Page 1

MODEL SB1264/SB1268

COLLET ATTACHMENT

FOR LATHE MODELS: SB1012–15, SB1037–39, SB1049–52

© February, 2010 by South Bend Lathe Co. Revised July, 2011 (BL)

For Collet Attachments Mfg. Since 10/09

Page 2

We stand behind our machines. If you have any service questions, parts requests or general questions

about your purchase, feel free to contact us.

South Bend Lathe Co.

P.O. Box 2027

Bellingham, WA 98227

Fax: (360) 676-1075 (International)

Fax: (360) 734-1639 (USA Only)

Email: sales@southbendlathe.com

For your convenience, any updates to this manual will be available to download free of charge

through our website at:

www.southbendlathe.com

Scope of Manual

This manual helps the reader understand the machine, how to prepare it for operation, how to control

it during operation, and how to keep it in good working condition. We assume the reader has a basic

understanding of how to operate this type of machine, but that the reader is not familiar with the

controls and adjustments of this specific model. As with all machinery of this nature, learning the

nuances of operation is a process that happens through training and experience. If you are not an

experienced operator of this type of machinery, read through this entire manual, then learn more

from an experienced operator, schooling, or research before attempting operations. Following this

advice will help you avoid serious personal injury and get the best results from your work.

We've made every effort to be accurate when documenting this machine. However, errors sometimes

happen or the machine design changes after the documentation process—so the manual may not

exactly match your machine. If a difference between the manual and machine leaves you in doubt,

contact our customer service for clarification.

We highly value customer feedback on our manuals. If you have a moment, please share your

experience using this manual. What did you like about it? Is there anything you would change to

make it better? Did it meet your expectations for clarity, professionalism, and ease-of-use?

South Bend Lathe, Inc.

C

/O Technical Documentation Manager

P.O. Box 2027

Bellingham, WA 98227

Email: manuals@southbendlathe.com

Manual Feedback

Updates

Customer Service

Page 3

Table of Contents

INTRODUCTION ...............................................................2

About This Collet Attachment ............................2

Capabilities ......................................................... 2

Specifications.......................................................2

Features ..............................................................2

Identification ........................................................ 3

SAFETY ................................................................................4

Understanding Risks of Machinery .................... 4

Basic Machine Safety ..........................................4

Additional Collet Attachment Safety ..................6

PREPARATION .................................................................7

Things You'll Need ...............................................7

Unpacking ............................................................ 7

Inventory ..............................................................7

Cleaning & Protecting ......................................... 8

Installation ........................................................... 9

Test Run ............................................................. 12

OPERATION ....................................................................13

Operation Overview ...........................................13

Collet Attachment Removal ..............................13

Accessories .........................................................14

MAINTENANCE .............................................................15

Maintenance Schedule .......................................15

Parts Diagram ....................................................16

Parts List ............................................................16

Warranty ............................................................ 17

Page 4

Model SB1264/SB1268

INTRODUCTION

INTRODUCTION

About This Collet Attachment

For Machines Mfg. Since 10/09

Capabilities

If many workpieces of the same diameter are

to be turned or threaded on the lathe, and

productivity is dependent on the ease of loading

and unloading workpieces, this collet attachment

provides the capability of increased productivity.

This collet attachment accepts 5-C collets and is

easily installed and removed from the lathe.

The Model SB1264 Collet Attachment fits the

following South Bend Lathes: SB1039, SB1049,

SB1050, SB1051, SB1052.

Model SB1268 Collet Attachment fits the

following South Bend Lathes: Model SB1012,

SB1013, SB1014, SB1015, SB1037, SB1038.

Specifications

• ColletSize .......................................5-C Collets

• QuickRemovalDesign ...............................Yes

• AllMetalConstruction ..............................Yes

• ColletAdapter .............................. MT-6 to 5-C

• InstallationTime .......................... 45 Minutes

• ShippingWeight ............................... 26.5 lbs.

• NetWeight ...........................................25 lbs.

• Origin ................................................... Taiwan

Features

This collet attachment takes advantage of the

South Bend factory-made collet port in the lathe

gear cover. This accessory installs easily on

the listed South Bend Lathes without having

to modify the gear cover. The Model SB1264/

SB1268 is capable of delivering years of troublefree service. It is manufactured with the same

high-quality workmanship, materials, and

tolerances South Bend machinery is known for.

For ease of use, a collet attachment lever locks

the 5-C collet and workpiece in place. To ensure

accurate clamping pressure, a chuck sleeve with

a thumb operated lock lever allows the length

of the draw tube to be lengthened or shortened

in fine increments. For speedy installation and

removal of the entire collet attachment assembly,

this unit is designed with a quick-release clevis

and pin that has an overall slide-out design.

