READ THIS FIRST

MODEL SB1102

***IMPORTANT UPDATE***

SINCE

1906

Applies to Models Mfd. Since 06/24

and Owner’s Manual Revised 11/23

The following change was recently made since the owner’s manual was printed:

• Conveyor motor changed.

Aside from this information, all other content in the owner’s manual applies and MUST be read and

understood for your own safety. IMPORTANT: Keep this update with the owner’s manual for future

reference.

If you have any further questions about this manual update or the changes made to the machine,

contact our Technical Support at (360) 734-1540 or email www.southbendtools.com.

SINCE

1906

Old Conveyor Motor

New Conveyor Motor

Revised Parts

39V2

39V2-1

39V2-2

REF PART # DE SCR IPTION

39V2 PSB1102039V2 CONVEYOR MOTOR 1/3HP 220V 1-PH V2.06.24

39V2-1 PSB1102039V2-1 MOTOR BRUS H 2-PC SET 1 6 X 6.4 X 7.4, 32

39V2-2 PSB1102039V2-2 MOTOR BRUS H C OVER

Copyright © June, 2024 by South Bend Tools

WARNING: No portion of this manual may be reproduced without written approval.

#JP23249 Printed in Taiwan

26" 5 HP Drum Sander

MODEL SB1102

***Keep for Future Reference***

OWNER'S MANUAL

®

South Bend Tools

A Tradition of Excellence

© November, 2021 by South Bend Tools, Revised November, 2023 (JP) For Machines Mfd. Since 01/24

We stand behind our machines. If you have any service questions, parts requests or general questions

about your purchase, feel free to contact us.

South Bend Tools

P.O. Box 2027

Bellingham, WA 98227

Phone: (360) 734-1540

Fax: (360) 676-1075 (International)

Fax: (360) 734-1639 (USA Only)

Email: sales@southbendtools.com

For your convenience, any updates to this manual will be available to download free of charge

www.southbendtools.com

Scope of Manual

This manual helps the reader understand the machine, how to prepare it for operation, how to control

it during operation, and how to keep it in good working condition. We assume the reader has a basic

understanding of how to operate this type of machine, but that the reader is not familiar with the

controls and adjustments of this specific model. As with all machinery of this nature, learning the

nuances of operation is a process that happens through training and experience. If you are not an

experienced operator of this type of machinery, read through this entire manual, then learn more

from an experienced operator, schooling, or research before attempting operations. Following this

advice will help you avoid serious personal injury and get the best results from your work.

We've made every effort to be accurate when documenting this machine. However, errors sometimes

happen or the machine design changes after the documentation process—so

exactly match your machine.

contact our

We highly value customer feedback on our manuals. If you have a moment, please share your

experience using this manual. What did you like about it? Is there anything you would change to

make it better? Did it meet your expectations for clarity, professionalism, and ease-of-use?

South Bend Tools

C

P.O. Box 2027

Bellingham, WA 98227

Email: manuals@southbendtools.com

Manual Feedback

If a difference between the manual and machine leaves you in doubt,

customer service for clarification.

the manual may not

/O Technical Documentation Manager

Updates

through our website at:

Customer Service

Table of Contents

IDENTIFICATION .............................................................2

Identification ............................................2

Description of Controls & Components ........... 3

Product Specifications ................................4

SAFETY ................................................................................6

Understanding Risks of Machinery ................ 6

Basic Machine Safety .................................. 6

Additional Drum Sander Safety .................... 8

PREPARATION .................................................................9

Preparation Overview .................................9

Required for Setup .....................................9

Power Supply Requirements ....................... 10

Unpacking .............................................. 12

Inventory ............................................... 12

Location ................................................. 13

Lifting & Placing ..................................... 14

Assembly ................................................ 14

Power Connection ..................................... 15

Dust Collection ........................................ 15

Test Run ................................................ 16

Inspections & Adjustments ........................ 17

OPERATION .................................................................... 18

Operation Overview .................................. 18

Stock Inspection & Requirements ................ 19

Choosing Sandpaper ................................. 19

Sanding Tips ........................................... 20

Sanding ................................................. 21

Setting Depth of Cut ................................. 21

Setting Conveyor Speed ............................. 22

Monitoring Sanding Load .......................... 22

Installing/Replacing Sandpaper ................. 23

Cleaning Sandpaper .................................. 25

ACCESSORIES .............................................................. 26

MAINTENANCE ............................................................. 27

Maintenance Schedule............................... 27

Machine Storage ...................................... 27

Cleaning & Protecting ............................... 28

Lubrication ............................................. 28

SERVICE .......................................................................... 30

Aligning Drums ....................................... 30

Adjusting Pressure Rollers ........................ 34

Adjusting Dust Scoop ............................... 35

Adjusting Conveyor Belt Tension & Tracking . 36

Adjusting/Replacing V-Belts ..................... 37

Replacing Bearings .................................. 39

Replacing Conveyor Motor Brushes ............. 40

ELECTRICAL ................................................................... 45

Electrical Safety Instructions ..................... 45

Wiring Diagram ....................................... 46

Electrical Component Photos ...................... 47

PARTS ...............................................................................48

Stand & Motor......................................... 48

Conveyor Table ........................................ 50

Drums & Rollers ...................................... 52

Control Panel & Handwheel ........................ 54

Electrical Components .............................. 55

Machine Labels ........................................ 56

WARRANTY ..................................................................... 57

South Bend Tools

Mo del SB1102

IDENTIFICATION

Identication

INTRODUCTION

For Machines Mfd. Since 01/24

Rear Sanding DrumRear Sanding Drum

4" Dust Ports4" Dust Ports

Control PanelControl Panel

Front Sanding DrumFront Sanding Drum

Rear Sanding Drum Rear Sanding Drum

Micro-Adjustment KnobMicro-Adjustment Knob

ConveyorConveyor

Table Height Table Height

HandwheelHandwheel

Serious personal injury could occur if

you connect the machine to power before

completing the setup process. DO NOT

connect power until instructed to do so later

in this manual.

-2-

Untrained users have an increased risk

of seriously injuring themselves with this

machine. Do not operate this machine until

you have understood this entire manual and

received proper training.

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

INTRODUCTION

Description of Controls & Components

Refer to Figures 1–3 and the following

descriptions to become familiar with the basic

controls and components used to operate this

machine. Understanding these items and how

they work will help you understand the rest of

the manual and stay safe when operating this

machine.

Control Panel

AA

BB

DD

CC

EE

Figure 1. Control Panel.

A. Sanding Load Display: Displays current amp

draw of sanding motor. Buttons on display

have no function for this machine.

B. Emergency Stop Button: Stops motors when

pressed and disables ON buttons.

FF

GG

Sanding Controls

HH

LL

H. Conveyor Table w/Belt: Adjusts up and down

and has conveyor belt that feeds workpieces

under sanding drums.

I. Table Height Handwheel: Rotates to raise or

lower conveyor table according to workpiece

thickness.

J. Rear Sanding Drum Micro-Adjustment Knob:

Rotates to make fine adjustments to rear

sanding drum.

K. Micro-Adjustment Lock Lever: Locks rear

sanding drum micro-adjustment knob in

place.

L. Depth-of-Cut Scale: Indicates distance

between conveyor table and sanding drums.

II

Figure 2. Sanding Controls.Sanding Controls.

JJ

KK

C. Conveyor Speed Control Dial: Rotates to

adjust conveyor belt speed between 0–20 FPM.

D. Sanding Drum Motor ON Button: Turns

sanding motor ON. Illuminates when

pressed.

E. Sanding Drum Motor OFF Button: Turns

sanding motor OFF. Illuminates when

pressed.

F. Conveyor Motor ON Button: Turns conveyor

motor ON. Illuminates when pressed.

G. Conveyor Motor OFF Button: Turns conveyor

motor OFF. Illuminates when pressed.

Sanding Drums

MM

Figure 3. Sanding drums.Sanding drums.

M. Sanding Drums: Rotate against incoming

workpiece to achieve flat, smooth surface.

-3-

South Bend Tools

Mo del SB1102

INTRODUCTION

Model SB1102

Model SB1102

For Machines Mfd. Since 01/24

26" 5 HP Single‐Phase Drum Sander

Product Dimensions

Weight.............................................................................................................................................................

Width (side-to-side) x Depth (front-to-back) x Height................................................... 50-1/2 x 36-1/2 x 50-1/2 in.

Footprint (Length x Width)................................................................................................................. 23-1/2 x 37 in.

