Page 1

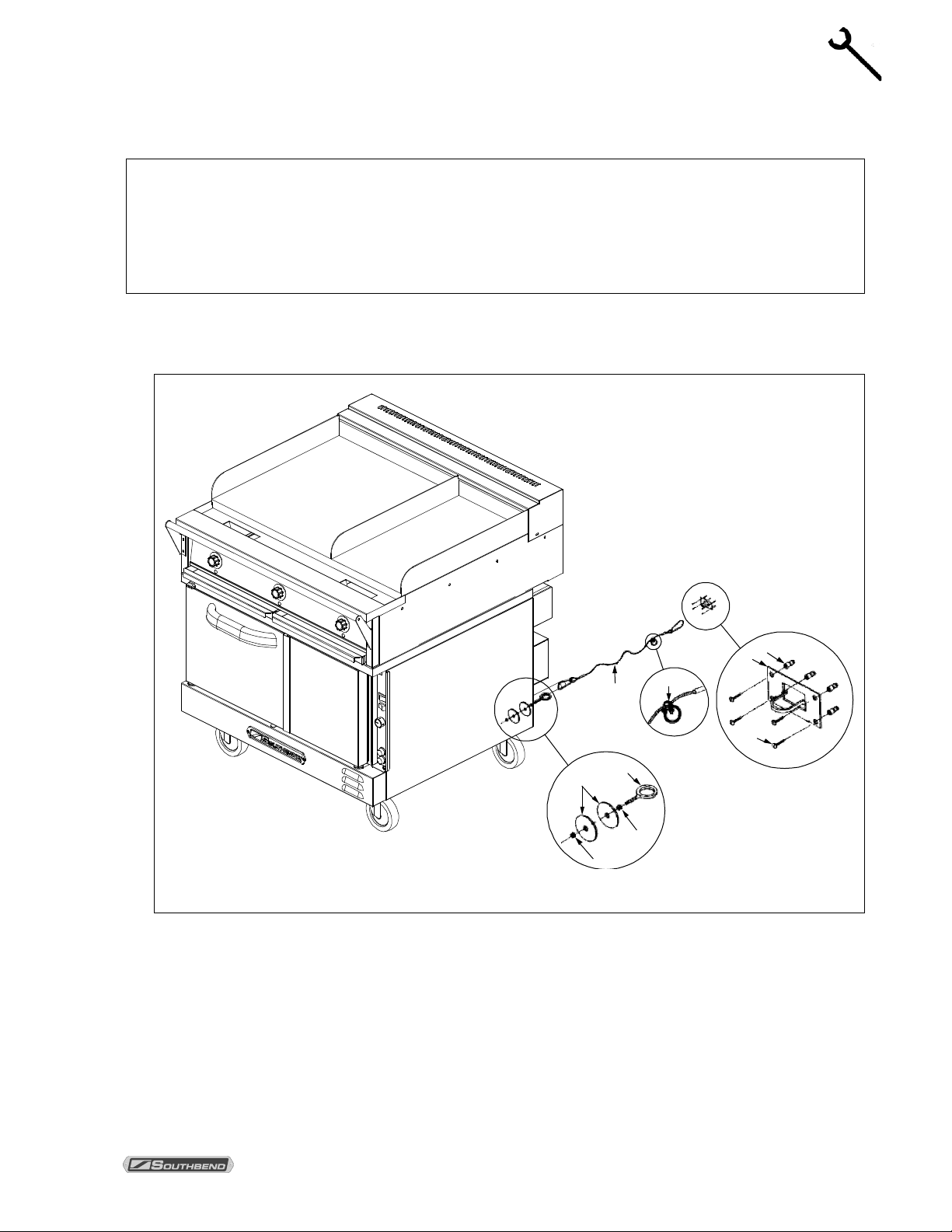

OVEN RANGE

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

IMPORTANT FOR FUTURE REFERENCE

Please compl ete this information and retain this

manual for the l ife of the equi pment:

Range-Top Model #: __________________

Range-Top Serial #: __________________

Oven-Base Model #: __________________

Oven-Base Serial #: __________________

Date Purchased: ____________________

OWNER’S MANUAL

Wendy’s Electr i c Ra nge

Range-Top Model SE36N-TTT, Oven-Base Model TVES/10WC

WARNING

injury or death. Read the installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

MANUAL 1195746 (05/12)

$30.00

1100 Old Honeycutt Road, Fuquay Varina, NC 27526 USA

www.southbendnc.com

MANUAL SECTION CO

Page 2

WENDY’S ELECTRIC RANGE

death.

injury, product damage, or property damage.

understood, even though not dangerous.

SAFETY PRECAUTIONS

Before installing and operating this equipment, be sur e everyone involved in its operation is fully trained

and aware of precautio ns. Accidents and problems can be ca used by failure to follow fundam ental rules

and precautions.

The following symbols , found throughout this m anual, alert you to potentiall y dangerous conditions to t he

operator, service personnel, or to the equipment.

DANGER

WARNING

CAUTION

NOTICE

This symbol warns of immediate hazards which will result in severe injury or

This symbol refers to a pot ential hazard or unsaf e practice which could resu lt in

injury or death.

This symbol refers to a pot ential hazard or unsaf e practice which could resu lt in

This symbol refers to information that needs special attention or must be fully

WARNING

FIRE H AZARD

FOR YOUR SAFETY

Do not store or use gasoline or other flamm able vapors and liquids in the vicinit y of this or an y other

appliance.

Keep area around appliances free and clear of combustibles.

Purchaser of equipm ent must post in a prominent loc ation detailed instr uctions to be fol lowed in the

event the operator smells smoke. Obtain the instructions from the local electrician/installer.

NOTICE

Be sure this Owner’s Manual and important papers are given to the proper authority to retain for

future reference.

NOTICE

This product is intended for commercial use only. NOT FOR HOUSEHOLD USE.

Copyright © 2012 by Southbend. All rights reserved. Published in the United States of America.

PAGE 2 OWNER’S MANUAL 1195746

Page 3

WENDY’S ELECTRIC RANGE TABLE OF CONTENTS

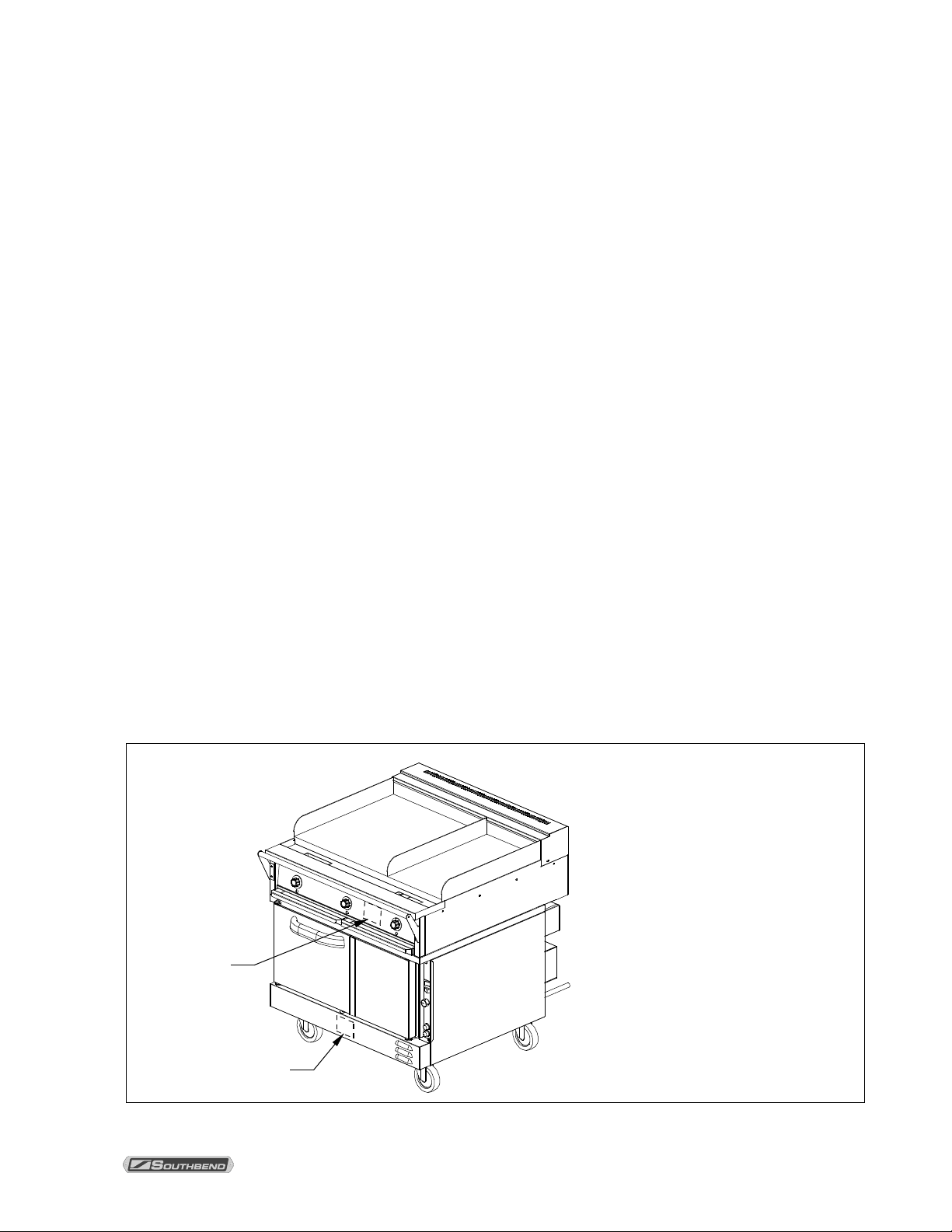

Range-Top

Serial Plate

(inside panel)

Oven-Base Serial Plate

(inside panel)

Congratulations! You have purchased one of the finest pieces of heavy-duty commercial cooking

equipment on the market.

You will find that your n e w equ ipment, like all Southbe nd e qu ipment, has been de signe d a nd manufactured

to meet the toughest stand ards in the i ndustr y. Each piec e of S outhbe nd equipm ent is c arefull y engineer ed

and designs are verified through laboratory tests and field installations. With proper care and field

maintenance, you will experience years of reliable, trouble-free operation. For best results, read this

manual carefully.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Table of Contents

Description .............................................................................................................................. 4

Specifications ......................................................................................................................... 5

Installation .............................................................................................................................. 9

Operation .............................................................................................................................. 19

Cooking Hints (Oven) ........................................................................................................... 23

Cleaning ............................................................................................................................... 25

Adjustments .......................................................................................................................... 28

Troubleshooting .................................................................................................................... 36

Read these instructions carefully before attempting installation. Installation and initial startup should be

performed by a qualified installer. Unless the installation instructions for this product are followed by a

qualified service tech nic i an (a per s on exper i enced in and knowledgeable with the insta lla tio n of c om mercial

gas and/or electric cooking equipment) then the terms and conditions on the Manufacturer’s Limited

Warranty will be rendered void and no warranty of any kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, contact:

Southbend Technical Service

1100 Old Honeycutt Road

Fuquay Varina, North Carolina 27526 USA

www.southbendnc.com

The range-top serial plate is located on t he interior side of the top front panel, while t he oven-base serial

plate is located on the interior side of the lower front panel, as shown below.

It is the responsibility of the owner to

have accurate information regarding unit

Serial & Model Numbers when

contacting Southbend regarding

questions on a specific unit.

It is STRONGLY SUGGESTED that this

information to be copied from the unit

(or from the shipping-container labels)

into this manual and/or in a secure place

for future reference.

Because of unforeseen circumstances

and the working environment of the unit,

the serial plates may become difficult to

read over time.