-2-

Page 5

For Machines Mfg. Since 10/09 Model SB1264/SB1268

INTRODUCTION

Identification

Quick-Release Pin

Thumb Lever

Lathe

Adjusting

Sleeve

Spindle

Spindle

Adapter

Inboard View

Lathe

Spindle

MT-6 Collet Adapter

5-C Collet

Serious personal injury could occur if you

connect the lathe to power before completing

the collet adapter setup process. DO NOT

connect power until instructed to do so later

in this manual.

Collet

Closer

Lever

Outboard

View

Untrained users have an increased risk of

seriously injuring themselves with this tooling.

Do not operate the lathe or collet adapter until

you have understood this entire manual and

received proper training.

-3-

Page 6

Model SB1264/SB1268

Operating all machinery and machining equipment can be dangerous or relatively safe depending

on how it is installed and maintained, and the operator's experience, common sense, risk awareness,

working conditions, and use of personal protective equipment (safety glasses, respirators, etc.).

The owner of this machinery or equipment is ultimately responsible for its safe use. This

responsibility includes proper installation in a safe environment, personnel training and usage

authorization, regular inspection and maintenance, manual availability and comprehension,

application of safety devices, integrity of cutting tools or accessories, and the usage of approved

personal protective equipment by all operators and bystanders.

The manufacturer of this machinery or equipment will not be held liable for injury or property

damage from negligence, improper training, machine modifications, or misuse. Failure to read,

understand, and follow the manual and safety labels may result in serious personal injury, including

amputation, broken bones, electrocution, or death.

The signals used in this manual to identify hazard levels are defined as follows:

Death or catastrophic

harm WILL occur.

Moderate injury or fire

MAY occur.

Death or catastrophic

harm COULD occur.

Machine or property

damage may occur.

Owner’s Manual: All machinery and machining

equipment presents serious injury hazards

to untrained users. To reduce the risk of

injury, anyone who uses THIS item MUST

read and understand this entire manual

before starting.

Personal Protective Equipment:

Operating or

servicing this item may expose the user

to flying debris, dust, smoke, dangerous

chemicals, or loud noises. These hazards

can result in eye injury, blindness, longterm respiratory damage, poisoning,

cancer, reproductive harm or hearing loss.

Reduce your risks from these hazards

by wearing approved eye protection,

respirator, gloves, or hearing protection.

Trained/Supervised Operators Only: Untrained

users can seriously injure themselves

or bystanders. Only allow trained and

properly supervised personnel to operate

this item. Make sure safe operation

instructions are clearly understood. If

electrically powered, use padlocks and

master switches, and remove start switch

keys to prevent unauthorized use or

accidental starting.

Guards/Covers:

Accidental contact with

moving parts during operation may cause

severe entanglement, impact, cutting,

or crushing injuries. Reduce this risk by

keeping any included guards/covers/doors

installed, fully functional, and positioned

for maximum protection.

SAFETY

SAFETY

For Machines Mfg. Since 10/09

Understanding Risks of Machinery

Basic Machine Safety

-4-

Page 7

For Machines Mfg. Since 10/09 Model SB1264/SB1268

Entanglement: Loose clothing, gloves, neckties,

jewelry or long hair may get caught in

moving parts, causing entanglement,

amputation, crushing, or strangulation.

Reduce this risk by removing/securing

these items so they cannot contact moving

parts.

Mental Alertness: Operating this item with

reduced mental alertness increases the

risk of accidental injury. Do not let a

temporary influence or distraction lead to a

permanent disability! Never operate when

under the influence of drugs/alcohol, when

tired, or otherwise distracted.

Safe Environment:

Operating electrically

powered equipment in a wet environment

may result in electrocution; operating near

highly flammable materials may result in a

fire or explosion. Only operate this item in

a dry location that is free from flammable

materials.

Electrical Connection: With electically powered

equipment, improper connections to the

power source may result in electrocution

or fire. Always adhere to all electrical

requirements and applicable codes when

connecting to the power source. Have all

work inspected by a qualified electrician to

minimize risk.

Disconnect Power: Adjusting or servicing

electrically powered equipment while it

is connected to the power source greatly

increases the risk of injury from accidental

startup. Always disconnect power

BEFORE any service or adjustments,

including changing blades or other tooling.

Secure Workpiece/Tooling:

Loose workpieces,

cutting tools, or rotating spindles can

become dangerous projectiles if not

secured or if they hit another object during

operation. Reduce the risk of this hazard

by verifying that all fastening devices are

properly secured and items attached to

spindles have enough clearance to safely

rotate.

