Page 1

MODEL SB1263

TAPER ATTACHMENT

Instruction Sheet

PHONE: (360) 734-1540 • www.southbendlathe.com

This taper attachment is heavy! Get

assistance when installing it on the lathe.

Wear heavy-duty leather boots with toe

protection, and keep hands and fingers away

from all pinch points. Ignoring this warning

can lead to severe crushing injuries!

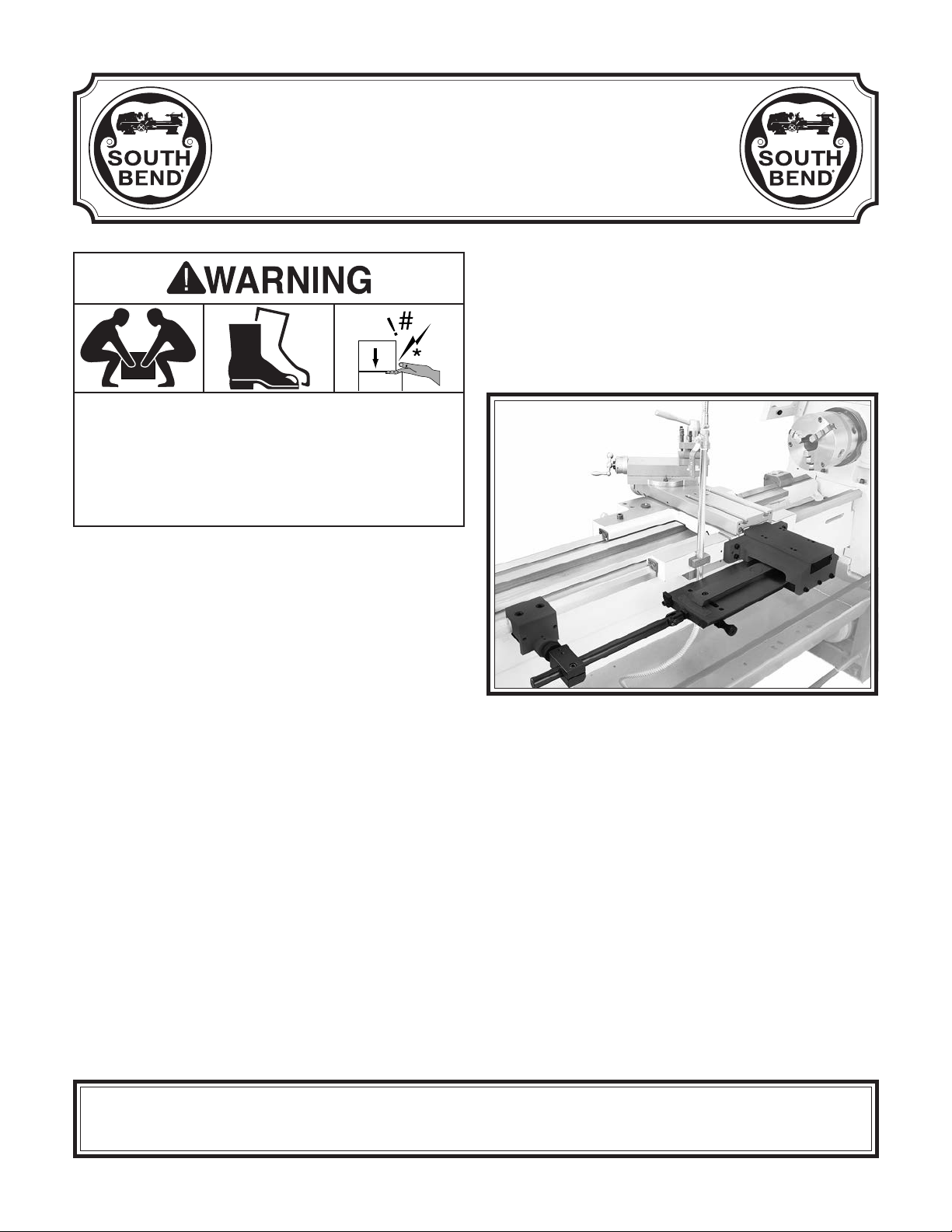

Introduction

This taper attachment mounts quickly to the

back bedway of your lathe, as shown in Figure 1.

Accurate tapers can be cut without repositioning

the attachment or having to offset the tailstock.

Specifications

Designed for Lathe Models ... SB1039, SB1049–52

Taper Per Inch Range ........................ ±0.00°–0.18”

Maximum Taper Length ......................................9"

Minor Inch Scale Divisions .............................0.01”

Major Inch Scale Divisions .............................0.02”

Taper Angle Range ....................................±0°–10°

Minor Angle Scale Divisions...............................

Major Angle Scale Divisions ................................1°

Construction .................................. Cast Iron, Steel

Net Weight ................................................... 49 lbs.

Shipping Weight ........................................... 60 lbs.

Factory ........................................................ Taiwan

1

⁄2°

Figure 1. Taper attachment installed on rear of lathe.

Note: Splash guard removed for clarity.

The Model SB1263 features an inches scale and

a degree scale. An angle adjusting knob with fine

threads achieves precise control when setting

tapers.