Range-Top Model #: _____________________

Range-Top Serial #: ______________________

Oven-Base Model #: _____________________

Oven-Base Serial #: ______________________

OWNER’S MANUAL 1195746 PAGE 3

Page 4

DESCRIPTION WENDY’S ELECTRIC RANGE

DESCRIPTION

DESCRIPTION

The Wendy’s Electric Range consists of a split electric griddle top (model SE36N-TTT) attached to a

convection oven bas e (model TVES/10WC). T he Range can b e ordered with various electrical conn ection

options including 208, 240, 380, 4 15, or 480 volts at 50 or 60 hertz. The oven base is 1-phase, while the

range top is 3-phase. See the Installation section of this manual for specific information.

Operating power must be supplied via either a fused disconnect switch or a circuit breaker, sized in

compliance with the local gov erning electrical codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70 or the Canadian Electrical Code, CSA C22.2, as applicable.

OVEN BASE

The oven base is a Southbend m odel TVES/10WC electric range convection oven that is rated h eavy dut y

for commercial use. T he heatin g elem ent is locate d behind th e air baff le in the ov en chamber . An impellertype blower fan dr aws air in and circu lates it across the h eating elements to tra nsfer the heat to the food

product being cooked or baked. Standard features of the oven base include:

• Oven 7.5 kW

• Solid, 60/40-split, dependent doors

• Stainless steel interior

• Soft Air, one-speed, 1/2 hp fan motor

• Four-position, removable rack guides with three standard, chrome-plated racks and one divided

rack (stainless steel racks are an option)

• Cool-down fan mode

• Oven “ready” light

• Three-position oven thermostat: Low 325°F (163°C), M edium 335°F(168°C), and High 375°F

(191°C)

• Optional casters with cable restraint kit

• Optional 72" (1829mm) NEMA 6-50P cord and plug

RANGE TOP

The range top is a Southbend Model SE36N-TTT 36" (914mm) wide sp lit griddle with separ ate 23"×24"

(584mm×610mm) and 13"×24" (330mm×610mm) cooking areas, and featuring three separate

thermostatically contro lled cooking regions. Each therm ostat has a temperature range of 250°F to 850°F

(121°C to 454°C). Standard features of the range top include:

• Heavy-duty griddle plate with divider and side-and-rear splash guards

• Front rail with belly bar

• Aluminized-steel frame with stainless-steel front, sides, and rear

• “Insta-On” thermostatic control of griddle surface temperature: 250°F to 850°F (121°C to 454°C)

• Optional 72" (1829mm) NEMA 15-60P cord and plug

PAGE 4 OWNER’S MANUAL 1195746

Page 5

WENDY’S ELECTRIC RANGE SPECIFICATIONS

SPECIFICATIONS

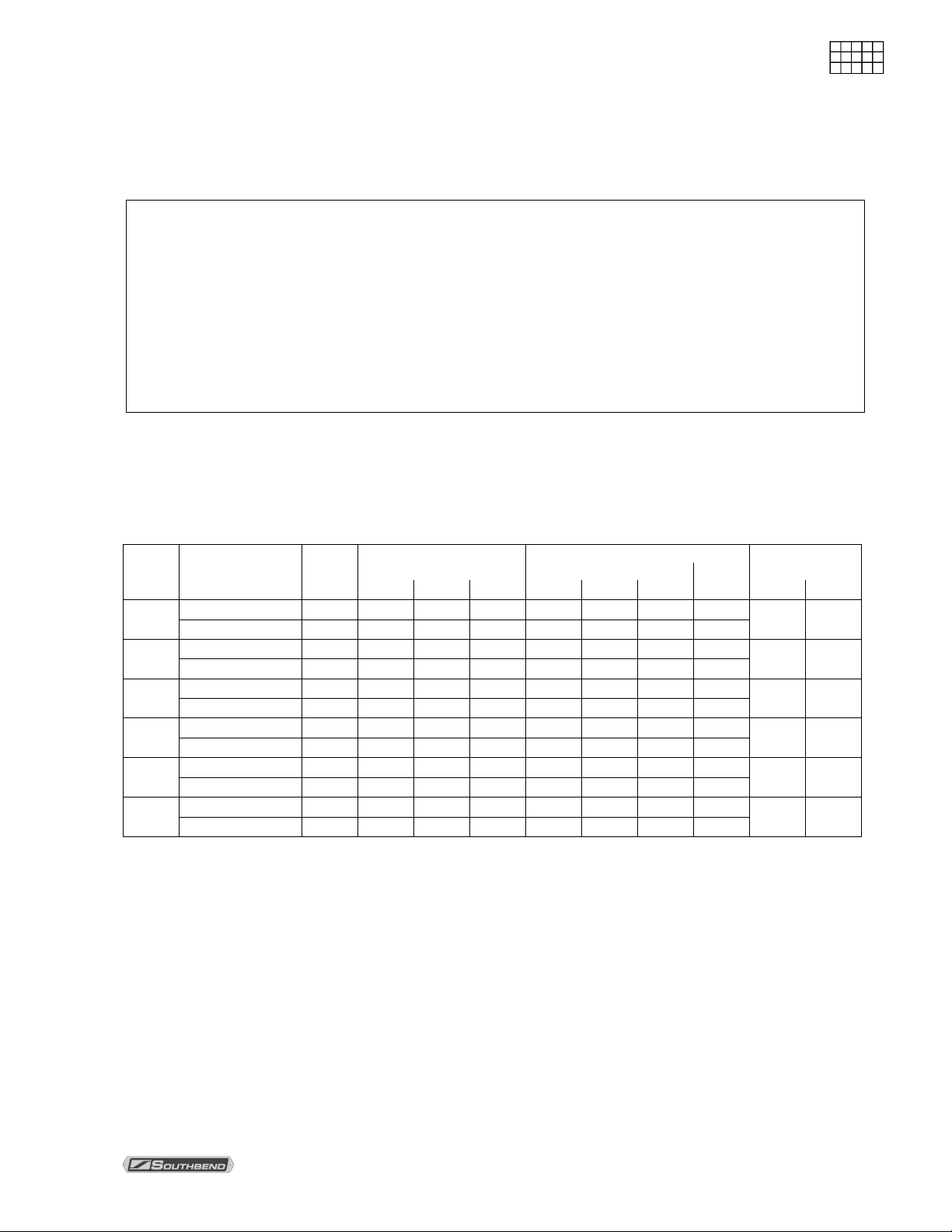

Nominal Amperes per Line-Wire

Minimum Supply

L1-L2

L2-L3

L1-L3

L1

L2

L3

3-Phase

1-Phase

Heating Elements

7.50

2.50

2.50

2.50

10.4

10.4

10.4

18.1

Motor & Controls

0.90

0.00

L1-N

0.90

0.0

0.0

4.1

4.1

Heating Elements

7.50

2.50

2.50

2.50

18.0

18.0

18.0

31.3

Motor & Controls

0.90

0.00

0.00

0.90

4.1

0.0

4.1

4.1

Heating Elements

7.50

2.50

2.50

2.50

21.0

21.0

21.0

36.1

SPECIFICATIONS

NOTICE

The appliance, when instal led, m us t be electricall y grounde d in accor danc e with local c odes, or in the

absence of local codes , with the Nationa l Electrical C ode, ANSI/NF PA 70, or the Canadian Electr ical

Code, CSA C22.2, as applicable.

Southbend reserves the right to change specifications and product design without notice. Such

revisions do not entit le the buyer to c orres pond ing cha nges, a dditi ons, or r eplace m ents for previousl y

purchased equipment.

This product is intended for commercial use only, not for household use.

ELECTRICITY SUPPLY

The electrical connections for th e oven base and the range top are made separately.

Use 167°F (75°C) wire for all supply lines.

The following table lists the electricity supply requirements for the oven base.

Supply

Voltage

480

415

380

240

220

(50Hz)

208

Oven Component

Heating Elements 7.50 2.50 2.50 2.50 9.0 9.0 9.0 16.0

Motor & Controls 0.90 0.00 0.00 0.90 2.2 0.0 2.2 2.2

Motor & Controls 0.90 0.00 L1-N 0.90 0.0 0.0 3.8 3.8

Heating Elements 7.50 2.50 2.50 2.50 11.4 11.4 11.4 20.0

Motor & Controls 0.90 0.00 0.00 0.90 3.8 0.0 3.8 3.8

Heating Elements 7.50 2.50 2.50 2.50 19.7 19.7 19.7 34.1

Motor & Controls 0.90 0.00 0.00 0.90 4.3 0.0 4.3 4.3

Total

3-Phase Loading (kW/phase)

kW

3-Phase

1-Phase

Total

Wire (AWG) Size

14 10

12 10

12 8

10 8

10 8

8 8

An electrical diagram is located on the side of the control panel assembly (see drawing on page 37).

Electrical diagrams can also be found in this manual beginning on page 38.

The electrical connect ions for the o ven base are made directly to a terminal block that is locate d inside the

control-panel com partment on the back-right side of the oven. A circular ope ning sized for a strain-relief

fitting is located on the back of the oven near the right side (right as seen fr om the front of the oven, see

drawing on page 16).

The oven base is shipped wired for single-phase. If necessary, the oven base c an be field-converted to

three-phase power (see page 34).

OWNER’S MANUAL 1195746 PAGE 5

Page 6

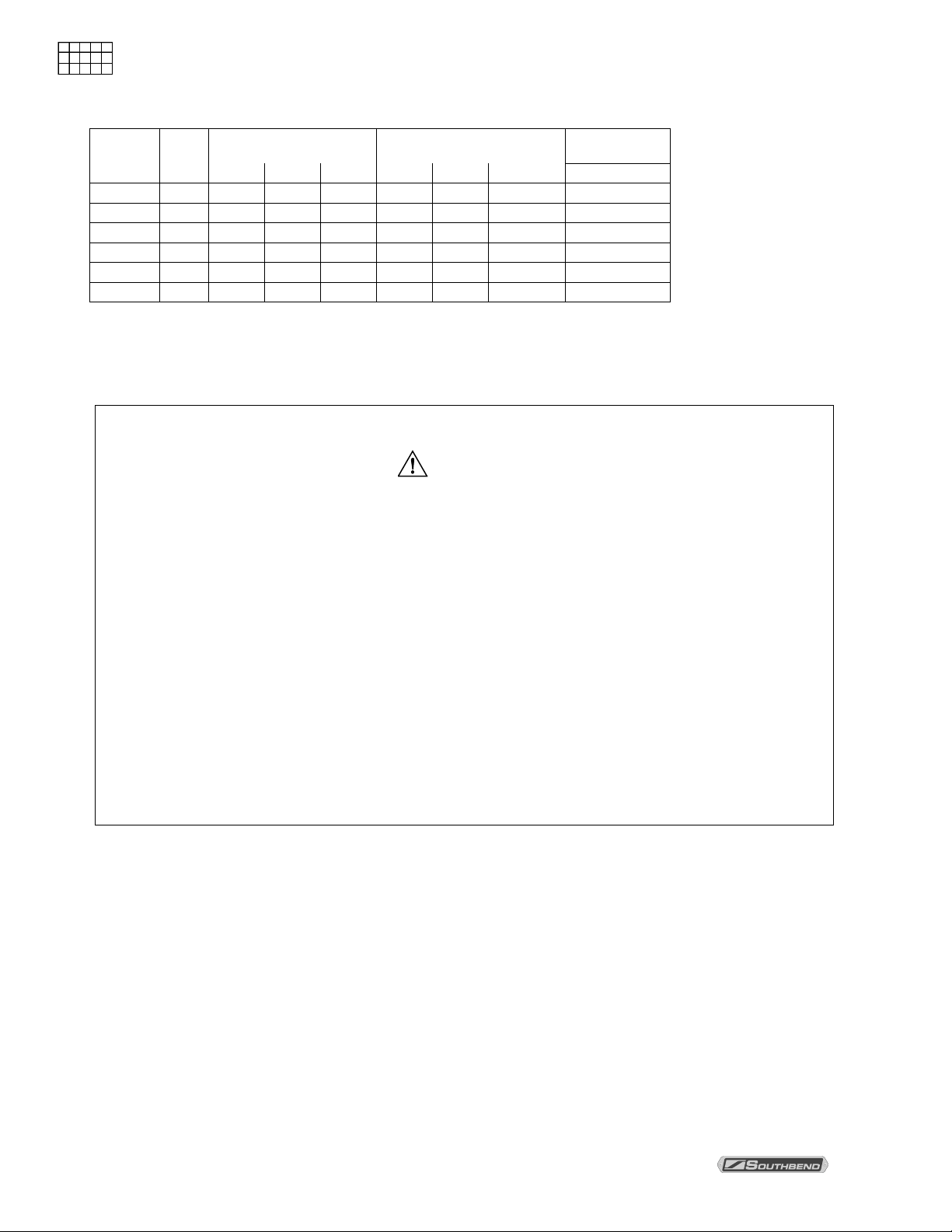

SPECIFICATIONS WENDY’S ELECTRIC RANGE

SPECIFICATIONS

L1-L2

L2-L3

L1-L3

L1

L2

L3 480

24.2

5.3

5.3

5.3

19.1

19.1

19.1

8

240

24.2

5.3

5.3

5.3

38.2

38.2

38.2

4

220 (50Hz)

24.2

5.3

5.3

5.3

41.7

41.7

41.7

4

The following table lists the electricity supply requirements for the range top.