Shipping Dimensions

Type.......................................................................................................................................................... Wood Crate

Content..........................................................................................................................................................

Weight.............................................................................................................................................................

Length x Width x Height................................................................................................................... 52 x 41 x 47 in.

Must Ship Upright................................................................................................................................................ Yes

Electrical

Power Requirement......................................................................................................... 220V, Single-Phase, 60 Hz

Full-Load Current Rating....................................................................................................................................

Minimum Circuit Size..........................................................................................................................................

Connection Type..................................................................................................................................... Cord & Plug

Power Cord Included............................................................................................................................................. Yes

Power Cord Length.......................................................................................................................................... 126 in.

Power Cord Gauge.........................................................................................................................................

Plug Included..........................................................................................................................................................

Recommended Plug Type.................................................................................................................................. L6-30

Switch Type....................................................................................... Control Panel w/Magnetic Switch Protection

26" 5 HP Drum Sander

443 lbs.

Machine

498 lbs.

27A

30A

10 AWG

No

Motors

Main

Horsepower............................................................................................................................................... 5 HP

Phase............................................................................................................................................

Amps...........................................................................................................................................................

Speed................................................................................................................................................ 3450 RPM

Type............................................................................................................. TEFC Capacitor-Start Induction

Power Transfer .......................................................................................................................................... Belt

Bearings....................................................................................................

Centrifugal Switch/Contacts Type.....................................................................................................

Conveyor

Horsepower............................................................................................................................................ 1/3 HP

Phase............................................................................................................................................ Single-Phase

Amps............................................................................................................................................................. 2A

Speed....................................................................................................................................................

Type...................................................................................................................................................

Power Transfer ....................................................................................................................................... Chain

Bearings.................................................................................................... Sealed & Permanently Lubricated

-4-

Single-Phase

25A

Sealed & Permanently Lubricated

External

60 RPM

Universal

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

INTRODUCTION

Main Specifications

Operation Information

Number of Sanding Heads..............................................................................................................................

Maximum Board Width...........................................................................................................................

Minimum Board Width............................................................................................................................. 2 in.

Maximum Board Thickness................................................................................................................ 3-3/4 in.

Minimum Board Thickness.................................................................................................................... 1/8 in.

Minimum Board Length............................................................................................................................

Sandpaper Speed.............................................................................................................................

Conveyor Feed Rate........................................................................................................................ 0 - 20 FPM

Sandpaper Length................................................................................................................................. 195 in.

Sandpaper Width....................................................................................................................................... 3 in.

Drum Information

Infeed Sanding Drum Type............................................................................................................

Infeed Sanding Drum Size........................................................................................................................

Outfeed Sanding Drum Type.......................................................................................................... Aluminum

Outfeed Sanding Drum Size...................................................................................................................... 6 in.

Construction

Conveyor Belt........................................................................................................................................ Rubber

Body...........................................................................................................................................................

Paint Type/Finish....................................................................................................................

Powder Coated

2300 FPM

Aluminum

2

26 in.

9 in.

6 in.

Steel

Other Related Information

Floor To Table Height.......................................................................................................... 28-1/8 - 32-1/8 in.

Sanding Belt Tension.................................................................................................................. Hook & Loop

Number of Pressure Rollers........................................................................................................................... 3

Pressure Roller Type............................................................................................................................

Pressure Roller Size............................................................................................................................

Conveyor Belt Length.............................................................................................................................. 74 in.

Conveyor Belt Width............................................................................................................................... 26 in.

Belt Roller Size.................................................................................................................................... 1-7/8 in.

Number of Dust Ports.....................................................................................................................................

Dust Port Size............................................................................................................................................

Other

Country of Origin ........................................................................................................................................... Taiwan

Warranty ........................................................................................................................................................ 2 Years

Approximate Assembly & Setup Time ................................................................................................... 30 Minutes

Serial Number Location .............................................................................................................................. ID Label

ISO 9001 Factory ................................................................................................................................................. Yes

Features

Hook & Loop Sanding Belt Tension/Sandpaper

Industrial-Duty Rubber Conveyor Belt

Two 4" Dust Ports

Variable-Speed Conveyor

Dual 6" Aluminum Sanding Drums

Four Leadscrew Table Lift System

Easy Access Control Panel with Amp Load Meter

External Micro-Adjustment on Outfeed Drum

Rubber

1-5/8 in.

2

4 in.

-5-

South Bend Tools

Mo del SB1102

Operating all machinery and machining equipment can be dangerous or relatively safe depending

on how it is installed and maintained, and the operator's experience, common sense, risk awareness,

working conditions, and use of personal protective equipment (safety glasses, respirators, etc.).

The owner of this machinery or equipment is ultimately responsible for its safe use. This

responsibility includes proper installation in a safe environment, personnel training and usage

authorization, regular inspection and maintenance, manual availability and comprehension,

application of safety devices, integrity of cutting tools or accessories, and the usage of approved

personal protective equipment by all operators and bystanders.

The manufacturer of this machinery or equipment will not be held liable for injury or property

damage from negligence, improper training, machine modifications, or misuse. Failure to read,

understand, and follow the manual and safety labels may result in serious personal injury, including

amputation, broken bones, electrocution, or death.

The signals used in this manual to identify hazard levels are as follows:

Owner’s Manual: All machinery and machining

Trained/Supervised Operators Only: Untrained

SAFETY

SAFETY

For Machines Mfd. Since 01/24

Understanding Risks of Machinery

Death or catastrophic

harm WILL occur.

Death or catastrophic

harm COULD occur.

Moderate injury or fire

MAY occur.

Machine or property

damage may occur.

Basic Machine Safety

equipment presents serious injury hazards

to untrained users. To reduce the risk of

injury, anyone who uses THIS item MUST

read and understand this entire manual

before starting.

Personal Protective Equipment:

servicing this item may expose the user

to flying debris, dust, smoke, dangerous

chemicals, or loud noises. These hazards

can result in eye injury, blindness, longterm respiratory damage, poisoning,

cancer, reproductive harm or hearing loss.

Reduce your risks from these hazards

by wearing approved eye protection,

respirator, gloves, or hearing protection.

Operating or

users can seriously injure themselves

or bystanders. Only allow trained and

properly supervised personnel to operate

this item. Make sure safe operation

instructions are clearly understood. If

electrically powered, use padlocks and

master switches, and remove start switch

keys to prevent unauthorized use or

accidental starting.

Guards/Covers:

moving parts during operation may cause

severe entanglement, impact, cutting,

or crushing injuries. Reduce this risk by

keeping any included guards/covers/doors

installed, fully functional, and positioned

for maximum protection.

Accidental contact with

-6-

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

Entanglement: Loose clothing, gloves, neckties,

rotate.

Chuck Keys or Adjusting Tools:

Tools used to

our Technical Support for assistance.

SAFETY

jewelry or long hair may get caught in

moving parts, causing entanglement,

amputation, crushing, or strangulation.

Reduce this risk by removing/securing

these items so they cannot contact moving

parts.

Mental Alertness: Operating this item with

reduced mental alertness increases the

risk of accidental injury. Do not let a

temporary influence or distraction lead to a

permanent disability! Never operate when

under the influence of drugs/alcohol, when

tired, or otherwise distracted.

Safe Environment:

powered equipment in a wet environment

may result in electrocution; operating near

highly flammable materials may result in a

fire or explosion. Only operate this item in

a dry location that is free from flammable

materials.

Electrical Connection: With electically powered

equipment, improper connections to the

power source may result in electrocution

or fire. Always adhere to all electrical

requirements and applicable codes when

connecting to the power source. Have all

work inspected by a qualified electrician to

minimize risk.

Disconnect Power: Adjusting or servicing

electrically powered equipment while it

is connected to the power source greatly

increases the risk of injury from accidental

startup. Always disconnect power

BEFORE any service or adjustments,

including changing blades or other tooling.

Operating electrically

adjust spindles, chucks, or any moving/

rotating parts will become dangerous

projectiles if left in place when the machine

is started. Reduce this risk by developing

the habit of always removing these tools

immediately after using them.

Work Area:

the risks of accidental injury. Only operate

this item in a clean, non-glaring, and welllighted work area.

Properly Functioning Equipment:

maintained, damaged, or malfunctioning

equipment has higher risks of causing

serious personal injury compared to

those that are properly maintained.

To reduce this risk, always maintain

this item to the highest standards and

promptly repair/service a damaged or

malfunctioning component. Always follow

the maintenance instructions included in

this documentation.