Another feature is the ability to use the taper

attachment without disengaging the cross slide

nut. This design allows the taper attachment to

be functional at any time by simply tightening

the two deadman clamp cap screws, which lock

the deadman clamp to the rear lathe way.

Copyright © January, 2012 by South Bend Lathe Co. Revised January, 2014 (ST)

WARNING: No portion of this manual may be reproduced without written approval.

For Product Manufactured Since 9/11 #TS14639 Printed in Taiwan

Page 2

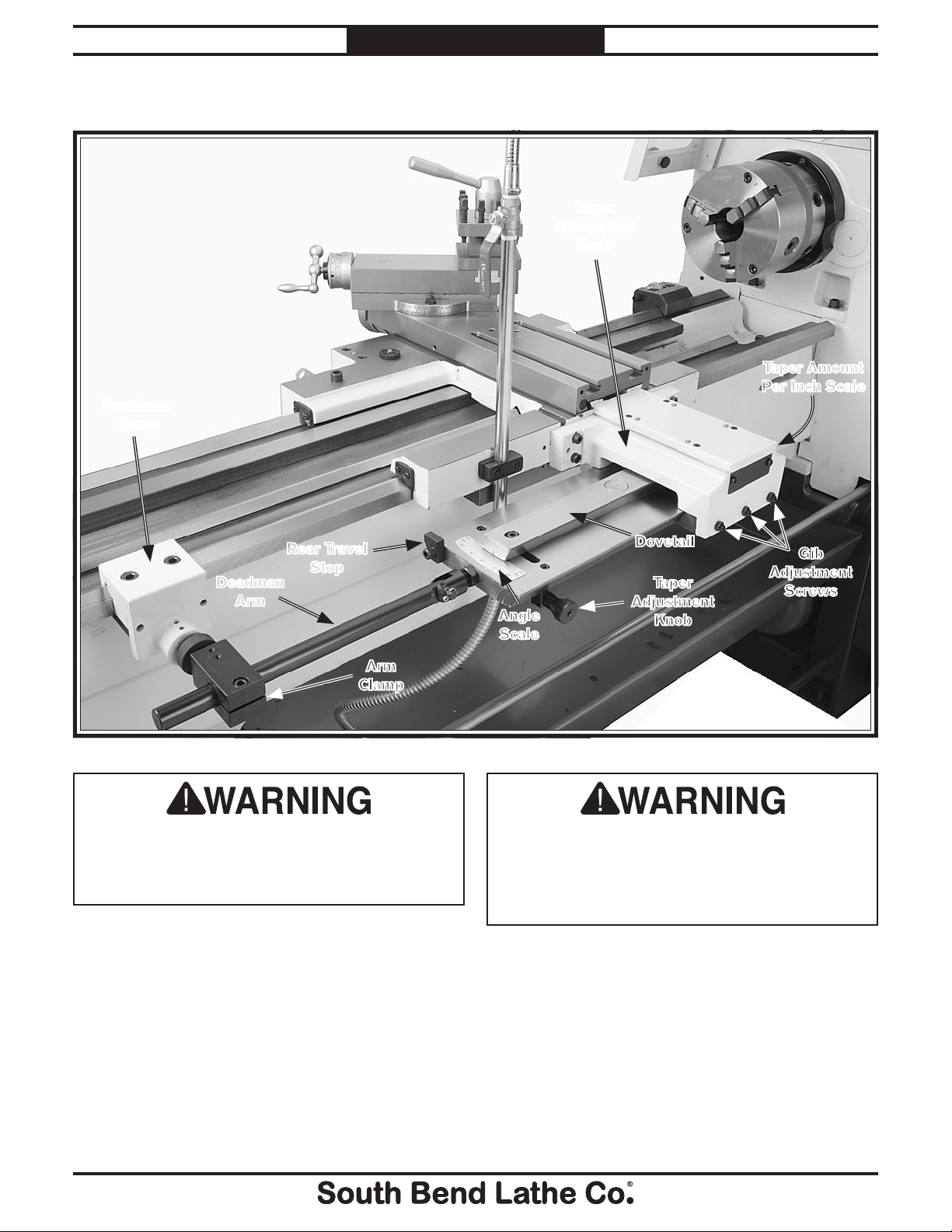

Model SB1263

Identification

Deadman

Clamp

INSTRUCTIONS

Taper

Attachment

Body

Mfg. Since 9/11

Taper Amount

Per Inch Scale

Rear Travel

Stop

Deadman

Arm

Arm

Clamp

Figure 2. Model SB1263 identification.

Serious personal injury could occur if you

connect the lathe to power before completing

the setup process. DO NOT connect power

until instructed to do so later in this manual.

Angle

Scale

Dovetail

Taper

Adjustment

Knob

Gib

Adjustment

Screws

Untrained users have an increased risk

of seriously injuring themselves with this

machine. Do not operate this taper attachment

until you have understood this entire manual

and received proper training.

-2-

Page 3

This item was carefully packaged to prevent

damage during transport. If you discover any

damage, please immediately call Customer

Service at

need to file a freight claim, so save the containers

and all packing materials for possible inspection

by the carrier or its agent.

