Southbend SB1015, SB1038, SB1037, SB1013, SB1014 User Manual

...

14" & 16" EVS TOOLROOM LATHES

MODELS SB1012/SB1014/SB1037 - 220V

MODELS SB1013/SB1015/SB1038 - 440V

OWNER'S MANUAL

Hundreds of Thousands of Lathes Sold With a Tradition of Quality Since 1906!

© March, 2010 by South Bend Lathe Co. For Machines Mfg. Since 7/09

Scope of Manual

This manual helps the reader understand the machine, how to prepare it for operation, how to control

it during operation, and how to keep it in good working condition. We assume the reader has a basic

understanding of how to operate this type of machine, but that the reader is not familiar with the

controls and adjustments of this specific model. As with all machinery of this nature, learning the

nuances of operation is a process that happens through training and experience. If you are not an

experienced operator of this type of machinery, read through this entire manual, then learn more

from an experienced operator, schooling, or research before attempting operations. Following this

advice will help you avoid serious personal injury and get the best results from your work.

Manual Feedback

We've made every effort to be accurate when documenting this machine. However, errors sometimes

happen or the machine design changes after the documentation process—so the manual may not

exactly match your machine. If a difference between the manual and machine leaves you in doubt,

contact our customer service for clarification.

We highly value customer feedback on our manuals. If you have a moment, please share your

experience using this manual. What did you like about it? Is there anything you would change to

make it better? Did it meet your expectations for clarity, professionalism, and ease-of-use?

South Bend Lathe, Inc.

C

/O Technical Documentation Manager

P.O. Box 2027

Bellingham, WA 98227

Email: manuals@southbendlathe.com

Updates

For your convenience, any updates to this manual will be available to download free of charge

through our website at:

www.southbendlathe.com

Customer Service

We stand behind our machines. If you have any service questions, parts requests or general questions

about your purchase, feel free to contact us.

South Bend Lathe Co.

P.O. Box 2027

Bellingham, WA 98227

Fax: (360) 676-1075 (International)

Fax: (360) 734-1639 (USA Only)

Email: cs@southbendlathe.com

Table of Contents

INTRODUCTION .................................................... 3

About These Machines.........................................3

Foreword ............................................................. 3

Capabilities ......................................................... 3

Features .............................................................. 3

Identification ........................................................ 4

SAFETY ..................................................................5

Understanding Risks of Machinery .................... 5

Basic Machine Safety ..........................................5

Additional Metal Lathe Safety ............................7

PREPARATION ...................................................... 8

Preparation Overview .......................................... 8

Things You'll Need ...............................................8

Unpacking ............................................................8

Inventory .............................................................. 9

Cleaning & Protecting ....................................... 10

Location .............................................................. 11

Physical Environment ........................................ 11

Electrical Installation ........................................ 11

Lighting ............................................................11

Weight Load ...................................................... 11

Space Allocation ................................................11

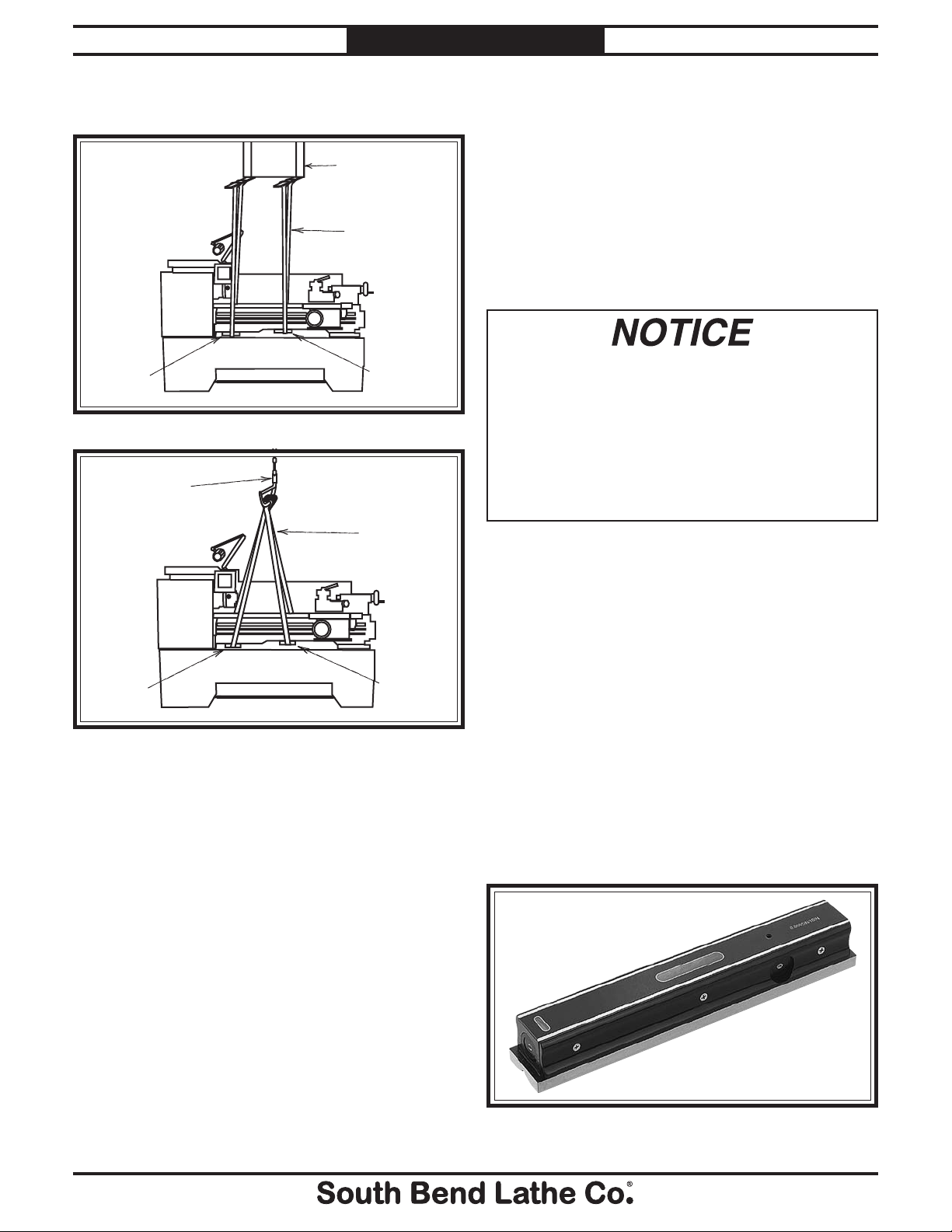

Lifting & Moving ................................................12

Leveling & Mounting ......................................... 13

Leveling ............................................................13

Bolting to Concrete Floors ..................................14

Assembly ............................................................14

Lubricating Lathe ..............................................14

Adding Cutting Fluid ......................................... 15

Power Connection ..............................................15

SB1012 (220V 3-Phase) ...................................... 15

SB1014, SB1037 (220V 3-Phase) ........................... 15

SB1013 (440V 3-Phase) ..........................................15

SB1015, SB1038 (440V 3-Phase) ........................... 15

Connecting Power Cord to Lathe ........................ 16

Hardwiring Lathe to Power Source ....................16

Correcting Out-of-Phase Wiring ......................... 17

Test Run ............................................................. 17

Spindle Break-In ................................................21

Recommended Adjustments ..............................22

OPERATION ........................................................23

Operation Overview ........................................... 23

Description of Controls & Components ............24

Main Power Switch ............................................ 24

Headstock Controls ............................................24

Carriage Controls ..............................................24

Control Panel ....................................................25

Tailstock Controls .............................................. 26

Foot Brake ........................................................26

Chuck & Faceplate Mounting ...........................27

Removing Chuck or Faceplate ............................ 27

Mounting Chuck or Faceplate ............................28

Installing and Adjusting Camlock Studs ............. 29

3-Jaw Chuck .......................................................30

Changing Jaws .................................................. 31

Mounting Workpiece .......................................... 31

4-Jaw Chuck .......................................................32

Mounting Workpiece .......................................... 32

Tailstock ............................................................. 32

Moving Along Bedway .......................................33

Using Quill ........................................................ 33

Installing Tooling ..............................................33

Removing Tooling .............................................. 33

Offsetting .......................................................... 34

Aligning ............................................................34

Faceplate ............................................................36

Mounting Workpiece with Clamps ...................... 36

Mounting Workpiece Between Centers ............... 36

Centers ...............................................................37

Dead Centers .....................................................37

Live Centers ...................................................... 37

Mounting Dead Center in Spindle ...................... 37

Removing Center from Spindle ........................... 38

Mounting Center in Tailstock ............................. 38

Removing Center from Tailstock ........................38

Steady Rest ........................................................39

Follow Rest ......................................................... 39

Compound Slide ................................................. 40

Four-Way Tool Post ...........................................40

Aligning Cutting Tool with Tailstock Center ....... 41

Aligning Cutting Tool with Tailstock Center ....... 41

Adjustable Apron Stop System .........................42

Carriage Stop ..................................................... 42

Manual Feed ......................................................43

Carriage Handwheel .......................................... 43

Compound Slide Handwheel ..............................43

Spindle Speed .....................................................43

Determining Spindle Speed ................................43

Setting Spindle Speed ........................................ 44

Power Feed ......................................................... 44

Power Feed Controls .......................................... 45

Understanding Thread & Feed Rate Chart ......... 46

Positioning Gearbox Levers ................................ 46

End Gear Setup ................................................. 47

Threading Controls ............................................ 48

Power Feed Lever .............................................. 48

Half Nut Lever ..................................................48

Thread Dial & Chart Overview ..........................48

Using Thread Dial and Chart .............................49

Chip Drawer ....................................................... 50

Cutting Fluid System ........................................51

ACCESSORIES ...................................................52

Accessories .........................................................52

MAINTENANCE ...................................................54

Maintenance Schedule ....................................... 54

Cleaning .............................................................54

Maintenance Chart ............................................ 55

Lubrication ......................................................... 56

Headstock .........................................................56

Gearbox .............................................................58

Apron ................................................................ 58

Lead Screw & Feedrod Bearings ........................59

Lead Screw ........................................................ 59

Ways & Slides ...................................................59

Unpainted & Machined Surfaces ........................ 59

Ball Oilers ......................................................... 60

Cleaning Electrical Box Filter ............................ 60

End Gearing ..................................................... 61

Cutting Fluid System ........................................62

Hazards.............................................................62

Adding Fluid .....................................................62

Changing Cutting Fluid ..................................... 63

Machine Storage ................................................64

SERVICE .............................................................. 65

Backlash Adjustment ........................................65

Compound Leadscrew ........................................ 65

Cross Slide Leadscrew .......................................65

Leadscrew End Play Adjustment ......................66

Gib Adjustment .................................................. 66

Half Nut Adjustment ......................................... 67

Feedrod Clutch Adjustment .............................. 68

V-Belts ................................................................ 69

Brake & Switch .................................................. 69

Leadscrew Shear Pin Replacement ..................71

Gap Removal & Installation .............................. 73

TROUBLESHOOTING .........................................74

WARRANTY & RETURNS ................................... 77

16" South Bend Precision Toolroom Lathe (Circa 1958)

For Machines Mfg. Since 7/09 EVS Toolroom Lathes

INTRODUCTION

INTRODUCTION

About These Machines

Foreword

"The screw cutting engine lathe is the oldest and

most important of machine tools and from it all

other machine tools have been developed. It was

the lathe that made possible the building of the

steamboat, the locomotive, the electric motor, the

automobile and all kinds of machinery used in

industry. Without the lathe our great industrial

progress of the last century would have been

impossible." —How To Run a Lathe, 15th

Edition, South Bend Lathe.

The lathes represented in this manual are a

modern day version of the screw cutting lathes

that trace their roots back to the 1700's, which

were themselves technological improvements of

the bow lathe that can be traced back thousands

of years to the ancient Egyptians.