Chuck Keys or Adjusting Tools:

Tools used to

adjust spindles, chucks, or any moving/

rotating parts will become dangerous

projectiles if left in place when the machine

is started. Reduce this risk by developing

the habit of always removing these tools

immediately after using them.

Work Area:

Clutter and dark shadows increase

the risks of accidental injury. Only operate

this item in a clean, non-glaring, and welllighted work area.

Properly Functioning Equipment:

Poorly

maintained, damaged, or malfunctioning

equipment has higher risks of causing

serious personal injury compared to

those that are properly maintained.

To reduce this risk, always maintain

this item to the highest standards and

promptly repair/service a damaged or

malfunctioning component. Always follow

the maintenance instructions included in

this documentation.

Unattended Operation:

Electrically powered

equipment that is left unattended while

running cannot be controlled and is

dangerous to bystanders. Always turn the

power OFF before walking away.

Health Hazards: Certain cutting fluids and

lubricants, or dust/smoke created when

cutting, may contain chemicals known to

the State of California to cause cancer,

respiratory problems, birth defects,

or other reproductive harm. Minimize

exposure to these chemicals by wearing

approved personal protective equipment

and operating in a well ventilated area.

Difficult Operations:

Attempting difficult

operations with which you are unfamiliar

increases the risk of injury. If you

experience difficulties performing the

intended operation, STOP! Seek an

alternative method to accomplish the

same task, ask a qualified expert how the

operation should be performed, or contact

our Technical Support for assistance.

SAFETY

-5-

Page 8

Model SB1264/SB1268

SAFETY

For Machines Mfg. Since 10/09

Additional Collet Attachment Safety

Tool Selection: Cutting with an incorrect or

dull tool increases the risk of accidental

injury because extra force is required, which

increases risk of breaking or dislodging

components. Always select the right cutter

for the job, and make sure it is sharp. A

correct, sharp tool decreases strain and

provides a better finish.

Securing the Workpiece: Before starting the

lathe, make sure the collet and workpiece

are properly secured with the draw tube,

and that the collet attachment lever is in the

locked position. A thrown workpiece may

cause severe injury or even death.

Long Stock Safety: Long stock can whip

violently if not properly supported, causing

serious impact injury and damage to the

lathe. Reduce this risk by supporting any

stock that extends from the chuck/headstock

more than three times its own diameter.

Always turn long stock at slow speeds.

Speed Rates: Operating the lathe at the wrong

speed can cause nearby parts to break or the

workpiece to come loose, which could result

in them becoming dangerous projectiles.

Large workpieces must be turned at slow

speeds. Always use the appropriate feed and

speed rates.

Stopping the Lathe by Hand: Stopping

the spindle by putting your hand on the

workpiece creates an extreme risk of

entanglement, impact, crushing, friction, or

cuttinghazards.Neverattempttoslowor

stop the lathe by using your hand. Allow the

spindle to come to a stop on its own or use

the brake (if equipped).

Projectile Hazard: A camlock or chuck key

left in the spindle or chuck can become a

dangerous projectile if the lathe is started.

And never walk away from the lathe leaving

any of these tools in the spindle or chuck.

Always remove all keys and tooling after use.

Crushing Hazard: Chucks can be heavy

and difficult to grasp, which can lead to

crushed fingers or hands if mishandled.

Get assistance when installing or removing

chucks to reduce this risk. Protect your

hands and the precision ground ways by

using a chuck cradle or piece of plywood over

the ways of the lathe when servicing chucks.

Avoiding Entanglement: Disconnect the lathe

from power before installing and removing

the collet attachment, collets, and work

pieces. Accidental lathe startup can cause

severe injury or death.

-6-

Page 9

For Machines Mfg. Since 10/09 Model SB1264/SB1268

This item was carefully packaged to prevent

damage during transport. If you discover any

damage, please immediately call Customer

Service at (360) 734-1540 for advice. You may

need to file a freight claim, so save the containers

and all packing materials for possible inspection

by the carrier or its agent.

PREPARATION

Things You'll Need

PREPARATION

Inventory

During the setup process, operation, and

maintenance of your machine, you'll need the

following items:

For Assembly:

• Mineral Spirits

• SafetyGlasses

• Shop Vacuum

• Assistant

• Oil Can with Way Oil

• CottonShopRags

• HexWrench5mm

• HexWrench8mm

• Open-EndWrench19mm

• Open-EndWrench24mm

• DrillBit5mmor#9(0.196")

• DrillBit

• CenterPunch

• ThreadingTapM6-1

• Tube of Thread Sealant

• ElectricHand-Drill

• Hacksaw

• Bench-MountedVise

1

⁄8"

1

⁄4"

If you can't find an item on this list, check the

mounting location on the collet attachment or

examine the packaging materials carefully.