Mfg. Since 9/11 Model SB1263

INSTRUCTIONS

Unpacking

(360) 734-1540 for advice. You may

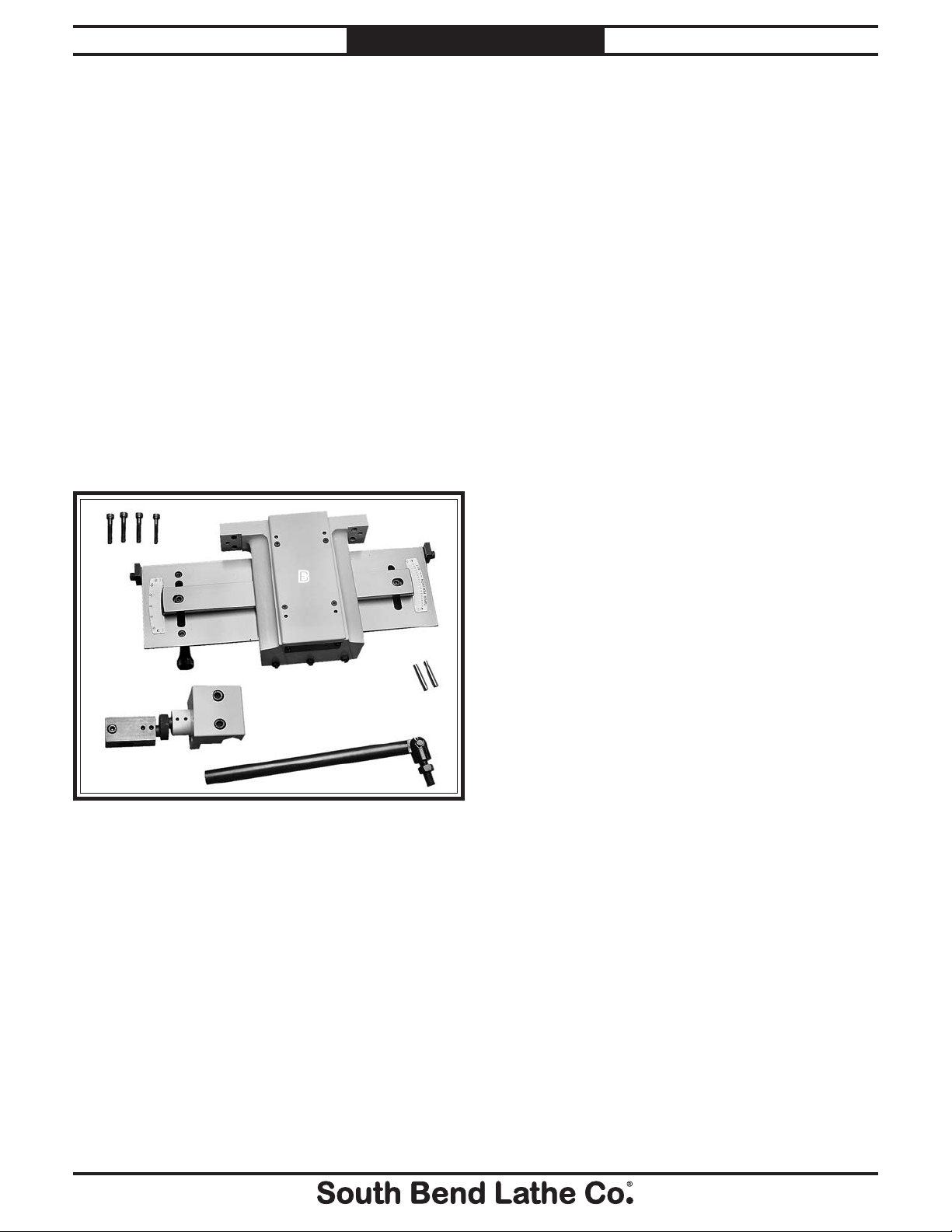

Inventory

Inventory (Figure 3) Qty

A. Cap Screws M8-1.25 x 45mm ........................4

B. Taper Attachment Assembly ......................... 1

C. Taper Pins 8.7 x 7.7 x 47mm ......................... 2

D. Deadman Clamp Assembly ...........................1

E. Deadman Arm Assembly ............................... 1

A

B

Required for Setup

The items listed below are required to

successfully set up and prepare this taper

attachment for operation. The installation

is intended to be permanent and will take

approximately one hour.

For Assembly

• Another person

• Cotton shop rags

• Mineral spirits

• Safety glasses

• Oil can with any general machine oil

• White lithium grease

• Wrench 17mm

• Hex wrenches 3, 4, 5, 6, and 8mm

• Phillips screwdriver #2

• Precision ruler

• Drill bit

• Tapered drill bit 8mm

• Spiral pin reamer #6

— Small end diameter: 0.2773"

— Large end diameter: 0.3540"

• Small metal hammer

• Dial indicator w/magnetic base

19

⁄64"

D

Figure 3. Model SB1263 inventory.

C

E

-3-

Page 4

Model SB1263

INSTRUCTIONS

Mfg. Since 9/11

Cleanup

The unpainted surfaces of your taper attachment

are coated with a heavy-duty rust preventative

that prevents corrosion during shipment and

storage. This rust preventative works extremely

well, but it will take a little time to remove.

