Southbend SB1021, SB1022 User Manual 2

14" METAL CUTTING BANDSAW

MODEL SB1021 - SINGLE PHASE

MODEL SB1022 - THREE PHASE

Copyright © August, 2009 For Machines Mfg. Since 8/09

Scope of Manual

This manual helps the reader understand the machine, how to prepare it for operation, how to control

it during operation, and how to keep it in good working condition. We assume the reader has a basic

understanding of how to operate this type of machine, but that the reader is not familiar with the

controls and adjustments of this specific model. As with all machinery of this nature, learning the

nuances of operation is a process that happens through training and experience. If you are not an

experienced operator of this type of machinery, read through this entire manual, then learn more

from an experienced operator, schooling, or research before attempting operations. Following this

advice will help you avoid serious personal injury and get the best results from your work.

Manual Feedback

We've made every effort to be accurate when documenting this machine. However, errors sometimes

happen or the machine design changes after the documentation process—so the manual may not

exactly match your machine. If a difference between the manual and machine leaves you in doubt,

contact our customer service for clarification.

We highly value customer feedback on our manuals. If you have a moment, please share your

experience using this manual. What did you like about it? Is there anything you would change to

make it better? Did it meet your expectations for clarity, professionalism, and ease-of-use?

South Bend Lathe, Inc.

C

/O Technical Documentation Manager

P.O. Box 2027

Bellingham, WA 98227

Email: manuals@southbendlathe.com

Updates

For your convenience, any updates to this manual will be available to download free of charge

through our website at:

www.southbendlathe.com

Customer Service

We stand behind our machines. If you have any service questions, parts requests or general questions

about the machine, feel free to contact us.

South Bend Lathe Co.

P.O. Box 2027

Bellingham, WA 98227

Phone: (360) 734-1540

Parts Department: (417) 886-2954

Fax: (360) 676-1075 (International)

Fax: (360) 734-1639 (USA Only)

Email: cs@southbendlathe.com

Table of Contents

INTRODUCTION ...............................................................2

About This Machine .............................................2

Capabilities ......................................................... 2

Features .............................................................. 2

Identification ........................................................ 3

Machine Specifications ........................................ 4

SAFETY ................................................................................8

Understanding Risks of Machinery .................... 8

Basic Machine Safety ..........................................8

Additional Metal Cutting Bandsaw Safety ......10

PREPARATION .............................................................. 11

Preparation Overview ........................................ 11

Things You'll Need .............................................11

Unpacking ..........................................................11

Cleaning & Protecting ....................................... 12

Location .............................................................. 13

Lifting & Moving ................................................14

Leveling & Mounting ......................................... 14

Leveling ............................................................14

Bolting to Concrete Floors ..................................15

Machine Mounts ................................................ 15

Assembly ............................................................15

Initial Lubrication .............................................15

Inspections & Adjustments ............................... 15

Power Connection .............................................. 16

220V Conversion for SB1021 .............................. 16

SB1021 110V (Prewired) Power Source ..............16

SB1021 (220V) Power Source .............................16

SB1022 (220V 3-Phase) Power Source ................16

Test Run ............................................................. 17

OP ER ATIO N .................................................................... 18

Operation Overview ........................................... 18

Controls ..............................................................19

Blade Selection ...................................................20

Blade Terminology .............................................20

Blade Length ..................................................... 20

Blade Width ......................................................20

Tooth Set ...........................................................21

Tooth Type ........................................................21

Blade Pitch (TPI) ............................................... 22

Blade Changes ...................................................23

Blade Tensioning ............................................... 23

Blade Breakage .................................................. 24

Blade Care & Break-In ...................................... 24

Blade Care ........................................................24

Blade Break-In .................................................. 24

Blade Speed Chart .............................................25

Chip Inspection Chart ....................................... 25

Positioning Guide Post ...................................... 26

Adjusting Blade Guides ..................................... 26

Tilting Table .......................................................28

Blade Welding ....................................................28

MAINTENANCE ............................................................. 32

Maintenance Schedule .......................................32

Cleaning .............................................................32

Dressing Grinding Wheel .................................. 32

Lubrication ......................................................... 33

V-Belts ................................................................ 34

Speed Hub Belts ................................................ 34

Sprocket Drive Belt ...........................................34

Air Pump Belt ...................................................34

Dressing Rubber Tires ....................................... 34

SERVICE........................................................................... 35

Blade Tracking ................................................... 35

Table Calibration ............................................... 35

Guide Post Alignment........................................36

Pinion Gear Backlash ........................................37

Leadscrew End Play .......................................... 37

TROUBLESHOOTING .................................................38

ELECTRICAL ...................................................................42

Electrical Safety Instructions ...........................42

Wiring Overview ................................................ 43

SB1021/2 Control Panel & Welding Unit ......... 44

SB1021 110V Electrical Panel, Motor & Cord .45

SB1021 220V Electrical Panel, Motor & Cord .46

SB1022 220V Electrical Panel, Motor & Cord .47

Electrical Component Pictures..........................48

PARTS................................................................................49

Lower Frame ......................................................49

Drive System ...................................................... 51

Upper Frame ...................................................... 53

Table & Tensioning System ..............................55

Electrical Cabinet .............................................. 57

Welder & Control Panel ....................................58

Machine Labels .................................................. 60

WARRANTY & RETURNS ..........................................61

Model SB1021/SB1022

INTRODUCTION

INTRODUCTION

About This Machine

For Machines Mfg. Since 8/09

Capabilities

This 14" Metal-Cutting Bandsaw allows you to

make exterior and interior contoured or straight

cuts. To better understand these capabilities,

imagine making a "doughnut" out of 1" steel

plate.

The outside circular shape can be easily cut by

moving the workpiece around the blade, using a

pre-drawn line as a cutting guide.

Cutting the inside hole would normally be a

difficult task with a bandsaw. But this machine

makes it easy. First, the bandsaw blade is cut

with the built-in blade shear. A hole slightly

larger than the blade is then drilled into the

center of the workpiece, so the blade can be

threaded through the hole. The ends of the blade

are then clamped into the built-in welder, welded

back together, annealed, and ground flat with the

built-in grinder. Once the blade is re-installed on

the wheels, it can then be used to cut the interior

hole and complete the doughnut shape. After

completion, the blade is sheared again to remove

it from the workpiece.

Aside from the above capabilities, this machine

can also be used for straight cuts in sheets too

large to fit in the vise of a horizontal metalcutting bandsaw

Features

Now that you know the basics of what this

machine can do, take a minute to consider its

features.

This machine is equipped with a built-in air

blower near the blade guides. This feature keeps

metal chips away from the cutting area, so you

can accurately follow pre-drawn cutting lines

without metal chips getting in the way.

An adjustable work lamp is also provided above

the table to eliminate shadows from the work

area. This is a great feature when doing close up

work near moving blades!

