Page 1

MODEL SB1044

This item was carefully packaged to prevent

damage during transport. If you discover any

damage, please immediately call Customer

Service at (360) 734-1540 for advice. You may

need to file a freight claim, so save the containers

and all packing materials for possible inspection

by the carrier or its agent.

CUTTING FLUID KIT

Instruction Sheet

PHONE: (360) 734-1540 • www.southbendlathe.com

BIOLOGICAL & POISON

HAZARD!

Use the correct personal

protection equipment

when handling cutting

fluid. Follow federal, state,

and fluid manufacturer

requirements for proper

disposal.

Introduction

This cutting fluid kit is for the Model SB1029

Surface Grinding Machine. The system is

designed to pump water-soluble cutting fluid to

minimize grinding wheel wear, load-up, glazing,

and heat. Using cutting fluid helps maximize

the quality of workpiece results, especially on

materials that should not be ground dry.

Figure 1. Model SB1044.

Unpacking

Specifications

• Motor .......................................................1⁄8 HP

• Phase & Cycle .................3-Phase & 50/60 Hz

• Voltage ............................................220V/440V

• Current ..................................... 0.3/0.15 Amps

• Pump Type ..................................................Jet

• Pump Flow ........................................ 8.2 GPM

• Cutting Fluid Type ......... Water-Soluble Only

• Maximum Tank Capacity ...................... 9 Gal.

• Net Weight .............................................73 lbs

• Country of Origin ................................ Taiwan

If you need help with your new model

SB1044 Cutting Fluid Kit, contact us at:

PHONE: (360) 734-1540

FAX: (360) 676-1075

EMAIL: sales@southbendlathe.com

WARNING: No portion of this manual may be reproduced without written approval.

Copyright © December, 2010 by South Bend Lathe Co.

#CR13482 Printed in Taiwan

Inventory

Item: Qty

• Tank Assembly w/Pump ................................1

—Drain Hose 1

—Hose Clamp 1

—Delivery Hose

—Hose Clamp 1

—Flex Conduit Power Cord 9' .......................1

—Drain Adapter .............................................1

—Swivel Caster Wheels .................................4

• Splash Guard .................................................1

—Button Head Cap Screw M6-1 x 10 ........... 4

—Front & Rear Splash Panel .................. 1 Ea

• Coolant Trough ..............................................1

3

⁄4" x 5' ....................................1

3

⁄4" ........................................ 1

1

⁄2'' x 9' .................................1

3

⁄4'' .........................................1

Page 2

Model SB1044

Spash

Po r t

Tank

Trough

Power

Cord

Guard

Shield

Drain

Hose

Connect Delivery

Hose to Desired

Cutting Fluid Nozzle

SB1029

Chip

Cover

Drain

INSTRUCTIONS

Installation

During the installation process of your cutting

fluid kit, you'll need the following items:

For Power Connection

• Apowersourcethatmeetstheminimum

circuit requirements for this machine.

• Aqualifiedelectriciantoensureasafeand

code-compliant connection to the power

source.

