Southbend SC524, SCBC-24, SCB-36, SCBC-36, SCB-46 Operation Manual

...

I

----LR-I---

-7

A MIDDLEBY COMPANY

1

FOR FUTURE REFERENCE

Please complete this information and retain this manual for

the life of the equipment.

MODEL #

SERIAL #

DATE PURCHASED

---__ _,

IMPORTANT

OWNER’S MANUAL

INSTALLATION

USER’S GUIDE

SERVICE

PARTS

GAS CHAR BROILER

MODELS: SC524 SCBC-24

SCB-36 SCBC-36

SCB-46 SCBG46

SCBC-60

(Includes all models with suffixes R, A, AR)

These instructions should be read thoroughly before attempting installation. installation

and Start Up should be performed by a qualified service technician. The Manufacturer,

Southbend (1100 Old Honeycutt Rd., Fuquay-Varfna, North Carolina 27526), informs you

that unless the installation instructions for the above described Southbend product are

followed and performed by a qualiied service technician, (a person experienced in and

knowledgeable concerning the installation of commercial gas and/or electrical cooking

equipment) then the terms and conditions of the Manufacturer’s Limited Warranty will be

rendered void and no warranty of any kind shall apply.

If the equipment has been changed, altered, modified or repaired by other than a

qualified service technician during or after the 12-month limited warranty period, then

the manufacturer shall not be liable for any incidental or consequential damages to any

person or to any property which may result from the use of the equipment thereafter.

Some States do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion thereto may not apply to you.

In the event you have any questions concerning the installation, use, care, or service of

the product, write Customer Service Department, Southbend, 1100 Old Honeycutt Rd.,

Fuquay-Varina, North Carolina 27526.

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury or

death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this

equipment.

CHAR BROILERS

(Manual

Section

BR)

Congratulations! You have just purchased one of the finest pieces of heavyduty, commercial cooking

equipment on the market today.

You will fmd that your new equipment, like all Southbend equipment, has been designed and manufactured

to some of the toughest standards in the industry - those of Southbend Corporation. Each piece of

Southbend equipment has been carefully engineered and designs have been verified through laboratory

tests and field in&al&ions in some of the more strenuous commercial cooking applications- With proper

care and field maintenance, you will experience years of reliable, trouble-free operation from your

Southbend equipment. To get the best results, it’s important that you read tbis manual carefully.

TABLE OF CO-

SECTION ONE - INSTALLATION

spf?cifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..-....-.....-..l

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..-......2

SECTION TWO - USERS GUIDE

Warranty.....................................................................-..l

(3&&&n& . . . . . . * . . . . . . . . * . . . . . . . . . . . . . . . . * . _ . . . . . _ . . . _ . . . ~ . _ . . . . . . . . . . . . . . . . -2

. . . . . . . . . . . . . . ..~..-.....................-....~..................... 4

SECTION THREE - SERVICE

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..-.........................~........ 1

Troubleshooting.................................................................2

SECTION FOUR - PARTS

PartsList ..-.................

. . . . ..__........................................... 1

CAUTION: POST IN PROMINENT LOCATION INSTRUCTIONS TO BE

FOLLOWED IN THE EVENT THE SMELL OF GAS IS DETECTED. THIS

INFO-ON SHALL BE OBTA12vED FROM LOCAL GAS SUPPLIER.

I

INTENDED FOR COMMERCIAL USE ONLY. NOT FOR HOUSEHOLD USE.

I

DO NOT STORE OR USE GASOLINE OR OTHER

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

KEEP AREA AROUND APPLIANCES FREE AND CLEAR FROM

coMBusTlBLEs.

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN EQUIPMEXW AT

THE MAIN SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY

OR GAS SUPPLIERFOR SERVICE.

RiETAIN THIS MANUAL FOR FUTTJRE REFERENCE.