We also equipped this bandsaw with variable

speed, so you can precisely control cutting

results for the type of blade installed and type

of material being cut. This is a great feature to

have when doing precision cutting.

Aside from features, we designed this machine to

be extremely solid and durable. We used heavy

gauge steel for the wheel doors, ridiculously thick

table trunnions and frame castings, USA-made

Allen-Bradley electronics, and Japanese-made

NSK ball bearings.

For example, if you needed to cut a 24" x

24" sheet of 1" steel in half, you can clamp a

straightedge to the bandsaw table, then guide

the sheet along the straightedge to make a nice

straight cut. Cutting this same size of stock on a

horizontal bandsaw would require a very large

machine.

On the other hand, if you need to "resaw" an 8"

x 8" billet into a series of 1" thick plates, clamp

a straightedge 1" away from the blade, raise the

blade guides to accommodate the height of the

billet, and each cut you make will produce an 8"

x 1" plate.

Both of these types of straight cuts can also be

made with the table tilted to 15°, which creates a

beveled cut.

-2-

For Machines Mfg. Since 8/09 Model SB1021/SB1022

INTRODUCTION

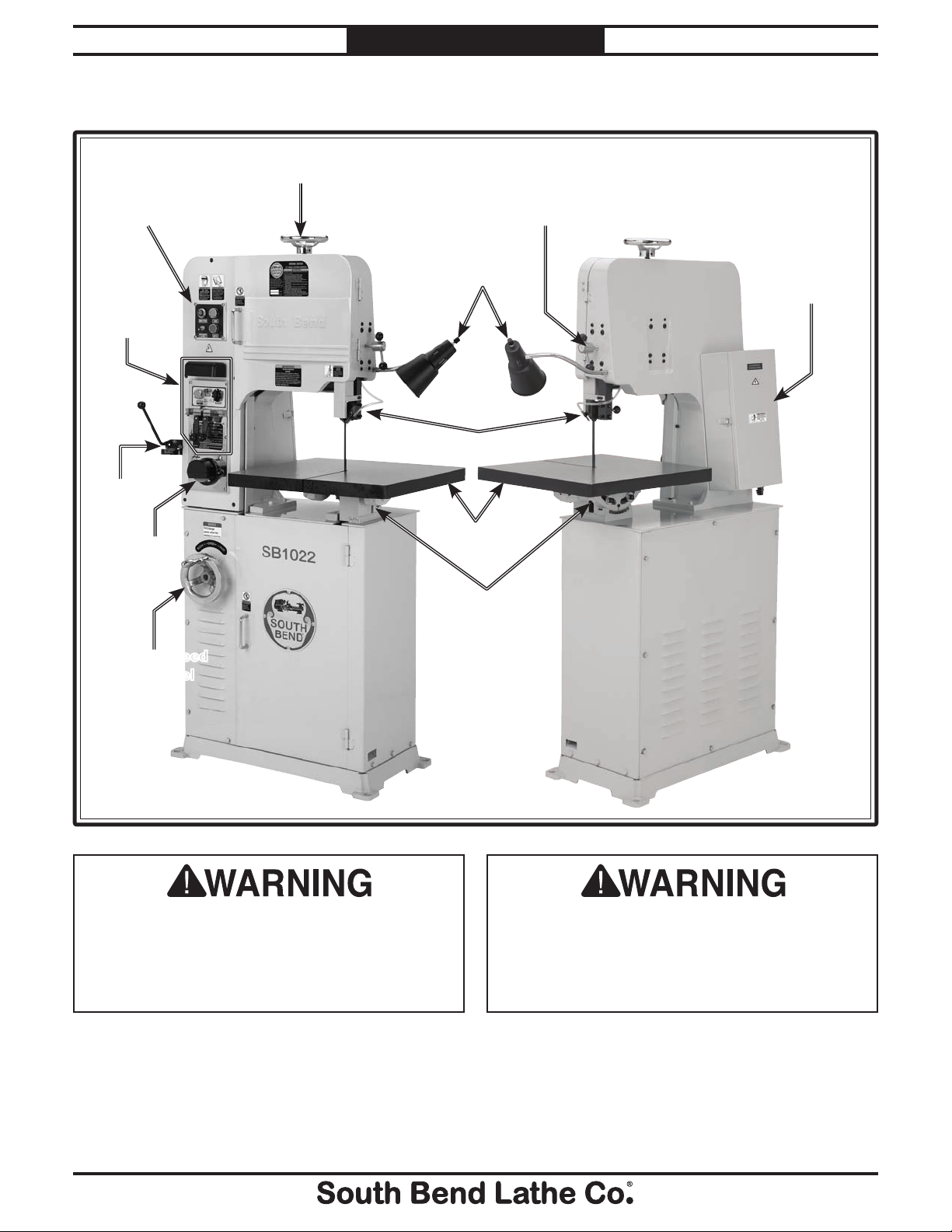

Identification

Blade Tension Handwheel

Operation

Controls

Welding

Area

Air Blower

Blade

Shear

Table

Grinder

Guide Post

Elevation Knob

Work

Lamp

Electrical

Control Box

Variable Speed

Handwheel

Front View Rear View

Serious personal injury could occur if

you connect the machine to power before

completing the setup process. DO NOT

connect power until instructed to do so later

in this manual.

Table Trunnions

Untrained users have an increased risk

of seriously injuring themselves with this

machine. Do not operate this machine until

you have understood this entire manual and

received proper training.

-3-

Model SB1021/SB1022

INTRODUCTION

Machine Specifications

Machine Specifications

Model SB1021 14" Variable Speed

Vertical Metal Cutting Bandsaw

Product Dimensions:

Weight ..........................................................................................................................................................................697 lbs.

Length/Width/Height ................................................................................................................................... 22" x 36" x 67

Foot Print (Length/Width) ......................................................................................................................................16

Shipping Dimensions:

Type ...................................................................................................................................................................................Wood

Content ........................................................................................................................................................................ Machine

Weight ...........................................................................................................................................................................926 lbs.

Length/Width/Height ....................................................................................................................................... 77" x 42" x 29"

P.O. Box 2027, Bellingham, WA 98227 U.S.A.

0(/.%s

www.southbendlathe.com

For Machines Mfg. Since 8/09

© South Bend Lathe Co.

1

⁄4" x 31"

1

⁄2"

Electrical:

Required Power Source ..................................................................................................................... 110/220V, Single-Phase

Switch ..................................................................................................... Magnetic Contactor with Thermal Overload Relay

Switch Voltage ........................................................................................................................................................... 110/220V

Included Plug Type ................................................................................................................................................NEMA 5-15

Recommended Circuit Size ................................................................................................................................................ 15A

Motors:

Main

Type ............................................................................................................................TEFC Capacitor Start Induction

Horsepower .............................................................................................................................................................. 1 HP

Voltage .............................................................................................................................................................. 110/220V

Phase ..................................................................................................................................................................... Single

Amps ..........................................................................................................................................6A @ 220V/12A @ 110V

Speed ............................................................................................................................................................... 1725 RPM

Cycle .......................................................................................................................................................................60 Hz

Number Of Speeds .........................................................................................................................................................1

Power Transfer ............................................................................................................................................... Belt Drive

Bearings ............................................................................................................ Shielded and Permanently Lubricated

Grinder

Type ..................................................................................................................................... Open Drip Proof Induction

Horsepower .............................................................................................................................................................

