Southbend SB-5-ES, SB-10-ES User Manual

Installation & Operations Manual

Oven - Smoker

SB-5-ES / SB-10-ES

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain

this manual for the life of the equipment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

WARNING

Improper installation, adjustment, alteration, service, or maintenance can cause property damage, injury, or death.

Read installation, operation, and maintenance instructions thoroughly before installing or servicing this equipment.

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526 USA • www.Southbend nc.com

MANUAL 1188200 REV 0 (12/06)

$30.00

OVEN / SMOKER

SAFETY PRECAUTIONS OVEN / SMOKER

SAFETY PRECAUTIONS

Before installing and operating this equipment, be sure everyone involved in its operation is fully trained and aware of

precautions. Accidents and problems can be caused by failure to follow fundamental rules and precautions.

The following symbols, found throughout this manual, alert you to potentially dangerous conditions to the operator,

service personnel, or to the equipment.

WARNING

FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

WARNING

Improper installation, adjustment, alteration, service, or

maintenance can cause property damage, injury, or death. Read the

installation, operating, and maintenance instructions thoroughly

before installing or servicing this equipment.

NOTICE

Contact your authorized Service Agency to perform maintenance and repairs.

NOTICE

Using any parts other than genuine Southbend factory-manufactured parts relieves the

manufacturer of all warranty and liability.

NOTICE

Southbend (Manufacturer) reserves the right to change specifications at any time.

KEEP THIS MANUAL IN A VISIBLE LOCATION NEAR THE OVEN FOR FUTURE

REFERENCE.

Copyright © 2006 by Southbend . All rights reserved. Published in the United States of America.

PAGE 2 OF 24 INSTALLATION & OPERATIONS MANUAL 1189200 REV 0 (12/06)

INTRODUCTION

Congratulations! You have purchased one of the finest pieces of heavy-duty commercial cooking equipment on the

market.

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to meet

the toughest standards in the industry. Each piece of Southbend equipment is carefully engineered and designs are

verified through laboratory tests and field installations. With proper care and field maintenance, you will experience

years of reliable, trouble-free operation. For best results, read this manual carefully.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

This manual is for the Southbend Oven/Smoker. Read these instructions carefully before attempting installation.

Installation and initial startup should be performed by a qualified installer. Unless the installation instructions for this

product are followed by a qualified service technician (a person experienced in and knowledg eable of the installation

of commercial gas and/or electric cooking equipment) then the terms and conditions on the Manufacturer’s Limited

Warranty will be rendered void and no warranty of any kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, contact:

Southbend Technical Service

1100 Old Honeycutt Road

Fuquay-Varina, North Carolina 27526 USA

919-552-9161

www.Southbend nc.com

SPECIFICATIONS

NOTICE

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association,

Inc. states in its NFPA 96 latest edition that local codes are the “authority having jurisdiction” when it comes to

installation requirements for equipment. Therefore, installations must comply with all local codes

Southbend reserves the right to change specifications and product design without notice. Such revisions do not

entitle the buyer to corresponding changes, additions, or replacements for previously purchased equipment.

This product is intended for commercial use only, not for household use.

CLEARANCES

There must be adequate clearance between the broiler and adjacent construction due to the heat generated by the

broiler. Clearance must also be provided for servicing and for operation.

The minimum clearance from non-combustible construction is 4” on the sides and 4" on rear (to permit combustion air

to enter the rear of the broiler).

Adequate clearance must be provided in front of the broiler for operation and cleaning.

INSTALLATION & OPERATIONS MANUAL 1189200 REV 0 (12/06) PAGE 3 OF 24

ABOUT YOUR EQUIPMENT Oven / Smoker

SOUTHBEND OVEN/SMOKER

Southbend utilizes separate controls in conjunction with the desired air movement to supply the

desired level of heat and moisture. When using both heat and moisture the temperature of the

unit's atmosphere results from a combination of the heat and moisture sources.