Now, almost 300 years later, these modern

"screw cutting" lathes are not just a piece of

refined machinery, but a culmination of human

ingenuity and knowledge embodied into the

design and synergy of thousands of interworking

parts—some of which represent the life's work

and dreams of many inventors, mechanical

engineers, and world-class machinists—including

the likes of Leonardo da Vinci, Henry Maudsley,

and the founders of South Bend Lathe, John and

Miles O'Brien.

And now the torch is passed to you—to take

the oldest and most important type of machine

tool—and carry on the tradition. As the operator

of a South Bend Lathe, you now join the ranks

of some very famous and important customers,

such as Henry Ford, who used the machines he

purchased to help him change the world.

Capabilities

These EVS Toolroom Lathes are built for daily

use in a busy industrial setting. Loaded with

many nice features and high-precision parts,

these lathes excel at making fine tools, dies,

thread gauges, jigs, and precision test gauges—

however, they are by no means delicate. Thick

castings, heavy weight, and quality construction

throughout provide the necessary brawn for

demanding production and manufacturing tasks.

Features

As the name implies, these lathes feature EVS

(Electronic Variable Speed) spindle control,

which allows the operator to quickly set the

exact spindle speed within the available range of

20–2500 RPM. Spindle speed is displayed on a

digital readout and controlled within each speed

range with the use of a dial—no changing gears

or looking up complex lever positions on a chart.

The beds of these lathes are constructed with

Meehanite castings that have been precision

hardened and ground in the traditional 3-V

prismatic design—long used on South Bend

Lathes for its accuracy, durability, and rigidity.

The headstock features quick-change gear levers

and an adjustable clutch mechanism for the feed

rod that can be set to prevent damage in the

event of a crash.

To further ensure a high degree of accuracy,

these lathes are equipped with NSK or NTN

spindle bearings. The spindles are the D1-6

camlock type with an MT#6 taper and 2.0625"

bore. The tailstock quills have an MT#4 taper

and offer 6" of travel.

The EVS lathes also include a pressurized

headstock oiling system that pre-lubricates

bearings/gears before the spindle starts and

delivers perfect lubrication during low speed

operations (compare to conventional splash

and bath oil systems that leave bearings/gears

starved for oil when the spindle is first started

and during low speed operations).

Finally, these EVS toolroom lathes are packed

with standard features, such as a complete

coolant system, easy-to-clean chip drawer, oneshot way lubrication system, included steady and

follow rests, adjustable work lamp, foot brake,

and powered cross feed.

-3-

EVS Toolroom Lathes

Identification

INTRODUCTION

For Machines Mfg. Since 7/09

AB

C

B

A

AA

Z

X

Y

W

V

D

E

U

T

F

H

G

S

I

J

K

R

Q

L

M

N

O

P

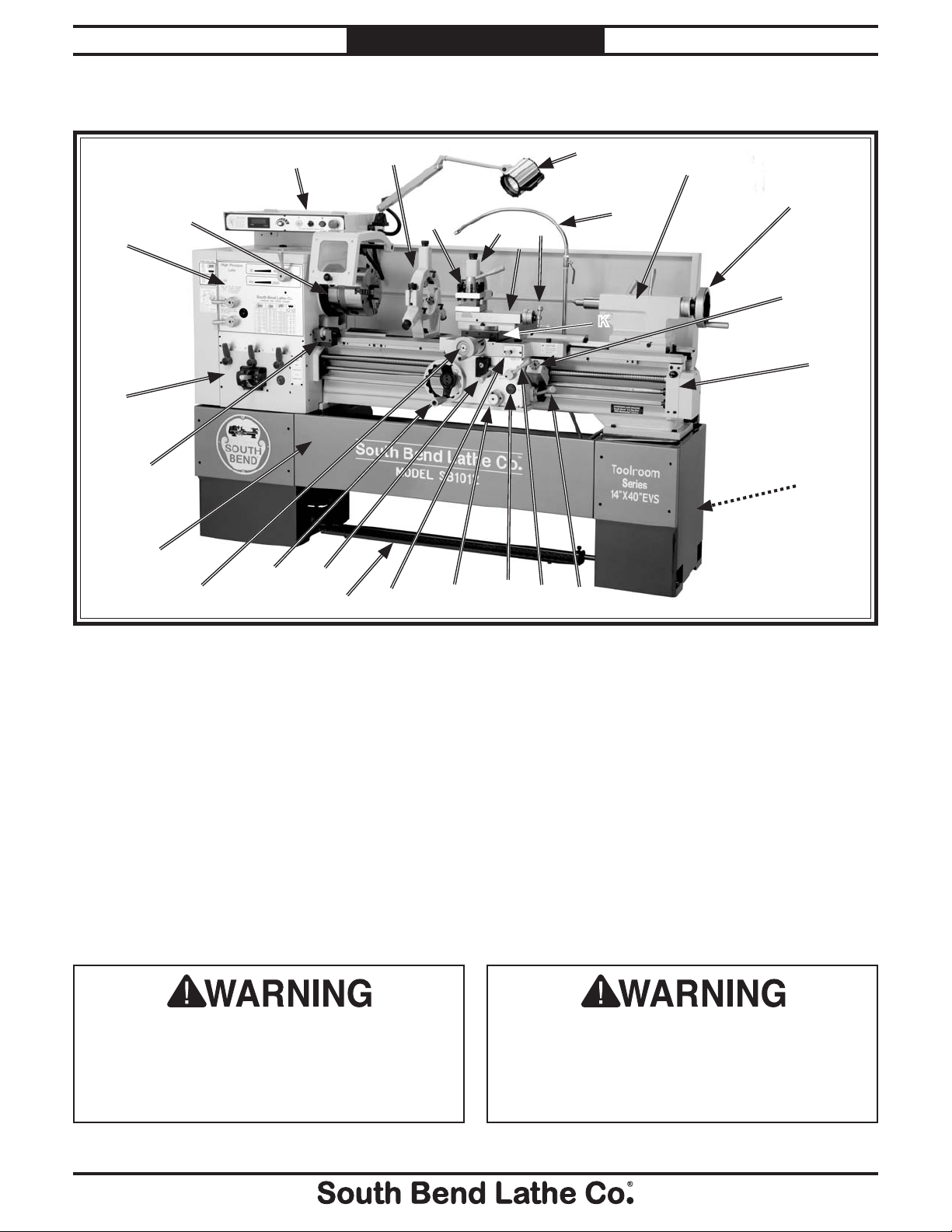

Figure 1. The 14" & 16" EVS Lathe.

A. Headstock

B. D1-6 Camlock MT#6 Spindle

C. Control Panel

D. Ball Bearing Style Steady Rest

E. 4-Position Tool Holder

F. Follow Rest

G. Compound Slide

H. Compound Slide Handwheel

I. Work Lamp

J. Universal Cutting Fluid Tube and Nozzle

K. Cross Slide

L. Tailstock

M. Tailstock Handwheel

N. Thread Dial

Serious personal injury could occur if

you connect the machine to power before

completing the setup process. DO NOT

connect power until instructed to do so later

in this manual.

O. Leadscrew Bearing Housing

P. Cutting Fluid Pump/Tank

Q. Spindle Rotation ON/OFF Lever

R. Half Nut Lever

S. Apron Oil Level Sight Glass

T. Quick Change Apron Feed Direction Knob

U. Manual Way Oil Pump

V. Brake Pedal

W. Feed Control Lever

X. Apron Handwheel

Y. Cross Slide Handwheel

Z. Removable Chip Drawer

AA. Micrometer Stop

AB. Quick Change Gearbox

Untrained users have an increased risk

of seriously injuring themselves with this

machine. Do not operate this machine until

you have understood this entire manual and

received proper training.

-4-

For Machines Mfg. Since 7/09 EVS Toolroom Lathes

SAFETY

SAFETY

Understanding Risks of Machinery

Operating all machinery and machining equipment can be dangerous or relatively safe depending

on how it is installed and maintained, and the operator's experience, common sense, risk awareness,

working conditions, and use of personal protective equipment (safety glasses, respirators, etc.).

The owner of this machinery or equipment is ultimately responsible for its safe use. This

responsibility includes proper installation in a safe environment, personnel training and usage

authorization, regular inspection and maintenance, manual availability and comprehension,

application of safety devices, integrity of cutting tools or accessories, and the usage of approved

personal protective equipment by all operators and bystanders.

The manufacturer of this machinery or equipment will not be held liable for injury or property

damage from negligence, improper training, machine modifications, or misuse. Failure to read,

understand, and follow the manual and safety labels may result in serious personal injury, including

amputation, broken bones, electrocution, or death.

The signals used in this manual to identify hazard levels are defined as follows:

Death or catastrophic

harm WILL occur.

Death or catastrophic

harm COULD occur.

Basic Machine Safety

1. Owner’s Manual: All machinery and

machining equipment presents serious

injury hazards to untrained users. To

reduce the risk of injury, anyone who uses

THIS item MUST read and understand

this entire manual before starting.

2. Personal Protective Equipment:

or servicing this item may expose the user

to flying debris, dust, smoke, dangerous

chemicals, or loud noises. These hazards

can result in eye injury, blindness, longterm respiratory damage, poisoning,

cancer, reproductive harm or hearing loss.

Reduce your risks from these hazards

by wearing approved eye protection,

respirator, gloves, or hearing protection.

Operating

Moderate injury or fire

MAY occur.

Machine or property

damage may occur.

3. Trained/Supervised Operators Only:

Untrained users can seriously injure

themselves or bystanders. Only allow

trained and properly supervised personnel

to operate this item. Make sure safe

operation instructions are clearly

understood. If electrically powered, use

padlocks and master switches, and remove

start switch keys to prevent unauthorized

use or accidental starting.

4. Guards/Covers:

moving parts during operation may cause

severe entanglement, impact, cutting,

or crushing injuries. Reduce this risk by

keeping any included guards/covers/doors

installed, fully functional, and positioned

for maximum protection.

Accidental contact with

-5-

EVS Toolroom Lathes

SAFETY

For Machines Mfg. Since 7/09

5. Entanglement: Loose clothing, gloves,

neckties, jewelry or long hair may

get caught in moving parts, causing

entanglement, amputation, crushing,

or strangulation. Reduce this risk by

removing/securing these items so they

cannot contact moving parts.

6. Mental Alertness: Operating this item

with reduced mental alertness increases

the risk of accidental injury. Do not let a

temporary influence or distraction lead to a

permanent disability! Never operate when

under the influence of drugs/alcohol, when

tired, or otherwise distracted.

7. Safe Environment:

powered equipment in a wet environment

may result in electrocution; operating near

highly flammable materials may result in a

fire or explosion. Only operate this item in

a dry location that is free from flammable

materials.

8. Electrical Connection: With electically

powered equipment, improper connections

to the power source may result in

electrocution or fire. Always adhere to all

electrical requirements and applicable

codes when connecting to the power source.

Have all work inspected by a qualified

electrician to minimize risk.

9. Disconnect Power: Adjusting or servicing

electrically powered equipment while it

is connected to the power source greatly

increases the risk of injury from accidental

startup. Always disconnect power

BEFORE any service or adjustments,

including changing blades or other tooling.

Operating electrically

11. Chuck Keys or Adjusting Tools:

to adjust spindles, chucks, or any moving/

rotating parts will become dangerous

projectiles if left in place when the machine

is started. Reduce this risk by developing

the habit of always removing these tools

immediately after using them.

12. Work Area:

increase the risks of accidental injury.

Only operate this item in a clean, nonglaring, and well-lighted work area.

13. Properly Functioning Equipment:

maintained, damaged, or malfunctioning

equipment has higher risks of causing

serious personal injury compared to

those that are properly maintained.