For Assembly

• Phillips Screwdriver #2

• Cotton Rags and Silicone Sealant

• Hex Wrenches 3, 5mm

• Safety Goggles

• Wrench 27mm

Mfg. Since 6/10

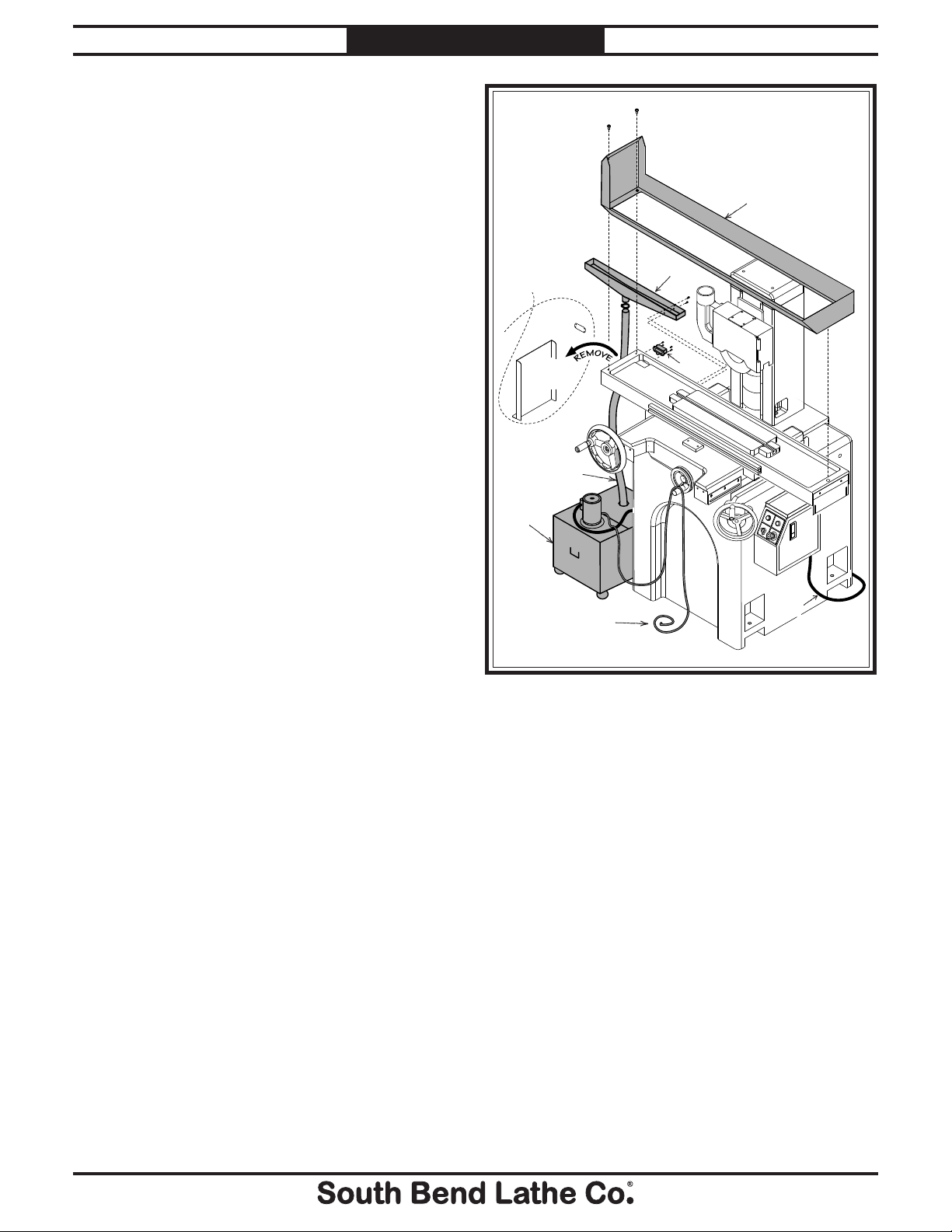

To install the cutting fluid kit:

1. DISCONNECT THE SURFACE GRINDER

FROM POWER.

2. Fasten the four swivel caster wheels to the

tank, and make sure the drain plug is tight.

Tip: Place one or more strong magnets at the

bottom of the tank to collect fine metal

particles from the cutting fluid.

3. Route the pump power cord around the

backside of the surface grinder, or fasten it

up and away from the floor.

4. Connect the SB1044 power cord to the

surface grinder as outlined on the Model

SB1029 Pump Connection Wiring

Diagram on Page 7.

If the surface grinder uses a 440V power

supply, the pump motor must be rewired as

shown in the OPTIONAL 440V 3-PHASE

CONNECTION diagram on Page 7.

5. Remove the existing chip shield and drain

cover from the table, as shown in Figure 2.

Retain the fasteners to install the SB1044

splash guard and port.

Note: For shipping purposes, the front and rear

splash panels are fastened together with four

wing nuts on the rear splash guard wall.

-2-

Figure 2. Cutting fluid system installation.

6. Apply silicone sealant to the mounting flange

of the port shown in Figure 2.

7. Using the fasteners from the machine in

Step 5, install the port, splash guard, and

the trough to the machine, as shown in

Figure 2.

8. Insert one end of the drain hose into the

tank, and fasten the other end to the trough

using the hose clamp.

9. Route the delivery hose out of the way and

fasten the delivery hose to your desired

cutting fluid nozzle with the hose clamp.

10. Fill the tank with premixed water soluble

cutting fluid.