Voltage ..................................................................................................................................................................... 110V

Phase ..................................................................................................................................................................... Single

Amps ......................................................................................................................................................................... 0.6A

Speed ............................................................................................................................................................... 3450 RPM

Cycle .......................................................................................................................................................................60 Hz

Number Of Speeds .........................................................................................................................................................1

Power Transfer ............................................................................................................................................ Direct Drive

Bearings ...................................................................................................................................... Sealed and Lubricated

1

⁄8 HP

-4-

For Machines Mfg. Since 8/09 Model SB1021/SB1022

INTRODUCTION

Main Specifications:

Operation Information

Number of Blade Speeds .................................................................................................................................. Variable

Blade Speed Range .................................................................................................................................... 88–384 FPM

Blade Size Range ..................................................................................................................................................

Blade Length Range .................................................................................................................................118

1

⁄8"– 1⁄2"

1

⁄4"–119 1⁄2"

Cutting Capacity

Maximum Cutting Height ........................................................................................................................................ 7

Cutting Capacity Left of Blade .............................................................................................................................. 14

7

⁄8"

1

⁄8"

Table Information

Table Tilt .................................................................................................................. 15° Left/Right, 10° Forward/Back

Table Size ....................................................................................................................... 22

Floor to Table Height .............................................................................................................................................. 39

1

⁄8"W x 19 7⁄8" L x 1 5⁄8" Thick

1

⁄2"

Construction

Table ...................................................................................................................................Precision Ground Cast Iron

Wheels ............................................................................................................................................. Balanced Cast Iron

Tires ......................................................................................................................................................................Rubber

Blade Guide ........................................................................................................................... Hardened Steel/Tungsten

Body (Upper) .................................................................................................................................................... Cast Iron

Body (Lower) ........................................................................................................................................................... Steel

Base ..................................................................................................................................................................Cast Iron

Wheel Cover (Upper) ............................................................................................................................ Cast Aluminum

Wheel Cover (Lower) ......................................................................................................................... Pre-Formed Steel

Wheel Bearings ...................................................................... Japanese NSK Shielded and Permanently Lubricated

Paint .................................................................................................................................................................Urethane

Other Related Information

Wheel Diameter ...................................................................................................................................................... 14

Electric Blade Welder ............................................................................................................................. 220V, 2.0 KVA

Annealing Voltage ................................................................................................................................................... 220V

Other Specifications:

Country Of Origin ........................................................................................................................................................ Taiwan

Warranty .........................................................................................................................................................................1 Year

Serial Number Location ........................................................................................................ID Label on Upper Wheel Door

Assembly Time............................................................................................................................................................... 1 Hour

Features:

Allen Bradley Controls

Welding Station for Joining Blade Ends

Includes Blade Cutter, Electric Welder w/Clamp, Annealer, and Grinder

Infinitely Variable Cutting Speeds

Lower Wheel Cleaning Brush

Work Light

Chip Blower

Rubber Bonded Saw Wheels

1

⁄8"

-5-

Model SB1021/SB1022

Machine Specifications

Model SB1022 14" Variable Speed

Vertical Metal Cutting Bandsaw

Product Dimensions:

Weight ..........................................................................................................................................................................697 lbs.

Length/Width/Height ................................................................................................................................... 22" x 36" x 67

Foot Print (Length/Width) ......................................................................................................................................16

Shipping Dimensions:

Type ...................................................................................................................................................................................Wood

Content ........................................................................................................................................................................ Machine

Weight ...........................................................................................................................................................................926 lbs.

Length/Width/Height ....................................................................................................................................... 77" x 42" x 29"

INTRODUCTION

P.O. Box 2027, Bellingham, WA 98227 U.S.A.

0(/.%s

© South Bend Lathe Co.

www.southbendlathe.com

For Machines Mfg. Since 8/09

1

⁄2"

1

⁄4" x 31"

Electrical:

Required Power Source .....................................................................................................................................220V, 3-Phase

Switch ..................................................................................................... Magnetic Contactor with Thermal Overload Relay

Switch Voltage .................................................................................................................................................................. 220V

Cord Included .......................................................................................................................................................................No

Recommended Cord Type .............................................................................................................16 Gauge, 4 Wire, 300VAC

Recommended Plug Type ..................................................................................................................................NEMA L15-15

Recommended Circuit Size .......................................................................................................................................... 15 amp

Motors:

Main

Type ............................................................................................................................TEFC Capacitor Start Induction

Horsepower .............................................................................................................................................................. 1 HP

Voltage ..................................................................................................................................................................... 220V

Phase ......................................................................................................................................................................Three

Amps ............................................................................................................................................................................ 3A

Speed ............................................................................................................................................................... 1725 RPM

Cycle .......................................................................................................................................................................60 Hz

Number Of Speeds .........................................................................................................................................................1

Power Transfer ............................................................................................................................................... Belt Drive

Bearings ............................................................................................................ Shielded and Permanently Lubricated

Grinder

Type ..................................................................................................................................... Open Drip Proof Induction

Horsepower .............................................................................................................................................................

Voltage ..................................................................................................................................................................... 110V

Phase ..................................................................................................................................................................... Single

Amps ......................................................................................................................................................................... 0.6A

Speed ............................................................................................................................................................... 3450 RPM

Cycle .......................................................................................................................................................................60 Hz

Number Of Speeds .........................................................................................................................................................1

Power Transfer ............................................................................................................................................ Direct Drive

Bearings ...................................................................................................................................... Sealed and Lubricated

1

⁄8 HP

-6-

For Machines Mfg. Since 8/09 Model SB1021/SB1022

INTRODUCTION

Main Specifications:

Operation Information

Number of Blade Speeds .................................................................................................................................. Variable

Blade Speed Range .................................................................................................................................... 88–384 FPM

Blade Size Range ..................................................................................................................................................