To reduce this risk, always maintain

this item to the highest standards and

promptly repair/service a damaged or

malfunctioning component. Always follow

the maintenance instructions included in

this documentation.

14. Unattended Operation:

powered equipment that is left unattended

while running cannot be controlled and is

dangerous to bystanders. Always turn the

power OFF before walking away.

15. Health Hazards: Certain cutting fluids

and lubricants, or dust/smoke created

when cutting, may contain chemicals

known to the State of California to cause

cancer, respiratory problems, birth defects,

or other reproductive harm. Minimize

exposure to these chemicals by wearing

approved personal protective equipment

and operating in a well ventilated area.

Clutter and dark shadows

Electrically

Tools used

Poorly

10. Secure Workpiece/Tooling:

workpieces, cutting tools, or rotating

spindles can become dangerous projectiles

if not secured or if they hit another object

during operation. Reduce the risk of this

hazard by verifying that all fastening

devices are properly secured and items

attached to spindles have enough clearance

to safely rotate.

-6-

Loose

16. Difficult Operations:

difficult operations with which you are

unfamiliar increases the risk of injury.

If you experience difficulties performing

the intended operation, STOP! Seek an

alternative method to accomplish the

same task, ask a qualified expert how the

operation should be performed, or contact

our Technical Support for assistance.

Attempting

For Machines Mfg. Since 7/09 EVS Toolroom Lathes

SAFETY

Additional Metal Lathe Safety

1. Clearing Chips. Metal chips can easily cut

bare skin—even through a piece of cloth.

Avoid clearing chips by hand or with a rag.

Use a brush or vacuum to clear metal chips.

2. Chuck Key Safety. A chuck key left in the

chuck can become a deadly projectile when

the spindle is started. Always remove the

chuck key after using it. Develop a habit of

not taking your hand off of a chuck key unless

it is away from the machine.

3. Tool Selection. Cutting with an incorrect

or dull tool increases the risk of accidental

injury because extra force is required for the

operation, which increases risk of breaking

or dislodging components, which can cause

small shards of metal to become dangerous

projectiles. Always select the right cutter for

the job and make sure it is sharp. A correct,

sharp tool decreases strain and provides a

better finish.

4. Securing Workpiece. An improperly secured

workpiece can fly off of the lathe spindle with

deadly force, which can result in a severe

impact injury. Make sure the workpiece is

properly secured in the chuck or faceplate

before starting the lathe.

5. Large Chucks. Large chucks are very heavy

and difficult to grasp, which can lead to

crushed fingers or hands if mishandled. Get

assistance when installing or removing large

chucks to reduce this risk. Protect your hands

and the precision-ground ways by using a

chuck cradle or piece of plywood over the

ways of the lathe when servicing chucks.

6. Safe Clearances. Workpieces that crash into

other components on the lathe may throw

dangerous projectiles in all directions, leading to impact injury and damaged equipment.

Before starting the spindle, make sure the

workpiece has adequate clearance by handrotating it through its entire range of motion.

Also, check the tool and tool post clearance,

chuck clearance, and saddle clearance.

7. Speed Rates. Operating the lathe at the

wrong speed can cause nearby parts to break

or the workpiece to come loose, which will

result in dangerous projectiles that could

cause severe impact injury. Large workpieces

must be turned at slow speeds. Always use

the appropriate feed and speed rates.

8. Stopping Spindle by Hand. Stopping the spin-

dle by putting your hand on the workpiece or

chuck creates an extreme risk of entanglement, impact, crushing, friction, or cutting

hazards. Never attempt to slow or stop the

lathe spindle with your hand. Allow the

spindle to come to a stop on its own or use the

brake (if equipped).

9. Crashes. Driving the cutting tool or other

lathe components into the chuck may cause

an explosion of metal fragments, which can

result in severe impact injuries and major

damage to the lathe. Reduce this risk by

releasing automatic feeds after use, not leaving lathe unattended, and checking clearances before starting the lathe. Make sure no

part of the tool, tool holder, compound slide,

cross slide, or carriage will contact the chuck

during operation.

10. Long Stock Safety. Long stock can whip vio-

lently if not properly supported, causing serious impact injury and damage to the lathe.

Reduce this risk by supporting any stock that

extends from the chuck/headstock more than

three times its own diameter. Always turn

long stock at slow speeds.

11. Coolant Safety. Contaminated cutting fluid

is a very poisonous biohazard that can cause

personal injury from skin contact alone.

Incorrectly positioned cutting fluid nozzles

can splash on the operator or the floor,

resulting in an exposure or slipping hazard.

To decrease your risk, change cutting fluid

regularly and position the cutting fluid nozzle

where it will not splash or end up on the

floor.

-7-

EVS Toolroom Lathes

PREPARATION

PREPARATION

For Machines Mfg. Since 7/09

Preparation Overview Things You'll Need

The purpose of the preparation section is to help

you prepare your machine for operation. The

list below outlines the basic process to follow to

prepare the lathe for operation. Specific steps for

each of these points will be covered in detail later

in this section.

The typical preparation process is as follows:

1. Unpack the lathe and inventory the contents

of the box/crate.

2. Clean the lathe and its components.

3. Identify an acceptable location for the lathe

and move it to that location.

4. Level the lathe and either bolt it to the floor

or place it on mounts.

5. Assemble the loose components and make

any necessary adjustments or inspections to

ensure the lathe is ready for operation.

6. Connect the lathe to the power source.

7. Test run the lathe to make sure it functions

properly and is ready for operation.

To complete the preparation process, you will

need the following items:

For Lifting and Moving

s !&ORKLIFTOR/THER0OWER,IFTING$EVICE

(rated for at least 5000 lbs).

s ,IFTING3TRAP or Chain with Hook

(rated for at least 5000 lbs.)

s Helper for moving machine.

s Two 12" 2x6's

s 0RECISION,EVEL

For Power Connection

s !QUALIFIEDELECTRICIANTOENSUREASAFEAND

code-compliant connection to the power

source. (Refer to Page 15 for details.)

For Assembly

s Cotton Rags

s Mineral Spirits

s Quality Metal Protectant Oil

s 3AFETY'LASSES

s Wrench or Socket 21mm

s Wrench or Socket 19mm

s &LOOR-OUNTING(ARDWARE as Needed

s Standard Screwdriver #2

Unpacking

This item was carefully packaged to prevent

damage during transport. If you discover any

damage, please immediately call Customer

Service at (360) 734-1540 for advice. You may

need to file a freight claim, so save the containers

and all packing materials for possible inspection

by the carrier or its agent.