Page 3

Mfg. Since 6/10 Model SB1044

INSTRUCTIONS

Operation

Only use high quality water-soluble cutting

fluid in this system. Never attempt to pump

straight cutting oils or kerosene. If you do, the

higher viscosity of the oil will overload the motor,

causing damage, or flammable liquids may

ignite.

Following the cutting fluid manufacturer’s

guidelines, check and maintain the specific

gravity of the cutting fluid to its required level.

Change the fluid when it becomes overly dirty,

rancid, or contaminated.

BIOLOGICAL & POISON

HAZARD!

Use the correct personal

protection equipment

when handling cutting

fluid. Follow federal, state,

and fluid manufacturer

requirements for proper

disposal.

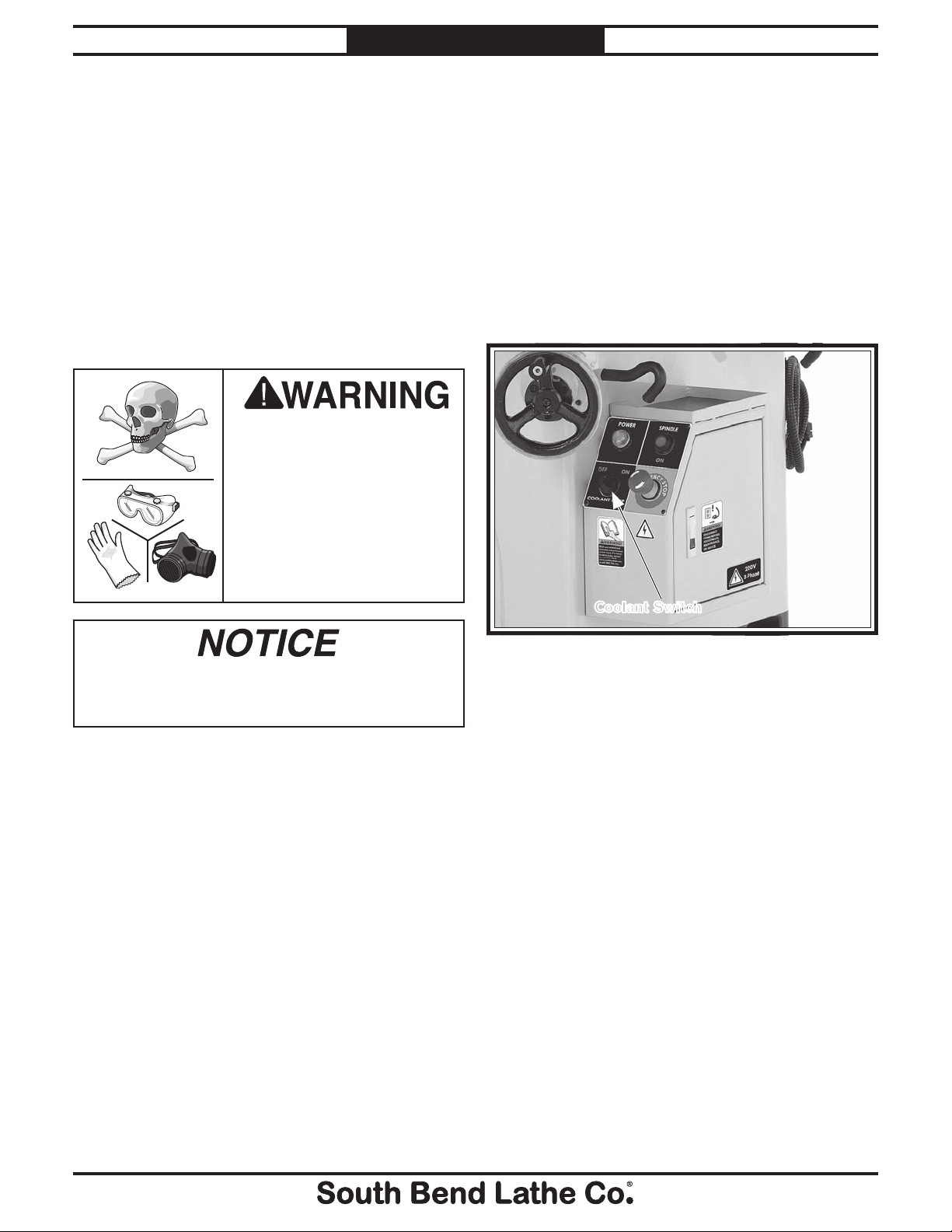

To use the cutting fluid system:

1. Make sure the cutting fluid is properly

serviced and the tank is filled.