Unattended Operation:

equipment that is left unattended while

running cannot be controlled and is

dangerous to bystanders. Always turn the

power OFF before walking away.

Health Hazards: Certain cutting fluids and

lubricants, or dust/smoke created when

cutting, may contain chemicals known to

the State of California to cause cancer,

respiratory problems, birth defects,

or other reproductive harm. Minimize

exposure to these chemicals by wearing

approved personal protective equipment

and operating in a well ventilated area.

Clutter and dark shadows increase

Poorly

Electrically powered

Secure Workpiece/Tooling:

cutting tools, or rotating spindles can

become dangerous projectiles if not

secured or if they hit another object during

operation. Reduce the risk of this hazard

by verifying that all fastening devices are

properly secured and items attached to

spindles have enough clearance to safely

Loose workpieces,

Difficult Operations:

operations with which you are unfamiliar

increases the risk of injury. If you

experience difficulties performing the

intended operation, STOP! Seek an

alternative method to accomplish the

same task, ask a qualified expert how the

operation should be performed, or contact

Attempting difficult

-7-

South Bend Tools

Mo del SB1102

Serious injury or death can occur from getting hands trapped between workpiece and conveyor table

and being pulled into machine, or becoming entangled in rotating parts inside machine. Workpieces

thrown by sander can strike nearby operator or bystanders with signi cant force. Long-term

respiratory damage can occur from using sander without proper use of a respirator. To reduce the risk

of these hazards, operator and bystanders MUST completely heed the hazards and warnings below.

Feeding Workpiece:

Sanding Dust:

Power Disconnect:

Sandpaper Contact:

SAFETY

Additional Drum Sander Safety

For Machines Mfd. Since 01/24

Placing fingers between

workpiece and conveyor can result in

pinching injuries, or possibly getting

trapped and pulled into sanding area of

machine. DO NOT place fingers under

bottom of workpiece while feeding it into

sander.

Sanding creates large amounts of

fine airborne dust that can lead to eye injury

or serious respiratory illness. Reduce your

risk by always wearing approved eye and

respiratory protection when sanding. Never

operate without adequate dust collection

system in place and running. However, dust

collection is not a substitute for using a

respirator.

An accidental startup while

changing sanding belts or performing

adjustments or maintenance can result

in serious entanglement or abrasion

injuries. Make sure machine is turned OFF,

disconnected from power and air, and all

moving parts are completely stopped before

changing belts, doing adjustments, or

performing maintenance.

Rotating sandpaper can

remove a large amount of flesh quickly.

Keep hands away from rotating sanding

drum(s) during operation. Never touch

moving sandpaper.

Avoiding Entanglement: Tie back long hair,

remove jewelry, and do not wear loose

clothing or gloves. These can easily get

caught in moving parts. Never reach

inside machine or try to clear jammed

workpiece while machine is operating.

Keep all guards in place and secure.

Workpiece Material: This sander is designed to

sand only natural wood products or manmade products made from natural wood

fiber. DO NOT sand any metal products.

Workpiece Inspection: Nails, staples, knots,

or other imperfections in workpiece can

be dislodged and thrown from sander

at high rate of speed into operator or

bystanders, or cause damage to sandpaper

or sander. Never try to sand stock that has

embedded foreign objects or questionable

imperfections.

Kickback: Occurs when a workpiece is ejected

out the front of sander at a high rate of

speed toward operator or bystanders. To

reduce risk of kickback-related injuries,

always stay out of workpiece path, only

feed one board at a time, and always

make sure pressure rollers are properly

adjusted below sanding roller. Never sand

workpieces below minimum specifications

listed in Machine Data Sheet.

No list of safety guidelines can be complete. Every shop environment is different. Always consider

safety first, as it applies to your individual working conditions. Use this and other machinery with

caution and respect. Failure to do so may result in serious personal injury or property damage.

-8-

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

PREPARATION

PREPARATION

Preparation Overview Required for Setup

The purpose of the preparation section is to help

you prepare your machine for operation. The list

below outlines the basic process. Specific steps

for each of these points will be covered in detail

later in this section.

The typical preparation process is as follows:

1. Unpack the machine and inventory the

contents of the box/crate.

2. Clean the machine and its components.

3. Identify an acceptable location for the

machine and move it to that location.

4. Level the machine and either bolt it to the

floor or place it on mounts.

5. Assemble the loose components and make

any necessary adjustments or inspections to

ensure the machine is ready for operation.

6. Connect the machine to the power source.

7. Test run the machine to make sure it

functions properly and is ready for

operation.

The following items are needed, but not included

for the setup/assembly of this machine.

For Lifting

• Forklift (Min. 750 lb. rating)

For Power Connection

• A power supply that meets the minimum

circuit requirements for this machine. (Refer

to the Power Supply Requirements section

for details.)

• L6-30 Plug

For Assembly

• Additional Person for Moving

• Safety Glasses (for each person)

• Phillips Screwdriver #2

• Wrench or Socket

• Hex Wrench 5mm

• Open-Ended Wrench 12mm

• Double-Sided Tape

• Dust-Collection System

• 4" Dust Hoses (length as needed)

• 4" Hose Clamps

• 4" Y Adapter

7

⁄16"

1

⁄16"

Like all machinery there is potential danger

when operating this machine. Accidents are

frequently caused by lack of familiarity or

failure to pay attention. Use this machine with

respect and caution to decrease the risk of

operator injury. If normal safety precautions are

overlooked or ignored, serious personal injury

may occur.

-9-

South Bend Tools

Mo del SB1102

Before installing the machine, consider the

availability and proximity of the required power

supply circuit. If an existing circuit does not meet

the requirements for this machine, a new circuit

must be installed.

To minimize the risk of electrocution, fire,

or equipment damage, installation work and

electrical wiring must be done by a

or qualified service personnel

applicable electrical codes and safety standards.

The full-load current rating is the amperage

a machine draws at 100% of the rated output

power. On machines with multiple motors, this is

the amperage drawn by the largest motor or sum

of all motors and electrical devices that might

operate at one time during normal operations.

The full-load current is not the maximum

amount of amps that the machine will draw. If

the machine is overloaded, it will draw additional

amps beyond the full-load rating.

If the machine is overloaded for a sufficient

length of time, damage, overheating, or fire may

result—especially if connected to an undersized

circuit. To reduce the risk of these hazards,

avoid overloading the machine during operation

and make sure it is connected to a power supply

circuit that meets the requirements in the

following section.

This machine is prewired to operate on a power

supply circuit that has a verified ground and

meets the following requirements:

Note: The circuit requirements in this manual

are for

machine will be running at a time. If this

machine will be connected to a shared circuit

where multiple machines will be running at

the same time, consult a qualified electrician to

ensure the circuit is properly sized.

A power supply circuit includes all electrical

equipment between the main breaker box or fuse

panel in your building and the incoming power

connections inside the machine. This circuit

must be safely sized to handle the full-load

current that may be drawn from the machine for

an extended period of time. (If this machine is

connected to a circuit protected by fuses, use a

time delay fuse marked D.)

Power Supply

PREPARATION

For Machines Mfd. Since 01/24

Requirements

Availability

Electrocution or fire may

occur if machine is not

correctly grounded and

attached to the power

supply. Use a qualified

electrician to ensure a safe

power connection.

n electrician

in accordance with

Serious injury could occur if you connect

machine to power before completing setup

process. DO NOT connect to power until

instructed later in this manual.

Circuit Requirements

Nominal Voltage ............208V, 220V, 230V, 240V

Cycle ............................................................. 60 Hz

Phase ................................................ Single-Phase

Circuit Rating ......................................... 30 Amps

Plug/Receptacle ..............................NEMA L6-30

Full-Load Current Rating

Full-Load Rating at 220V ...................... 27 Amps

-10 -

For your own safety and protection of property,

consult an electrician if you are unsure about

wiring practices or applicable electrical codes.

a dedicated circuit—where only one

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

This machine must be grounded! In the event

of

grounding provides a path of least resistance

for electric current

electric shock.

Improper connection of the equipment-grounding

wire can result in a risk of electric shock. The

wire with green insulation (with or without

yellow stripes) is the equipment-grounding wire.

If repair or replacement of the power cord or

plug is necessary, do not connect the equipmentgrounding wire to a live (current carrying)

terminal.

Check with an electrician or qualified service

personnel if you do not understand these

grounding requirements, or if you are in doubt

about whether the tool is properly grounded.

If you ever notice that a cord or plug is

damaged or worn, disconnect it from power, and

immediately replace it with a new one.