-8-

For Machines Mfg. Since 7/09 EVS Toolroom Lathes

PREPARATION

Inventory

B

C

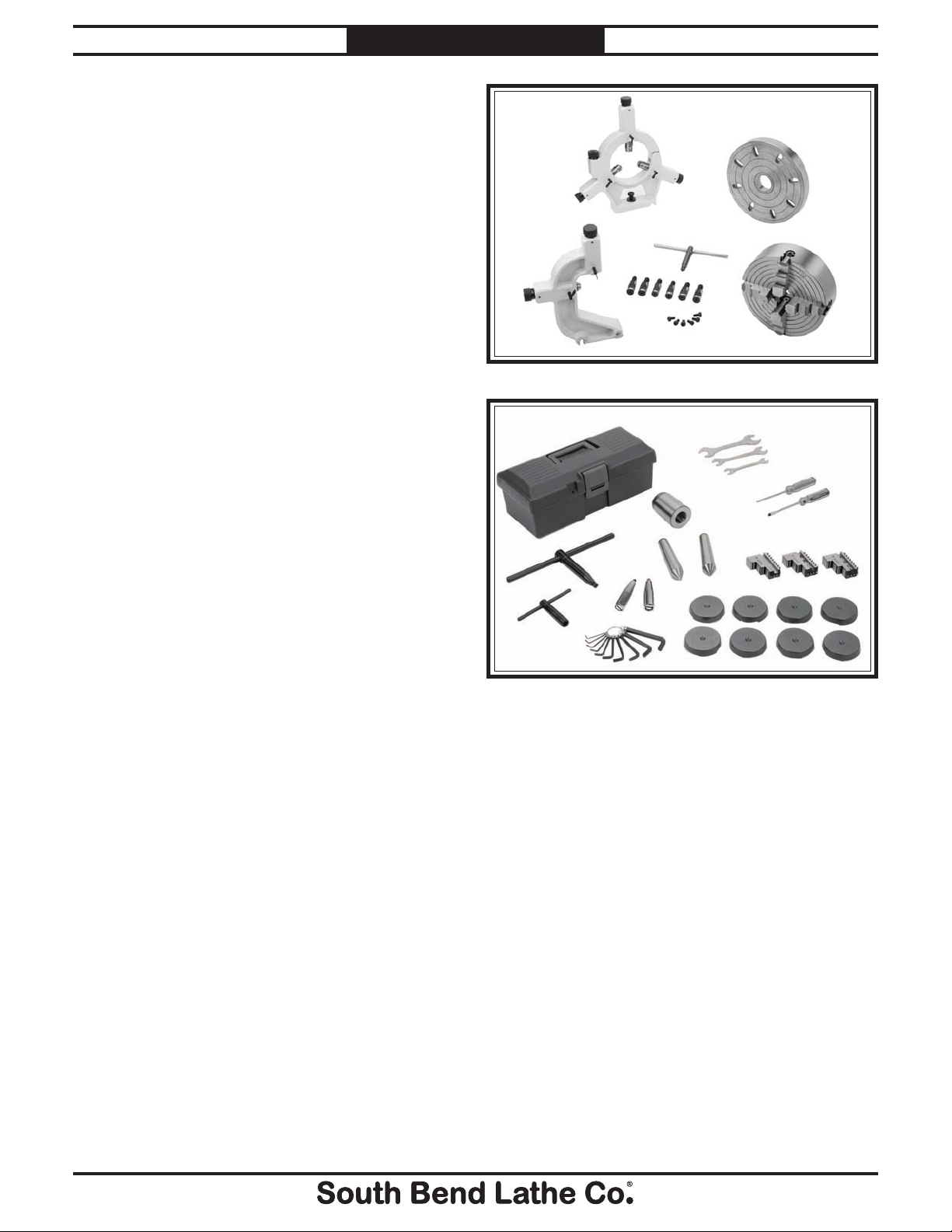

Main Inventory 1: (Figure 2) Qty

A. Steady Rest Assembly .................................... 1

B. 12" Faceplate w/D1-6 Camlock Stud Set ...... 1

C. 10" Four-Jaw Chuck w/Combo Jaws ............. 1

D. Four-Jaw Chuck Key .....................................1

E. Four-Jaw Chuck D1-6 Camlock Stud Set ..... 1

F. Follow Rest Assembly ....................................1

A

D

F

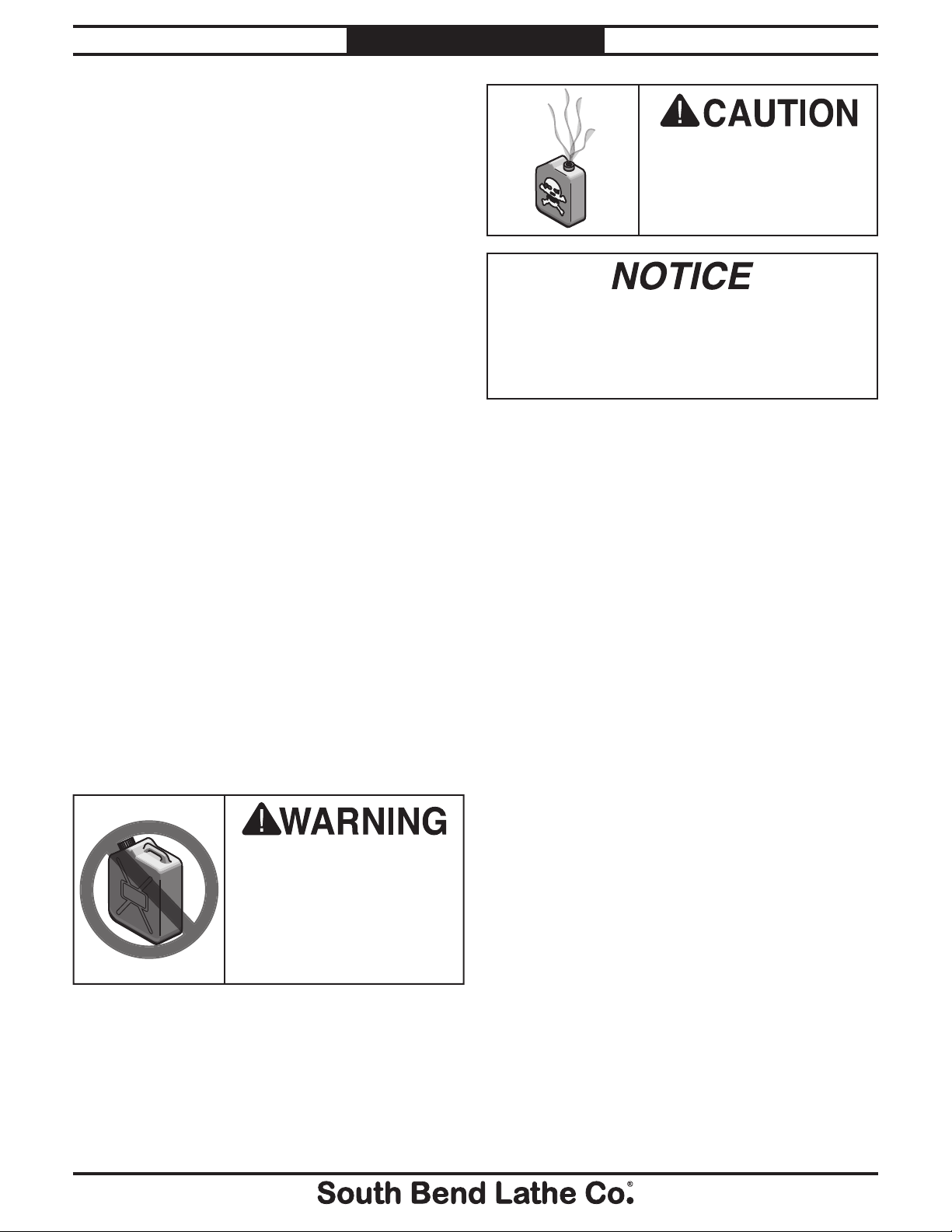

Tool Box Inventory: (Figure 3) Qty

G. Tool Box ..........................................................1

H. Three-Jaw Chuck Key ................................... 1

I. Tool Post T-Wrench ........................................ 1

J. Hex Wrench Set 1.5-10mm ............................ 1

K. Dead Center MT#4 ......................................... 1

L. Carbide-Tipped Dead Center MT#4 .............. 1

M. Tapered Spindle Sleeve MT#6-#4 .................1

N. Open End Wrench 22/24mm ......................... 1

O. Open End Wrench 14/17mm .........................1

P. Open End Wrench 10/12mm .........................1

Q. Phillips Screwdriver #2 ................................. 1

R. Standard Screwdriver #2 ...............................1

S. 9"-Chuck Jaws (SB1014-15, SB1037-38) ......3

8"-Chuck Jaws (SB1012-13) .......................... 3

T. Cast Iron Leveling Pads ................................8

U. Handwheel Handles .......................................2

Note: Some inventory components may be

shipped inside of the lathe electrical box. These

items MUST be removed before connecting the

lathe to the power source.

Figure 2. Main inventory.

G

H

I

J

Figure 3. Toolbox inventory.

N

M

K

U

E

O

P

L

T

Q

R

S

-9-

EVS Toolroom Lathes

A

PREPARATION

Cleaning & Protecting

For Machines Mfg. Since 7/09

The unpainted surfaces are coated at the factory

with a heavy-duty rust preventative that

prevents corrosion during shipment and storage.

The benefit of this rust preventative is that it

works very well. The downside is that it can be

time-consuming to thoroughly remove.

Be patient and do a careful job when cleaning

and removing the rust preventative. The time

you spend doing this will reward you with

smooth-sliding parts and a better appreciation

for the proper care of the unpainted surfaces.

lthough there are many ways to successfully

remove the rust preventative, we have cleaned

thousands of machines and found the following

process to be the best balance between efficiency

and minimized exposure to toxic fumes or

chemicals.

Before cleaning, gather the following:

s $ISPOSABLErags

s #LEANERDEGREASER (certain citrus-based

degreasers work extremely well and they

have non-toxic fumes)

s 3AFETYGLASSESDISPOSABLEGLOVES

Avoid chlorine-based solvents, such as

acetone or brake parts cleaner that may

damage painted surfaces. Always follow the

manufacturer’s instructions when using any

type of cleaning product.

Basic steps for removing rust preventative:

1. Put on safety glasses and disposable gloves.

2. #OATALLSURFACESTHATHAVERUSTPREVENTATIVE

with a liberal amount of your cleaner or

degreaser and let them soak for a few

minutes.

3. Wipe off the surfaces. If your cleaner or

degreaser is effective, the rust preventative

will wipe off easily.

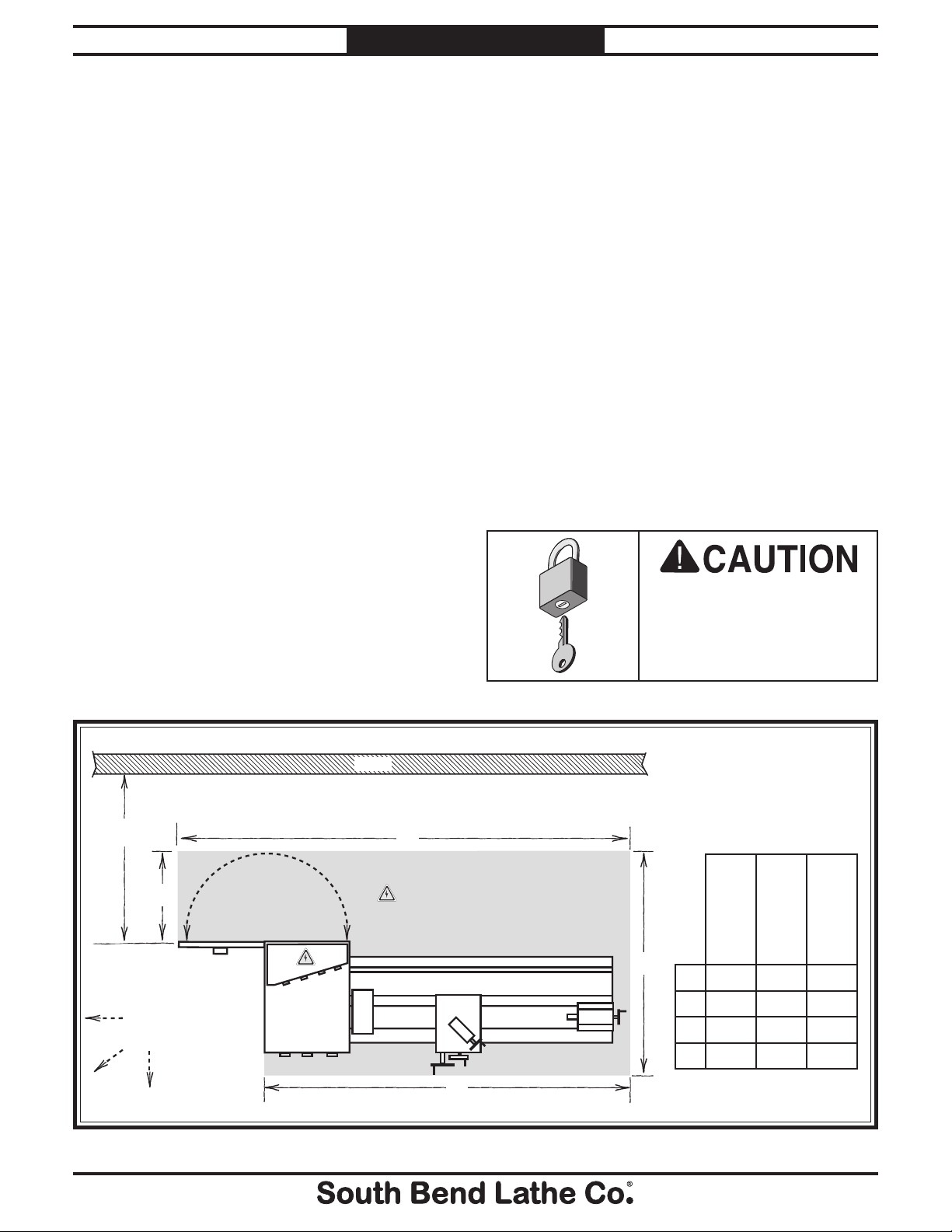

Many cleaning solvents are

toxic if inhaled. Minimize

your risk by only using

these products in a well

ventilated area.

Note: Automotive degreasers, mineral spirits, or

7$sCANBEUSEDTOREMOVERUSTPREVENTATIVE

Before using these products, though, test them

on an inconspicuous area of a painted area to

make sure they will not damage it.

Gasoline and petroleum

products have low flash

GAS

points and can explode

or cause fire if used for

cleaning. Avoid using these

products to remove rust

preventative.

Note: To clean off thick coats of rust preventative

on flat surfaces, such as beds or tables, use

A0,!34)#PAINTSCRAPERTOSCRAPEOFFTHE

majority of the coating before wiping it off

WITHYOURRAG$ONOTUSEAMETALSCRAPEROR

it may scratch the surface.)

4. Repeat Steps 2–3 as necessary until clean,

then coat all unpainted surfaces with a

quality metal protectant or light oil to

prevent rust.

-10-

For Machines Mfg. Since 7/09 EVS Toolroom Lathes

PREPARATION

Location

Physical Environment

The physical environment where your machine

Physical Environment

is operated is important for safe operation and

Electrical Installation

longevity of parts. For best results, operate this

machine in a dry environment that is free from

Lighting

excessive moisture, hazardous or flammable

Weight Load

chemicals, airborne abrasives, or extreme

Space Allocation

conditions. Extreme conditions for this type

of machinery are generally those where the

ambient temperature is outside the range of 41°–

104°F; the relative humidity is outside the range

of 20–95% (non-condensing); or the environment

is subject to vibration, shocks, or bumps.

Electrical Installation

Place this machine near an existing power

source. Make sure all power cords are protected

from traffic, material handling, moisture,

chemicals, or other hazards. Make sure to leave

access to a means of disconnecting the power

source or engaging a lockout/tagout device.

Weight Load

Refer to the Machine Specifications for the

weight of your machine. Make sure that the

surface upon which the machine is placed will

bear the weight of the machine, additional

equipment that may be installed on the machine,

and the heaviest workpiece that will be used.

Additionally, consider the weight of the operator

and any dynamic loading that may occur when

operating the machine.

Space Allocation

Consider the largest size of workpiece that will

be processed through this machine and provide

enough space around the machine for adequate

operator material handling or the installation

of auxiliary equipment. With permanent

installations, leave enough space around

the machine to open or remove doors/covers

as required by the maintenance and service

described in this manual.

Lighting

Lighting around the machine must be adequate

enough that operations can be performed

safely. Shadows, glare, or strobe effects that

may distract or impede the operator must be

eliminated.