Supply

Voltage

415 24.2 5.3 5.3 5.3 22.1 22.1 22.1 6

380 24.2 5.3 5.3 5.3 22.1 22.1 22.1 6

208 23.9 5.2 5.2 5.2 43.3 43.3 43.3 4

3-Phase Loading (kW/phase) Nominal Amperes per Line-Wire

Total

kW

Minimum Supply

Wire (AWG) Size

The electrical connections for the range top are made directly to a terminal block that is located on the

back-right side of the range top, behind an access panel. A circular opening sized for a strain-relief fitting is

located next to the access panel (see drawing on page 16).

MINIMUM CLEARANCES

WARNING

There must be adequate clearance between the unit and combustible construction.

Minimum Clearance from Minimum Clearance from

Combustible Construction Other Components

Back 2" (51mm) 2" (51mm)

Right Side 3" (76mm) 6" (152mm)

Left Side 3" (76mm) 6" (152mm)

Floor 0" 0"

Adequate clearance m ust be provided in the aisle in front of the unit to permit operation (including

opening of doors, the oven racks, and the grease drawers), as well as for servicing.

There must be a minimum clearance of 2" (51mm) between the motor on the back and noncombustible constr uction. C are must be tak en to prov ide adequ ate air c irculati on to pre vent the m otor

from overheating.

Do not locate the oven adjac ent to any high heat or grease-producing piece of equipm ent, such as a

range top, griddle, fr yer, etc., that could allow radiant heat to raise t he ex teri or tem per ature of the oven

above 130°F (54°C). DO NOT MOUNT ABOVE OTHER COOKING EQUIPMENT.

PAGE 6 OWNER’S MANUAL 1195746

Page 7

WENDY’S ELECTRIC RANGE SPECIFICATIONS

SPECIFICATIONS

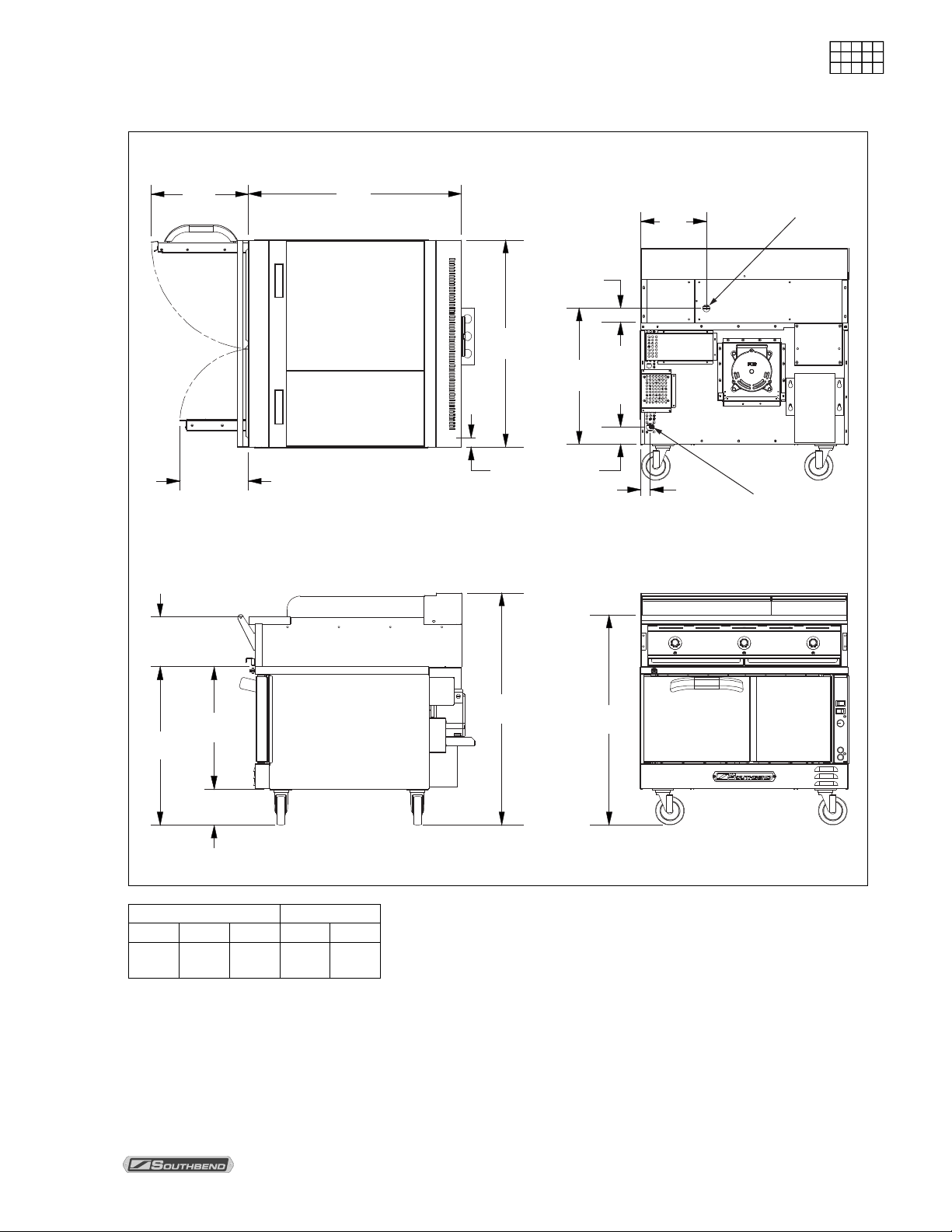

Dimensions are s hown in inches and (millimeters)

EXTERIOR DIMENSIONS

8.7

(221)

17.0

(432)

12.0

(303)

37.0

(940)

TOP VIEW

11.4

(288)

2.4 (62)

36.0

(914)

23.6

(600)

1.6 (41)

3.0 (75)

1.7 (44)

Range-Top

Electr ical Connection

Oven-Base

Electr ical Connection

REAR VIEW

27.5

(698)

21.2

(539)

6.3

(159)

40.4

(1025)

SIDE VIEW FRONT VIEW

36.5

(927)

Oven Interior Rack Clearance

width depth height width depth

29"

(737)

21.5"

(546)

14"

(356)

28.19"

(716)

21"

(533)

OWNER’S MANUAL 1195746 PAGE 7

Page 8

SPECIFICATIONS WENDY’S ELECTRIC RANGE

SPECIFICATIONS

VENTILATION

NOTICE

Proper ventilation is the owner’s responsibility. Any problem due to improper ventilation will not be

covered by the warranty.

The Southbend warranty does not require that a Wendy’s Electric Range be installed under a ventilation

canopy. However, local codes may require installation under a ventilation canopy.

If a ventilation canopy is used, it is recommended that a canopy extend 6" (152mm) past the appliance and

that the bottom edge be located 6'6" (1981mm) from the floor. Filters should be installed at an angle of 45°

or more from the horizontal. This position prevents dripping grease and facilitates collecting the run-off

grease in a drip pan, unusually installed with a filter.

If an exhaust fan is used, it should be installed at least 2" (51mm) above the rear of the unit. A strong

exhaust fan tends to create a vacuum in the room. In case of unsatisfactory performance on any

appliance, check the appliance with the exhaust fan in the OFF position. This should be done only long

enough to check equipm ent performance. T hen turn the exhaust fan back on and let it run to remove any

exhaust that may have accumulated during the test.

PAGE 8 OWNER’S MANUAL 1195746

Page 9

WENDY’S ELECTRIC RANGE INSTALLATION

INSTALLATION

INSTALLATION

NOTICE

These installation procedures must be followed by qualified personnel or warranty will be void.

Local codes regarding ins tallation var y greatl y from one area to anot her. The Nati onal Fire Protectio n

Association, Inc. states in its NFPA 96 latest edition that local codes are the “authority having

jurisdiction” when it com es to installation requirem ents for equipment. T herefore, installations should

comply with all local codes.

The appliance, when instal led, m us t be electricall y grounde d in accor danc e with local c odes, or in the

absence of local codes , with the Nationa l Electrical C ode, ANSI/NF PA 70, or the Canadian Electr ical

Code, CSA C22.2, as applicable.

Step 1: Unpacking

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If damaged equipment is received, either

apparent or concealed, a claim must be made with the delivering carrier.

Apparent damage or loss m ust be noted on the fr eight b ill at the t ime of de livery. T he f reight bill m us t

then be signed by the carrier representative (D river). If the bill is not signe d, the carrier may refuse

the claim. The carrier can supply the necessary forms.

A request for inspect ion must be m ade to the carrier within 15 da ys if there is c oncealed dam age or

loss that is not apparent until after the equipment is uncrated. The carrier should arrange an

inspection. Be certain to hold all contents plus all packing material.