Because of the separate controls it is possible to have a number of different conditions:

• Heat, moisture, natural air • Heat, moisture, fan

• Heat, no moisture, natural air • Heat, no moisture, fan

• Moisture, no heat, natural air • Moisture, no heat, fan

By providing separate controls it is possible to obtain any of the above conditions. In addition to

the above conditions, based on normal heat and moisture conditions, the use of a STEAM or

SMOKE option offers other variations.

The Southbend SB-5-ES and SB-10-ES Smokers are electrically powered and generally do

require exhaust hoods. However, the ultimate decision as to hood requirements rests with your

local authorities. The SB-5-ES stands 41" high (45" if installed with the 4" Appliance Legs) while

the SB-10-ES stands 78" high (including the Casters). Each unit is 32½" deep, 23¾" wide and

takes up less than 5½ square feet of your valuable floor space.

The Southbend SB-5-ES and SB-10-ES are equipped with a positioned air flow system. This

system allows the heated air and/or smoke to circulate completely and evenly around the interior

of the SB-5-ES or SB-10-ES for a uniform and consistent product without having to turn pans. All

processed product can be unloaded at the same time, allowing you to concentrate on things of

more importance without having to remember if and when to turn pans in your smoker.

The SB-5-ES or SB-10-ES can be used to cook, steam or smoke the following products:

• Meats • Fish

• Potatoes • Fowl

• Bacon • Vegetables

All units in this series are designed for the following:

• Automatic pan positioning • Dependability

• Rapid, even processing • Low energy consumption

• Easy cleaning • Low maintenance

• Simple operation • Rapid servicing

The Southbend SB-5-ES has a capacity of up to six (6) full-sized 18" x 26" sheet pans. The SB10-ES has a capacity of thirteen (13) 18" x 26" full-size pans. These pans are supported by

chromed Side Racks to provide a 3½" vertical spacing between pans. Smoke is generated in the

Smoke Box attached to the back wall of the Oven interior, or in the optional side-mounted External

Smoke Box.

Supplemental moisture can be added through the AUTOMIST Humidity System. The AUTOMIST

system adds moisture by injecting a water mist into the Blower Wheel for circulation throughout

the Oven cavity. This water injection is controlled by a Repeat Cycle Timer with a fixed "OFF" time

and a variable "ON" time. The "ON" time is adjusted by setting the Humidity Control on the front of

the unit. A higher setting on the Control allows for a longer water spray in the Oven, resulting in

higher moisture levels.

PAGE 4 OF 24 INSTALLATION & OPERATIONS MANUAL 1189200 REV 0 (12/06)

An optional Programmable Control is also available for the SB-5-ES and SB-10-ES. The

Programmable Control allows you to set and run specific programs as menus complete and total

control of your production program.

A Meat Probe is also available for either Manual or Programmable Control units. The Meat Probe

allows you to use the internal temperature of your product to control the operation of the SB-5-ES

or SB-10-ES. When used with the Hold feature of the Smoker you can load your product in the

morning (or the night before) and not bother with it again until you are ready to use it.

AVAILABILITY FOR TESTING:

A prospective customer may see a unit in operation as follows:

• At an existing installation

• At a dealer's showroom

• At the Southbend manufacturing facility

If contacted, Southbend will provide the information on the nearest location. In the event that a

customer desires to test a unit at his place of business, arrangements can be made based on a

specifically defined program. In the event that a customer wants to try a special product,

arrangements can be made to determine what conditions are necessary for baking so the

customer can determine the suitability for his program.

COMPARISON WITH OTHER UNITS:

Southbend will provide test data or a test unit for the comparison of results with any other unit on

the market; however, Southbend reserves the right to have its designated representatives

available during the test. All results of such comparison tests will be made available to Southbend

and may be used by Southbend. As stated previously, Southbend operating costs compare

favorably with gas convection ovens and our ovens generally do not require hoods. Based on

production of consistent quality products from the Southbend Oven, as well as baking times,

Southbend out-performs the competition.