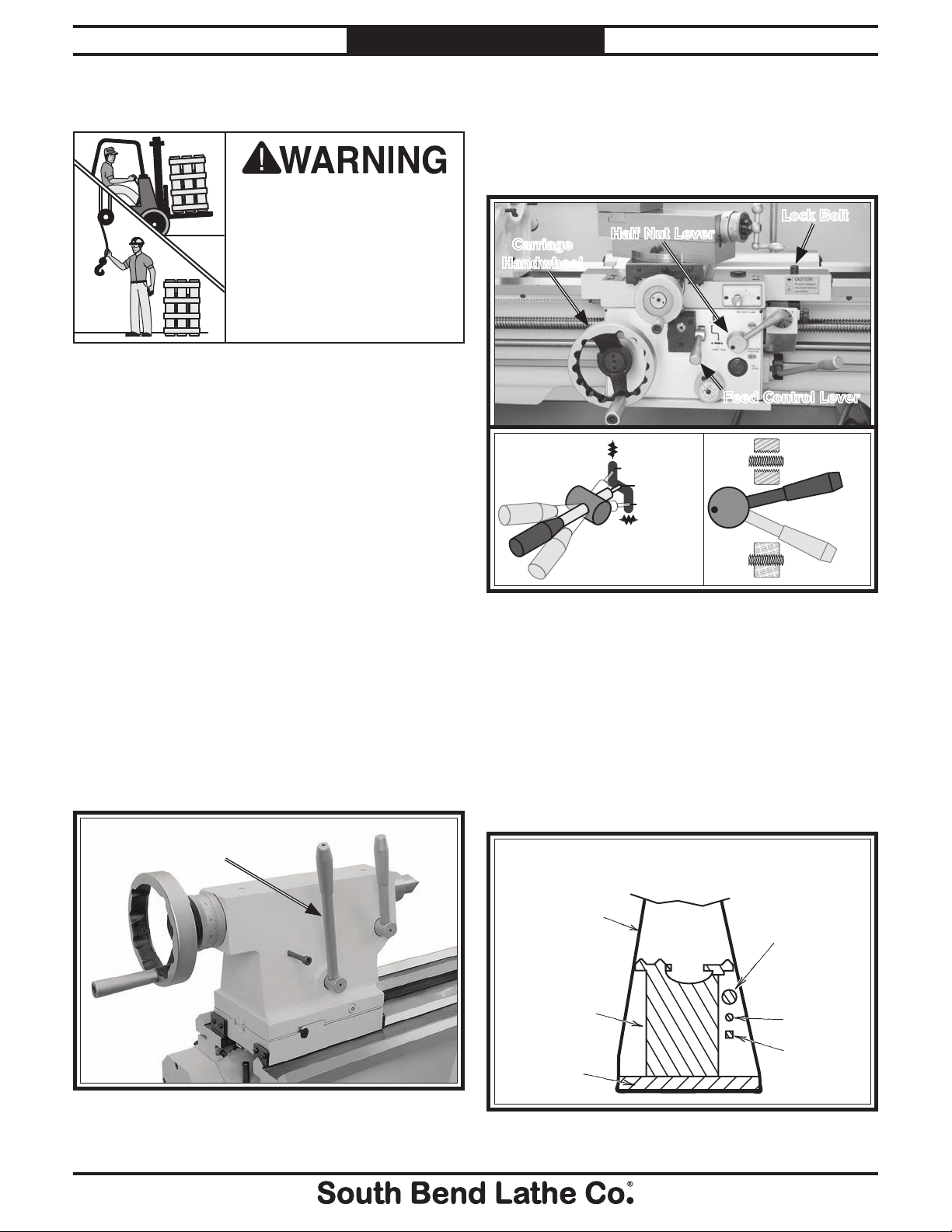

Wall

Min. 30"

Keep

Workpiece

Loading Area

Unobstructed

D

Electrical

Access

Door

Lathe

C

= Power Connection Location

Children or untrained

people may be seriously

injured by this machine.

Only install in an access

restricted location.

B

SB1012-13

90" 109" 90"

A

60" 60" 60"

B

112" 130" 112"

C

201⁄2"201⁄2"201⁄2"

D

SB1014-15

SB1037-38

A

Figure 4. Space required for full range of movement.

-11-

EVS Toolroom Lathes

PREPARATION

Lifting & Moving

This machine and its

parts are heavy! Serious

personal injury may occur

if safe moving methods are

not used. To reduce the

risk of a lifting or dropping

injury, ask others for help

and use power equipment.

Do not attempt to lift or move this lathe if you do

not have the proper equipment or the necessary

assistance from other people. All lifting

equipment must be rated to at least 5,000 lbs.

to account for dynamic loads from bouncing or

pulling that may be applied while lifting. Refer

to the Things You'll Need section on Page 8 for

details.

To lift and move your lathe:

1. Prepare the permanent location for the

lathe.

For Machines Mfg. Since 7/09

4. To further balance the load, loosen the

carriage lock bolt (see Figure 6), disengage

the half nut lever, put the feed control lever

in neutral, then use the carriage handwheel

to move the carriage next to the tailstock.

Lock Bolt

Carriage

Handwheel

Figure 6. Carriage controls set for moving the carriage.

Half Nut Lever

Cross Slide

Neutral

Carriage

FEED CONTROL

LEVER

Feed Control Lever

Disengaged

HALF NUT

LEVER

Engaged

2. Remove the shipping crate top and sides,

then remove the small components from the

shipping pallet.

3. To balance the lifting load, loosen the

tailstock lock lever (Figure 5), move the

tailstock to the end of the bedway, then lock

it in place.

Tailstock Lock Lever

Figure 5. Tailstock lock lever.

5. Position a 12" long 2x6 board under each end

of the bed, as shown in Figure 7, wrap the

lifting straps around the bottom of the 2x6's.

Note: The 2x6's extend the lifting straps away

from the bottom of the bed to prevent

machine damage from excessive strap

pressure against the leadscrew, feed rod, and

spindle control rod. Make sure to use them.

(Cross-Section View of Lifting Setup)

To Forklift or Lifting Hook

Lifting

Strap

Lathe

Bed

12" Long

2x6 Board

Figure 7. Cross section of lifting setup to keep strap

from putting pressure against leadscrew or rods.

Leadscrew

Feed Rod

Spindle

Control

Rod

-12-

For Machines Mfg. Since 7/09 EVS Toolroom Lathes

PREPARATION

6. Attach the lifting straps to forklift forks or a

hook and chain, as shown in Figures 8–9.

Leveling & Mounting

You must level your machine and either use the

Forklift

Forks

included foot pads and leveling hardware or bolt

your lathe to the floor. Because mounting your

lathe to the floor with permanent hardware is an

Lifting

Straps

optional step and floor materials may vary, floor

mounting hardware is not included.

Leveling

12" Long

2x6 Board

Figure 8. Lathe set up for lifting with forklift.

Lifting Hook

with Chain

12" Long

2x6 Board

Figure 9. Lathe set up for lifting with hook and chain.

12" Long

2x6 Board

Lifting

Straps

12" Long

2x6 Board

7. Unbolt the lathe from the shipping pallet,

then with an assistant to help keep the lathe

from swaying, raise the lathe a couple of

inches.

— If the load is not well balanced, or you

see any other difficulties with the lifting

equipment, immediately lower the lathe

to the pallet again. Resolve any lifting or

balancing issues, then repeat this step.

For accurate turning results and to prevent

warping the cast iron bed and ways, the lathe

bedways MUST be leveled from side-to-side

and from front-to-back.

Re-check the bedways 24 hours after

installation, two weeks after that, and then

annually to make sure they remain level.

Leveling machinery helps precision components,

such as bedways, remain straight and flat during

the lifespan of the machine. Components on an

unleveled machine may slowly twist due to the

dynamic loads placed on the machine during

operation.

For best results, use a precision level that

is at least 12" long and sensitive enough to

show a distinct movement when a 0.003" shim

(approximately the thickness of one sheet of

standard newspaper) is placed under one end of

the level.

See the figure below for an example of a high

precision level.

8. With assistance to steady the load, move it to

the prepared location and lower it in place.

Figure 10. Example of a precision level.

-13 -

EVS Toolroom Lathes

PREPARATION

To level the machine, use a precision level to

make sure the bedways are level from side-toside and from front-to-back.

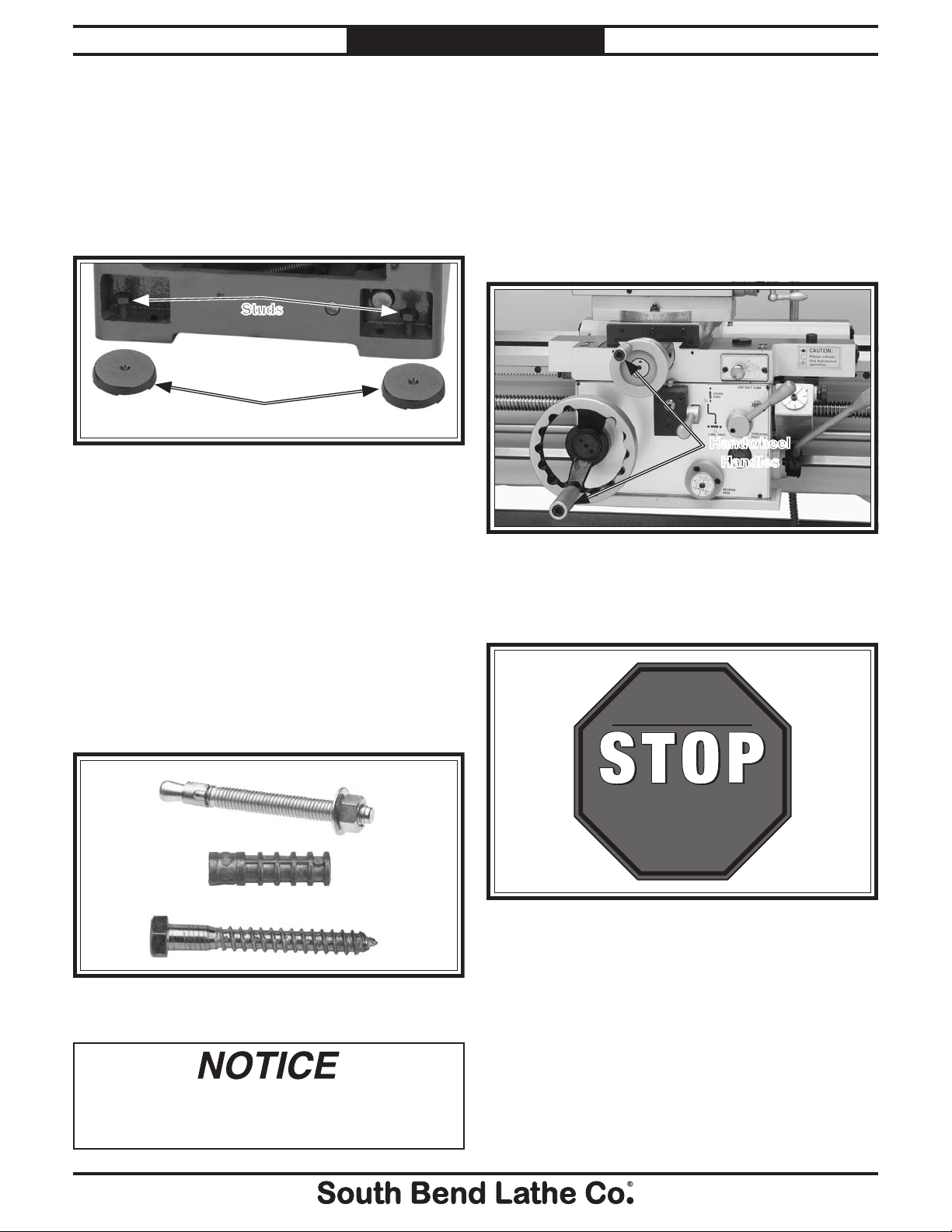

— If using the included leveling pads

(Figure 11), place them under the six

leveling stud locations, then adjust the

studs to level the lathe.