1. Cut banding straps and remove packing material.

2. Remove tie-down strap holding range to wooden skid.

OWNER’S MANUAL 1195746 PAGE 9

Page 10

INSTALLATION WENDY’S ELECTRIC RANGE

INSTALLATION

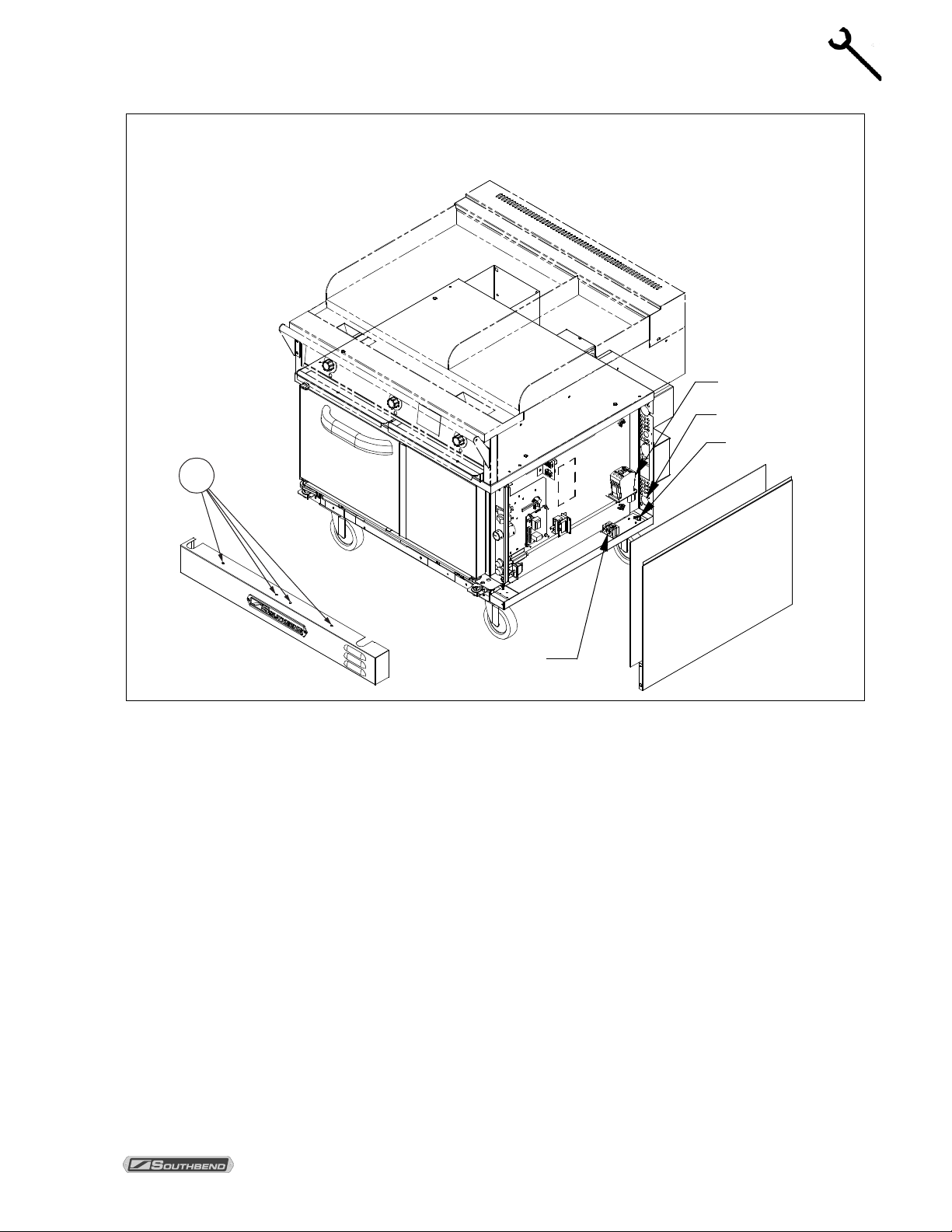

DO NOT REST THE UNIT ON ITS FRONT, SIDES, OR BACK. THIS CAN CAUSE PERMANENT

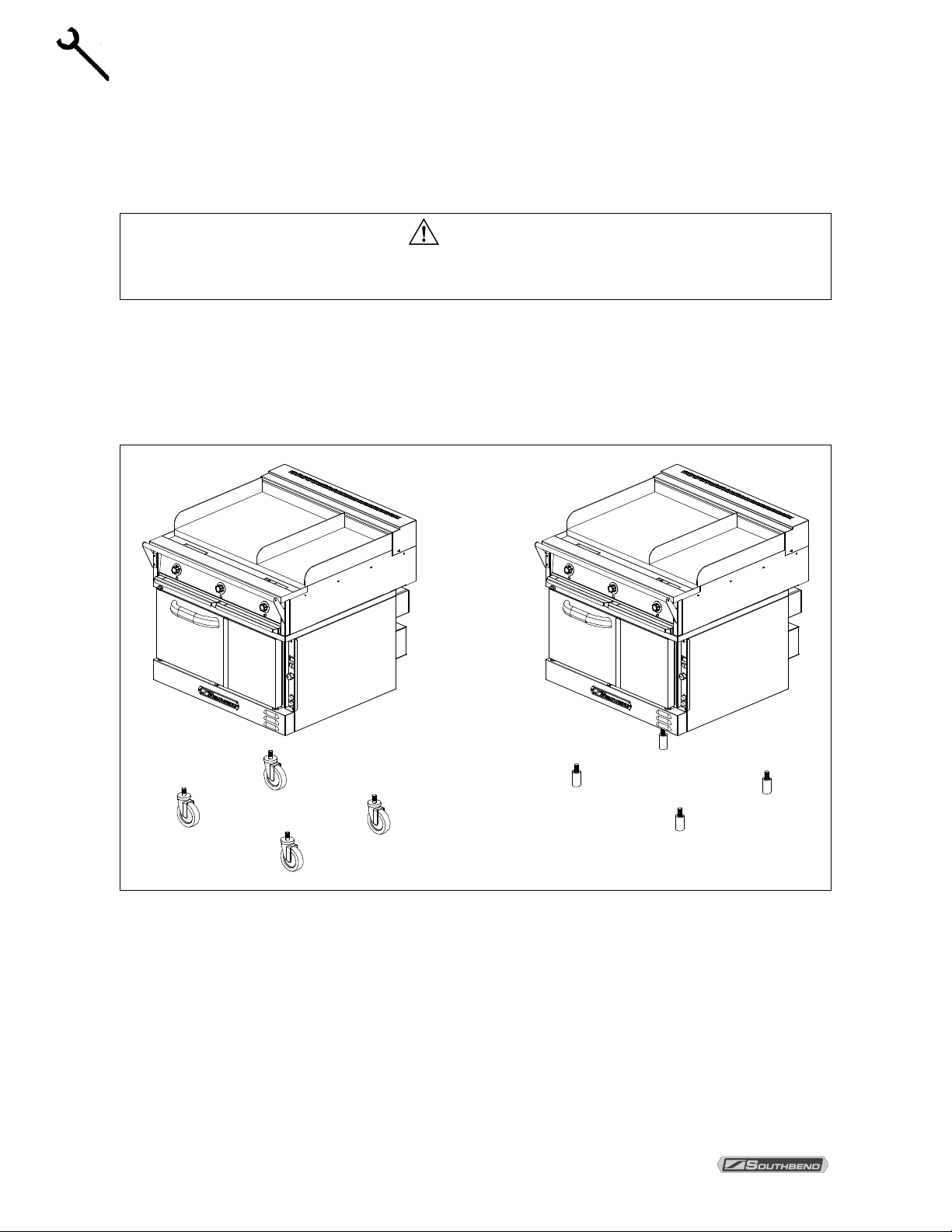

Step 2: Installation of Legs or Casters on Oven Base

1. Raise oven sufficiently to allow c learance for the legs or cas ters to be attached. Use of a lift tr uck or

other mechanical lif ting means is recom mended. For safety, “shor e up” and support the oven with an

adequate blocking arrangement strong enough to support the load.

WARNING

DAMAGE TO THE UNIT AND WILL VOID THE WARRANTY.

2. Screw into the bottom of eac h corner of the unit either an adjustable leg or a caster (dep ending on

which option was ord ered). If attaching casters, the tw o casters with br akes should be a ttached to the

front corners.

3. Lower the unit gently onto a level surface. Never drop or allow the unit to fall.

4. Use a level to make sure that th e unit is level. T he adj ustable legs can be sc rewed in or ou t to lower or

raise each corner of the oven.

5. If casters were installed, go to Installation Step 3 on the next page; otherwise go to Step 4 on page 12.

PAGE 10 OWNER’S MANUAL 1195746

Page 11

WENDY’S ELECTRIC RANGE INSTALLATION

INSTALLATION

E

D

A

C

B

G

F

I

H

Step 3: Installation of Rest r aint (Only for Units with Casters)

All units ordered with casters are supplied with a restraint kit.

NOTICE

For an appliance equipp ed with casters adequate m eans must be provided to limit the movement of

the appliance without depending on, or transmitting stress to, the electric conduit. The restraining

means should be att ached to a fram e member on the bac k of the unit , and the appliance should be

installed using a flexible conduit.

1. Secure the restraining-device bracket (item “B” in the following illustration) to a wall stud located as

close as possible to the ap pliance connector inl et and outlet connectio ns. Use four #12 scre ws (items

“C”) and plastic anchors (items “A”) if necessary.

Note: Kit can be purchased from Southbend (part number 1176867).

2. Install eye-bolt (item “F”) to a frame member on the rear of the equipment. After checking carefully

behind the frame member for adequate clearance, drill a 1/4" (6mm) hole through the frame member.

3. Thread hex nut (item “G”) and slide the was her (item “H”) onto the e ye-bolt. Ins ert the e ye-bolt through

the 1/4" (6mm) drilled hole and secure with a washer (item “H”) and nylon lock nut (item “I”).

4. Using the spring-loaded snap hooks, attach the restraining device to the bracket and the eye-bolt.

5. Using the cable clamp (item “D” ), adj us t the r estr ain in g de vic e ext end ed len gth t o preve nt o ver -bending

or kinking of the appliance connector.

Be sure all controls are turned off prior to disconnecting. After reconnecting, be sure that the range is

switched OFF.

OWNER’S MANUAL 1195746 PAGE 11

Page 12

INSTALLATION WENDY’S ELECTRIC RANGE

INSTALLATION

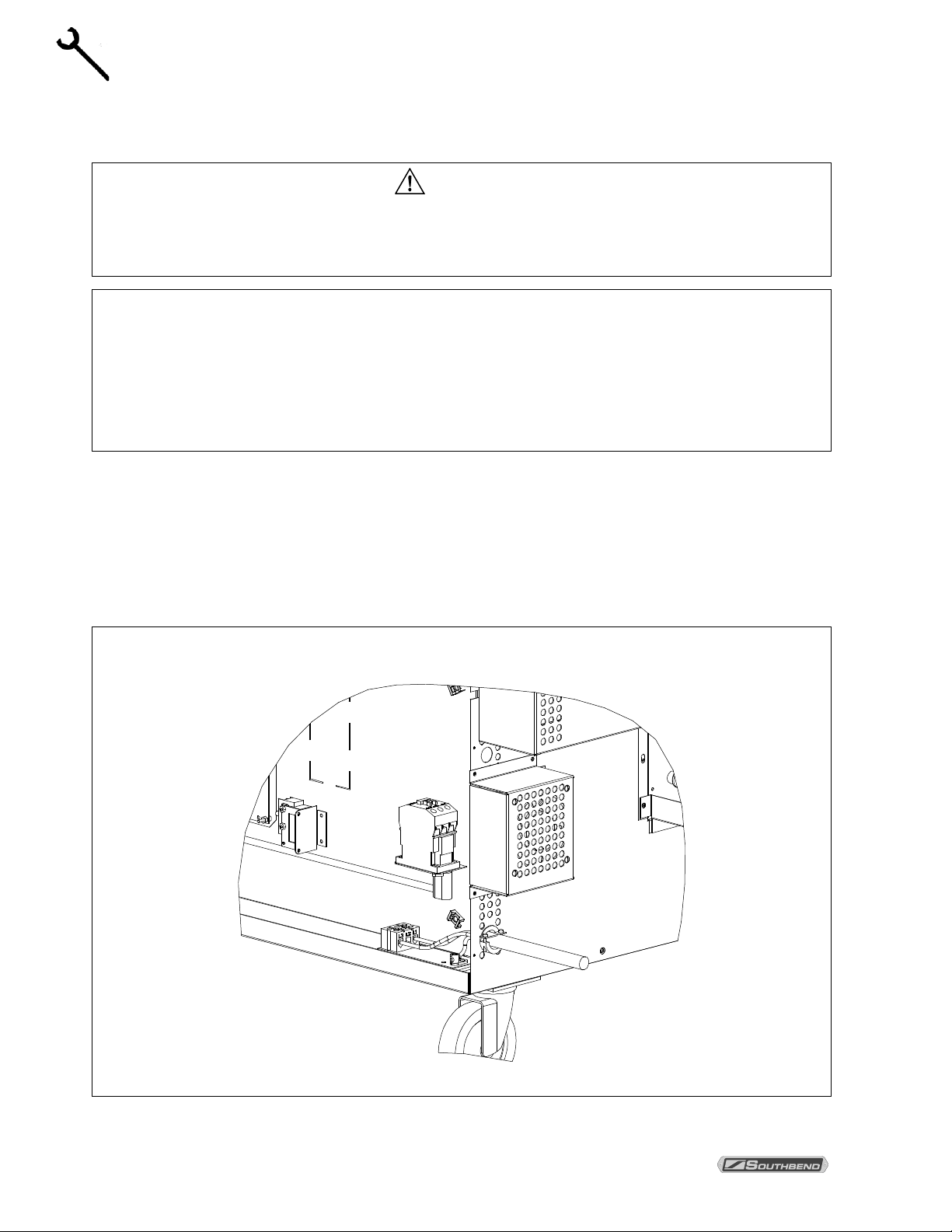

Step 4: Connect Electricity to Oven Base

WARNING

ELECTRIC GROUNDING INSTRUCTIONS

This appliance, when inst al led, must be electrically grounded in acc or da nc e with l ocal c odes, or in th e

absence of local codes, wit h the National Electrical C ode, ANSI/NFPA 70 or the Canad ian Electrical

Code, CSA C22.2, latest editions, as applicable.