FOR YOUR SAFETY

FLAMMABLE VAPORS

I

I

11000MHoneyarttRoad

Fuquay-Varina. NC 27626

GAS CHAR BROILER

INSTALLATION

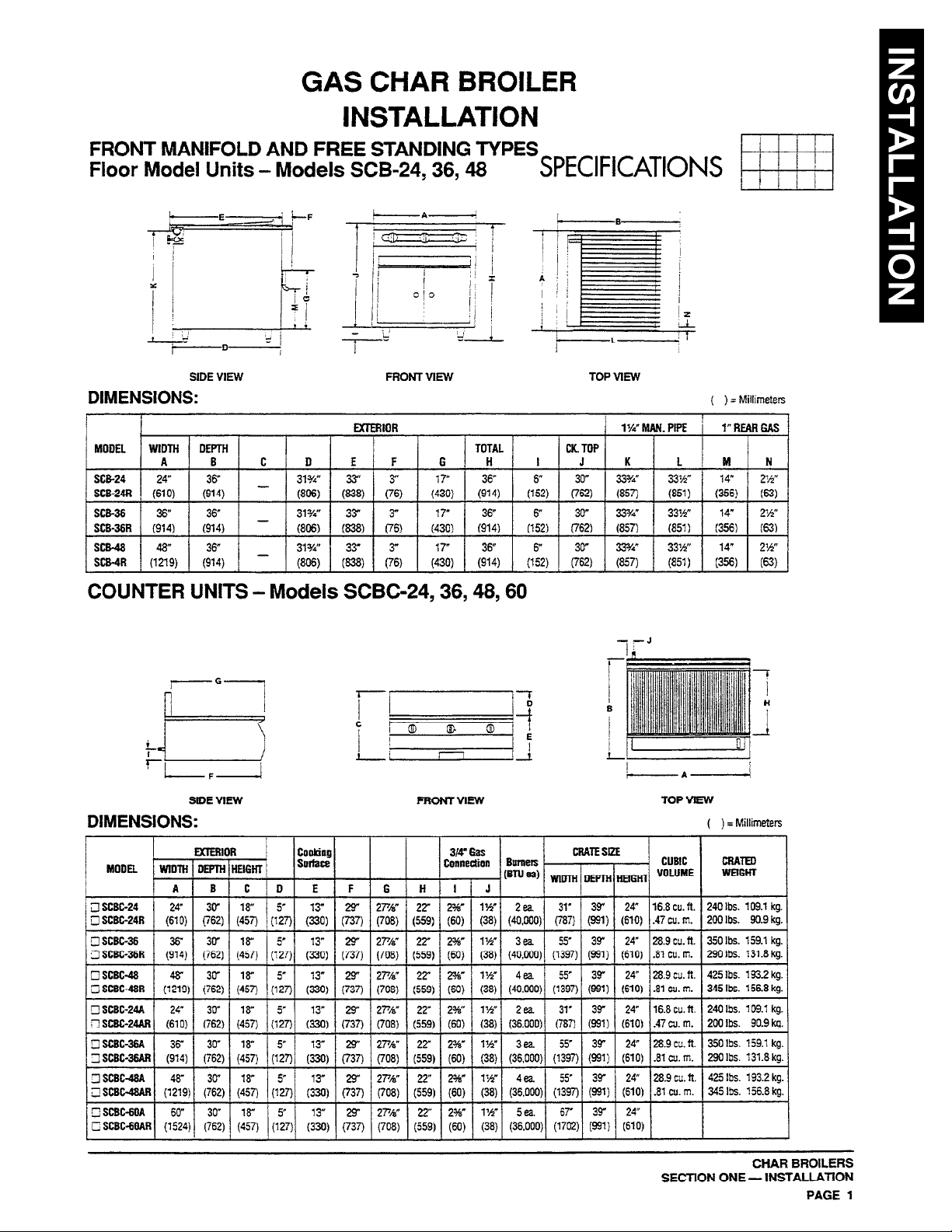

FRONT MANIFOLD AND FREE STANDING TYPES

Floor Model Units - Models SCB-24,36,48

SPECIFICATIONS

+=

~-D--+

-E

SIDEVIEW

1

-7;’ -

*-

-I-=

l=RoNrvlEw

DIMENSIONS:

scB-48 48”

