Southbend SCX-10S-10 User Manual

Two ComparTmenT ConveCTion

S

Teamer wiTh KeTTle wiTh

S

Team Coil operaTion

Job Item#

SPECIFICATIONS:

Shall be a Southbend Model _______________________, convection

steamer complete with 6 or 10 Gallon Kettle on a modular boiler base

operating on steam coil boiler base. The steamer shall be constructed

of satin nish stainless steel, type 304, with a cooking chamber of onepiece, all-welded, type 316 stainless steel and shall be

SCX-2S, 14” W x 10.625” H x 21 D (355 mm x 270 mm x 533 mm).

SCX-10S, 14” W x 17” H x 21 D (355 mm x 432 mm x 533 mm).

The doors shall have a removable inner liner of stainless steel with full

perimeter gasket seal, an outer liner of one-piece all welded stainless

steel, and a positive lock and seal mechanism with spring release. The

steamer shall be provided with removable stainless steel pan supports

and a stainless steel drip trough connected to drain in order to collect

condensate when door is opened.

Each compartment’s control housing shall be constructed of stainless

steel with a fully removable side access panel. The controls shall include

an illuminated on/off power switch. The timing of each compartment

shall be independently controlled by a pilot ready light, a pilot cooking

light and a 60 minute electric timer which sounds an audible signal

at the end of the cooking cycle. Steam ow to the chamber shall be

cut off when the door is opened during the cooking cycle and shall be

reactivated when the door is closed.

The cabinet base with steam coil boiler and controls shall be provided

with full perimeter painted angle frame, reinforced counter and boiler

mountings, hinged door(s) with magnetic latch and 6” (152 mm) stainless

steel legs with adjustable bullet feet on the front and adjustable anged

feet on the rear for securing to the oor.

Boiler controls shall include automatic water level control, pressure

gauge, water gauge glass, operating pressure control, safety high-limit

pressure control and safety relief valve. Unit comes standard with a split

water line, CSD-1 boiler code, “Y” - strainer, and automatic blowdown.

The unit shall be ASME code stamped and National Board registere,

c-CSA-us and NSF certied.