We do not recommend using an extension cord

with this machine. If you must use one, only

use it if absolutely necessary and only on a

temporary basis.

Extension cords cause voltage drop, which may

damage electrical components and shorten motor

life. Voltage drop increases as the extension cord

size gets longer and the gauge size gets smaller

(higher gauge numbers indicate smaller sizes).

Any extension cord used with this machine

must contain a ground wire, match the required

plug and receptacle listed in the

Requirements

meet the following requirements:

No adapter should be used with plug. If

plug does not fit available receptacle, or if

machine must be reconnected for use on a

different type of circuit, reconnection must

be performed by an electrician or qualified

service personnel, and it must comply with all

local codes and ordinances.

Use the plug type listed in the Circuit

Requirements

(similar to the figure below) has an equipmentgrounding wire to safely ground the machine.

The plug

receptacle (outlet)

grounded in accordance with all local codes and

ordinances.

PREPARATION

Grounding Requirements

certain types of malfunctions or breakdowns,

in order to reduce the risk of

for this voltage. The listed plug

must only be inserted into a matching

that is properly installed and

GROUNDED

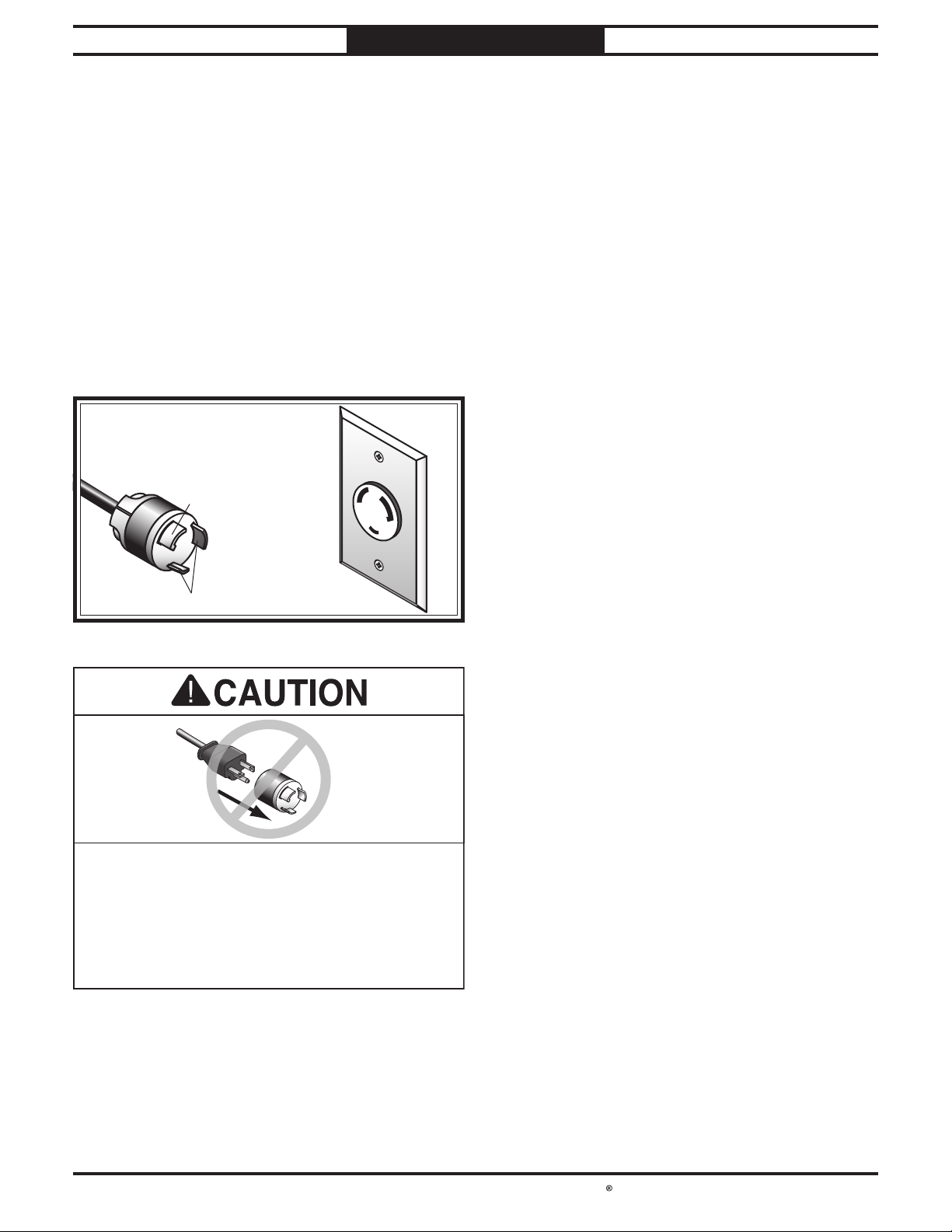

L6-30 LOCKING

RECEPTACLE

Extension Cords

Grounding Prong

is Hooked

L6-30

LOCKING

PLUG

Current Carrying Prongs

Figure 4. NEMA L6-30 plug and receptacle.NEMA L6-30 plug and receptacle.

Circuit

for the applicable voltage, and

Minimum Gauge Size .............................. 10 AWG

Maximum Length (Shorter is Better) ..........50 ft.

-11-

South Bend Tools

Mo del SB1102

This item was carefully packaged to prevent

damage during transport. If you discover any

damage, please immediately call Customer

Service at

need to file a freight claim, so save the containers

and all packing materials for possible inspection

by the carrier or its agent.

PREPARATION

For Machines Mfd. Since 01/24

Unpacking

(360) 734-1540 for advice. You may

Inventory

The following is a list of items shipped with your

machine. Before beginning setup, lay these items

out and inventory them.

If any non-proprietary parts are missing (e.g. a

nut or a washer), we will gladly replace them; or

for the sake of expediency, replacements can be

obtained at your local hardware store.

Box 1 (Figures 5–6) Qty

A. Drum Sander ........................................ 1

B. Handwheel ........................................... 1

C. 4" Dust Port (Flat) ................................. 1

D. 4" Dust Port (Concave) ........................... 1

E. Handwheel Handle ................................. 1

F. Hex Bolts

G. Flat Washers

H. Tap Screws #8 x

I. Flat Washers #8 ....................................8

J. Hex Wrench 3, 5mm ..........................1 Ea.

K. Tension Tool ......................................... 1

1

⁄4"-20 x 1⁄2" ............................. 3

1

⁄4" .................................... 3

1

⁄2" ................................ 8

NOTICE

If you cannot nd an item on this list, carefully

check around/inside the machine and

packaging materials. Often, these items get

lost in packaging materials while unpacking or

they are pre-installed at the factory.

AA

Figure 5. Drum sander.Drum sander.

BB

EE

CC

FF

GG

JJ

DD

HH

KK

II

-12 -

Figure 6.

Loose inventory.Loose inventory.

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

Weight Load

equipment that may be installed on the machine,

Physical Environment

The physical environment where your machine

is operated is important for safe operation and

longevity of

machine in a dry environment that is free from

excessive moisture, hazardous

chemicals, airborne abrasives, or extreme

conditions. Extreme conditions for this type

of machinery are generally those where the

ambient temperature

104°F; the relative humidity

of

is subject to vibration, shocks, or bumps.

Electrical Installation

Place this machine near an existing power

source. Make sure all power cords are protected

from traffic, material handling, moisture,

chemicals, or other hazards. Make sure to leave

access to a means of disconnecting the power

source or engaging a lockout/tagout device.

Lighting

Lighting around the machine must be adequate

enough to perform operations safely. Shadows,

glare, or strobe effects that may distract or

impede the operator must be eliminated.

PREPARATION

Location

Physical Environment

Electrical Installation

Lighting

Weight Load

Space Allocation

20–95% (non-condensing); or the environment

parts. For best results, operate this

or flammable

is outside the range of 41°–

is outside the range

Refer to the Machine Specifications for the

weight of your machine. Make sure that the

surface upon which the machine is placed will

bear the weight of the machine, additional

and the heaviest workpiece that will be used.

Additionally, consider the weight of the operator

and any dynamic loading that may occur when

operating the machine.

Space Allocation

Consider the largest size of workpiece that will

be processed through this machine and provide

enough space around the machine for adequate

operator material handling or the installation

of auxiliary equipment. With permanent

installations, leave enough space around

the machine to open or remove doors/covers

as required by the maintenance and service

described in this manual.

Wall

Min. 30"

for Maintenance

36 1/

2

"

= Electrical Connection

Figure 7. Minimum working clearances.Minimum working clearances.