SCWR (1219) (914) -

36 313/d' 33" 3"

W)

(838) (76)

17"

(430)

36" 6"

(914)

COUNTER UNITS - Models SCBC-24,36,48,60

(=a

TOPVIEW

n

(Z2,

33%"

em

-ir

J

33w

(851)

( ) = Millimeters

n

2w

(&

63)

G

-1

F==T

>H

F

SIDEVIEW

DIMENSIONS:

I I I 1 1 I 1 , I / 1 I

MODEL

~SCBC-24 "

DSCBC-24R

[OSCBC-36 136"~30"(18" 15"~ 13" 1 29 1 27%" 1 22" ) 2%" 1 lw[ 3ea 1 55" I 39" I 24" 123.9cu.ft. 1 350Ibs. 159.1 kg.1

3 SCBC-36R

q

lSCBC-48 48" 30" 18" 5" 13" 29" 27w 22" 2%" 1%" 4ea 55" 39"

OSCBC-.%R

[3SCBC-24A 24" 30" 18" 5" 13"

JSCBC-24AR (610) (762) (457) (127) (330) (737) (708) (559) (60) (38) (36.000) (787) (9%) (610) A7cu.m. 2OUIbs. 90.9kg.

EISCBC-36A 36" 30" 18" 5" 13" 29 27%" 22" 2%" 1%" 3ea

3SCBCQSAR (914) (762) (457) (127) (330) (737) (708) (559) (60) (38) (36,000) (1397) (991) (610) .Blw.m. 2901bs. 131.8kg.

3SCBCd8A 48" 30" 18" 5" 13" 2s 2i?h" 22" 2%" 1%" 4ea. 55" 39"

~SC%4BAll (1219) (762) (457) (127) (330) (737) (708) (559) (60) (38) (36.000) (1397) (991) (610) .81 cu.m.

OSCBCdOA 60" 30" 18" 5' 13"

CSCBC-WAR (1524) (762) (457) (127) (330) (737) (708) (559) (60) (38) (36.000) (1702) (997) (610)

EXlERlOR

WlOTH DEPTH HEIGHT

A B C D E F G H I J

(go) (%I (i& (I?& (ii01 (f& Fz) (iii) Fg ig (4$0) (787) (991) (610) .47cu.m.

(914) (762) (457) (127) (330) (737) (708) (559) (60) (38) (40,COO) (1397) (991) (610) .8lcu.m. 29Ofbs. 131.8kg.

(1219) (762) (457) (127) (330) (737) (708) (559) (60) (38) (40.000) (1397) (991) (610) .81cu.m. 345Ibs. 156.8kg.

cooking 3/4'Gas

smlace

I :

I I

29" 2?%" 22" 2%

29 27%"

I

PRONT VIEW

Connection

1%" 2ea

2r 2%" l'h"

i

Bomels

(BTU ea) wlm uEm mG; 'JOWME ==

31" 3r

31' 39"

55' 39"

5ea. 67" 39"

l-1’

CRATE SIZE

i-----A------i

TOPVIEW

( ) = Millimeters

CUBIC

24" 16.8 cu.ft. 2401bs. 109.1 kg.

200 Ibs. 90.9 kg.

24" 28.9 cu.ft. 425Ibs. 1932 kg.

24" 16.8cu.fl. 240 Ibs. 109.1 kg.

24" 28.9cu.ft. 360lbs. 159.1 kg.

24" 28.9 cu.lt. 425 Ibs. 193.2 kg.

345Ibs. 156.8kg.

24"

SECTION ONE - INSTALLATION

CHAR BROILERS

PAGE 1

INSTALLATION

\

WARNING TaESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED

PERSONNEL OR WARRANTY WILL BE VOIDED.