WARNING

INSTALLATION AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

ELECTRICIAN O R TECHNICIAN WHO IS EXPERIEN CED IN, AND KNOWLEDGEABLE WITH, THE

OPERATION OF COMMERCIAL COOKING EQUIPMENT.

NOTICE

For an appliance equipp ed with casters adequate m eans must be provided to limit the movement of

the appliance without depending on, or transmitting stress to, the electric conduit. The restraining

means should be att ached to a fram e member on the bac k of the unit , and the applianc e should be

installed using a flexible conduit.

NOTICE

The electrical connections for the oven base and for the range top are made separately.

The oven base requires a 1-phase connection, but can be field-converted to use a 3-phase

connection (see page 34).

Local and/or national electric codes supersede any instructions or illustrations in this manual.

The wiring diagram for the oven base is located on the side of the oven control panel assem bly ( see page

37). Wiring dia grams are also printed in th is m anual (beginning o n page 38). Be sure that the in put voltage

and phase match the re quirements shown on th e oven-base serial plate, which is located inside the lower

front panel (see drawing on page 3).

The unit must be adequately grounded. Use 167°F (75°C) wire for all supply lines.

The optional (6/3) cable assembly supplied with the oven base (1-phase ONLY), should only be installed by

a licensed electrician or qualified service technician to ens ure compliance with all electrical co des at the

installation location.

1. CHECK THAT THE POWER SUPPLY CIRCUIT BREAKER IS OPEN.

2. Locate and remove the four screws that secure the lower f ront panel (item s “A” in the drawing on page

13). Lift up the panel and pull it forward to remove it, then set it aside.

3. Locate and remove the five screws (3 bac k, 2 front) that secure th e right side pane l of the oven base.

Remove and set aside the side panel and insulation.

4. Route the supply wires and the grou nding wire through th e hole on the back of the oven base. Use a

strain-relief fitting.

5. Attach each supply wire to the appropr iate term inal of the term inal bloc k (acc ording to t he appropr iatevoltage/phase wiring diagr am found in this m anual starting on page 38), taking c are not to disconnect

any wires that may already be connected to the terminal block.

PAGE 12 OWNER’S MANUAL 1195746

Page 13

WENDY’S ELECTRIC RANGE INSTALLATION

INSTALLATION

Oven Base Electrical Connection

Contactor

Hole

Grounding Lug

A

Terminal Block

6. Insert the ground wire into the grounding lug and tighten the screw.

7. Check that all connections match the wiring diagram and are tight.

8. Reattach the right-side panel of the oven base and insulation, and the lower-front panel.

OWNER’S MANUAL 1195746 PAGE 13

Page 14

INSTALLATION WENDY’S ELECTRIC RANGE

INSTALLATION

Oven-Base Connection Using Power Cord (208/240V and 480V, 1-Phase ONLY)

WARNING

INSTALLATION AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

ELECTRICIAN O R TECHNICIAN WHO IS EXPERIEN CED IN, AND KNOWLEDGEABLE WITH, THE

OPERATION OF COMMERCIAL COOKING EQUIPMENT.

NOTICE

For an appliance equipp ed with casters adequate m eans must be provided to limit the movement of

the appliance without depending on, or transmitting stress to, the electric conduit. The restraining

means should be att ached to a fram e member on the bac k of the unit , and the appliance should be

installed using a flexible conduit.

Local and/or national electric codes supersede any instructions or illustrations in this manual.

1. CHECK THAT THE POWER SUPPLY CIRCUIT BREAKER IS OPEN.

2. Locate and remove the four screws that secure the lower f ront panel (item s “A” in the drawing on pag e

13). Lift up the panel and pull it forward to remove it, then set it aside.

3. Locate and remove the five screws (3 bac k, 2 front) that secure th e right side pane l of the oven base.

Remove and set aside the side panel and insulation.

4. Route the supply wires and the grounding wire through the hole on the back of the oven base, as

shown in the illustration belo w. Use a strain-relief fitting.

Oven Base Electrical Connection Using Power Cord

(Shown with right side panel removed.)

PAGE 14 OWNER’S MANUAL 1195746

Page 15

WENDY’S ELECTRIC RANGE INSTALLATION

INSTALLATION

5. Attach cable conductors to indicated terminals, as shown, using an “APPROVED” three-conductor

cable (1-phase ONLY). Tighten all cable clamps securely.

BLACK – L1

WHITE – L3

GREEN – GND. LUG

(For conversion to a 3-phase connection, see page 34.)

6. Check that all connections match the wiring diagram and are tight.

7. Reattach the right-side panel of the oven base and insulation; and the lower-front panel.

Step 5: Connect Electricity to Range Top

WARNING

ELECTRIC GROUNDING INSTRUCTIONS

This appliance, when inst al led, must be electrically grounded in acc or da nc e with l ocal c odes, or in th e

absence of local codes, wit h the National Elec trical Code , ANSI/NFPA 70 or the Canadian Electrical

Code, CSA C22.2, latest editions, as applicable.

WARNING

INSTALLATION AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

ELECTRICIAN O R TECHNICIAN WHO IS EXPERIEN CED IN, AND KNOWLEDGEABLE WITH, THE

OPERATION OF COMMERCIAL COO KIN G EQ UI PMENT.

NOTICE

For an appliance equipp ed with casters adequate m eans must be provided to limit the movement of

the appliance without depending on, or transmitting stress to, the electric conduit. The restraining

means should be att ached to a fram e member on the back of the unit , and the appliance should be

installed using a flexible conduit.

NOTICE

The electrical connections for the oven base and for the range top are made separately.

The range top requires a 3-phase connection.

Local and/or national electric codes supersede any instructions or illustrations in this manual.

The wiring diagram for the range top is located on the interior side of the rear access panel (see drawing on

page 16). W iring diagrams are also print ed in this manual (be ginning on page 38). Be sure that the input

voltage and phase match the requirements shown on the serial plate, which is located inside the upper

front panel (see drawing on page 3). When shipped from the factory, the oven base requires 1-phase

power, while the range top requires 3-phase power.

The unit must be adequately grounded. Use 167°F (75°C) wire for all supply lines.

The optional (4/4) cable as sembly supplied with the Range T op (3-Phase ON LY), should on ly be installed

by a licensed elec tricia n or qualif ied ser vice t echn ician to ens ure com pliance with all elec trica l codes at th e

installation location.

OWNER’S MANUAL 1195746 PAGE 15

Page 16

INSTALLATION WENDY’S ELECTRIC RANGE

INSTALLATION

Terminal Block

Grounding Lug

Neutral Terminal Block

(for 380 & 415V Units Only)

Access Panel

Range Top Electrical Connection

1. CHECK THAT THE POWER SUPPLY CIRCUIT BREAKER IS OPEN.

2. Locate and remove the five screws that secure the range-top rear access panel (see the drawing

above), then remove the access panel and set it aside.

3. Route the supply wires and the groundin g wire through the hole on the back of the range top. Use a

strain-relief fitting to secure the cable to the range top.

4. Attach each supply wire to the appropr iate term inal of the term inal block (acc ording to the appropr iatevoltage wiring diagr am found in this manual starting on p age 38), taking care not to disc onnect any

wires that may already be connected to the terminal block.

5. Insert the ground wire into the grounding lug and tighten the screw.

6. The additional terminal block required f or connecting the neutr al wire on a 380V or 415V unit is s hown

in the above drawing. Reference the appropriate wiring diagram starting on page 38.

7. Check that all connections match the wiring diagram and are tight.

8. Ensure that the cable clamp has been secured onto the rear of the range top and tightened on the

cable.

9. Reattach the range-top rear access panel.

PAGE 16 OWNER’S MANUAL 1195746

Page 17

WENDY’S ELECTRIC RANGE INSTALLATION

INSTALLATION

Range-Top Connection Using Power Cord (208/240V and 480V, 3-Phase ONLY)

WARNING

INSTALLATION AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

ELECTRICIAN O R TECHNICIAN WHO IS EXPERIEN CED IN, AND KNOWLEDGEABLE WITH, THE

OPERATION OF COMMERCIAL COOKING EQUIPMENT.

NOTICE

For an appliance equipp ed with casters adequate m eans must be provided to limit the movem ent of

the appliance without depending on, or transmitting stress to, the electric conduit. The restraining

means should be att ached to a fram e member on the bac k of the unit , and the appliance should be

installed using a flexible conduit.

Local and/or national electric codes supersede any instruc tions or illustrations in this manual.

1. CHECK THAT THE POWER SUPPLY CIRCUIT BREAKER IS OPEN.

2. Locate and remove the five s crews that secur e the range-top rear acc ess panel ( see drawing on p age

16), then remove the access panel and set it aside .

3. Route the supply wires and the groundin g wire through the hole on the back of the range top. Use a

strain-relief fitting to secure the cable to the range top.

4. Attach cable conductors to terminal block, as shown in the illustration on the next page, using an

“APPROVED” NEMA 15-60P cord and plug. Tighten all cable clamps securely.

BLACK – L1 (X)

WHITE – L2 (Y)

RED – L3 (Z)

GREEN – GND. LUG

5. Check that all connections match the wiring diagram and are tight.

6. Ensure that the cable clamp has been secured onto the rear of the range top and tightened on the

cable.

7. Reattach the range-top rear access panel.

Step 6: Check the Installation

Check the installation, as follows:

1. Check that all screws and bolts are tightened.

2. Check electrical connections, including proper grounding.

3. Move the unit into the final position at which it will be operated.

4. For units with casters, check that the restraint has been properly installed and is connected.

5. Check that the unit is level. If not, adjust the legs or casters.

6. Check that the appropriate minimum clearances are satisfied (see page 6).

7. Check that there is sufficient clearance to open oven doors, and to pull out oven racks and grease

drawers.

OWNER’S MANUAL 1195746 PAGE 17

Page 18

INSTALLATION WENDY’S ELECTRIC RANGE

INSTALLATION

Step 7: Initial Cleaning of the Range Top

1. Remove the rust preventative mater ial from the entire s urface of the range top us ing a non-flammable

grease solvent.

2. Clean the entire griddle surfac e by wiping it with a clean cloth d ampened with war m water and a mild

detergent.

3. Rinse the surface by wiping it with a clean, damp cloth. Wipe dry.

4. “SEASON” the entire griddle before proceeding (see procedure on page 20 of this manual).

Step 8: Check Operation of the Unit

Check the operation of the range top, as follows:

1. AFTER SEASONING the griddle surf ace, check that all range-top and oven-ba se controls are set to

the OFF position.

2. Verify the electricity supply to the unit is turned on.

3. Check each griddle zone one at a time starting from the left side. Confirm that each griddle zone begins

heating, then turn the control for that zone to OFF.

4. Repeat step 3 for each zone of the griddle.

Check the operation of the oven base, as follows:

5. Set the oven temperature control to LOW.

6. Switch the POWER switch located on the Oven Control Panel to ON.

7. After a few minutes, open the door of the oven and confirm that the oven is heating.

8. Switch OFF all range and oven controls.

Step 9: Wipe Clean and Shut-Down Range

Complete the installation by leaving the unit ready for customer use:

1. Turn-off all power controls and allow unit to cool.

2. Wipe clean all surfaces.

3. Unless the unit is to be placed in service immediately, shut off the electricity.

4. Make sure that a copy of this manual will be available to the people who will operate and maintain the

unit.

