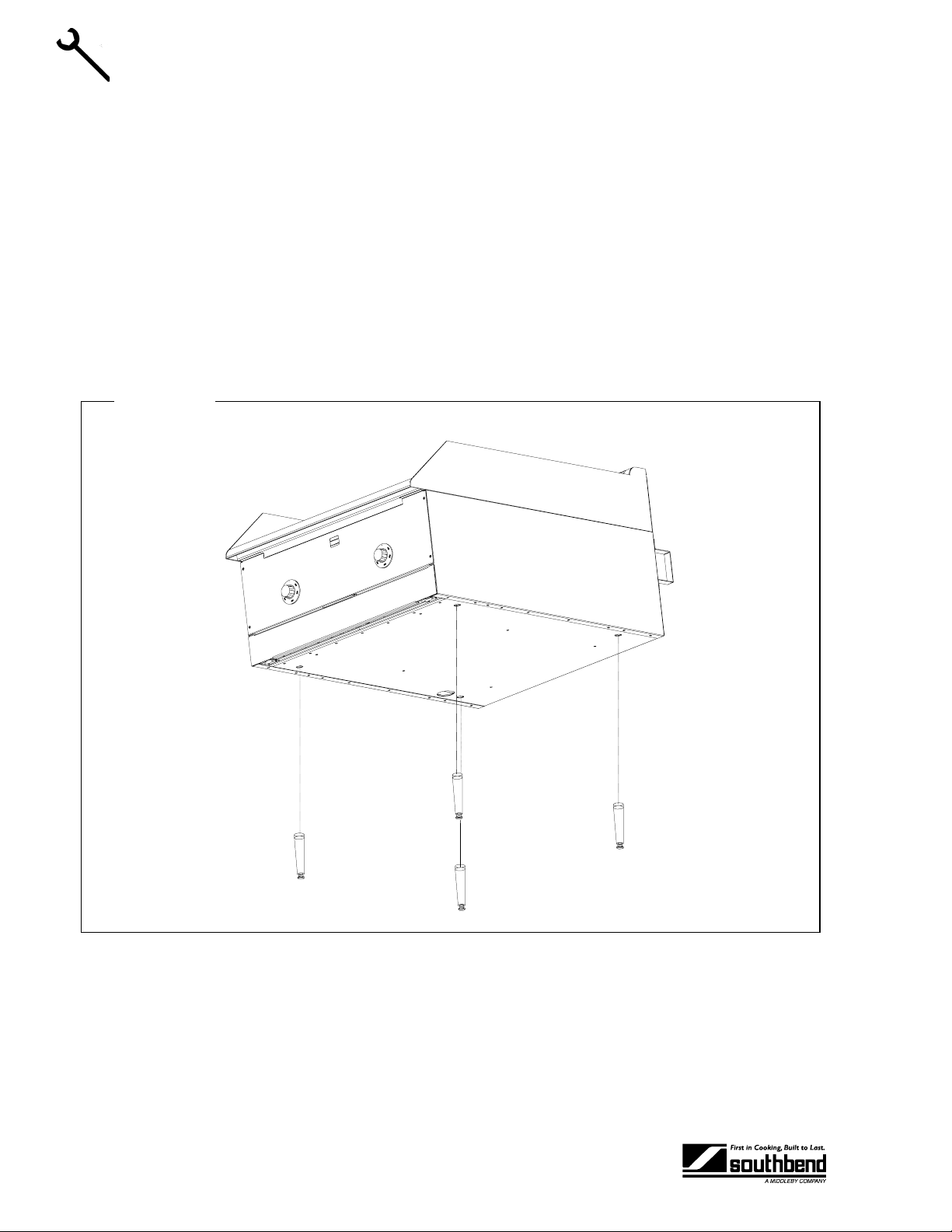

Step 2b: Installation Directly on a Non-Combustible Countertop Surface

The griddle may be installed directly onto a flat NON-COMBUSTIBLE surface, as follows:

1. Place the gri ddle in the position that it will be used. Lift the grid dle only from the ends , never from the

middle!