2. Put on the necessary personal protection

equipment.

3. Position the cutting fluid nozzle for your

operation.

4. Use the control panel coolant switch to turn

the cutting fluid pump ON.

Coolant Switch

Running the pump without adequate fluid in

the tank may permanently damage it. This

damage is not covered by warranty.

Figure 3. SB1029 control panel.

5. Adjust the flow of cutting fluid for the type of

flooding required.

Note: Promptly clean any splashed cutting fluid

from the floor to avoid a slipping hazard.

-3-

Page 4

Model SB1044

INSTRUCTIONS

Maintenance

When you replace the old cutting fluid, take the

time to thoroughly clean out both sides of the

tank. Make sure to dispose all old fluid according

to local regulations. Cutting fluid is considered

hazardous waste by the EPA. Follow all disposal

and storage guidelines when changing and

disposing of cutting fluid.

Tip: Maintaining the specific gravity of cutting

fluid with a hydrometer or refractometer can

greatly extend the life of cutting fluid and

reduce operating costs. Properly maintained

cutting fluid allows for better cutting and longer

grinding wheel life.

Items Needed: Qty

New Pre-Mixed Cutting Fluid ................ 9 Gallons

Safety Goggles ....................................................... 1

Rubber Gloves ...............................................1-Pair

Wrench 28mm ....................................................... 1

5-Gallon Bucket w/Lid .......................................... 2

Hex Wrench 3mm .................................................1

Hot Soapy Water or Mineral Spirits .... As Needed

Waste Coolant Drain Hose ................... As Needed

Cotton Rags ........................................... As Needed

Mineral Spirits ...................................... As Needed

Magnets .................................................... Optional

Mfg. Since 6/10

Leaving the pump running with an empty

cutting fluid tank can damage a pump. Shut

the pump OFF immediately when the fluid

slows or stops coming from the drain hose.

6. When the fluid stops flowing, immediately

turn the pump OFF, and disconnect the

drain hose.

7. Disconnect the machine from power, lift the

pump and cover from the tank, and set it

aside for cleaning and inspection.

8. Remove the drain plug, and pour the

remaining cutting fluid from the tank into

the 5-gallon bucket.

9. Seal the buckets with their lids.

10. Mark or tag the buckets as hazardous waste

(according laws and regulations).

11. Using a solution of soapy hot water and rags,

clean and dry the tank, the pump, and the

cover. If the tank residue is oily, clean with

mineral spirits instead of soapy water.

To change the cutting fluid:

1. Remove the four button head screws and

washers from the tank cover.

2. Open the tank cover so the cutting fluid can

be seen.

3. Fasten the waste coolant drain hose to

the coolant nozzle. If the connection is

questionable, use a hose clamp to ensure it

does not leak.

4. Place the other end of the drain hose into one

of the 5-gallon buckets. Clip or wire the hose

in place so it won’t come out of the bucket

when the pump is turned ON.

5. Open the flow lever on your cutting-fluid

nozzle all the way open, and turn the cutting

fluid pump ON. Do not leave the area as

you will need transfer the hose to the other

bucket to prevent over-filling and spills.

Tip: Place one or more strong magnets at the

bottom of the tank to collect fine metal

particles from the cutting fluid.

12. Reinstall the drain plug.

13. Mix the new cutting fluid with water in

the required ratio until the fluid reaches

the specific gravity indicated by the fluid

manufacturer.

14. Pour the cutting fluid into the tank. To

prevent the pump from running dry, never

use less than four gallons of cutting fluid.

15. Point the cutting fluid nozzle into the coolant

trough and open the valve.

16. Turn the machine and pump ON to verify

that fluid cycles properly, then turn it OFF.

-4-

Page 5

Mfg. Since 6/10 Model SB1044

INSTRUCTIONS

Troubleshooting

Symptom Possible Cause Possible Solution

Little or no cutting

fluid is being

pumped. Pump and

motor may also

vibrate or be noisy.

1.

No power; voltage is incorrect.

2.

Blown fuse/tripped circuit breaker

at main panel.

3.

Coolant level is too low, and pump

cavitation is occurring.

4.