Be patient and do a thorough job cleaning your

taper attachment. The time you spend doing this

now will give you a better appreciation for the

proper care of the unpainted surfaces.

There are many ways to remove this rust

preventative, but the following steps work well

in a wide variety of situations. Always follow the

manufacturer’s instructions with any cleaning

product you use and make sure you work in a

well-ventilated area to minimize exposure to

toxic fumes.

Note: The inner surfaces of the taper attachment

body were lubricated at the factory and do not

need to be cleaned at this time.

Before cleaning, gather the following:

• Disposable rags

• Cleaner/degreaser (WD•40 works well)

• Safety glasses & disposable gloves

• Plastic paint scraper (optional)

Basic steps for removing rust preventative:

1. Put on safety glasses and gloves.

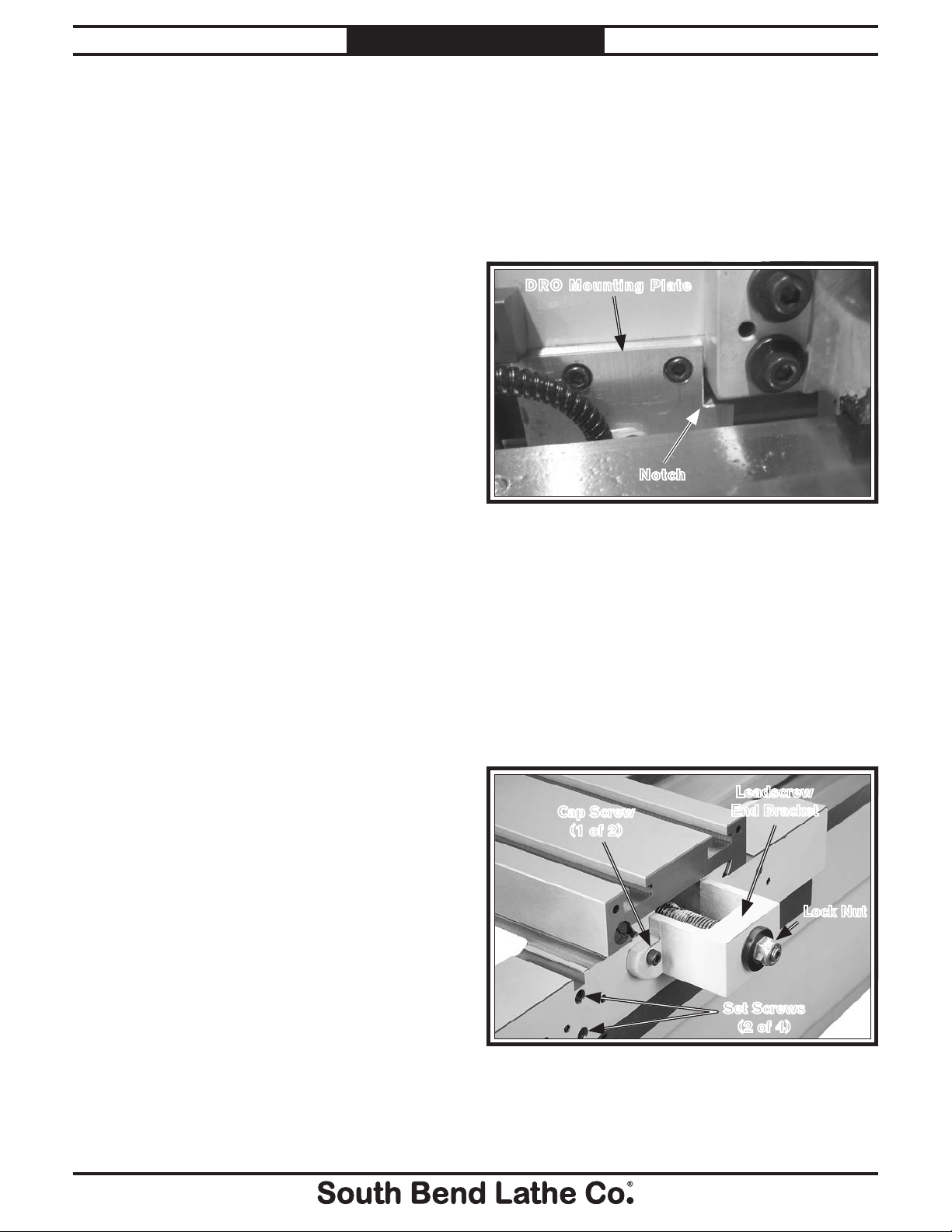

Installation

This procedure explains installation of the taper

attachment on a lathe without a DRO installed.

If the lathe has a Fagor DRO, the aluminum

mounting plate (or the taper attachment

housing) will need to have a small notch cut into

it (see Figure 4) to ensure proper fit.

DRO Mounting Plate

Notch

Figure 4. Notch in DRO mounting plate, allowing taper

attachment housing to fit.

To install the taper attachment:

1. DISCONNECT LATHE FROM POWER!

2. With the help of another person, remove the

splash guard on the rear of the lathe.