Studs

Pads

For Machines Mfg. Since 7/09

Assembly

With the exception of the handwheel handles, the

lathe is shipped fully assembled.

To install the handwheel handles, thread the

large handle into the carriage handwheel and the

small handle into the cross slide handwheel, as

shown in Figure 13.

Figure 11. Leveling pads and screws.

— If using mounting hardware that does not

allow for adjustment, level the lathe by

placing metal shims between the lathe

base and the floor before bolting down.

Bolting to Concrete Floors

Lag screws and anchors, or anchor studs

(below), are two popular methods for securing

machinery to a concrete floor. We suggest you

research the many options and methods for

securing your machine and choose the best one

for your specific application.

Anchor

Stud

Lag Screw

and Anchor

Figure 12. Common types of fasteners for bolting

machinery to concrete floors.

Most electrical codes require that machines

connected to the power source by fixed

conduit MUST be secured to the floor.

Handwheel

Handles

Figure 13. Handwheel handles installed.

Lubricating Lathe

GEARBOXES MUST

BE FILLED WITH OIL!

NO OIL SHIPPED WITH

MACHINE!

Refer to the Lubrication

Section in this Manual

for Recommended

Oil Type.

The headstock, gearbox, and apron oil reservoirs

must have the proper amount of oil in them

before the lathe can be operated for the first

time.

Running the lathe without oil in a gearbox is

considered unwarrantable abuse, which may

result in damage to the bearings and gears. Refer

to the Lubrication section, beginning on Page

56, for details on how to check and add oil.

-14-

For Machines Mfg. Since 7/09 EVS Toolroom Lathes

In addition to the gearboxes, we also recommend

that you lubricate all other points on the

machine at this time. This can be accomplished

by following the maintenance schedule on Page

54.

Note: If your lathe was shipped with oil in the

gearboxes, do not change that oil until after the

break-in period.

PREPARATION

This machine is equipped with a frequency

drive that contains sensitive electronics,

which can be damaged by a phase converter.

DO NOT use a phase converter to power this

machine. Doing so will void the warranty.

SB1012 (220V 3-Phase)

Full Load Amp Draw ............................ 15.7 Amps

Adding Cutting Fluid

Add the cutting fluid of your choice now. For

detailed instructions on where the cutting fluid

tank is located and how to add fluid, refer to

Cutting Fluid System on Page 62.

Phase ..........................................................3-Phase

Frequency ...................................................... 60 Hz

Minimum Circuit Size ............................. 20 Amps

Recommended Plug/Receptacle ......NEMA L15-20

Minimum Cord Size .......... 12 AWG, 4-Wire, 300V

Maximum Cord Length ................................. 50 ft.

SB1014, SB1037 (220V 3-Phase)

Power Connection

Electrocution or fire

may occur if machine is

ungrounded, incorrectly

connected to power, or

connected to an undersized

circuit. Use a qualified

electrician to ensure a safe

power connection.

Once all preparation steps previously described

in this manual have been completed, the

machine can be connected to the power source.

In order to be connected to the power source, a

circuit must be installed/prepared that meets

the requirements of the lathe, and a power

connection method must be established for that

circuit. The following lists show the minimum

requirements for each model, and instructions

follow for each connection method.

Note About Power Cords: Using an incorrectly

sized cord causes electrical components on

the machine and the cord to become very hot,

which will greatly decrease the life of electrical

components or result in fire. For best results,

use the shortest length of cord possible for your

machine, and never use a smaller cord gauge

than the specified minimum.

Full Load Amp Draw ............................ 21.7 Amps

Phase ..........................................................3-Phase

Frequency ...................................................... 60 Hz

Minimum Circuit Size ............................. 30 Amps

Recommended Plug/Receptacle ......NEMA L15-30

Minimum Cord Size ............ 8 AWG, 4-Wire, 300V

Maximum Cord Length ................................. 50 ft.

SB1013 (440V 3-Phase)

Full Load Amp Draw ............................ 7.75 Amps

Phase ..........................................................3-Phase

Frequency ...................................................... 60 Hz

Minimum Circuit Size ............................. 15 Amps

Recommended Power Connection ........ Hardwire*

SB1015, SB1038 (440V 3-Phase)

Full Load Amp Draw .......................... 10.75 Amps

Phase ..........................................................3-Phase

Frequency ...................................................... 60 Hz

Minimum Circuit Size ............................. 15 Amps

Recommended Power Connection ........ Hardwire*

* Hardwire setups must include a locking

disconnect switch between the power source and

the lathe. Refer to Page 16 for more details.

-15 -

EVS Toolroom Lathes

L3

L1

Gn

Wt

Rd

1

3

5

L2

Bk

PREPARATION

For Machines Mfg. Since 7/09

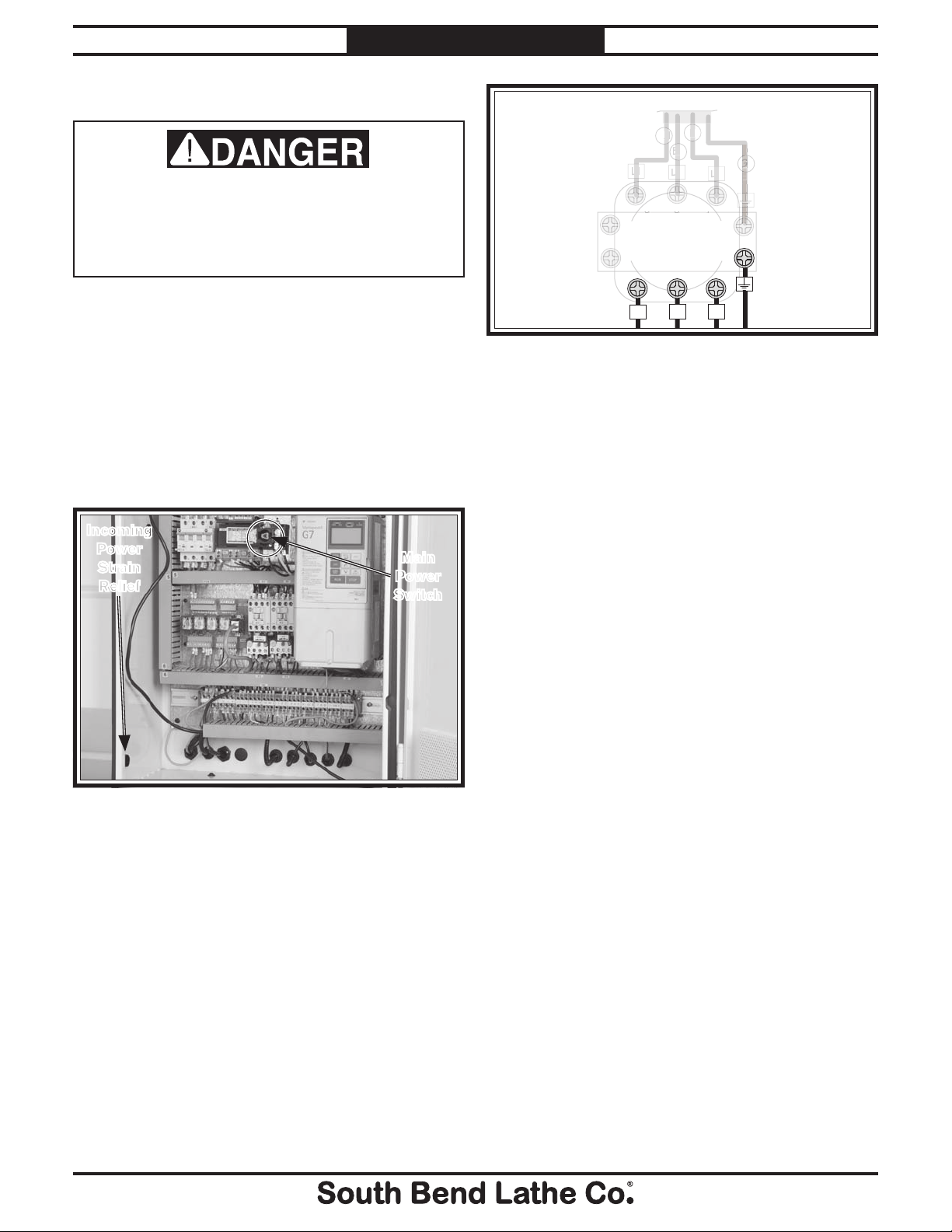

Connecting Power Cord to Lathe

Electrocution or death will occur if you

attempt this procedure with the power cord

connected to the power source. The cord

must be disconnected from power before

performing this procedure.

These instructions are for setups where the lathe

will be connected to the power source with a

power cord and plug, as opposed to a hardwire

setup.

To connect power cord to the lathe:

1. Unlock and open the main electrical cabinet

door, and install a strain relief in the

location shown in Figure 14.

Incoming

Power

Strain

Relief

Main

Power

Switch

To Power Source

Ground

MASTER

POWER SWITCH

6

4

L1

Figure 15. Power connection at main power switch.

2

L3

L2

Power

Connection

Terminals

4. Make sure the cord/wires have loose slack

between the strain relief and terminal

connections, then tighten the strain relief to

secure the power cord.

Note: The strain relief must be tightened against

the outermost jacket of the cord. Avoid overtightening the strain relief or it may crush

the cord and cause a short.

5. Test the strain relief to ensure it is properly

tightened by pulling the cord from outside

the box with light-to-moderate force. When

the strain relief is properly tightened, the

cord will not slide.

Figure 14. Location to connect power inside main

electrical cabinet.

2. Thread the power cord through the strain

relief, and up to the main power switch

shown in Figure 14.

3. Connect the incoming L1, L2, L3 and ground

wires to the main power switch terminals, as

illustrated in Figure 15.

6. Close and lock the main electrical box door.

Hardwiring Lathe to Power

Source

Hardwire setups require power supply lines to

be enclosed inside of conduit, which is securely

mounted and constructed in adherence to

applicable electrical codes.

A hardwire setup for this machine must be

equipped with a locking disconnect switch

as a means to disconnect the power during

adjustments or maintenance, which is a typical

requirement for lock-out/tag-out safety programs

(commonly required by OSHA).

Figure 16 shows a simple diagram of a hardwire

setup with a locking disconnect switch between

the power source and the machine.

-16 -

For Machines Mfg. Since 7/09 EVS Toolroom Lathes

PREPARATION

Locking

Power Source

Conduit Conduit

Figure 16. Typical hardwire setup with a locking

Due to the complexity required for planning,

bending, and installing the conduit necessary for

a hardwire setup, this type of setup can only be

performed by an experienced electrician.

For Electrician: Connect the incoming power

wires as shown in Figure 15.

Disconnect Switch

disconnect switch.

Machine

Correcting Out-of-Phase Wiring

This sub-section is only provided for

troubleshooting. If you discover during the test

run that the lathe will not operate, or that the

spindle runs backwards, the lathe may be wired

out of phase. Without the proper test equipment

to determine the phase of power source legs,

wiring machinery to 3-phase power may require

trial-and-error. Correcting this is simply a

matter of reversing the positions where two of

the incoming power source wires are connected.

To correct wiring that is out of phase:

1. Push the stop button, turn the main power

switch to OFF, and disconnect the machine

from power (or shut OFF and lock out the

power source if hardwired).

2. Open the electrical box and disconnect the

L1 and L2 wires shown in Figure 15 on the

"To Power Source" side of the switch.

3. Connect the L1 wire to the terminal where

the L2 wire was connected originally.

4. Connect the L2 wire to the terminal where

the L1 wire was connected originally.

5. Close and latch the electrical box, and

reconnect the machine to the power source.

Test Run

After all preparation steps have been completed,

the machine and its safety features must be

tested to ensure correct operation. If you discover

a problem with the operation of the machine or

its safety components, shut the machine down,

disconnect it from power, and do not operate it

again until you have resolved the problem.