Coolant is incorrect, or is too thick

and incorrectly mixed.

5.

Pump is operating in reverse.

6.

Motor or cover is loose.

Debris is obstructing pump suction

7.

or impeller is damaged.

8.

Plug or receptacle is corroded or

mis-wired.

9.

Break or short in wiring; or loose

connections.

10.

Pump ON/OFF switch at fault.

11.

Motor connection wired incorrectly.

12.

Emergency stop button is at fault.

13.

Thermal relay has tripped.

14.

Transformer is at fault.

15.

Contactor not energized/has poor

contacts.

16.

Motor at fault.

1.

Switch power supply ON/verify machine and pump

voltages match.

2.

Correct the cause of overload, then reset/replace

fuse or breaker.

3.

Fill coolant tank with a minimum of four gallons of

cutting fluid.

4.

Use water-soluble cutting fluid, or add water to

lower fluid viscosity.

5.

Pump power supply wires are connected out of

phase. Swap any two pump power supply power

leads.

6.

Tighten any loose fasteners.

Remove pump, remove impeller cover, clean and

7.

replace as required.

8.

Clean/retighten contacts; correct the wiring.

9.

Trace/replace broken or corroded wires; fix loose

connections.

10.

Replace switch.

11.

Wire motor correctly (refer to inside junction box

cover or manual).

12.

Reset or replace emergency stop switch assembly.

13.

Improve pump motor cooling and airflow.

Disconnect machine from power, manually reset

thermal relay, and slightly turn-up trip setting.

14.

Test/replace transformer.

15.

Test all legs for power, test field coil and replace if

at fault.

16.

Test for shorted windings, bad bearings and repair

or replace.

-5-

Page 6

Model SB1044

1. Shock Hazard: It is extremely dangerous to

perform electrical or wiring tasks while the

machine is connected to the power source.

Touching electrified parts will result in

personal injury including but not limited to

severe burns, electrocution, or death. For

your own safety, disconnect machine from

the power source before servicing electrical

components or performing any wiring tasks!

2.

Wire Connections: All connections must be

tight to prevent wires from loosening during

machine operation. Double-check all wires

disconnected or connected during any wiring

task to ensure tight connections.

3.

Modifications: Using aftermarket parts or

modifying the wiring beyond what is shown

in the diagram may lead to unpredictable

results, including serious injury or fire.

4.

Motor Wiring: The motor wiring shown

in these diagrams is current at the time of

printing, but it may not match your machine.

Always use the wiring diagram inside the

5.

Circuit Requirements: Connecting the

machine to an improperly sized circuit will

greatly increase the risk of fire. To minimize

this risk, only connect the machine to a

power circuit that meets the minimum

requirements given in this manual.

6.

Capacitors/Inverters: Some capacitors and

power inverters store an electrical charge for

up to 10 minutes after being disconnected

from the power source. To reduce the risk of

being shocked, wait at least this long before

working on capacitors.

7.

Wire/Component Damage: Damaged wires

or components increase the risk of serious

personal injury, fire, or machine damage. If

you notice that any wires or components are

damaged while performing a wiring task,

replace those wires or components before

completing the task.

8.

Experiencing Difficulties: If you are

experiencing difficulties understanding the

information included in this section, contact

The photos and diagrams included in this section are best viewed in color. You can

see them in color at www.southbendlathe.com.

BLACK

WHITE

GREEN

RED

BLUE

BROWN

G RAY

ORANGE

YEL LOW

YEL LOW

GREEN

PURPLE

PINK

LIGHT

BLUE

BLUE

WHITE

TURQUIOSE

NOTICE:

WIRING DIAGRAM COLOR KEY

INSTRUCTIONS

Mfg. Since 6/10

Electrical Safety Instructions

These pages are accurate at the time of printing. In the constant effort to improve, however, we may

make changes to the electrical systems of future machines. Study this section carefully. If you see

differences between your machine and what is shown in this section, call Technical Support at (360)

734-1540 for assistance BEFORE making any changes to the wiring on your machine.

-6-

Page 7

Mfg. Since 6/10 Model SB1044

!