GENERALZ

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1- Latest Edition. Canadian installation must comply with CAN/CGA-B149.1 Natural Gas

Installation Code, Code CAN/CGA-B1492 Propane Installation Code.

These models are design certified for operation on Natural or Propane gases.

The appliance should be connected ONLY to the type of gas for which it is equipped AI1 Southbend equipment

is adjusted at the factory.

NOTE: Check type of gas on serial plate.

Models: SCB-Series - serial plate located left front corner on bottom inside lower compartment.

Models: SCBC-Series - remove front control panel. Serial plate attached in the center on the

compartment front shield to unit.

NOTE: Each SCB-Series Broiler is a complete unit with an individual 1%” NFT manifold across its entire

width. Units can be batteried by joining the unions at the ends of the manifolds- This manifold is not

equipped directly with a pressure regulator. However, the manifold must be connected with an adequately

sized gas appliance pressure regulator adjusted to supply a pressure to this manifold as marked on the

serial plate; 6” W.C. for natural gas and 10” WC. for propane gas. In addition, the pressure regulator must

meet the following requirements:

1. The pressure regulator installed should be certified by a nationally recoO&ed testing agency.

2. The regulator must have a maximum regulation capacity for the total connected load.

3. The regulator must have a pressure adjustment range to allow adjustment to the manifold pressure on the

appliance rating plate.

4. Unless the manifold pressure of all connected appliances is the same, a separate regulator must be

supplied for each unit(s) to indicate unit or units having differing manifold pressures.

5. If applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in

accordance with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI

223.1 - Latest Edition. Canadian installation must comply with CAN/CGA-B149.1 Natural Gas

Installation Code, Code CAN/CGA-B149.2 Propane Installation Code.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas required

for satisfactory performance. A steady supply pressure, between 7” W.C. and 8” WC. for natural gas and 11”

W.C. and 12” WC. for propane gas is recommended. With all units operating simultaneously, the manifold

pressure on all units should not show any appreciable drop. Fluctuations of more than 25% on natural and 10%

on propane gas will create pilot problems and affect burner operating characteristics. Contact your gas

company for correct supply line sizes.

As an option, the unit may be supplied with a rear gas connection. The pipe size of this connection is one inch.

Unless otherwise specified, this connection is welded to the right side of the manifold.

NOTE: Each SCBC-Series Counter Broiler is a complete unit with an individual %” NBT supply connection at

the rear. An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of

gas required for satisfactory performance. A pressure regulator, which is provided with each unit, is set to

maintain a 4” W.C. manifold pressure for natural gas and a 10” W.C. manifold pressure for propane gas.

However, to maintain these conditions the pressure on the supply line, when all units are operating

simultaneously, should not drop below 7” WC. for natural gas or 11” WC. for propane gas.

A %” pressure tap is located on the manifold of each unit.

All pipe joints should be tested for leaks with a soap and water solution before operating the unit. The test

pressure should not exceed 14” WC.

CAUTION: THIS APPLIANCE AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE

DISCONNECTED FROM THE GAS SUPPLY PIPING SYSTEM DURING ANY PRESSURE

TESTING OF THAT SYSTEM AT TEST PRESSURES IN EXCESS OF l/2 PSIG (3.45 kPa).

THIS APPLLANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPlNG SYSTEM BY

CLOSING ITS INDIVIDUAL MANUAL SHUTOFF VALVE DURING ANY PRESSURE

TESTING OF THE GM SUPPLY PIPING SXSlZM AT TEST PRESSURES EQUAL TO OR

LESS THAN 1 I2 PSIG (3.45 kPa).

CHAR BROILERS

SECTION ONE - INSTALLATION

PAGE 2

Litho in U.S.A.