CONSTRUCTION:

All combination Ovens in this series are constructed of stainless steel inside and outside. All of the

frame members are welded to provide long life construction. Components such as temperature

and humidity controls, timers, switches, motors, heating elements and other such items are

thoroughly tested before shipment. On-going research and development projects are used to

introduce the latest and most dependable parts.

SHIPMENT:

Southbend units are usually shipped directly from the factory or delivered from a dealer, unless

sold at a show or after a test or demonstration. Unless otherwise agreed to by Southbend , freight

is paid by the buyer F.O.B. from the Southbend manufacturing facility in Menominee, Michigan.

Shipping time varies, depending upon the shipping point, the time of year, and shippers used.

Usually Southbend prefers three weeks lead time, but can reduce the time, in some instances, on

an emergency basis.

Southbend employs accepted packaging standards to ensure that your equipment arrives in

excellent condition. However, damage may still occur through negligent handling or accident on

the part of the shipping company. Southbend works closely with all of its customers in tracing

shipments to delivery and to minimize handling.

INSTALLATION & OPERATIONS MANUAL 1189200 REV 0 (12/06) PAGE 5 OF 24

OPERATING INSTRUCTIONS OVEN / SMOKER

RECEIPT AND INSTALLATION

RECEIPT:

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has assumed

responsibility for its safe transit and delivery. If damaged equipment is received, either apparent or concealed, a

claim must be made with the delivering carrier.

Apparent damage or loss must be noted on the freight bill at the time of delivery. The freight bill must then be

signed by the carrier representative (Driver). If the bill is not signed, the carrier may refuse the claim. The carrier

can supply the necessary forms.

A request for inspection must be made to the carrier within 15 days if there is concealed damage or loss that is

not apparent until after the equipment is uncrated. The carrier should arrange an inspection. Be certain to hold all

contents plus all packing material.

A. Inspect the entire perimeter of the package for damage or punctures to the packing material.

This may indicate damage to the unit inside. Call any and all packing damage to the

attention of the delivery person.

B. If any packing damage is found uncrate the unit immediately in the presence of the delivery

person to determine if the unit is damaged. If any damage is found indicate the type and

amount of damage on the shipping documents and notify Southbend at (919) 552-9161

immediately after filing a freight claim.

C. Uncrate the unit carefully and check the entire unit (top, front, back and both sides) for any

visible or hidden damage.

D. Remove the unit from the shipping pallet and inspect the bottom for any damage.

E. If any damage is noted after the driver leaves immediately contact t he freight company and

Southbend.

F. Check each Oven Door. Make sure the Door closes completely, and that the Door Gasket

seals firmly. If the Gasket does not seal correctly please contact the Southbend Service

Department for instructions and assistance in any required adjustments.

INSTALLATION:

A. Check to determine that the power source is the same voltage and phase as that indicated

on the label on the side of the unit.

B. If you have received an SB-5-ES you should attach the included Appliance Legs to the

bottom of the unit. Each Leg stud screws into a th readed h ole in each corner of the base.

C. Position the unit wher e it is to be oper ated and adjust the Applianc e Legs of the SB-5-ES so

the unit stands level and solid. If you have an SB-10-ES you may need to use metal shims

under the Casters to level the uni t.

D. For the SB-5-ES: Make sure the GREASE PAN is installed inside the bottom of the unit. This

PAN will catch most of the drippings from your product as it is processed, making clean-up

that much easier.

For the SB-10-ES: Make sure the GREASE PAN is installed beneath the unit. This PAN will

catch the liquid that accumulates in the bottom of the unit while you are processing your

product.