Occasionally we pre-install certain components

for shipping purposes.

If any nonproprietary parts are missing (e.g. a

nut or a washer), we will gladly replace them; or

for the sake of expediency, replacements can be

obtained at your local hardware store.

Contents: (Figure 1) Qty

A. Draw Tube ...................................................... 1

B. Collet Attachment Assembly .........................1

C. Spindle Adapter .............................................1

D. Collet Adapter ................................................ 1

E. Lock Lever ...................................................... 1

F. Mounting Arm Assembly ............................... 1

G. Cap Screws M6-1 x 20 .................................... 3

H. Mounting Base .............................................. 1

A

Unpacking

B

C

H

Figure 1. Inventory

D

G

E

F

-7-

Page 10

Model SB1264/SB1268

The unpainted surfaces are coated at the factory

with a heavy-duty rust preventative that

prevents corrosion during shipment and storage.

The benefit of this rust preventative is that it

works very well. The downside is that it can be

time-consuming to thoroughly remove.

Be patient and do a careful job when cleaning

and removing the rust preventative. The time

you spend doing this will reward you with

smooth-sliding parts and a better appreciation

for the proper care of the unpainted surfaces.

Although there are many ways to successfully

remove the rust preventative, we have cleaned

thousands of machines and found the following

process to be the best balance between efficiency

and minimized exposure to toxic fumes or

chemicals.

Before cleaning, gather the following:

s $ISPOSABLErags

s #LEANERDEGREASER (certain citrus-based

degreasers work extremely well and they

have non-toxic fumes)

s 3AFETYGLASSESDISPOSABLEGLOVES

Note: Automotive degreasers, mineral spirits, or

7$sCANBEUSEDTOREMOVERUSTPREVENTATIVE

Before using these products, though, test them

on an inconspicuous area of a painted area to

make sure they will not damage it.

Basic steps for removing rust preventative:

1. Put on safety glasses and disposable gloves.

2. #OATALLSURFACESTHATHAVERUSTPREVENTATIVE

with a liberal amount of your cleaner or

degreaser and let them soak for a few

minutes.

3. Wipe off the surfaces. If your cleaner or

degreaser is effective, the rust preventative

will wipe off easily.

Note: To clean off thick coats of rust preventative

on flat surfaces, such as beds or tables, use

A0,!34)#PAINTSCRAPERTOSCRAPEOFFTHE

majority of the coating before wiping it off

WITHYOURRAG$ONOTUSEAMETALSCRAPEROR

it may scratch the surface.)

4. Repeat Steps 2–3 as necessary until clean,

then coat all unpainted surfaces with a

quality metal protectant or light oil to

prevent rust.

GAS

Gasoline and petroleum

products have low flash

points and can explode

or cause fire if used for

cleaning. Avoid using these

products to remove rust

preventative.

Many cleaning solvents are

toxic if inhaled. Minimize

your risk by only using

these products in a well

ventilated area.

Avoid chlorine-based solvents, such as

acetone or brake parts cleaner that may

damage painted surfaces. Always follow the

manufacturer’s instructions when using any

type of cleaning product.

PREPARATION

Cleaning & Protecting

For Machines Mfg. Since 10/09

-8-

Page 11

For Machines Mfg. Since 10/09 Model SB1264/SB1268

PREPARATION

5. To reduce the risk of metal shavings

Installation

To install the collet attachment:

contaminating the headstock gear case, have

your assistant vacuum the filings while you

drill and cut the threads into the headstock.