11-92

INSTALLATION

t

W-G: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED

PERSONNEL OR Wm

EXHAUST FANS AND CANOPIES:

Canopies are set over ranges, ovens, etc., for ventilation purposes. It is recommended that a canopy extend 6”

past appliance and be located 6’6” from the floor. Filters should be installed at an angle of 45 degrees or more

with the horizontal. ‘Ibis prevents dripping grease and facilitates collecting the run-off

usually installed with a filter. A strong exhaust fan tends to create a vacuum in the room and may interfere

with burner performance or may extinguish pilot flames. Fresh air openings approximately equal to the fan

area will relieve such vacuum. In case of unsatisfactory

fan in the “OFF” position.

WALL EXHAUST FAN: Should be installed at least 2 feet above the vent opening at the top of the

backsplash.

NOTE: Be sure to inspect and clean ventilation system according to the ventilation equipment

manufacturers instructions.

CLEARANCES

Minimum clearances from combustible construction are: (Canadian installations only)

MODEL TYPE SIDES

FLOOR MODELS

t

COUNTER MODELS

I

Minimum clearances from non-combustible construction are: >

MODEL TYPE

ALL MODELS

WILL BE VOIDED.

grease in

performance on any appliance, check with the exhaust

12 IN.

I

12 IN.

a drip pan,

6IN.

81N.

SIDES

OIN.

OIN.

WARNING: All units must be installed in such a manner that the flow of combustion and

ventilation air are not obstructed. Provisions for an adequate air supply must also be provided.

Do not obstruct the front of the unit at the top by the control panel.

NOTE: No additional clearance from the sides and back is required for service, as the units are

serviceable from the front.

