Page 1

MODEL SB1038F

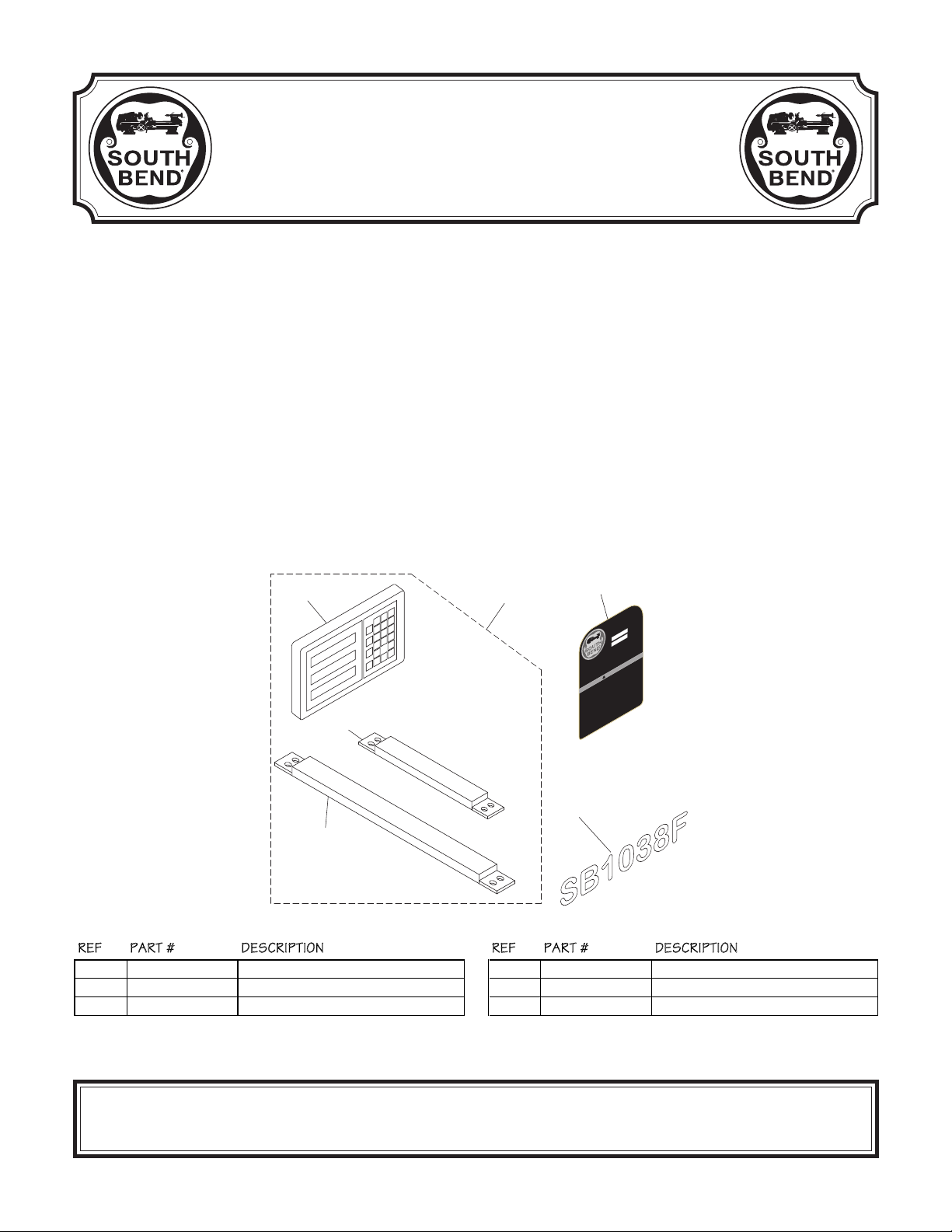

REF PART # DESCRIPTION REF PART # DESCRIPTION

2318 PSB1037F2318 DRO ASSEMBLY FAGOR 2-AXIS 2318-3 PSB1014F2318-3 DRO Y-AXIS SCALE FAGOR MKT-27

2318-1 PSB1014F2318-1 DRO DISPLAY FAGOR 20-iT 2407 PSB1038F2407 MACHINE ID LABEL

2318-2 PSB1037F2318-2 DRO X-AXIS SCALE FAGOR MKT-102 2416 PSB1038F2416 MODEL NUMBER LABEL

MODEL SB1038F

16" x 40" EVS

TOOLROOM LATHE

w/DIGITAL READOUT

TO REDUCE THE RISK OF SERIOUS PERSONAL INJURY WHILE USING THIS

MACHINE:

WARNING!

!