Blade Length Range .................................................................................................................................118

1

⁄8"– 1⁄2"

1

⁄4"–119 1⁄2"

Cutting Capacity

Maximum Cutting Height ........................................................................................................................................ 7

Cutting Capacity Left of Blade .............................................................................................................................. 14

7

⁄8"

1

⁄8"

Table Information

Table Tilt .................................................................................................................. 15° Left/Right, 10° Forward/Back

Table Size ....................................................................................................................... 22

Floor to Table Height .............................................................................................................................................. 39

1

⁄8"W x 19 7⁄8" L x 1 5⁄8" Thick

1

⁄2"

Construction

Table ...................................................................................................................................Precision Ground Cast Iron

Wheels ............................................................................................................................................. Balanced Cast Iron

Tires ......................................................................................................................................................................Rubber

Blade Guide ........................................................................................................................... Hardened Steel/Tungsten

Body (Upper) .................................................................................................................................................... Cast Iron

Body (Lower) ........................................................................................................................................................... Steel

Base ..................................................................................................................................................................Cast Iron

Wheel Cover (Upper) ............................................................................................................................ Cast Aluminum

Wheel Cover (Lower) ......................................................................................................................... Pre-Formed Steel

Wheel Bearings ................................................................................................ Shielded and Permanently Lubricated

Paint .................................................................................................................................................................Urethane

Other Related Information

Wheel Diameter ...................................................................................................................................................... 14

Electric Blade Welder ............................................................................................................................. 220V, 2.0 KVA

Annealing Voltage ................................................................................................................................................... 220V

Other Specifications:

Country Of Origin ........................................................................................................................................................ Taiwan

Warranty .........................................................................................................................................................................1 Year

Serial Number Location ........................................................................................................ID Label on Upper Wheel Door

Assembly Time............................................................................................................................................................... 1 Hour

Features:

Allen Bradley Controls

Welding Station for Joining Blade Ends

Includes Blade Cutter, Electric Welder w/ Clamp, Annealer, and Grinder

Infinitely Variable Cutting Speeds

Lower Wheel Cleaning Brush

Work Light

Chip Blower

Rubber Bonded Saw Wheels

1

⁄8"

-7-

Model SB1021/SB1022

SAFETY

SAFETY

For Machines Mfg. Since 8/09

Understanding Risks of Machinery

Operating all machinery and machining equipment can be dangerous or relatively safe depending

on how it is installed and maintained, and the operator's experience, common sense, risk awareness,

working conditions, and use of personal protective equipment (safety glasses, respirators, etc.).

The owner of this machinery or equipment is ultimately responsible for its safe use. This

responsibility includes proper installation in a safe environment, personnel training and usage

authorization, regular inspection and maintenance, manual availability and comprehension,

application of safety devices, integrity of cutting tools or accessories, and the usage of approved

personal protective equipment by all operators and bystanders.

The manufacturer of this machinery or equipment will not be held liable for injury or property

damage from negligence, improper training, machine modifications, or misuse. Failure to read,

understand, and follow the manual and safety labels may result in serious personal injury, including

amputation, broken bones, electrocution, or death.

The signals used in this manual to identify hazard levels are defined as follows:

Death or catastrophic

harm WILL occur.

Death or catastrophic

harm COULD occur.

Basic Machine Safety

1. Owner’s Manual: All machinery and

machining equipment presents serious

injury hazards to untrained users. To

reduce the risk of injury, anyone who uses

THIS item MUST read and understand

this entire manual before starting.

2. Personal Protective Equipment:

or servicing this item may expose the user

to flying debris, dust, smoke, dangerous

chemicals, or loud noises. These hazards

can result in eye injury, blindness, longterm respiratory damage, poisoning,

cancer, reproductive harm or hearing loss.

Reduce your risks from these hazards

by wearing approved eye protection,

respirator, gloves, or hearing protection.

Operating

Moderate injury or fire

MAY occur.

Machine or property

damage may occur.

3. Trained/Supervised Operators Only:

Untrained users can seriously injure

themselves or bystanders. Only allow

trained and properly supervised personnel

to operate this item. Make sure safe

operation instructions are clearly

understood. If electrically powered, use

padlocks and master switches, and remove

start switch keys to prevent unauthorized

use or accidental starting.

4. Guards/Covers:

moving parts during operation may cause

severe entanglement, impact, cutting,

or crushing injuries. Reduce this risk by

keeping any included guards/covers/doors

installed, fully functional, and positioned

for maximum protection.

Accidental contact with

-8-

For Machines Mfg. Since 8/09 Model SB1021/SB1022

SAFETY

5. Entanglement: Loose clothing, gloves,

neckties, jewelry or long hair may

get caught in moving parts, causing

entanglement, amputation, crushing,

or strangulation. Reduce this risk by

removing/securing these items so they

cannot contact moving parts.

6. Mental Alertness: Operating this item

with reduced mental alertness increases

the risk of accidental injury. Do not let a

temporary influence or distraction lead to a

permanent disability! Never operate when

under the influence of drugs/alcohol, when

tired, or otherwise distracted.

7. Safe Environment:

powered equipment in a wet environment

may result in electrocution; operating near

highly flammable materials may result in a

fire or explosion. Only operate this item in

a dry location that is free from flammable

materials.

8. Electrical Connection: With electically

powered equipment, improper connections

to the power source may result in

electrocution or fire. Always adhere to all

electrical requirements and applicable

codes when connecting to the power source.

Have all work inspected by a qualified

electrician to minimize risk.

9. Disconnect Power: Adjusting or servicing

electrically powered equipment while it

is connected to the power source greatly

increases the risk of injury from accidental

startup. Always disconnect power

BEFORE any service or adjustments,

including changing blades or other tooling.

Operating electrically

11. Chuck Keys or Adjusting Tools:

to adjust spindles, chucks, or any moving/

rotating parts will become dangerous

projectiles if left in place when the machine

is started. Reduce this risk by developing

the habit of always removing these tools

immediately after using them.

12. Work Area:

increase the risks of accidental injury.

Only operate this item in a clean, nonglaring, and well-lighted work area.

13. Properly Functioning Equipment:

maintained, damaged, or malfunctioning

equipment has higher risks of causing

serious personal injury compared to

those that are properly maintained.

To reduce this risk, always maintain

this item to the highest standards and

promptly repair/service a damaged or

malfunctioning component. Always follow

the maintenance instructions included in

this documentation.

14. Unattended Operation:

powered equipment that is left unattended

while running cannot be controlled and is

dangerous to bystanders. Always turn the

power OFF before walking away.

15. Health Hazards: Certain cutting fluids

and lubricants, or dust/smoke created

when cutting, may contain chemicals

known to the State of California to cause

cancer, respiratory problems, birth defects,

or other reproductive harm. Minimize

exposure to these chemicals by wearing

approved personal protective equipment

and operating in a well ventilated area.

Clutter and dark shadows

Electrically

Tools used

Poorly

10. Secure Workpiece/Tooling:

workpieces, cutting tools, or rotating

spindles can become dangerous projectiles

if not secured or if they hit another object

during operation. Reduce the risk of this

hazard by verifying that all fastening

devices are properly secured and items

attached to spindles have enough clearance

to safely rotate.

Loose

16. Difficult Operations:

difficult operations with which you are

unfamiliar increases the risk of injury.

If you experience difficulties performing

the intended operation, STOP! Seek an

alternative method to accomplish the

same task, ask a qualified expert how the

operation should be performed, or contact

our Technical Support for assistance.