1. DISCONNECTLATHEFROMPOWER!

2. Remove the lathe chuck.

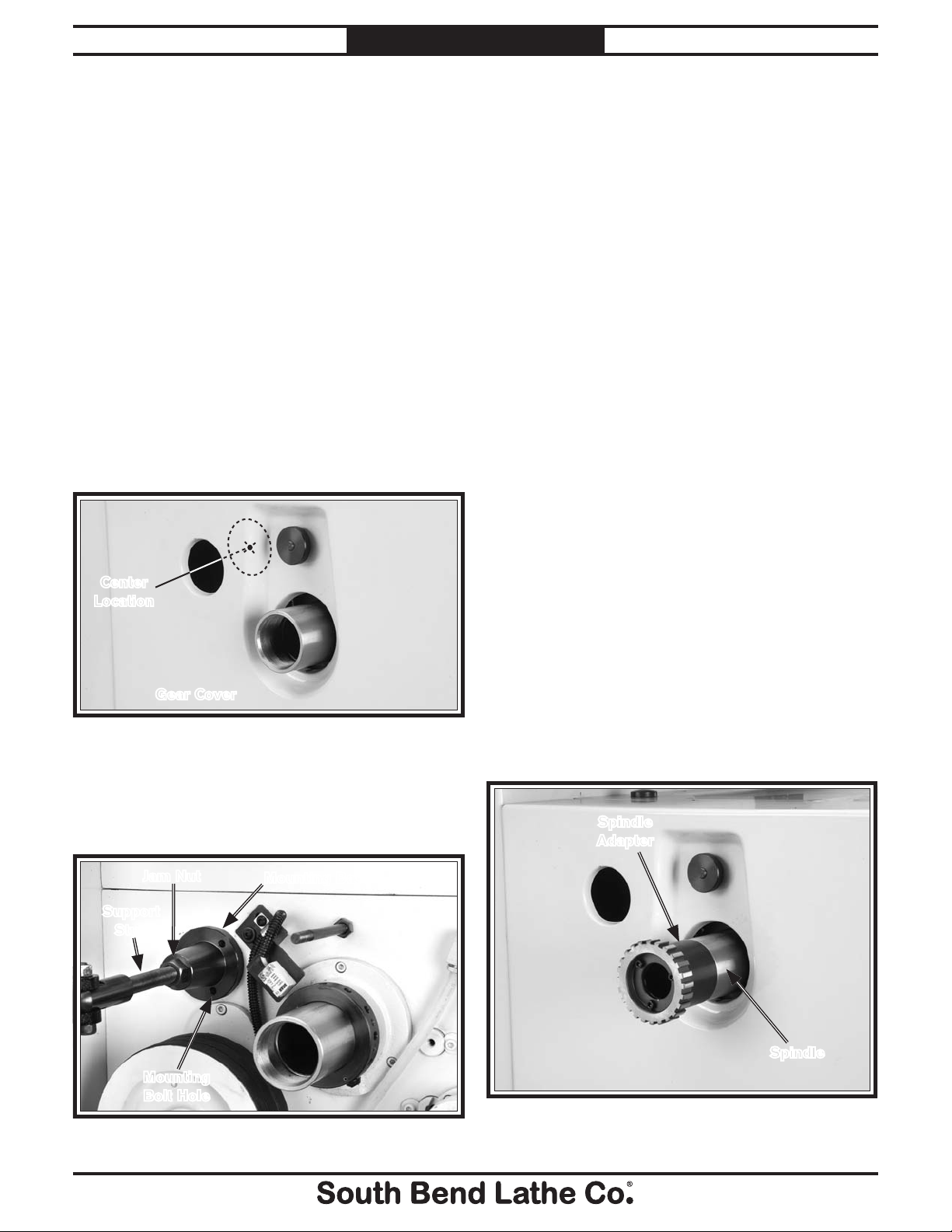

3. Looking through the hole in the gear cover,

mark the center location of the hole on the

headstock (Figure 2). The center location

is where the center of the collet attachment

base must be mounted.

Note: Depending on date of lathe manufacture,

the mounting location shown in Figure 3

may have been pre-drilled at the factory to

mount the collet attachment base. If this is

the case, remove the three fasteners that

plug the holes and proceed to Step 8.

Center

Location

6. Carefully, so as not to run the drill bit too

deep into the headstock gearbox, center-drill

1

the three mounting holes with an

1

approximately

⁄2"deep.

⁄8"drillbit

7. Usinga5mmor#9drillbitandanM6-1tap,

drill and cut threads in the headstock case

for the three mounting holes.

8. Apply a coat of thread sealant on the three

M6-1 x 20 cap screws. Next, use a 5mm hex

wrench to fasten the base to the headstock

with the three cap screws.

9. Threadthesupportstudapproximately1"

into the base. Then, using a 19mm wrench,

tighten the jam nut shown in Figure 3.

10. Reinstall the gear cover.

11. Using a lightly oiled rag, wipe the inboard

and outboard ends of the lathe spindle until

they are clean.

Gear Cover

Figure 2. Base mounting location behind cover.

4. Put on your safety glasses, then using a 1⁄4"

center punch and the base shown in Figure

3 as a template, mark the three mounting

bolt holes on the side of the headstock.

Jam Nut

Support

Stud

Mounting

Bolt Hole

Figure 3. Base positioning on the headstock.

Mounting Base

12. Wipe the spindle adapter clean with the

same rag. Next, thread the adapter onto the

spindle in a counterclockwise direction until

the adapter seats flush with the spindle as

shown in Figure 4.

Spindle

Adapter

Spindle

Figure 4. Spindle adapter installation.