2. Connect the gas supply (see Step 4 on page 16), then return to this procedure.

3. Check that the griddle is in the position you want it to be in.

4. Seal the griddle to the countertop using G.E. or Dow Corning RTV, or the eq uivalent (as show n in Fig ure

4 below). Consult local codes for exact requirements. A small bead of RTV around all four bottom

edges should be adequate. Open the front door to seal along the front edge of the frame.

5. Go on to Step 5 on page 17.

Figure 4

INSTALLATION

OPERATOR’S MANUAL 1182629 REV 2PAGE 9

INSTALLATION COUNTER GRIDDLE

Step 2c: Installation on Insulated Base

The griddle may be installed ont o a flat NON-CO MBUSTIBLE ( but heat se nsitive) sur face using the optional

insulated base, as follows:

1. Attach the side pi eces of the insulated base (it ems “A” in Figure 5 belo w) to the front piece (item “B”)

using the four sheet metal screws provided.

2. Position the insulated base on the surface wher e you want the gr idd le to be locat ed.

3. Position the griddle on top of the insulated base. Lift the griddle only from the ends, never from the

middle!

4. Go on to Step 4 on page 16.

INSTALLATION

Figure 5

PAGE 10 OPERATOR’S MANUAL 1182629 REV 2

COUNTER GRIDDLE INSTALLATION

Step 2d: Installation on Floor Stand (24", 36", and 48" Models)

The 24", 36", and 4 8" griddles m ay be installe d on top of an opt ional flo or stand ( for 60" griddl es, go to Ste p

2e on page 13). The floor stand is shipped in a separate crate and must be assembled, as follows:

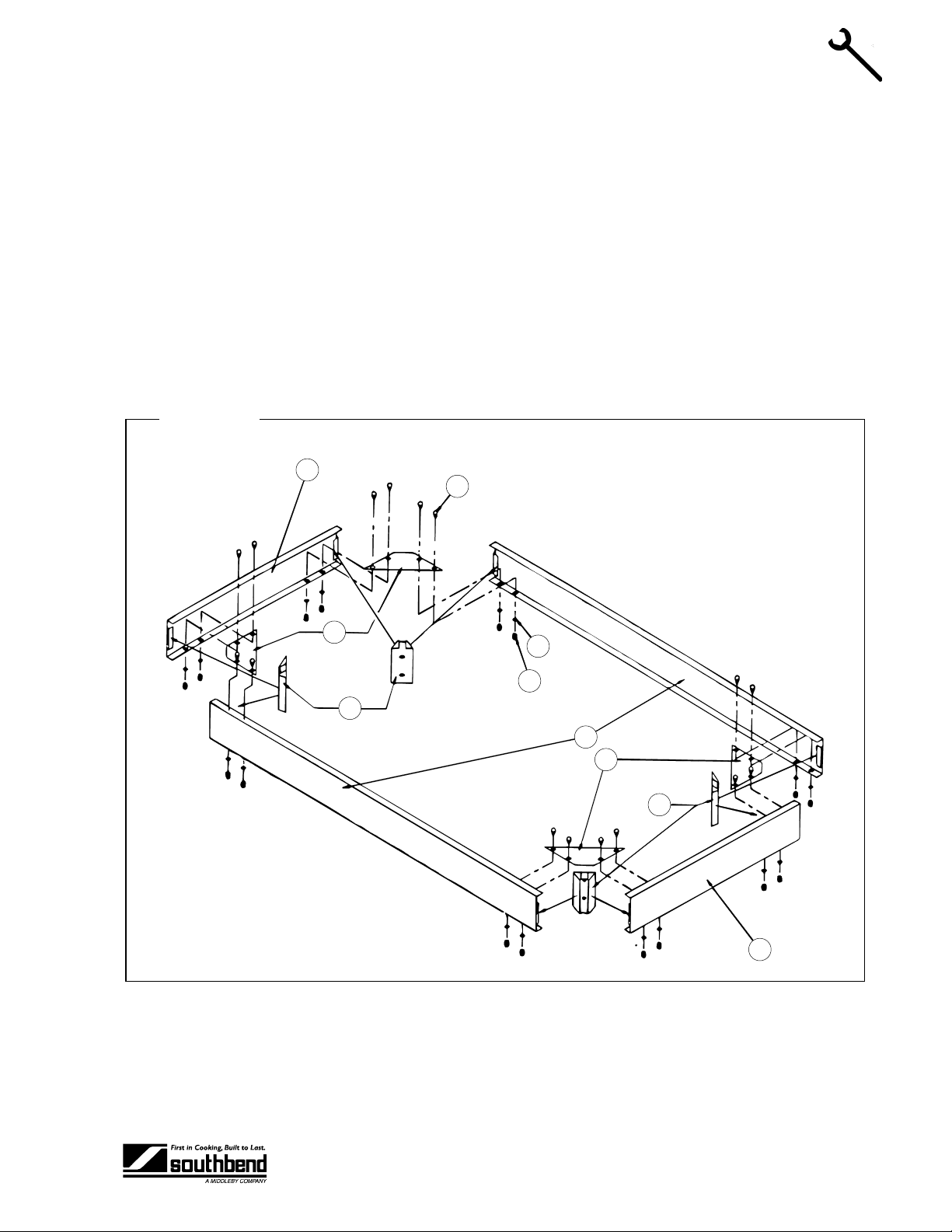

1. Pos ition the bottom -brace pieces on a f lat surface, as shown in Figure 6 b elow. There are two b ottomside braces (items “A”), a bottom-front brace (item “B”), and an identical bottom-rear brace (item “B”).

2. Position a corn er brace (item “C”) in eac h corner, matching the pre-pu nched holes on the lower inside

flange of the bottom braces.

3. Position a leg bracket (item “ D”) into eac h corn er. Be sure that the brac k et f langes ar e engag ed into the

open hem of the bottom braces.

4. Use the sixteen 1/2"-long hex head bolts (item s “E”), lock washers ( items “F”), and acorn nuts ( it ems “G”)

to bolt the corner braces to the bottom braces. Only hand-tighten for now.