AMP

THER MAL

RELAY

CONTACTOR

Allen Bradley

C09400

3 5 7L1 L2 L3

2 4 6 8T1 T2 T3 T4

95

4

5

6

96 NONC 97 98

8

O

U V W

Ground

3

2

1

4

6

5

Gn

Ground

PREWIRED

220V 3-PHASE

CONNECTION

W1

V1

U1

T

S

R

U1

W

V

U

0

7

6

4

3

2

R1

T1

1

GND

T1

R1

R1

R1

1

1

1

1

2

2

2

3

3

6 7

3

3

0

0

UUV

V R S T

R S T

W W1V1U1

W

4

4

4

1

Fuses

4A

0

W1

V1

U1

W1V1U1

NO 98

Ground

3

2

1

4

6

5

W1

V1

U1

Gn

OPTIONAL

440V 3-PHASE

CONNECTION

T

S

R

U1

W

V

U

0

7

6

4

3

2

R1

T1

1

GND

T1

R1

R1

R1

1

1

1

1

2

2

2

3

3

6 7

3

3

0

UUV

V R S T

R S T

W W1V1U1

W

4

4

4

1

To Control

Panel

Fuses

4A

0

W1

V1

U1

W1V1U1

INSTRUCTIONS

Model SB1029 Pump Connection Wiring Diagram

If the pump motor runs in a

counterclockwise direction as

viewed through the motor shaft

sight glass, disconnect machine

from power and swap wire

positions U1 and V1 on the

terminal bar shown below.

SB1029 Surface

Grinder

-7-

Page 8

Model SB1044

This quality product is warranted by South Bend Lathe Company to the original buyer for one year

from the date of purchase. This warranty does not apply to consumable parts, or defects due to any

kind of misuse, abuse, negligence, accidents, repairs, alterations or lack of maintenance. We do not

reimburse for third party repairs. In no event shall we be liable for death, injuries to persons or

property, or for incidental, contingent, special or consequential damages arising from the use of our

products.

We do not warrant or represent that this machine complies with the provisions of any law, act, code,

regulation, or standard of any domestic or foreign government, industry, or authority. In no event

shall South Bend’s liability under this warranty exceed the original purchase price paid for this

machine. Any legal actions brought against South Bend Lathe Company shall be tried in the State of

Washington, County of Whatcom.

This is the sole written warranty for this machine. Any and all warranties that may be implied by

law, including any merchantability or fitness, for any purpose, are hereby limited to the duration of

this warranty. To take advantage of this warranty, contact us by mail or phone to give us the details

of the problem you are having.

Thank you for your business and continued support.

REF PART # DESCRIPTION

1 PSB1044001 CUTTING FLUID TANK

2 PSB1044002 HINGED TANK COVER

3 PSB1044003 MOTOR/PUMP 1/8HP 3-PH 220V/440V

4 PSB1044004 FLUID DELVERY HOSE 1/2" X 9ft

5 PSB1044005 ELBOW FITTING

6 PSB1044006 SWIVEL CASTER

7 PSB1044007 SPLASH GUARD

8 PSB1044008 COOLANT TROUGH

9 PSB1044009 DRAIN PORT

10 PBHS09M BUTTON HD CAP SCR M6-1 X 12

11 PWN01M WING NUT M6-1

12 PSBHS35M BUTTON HD CAP SCR M5-.8 X 10

13 PCAP26M CAP SCREW M6-1 X 12

14 PCAP24M CAP SCREW M5-.8 X 16

15 PBHS03M BUTTON HD CAP SCR M8-1.25 X 16

16 PW01M FLAT WASHER 8MM

17 PW02M FLAT WASHER 5MM

18 PW03M FLAT WASHER 6MM

19 PSB1044019 REAR SPLASH PANEL

20 PSB1044020 FRONT SPLASH PANEL

21 PSB1044021 HOSE CLAMP 1-3/4"

22 PSB1044022 DRAIN HOSE 1-3/4" X 5ft

23 PSB1044023 PLUG

24 PSB1044024 FLEX-CONDUIT POWER CORD 9ft

25 PSB1044025 STRAIN RELIEF

26 PSB1044026 HOSE CLAMP 3/4"

1

5

26

24

2

14

18

7

11

20

18

19

23

17

12

17

9

8

15

16

13

18

6

22

21

10

3

4

26

17

25

12

INSTRUCTIONS

Parts ListParts Diagram

Mfg. Since 6/10

Please Note: We included this parts breakdown for

service purposes only. Not all parts may be available as

individual items.

Warranty

-8-

Loading...

Loading...