Attempting

-9-

Model SB1021/SB1022

SAFETY

For Machines Mfg. Since 8/09

Additional Metal Cutting Bandsaw Safety

Blade Condition: Do not operate with a

1.

dull, cracked or badly worn blade—they can

break during use or greatly decrease cutting

performance. Inspect blades for cracks and

missing teeth before each use.

Blade Replacement: Wear gloves to protect

2.

hands and safety glasses to protect eyes

when replacing the blade. When replacing

blades, make sure teeth face forward and

down toward the table in the direction of

blade travel.

Workpiece Handling: Your hands can be cut

3.

or drawn into the blade during operation if

the workpiece moves unexpectedly. Always

keep your hands a safe distance away from

the moving blade.

Welding And Grinding Safety: The welding

4.

station can be hazardous if used incorrectly

and without proper personal protection.

Always wear welding-approved gloves,

eye protection, and clothing when welding

blades. Touching any metal parts of the

blade, welder, or machine when activating

the welder could lead to electrocution.

Welding near flammables could cause a fire.

Hot Surfaces: Be aware that touching hot

5.

workpieces or chips after welding, grinding,

or cutting can cause burns.

7. Magnesium Fire Hazard: Use EXTREME

CAUTION if cutting magnesium. Using

the wrong cutting fluid or overheating the

material could lead to an extremely hot fire

that is difficult to extinguish. Additionally,

do not allow magnesium swarf or dust to pile

up around the machine and only dispose of

the waste using approved methods.

Entanglement Hazards: Always keep the

8.

blade guard correctly positioned and wheel

doors closed and secured when bandsaw is in

operation. Loose clothing, jewelry, long hair

and work gloves can be drawn into working

parts.

Maintenance/Service: All inspections,

9.

adjustments, and maintenance are to be

done with the power OFF and the plug

pulled from the outlet. Wait for all moving

parts to come to a complete stop.

Unstable Workpieces: Workpieces that

10.

cannot be supported or stabilized without

a vise or jig should not be cut on a vertical

metal-cutting bandsaw, because they can

unexpectedly move while cutting and

draw the operator's hands into the blade

causing serious personal injury. Examples

are chains, cables, round or oblong-shaped

workpieces, workpieces with internal or

built-in moving or rotations parts, etc.

Cutting Fluid Safety: This machine is

6.

designed for dry cutting operations. Floodtype cutting fluid setups should not be used

because the machine is not waterproof.

-10-

Clearing Chips: Metal chips can easily cut

11.

skin—even through a piece of cloth. Avoid

clearing chips by hand or with a rag. Use a

brush or vacuum to clear metal chips.

For Machines Mfg. Since 8/09 Model SB1021/SB1022

prop

PREPARATION

Preparation Overview

PREPARATION

Things You'll Need

The purpose of the preparation section is to help

you prepare your machine for operation.

The typical preparation process is as follows:

1. Unpack the machine and inventory the

contents of the box/crate.

2. Clean the machine and its components.

3. Identify an acceptable location for the

machine and move it to that location.

4. Level the machine and either bolt it to the

floor or place it on mounts.

5. Assemble the loose components and make

any necessary adjustments or inspections to

ensure the machine is ready for operation.

6. Connect the machine to the power source.

7. Test run the machine to make sure it

functions

erly and is ready for operation.

During the setup process, operation, and

maintenance of your machine, you'll need the

following items:

For Lifting

s !FORKLIFTOROTHERPOWERLIFTINGDEVICE

rated for the weight of the machine.

s ,IFTING3TRAP or Chain (rated for at least

1000 lbs.)

For Power Connection

s !QUALIFIEDELECTRICIANTOENSUREASAFE

and code-compliant connection to the

power source. (Refer to Page 16 for

details.)

For Assembly

s Cotton Rags

s Mineral Spirits

s 3AFETY'LASSES

s Oil Can with any General Machine Oil

s Blade Tension Tool

s Grease Gun with any API GL 2 Grease

s Stiff Grease Brush

s Phillips Screwdriver #2

s &LOOR-OUNTING(ARDWARE!S.EEDED

s Hex Wrench 5mm

s Hex Wrench 6mm

s Combo Wrench

Socket

1

⁄2" or Ratchet and 1⁄2"

Unpacking

This item was carefully packaged to prevent

damage during transport. If you discover any

damage, please immediately call Customer

Service at (360) 734-1540 for advice. You may

need to file a freight claim, so save the containers

and all packing materials for possible inspection

by the carrier or its agent.

-11-

Model SB1021/SB1022

A

PREPARATION

Cleaning & Protecting

For Machines Mfg. Since 8/09

The unpainted surfaces are coated at the factory

with a heavy-duty rust preventative that

prevents corrosion during shipment and storage.

The benefit of this rust preventative is that it

works very well. The downside is that it can be

time-consuming to thoroughly remove.

Be patient and do a careful job when cleaning

and removing the rust preventative. The time

you spend doing this will reward you with

smooth-sliding parts and a better appreciation

for the proper care of the unpainted surfaces.

lthough there are many ways to successfully

remove the rust preventative, we have cleaned

thousands of machines and found the following

process to be the best balance between efficiency

and minimized exposure to toxic fumes or

chemicals.

Before cleaning, gather the following:

s $ISPOSABLErags

s #LEANERDEGREASER (certain citrus-based

degreasers work extremely well and they

have non-toxic fumes)

s 3AFETYGLASSESDISPOSABLEGLOVES

Avoid chlorine-based solvents, such as

acetone or brake parts cleaner that may

damage painted surfaces. Always follow the

manufacturer’s instructions when using any

type of cleaning product.

Basic steps for removing rust preventative:

1. Put on safety glasses and disposable gloves.

2. #OATALLSURFACESTHATHAVERUSTPREVENTATIVE

with a liberal amount of your cleaner or

degreaser and let them soak for a few

minutes.

3. Wipe off the surfaces. If your cleaner or

degreaser is effective, the rust preventative

will wipe off easily.

Many cleaning solvents are

toxic if inhaled. Minimize

your risk by only using

these products in a well

ventilated area.

Note: Automotive degreasers, mineral spirits, or

7$sCANBEUSEDTOREMOVERUSTPREVENTATIVE

Before using these products, though, test them

on an inconspicuous area of a painted area to

make sure they will not damage it.

Gasoline and petroleum

products have low flash

GAS

points and can explode

or cause fire if used for

cleaning. Avoid using these

products to remove rust

preventative.

Note: To clean off thick coats of rust preventative

on flat surfaces, such as beds or tables, use

A0,!34)#PAINTSCRAPERTOSCRAPEOFFTHE

majority of the coating before wiping it off

WITHYOURRAG$ONOTUSEAMETALSCRAPEROR

it may scratch the surface.)

4. Repeat Steps 2–3 as necessary until clean,

then coat all unpainted surfaces with a

quality metal protectant or light oil to

prevent rust.