Note: The variable speed on this machine is

controlled by a frequency drive unit constructed

with sensitive electronics. These electronics

can be damaged if power is disconnected during

operation. Therefore, unless the stop button and

brake lose functionality, always properly shut

the machine down before disconnecting it from

the power source.

A Troubleshooting section is provided, starting

on Page 74, to assist you with solutions if a

problem occurs or if the lathe does not function

as described in this section.

If you need additional help after reviewing the

troubleshooting section, or you are not confident

troubleshooting the machine on your own,

contact our tech support at (360) 734-1540.

To test run your machine:

1. Read and follow the safety instructions at

the beginning of the manual, take required

safety precautions, and make sure all

previous preparation steps discussed in this

manual have been followed and completed.

2. Clear away all tools and objects used during

assembly, lubrication, and preparation.

3. DISCONNECT LATHE FROM POWER!

4. Make sure that the chuck and jaws, if

installed, are secure (refer to Chuck and

Faceplate Mounting on Page 27).

Note: If a chuck is not installed on the lathe, you

do not need to install one for this test.

5. Turn the pump switch (Figure 17) to the

OFF position, and point the fluid nozzle into

the chip drawer.

-17-

EVS Toolroom Lathes

PREPARATION

Stop Button

For Machines Mfg. Since 7/09

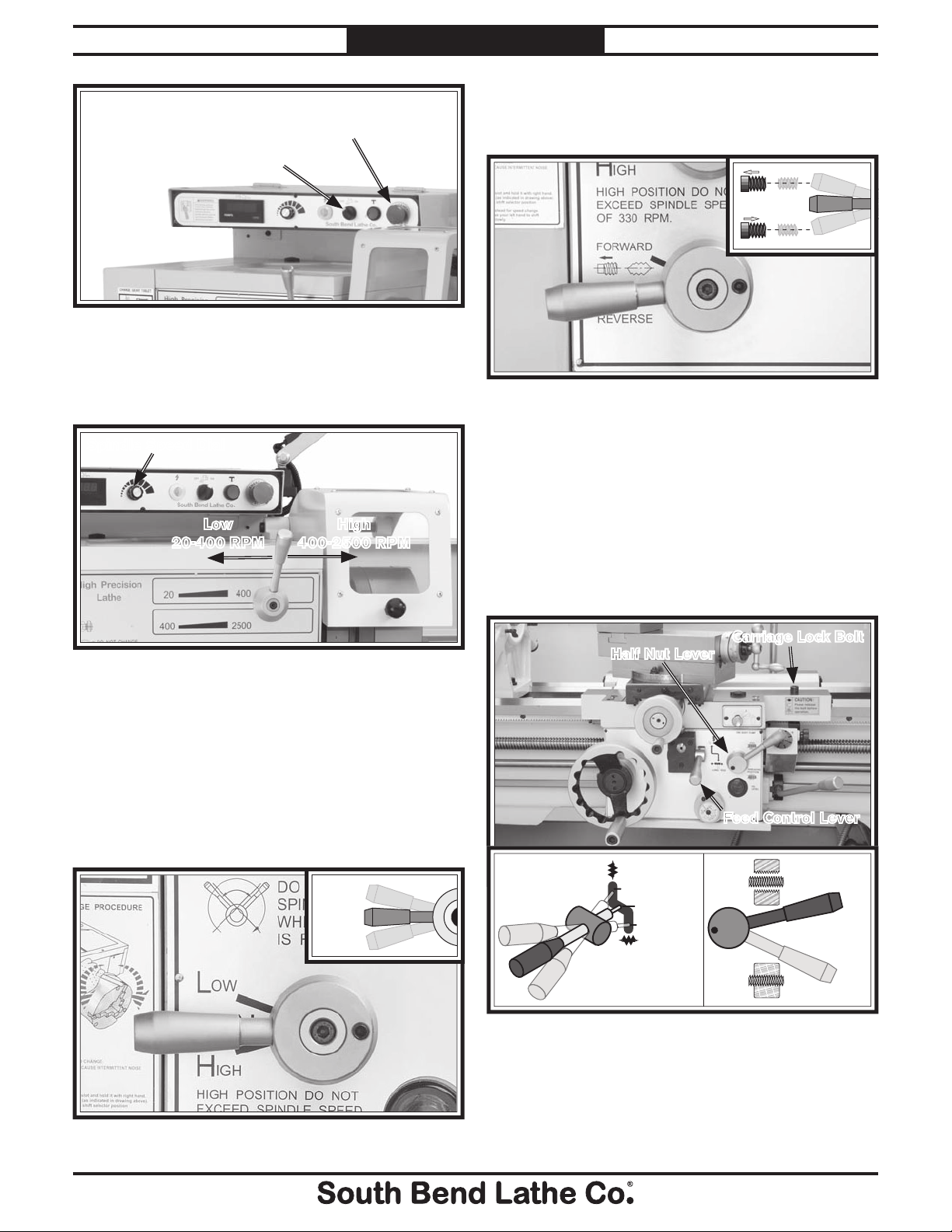

9. Move the feed direction forward/reverse lever

to the middle (neutral) position, as shown in

Figure 20.

Pump Switch

Figure 17. Control panel-test run.

6. Turn the spindle speed dial (Figure 18) all

the way counterclockwise (lowest speed) to

avoid possibility of a high-speed start.

Spindle Speed Dial

Low

20-400 RPM

High

400-2500 RPM

FORWARD

NEUTRAL

REVERSE

Figure 20. Feed direction forward/reverse lever in the

neutral position.

10. Disengage the half nut lever, put the feed

control lever in neutral, and make sure the

carriage lock bolt is loose (see Figure 6).

This step will allow the carriage to move

freely when the handwheel is rotated and

make sure that the carriage will not move

when the lathe is started.

Figure 18. Spindle speed controls.

7. Move the spindle speed range lever (Figure

18) to the left so the headstock is set in the

low range (20-400 RPM). (You may need to

slightly rotate the chuck by hand to engage

the lever.)

8. Move the gearbox range lever to the middle

(neutral) position, as shown in Figure 19.

LOW

Neutral

HIGH

Carriage Lock Bolt

Half Nut Lever

Feed Control Lever

Cross Slide

Neutral

Carriage

FEED CONTROL

LEVER

Figure 21. Controls used to disengage carriage so that

it will move freely when the handwheel is turned.

Disengaged

HALF NUT

LEVER

Engaged

Figure 19. Gearbox range lever in middle position.

-18 -

For Machines Mfg. Since 7/09 EVS Toolroom Lathes

PREPARATION

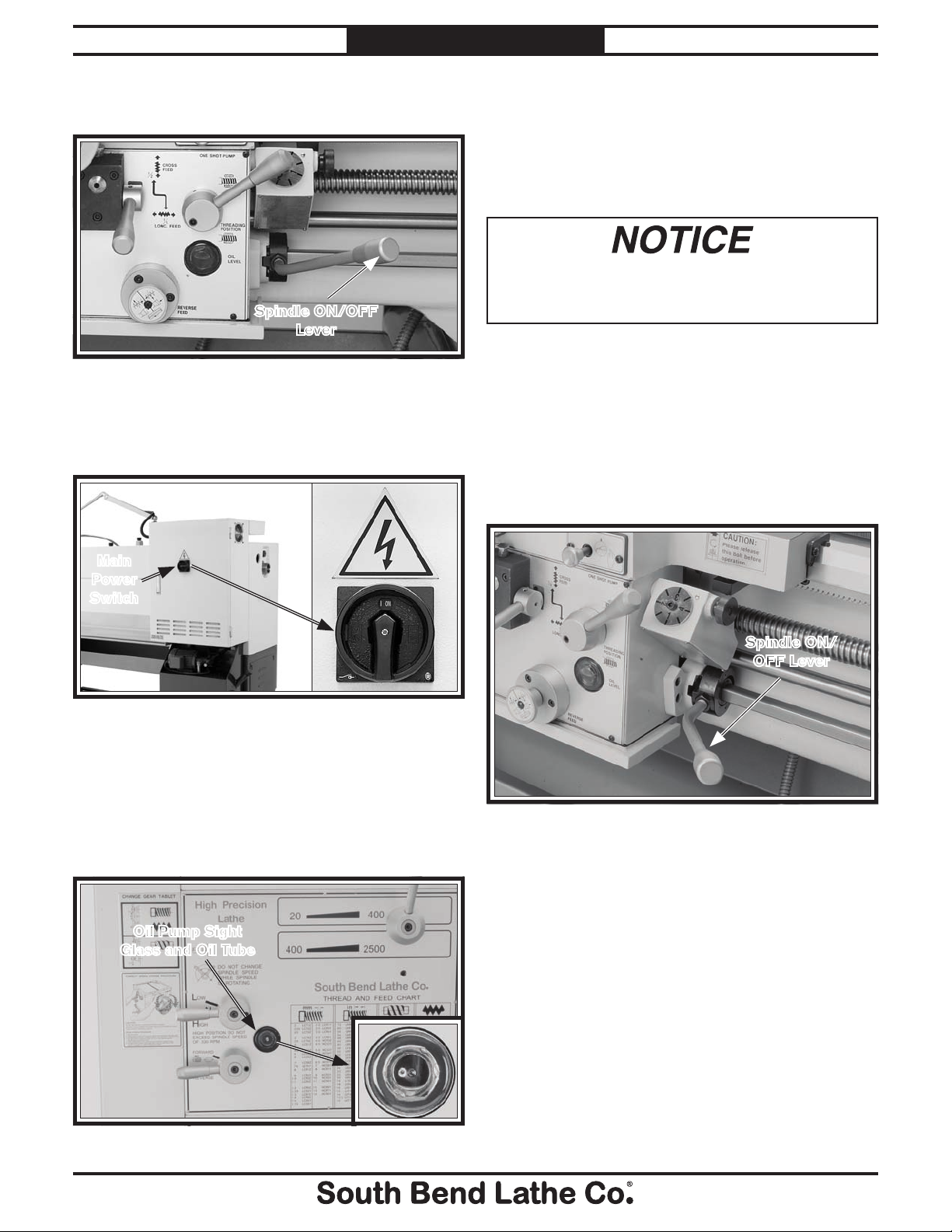

11. Move the spindle ON/OFF lever to the OFF

(center) position, as shown in Figure 22.

Spindle ON/OFF

Lever

Figure 22. Spindle ON/OFF lever-setup.

12. Connect the lathe to power source, then turn

the main power switch (Figure 23) to the

ON position.

Note: This headstock has a pressurized oil

system that is equipped with an oil pressure

safety switch. If oil stops flowing or does not

flow to start with, the lathe will not operate

until the oil is properly flowing. Refer to

Troubleshooting to correct.

Never bypass the oil pressure safety switch!

If you do, you will void the warranty, and

headstock damage may occur.

14. Make sure that all bystanders are out of the

way, tools are cleared away, and the chuck

key is removed from the chuck.

15. Move the spindle ON/OFF lever (Figure

25) down and the chuck will rotate counter-

clockwise (down and toward you, as you face

the front of the lathe).

Main

Power

Switch

Figure 23. Main power switch in ON position.

13. Rotate the stop button (Figure 17 on Page

18) clockwise until it pops out. The pump

will turn ON. Observe the oil pump tube

sight glass (Figure 24). Verify that you see

oil flowing out of the tube and against the

sight glass.

Oil Pump Sight

Glass and Oil Tube

Spindle ON/

OFF Lever

Figure 25. Spindle Lever in ON position.

16. Observe the lathe and listen for any

abnormal noises or vibration. The lathe

should run smoothly with little or no

vibration or rubbing noises.

17. Push the stop button. The lathe should stop.

Figure 24. Oil pump sight glass and oil tube.

-19 -

EVS Toolroom Lathes

PREPARATION

For Machines Mfg. Since 7/09

18. Move the spindle ON/OFF lever up to the

OFF position, reset the stop button by

twisting it clockwise until it pops out, then

restart the spindle with the lever.