.

PAGE 18 OWNER’S MANUAL 1195746

Page 19

WENDY’S ELECTRIC RANGE OPERATION

OPERATION

Power Indicator

Grease Drawers

Temperature

Control Knob

(OFF, temperature)

Grease Trough

OPERATION

NOTICE

Do NOT cook on a griddle before “seasoning” it each day (as described later in this section).

OPERATON OF RANGE TOP

The Range Top is t herm ostatica ll y control led. Each 12" (30 5mm ) wid e griddle zone has a control knob tha t

can be turned to OFF, or to any temperature in the range 250°F to 850°F (121°C to 454°C).

To start cooking, turn on the appropriate control knob(s) to the desired temperature(s).

Never leave utensils on the griddle.

Do not abuse the equipment by leaving t he thermostat at a high temperature all the time. During idling

periods, turn the t hermostat to a low temperature to keep the griddle warm. (D o not allow the griddle to

overheat above 850°F (454°C), as this will cause warping or breakage.) W hen necessary while cooking,

pull out and empty the grease drawers.

When done cooking, turn the appropriate control knob to OFF.

Cleaning instructions begin on page 25 of this manual.

Temperature Control Knob – Each knob controls the corresponding zone of the griddle surface. Each

knob can be

turned to OFF, or to any temperature in the range 250°F to 850°F (121°C to 454°C).

Power Indicator – The indicator glows amber when the corr esponding gr idd le zone is being h eated. When

the setting temperatur e is reached, the indicator will turn off, then blink on-and-off as the temperature is

held steady.

Grease Trough – Two chutes located at the front of the gri ddle surface provide drainag e into the grease

drawers.

Grease Drawers – Conta iners f or grease drain ing through t he greas e chutes f rom greas e trough. Pull out

to empty and clean.

OWNER’S MANUAL 1195746 PAGE 19

Page 20

OPERATION WENDY’S ELECTRIC RANGE

OPERATION

NEVER TOUCH AN OPERATING GRIDDLE. ALWAYS WAIT UNTIL THE TEMPERATURE

SEASONING OF GRIDDLE SURFACE

WARNING

CONTROL KNOBS HAVE BEEN SET TO “OFF” FOR AT LEAST 30 MINUTES.

Griddle should be “seasoned” each day before beginning operations. Do the following:

1. If necessary, clean the griddle surface (see page 25).

2. Spread a light film of unsalted cooking oil over the entire griddle surface with a soft cloth.

3. Set all of the griddle temperature controls to 350°F (175°C).

4. Operate the griddle for at least two m inutes to allow t he oil to w ork into the pores of the m etal, form ing

a smooth coating over the surface of the griddle. Use a spatula to spread the oil, if necessary.

5. Set the griddle controls to O FF and wait at least 30 m inutes for the griddle to cool bef ore wipin g of f the

excess oil with clean cloths.

DAILY OPERATION

1. “Season” the griddle daily before operation (see procedure in preceding subsection of this manual).

2. Set the Temperature Control Knob of each griddle zo ne to the recommended tem perature setting for

the type(s) of food to be heated/cooked.

3. Wait 15 minutes before loading the griddle with food to be sure of heating/cooking the food properly.

4. Observe the indicator below each T emperature Control Knob. Each indicator is lit steadily when the

corresponding zone is h eating to the temperature setting . Each indicator will blink on and off as the

temperature setting is being held almost constant by the thermostatic control.

5. At the end of each day (or shift) clean the griddle as described on page 25 of this manual.

GRIDDLE OPERATING HINTS AND SAFETY TIPS

Never leave the griddle operating without an attendant.

Never place utensils on the griddle.

Do not abuse the equipm ent by leaving the thermostats at a high t emperature all the time. During idlin g

periods, turn the t hermostat to a low temperature to keep the griddle warm. (Do not allow the griddle to

overheat above 850°F (454°C) as this will cause warping or breakage.)

Do not operate the entire griddle at a high temperature when small amounts of food are being

heated/cooked, or during idle periods. Set the Temperature Co ntrol Knob(s) to 200º F (93º C) during idle

periods. Only a few minutes is required to regain the desired operating temperature when food orders

become more frequent. Use only one zone when heating/cooking a small amount of food.

Heat/cook different types of foods at the same time by setting the Temperature Control Knob of each

griddle zone to the temperature for heating/cooking each food type.

“Hold” (keep warm), food in one zone by decreasing the temperature setting.

Use a spatula to remove excess grease or oil into the grease trough after each load of food is

heated/cooked. This reduces the smoking and carbonizing of hot grease.

Pull out and empty the grease drawers when necessary.

When done cooking, turn the appropriate control knob to OFF.

PAGE 20 OWNER’S MANUAL 1195746

Page 21

WENDY’S ELECTRIC RANGE OPERATION

OPERATION

Turning the control knob opens

Locat ion of

OPERATON OF OVEN BASE

WARNING

If the WARNING light turns on, the appliance is m alfunctioning. Turn off or disconnect power f rom

power supply and have the unit serviced by a qualified technician.

The oven-base controls are sho wn in the f igure on the follow ing page of this m anual. To operate t he oven,

do the following:

1. Turn the POWER switch on the oven-base control panel to ON.

2. Switch the FAN MODE switch to COO K. The fan will r un continu ously when the oven doors are close d

(the fan does not cycle o n and off with the heating elements ). If this switch is set to COOL the only

difference is that the fan will continue to run when the oven doors are open.

3. Set the cooking temperature by turning the CO OK TEMPERAT URE contro l un til the indicator m ark on

the knob is pointing at t he desired cook ing temperature (HIG H, MEDIUM, or LO W). The indicator light

near the control knob will be lit while the oven preheats.

4. Wait until the heat-on indicator has gone-out a nd come-on three times . At that time the oven will have

reached the set cooking temperature.

5. Open the oven doors, load the product into the ove n, and close the d oors. When you open the oven

doors, the heating elements and fan will shut off until you close the doors.

6. When the load has finished cook ing, you can rapidl y cool the load b y opening the oven doors (which

will shut off the heat ing elements ) and switching th e FAN MOD E switch to COOL ( which will c ause the

fan to run even though the doors are open).

7. When you are done cooking, turn the COOK T EMPERATUR E control to LOW (full y counterclockwise)

and turn the POWER switch to OFF.

MOISTURE VENT

The oven has a moisture vent that is opened and closed using the s mall knob located near the top lef t

corner of the front of the oven (see i llustration below). Usually the vent is k ept open to allow moisture to

escape. Close the vent (turn the knob clockwise) when doing fine baking.

Moisture Vent

Moisture Vent

Control Knob

or closes moistu re vent (shown

below with its cover removed).

OWNER’S MANUAL 1195746 PAGE 21

Page 22

OPERATION WENDY’S ELECTRIC RANGE

OPERATION

Power Switch

Turn knob to select desired cooking

n indicator will go

temperature.

Fan Mode

uously except when the doors

Heat-On Indicator

Fuses

Warning Light

alfunctions. Turn off or disconnect

Oven Control Panel

OFFON

Switch ON to use the oven, switch

OFF when done using the oven.

POWER

COOLCOOK

FAN MODE

MEDIUM

Cook Temperature Control

In COOK mode, the fan runs

contin

are open. The fan does NOT cycle

with the operation of the heating

elements. In COOL mode, the fan

runs continuously even if the doors

are open. Since the elements will

not operate if the oven doors are

open, to rapidly cool the oven after

cooking is completed, open the

doors and switch the fan mode to

COOL.

temperature (LOW, MEDIUM, or

HIGH). The heat-o

out when the oven reaches the set

temperature, and will cycle on and

off as the elements operate to

maintain the set cooking

PAGE 22 OWNER’S MANUAL 1195746

LOW

COOK TEMPERATURE

HIGH

Indicator is lit when the elements

are operating. It goes out when the

selected temperature is reached.

Indicator is lit if and when unit

m

power from power supply and have

W

A

R

N

I

N

G

the unit serviced by a qualified

technician.

Page 23

WENDY’S ELECTRIC RANGE COOKING HINTS

COOKING HINTS

COOKING HINTS (OVEN)

A convection oven is a different type of oven that offers many features and advantages to food service

operation. The additional capabilities and features of the oven require some learning. However, the

operation of the oven is not difficult to understand or control once you have some practice.

Convection ovens operate much like a standard oven: you turn the oven ON and select a cooking

temperature. An additional control is used to operate the fan (as described on page 19).

In a standard (non-c onvection) oven, the air is relat ively still and an insulating la yer of moistur e surrounds

the cooking food product. In a convection oven, the fan-blown circulating air strips away this insulating layer

allowing the heat to penetrate f aster for q uicker bak ing and roasting. Hence, in a convecti on oven cook ing

procedures and tech niques may require some modific ation for successful results. As a general rule, the

cooking time will be shorter and the cooking temperature will be 25°F to 75°F (14°C to 42 °C) lower than

those called for in recipes for a standard oven.

TIME & TEMPERATURE

Time and temperature ar e important. The best c ooking time and tem perature will depen d on such factor s

as size of load and mixtur e of recipe (par ticularl y moistur e). Onc e an appropr iate tim e and tem perature has

been established for a particular product and load, you will find the result of succeeding loads to be similar.

OVERLOADING

Do NOT overload the oven . The size of the load that can be cook ed satisfactorily depends largely on the

particular product. As a rul e, four racks can be successf ully used for shallo w cakes, cook ies, pies, etc. For

deeper cakes (s uch as angel food), use only three racks because of the size of the pan and the space

required for rising. For ha mburger patties, fis h sticks, cheese sandwic hes, etc., a full com plement of racks

and pans is usually satisfactory.

HELPFUL SUGGESTIONS

Here are some suggestions that will assist in getting the best possible performance from a convection

oven:

• Pre-heat the oven thoroughly before use.

• When re-thermali zing frozen products, pre-heat the o ven to 50°F (28°C) higher than the planned

cooking temperature. After loading, reduce the temperature setting to the appropriate cooking

temperature.

• Space the racks and pans as evenly as possible to allow air circulation.

• Center the load on th e racks to allow f or proper air ci rculation around the s ides. Do not cover the

racks completely with pans.

• Do not use a deep pan for shallow cak es or cookies, etc. A ir circulation acros s the surface of the

product is essential.

WARNING

THE USE OF ALUMINUM FOIL CAN CAUSE HEAT DISTRIBUTION PROBLEMS IN OVENS.

EXTREME CARE MUST BE USED WHEN PL ACING AL UMINUM FOIL IN THE OVEN TO ENSURE

THAT IT DOES NOT BLOCK OR CHANG E THE AIR FLOW . THE USE OF ALUMINU M FOIL MAY

VOID THE PRODUCT WARRANTY IF ITS USE IS ASCERTAINED TO BE A PROBLEM.

OWNER’S MANUAL 1195746 PAGE 23

Page 24

COOKING HINTS WENDY’S ELECTRIC RANGE

COOKING HINTS

COOKING PROBLEMS AND SOLUTIONS

If… then…

Cakes are dark on the sides and not done in the center… lower oven temperature.

Cake edges are too brown… reduce number of pans or lower oven temperature.

Cakes have a light outer color… raise temperature.

Cakes settle slightly in the center… bake longer or raise oven temperature slightly. Do not open

doors except to load or unload product.

Cakes ripple… do not overload pans or use batter that is too thin.

Cakes are too coarse… lower oven temperature.

Pies have uneven color… reduce number of pies per rack or eliminate use of bake pans.

Brown sugar topping or meringue blows off… after oven is preheated, turn off oven and put product in oven

until topping sets, then turn oven back on.

Rolls have uneven color… reduce number or size of pans.

Meats are browned and not done in center… lower oven temperature and roast longer.

Meats are well done and not browned… raise temperature. Limit amount of moisture.

Meats develop hard crust… reduce temperature or place pan of water in oven.

Excessive meat shrinkage occurs… lower oven temperature.