-12-

For Machines Mfg. Since 8/09 Model SB1021/SB1022

PREPARATION

Location

Physical Environment

The physical environment where your machine

is operated is important for safe operation and

longevity of parts. For best results, operate this

machine in a dry environment that is free from

excessive moisture, hazardous or flammable

chemicals, airborne abrasives, or extreme

conditions. Extreme conditions for this type

of machinery are generally those where the

ambient temperature is outside the range of 41°–

104°F; the relative humidity is outside the range

of 20–95% (non-condensing); or the environment

is subject to vibration, shocks, or bumps.

Electrical Installation

Place this machine near an existing power

source. Make sure all power cords are protected

from traffic, material handling, moisture,

chemicals, or other hazards. Make sure to leave

access to a means of disconnecting the power

source or engaging a lockout/tagout device.

Weight Load

Refer to the Machine Specifications for the

weight of your machine. Make sure that the

surface upon which the machine is placed will

bear the weight of the machine, additional

equipment that may be installed on the machine,

and the heaviest workpiece that will be used.

Additionally, consider the weight of the operator

and any dynamic loading that may occur when

operating the machine.

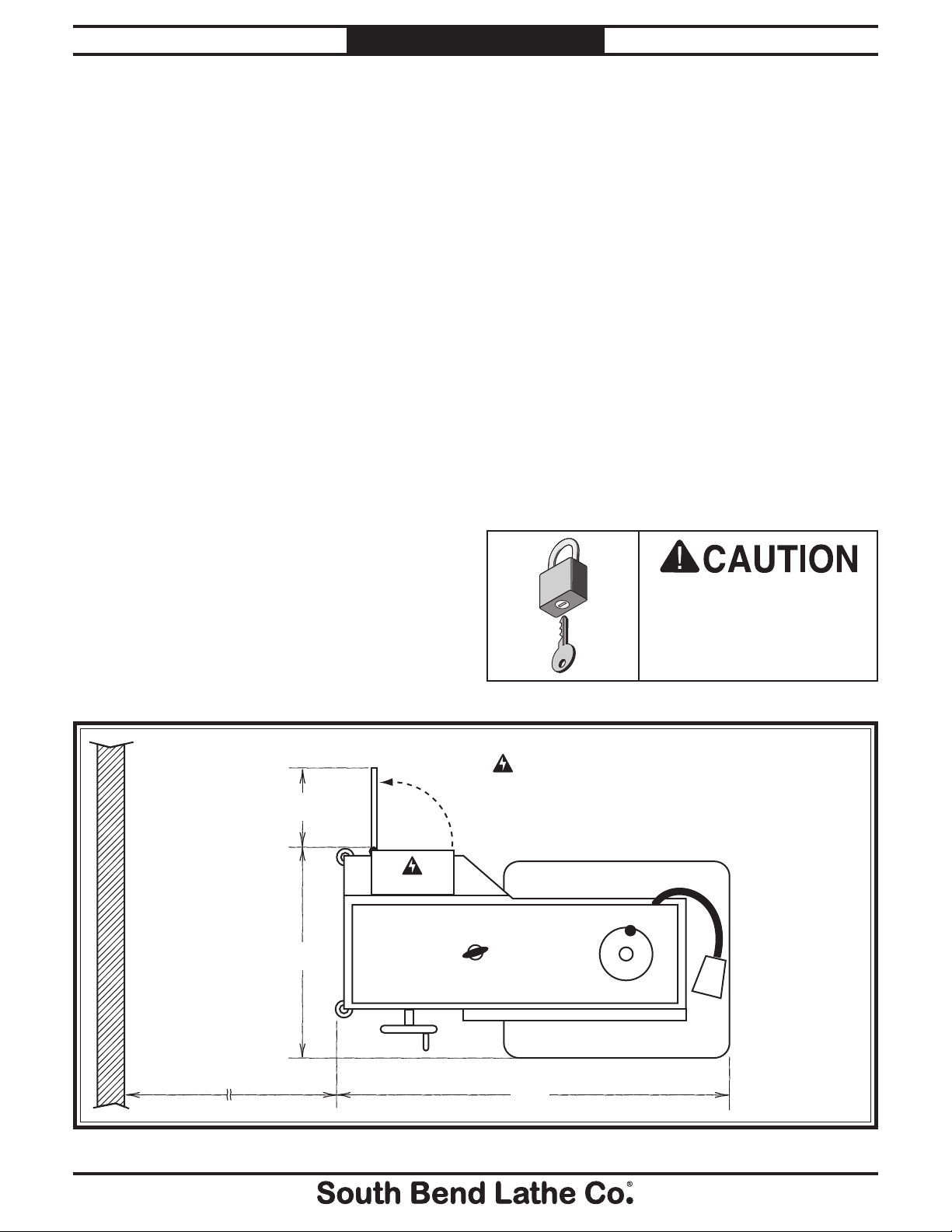

Space Allocation

Consider the largest size of workpiece that will

be processed through this machine and provide

enough space around the machine for adequate

operator material handling or the installation

of auxiliary equipment. With permanent

installations, leave enough space around

the machine to open or remove doors/covers

as required by the maintenance and service

described in this manual.

Lighting

Lighting around the machine must be adequate

enough that operations can be performed

safely. Shadows, glare, or strobe effects that

may distract or impede the operator must be

eliminated.

8"

Wall

22"

Children or untrained

people may be seriously

injured by this machine.

Only install in an access

restricted location.

= Power connection

30"

37"

Figure 1. Clearances.