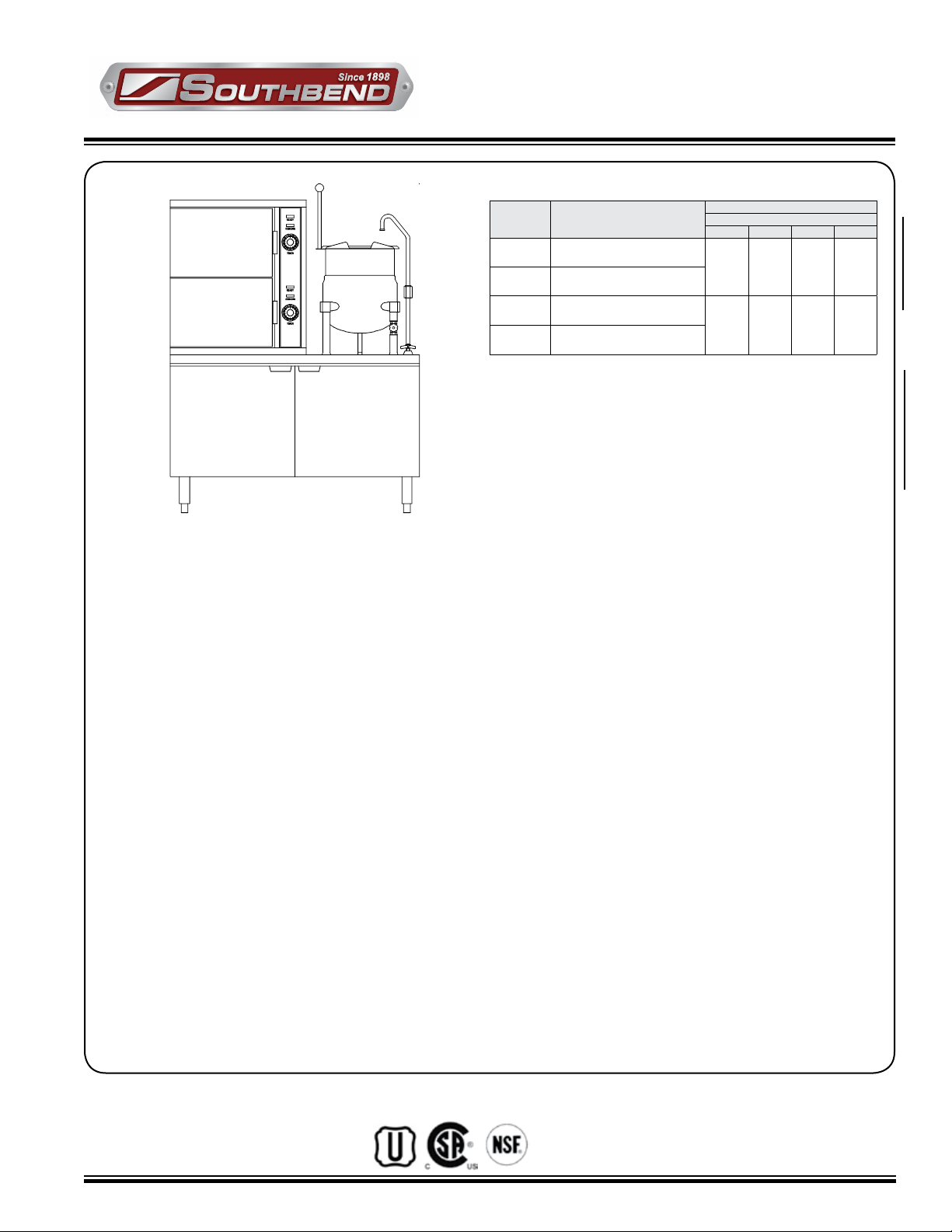

Model description

SCX-2S-6 6 pan steamer with 6 gallon kettle.

SCX-2S-10 6 pan steamer with 10 gallon kettle.

SCX-10S-6 10 pan steamer with 6 gallon kettle.

SCX-10S-10 10 pan steamer with 10 gallon kettle.

OPERATION SHALL BE BY:

Steam coil heated steam boiler operating at 9-11 psi (62-76 kPa).

The boiler shall be equipped for operation on incoming steam

pressure of 25-45 psi (170-310 kPa) and a ow of 200 lbs. (90

kg) per hour. The controls shall be equipped for operation on:

115 VAC, 1 Phase, 60 Hz

OPTIONAL ITEMS AT EXTRA COST:

220 VAC, 1 Phase, 50 Hz

Secondary low water cut-off (California Code)

Solid state digital controls

Stainless steel back on cabinet

Stainless steel frame

Adjustable front anged feet

Load compensating timers

Correctional package

ACCESSORIES:

Ball oat trap (BFT)

Spray and rinse assembly

pan capacity per coMpartMent

pan depth

1” 2-1/2” 4” 6”

6 3 2 1

10 5 3 2

Form SCX2-6 Rev 3 (December/2013)