E. Carefully set all Controls and Switches to their OFF positions.

PAGE 6 OF 24 INSTALLATION & OPERATIONS MANUAL 1189200 REV 0 (12/06)

OVEN / SMOKER INITIAL START-UP

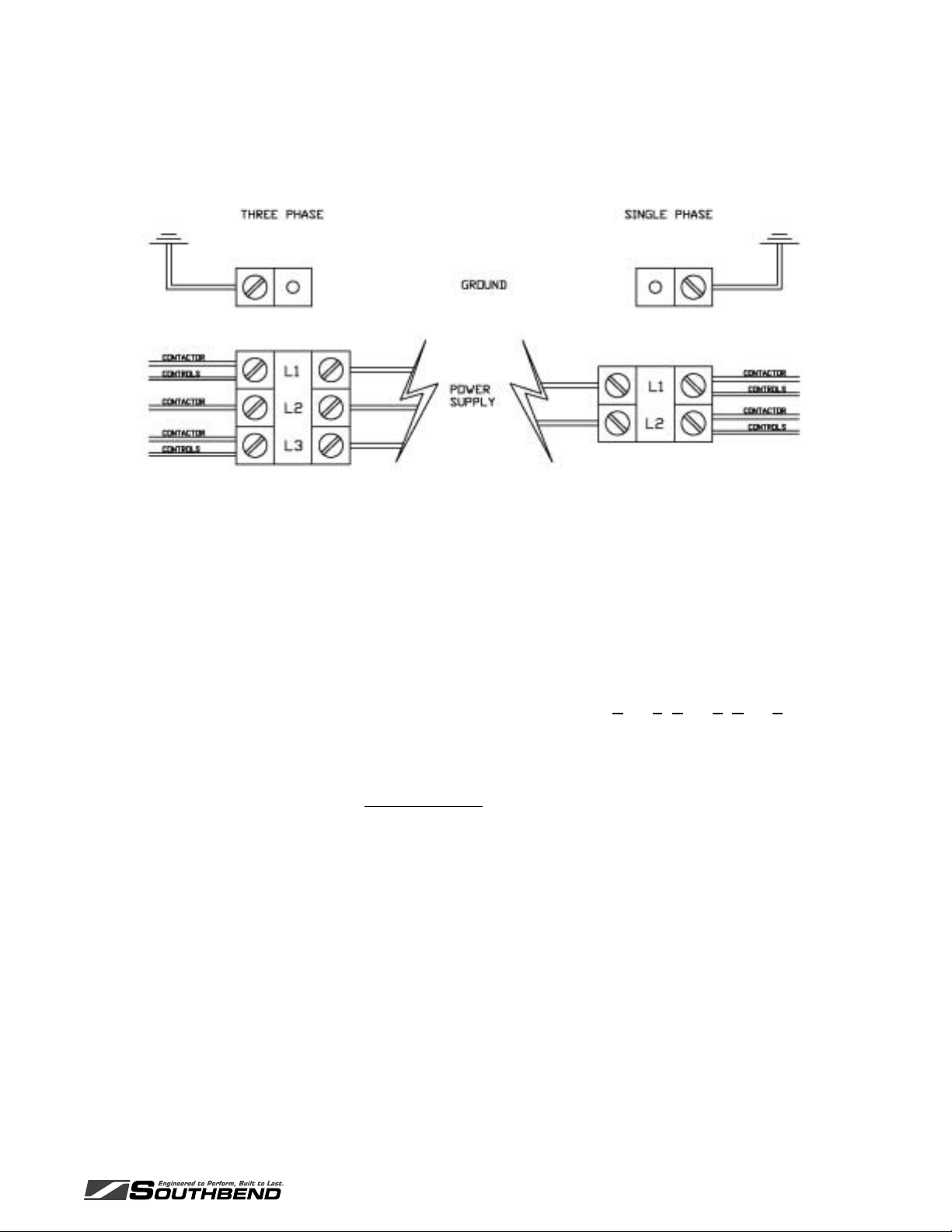

ELECTRICAL CONNECTIONS

F. Install the water supply if your unit was ordered with the optional AUTOMIST feature (refer to

WATER SUPPLY CONNECTION on the following page).