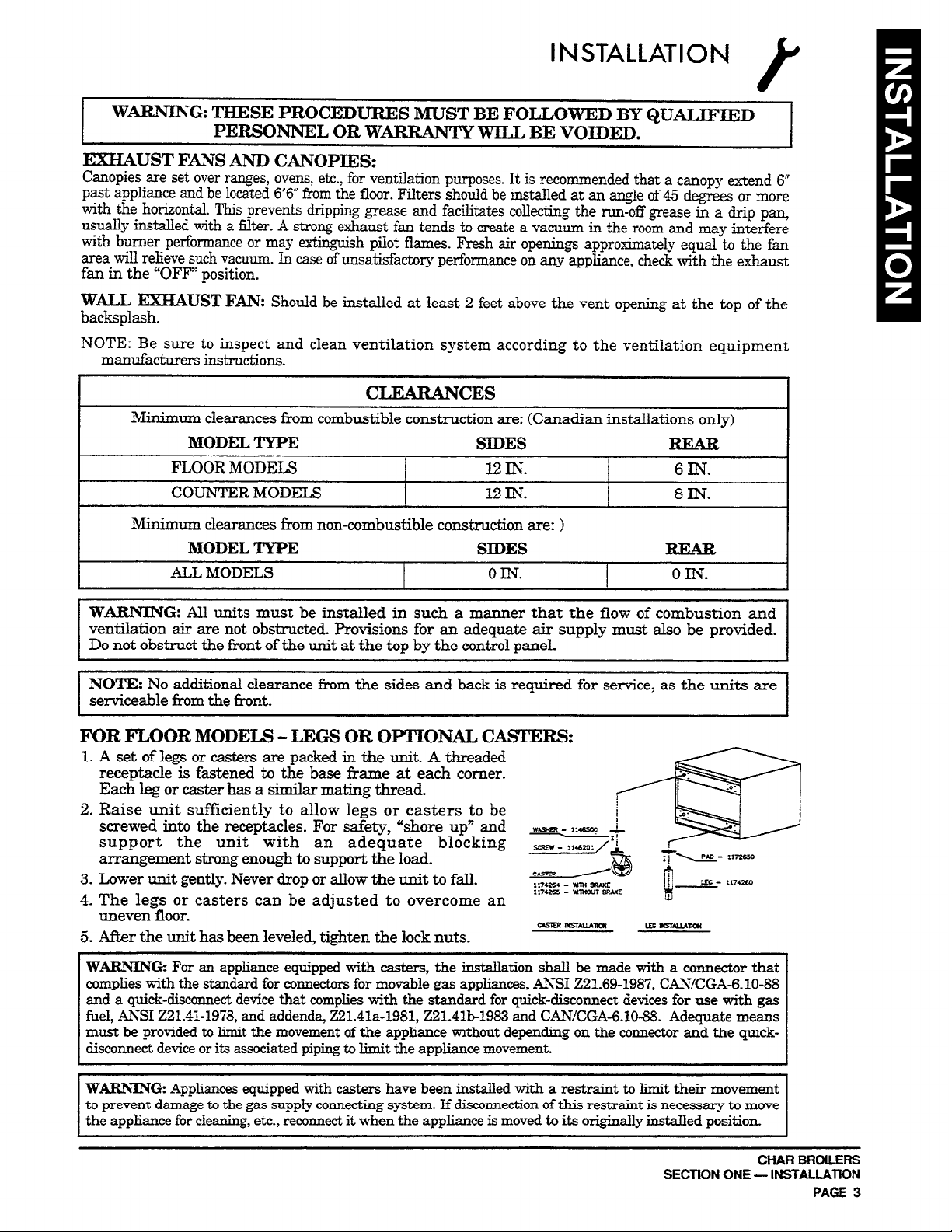

FOR FLOOR MODELS - LEGS OR OPTIONAL CASTERS:

1. A set of legs or casters are packed in the unit. A threaded

receptacle-is fastened to the base frame at each corner.

Each leg or caster has a similar mating thread.

2.

Raise unit sufficiently to allow legs or casters to be

screwed into the receptacles. For safety, “shore up” and

support the unit with an adequate blocking -- lwxI:/ I

arrangement strong enough to support the load.

Lower unit gently. Never drop or allow the unit to fall.

3.

4.

The legs or casters can be adjusted to overcome an

uneven

After the unit has been leveled, tighten the lock nuts.

5.

WARNING

complies with the standard for connectors for movable gas apphances, ANSI 221.69-1987, CAN/CGA-6.10-88

and a quick-disconnect device that complies with the standard for quick-disconnect devices for use with gas

fuel, ANSI 221.41-1978, and addenda, Z21.41a-1981,221.41b-1983 and CANKGA-6.10~88. Adequate means

must be provided to limit the movement of the appliance without depending on the connector and the quickdisconnect device or its associated piping to limit the appliance movement.

floor.

For an appliance equipped with casters, the instahation shall be made with a connector that

_ g?JJ

W- - I1”o +

zz, _ 6

117‘265 - III*OUT BR*)(E

GB

y-u- *1-

LEc-xl,*zM)

@

WARNING Appliances equipped with

to prevent damage to the gas supply connecting

the appliance for cleaning, etc., reconnect it when the appliance is moved to its originahy installed position-

casters

have been installed with a restraint to limit their movement

system.

If disconnection of this restraint is necessary to move

SECTION ONE - INSTALLATION

CHAR BROILERS

PAGE 3

INSTALLATION

1

WAR;NING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFD3D

I

TO INSTALL COUNTER MODELS:

1. Seal to counter top with sealer such as G.E. or DOW Coming RTV type sealant. (Consult local code for exact

requirements.)