Children or untrained

people may be seriously

2

50 1/

"

Dust Ports

injured by this machine.

Only install in an access

restricted location.

Keep Outfeed Area

Unobstructed

Min. 30"

for Maintenance

Keep Infeed Area

Unobstructed

Wall

-13 -

South Bend Tools

Mo del SB1102

HEAV Y LIFT!

This machine and its parts

are heavy! Serious personal

injury may occur if safe

moving methods are not

used. To reduce the risk of

a lifting or dropping injury,

ask others for help and use

power equipment.

This machine must be fully assembled before it

can be operated. Before beginning the assembly

process, refer to Required for Setup and gather

all listed items. To ensure the assembly process

goes smoothly, first clean any parts that are

covered or coated in heavy-duty rust preventative

(if applicable).

PREPARATION

For Machines Mfd. Since 01/24

Lifting & Placing

DO NOT attempt to lift or move machine without

using a forklift or necessary assistance from

other people.

Review the Power Supply section (Page10)

and Location section (Page13), then prepare a

permanent location for the machine.

IMPORTANT: Make sure prepared location is

clean and level.

To lift and place machine:

1. Move machine near its prepared location

while still inside shipping crate.

Assembly

To assemble machine:

1. Loosen pre-installed hex bolt, and remove

cardboard protection from base of control

panel pedestal.

2. Carefully rotate control panel to upright

position and attach pedestal to side of

machine with (3)

1

⁄4" flat washers, plus the hex bolt and flat

(3)

washer that was loosened in Step 1, as shown

in Figure 8.

Control Control

Panel Panel

PedestalPedestal

1

⁄4"-20 x 1⁄2" hex bolts and

2. Remove top and sides of shipping crate, then

place small items aside in safe location.

3. Unbolt machine from pallet.

4. Carefully lift machine off pallet and move

it to prepared location, then lower machine

into position.

-14-

x 4

Figure 8. Attaching control panel to machine base.Attaching control panel to machine base.

3. Attach handwheel to spindle and tighten pre-

installed set screw, then attach handwheel

handle (see Figure 9).

HandwheelHandwheel

Figure 9. Handwheel and handle attached.Handwheel and handle attached.

Handwheel Handwheel

HandleHandle

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

This machine creates a lot of wood chips/

dust during operation. Breathing airborne dust

on a regular basis can result in permanent

respiratory illness. Reduce your risk by

wearing a respirator and capturing the dust

with a dust-collection system.

PREPARATION

4. Apply 1⁄16" double sided tape to bottom

perimeter of each dust port, then attach to

dust hood as shown in Figure 10.

Dust hoodDust hood

Figure 10. Dust ports attached to dust hood.Dust ports attached to dust hood.

5. Secure dust ports to dust hood with

(8) #8x

washers.

1

⁄2" tap screws and (8) #8 flat

4" Dust Ports4" Dust Ports

Power Connection

Dust Collection

Minimum CFM at each Dust Port: 400 CFM

Do not confuse this CFM recommendation

with the rating of the dust collector. To

determine the CFM at the dust port, you

must consider these variables: (1) CFM

rating of the dust collector, (2) hose type

and length between the dust collector and

the machine, (3) number of branches or

wyes, and (4) amount of other open lines

throughout the system. Explaining how

to calculate these variables is beyond the

scope of this manual. Consult an expert or

purchase a good dust collection "how-to"

book.

Before the machine can be connected to the power

source, there must be an electrical circuit that

meets the Circuit Requirements on Page 10,

and the correct plug must be installed according

to instructions and wiring diagrams provided by

the manufacturer.

If the plug manufacturer did not include

instructions, the wiring of a generic

NEMA L6-30 plug is illustrated in the Wiring

Diagram on Page 46.

To minimize the risk of elctrocution, fire,

or equipment damage, installation work and

electrical wiring MUST be done by an electrician

or qualified service personnel.

To connect machine to dust collect system:

1. Fit (2) 4" dust hoses over dust ports as shown

in Figure 11 and secure in place with (2) hose

clamps.

4" Dust Hose4" Dust Hose

Figure 11. Dust hoses attached.Dust hoses attached.

2. Tug hoses to make sure they do not come

off. A tight fit is necessary for proper

performance.

-15 -

South Bend Tools

Mo del SB1102

PREPARATION

For Machines Mfd. Since 01/24

Test Run

After all preparation steps have been completed,

the machine and its safety features must be

tested to ensure correct operation. If you

discover a problem with the operation of the

machine or its safety components, do not operate

it further until you have resolved the problem.

Note: Refer to Troubleshooting on Page 41 for

solutions to common problems that occur with

all drum sanders. If you need additional help,

contact our Tech Support at (360) 734-1540.

The test run consists of verifying the following:

• Motors power up and run correctly.

• Emergency Stop button works correctly.

Serious injury or death can result from using

this machine BEFORE understanding its

controls and related safety information. DO

NOT operate, or allow others to operate,

machine until the information is understood.

Refer to Figure 12 during Test Run. Each control

has an alphabetical callout for identification.

AA

BB

DD

CC

EE

FF

GG

DO NOT start machine until all preceding

setup instructions have been performed.

Operating an improperly set up machine may

result in malfunction or unexpected results

that can lead to serious injury, death, or

machine/property damage.

Figure 12. Control panel.

To test run machine:

1. Clear all setup tools away from machine.

2. Press Emergency Stop button (B) in.

3. Turn Conveyor Speed Control dial (C) to "0".

4. Connect machine to power source. Digital

readout (A) should illuminate.

— If digital readout does not illuminate,

check power source.

-16-

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

PREPARATION

5. Twist Emergency Stop (B) button clockwise

until it pops out to reset switch (see Figure

13).

— Both motor OFF buttons (E and G) will

illuminate after Emergency Stop button

is reset.

s

i

t

w

T

t

e

s

e

R

o

T

C

l

o

c

k

w

i

s

e

Emergency Stop Button

Figure 13. Emergency Stop button.

6. Press Sanding Drum Motor ON button

(D) to start drum motor (see Figure 12

on Page 16). ON button will illuminate

and sanding drums will start. Sanding

drums should run smoothly with little to no

vibration or rubbing noises.

— If sanding drums are operating smoothly,

proceed to Step 7.

— If sanding drums are not operating

smoothly, turn machine OFF and correct

the problem before continuing. Refer to

Troubleshooting on Page 41 or call

Tech Support for help.

7. Press Conveyor Motor ON button (F) to

start conveyor motor (see Figure 12 on

Page 16). ON button will illuminate.

Turn the Conveyor Speed Control dial (C)

clockwise to increase speed. Conveyor should

move smoothly with little to no vibration or

rubbing noises.

— If conveyor belt is running smoothly,

proceed to Step 8.

8. Push Emergency Stop button (B) to turn

machine OFF.

9. WITHOUT resetting Emergency Stop

button, press Sanding Drum ON button (D)

and Conveyor Motor ON button (F). Motors

should not start.

— If both motors do not start, the

Emergency Stop safety feature is working

correctly. Congratulations, the Test Run

is complete!

— If either motor does start (with

Emergency Stop button depressed),

immediately disconnect machine

from power and DO NOT USE. The

Emergency Stop safety feature must work

properly before proceeding with regular

operations. Call Tech Support for help.