3. Move the cross slide all the way toward the

front of the lathe to fully expose the leadscrew end bracket (see Figure 5).

2. Coat the rust preventative with a liberal

amount of cleaner/degreaser, then let it soak

for 5–10 minutes.

3. Wipe off the surfaces. If your cleaner/

degreaser is effective, the rust preventative

will wipe off easily. If you have a plastic

scraper, scrape off as much as you can first,

then wipe off the rest with a rag.

4. Repeat Steps 2–3 as necessary until clean,

then coat all unpainted surfaces with a

quality way oil to prevent rust.

-4-

Leadscrew

Cap Screw

(1 of 2)

Figure 5. Leadscrew end bracket and fasteners.

4. Remove the two cap screws from the end

bracket (see Figure 5).

End Bracket

Lock Nut

Set Screws

(2 of 4)

Page 5

!

Mfg. Since 9/11 Model SB1263

INSTRUCTIONS

5. Remove the four set screws (see Figure 5)

from the saddle. These holes will be used to

mount the taper attachment to the saddle in

a later step.

6. Remove the lock nut (see Figure 5) from the

end of the leadscrew.

7. Keep the bearing parts together in the same

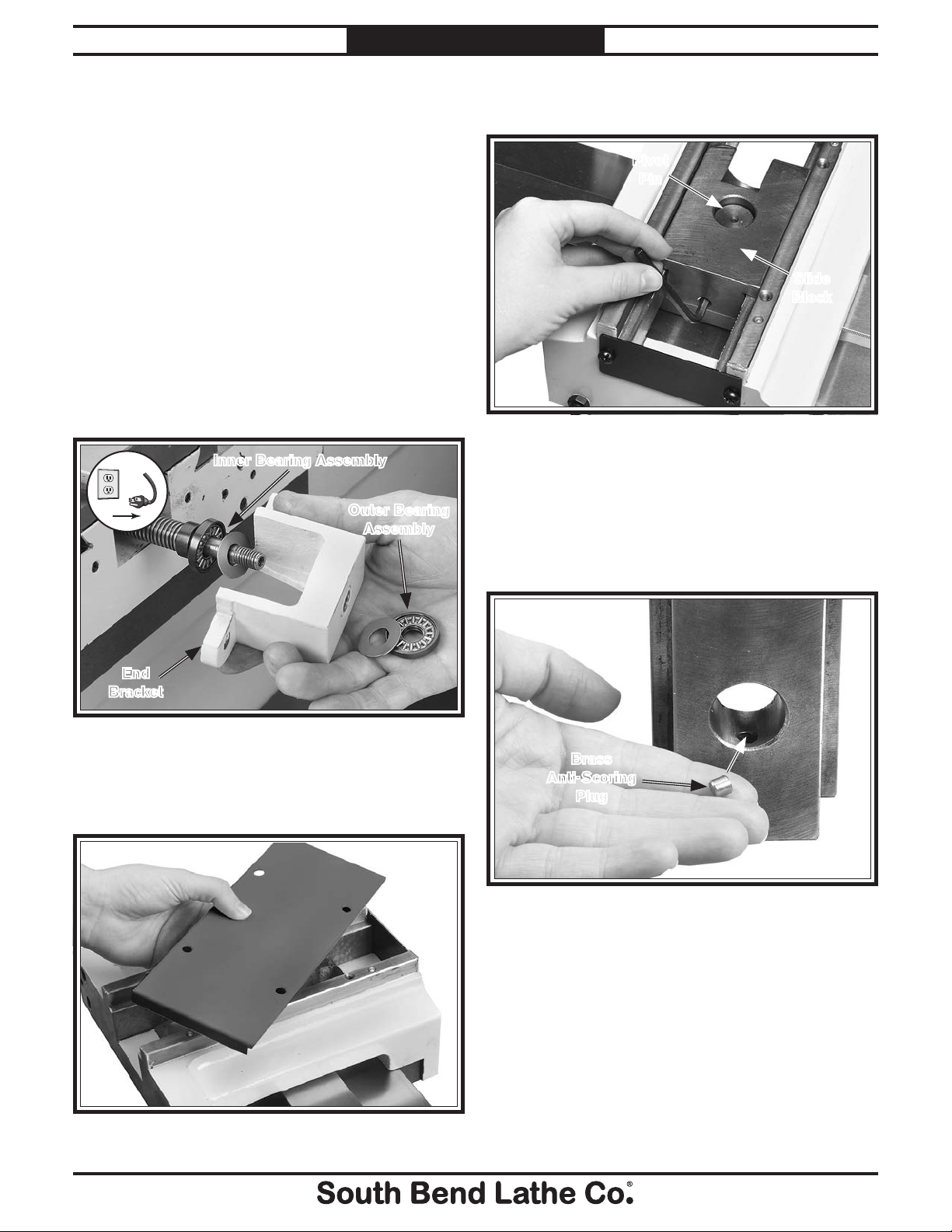

orientation as they were installed as you

remove them and the end bracket from the

leadscrew (see Figure 6).

Important: If a race is stuck to the surface of the

end bracket, use penetrating oil or mineral

spirits to separate the parts. Do not pry a

race loose, as this can damage it.