-13 -

Model SB1021/SB1022

A

PREPARATION

For Machines Mfg. Since 8/09

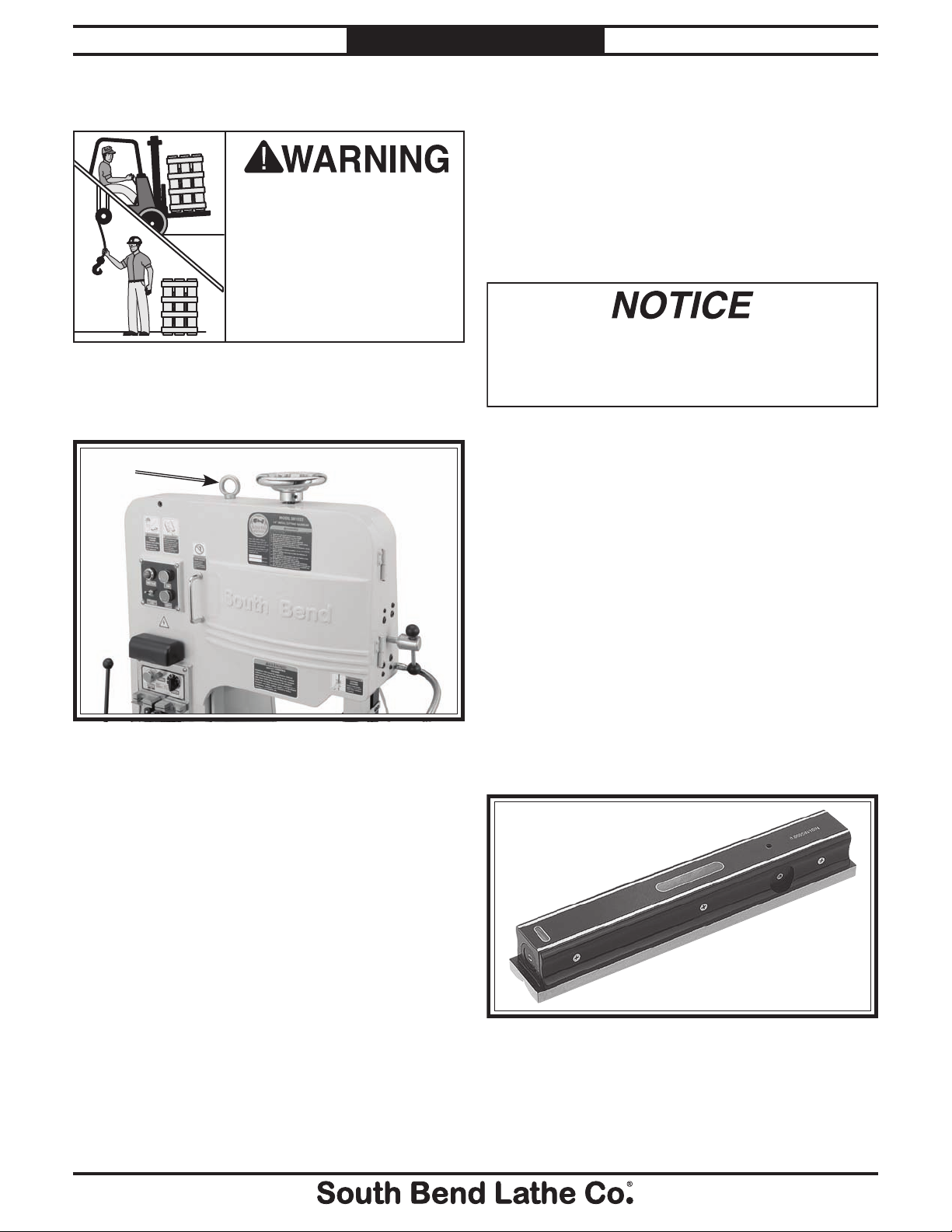

Lifting & Moving

This machine and its

parts are heavy! Serious

personal injury may occur

if safe moving methods are

not used. To reduce the

risk of a lifting or dropping

injury, ask others for help

and use power equipment.

Use a forklift to lift the machine off the pallet

and onto a suitable location using the lifting eye

shown in Figure 2.

Leveling & Mounting

Generally, you can either bolt your machine

to the floor or mount it on machine mounts.

lthough not required, we recommend that you

secure the machine to the floor and level it while

doing so. Because this is an optional step and

floor materials may vary, hardware for securing

the machine to the floor is not included.

We strongly recommend securing your

machine to the floor if it is hardwired to the

power source. Consult with your electrician to

ensure compliance with local codes.

Leveling

Leveling machinery helps precision components,

such as bed ways, remain straight and flat

during the lifespan of the machine. Components

on an unleveled machine may slowly twist due to

the dynamic loads placed on the machine during

operation.

For best results, use a precision level that

is at least 12" long and sensitive enough to

show a distinct movement when a 0.003" shim

(approximately the thickness of one sheet of

standard newspaper) is placed under one end of

the level.

Figure 2. Lifting location.

See the figure below for an example of a high

precision level.

Figure 3. Example of a precision level.

-14-

For Machines Mfg. Since 8/09 Model SB1021/SB1022

A

PREPARATION

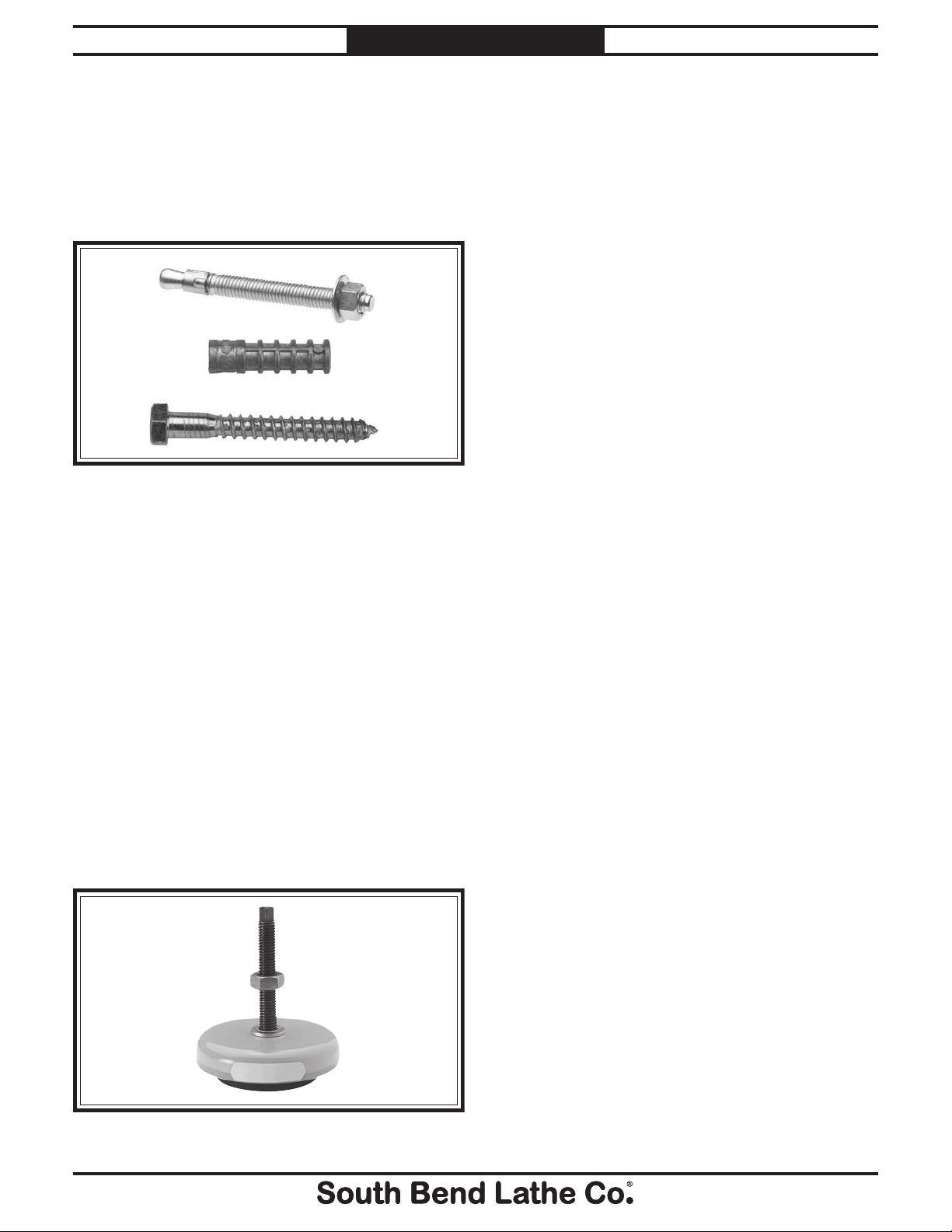

Bolting to Concrete Floors

Lag screws and anchors, or anchor studs

(below), are two popular methods for securing

machinery to a concrete floor. We suggest you

research the many options and methods for

securing your machine and choose the best one

for your specific application.