www.yatesgd.com www.yatesgraphicdesign.com

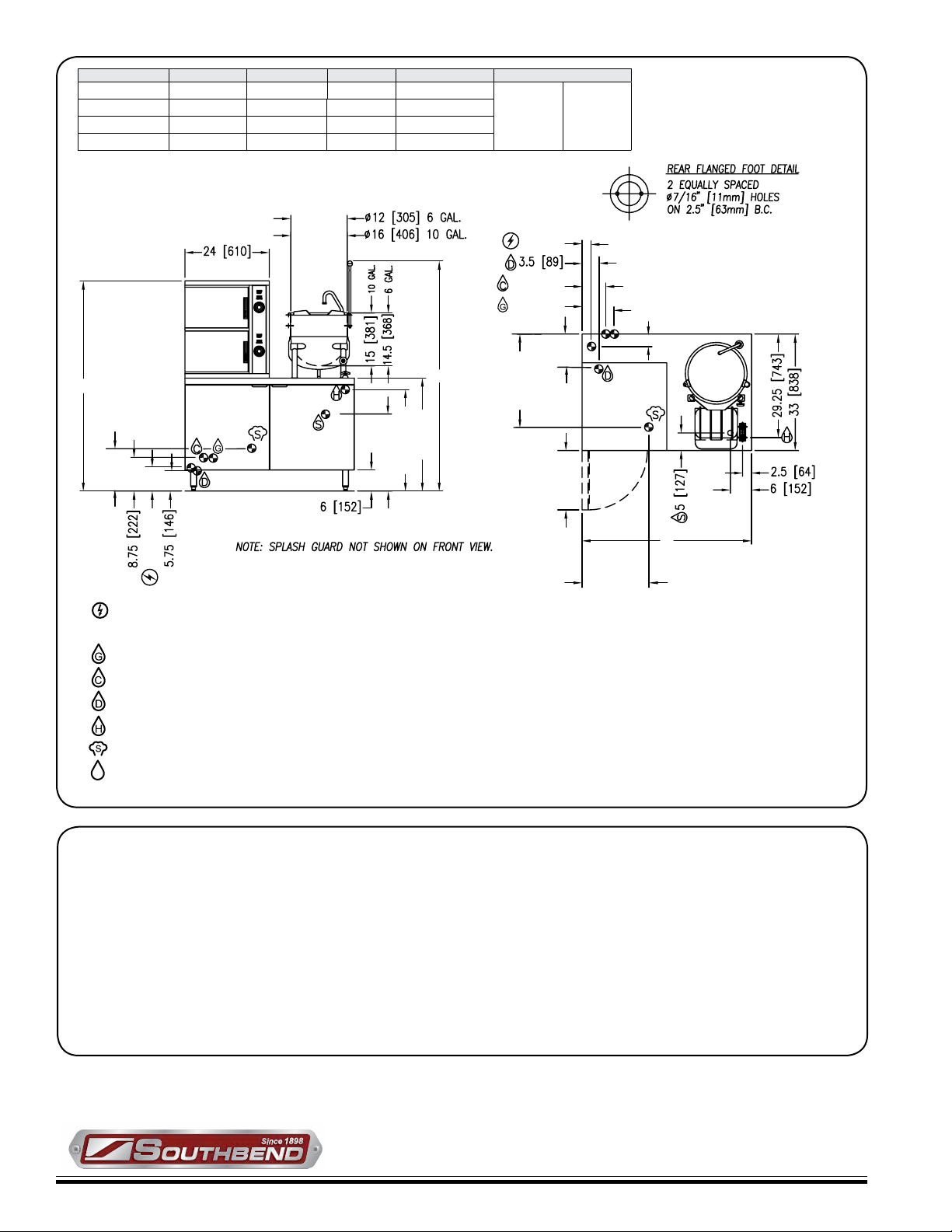

Models:

A

SCX-2S-6 SCX-2S-10 SCX-10S-6 SCX-10S-10

Model a B c

shipping Weight

SCX-2S-6 55.5 [1410] 62.13 [1578] 44 [1118] 700 lbs. [318]

SCX-2S-10 55.5 [1410] 61.13 [1553] 48 [1219] 750 lbs. [340]

SCX-10S-6 68.5 [1740] 62.13 [1578] 44 [1219] 1000 lbs. [453]

SCX-10S-10 68.5 [1740] 61.13 [1553] 48 [1219] 1020 lbs. [462]

B

28 [711]

24.75 [629]

20.25 [514]

Min clearance

SIDES

BACK

2 [51]

4.75 [121]

6.75 [171]

9.5

27.63 [702]

0

0

2.5 [64]

[241]

16.75 [425]

10 [254]

6.25 [159]

SERVICE CONNECTIONS

– ELECTRICAL CONNECTION: 1/2” (13 mm) conduit connection to controls.

18.75 [476]

C

2 Amps per compartment or to be as specied on data plate.

– BOILER FEED WATER: 1/2” (13 mm) NPT at 25-50 PSI (170-345 kPa).

– CONDENSATE COLD WATER: 1/2” (13 mm) NPT at 25-50 PSI (170-345 kPa) (OPTIONAL)

– DRAIN: 2” (51 mm) IPS piped to open oor drain. No solid connection.

– HOT WATER: 3/8” (10 mm) O.D. tubing at 25-50 PSI (170-345 kPa).

– STEAM SUPPLY: 3/4” (19 mm) IPS for incoming steam at 40-50 PSI(276-345 kPa)*

– SINK DRAIN: 1-1/8” (29 mm) O.D. tubing.

s

* Pressure reducing valve is required if incoming pressure exceeds 50 PSI(345 kPa).

WATER QUALITY STATEMENT

Water quality is the major factor affecting the performance of your appliance. If you are unsure of water quality, consult a local water

treatment specialist and have the water analyzed. Your water supply must be within these general guidelines:

Total dissolved solids ....................Less than 60 PPM

Total alkalinity ................................Less than 20 PPM

Silica ...............................................Less than 13 PPM

Chlorine .........................................Less than 1.5 PPM

pH Factor ......................................7.0 - 8.5

Water which fails to meet these standards should be treated by installation of water conditioner.

FAILURE OR MALFUNCTION OF THIS APPLIANCE DUE TO POOR WATER QUALITY IS NOT COVERED UNDER WARRANTY.

CONTACT SOUTHBEND FOR WATER QUALITY SOLUTIONS.

Form SCX2-6 Rev 3 (December/2013)

INTENDED FOR COMMERCIAL USE ONLY.

NOT FOR HOUSEHOLD USE

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(919) 762-1000 www.southbendnc.com

.

Loading...

Loading...