Inner Bearing Assembly

Outer Bearing

Assembly

9. Loosen the set screw that secures the slide

block to the pivot pin, as shown in Figure 8.

Pivot

Pin

Slide

Block

Figure 8. Slide block removal.

10. Lift the slide block off the pivot pin. Make

sure not to dislodge the brass anti-scoring

plug shown in Figure 9.

Note: If the anti-scoring plug falls out of the slide

block, use a dab of grease to hold it in place.

End

Bracket

Figure 6. Leadscrew end bracket removed.

8. Remove the four flat head screws that secure

the top cover, then remove the cover (see

Figure 7).

Brass

Anti-Scoring

Plug

Figure 9. Slide block brass anti-scoring plug.

Figure 7. Attachment body top cover removed.

-5-

Page 6

!

!

Model SB1263

INSTRUCTIONS

Mfg. Since 9/11

11. Unthread the two cap screws that secure the

end bracket (see Figure 10) and remove it

from the slide block.

End

Bracket

Slide Block

Figure 10. End bracket removed from slide block.

12. Carefully clean the bearing parts that you

removed in Step 7 with mineral spirits.

When they are dry, repack them with white

lithium grease and re-assemble them.

13. Install the inner bearing assembly, the end

bracket, and the outer bearing assembly

onto the leadscrew in the order shown in

Figure 11, then secure them with the

leadscrew lock nut removed in Step 6.

Note: Tighten the lock nut until the bearings are

slightly pre-loaded and the end bracket has

zero end play—do not over-tighten it.

14. Secure the slide block onto the end bracket

with the two cap screws removed in Step 11,

as shown in Figure 12.

Pivot

Bore

Slide Block

Way (1 of 2)

Figure 12. Slide block installation.

15. Apply a thin coat of white lithium grease to

the inside of the pivot bore and both slide

block ways (see Figure 12).

Note: Make sure the brass plug remains inside

the slide block.

16. With the help of another person, raise the

taper attachment body underneath the

slide block so the pivot pin slides into the

pivot bore (see Figure 13), then secure the

assembly to the saddle with the four M8-1.25

x 45 cap screws.

Cap Screw

(1 of 4)

Pivot Pin

& Bore

Figure 11. End bracket and outer bearing assembly

installation.

-6-

Taper Attachment

Body

Figure 13. Taper attachment body installed.

Page 7

!

Mfg. Since 9/11 Model SB1263

INSTRUCTIONS

1 7. Snug the slide block set screw until the brass

plug is slightly pre-loaded against the pivot

pin (see Figure 14).

Figure 14. Slide block set screw adjustment.

18. Replace the attachment body top cover.

19. Loosen the two cap screws on top of the

deadman clamp (see Figure 15), then slide

the clamp onto the rear bedway from the

tailstock end.

20. Thread the arm clevis into the taper

attachment, then position the deadman

clamp so the end of the arm slides into the

arm clamp, as shown in Figure 16.

Note: Do not tighten the arm clamp cap screw or

the arm clevis hex nut at this time.

Deadman Clamp

Cap Screws

Arm

Clevis

Arm Clamp

Figure 16. Deadman clamp and arm.

21. Position the deadman clamp towards the end

of the arm, then tighten the deadman clamp

cap screws to secure the assembly to the

bedway.

Cap Screws

Arm

Clamp

22. Loosen the dovetail cap screws at each end of

the taper attachment body (see Figure 17).

Dovetail Cap

Screw (1 of 2)

Clamping

Plate

Figure 15. Deadman clamp.

Rear

Angle Scale

Adjustment Knob

Figure 17. Taper adjustment knob and controls.

23. Turn the taper adjustment knob to bring the

dovetail to zero on both scales.

-7-

Page 8

Model SB1263

INSTRUCTIONS

Mfg. Since 9/11

24. Re-tighten both dovetail cap screws to secure

the zero setting.

25. Move the carriage toward the tailstock until

the taper attachment body is against the

rear travel stop (see Figure 18).

Note: If necessary, reposition the deadman clamp

on the arm so that it is at least 1" away from

the saddle (see Figure 18) and re-tighten

the clamp cap screws. This “saddle safety

gap” will prevent the saddle crashing into

the deadman clamp during taper operations.

Complete Travel Without

Deadman Clamp Contact

1" Saddle

Safety Gap

2 7. Inspect the assembly to determine if the

deadman arm is parallel horizontally and

vertically with the bedway.

— If the arm is parallel horizontally and

vertically with the bedway, proceed to

Step 26.

— If the arm is not horizontally parallel with

the bedway:

a. Loosen the four adjustment cam set

screws shown in Figure 19.

Adjustment Cam

Set Screws

Rear Travel Stop

Figure 18. Saddle gap.

You will need to perform Step 25 each time

you secure the deadman clamp to the bedway

to cut a taper to prevent the carriage crashing

into the deadman clamp.

26. Move the carriage toward the headstock

until the taper attachment is against the

front travel stop.

Note: In the following step, it may be necessary

to rotate the arm so the clevis allows the arm

to tilt in a particular direction.

Adjustment

Cam

Figure 19. Adjustment cam set screws.

b. Slide the adjustment cam and arm

clamp toward or away from the

deadman clamp until the arm is

horizontally parallel with the bedway.

c. Re-tighten the adjustment cam set

screws.