PAGE 24 OWNER’S MANUAL 1195746

Page 25

WENDY’S ELECTRIC RANGE CLEANING

CLEANING

CLEANING

Southbend equipment is sturdily constructed of the best materials and is designed to provide durable

service when treated with ordinary care. To expect the best performance, your equipment must be

maintained in good condit ion and clea ned dai ly. Natura ll y, the periods f or this c are and clean ing depend on

the amount and degree of usage.

Following daily and p eriodic maintenance procedures will e nhance long life for your equipm ent. Climatic

conditions (such as s alt air) ma y require more thorou gh and frequent c leaning or the life of the equ ipment

could be adversely affected .

The oven interior is finished with a porcelain enamel coating. “Spillovers” should be cleaned from the

interior bottom surfac e as soon as p ossibl e to pr event car bonizing and a burnt -on cond ition. Grease or a n y

residue should be cleaned from interior surfaces as soon as it accumulates.

WARNING

FOR YOUR SAFETY, DISCONNECT THE POWER SUPPLY TO THE APPLIANCE BEFORE

CLEANING.

WHEN CLEANING THE BLOWER WHEEL, BE SURE TO HAVE THE POWER SWITCH IN THE

“OFF” POSITION.

WARNING

NEVER TOUCH AN OPERATING GRIDDLE. ALWAYS WAIT UNTIL THE TEMPERATURE

CONTROL KNOBS HAVE BEEN SET TO “OFF” FOR AT LEAST 30 MINUTES.

Clean Areas of Griddle that were used to Cook Food

1. Clean the griddle surface by pushing the greas e and/o r oil into the gr ease tr ough. T hen rub the s urfac e

with a pumice stone or a “griddle stone.” Rub the griddle surface in the direction of the metal grain

while the surface is still warm (NOT hot).

2. Wipe the griddle surface clean of residue from the rubbing stone, using clean cloths.

3. Thoroughly clean the grease troug h, grease c hutes, a nd grease dr awers at l east onc e each da y (more

often if necessary).

4. Allow the griddle to cool. Clean the sides of the griddle and all surfaces surrounding the griddle by

wiping them with a clean cloth dampened in warm water and a mild detergent.

5. Rinse all washed surfaces using a clean clot h dam pened with warm clean water . W ipe dr y with a clean

cloth.

6. Empty each grease drawer as often as necess ary, at least once per shift, and at the en d of each day.

Wash the grease drawers with hot water and a mild detergent. Rinse with clean hot water. Wipe dry.

7. Be sure to replace the grease drawers after each cleaning.

Clean Areas of Griddle that were used to h eat Pots and Cooking Vessels

Areas that have been use d for heating pots or o ther cooking vessels should be cleaned and “seasoned”

prior to cooking/heating any type of food product in that area of the griddle.

8. Allow the griddle section to cool. W ash the entire divided ( 23"×24" or 13"×24") section of the griddle

with warm water and a mild deterg ent. Also, clean all areas near that s ection of the griddle. DO NOT

USE COLD WATER.

OWNER’S MANUAL 1195746 PAGE 25

Page 26

CLEANING WENDY’S ELECTRIC RANGE

CLEANING

9. Rinse the cleaned section of the griddle (and adjacent surfaces) with clean, warm water.

10. Wipe dry with clean cloths.

11. “Season” the cleaned griddle section according to the procedure on page 20 of this manual.

Clean Oven

12. Turn the POWER switch to OFF and allow the oven to cool.

13. Remove the oven-interior rac ks and r ack slide fr am es. (T he rack slide fr am es are readil y rem ovable by

merely raising to disengag e them from their sockets.) W ash the racks and rack slides i n a sink with

mild detergent and warm water. Dry them thoroughly with a clean cloth.

14. Look to see if any foreign matter has accumulated o n the blades of the blower wheel (which wil l re duc e

air circulation). If nec essar y, rem ove the re ar lini ng of t he o ven, wh ich is sec ured b y thumbs crews near

each corner. Use a stiff brush to remove accumulations f rom the blower blades, then wash w ith soap

and water.

15. Wash the interior surfaces with mild detergent and warm water. Rinse with clean water, and dry

thoroughly with a clean cloth. For stubborn accumulations, a commercial oven cleaner may be used.

16. Clean the control panel with warm water and mild soap. Never use cleaning solvents with a

hydrocarbon base.

17. Wipe the other exterior surfaces with a c l ean damp cloth. If the exter i or s urfaces require more thorough

cleaning, see “Cleaning Stainless Steel Surfaces” below.

18. Reinstall the rear baffle (if removed), and return the side rack guides and oven racks to their

appropriate locations inside the oven.

19. LEAVE THE DOOR OPEN AT NIGHT AFTER CLEANING. This allows the oven to dr y thorou ghl y after

cleaning and also prolongs the life of the door gasket.

MONTHLY CLEANING

Clean around rear of motor (where the vent screen is located), louvered panels, and primary air holes in

the rear of the oven where grease or lint may have accumulated.

SEMI-ANNUAL CLEANING

At least twice a year have your Southbend Authorized Service Agency or another qualified service

technician clean and adjust the unit for maximum performance.

At least twice a year the oven’s venting system should be examined and cleaned.

CLEANING STAINLESS STEEL SURFACES

To remove normal dirt, gre ase and produc t residue f rom stainless s teel that ope rates at LOW temperatur e,

use ordinary soap a nd wat er (with or without deter gent) app lied with a s pon ge or cloth. Dr y thorough ly with

a clean cloth.

To remove grease and food splatter, or condensed vapors, that have BAKED on the equipment, apply

cleanser to a damp cloth o r sponge and rub cleans er on the met al in the directio n of the polishing lin es on

the metal. Rubbing cleans er, as gently as possible, in the direction of the pol ished lines will not mar the

finish of the stainless steel. NEVER RUB WITH A CIRCULAR MOTION. Soil and burnt depos its which do

not respond to the above p rocedure can usuall y be removed by rubbing the s urface with SCOT CH-BRITE

scouring pads or ST AINLESS scouring p ads. DO NOT USE ORD INARY STEEL W OOL, as any particles

left on the surface will rust and further spoil the appearance of the finish. NEVER USE A W IRE BRUSH,

STEEL SCOURING PADS (EXCEPT STAINLESS), SCRAPER, FILE OR OTHER STEEL TOOLS.

Surfaces which are marred collect dirt more rapidly and become more difficult to clean. Marring also

increases the possibility of corrosive attack. Refinishing may then be required.

PAGE 26 OWNER’S MANUAL 1195746

Page 27

WENDY’S ELECTRIC RANGE CLEANING

CLEANING

To remove heat tint – Darkened areas som etimes appear on sta inless stee l surfaces where th e area has

been subjected to excessive heat. These darkened areas are caused by thickening of the protective

surface of the stainless s teel and are not harm ful. Heat tint can norm ally be removed b y the foregoing, but

tint which does not respond to this procedure calls for a vigorous scouring in the direction of the polish

lines, using SCOTC H-BRITE scouri ng pads or a STAINLESS scourin g pad in combination with a po wered

cleanser. Heat tint ac tion ma y be lessene d by not ap plying, or by reduci ng, heat to equipm ent during s lack

periods.

CARE OF GRIDDLE

A griddle should be caref ully cared for in ord er to avoid poss ible damage. The griddle must be “ seasoned”

before operation (see “SEASONING OF GRIDDLE SURFACE” on page 20). Use a pumice stone or a

“griddle stone” to clea n the griddle. Do not use any type of s teel wool. Small particles ma y be left on the

surface and get into food products. Do not clean spatula by hitting the edge on the griddle plate. Such

action will only cut and pit the griddle plate, leaving it rough and hard to clean.

OWNER’S MANUAL 1195746 PAGE 27

Page 28

ADJUSTMENTS WENDY’S ELECTRIC RANGE

ADJUSTMENTS

ADJUSTMENTS

WARNING

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

TECHNICIAN W HO IS EXPER IENCED IN, AND KNOWLEDGEABLE W ITH, TH E OPERATION OF

COMMERCIAL COOKING EQUIPMENT. HOWEVER, TO ASSURE YOUR CONFIDENCE,

CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR RELIABLE SERVICE, DEPENDABLE

ADVICE OR OTHER ASSISTANCE, AND FOR GENUINE FACTORY PARTS.

NOTICE

Warranty will be void and the m anufacturer is relieved of all liabilit y if service work is performed b y

other than a qualified technician, or if other than genuine Southbend replacement parts are installed.

LUBRICATION

The door chains and sprockets have been lubr icated at the factory with high temperature “Never Seez”

lubricant. After each six months of usage, lubricate the door chains and sprockets with the same t ype of

lubricant.

Motor lubrication information can be found on the permanent label located on the motor.

Casters are provided with a fitting for proper lubrication when required.

CALIBRATION/OBSERVATION OF ELECTRIC GRIDDLE THERMOSTATS

Each 12" (305mm) section of the griddle is controlled by a snap-action thermostatic control. If griddle

temperatures vary from the set point on the corresponding front-panel control, then calibration may be

needed. Use the following procedure to calibrate the griddle thermostats.

NOTICE

The following starting conditions must be followed in order to ensure proper calibration.

1. The griddle surface must be scraped clean. No product should be present on the griddle during

calibration.

2. Set all thermostats to 300°F (149°C) and allow them to cycle three to four times and allow the griddle to

preheat for 1 hour before proceeding.

3. Using a surface type thermom eter placed at each Point “A” (as sho wn in the f ollo wing diagram ), c heck

the temperature for all of the thermostats by comparing the corresponding control setting to the

measured temperature. A tape measure should be used to verify the proper positioning of the

thermometer probe. If the temperature is not within 15°F (8°C), you need to adjust the thermostat

control.

PAGE 28 OWNER’S MANUAL 1195746

Page 29

WENDY’S ELECTRIC RANGE ADJUSTMENTS

ADJUSTMENTS

Points “A”

6 inches

(152 mm)

HOT

6 inches

(152 mm)

12 inches

(305 mm)

12 inches

(305 mm)

HOT HOT

11-1/8 inches

(283 mm)

4. Remove the knob and firmly gras p the stem of the thermostat. With a sm all screwdriver, turn t he set

screw (Point “B” in the following diagram) to make the adjustments. If the temperature is lower than the

dial setting, turn the screw in a counterclockwise direction to increase the temperature. If the

temperature is higher than the knob setting, turn the screw in a clockwise direction to decrease the

temperature. These adjustments must be made in very small increments.

OWNER’S MANUAL 1195746 PAGE 29

Page 30

ADJUSTMENTS WENDY’S ELECTRIC RANGE

ADJUSTMENTS

Point “B”

Calibration Screw

(remove knob to access)

Turn counterclockwise to

INCREASE temperature

Tu rn clockwise to

DECREASE temperature

5. Allow the griddle temperature to stabilize, then check the griddle surface temperature again, as

described above. When the temperature is correct, replace the control knobs.

PAGE 30 OWNER’S MANUAL 1195746

Page 31

WENDY’S ELECTRIC RANGE ADJUSTMENTS

ADJUSTMENTS

Turnbuckles

ADJUSTING DOOR CHAIN MECHANIS M

The door chain mec hanism causes the lef t and right doors to op en and close together . To adjust the door

chain mechanism, do the following:

1. Remove lower front panel that covers the door chain mechanism (shown in following drawing).

2. Close both doors.

3. Check the positioning of the chai n on the sproc kets. T here should be five reg ular links and one m aster

link visible on the front side of eac h chain. If not , open the turnbuckles and reposition the chai n ov er the

sprockets.

4. Adjust the turnbuckles so that the right d oor closes ab out 1/4" to 1/2 " (6mm to 13m m) ahead of the l eft

door. The left door should be pus hed tight over the fric tion catch so both doors are c ompletely closed

against the frame.