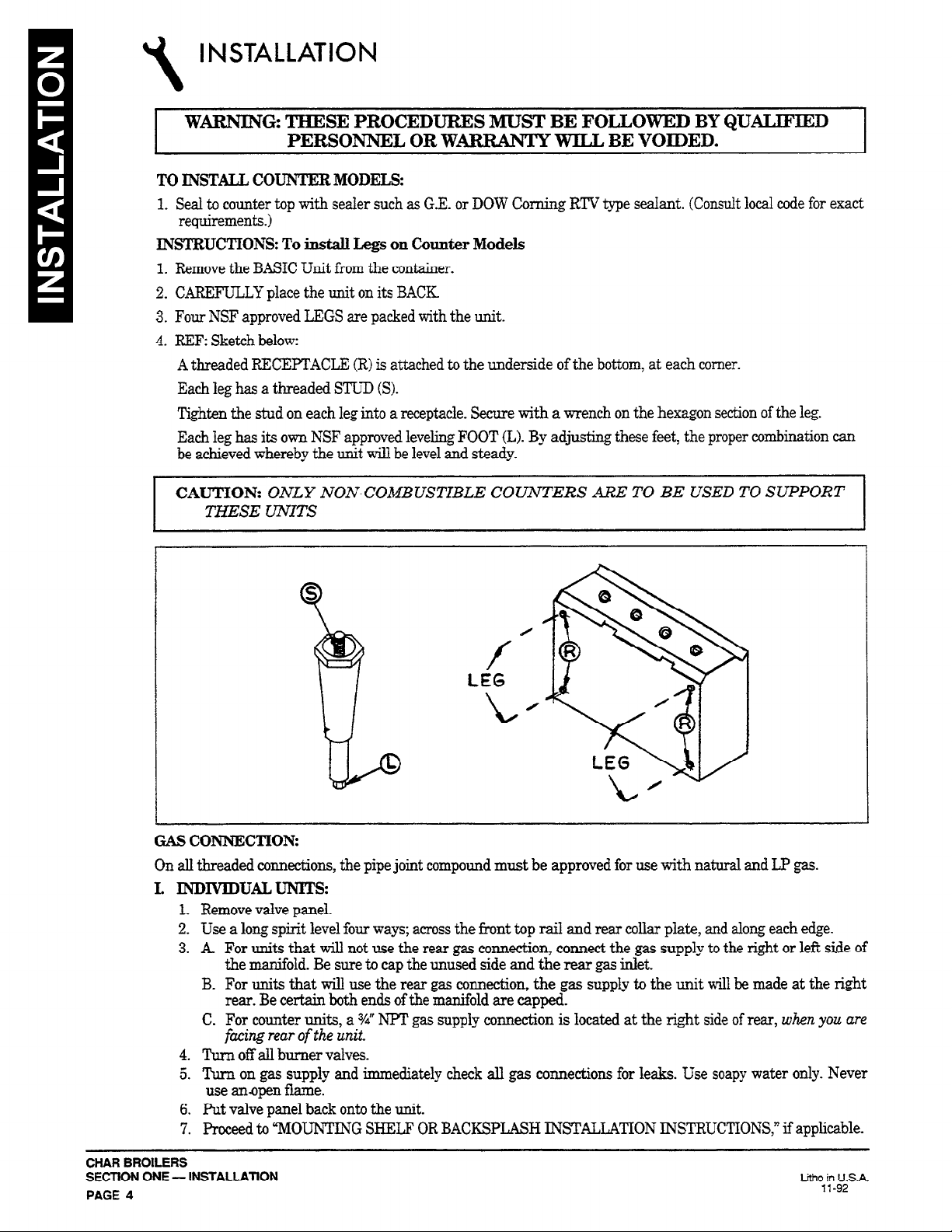

INSTRUCTIONS: To install Legs on Counter Models

1. Remove the BASIC Unit from the container.

2. CAREFULLY place the unit on its BACK

3. Four NSF approved LEGS are packed with the unit.

4. REF: Sketch below:

A threaded RECEPTACLE (R) is attached to the underside of the bottom, at each comer.

Each leg has a threaded STUD (S).

Tighten the stud on each leg into a receptacle. Secure with a wrench on the hexagon section of the leg.

Each leg has its own NSF approved leveling FOOT (L). By adjusting these feet, the proper combination can

be achieved whereby the unit will be level and steady.

CAUTION: ONLY NON-COMBUSTIBLE COUNTERS ARE TO BE USED TO SUPPORT

THESE UNITS

PERSONNEL OR W-

WILL BE VOIDED.

I

I

0

f

LEG

0

L

GAS coNNEcmoNz

On all threaded connections, the pipe joint compound must be approved for use with natural and LP gas.