— If the arm is not vertically parallel with

the bedway:

a. Loosen the four adjustment cam set

screws shown in Figure 19.

b. Rotate the knurled adjustment cam

until the arm is vertically parallel with

the bedway.

-8-

c. Re-tighten the adjustment cam set

screws.

Page 9

!

Mfg. Since 9/11 Model SB1263

INSTRUCTIONS

28. Tighten the arm clamp cap screw (see

Figure 20) to secure the deadman clamp

assembly to the arm.

Clevis

Hex Nut

Arm Clamp

Cap Screw

Figure 20. Arm clamp cap screw and clevis hex nut.

29. Tighten the arm clevis hex nut to secure the

attachment to the arm.

32. Move the carriage and taper attachment to

the other end and note any change in the

reading.

— If the indicator reading is 0.025" or

less, the tilt of the attachment table

is considered acceptable. Proceed to

Step 35.

— If the indicator reading is greater than

0.025", proceed to Step 33 to correct the

attachment table tilt.

33. Loosen the four cap screws that secure the

attachment to the saddle, then rotate the

attachment assembly left or right to correct

the table tilt (see Figure 22).

Rotate

Body

30. Move the carriage toward the headstock

until the taper attachment is against the

front travel stop.

31. Mount the dial indicator magnetic base on

top of the saddle so that the indicator needle

is resting on the attachment table, as shown

in Figure 21, then zero the indicator.

Figure 22. Attachment table tilt adjustment.

34. Re-tighten the four cap screws to secure the

setting, then repeat Steps 32–33 to re-check

the table tilt.

Figure 21. Taper attachment alignment.

-9-

Page 10

Model SB1263

35. Drill two 19⁄64" holes into the saddle through

the pilot holes in the attachment casting (see

Figure 23).

INSTRUCTIONS

Mfg. Since 9/11

Operation

The taper attachment is engaged for operation

when the deadman clamp is tightened on the

bedway and disengaged for operation when the

deadman clamp is loosened.

Engaging Taper Attachment

1. DISCONNECT LATHE FROM POWER!

Pre-Drilled Pilot

Holes for Taper Pins

Figure 23. Taper pin pilot holes.

36. Ream the holes with the #6 spiral pin reamer

deep enough so that the taper pins will fit

flush to the attachment casting surface.

3 7. Carefully tap the taper pins into the holes

until they are flush with the casting surface

to secure the attachment tilt alignment with

the saddle.

Note: If you need to remove the taper pins, the

internal pin threads are M6-1.

38. Re-install the lathe splash guard.

2. Position the cutting tool at the proper

beginning position for the turning operation.

Note: Make sure that there will be at least 1"

clearance between the deadman clamp and

the saddle when the saddle is moved all the

way toward the tailstock (refer to Step 25 on

Page 8 for additional information).

3. Tighten the deadman clamp cap screws to

secure the clamp and taper attachment to

the bedway (see Figure 24).

Deadman Clamp

Cap Screws

-10-

Figure 24. Deadman clamp cap screws.

Page 11

Mfg. Since 9/11 Model SB1263

INSTRUCTIONS

4. Loosen both dovetail cap screws (see

Figure 25).

Dovetail Cap

Screw (1 of 2)

Figure 25. Dovetail cap screw

(1 of 2).

Note: Depending on the operation, use either the

rear scale (degrees of taper) or the front scale

(amount of taper per inch of workpiece) in

the next step (see Figure 26).

Disengaging Taper Attachment

1. DISCONNECT LATHE FROM POWER!

2. Loosen both deadman clamp cap screws (see

Figure 27)

Deadman Clamp

Cap Screws

Figure 27. Deadman clamp cap screws.

3. Loosen the dovetail way cap screws at each

end (see Figure 28).

Rear Scale Front Scale

Taper Angle

Taper Per/Inch

Workpiece

Length

Figure 26. Rear and front scales.

Dovetail Cap

Screw (1 of 2)

Figure 28. Dovetail way cap screw

(1 of 2).

4. Turn the taper adjustment knob until both

scales read zero.

5. Re-tighten both dovetail way cap screws.

5. Turn the taper adjustment knob to set the

required taper, then re-tighten both dovetail

cap screws.

-11-

Page 12

!

Model SB1263

INSTRUCTIONS

Mfg. Since 9/11

Maintenance

Always disconnect

lathe from power before

performing maintenance or

serious personal injury may

result.

Maintenance Schedule

For optimum performance from your taper

attachment, follow the maintenance schedule

below and refer to any specific instructions given

in this section.

Daily

• Check/correct loose mounting fasteners.

• Clean debris and grime from all attachment

surfaces.

• Clean/protect attachment table and dovetail

ways.

• Correct any other unsafe condition.

Monthly

• Disassemble, clean, and lubricate slide block,

pivot pin, and internal ways.

Cleaning & Protecting

Typically, the easiest way to clean debris and

grime from the attachment is to use a wet/dry

shop vacuum that is dedicated for this purpose.

The small chips left over after vacuuming can be

wiped up with a slightly oiled rag. Avoid using

compressed air to blow off chips, as it may drive

them deeper into moving surfaces and could

cause sharp chips to fly into your face or hands.