-9-

Page 12

Model SB1264/SB1268

PREPARATION

For Machines Mfg. Since 10/09

13. Thread the draw tube into the collet

attachment assembly, as shown in Figure 5.

Figure 5. Draw tube installation.

14. Carefully insert the collet attachment draw

tube into the lathe spindle, as shown in

Figure 6.

When fully installed, the lock ring will

be hidden and the thumb lever will have

dropped down into a lock ring slot.

16. Position the collet attachment lock lever so

it is parallel with the gear cover, and mark

how much of the support stud must be cut

off (Figure 8 ) in order for the lever to be

parallel with the cover surface. Next, cut off

the excess support stud length.

Note: The amount to be cut-off is dependent on

your desired lever position.

Cut-Off Excess

Support Stud

Length

Hex Nut

Figure 6. Collet attachment installation.

15. When the chuck sleeve contacts the lock ring,

press down on the thumb lever, as shown in

Figure 7, and engage the lock ring with the

chuck sleeve.

Thumb Lever

Lock Ring

Clevis

Retain 1" to

Thread Into

the Clevis

Figure 8. Support stud sizing.

17. Remove the clevis and thread it onto the

supportstudapproximately1".Adjustitso

when the clevis is reinstalled onto the collet

attachment, the lock lever is parallel with

the gear cover, as shown in Figure 9.

-10-

Chuck

Sleeve

Figure 7. Chuck sleeve installation.

Figure 9. Clevis positioning so lock lever is parallel

with gear cover.

Page 13

For Machines Mfg. Since 10/09 Model SB1264/SB1268

PREPARATION

18. Tighten the hex nut on the support stud

against the clevis (Figure 8).

19. Wipe the collet adapter clean and insert it

into the lathe spindle.

20. Align the slot in the collet with the pin in

the collet adapter, and install the collet, as

shown in Figure 10.

Pin

Figure 10. Collet alignment.

Slot

21. While holding the collet against the collet

adapter with your right hand, use your left

hand to push down on the chuck-sleeve

thumb lever (Figure 7) and rotate the chuck

sleeve until the draw tube threads onto the

collet.

22. With the chuck sleeve unlocked, rotate it

3

counterclockwise

⁄4 –1 turn. Then, pull the

collet attachment lever outward.

— If the lever locks loosely or the workpiece

slips in the collet, release the lever and

tighten the chuck sleeve until the lever

snaps to the locked position easily, and

the workpiece is held tightly.

— If the lever does not move far enough to

lock, loosen the chuck sleeve until the

lever snaps to the locked position easily

and the workpiece is held tightly. Do not

force it into the locked position if over

tightened.

Note: When the lever is locked, the pawls will be

positioned on the highest point of the chuck

cam, and there will be a gap of approximately 16mm exposing the pawls, as shown

in Figure 12.

Note: You may have to wiggle the collet attach-

ment assembly, so the leading thread of the

draw tube and collet catch one another.

The collet is seated properly when the chuck

sleeve is snug, the collet is seated, and the

workpiece or dowel slides into the collet with

a slight drag, as shown in Figure 11.

Pawl

Locked

on High

Point of

Chuck Cam

Chuck

Cam

Figure 12. Pawls in the locked position.

Thumb

Lever in

the

Locked

Position

23. Push the thumb lever back into its locked

position (Figures 13–14),soitishorizontal

with the chuck sleeve surface. You may have

to rotate the chuck sleeve slightly to get the

lever to drop back down into a lock ring slot.

Figure 11. Installing a workpiece.

-11-

Page 14

Model SB1264/SB1268

PREPARATION

For Machines Mfg. Since 10/09

Locked

Figure 13. Chuck sleeve thumb lever locked.

Unlocked

Figure 14. Chuck sleeve thumb lever unlocked.

Test Run

Once the assembly is complete, test run your

lathe with the collet attachment installed to

make sure the unit is ready for regular operation.

The test run consists of verifying the collet

attachment is concentric with the lathe spindle

and is free of vibration.

If, during the test run, you detect an unusual

noise or vibration, stop using lathe immediately,

and correct the problem.

If you still cannot remedy a problem, contact our

Tech Support at (360) 734-1540.

To test run lathe with collet attachment

installed:

1. Make sure you have read the safety

instructions at the beginning of the manual

and that the collet attachment is setup

properly.

24. At this point, the chuck sleeve and the collet

attachment lever should be locked and

positioned outward from the gear cover as

shown in Figure 15. The workpiece or dowel

must be held firmly without slippage when

pulled by hand.

Locked

Lever

Snaps

Into

Locked

Position

Figure 15. Collet attachment completely locked and

ready for use.