Inspections & Adjustments

The following list of adjustments were performed

at the factory before your machine was shipped:

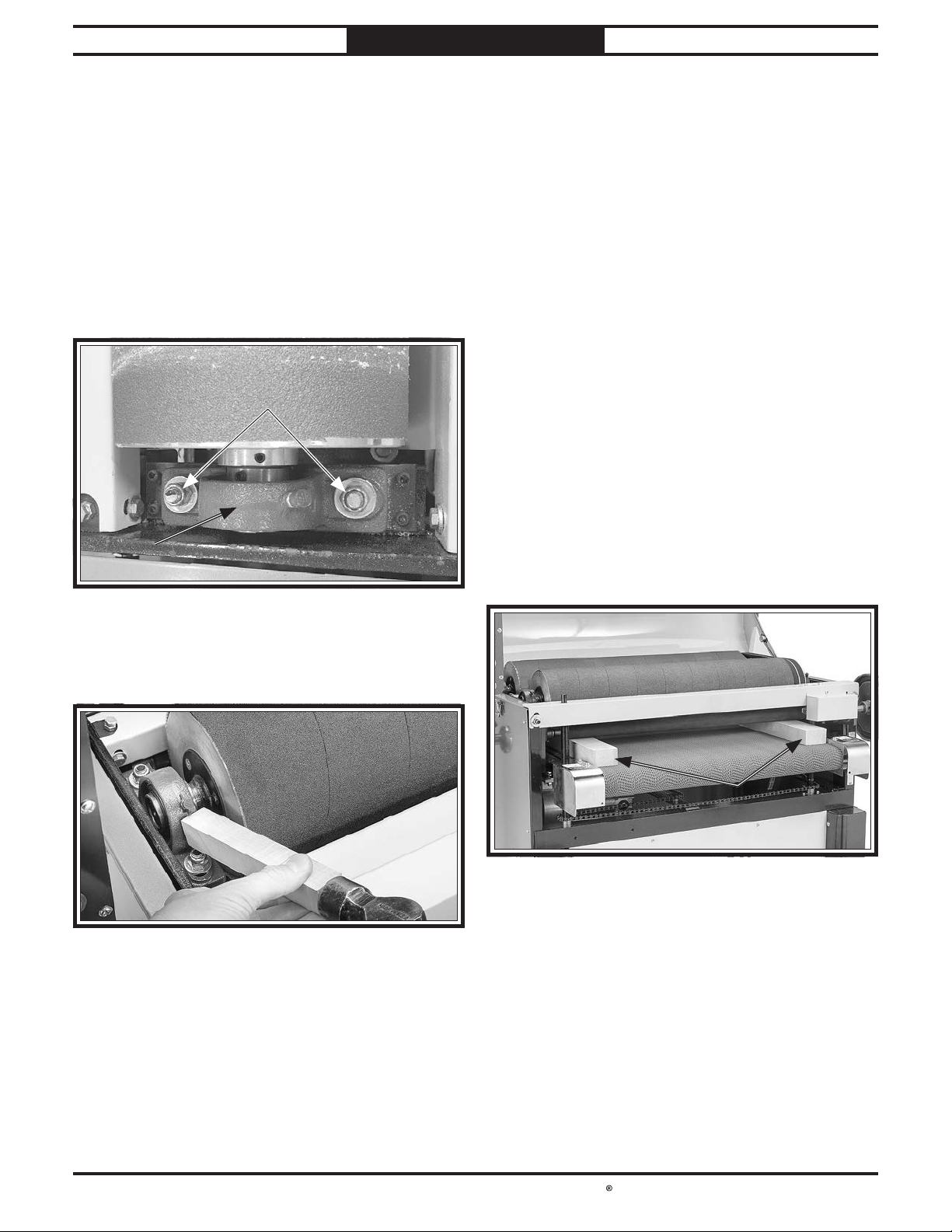

• Drum Alignment ................................. Page 30

• Pressure Roller Height .......................Page 34

• Conveyor Belt Tracking ......................Page 36

• V-Belt Tension .................................... Page 37

Be aware that machine components can shift

during the shipping process. Pay careful

attention to these adjustments as you test run

your machine. If you find that the adjustments

are not set according to the procedures in this

manual or your personal preferences, re-adjust

them.

Note: New V-belts often stretch and loosen up

during the first 16 hours of use. After this period,

they should be inspected and re-tensioned if

necessary.

— If conveyor is not operating smoothly,

turn machine OFF and correct the

problem before continuing. Refer to

Troubleshooting on Page 41 or call

Tech Support for help.

-17-

South Bend Tools

Mo del SB1102

The purpose of this overview is to provide

the novice machine operator with a basic

understanding of how the machine is used during

operation, so they can more easily understand

the controls discussed later in this manual.

Note:

it is not intended to be an instructional guide

for performing actual machine operations.

To learn more about specific operations and

machining techniques, seek training from people

experienced with this type of machine, and do

additional research outside of this manual by

reading "how-to" books, trade magazines, or

websites.

OPERATION

For Machines Mfd. Since 01/24

OPERATION

Operation Overview

Due to the generic nature of this overview,

To reduce the risk of

serious injury when using

this machine, read and

understand this entire

manual before beginning

any operations.

To complete a typical sanding operation, the

operator does the following:

1. Examines workpiece to verify it is suitable

for sanding and determines which sandpaper

grit size to use.

2. Verifies workpiece has necessary outfeed

clearance and support. If workpiece is overly

long and difficult to handle, operator uses a

roller support stand or an assistant to assist

with feeding.

3. Adjusts table height to approximate

workpiece thickness.

Note: During initial pass with a new

workpiece, operator adjusts table height as

necessary so workpiece only makes light

contact with sanding drums and does not

overload sander.

4. Puts on safety glasses, respirator, and any

other required protective equipment.

5. Starts dust collection system and then drum

sander. Waits for sanding drums to reach

full speed and then sets conveyor speed for

the specific type and finish of workpiece.

Loose hair, clothing, or

jewelry could get caught

in machinery and cause

serious personal injury.

Keep these items away

from moving parts at all

times to reduce this risk.

To reduce risk of eye injury

from flying chips or lung

damage from breathing dust,

always wear safety glasses

and a respirator when

operating this machine.

6. Feeds workpiece into sander by placing front

end on infeed side of conveyor table and

supporting back end until workpiece engages

with pressure rollers. Adjusts conveyor

speed as needed to maintain safe amperage

level.

7. Receives workpiece from outfeed side of

conveyor table.

8. Raises height of conveyor table a small

amount (typically

then repeats the feeding process of workpiece

through sander.

9. Changes sandpaper to a finer grit, as needed.

10. Repeats Steps 6–9 as needed, turns sander

OFF, then disconnects it from power.

1

⁄4 rotation of handwheel),

-18 -

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

OPERATION

Stock Inspection & Requirements

Some workpieces are not safe to sand, or they

may require further preparation before they can

be safely sanded without increasing risk of injury

to the operator or damaging the sanding belt or

the sander.

Before sanding, inspect all workpieces for the

following:

• Material Type: This machine is intended

for sanding natural and man-made wood

products, and laminate-covered wood

products. This machine is NOT designed

to sand glass, stone, tile, plastics, drywall,

cementious backer board, metal, etc.

Sanding metal objects can increase the

risk of fire. Sanding improper materials

increases the risk of respiratory harm to the

operator and bystanders due to the especially

fine dust inherently created by all types of

sanding operations—even if a dust collector

is used. Additionally, the life of the machine

and sanding belts may be greatly reduced

(or immediately damaged) from sanding

improper materials.

• Foreign Objects: Tramp metal, nails, staples,

dirt, rocks and other foreign objects are

often embedded in wood. While sanding,

these objects can become dislodged and tear

the sanding belt. Always visually inspect

your workpiece for these items. If they can't

be removed, DO NOT sand the workpiece.

• Wet or "Green" Stock: Sanding wood

with a moisture content over 20% causes

unnecessary clogging and wear on the

sanding belt, increases the risk of kickback,

and yields poor results.

• Excessive Warping: Workpieces with

excessive cupping, bowing, or twisting

are dangerous to sand because they are

unstable and often unpredictable when being

sanded. DO NOT use workpieces with these

characteristics!

• Excessive Glue or Finish: Sanding

workpieces with excess glue or finish will

load up the abrasive, reducing its usefulness

and lifespan.

• Minimum Stock Dimensions: DO NOT sand

boards less than 9" long, 2" wide, and

thick to prevent damage to the workpiece

and to reduce the risk of your hands

contacting the abrasive belt (see Figure 14).

9" Min.

1

/8" Min.

2" Min.

Figure 14. Minimum dimensions for sanding.Minimum dimensions for sanding.

1

⁄8"

Choosing Sandpaper

There are many types of sandpaper rolls to choose

from. We recommend Aluminum Oxide for

general workshop environments. Below is a chart

that groups abrasives into different classes, and

shows which grits fall into each class.

This machine comes from the factory with 80

grit installed on the front drum and 120 grit on

the rear.

Grit Class Usage

36 Extra

Coarse

60 Coarse Thickness sanding

80–100 Medium Removing planer

120–180 Fine Finish sanding.

Rough sawn boards,

thickness sanding,

and glue removal.

and glue removal.

marks and initial

finish sanding.

-19 -

South Bend Tools

Mo del SB1102

OPERATION

For Machines Mfd. Since 01/24

The Model SB1102 allows you to place a different

grit sandpaper on each drum. The front drum

should have a coarser grit than the rear. Usually

this translates into combinations of successive

group types. A common selection for stock that is

planed before being sanded is a 80-100/120-150

grit combination.