To keep the unpainted surfaces of the

attachment table and dovetail ways rust-free and

in top condition, apply a thin coat of a quality

way oil after cleaning them.

Lubricating Slide Block, Pivot Pin,

& Internal Ways

1. DISCONNECT LATHE FROM POWER!

2. Referring to the assembly instructions,

remove the attachment body top cover and

the slide block.

3. Clean the slide block, pivot pin, and the

internal ways with mineral spirits and shop

rags.

Important: Make sure the brass plug in the slide

block set screw hole remains in place during

cleaning and lubrication.

-12-

4. When dry, apply a thin coat of white lithium

grease to all surfaces of the slide block, pivot

pin, and internal ways of the attachment

body, then re-assemble the parts.

Page 13

Mfg. Since 9/11 Model SB1263

INSTRUCTIONS

Gib Adjustment

The goal of adjusting the gib screws is to remove

sloppiness or “play” from the ways without overadjusting them to the point where they become

stiff and difficult to move.

In general, loose gibs cause poor finishes and

inaccurate tapers; however, over-tightened gibs

cause premature wear and make it difficult to

move the carriage and cross slide.

Internal Gib

The internal gib is tapered and held in position

by a screw at each end (see Figure 29). To

adjust this gib, turn one screw

1

and the other screw

⁄4 turn counterclockwise,

so both screws move in the same direction and

the same amount. Test the feel of the setting by

moving the carriage, and adjust the gib screws as

necessary to make it tighter or looser.

1

⁄4 turn clockwise

External Gib

The external gib is wedge-shaped and is held

in position by three set screws (see Figure 30).

To adjust this gib, loosen the hex nuts and turn

the set screws in equal amounts. Test the feel of

the setting by moving the carriage, and adjust

the set screws as necessary to make it tighter or

looser. When satisfied with the movement, retighten the hex nuts to secure the setting.

Gib

Hex Nuts

& Set Screws

Gib Screw

(1 of 2)

Figure 29. Internal gib.

Figure 30. External gib.

Gib

-13 -

Page 14

Model SB1263

Parts Breakdown

INSTRUCTIONS

2

Mfg. Since 9/11

7

8

9

50

51

49

46

10

1

2

5

12

13

20

22

23

36

37

46

11

48

45

33

34

35

38

39

40

33

42

28

30

31

32

41

40

10

13

12

12

11

14

15

16

17

18

20

19

21

36

23

24

25

26

27

-14-

47

43

44

Page 15

Mfg. Since 9/11 Model SB1263

INSTRUCTIONS

Parts List

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 PSB1263001 BUSHING BRASS 28 PSB1263028 PIVOT PIN

2 PSB1263002 CAP SCREW M6-1 X 20 30 PSB1263030 PIVOT SADDLE

5 PSB1263005 END CAP 31 PSB1263031 PIVOT SADDLE GIB

7 PSB1263007 FLAT HD SCR M6-1 X 8 32 PSB1263032 GIB SCREW

8 PSB1263008 TOP COVER 33 PSB1263033 CAP SCREW M8-1.25 X 25

9 PSB1263009 SLIDE BLOCK 34 PSB1263034 DOVETAIL WAY

10 PSB1263010 BRASS PLUG 35 PSB1263035 CAP SCREW M6-1 X 25

11 PSB1263011 SET SCREW M8-1.25 X 16 36 PSB1263036 CAP SCREW M8-1.25 X 20

12 PSB1263012 CAP SCREW M8-1.25 X 45 37 PSB1263037 COTTER PIN 4.5 X 30MM

13 PSB1263013 TAPER PIN 38 PSB1263038 CLEVIS

14 PSB1263014 BODY 39 PSB1263039 CLEVIS PIN

15 PSB1263015 PLATE 40 PSB1263040 NUT BLOCK M6-1 X 25

16 PSB1263016 PHLP HD SCR M6-1 X 10 41 PSB1263041 T-NUT M8-1.25

17 PSB1263017 SET SCREW M8-1.25 X 25 42 PSB1263042 NUT BLOCK

18 PSB1263018 HEX NUT M8-1.25 43 PSB1263043 LEADSCREW

19 PSB1263019 CAP SCREW M8-1.25 X 30 44 PSB1263044 KNOB

20 PSB1263020 STEEL FLUTED RIVET 2 X 5MM 45 PSB1263045 DEADMAN ARM

21 PSB1263021 INCH SCALE 0-14.5 46 PSB1263046 SET SCREW M6-1 X 12

22 PSB1263022 DEGREE SCALE 0-8.5 47 PSB1263047 ARM CLAMP

23 PSB1263023 STOP 48 PSB1263048 ECCENTRIC CAM

24 PSB1263024 TABLE 49 PSB1263049 CAP SCREW M10- 1.5 X 50

25 PSB1263025 T-NUT M8-1.25 50 PSB1263050 DEADMAN CLAMP

26 PSB1263026 TABLE GIB 51 PSB1263051 DEADMAN PLATE

27 PSB1263027 CAP SCREW M6-1 X 30

-15 -

Page 16

Loading...

Loading...