2. Lock a small dowel or workpiece in the collet,

and verify that the lathe spindle rotates

freely by hand.

3. Make sure all tools and objects used during

setup are cleared away from the collet

attachment.

4. Set the lathe to a low spindle speed, and

disengage any feed levers.

5. Put on safety glasses, connect the lathe to

power, and turn the lathe ON.

6. Run the lathe through its full range of

speeds.

— When operating correctly, the collet

attachment operates smoothly without

vibration or rubbing noises.

— Investigate and correct unusual noises

or vibrations before operating the collet

attachment further. Always disconnect

the collet attachment from power when

investigating or correcting potential

problems.

7. Turn the lathe OFF.

-12-

Page 15

For Machines Mfg. Since 10/09 Model SB1264/SB1268

OPERATION

OPERATION

Operation Overview

The purpose of the operation section is to

familiarizeyouwiththebasiccontrols,

terminology, capabilities, and adjustments that

are necessary to use this collet attachment.

To reduce the risk of

serious injury when using

this collet attachment, read

and understand this entire

manual before beginning

any operations.

Loose hair, clothing, or

jewelry could get caught

in machinery and cause

serious personal injury.

Keep these items away

from moving parts at all

times to reduce this risk.

the collet, and verifies the workpiece is

clamped securely.

— If clamping is too loose or too tight, the

operator releases the lock lever and

rotates the chuck sleeve to attain lever

locking and workpiece clamping.

6. Installs the required inboard and outboard

workpiece support with stands, the steady

rest, or the follow rest.

7. Installs the required tooling, puts on safety

glasses, and begins lathe operations.

Collet Attachment

Removal

To complete remove the collet attachment

from the lathe:

1. DISCONNECTLATHEFROMPOWER!

2. Place a wooden board on the lathe ways to

protect the ways.

During operation, small

metal chips may become

airborne, leading to serious

eye injury. Wear safety

glasses to reduce this risk.

To complete a typical operation, the operator

does the following:

1. Selectsthecorrect-sizedcolletforthe

diameter of the workpiece.

2. Verifies that no burrs exist on the workpiece.

3. Aligns the slot in the collet with the pin in

the collet adapter, and inserts the collet and

workpiece into the adapter.

4. Threads the draw tube onto the collet by

turning the chuck sleeve until the collet is

seated and the clutch sleeve is snug.

5. Applies the collet attachment lever to close

3. Support the collet with your right hand.

With your left hand, unlock the collet

attachment lever and turn the chuck sleeve

to un-thread the draw tube from the collet.

4. When the collet is free, remove the knurled

pin, and slide the collet attachment assembly

out of the spindle.

5. With your right hand, hold the spindle

collet adapter to keep it from falling out of

the lathe spindle, and with your left hand,

insert a wooden dowel into the spindle from

the outboard side and tap the spindle collet

adapter free from the lathe spindle.

-13 -

Page 16

Model SB1264/SB1268

1.73" 2.83" 4.29"

8.86"

2.99"

1.378"

60°

ACCESSORIES

For Machines Mfg. Since 10/09

Accessories

This section includes the most common

accessories available for your lathe, which may

be available through your local South Bend

Lathe Co. dealer. If you do not have a dealer in

your area, please call us at (360) 734-1540 or

email us at cs@southbendlathe.com.

SB1271—Taper Attachment for SB1016 &

SB1036 Lathes.

SB1271

SB1239—MT#5 High Performance Live Center

®

South Bend

brand live centers are the best centers in the industry made with pride and uncompromising quality.

• Shaftsaremadeofalloysteelandvacuum

heattreatedtoHRC60±1forhighrigidity

and durability.

• Centersuseacombinationofrollerbearings,

thrust ball bearings and ball bearings.

• ApplicableforCNClathesandhighspeed

turning.

• Waterproofdesign.

• 60°centers.

Figure 16. Taper attachment.

SB1279—10 Pc. Precision 5–C Collet Set

1

Setof10colletssizedfrom

⁄8"-3⁄4".Samequality

as the individual collets, only packaged in one

convenient set.

Figure 17. Model SB1279 10 Pc. 5-C Collet Set.

Figure 18. Model SB1239 High Performance Live

Center.

-14-

Page 17

For Machines Mfg. Since 10/09 Model SB1264/SB1268

!

MAINTENANCE

MAINTENANCE

Maintenance Schedule

Always disconnect

machine from power before

performing maintenance or

serious personal injury may

result.

For optimum performance from your collet attachment, follow this maintenance schedule and refer

to any specific instructions given in this section.

Cleaning your collet attachment is relatively easy.