5. Check that the leg brackets are in the proper position, and that the outside corners are square.

Figure 6

A

E

INSTALLATION

C

D

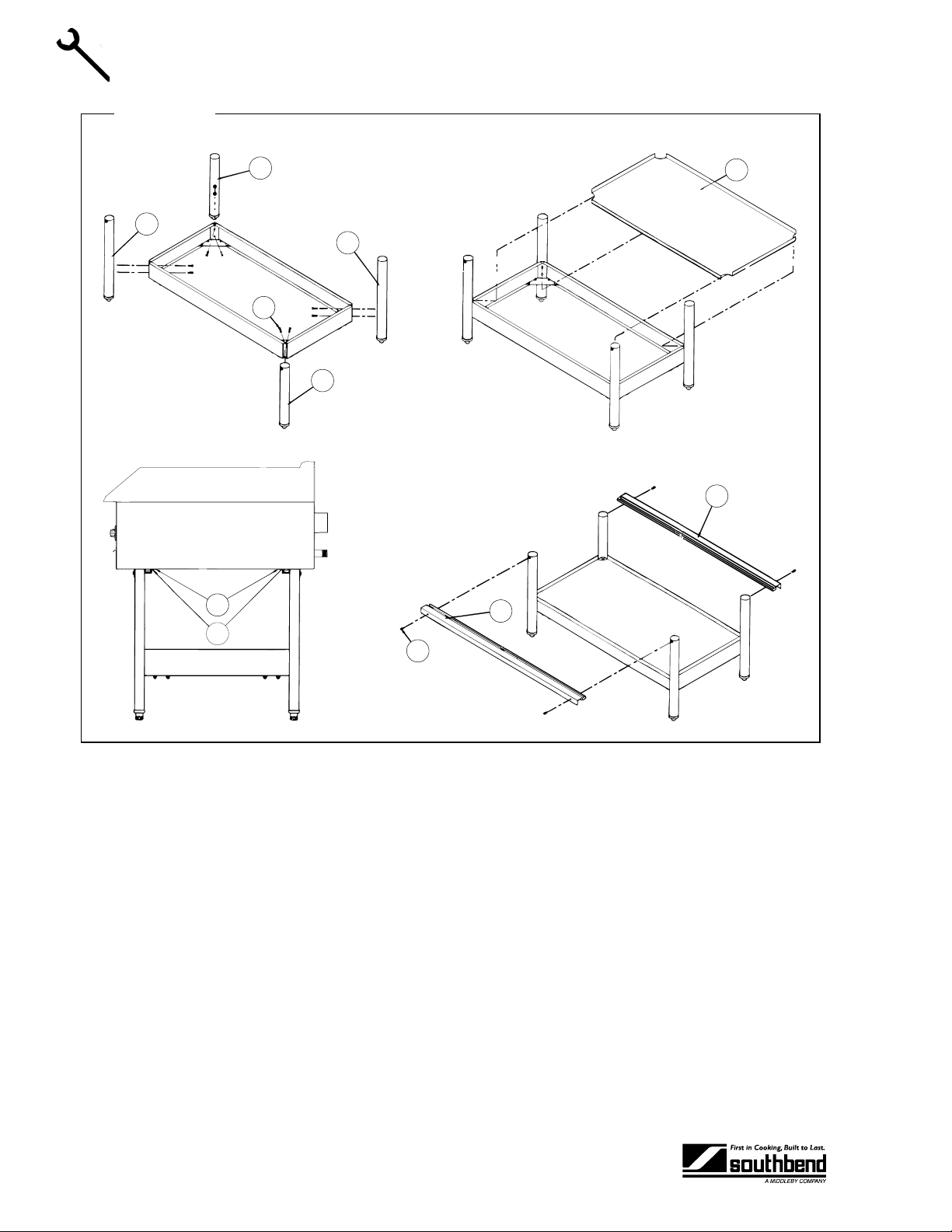

6. Use the eight 1- 1/2" hex bolts (items “H” in F igure 7) to attach the two lef t-legs (items “I”) and the two

right-legs (items “J”). “Left” and “ right” are as seen from the front or rear of the s tand. Be sure that the

small threaded-insert near the top of each leg faces either t he front or the rear of the stand, not a s ide.

Insert the bolts through the leg brackets and into the legs. Only hand-tighten the bolts for now.

F

G

B

C

D

A

OPERATOR’S MANUAL 1182629 REV 2PAGE 11

INSTALLATION COUNTER GRIDDLE

Figure 7

INSTALLATION

J

I

I

H

J

N

O

M

L

K

L

7. Check the partially assembled stand to make sure that the legs are straight and that all corners are

square. Now tighten all bolts, but do not over tighten.

8. If legs with casters were ordere d, lift the stand and screw the cas ter assemblies into the bottom of the

legs. The two casters with wh eel- lock s go on t he fr ont legs. Afte r the stand is ass embled, be sure to

connect the required restraint to protect the flexible gas connection (see Step 3 on page 15).

9. If the optional shelf was ordered (item “K”), position it on top of the bottom braces. The down-flange

edge of the shelf should be on the front s ide of the stand. The shelf simply rests on th e bo ttom braces (it

is not bolted or screwed to the braces).

10. Position the front an d rear top supports (it ems “L”) over the legs. The pre-dril led holes should f ace the

outside of the stand to line up with the threaded- insert holes near the top of the legs. Use the four 5/8"

hex-head bolts (items “M”) to secure the top supports to the legs.

11. Attach the angle suppor t brackets (item “N”, shipped with the griddle) to the bott om of the of the gr iddle

using #10x1/2" sheet metal screws (item “O”, also shipped with the griddle).

12. Place the griddle on to p of the stand, m aking sure that the ang le brackets that you jus t installed on the

bottom of the griddle are inserted into the front an d rear top su pports. No add itional bolts or screws are

required. Lift the griddle only at the ends, never in the middle!

13. Go on to Step 4 on page 16.

PAGE 12 OPERATOR’S MANUAL 1182629 REV 2

Loading...

Loading...