19. Push the foot brake. The lathe should come

to a quick stop.

— If the brake pedal has no effect on the

lathe, push the stop button, and refer to

V-Belts and Brake & Switch on Page

69 to make any required adjustments.

20. Remove the lathe headstock side cover. The

kill switch mounted to the headstock should

prevent the lathe from starting while this

cover is removed.

21. Stand away from all the exposed gears on

the side of the headstock, and attempt to

start the lathe.

— If the lathe starts, the safety switch is not

functioning properly and may need to be

replaced before the machine can be safely

operated.

22. Replace the headstock side cover, then start

the lathe again.

Note: The lathe will not start if the headstock

side cover is not properly installed.

23. Turn the cutting fluid pump ON, and open

the valve. Verify that fluid flows from the

nozzle, then turn the cutting fluid pump

OFF.

The test run is now finished. Shut the lathe down

and begin the Spindle Break-In procedure.

-20-

For Machines Mfg. Since 7/09 EVS Toolroom Lathes

PREPARATION

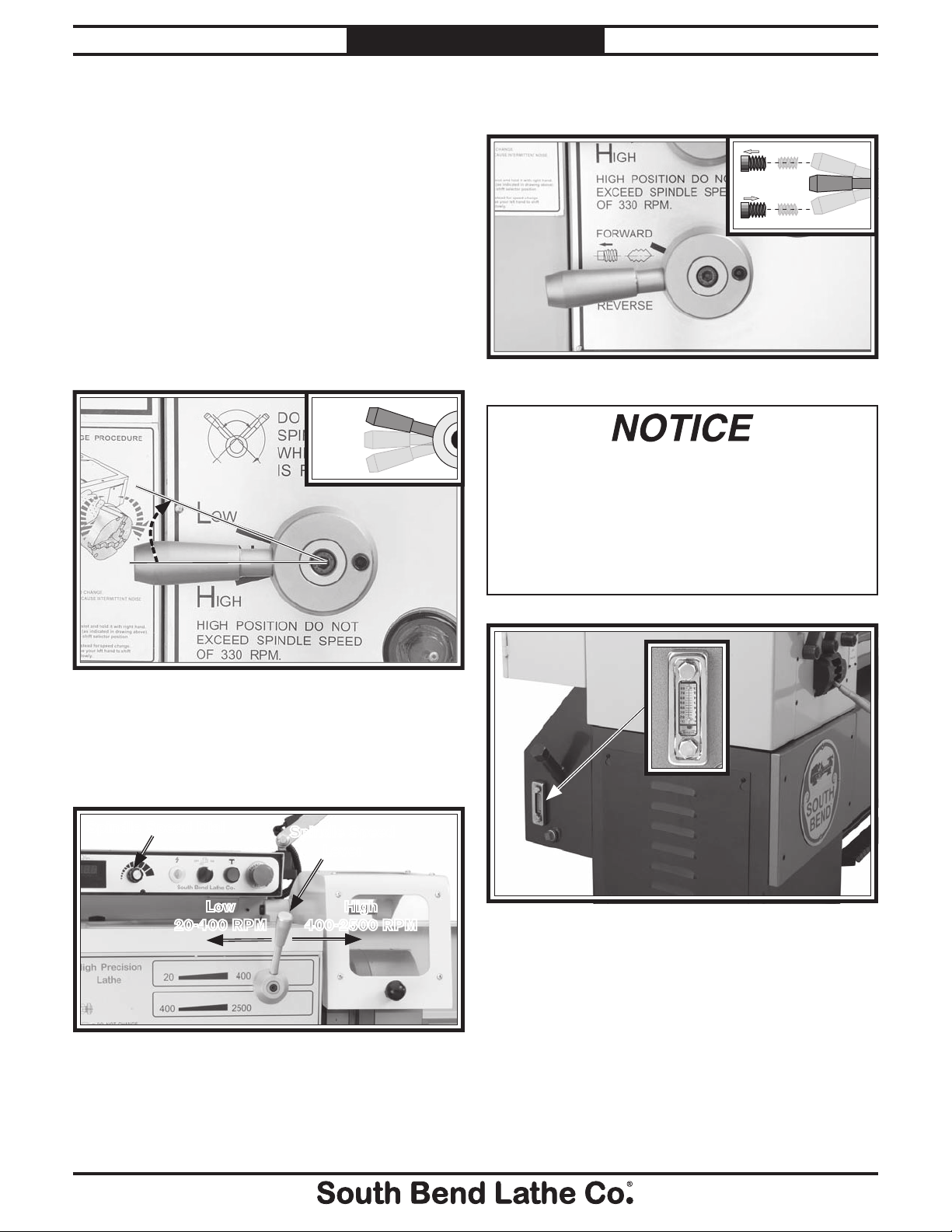

4. Move the feed direction forward/reverse lever

Spindle Break-In

It is essential to closely follow the proper break-in

procedures to ensure trouble-free performance.

Complete this process once you have familiarized

(Figure 28) to the neutral position.

FORWARD

NEUTRAL

yourself with all instructions in this manual and

completed the test run.

REVERSE

To complete the spindle break-in:

1. Successfully complete the Test Run

procedure beginning on Page 17.

2. Move the gearbox range lever to low range

position, as shown in Figure 26.

LOW

Neutral

HIGH

Figure 28. Feed direction lever in neutral position.

Do not leave the lathe unattended during the

break-in period. Make sure that you keep a

close eye on the headstock oil thermometer

(Figure 29) on the oil reservoir. If the

headstock oil temperature reaches 160°F,

shut the lathe down and let the system cool

before resuming break-in.

Figure 26. Gearbox range lever-break in.

3. Turn the spindle speed dial (Figure 27) all

the way counterclockwise to the minimum

speed, and move the spindle speed range

lever to the low range.

Spindle Speed Dial

Low

20-400 RPM

Figure 27. Spindle speed controls.

Spindle Speed

Lever

High

400-2500 RPM

Figure 29. Oil temperature thermometer.

-21-

EVS Toolroom Lathes

PREPARATION

For Machines Mfg. Since 7/09

5. Disengage the half nut and the feed control

levers shown in Figures 30–31.

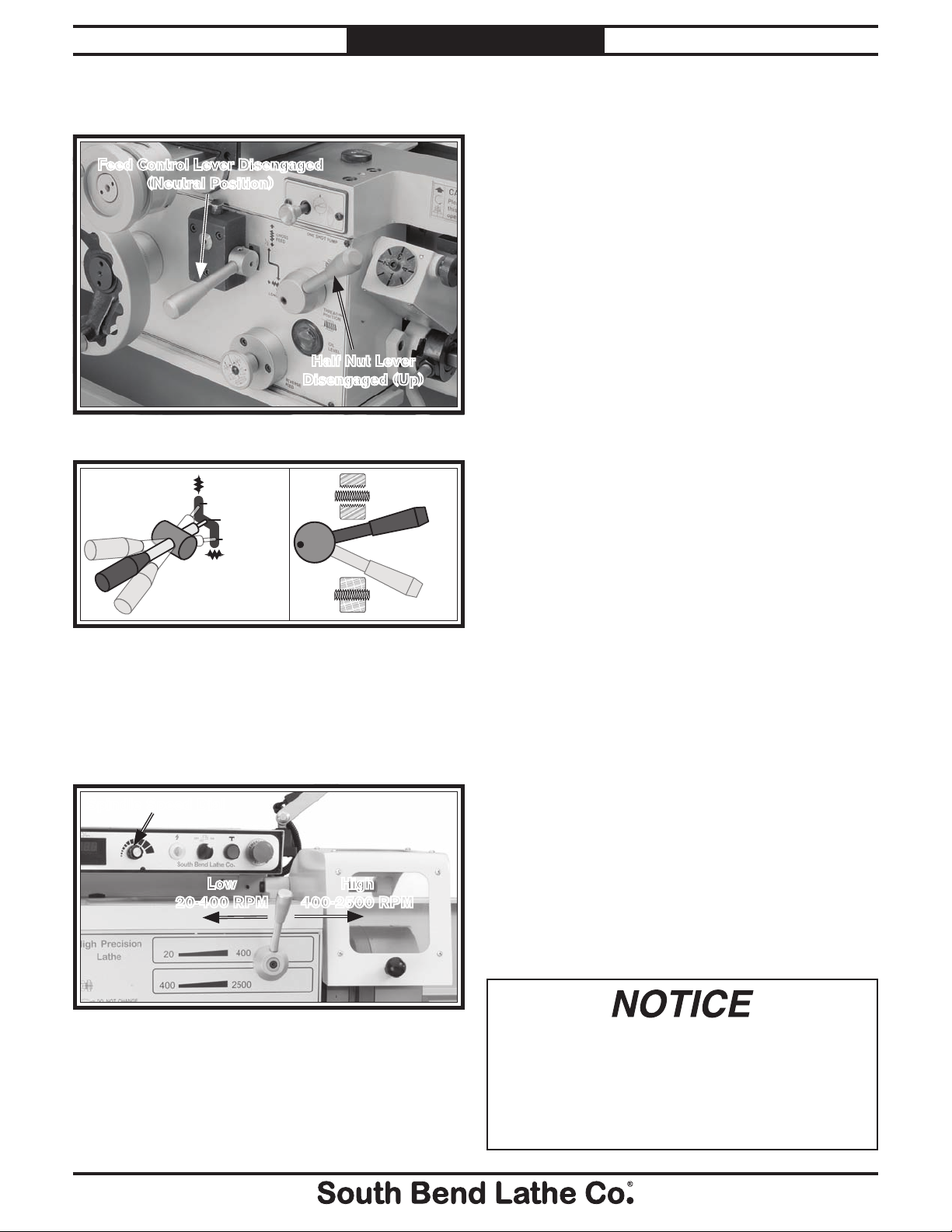

Feed Control Lever Disengaged

(Neutral Position)

Half Nut Lever

Disengaged (Up)

Figure 30. Power fed and half nut levers disengaged.

Cross Slide

Neutral

Carriage

FEED CONTROL

LEVER

Figure 31. Feed control lever and half nut in

disengaged positions.

6. Turn the lathe ON, and let it run for ten

minutes in each speed of 20, 200, and 400

RPM, using the spindle speed dial (Figure

32) to adjust the speed.

Spindle Speed Dial

Disengaged

HALF NUT

LEVER

Engaged

7. After completing the previous step, stop the

spindle and move the gearbox range lever to

neutral, then move the spindle speed range

lever to high.

8. Turn the lathe ON and let it run for ten

minutes in each speed of 400, 1000, and 2500

RPM.

9. After completing Step 8, reduce the spindle

speed to 400 RPM and let the lathe run for a

final 15 minutes as a cool-down.

10. Turn the lathe OFF.

11. Change the oil in all of the reservoirs,

tighten the V-belts, and perform all

other lubrication steps mentioned in the

Maintenance section of this manual.

Recommended

Adjustments

For your convenience, the adjustments listed

below have been performed at the factory.

However, because of the many variables involved

with shipping, we recommend that you at least

verify the following adjustments to ensure the

best possible results from your new machine.

Step-by-step instructions for these adjustments

can be found on the pages referenced below.

Factory adjustments that should be verified:

s 4AILSTOCKALIGNMENTPage 34).

-22-

Low

20-400 RPM

Figure 32. Spindle speed controls.

High

400-2500 RPM

s #OMPOUNDANDCROSSSLIDEBACKLASH

adjustment (Page 65).

s 'IBADJUSTMENTSPage 66).

After the first 16 hours of use, the V-belts will

stretch and seat into the pulley grooves. The

V-belts must be properly re-tensioned after

this period to avoid reducing their useful life.

Refer to the V-Belts section on Page 69 for

detailed instructions.

Loading...

Loading...