The general rule of thumb is to sand a workpiece

with progressively higher grit numbers, with no

one grit increase of more than 50 from one drum

to another. Avoid skipping grits; the larger the

grit increase, the harder it will be to remove the

scratches from the previous grit.

Ultimately, the type of wood you use and your

stage of finish will determine the best grit types

to install on your sander.

Take light passes. Overloading the motor or

pushing the sander to failure weakens the

electrical system. Repeatedly doing so is abuse

to the machine that will cause motor, capacitor,

or circuit breaker damage, which is not covered

under warranty.

• Extend sandpaper life by regularly using a

PRO-STICK® sanding pad (see Page26).

• When sanding workpieces with irregular

surfaces, such as cabinet doors, take very

light sanding passes to prevent gouges. When

the drum moves from sanding a wide surface

to sanding a narrow surface, the load on the

motor will be reduced, and the drum will

speed up, causing a gouge.

• DO NOT edge sand boards. This can cause

boards to kickback, causing serious personal

injury. Edge sanding boards also can cause

damage to the conveyor belt and sandpaper.

• When sanding workpieces with a bow or

crown, place the high point up (prevents the

workpiece from rocking) and take very light

passes.

• Feed the workpiece at an angle to maximize

stock removal and sandpaper effectiveness,

but feed the workpiece straight to reduce

sandpaper grit scratches for the finish

passes.

Sanding Tips

• Replace the sandpaper with a higher grit to

achieve a finer finish.

1

• Raise the table with a maximum of

the height handwheel after each pass until

the workpiece is the desired thickness.

• Reduce snipe when sanding more than one

board of the same thickness by feeding them

into the sander with the front end of the

second board touching the back end of the

first board.

• Feed boards into the sander at different

points on the conveyor to maximize

sandpaper life and prevent uneven conveyor

belt wear.

• DO NOT sand boards less than 9" long, 2"

wide, and

workpiece and the drum sander.

1

⁄8" thick to prevent damage to the

⁄4 turn of

• When removing glue, always use a coarse grit

sand paper and take light passes. This will

reduce the risk of overheating which can plug

the sandpaper and potentially damage the

machine.

Untrained users have an increased risk of seriously injuring themselves with this machine.

Do not operate this machine until you have

understood this entire manual and received

proper training.

-20 -

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

OPERATION

Sanding

DO NOT sand more than one board at a

time. Minor variations in thickness can

cause one board to be propelled by the rapidly spinning sanding drum and ejected from

he machine. NEVER stand directly in front

t

of the outfeed area of the machine. Failure

to do so could result in severe personal

injury.

To sand a workpiece:

1. Adjust table height (refer to Setting Depth

of Cut).

2. Make sure dust-collection hoses and

collection system are secured and turned ON

before starting sander.

3. Turn machine ON and feed workpiece

through sander. To reduce likelihood of

injury, retrieve workpiece by standing to

side of machine—not directly behind outfeed

end.

Setting Depth of Cut

The optimum depth of cut will vary based on

the type of wood, feed rate, and sandpaper

grit. Under most sanding conditions, the

depth should not exceed

of the handwheel). Each full turn of the table

height handwheel raises the conveyor table

approximately 0.020". Attempts to remove

too much material can cause jamming, wood

burning, rapid paper wear or tearing, poor

finish, and belt slippage.

To set depth of cut:

1. Using table height handwheel (see

Figure 15), adjust conveyor table until there

is a small gap between workpiece and sanding

drum.

Note: When adjusting the table to sand a

workpiece, lower and then raise the table

to remove backlash from the adjustment

mechanism.

1

⁄64" (approx. 3⁄4 turn

4. Run wide stock through two or three times

without adjusting table height. Turn stock

180° between passes to ensure an evenly

sanded surface.

Tip: For best sanding results, always sand

with the grain during finish passes.

5. Turn machine OFF.

Table Height Table Height

HandwheelHandwheel

Figure 15. Location of table height handwheel.Location of table height handwheel.

2. Start sanding drums then conveyor and

slowly feed workpiece into sander. SLOWLY

raise conveyor table until workpiece makes

light contact with sanding drums. This

is the correct height to begin sanding the

workpiece.

-21-

South Bend Tools

Mo del SB1102

OPERATION

For Machines Mfd. Since 01/24

Setting Conveyor Speed

The Conveyor Speed Control dial (see Figure 16)

allows you to set the conveyor speed from 0–10

(0–20 FPM). The correct speed to use depends

on the type of stock you are using (hardwood vs.

softwood) and the stage of finish you are at with

that workpiece.

As a general rule, a slower speed will sand the

surface smoother, but runs the risk of burning

the wood; a faster speed will remove material

faster, but runs the risk of overloading the

motor. Use trial-and-error to determine the best

settings for your specific applications.

To set conveyor speed:

1. Turn Conveyor Speed Control dial (see

Figure 16) to "0," and then turn conveyor

motor ON.

2. Turn Conveyor Speed Control dial

clockwise to increase conveyor speed.

Monitoring Sanding Load

The sanding load meter, shown in Figure 17,

displays the amperage draw of the sanding

drum motor. The number shown increases

when you increase the load on the sanding

drums and decreases when you decrease the

load. Use this meter to avoid overloading your

machine with too heavy of a cut.

IMPORTANT: NEVER exceed 25 amps—this

is the maximum that your machine can safely

handle!

Since various types of stock will react

differently with various loads, use trial-anderror to determine the best settings for your

applications. Always start with a small load

and work your way up. We recommend that

you do not push your machine to its maximum

load; instead, make multiple passes or install a

coarser grit paper.

— If conveyor speed is too high, turn dial

counterclockwise to decrease conveyor

speed.

Figure 16. Location of Conveyor Speed Control dial.Location of Conveyor Speed Control dial.

Sanding Sanding

Load MeterLoad Meter

Figure 17. Location of load meter.Location of load meter.

Overloading the motor or pushing the sander

to failure weakens the electrical system.

Repeatedly doing so is abuse to the machine

that will cause motor, capacitor, or circuit

breaker damage, which is not covered under

warranty.

-22-

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

!

OPERATION

Installing/Replacing Sandpaper

The Model SB1102 is designed for 3" hook-andloop sandpaper rolls. This model also uses a

spring clip on both ends of the drum to secure

the ends of the sandpaper. In addition to using

tension to keep the sandpaper tight, the drums

are wrapped with hook-and-loop material that is

used to secure the felt-backed sandpaper.