Vacuum excess metal chips away, and wipe off the

remaining metal parts with a rag that is moistened with the machine oil you use to lubricate

your lathe.

Daily Check:

• Cleanandinspectalltaperedmating

surfaces.

• Inspectforloosemountingcapscrews.

• Inspect collet adapter for missing pin.

• Inspect for missing or cracked pins or loose

set screws.

• Inspect for any other unsafe condition.

Monthly Check:

• Cleanandde-burrdrawtubethreads.

• Applyoiltoallmetalsurfacestopreventrust

and maintain smooth operation.

Storage:

• To prevent rust and corrosion, apply way

oil to all metal surfaces, and store the collet

attachment in a wooden box or cabinet that is

dry and free of paints and chemicals.

-15 -

Page 18

Model SB1264/SB1268

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 PSB1268001 KNURLED PIN 21 PSB1268021 LOCK RING

2 PSB1268002 CLEVIS 22 PCAP33M CAP SCREW M5-.8 X 12

3 PSB1268003 THREADED STUD 1/2-20 x 6 23 PCAP02M CAP SCREW M6-1 X 20

4 PSB1268004 MOUNTING BASE 24 PSB1264024 SPINDLE ADAPTER 41.5-16 V1.06.09 (SB1039)

5 PCAP143M CAP SCREW M10-1.5 X 50 24V2 PSB1264024V2 SPINDLE ADAPTER 43.5-16 V2.07.11 (SB1039)

6 PSB1268006 LOCK YOKE 24 PSB1268024 SPINDLE ADAPTER M55-2 LH (SB1012)

7 PSB1268007 LEVER 25 PRP44M ROLL PIN 3 X 10

8 PSB1268008 PLASTIC KNOB 1/2-20 26 PSB1264026 COLLET ADAPTER MT5/5C (SB1039)

9 PSB1268009 YOKE RING 26 PSB1268026 COLLET ADAPTER MT6/5C (SB1012)

10 PSB1268010 CHUCK RING 27 PSB1264027 DRAW TUBE 21.06 (SB1039)

11 PSB1268011 CHUCK HOUSING 27 PSB1268027 DRAW TUBE 24.5" (SB1012)

12 PSB1268012 BALL BEARING 6208ZZ KOYO 28 PCAP18M CAP SCREW M4-.7 X 8

13 PN03M HEX NUT M8-1.25 29 PSB1268029 PIVOT PIN

14 PSS74M SET SCREW M8-1.25 X 35 30 PSB1268030 LOCK BALL

15 PR37M EXT RETAINING RING 32MM 31 PSB1268031 COMPRESSION SPRING

16 PSB1268016 SPANNER NUT 32 PLN05M LOCK NUT M10-1.5

17 PSB1268017 COLLAR 33 PSB1268033 CLEVIS STUD M16-2

18 PSB1268018 THUMB LEVER 34 PN01 HEX NUT 1/2-20

19 PSB1268019 LOCK PAWL 35 PN13M HEX NUT M16-2

20 PSB1268020 ADJUSTMENT SLEEVE

20

16

6

17

15

9

13

14

12

1

10

2

34

3

8

7

4

34

32

33

35

5

2

11

19

18

29

31

30

28

23

27

21

26

25

22

34

24V2

(FOR MODELS MFG. SINCE 07.11)

24

(FOR MODELS MFG. FROM 06.09-06.11)

Parts Diagram

PARTS

For Machines Mfg. Since 10/09

Parts List

-16 -

Page 19

For Machines Mfg. Since 10/09 Model SB1264/SB1268

This quality product is warranted by South Bend Lathe Company to the original buyer for one year

from the date of purchase. This warranty does not apply to consumable parts, or defects due to any

kind of misuse, abuse, negligence, accidents, repairs, alterations or lack of maintenance. We do not

reimburse for third party repairs. In no event shall we be liable for death, injuries to persons or

property, or for incidental, contingent, special or consequential damages arising from the use of our

products.

We do not warrant or represent that this machine complies with the provisions of any law, act, code,

regulation, or standard of any domestic or foreign government, industry, or authority. In no event

shall South Bend’s liability under this warranty exceed the original purchase price paid for this

machine. Any legal actions brought against South Bend Lathe Company shall be tried in the State of

Washington, County of Whatcom.

This is the sole written warranty for this machine. Any and all warranties that may be implied by

law, including any merchantability or fitness, for any purpose, are hereby limited to the duration of

this warranty. To take advantage of this warranty, contact us by mail or phone to give us the details

of the problem you are having.

Thank you for your business and continued support.

WARRANTY

Warranty

-17-

Page 20

Printed In Taiwan #CR12466

Loading...

Loading...