5. Secure the turnbuckles by tightening their locknuts.

Door Chain Adjustment

OWNER’S MANUAL 1195746 PAGE 31

Page 32

ADJUSTMENTS WENDY’S ELECTRIC RANGE

ADJUSTMENTS

THIS PROCEDURE SHOULD ONLY BE PERFORMED BY A QUALIFIED S ERVICE TECHNICIAN

CALIBRATION OF OVEN TEMPERATURE

WARNING

FAMILIAR WITH ELECTRICITY AND ELECTRICAL COOKING EQUIPMENT REPAIR.

If the oven temperature requires calibration, do the following.

1. Unplug the oven (or disconnect the power) and remove the lower front panel, right side panel, and

insulation (see drawing on page 13). Locate the temperature control board on the control panel

assembly (as shown in the f ollowing drawing). Plug the oven back in (or reconnect power) and leave

the side panel and insulation off to perform this calibration.

Calibration Potentiometers on

Temperat ure Control Board

2. Clip the oven-temperature probe directly to the oven center shelf. Close the oven and place the

thermometer on the fr ont. Set the temperature selector to HIGH and tur n the oven ON. Let the oven

heat up and allow the oven tem perature light to cycle twice. O bserve the low an d high tem perature of

the last cycle.

3. The board has three potentiom eters that have miniature set screws f or temperature adjustment (see

following picture). Turning the screw o n a potentiometer clockwise will increas e the temperature, and

turning it counterclock wise will decrease the tem perature. Using a micro sc rewdriver, adjust the HIGH

temperature potentiometer by a small amount. Allow the oven to cycle twice and check the oven

temperature. Repeat until the oven temperature is 375°F ±10°F (191°C ±6°C).

WARNING

ENSURE THAT NEITHER YOU NOR YOUR SCREWDRIVER COMES IN CONTACT WITH THE

LIVE POWER IN THE UNIT.

PAGE 32 OWNER’S MANUAL 1195746

Page 33

WENDY’S ELECTRIC RANGE ADJUSTMENTS

ADJUSTMENTS

LOW

MEDIUM

HIGH

4. Repeat Step 3 to a djust the LOW to 325°F (163°C) and MEDIUM to 335°F (168°C) potentiometers.

Always allow the oven to cycle twice after adjustment to confirm accuracy. After completion of

calibration, remove th e oven thermometer, and reinstall the side pane l and insulation along with any

other steps necessary to return the unit to service.

OWNER’S MANUAL 1195746 PAGE 33

Page 34

ADJUSTMENTS WENDY’S ELECTRIC RANGE

ADJUSTMENTS

A

Contactor

CONVERSION OF OVEN FROM 1-PHASE TO 3-PHASE POWER (OR VICE VERSA)

Ovens are shipped wired for 1-phase power. If the oven installation requires changing the type of power

used by the oven, follow the proc edure below. T he following drawing sho ws the locations of items referr ed

to in the procedure.

1. DISCONNECT OVEN FROM POWER SUPPLY.

2. Locate and remove the four scr ews that secure the l ower front pan el (items “A” in the drawing above).

Lift up the panel and pull it forward to remove it, and then set it aside.

3. Locate and remove the two now-accessible screws that secure the lower front corner of the side panel.

4. Locate and remove the three screws that secur e the back edge of the side panel to t he oven. R emove

the side panel and insulation and set them aside.

5. Locate the wires running from the s upply-power terminal block to the con tactor. If converting from 3phase to 1-phase power, re m ove the wire T 2 (as s hown in the f ollowin g drawing) and go on to the nex t

step. If converting from 1-phas e to 3-phase power, locate the wires runn ing from the contactor to the

elements. Attached to thos e wires (with a wire tie) will be t wo wires that are not being used. Use the

shorter of the two extra wir es to make the additional connection ( T2) shown in the following drawin g.

Keep the longer wire to us e in th e nex t step. (Note: If you are c ha ng ing th e phas e-wiring of a 380/415V

oven, refer to the corresponding wiring diagram for conversion. See page 40.)

PAGE 34 OWNER’S MANUAL 1195746

Page 35

WENDY’S ELECTRIC RANGE ADJUSTMENTS

ADJUSTMENTS

Wiring is different for 380/415V ovens; refer to corresponding wiring diagram (see page 40).

6. Locate the wires running from the contactor to the elements. If converting from 3-phase to 1-phase

power, remove the wire L2 (as shown i n the above dra wing) and go on to the next step. If conv erting

from 1-phas e to 3-phase power, use the longer of the t wo extra wires foun d in the previous ste p to

make the additional connection (L2) shown in the above drawing. (Again, if you are changing the

phase-wiring of a 380/415V ov en, refer to the correspondin g wiring diagram for conversio n. See page

40.)

7. Rewire the connections to the elements (located o n the back of the oven) according to the diagram on

this page. I f convert ing from 3-phase to 1-ph ase, use the wire that you saved in Step 2 to mak e one of

the connections. (Onc e more, if you are changing th e phase-wiring of a 380/415V oven, refer to t he

corresponding wiring diagram for conversion. See page 40.)

8. Carefully compare the new wiring connections at the elements, contactor, and supply-power

terminal block to the wiring diagram for the oven. (A wiring diagr am is located on the side of the

control panel assembly, see page 37; or see the appropriate wiring diagram printed in this manual,

beginning on page 38). Verify that all connections are tight.

9. Reattach the right-side insulation, right-side panel, and lower-front panel.

10. Connect the oven to the power supply. Note that the supply-power connections depend on

whether the supply power is 3-phase or 1 phase, and so will be different than they were prior to

the conversion.

11. Double-check supply-wire sizing for new amperage load (see page 5).

OWNER’S MANUAL 1195746 PAGE 35

Page 36

TROUBLESHOOTING WENDY’S ELECTRIC RANGE

TROUBLESHOOTING

TROUBLESHOOTING

WARNING

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

TECHNICIAN W HO IS EXPERIENCED IN, AND KNOW LEDGEABLE WITH , THE OPERATION OF

COMMERCIAL COOKING EQUIPMENT. HOWEVER, TO ASSURE YOUR CONFIDENCE,

CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR RELIABLE SERVICE, DEPENDABLE

ADVICE OR OTHER ASSISTANCE, AND FOR GENUINE FACTORY PARTS.

NOTICE

Warranty will be void and the m anufacturer is relieved of all liabilit y if service work is performed b y

other than a qualified technician, or if other than genuine Southbend replacement parts are installed.

When any difficult y arises it is always a good idea to check that the oven has b ee n c onnec te d to th e t ype of

voltage for which it was manufac tured. The range-top ser ial plate is located on the interior side of the top

front panel, while the oven-base serial plate is located on the interior side of the lower front panel, as

shown on page 3. The serial plate will list the type of voltage for which the unit was manufactured. In

addition, a wiring diagram for the oven base is attached to the side of the oven-base slide-out control panel,

while a wiring diagram for the range top is located on the interior side of the rear access panel. Wiring

diagrams are also reproduced in this manual (beginning on page 38).

TROUBLESHOOTING GUIDE

The left column of the following table lists symptoms that indicate a problem, while the center and right

columns list the possible c auses and appropriate cor rective action. Note that the recommendations of this

table assume that the wiring connec tions are good . When check ing a component , always chec k the wiring

attached to the component as well.

Symptom Possible Cause Check or Replace

Oven will not operate,

but range top will.

Oven will not hold

correct temperature.

Temperature control not calling for heat.

Inadequate or improper ventilation. Check ventilation hood. Verify draw and make up air adjustment.

Out of calibration. Calibrate according to procedure described on page 32.

Bad contactor. Verify that contactor is pulling in and supplying power to the elements.

Blower motor will not

come on.

Loose wire connections. Check wire connections.

Motor bad. If power is being supplied but motor will not turn, replace motor.

Shut down switch bad.

POWER switch bad.

FAN MODE switch bad. Check FAN MODE switch.

Blown oven fuses. Check oven fuses located on oven-base control panel (see page 21).

Temperature probe not working.

No incoming electric power. Check incoming power and fuses.

Resistance across temperature probe leads at room temperature (70°F,

21°C) should be approximately 1096 ohms.

When heat is required, there should be continuity between terminals 6

and 7 on temperature control.

All power except for element supply comes through the shut down

switch. Check for continuity.

All power except for element supply comes through the POWER switch.

Check for continuity.

PAGE 36 OWNER’S MANUAL 1195746

Page 37

WENDY’S ELECTRIC RANGE TROUBLESHOOTING

TROUBLESHOOTING

CONTROL PANEL ACCESS AND SHUT-OFF SWITCH

To access the oven-base control panel components , remove the thumb screws at the top and bottom of the

control panel and pull the control pa nel out (see drawing below). A wiring di agram for the oven is located

on the side of the control panel assembly. When the control panel is pulled out, all power to the control

panel is cut off by a shut down switch that is located directly behind and below the control panel.

To re-energize the controls for troubleshooting, push in the plunger on the shut down switch.

Accessing Lower Control Panel Components

BLOWER WHEEL REPLACEMENT

To replace the blower wheel, do the following:

1. Remove racks and rack guides.

2. Remove rear air baffle in front of blower wheel.

3. Loosen the two square heads on blower wheel hub.

4. Pull blower wheel from motor shaf t. If blower wheel is diff icult to pull of f, use pu ller disk (availab le from

Southbend Technical Service department as part number 1179100).

OWNER’S MANUAL 1195746 PAGE 37

Page 38

TROUBLESHOOTING WENDY’S ELECTRIC RANGE

TROUBLESHOOTING

COIL

CONTACTOR

NOTE:

ELEMENTS ARE 2500WATTS EACH

3 PHASE

CONTACTOR

1 PHASE

L1 L2 L3

X Y

Z

TB1

Wiring Diagram for 208/240 Volt Ovens

PAGE 38 OWNER’S MANUAL 1195746

Page 39

WENDY’S ELECTRIC RANGE TROUBLESHOOTING

TROUBLESHOOTING

COIL

CONTACTOR

NOTE:

ELEMENTS ARE 2500WATTS EACH

3 PHASE

L1

CONTACTOR

L2 L3

1 PHASE

X Y

Z

TB1

Wiring Diagram for 480 Volt Oven

OWNER’S MANUAL 1195746 PAGE 39

Page 40

TROUBLESHOOTING WENDY’S ELECTRIC RANGE

TROUBLESHOOTING

COIL

CONTACTOR

NOTE:

ELEMENTS ARE 2500WATTS EACH

3 PHASE

ELEMENTS

L1

CONTACTOR

L2 L3

1 PHASE

TB1 TB2

N

Wiring Diagram for 380/415 Volt Wye Ovens

PAGE 40 OWNER’S MANUAL 1195746

Page 41

WENDY’S ELECTRIC RANGE TROUBLESHOOTING

TROUBLESHOOTING

125

135

165

Wiring Diagram for 208/240 Volt Range Tops

OWNER’S MANUAL 1195746 PAGE 41

Page 42

TROUBLESHOOTING WENDY’S ELECTRIC RANGE

TROUBLESHOOTING

125

135

165

Wiring Diagram for 480 Volt Range Top

PAGE 42 OWNER’S MANUAL 1195746

Page 43

WENDY’S ELECTRIC RANGE TROUBLESHOOTING

TROUBLESHOOTING

125

135

165

Wiring Diagram for 380/415 Volt Wye Range Tops

OWNER’S MANUAL 1195746 PAGE 43

Page 44

WENDY’S ELECTRIC RANGE

Wendy’s Electric Range

A product with the So uthbend name incor porates the best in d urability and low m aintenance. We

all recognize, however, that replacement parts and occasional professional service may be

necessary to extend the useful life of this unit. When service is needed, contact a Southbend

Authorized Service Age nc y, or your dea ler. T o avoid c onfus ion, al ways ref er to th e m odel num ber,

serial number, and type of your unit.

Southbend

1100 Old Honeycutt Road, Fuquay Varina, NC 27526 USA

www.southbendnc.com

PAGE 44 OWNER’S MANUAL 1195746

Loading...

Loading...