Motor: 7.5HP, 440V, 3-Ph, 60Hz

Full Load Amp Draw 10.75A

Swing Over Bed: 16.14"

Distance Between Centers: 40"

Swing Over Cross Slide: 10.375"

Swing Over Gap: 22.95"

Spindle Nose to Gap (max.): 6.5"

Cross Slide Travel: 9"

Compound Travel: 5.1"

Spindle Nose: D1-6 Camlock

Spindle Bore: 2-1/16"

Spindle Taper: MT#6

Tailstock Taper: MT#4

Weight: 3080 lbs.

1. Read and understand manual before starting.

2. Always wear approved eye protection.

3. Make sure the machine is connected to a grounded power source.

4. Keep all guards in place.

5. DO NOT wear loose clothing, gloves, or jewelry; secure long hair and

roll up long sleeves.

6. Disconnect power before service, maintenance, or adjustments.

7. DO NOT operate when tired or under the influence of drugs or alcohol.

8. Make sure the machine is properly adjusted/set up before starting.

9. Change cutting fluid regularly and avoid contact with skin.

10. Make sure workpiece is properly and securely held in the chuck and has

safe clearance through full rotation before starting the lathe.

11. Never leave the chuck key in the chuck.

12. Never touch the chuck or workpiece when it is in motion.

13. Never leave the lathe running unattended.

14. Make sure long workpieces are properly supported.

15. Always use the proper speed rate for the material you are turning.

16. Do not allow children to have unsupervised access to the machine.

2416

2407

2318

2318-1

2318-3

2318-2

16" X 40" LATHE 440V w/DRO

Manual Insert

PHONE: (360) 734-1540 • www.southbendlathe.com

The Model SB1038F Lathe is the same machine as the Model SB1038 except for the following:

• Addeda2-AxisFagorDigitalReadout(DRO).

Exceptforthedifferencesnotedinthisinsert,allothercontentintheModelSB1038Owner’sManual

appliestothismachine.Beforeoperatingyournewlathe,youMUSTreadandunderstandthisinsert,

theentireModelSB1038Owner’sManual,andtheFagorDROOwner’sManualtoreducetheriskof

injurywhenusingthismachine.Keepthisinsertforlaterreference.

IfyouhaveanyfurtherquestionsaboutthismanualinsertorthedifferencesbetweentheModel

SB1038FandtheModelSB1038,contactourTechnicalSupportat(360)734-1639oremail

sales@southbendlathe.com.

New & Changed Parts

Copyright © June, 2011 by South Bend Lathe Co.

WARNING: No portion of this manual may be reproduced without written approval.

#BL14238 Printed in USA

Page 2

Model SB1038F

South Bend 16" x 40" Lathe 440V with DRO

Product Dimensions

Weight........................................................................................................................................................... 3107 lbs.

Width (side-to-side) x Depth (front-to-back) x Height..................................................................... 86 x 33 x 61 in.

Footprint (Length x Width).................................................................................................................

82 x 19-1/2 in.

Shipping Dimensions

Type..................................................................................................................................................

Wood Slat Crate

Content.......................................................................................................................................................... Machine

Weight........................................................................................................................................................... 3374 lbs.

Length x Width x Height................................................................................................................... 94 x 45 x 69 in.

Electrical

Power Requirement.................................................................................................................

440V, 3-Phase, 60 Hz

Full-Load Current Rating...............................................................................................................................

10.75A

Minimum Circuit Size.......................................................................................................................................... 15A

Inverter Type............................................................................................................................... Yaskawa G7A25P5

Switch................................................................................................................. Magnetic with Thermal Protection

Switch Voltage....................................................................................................................................................

440V

Plug Included..........................................................................................................................................................

No

Recommended Plug/Outlet Type.............................................................. Hardwire to Locking Disconnect Switch

Motors

Main

Type........................................................................................................................................ TEFC Induction

Horsepower......................................................................................................................................... 7-1/2 HP

Voltage......................................................................................................................................................

440V

Phase....................................................................................................................................................

3-Phase

Amps........................................................................................................................................................... 10A

Speed.......................................................................................................................................... 0 – 4500 RPM

Cycle......................................................................................................................................................... 60 Hz

Number of Speeds...............................................................................................................................

Variable

Power Transfer .........................................................................................................................

V-Belt & Gear

Bearings.................................................................................................... Shielded and Permanently Sealed

Model SB1038F

MANUAL INSERT

Mfg.Since4/11

-2-

Page 3

Lubrication

Type........................................................................................................................................ TEFC Induction

Horsepower............................................................................................................................................ 1/4 HP

Voltage......................................................................................................................................................

440V

Phase....................................................................................................................................................

3-Phase

Amps.......................................................................................................................................................... 0.6A

Speed................................................................................................................................................ 1725 RPM

Cycle......................................................................................................................................................... 60 Hz

Number of Speeds...........................................................................................................................................

1

Power Transfer ............................................................................................................................

Direct Drive

Bearings.................................................................................................... Shielded and Permanently Sealed

Coolant

Type........................................................................................................................................ TEFC Induction

Horsepower............................................................................................................................................ 1/8 HP

Voltage......................................................................................................................................................