G. The installing technician or electrician should complete the electrical connections by

removing the Outside Top of the unit (this panel is pressed onto the top of the unit and

should lift off easily). Connect the unit to the available power supply either through an

attached cord and receptacle or through direct wiring by following these steps:

1.Take note of the labeling on the Power Terminal Block (Line 1, Line 2, Line 3, ).

2.Carefully identify the power source leads and attach them to the appropriate terminal

connections. Make sure all connections are clean and tight.

3.Properly ground the unit BEFORE USE by attaching a grounding wire to the Ground Lug

or Clamp provided next to the Power Terminal Block.

4.Allow enough slack in the wiring to allow for equipment to be moved about during

installation and any future servi cing .

H. Check the voltage at the terminals on the Power Terminal Block with a voltmeter and

compare the values with the label listings on the side of the Oven. If the values match the

unit is ready for its INITIAL START–UP. If the readings DO NOT coincide you must call the

Southbend Service Department for instructions on changing the voltage and/or the phase.

I. Carefully position the Outside Top on the unit but do not press it into place. Position the unit

in its final operating location and refer to the appropriate INITIAL START–UP PROCEDURE

for your Smoker.

INSTALLATION & OPERATIONS MANUAL 1189200 REV 0 (12/06) PAGE 7 OF 24

OPERATING INSTRUCTIONS OVEN / SMOKER

IMPORTANT: FAILURE TO FOLLOW THESE INSTRUCTIONS, FAULTY

INSTALLATION OR IMPROPER USE MAY CAUSE SEVERE EQUIPMENT

DAMAGE OR PERSONAL INJURY, AND MA Y A LSO VOID ALL OR PART

OF YOUR Southbend EQUIPMENT WARRANTY!!!

WATER SUPPLY CONNECTION:

IMPORTANT: Southbend strongly recommends that SOFT WATER only be used in any unit

requiring a water supply. Also, a good quality water filter MUST be installed in-line between the unit

connection and the water supply to guard against clogging and mineral build-up in the components.

This is extremely important in areas having hard water. This filter may be installed at the water

source or adjacent to the Water Inlet Fitting on the Smoker, whichever is more convenient for you.

This equipment is to be installed to comply with the federal, state and local plu mbing codes having

jurisdiction.

To correctly install a water supply to your SB-5-ES or SB-10-ES Smoker:

A. Run the correct size tubing from the water supply to the unit's location; this tubing should be at

least as big as the Water Inlet Fitting (¼") on the back of the unit. Allow some slack for final

unit positioning and service. Avoid any kinks or strains on the tubing and place the tubing

where it will not be damaged in any way.

B. The tubing end that attaches to the back of the Smoker must not be damaged or deformed in

any way. The cut end should be cut straight and clean with no deforming of the tubing. All

burrs and sharp edges should be removed to ensure a proper and leak-free connection.

C. Position the tubing so that the tubing runs straight into the Water Inlet Fitting. Be careful not to

kink the tubing if you bend it, and do not bend the tubing within two (2) inches of the end.

D. The two-part compression fitting (tapered coll ar and nut) is placed approximately 1" onto the

tubing so that the collar is inside of the nut and the threaded opening of the nut is toward the

Water Inlet Fitting.

E. Push the tubing all the way into the Water Inlet Fitting (approximately ¼") and hold it there

while you thread the compression nut onto t he Water Inlet Fitting. Us e an open-end wrench

to slowly tighten the compression nut until it is just snug, but d o not over-tighten t he fitting! If

the joint leaks when tested and further gentle tightening does not stop the leak the two-part

compression fitting mu st be replac ed .

Careful attention to these simple procedures will help to ensure an installation without leaks.

If you have any questions or problems please call the Southbend Service Department at

(919) 552-9161.

PAGE 8 OF 24 INSTALLATION & OPERATIONS MANUAL 1189200 REV 0 (12/06)

Loading...

Loading...