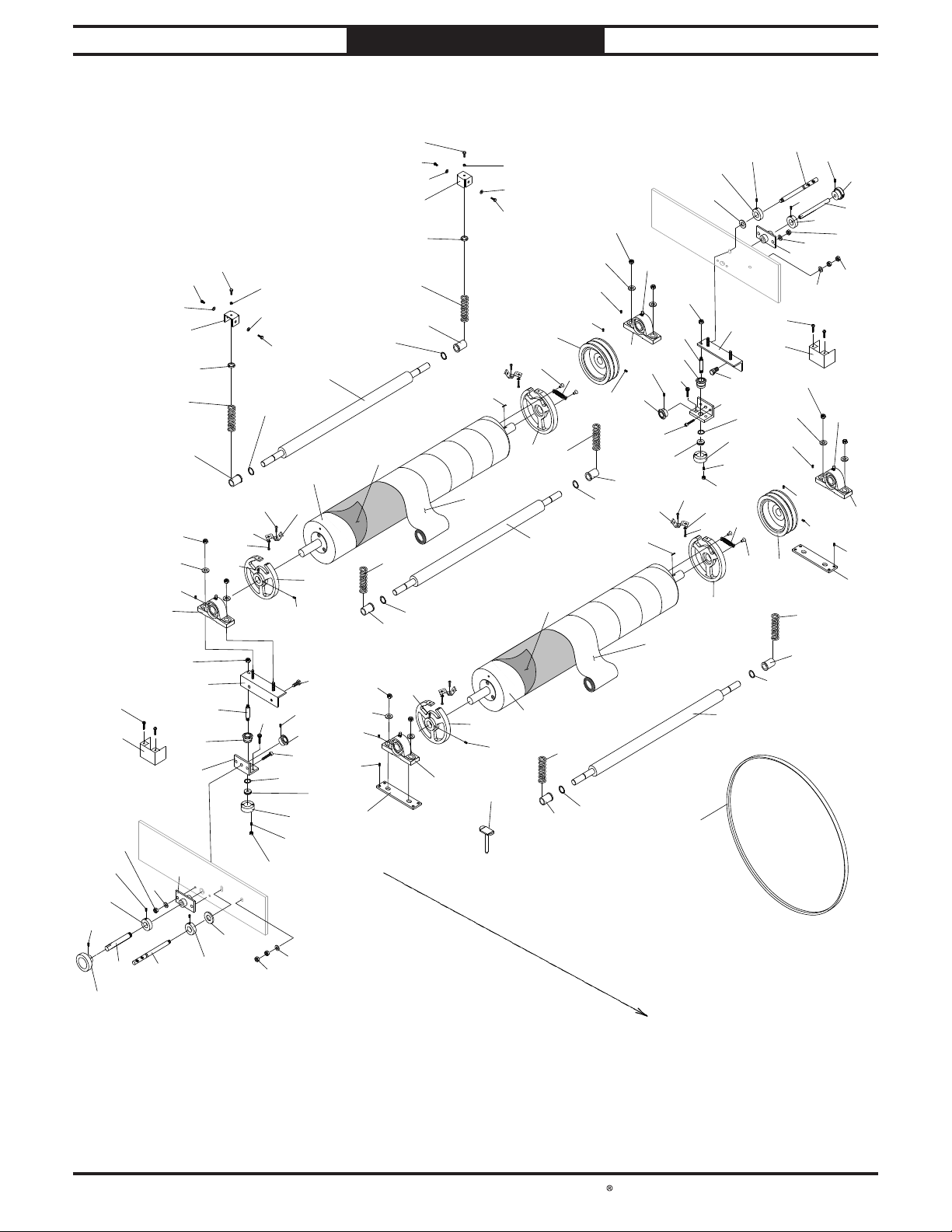

See Figure 18 to become familiar with the

tension wheel components.

Tension WheelTension Wheel

Spring Clip Spring Clip

Tension ScrewTension Screw

Spring ClipSpring Clip

3. Starting with right side of drum, turn

spring clip tension screw counterclockwise

2–3 turns to release spring clip tension, as

shown in Figure 19.

Spring Clip Tension ScrewSpring Clip Tension Screw

Figure 19. Loosening spring clip tension screw.Loosening spring clip tension screw.

4. Insert screwdriver in prying hole in spring

clip, as shown in Figure 20, and press

downward to slightly open spring clip and

release end of sandpaper.

Figure 18. Tension wheel spring clip components.Tension wheel spring clip components.

Items Needed Qty

Phillips Screwdriver #2 ................................ 2

Tension Tool ............................................... 1

Hex Wrench 5mm ........................................ 1

Straightedge 24" ........................................1

Razor Knife ...............................................1

Sandpaper (for each drum) ................ 3 " x 195"

Refer to Accessories on Page 26 for sandpaper

roll part numbers and ordering information.

To install/replace sandpaper:

1. DISCONNECT MACHINE FROM POWER!

2. Open dust hood to expose drums.

Prying HolePrying Hole

Figure 20.

5. Observing direction sandpaper is wrapped

around drum, unwind old sandpaper from

drum.

6. Use method outlined in Steps 3–4 to release

sandpaper from left side of drum, and

remove sandpaper completely.

Location of prying hole in spring clip.Location of prying hole in spring clip.

-23-

South Bend Tools

Mo del SB1102

OPERATION

For Machines Mfd. Since 01/24

7. Use old sandpaper as a pattern to cut new

sandpaper, or measure and cut sandpaper

taper yourself (see Figure 21). Cut 1" off

each tapered end.

DRUM

CIRCUMFERENCE

=

SANDPAPER

HYPOTENUSE

Figure 21. Finding sandpaper taper angle.Finding sandpaper taper angle.

8. Insert screwdriver into rear hole in pulley, as

shown in Figure 22.

1”

10. On left side of drum, use Phillips screwdriver

to pry spring clip slightly open and fold

about 1" of leading end of sandpaper over

tensioning wheel and under spring clip, as

shown in Figure 23.

Figure 23. Inserting leading end of sandpaper under Inserting leading end of sandpaper under

spring clip.spring clip.

11. Turn spring clip tension screw clockwise 2–3

turns to add tension to spring clip.

IMPORTANT: To avoid damage to grease

fitting, position hole in pulley so that

screwdriver is inserted between grease fitting

and machine frame.

9. Turn tension wheel clockwise as far as

tension spring will allow (about 20mm),

then fully insert tension tool in front hole

(see Figure 22), release tension wheel, then

remove screwdriver.

Tension WheelTension Wheel

Tension ToolTension Tool

Inserted ScrewdriverInserted Screwdriver

Grease FittingGrease Fitting

Note: Spring clip tension screw only needs to

be snug. DO NOT overtighten.

12. Carefully wrap sandpaper around drum from

left to right, keeping edges tight and without

any overlap or bubbles in sandpaper.

13. When you have reached the trailing end of

the sandpaper, insert screwdriver back into

rear hole in pulley (see Figure 24).

Screwdriver Screwdriver

Inserted Inserted

into Pulleyinto Pulley

Figure 24. Screwdriver inserted into pulley.Screwdriver inserted into pulley.

Figure 22. Pre-tensioning sandpaper tension wheel.Pre-tensioning sandpaper tension wheel.

-24-

South Bend Tools

For Machines Mfd. Since 01/24 Mo del SB1102

OPERATION

14. Follow procedure in Steps 10–11 to insert

trailing end of sandpaper into right side

spring clip.

— If sandpaper does not line up correctly

with spring clip at trailing end, unwind

sandpaper, then loosen (2)

cap screws and rotate left tension wheel

as necessary (see Figure 25); tighten cap

screws, then follow Steps 10–14 to install

sandpaper.

1

⁄4"-20 x 1⁄2"

Tension Wheel Cap Tension Wheel Cap

Screw (1 of 2)Screw (1 of 2)

Cleaning Sandpaper

When sandpaper becomes clogged with gum and

sawdust, it loses its effectiveness and begins

to create more heat and will eventually fail.

Regularly cleaning your sandpaper will help keep

your machine running efficiently and reduce the

amount of build up.

Refer to Accessories on Page 26 for cleaning

pad part number and ordering information.

To clean sandpaper:

1. Set table to thickness of cleaning pad.

2. Run pad through sander two or three times

in different locations across the width of

drums, as shown in Figure 26. DO NOT take

too deep of a cut—the sandpaper should

barely touch cleaning pad!

Figure 25.

15. Remove tension tool from pulley.

16. Repeat Steps 3–15 for second drum.

Location of tension wheel cap screw.Location of tension wheel cap screw.

Figure 26. Example of using D3003 PRO-STIK® Example of using D3003 PRO-STIK®

cleaning pad to clean sandpaper.cleaning pad to clean sandpaper.

-25-

South Bend Tools

Mo del SB1102

order online at www.grizzly.com or call 1-800-523-4777

ACCESSORIES

ACCESSORIES

Accessories

This section includes the most common

accessories available for your machine through

our exclusive dealer, Grizzly Industrial, Inc., at

grizzly.com.

Installing unapproved accessories may

cause machine to malfunction, resulting in

serious personal injury or machine damage.

To reduce this risk, only install accessories

recommended by South Bend or Grizzly.

Refer to Grizzly’s website or latest catalog for

additional recommended accessories.

For Machines Mfd. Since 01/24

T28000—"Bear Crawl" Mobile Base

With its 1200 lb. capacity, steel and rubber

heavy-duty ball bearing wheels, and toe flipstops, the Grizzly “Bear Crawl” mobile base will

be a staple under your machine for many years to

come. Adjusts from 19" x 21" to 29

Figure 28. T28000 Bear Crawl Mobile Base.T28000 Bear Crawl Mobile Base.

1

⁄2" x 291⁄2"!

Aluminum Oxide Sanding Rolls 3" x 50'

H4422—60-Grit: Use for thickness sanding and

glue removal.

H4779—80-Grit: Use for removing planer marks

and initial finish sanding.

H4423—100-Grit: Use for removing planer marks

and initial finish sanding.

H4780—120-Grit: Use for finish sanding.

H4424—150-Grit: Use for finish sanding.

T21255—180-Grit: Use for finish sanding.

T21256—220-Grit: Use for finish sanding.

D3003–PRO-STIK® 15" x 20" Cleaning Pad

The perfect accessory for wide-belt sanders, just

set your table and feed this cleaning pad through

for longer lasting abrasive belts. Pad measures

15" x 20" x

Figure 29. D3003 PRO-STIK® Cleaning Pad.D3003 PRO-STIK® Cleaning Pad.

3

⁄4" high.

Figure 27. Aluminum oxide sanding roll.Aluminum oxide sanding roll.