440V

Phase....................................................................................................................................................

3-Phase

Amps........................................................................................................................................................ 0.15A

Speed................................................................................................................................................ 3450 RPM

Cycle......................................................................................................................................................... 60 Hz

Number of Speeds...........................................................................................................................................

1

Power Transfer ............................................................................................................................

Direct Drive

Bearings.................................................................................................... Shielded and Permanently Sealed

Main Specifications

Operation Info

Swing Over Bed.................................................................................................................................. 16.14 in.

Distance Between Centers...................................................................................................................... 40 in.

Swing Over Cross Slide....................................................................................................................

10.375 in.

Swing Over Saddle.............................................................................................................................

15.67 in.

Swing Over Gap.................................................................................................................................. 22.95 in.

Maximum Tool Bit Size........................................................................................................................ 0.75 in.

Compound Travel.................................................................................................................................... 5.1 in.

Carriage Travel...................................................................................................................................

38.58 in.

Cross Slide Travel.................................................................................................................................

9.25 in.

Headstock Info

Spindle Bore...................................................................................................................................... 2.0625 in.

Spindle Taper.......................................................................................................................................... MT#6

Number of Spindle Speeds................................................................................................................. Variable

Spindle Speeds.........................................................................................................................

20 – 2500 RPM

Spindle Type..............................................................................................................................

D1-6 Camlock

Spindle Bearings................................................................................................ NSK or NTN Tapered Roller

Spindle Length.................................................................................................................................... 24.24 in.

Spindle Length with 3-Jaw Chuck.................................................................................................... 30.31 in.

Spindle Length with 4-Jaw Chuck....................................................................................................

34.08 in.

Tailstock Info

Tailstock Quill Travel................................................................................................................................

6 in.

Tailstock Taper........................................................................................................................................ MT#4

Tailstock Barrel Diameter.................................................................................................................. 2.047 in.

Mfg.Since4/11 Model SB1038F

MANUAL INSERT

-3-

Page 4

Threading Info

Number of Longitudinal Feeds..................................................................................................................... 17

Range of Longitudinal Feeds............................................................................................. 0.0.002 – 0.067 in.

Number of Cross Feeds.................................................................................................................................

17

Range of Cross Feeds.............................................................................................................

0.001 – 0.034 in.

Number of Inch Threads............................................................................................................................... 45

Range of Inch Threads..................................................................................................................... 2 – 72 TPI

Number of Metric Threads........................................................................................................................... 39

Range of Metric Threads..............................................................................................................

0.2 – 14 mm

Number of Modular Pitches..........................................................................................................................

18

Range of Modular Pitches................................................................................................................ 8 – 44 MP

Number of Diametral Pitches....................................................................................................................... 21

Range of Diametral Pitches.............................................................................................................. 8 – 44 DP

Dimensions

Bed Width..........................................................................................................................................

10-1/4 in.

Leadscrew Diameter............................................................................................................................

1-1/8 in.

Leadscrew TPI................................................................................................................................................. 4

Leadscrew Length............................................................................................................................... 63.58 in.

Steady Rest Capacity............................................................................................................. 5/16 – 4-5/16 in.

Follow Rest Capacity..................................................................................................................

5/8 – 3-1/8 in.

Faceplate Size..........................................................................................................................................

12 in.

Feed Rod Diameter................................................................................................................................. 3/4 in.

Floor to Center Height...................................................................................................................... 43-1/2 in.

Height With Leveling Jacks.............................................................................................................. 44-1/2 in.

Construction

Base....................................................................................................................................................

Cast Iron

Headstock..........................................................................................................................................

Cast Iron

Headstock Gears.......................................................................................................... Flame Hardened Steel

Bed.............................................................................................. Induction Hardened and Ground Cast Iron

Stand.................................................................................................................................................. Cast Iron

Other

Country Of Origin ..............................................................

Taiwan (Some Components Made in USA and Japan)

Warranty .........................................................................................................................................................

1 Year

Serial Number Location .................................................................................

ID Label on Rear Side of Left Stand

Assembly Time ......................................................................................................................

Approximately 1 Hour

Features

Allen Bradley Electrical Components

Fagor DRO

Meehanite Casting, Signature South Bend 3 V-Way Bed

Safety Chuck Guard with Micro-Switch Shut-Off

Halogen Work Light

4-Way Tool Post

Complete Coolant System

Micrometer Carriage Stop

Threading Dial Indicator

NSK or NTN Japanese Spindle Bearings

Full Length Splash Guard

Front Removable Sliding Chip Tray

Yaskawa G7A25P5 Inverter

Completely Enclosed Universal Gearbox for Cutting Inch, Metric, Modular and Diametral Pitches

Pressurized Lubrication System for Headstock Gears and Bearings

Dial Controlled, Variable Spindle Speeds with Digital Read Out

Model SB1038F

MANUAL INSERT

Mfg.Since4/11

-4-

Loading...

Loading...