I. rNDMDuALms:

1. Remove valve panel.

2. Use a long spirit level four ways; across the front top rail and rear collar plate, and along each edge.

3. A For units that will not use the rear gas connection, connect the gas supply to the right or left side of

the manifold. Be sure to cap the unused side and the rear gas inlet.

B. For units that will use the rear gas connection, the gas supply to the unit will be made at the right

rear. Be certain both ends of the manifold are capped.

C. For counter units, a 9’4” NPT gas supply connection is located at the right side of rear, when you are

the

facing rear of

4. Turn off all burner valves.

5. Turn on gas supply and immediately check all gas connections for leaks. Use soapy water only. Never

use amopen flame.

6. Put valve panel back onto the unit.

7. Proceed to “MOUNTING SHELF OR BACKSPLASH INSTALLATION INSTRUCTIONS,” if applicable.

unit.

CHAR BROILERS

SECTION ONE - INSTALLATION

PAGE 4

Litho in U.S.A.

11-92

INSTALLATION

WARNIN@ THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED

PERSONNEL OR WARRANTY WILL BE VOIDED.

ASSEMBLYOFBA~RY-FLOORMODELUNPI‘S:

1. Position the center range of the battery and

front top rail and the remar collar plate, and along each edge.

2.

Remove all valve panels. Mark, so they wil1 be returned to their respective unit.

3.

Bring up adjacent units, level by same method and by using the center uuit as reference. Match front rails

and rear collar plates. When battery is set on a masonry base and legs are not used, shims may be used.

Special attention should be given to Fry Top ranges to allow proper drainage on griddles.

4.

Where Spreader Plates are installed, refer to Sectional Battery Component Assembly Instructions supplied

with eachunit.

5.

Connect units together by mating the unions. Make unions just HAND TIGHT at this time.

Starting at the center and working toward the ends, tighten each union gradually, going from one to

6.

another, until all are finally tight. A special thin wrench, which fits the union nut, is provided with each

battery, or a chain wrench can be used.

Connect gas supply at right, left, or both ends. When a Spreader Plate with a “ree” connection is inserted

7.

in a battery, the gas supply may be connected at this point. Ranges with rear connections may also be used

in this respect. If five or more units are batteried, more than one supply line should be used. Each supply

line should have a readily accessible, approved hand shutoff valve.

8.

“Open” ends of the manifold must be capped.

9.

Turn off all burner valves.

Turn on gas supply and immediately check all the unions for leaks. USE SOAPY WATER ONLY FOR

10.

TESTING ON ALL GASES. NEVER USE AN OPEN FLAME TO CHECK FOR GAS LEAKS.

When entire gas system has been proved, turn off gas supply during additional installation.

11.

A filler to cover the ugap” between the range fronts and tops is provided. Refer to Sectional Battery

12.

Component Assembly Instructions supplied with each unit.

carefully

level unit. Use a long spirit level four wavs: across

- -

” I

t

A.SSEMBLYOFCOUNTERMODELs:

Each Char Broiler is a complete unit with an individual %’ NPT supply connection at the rear. A 3/d’ manual

1.

gas shutoff valve is recommended at the gas supply inlet for complete shutdown. Standard pipe fittings are

required.

2. The regulator shipped with the unit must be installed at the gas supply inlet. Be sure regulator is connected

so that the gas flow is in the same direction as the arrow on the bottom of the regulator.

3. The manifold pressure must be maintained at the pressure marked on the serial plate; 4” W.C. for natural

gas and 10” WC. for propane gas.

4. If applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in

accordance with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1Latest Edition. Canadian installation must comply with CAN/CGA-B149.1 Natural Gas Installation Code,

Code CAN/CGA-B149.2 Propane Installation Code.

WARNING: IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN THE

EQUIPMENT AT THE MAIN SHUTOFF V2l.L~ AJND CONTACT THE LOCAL

GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

SECTION ONE - INSTALLATION

CHAR BROILERS

PAGE 5

Loading...

Loading...