Anchor

Stud

Lag Screw

and Anchor

Figure 4. Common types of fasteners for bolting

machinery to concrete floors.

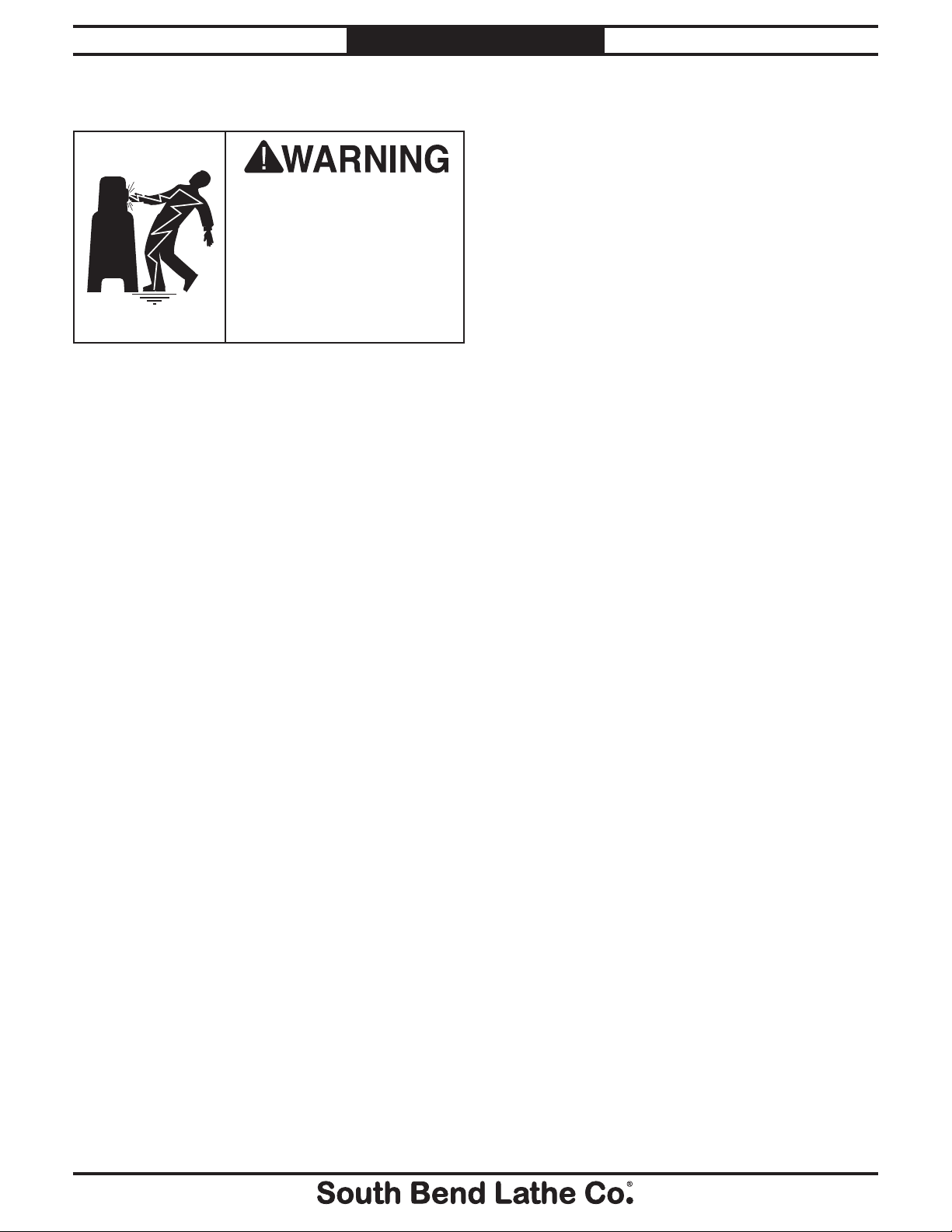

Machine Mounts

Machine mounts are rubber pads mounted to

a threaded stud, which can be fastened to the

bottom of the machine.

Assembly

This machine comes pre-assembled from the

factory. However, tension has been removed from

the blade for shipping purposes. Before operating

the machine for the first time, you MUST make

sure the blade is properly tensioned. Refer to the

Blade Tensioning procedure on Page 23 for

instructions about how to do this.

Initial Lubrication

Your machine was lubricated at the factory,

but we strongly recommend that you inspect all

lubrication points yourself and provide additional

lubrication if necessary. Refer to Lubrication on

Page 33 for specific details.

Inspections &

Adjustments

The following list of adjustments were performed

at the factory before your machine was shipped:

Machine mounts offer certain advantages such

as ease of installation, vibration dampening, and

easy leveling. They also make it easier to relocate

the machine later on.

The disadvantage of machine mounts is that the

machine can shift or move over time. For this

reason, electrical codes may limit their use if

the machine is hardwired to the power source.

lso, mounts may reduce the total surface area

of machine-to-floor contact, depending on the

design of the machine.

s Blade Guide Adjustment ..............Page 26

s V-Belt Adjustment ..........................Page 34

s Table Calibration ...........................Page 35

s Blade Tracking ................................Page 35

s Guide Post Alignment ...................Page 36

Be aware that machine components can shift

during the shipping process. Pay careful

attention to these adjustments as you test run

your machine. If you find that the adjustments

are not set according to the procedures in this

manual or your personal preferences, re-adjust

them.

Figure 5. Typical machine mount.

-15 -

Model SB1021/SB1022

Power Connection

PREPARATION

3. Locate the power transformer in the

electrical panel (see Page 48, Figure 50)

and remove the wire attached to the 110V

terminal and connect it to the 220V terminal.

For Machines Mfg. Since 8/09

Electrocution or fire

may occur if machine is

ungrounded, incorrectly

connected to power, or

connected to an undersized

circuit. Use a qualified

electrician to ensure a safe

power connection.

Once your machine is set up and assembled as

previously described in this manual, it is ready to

be connected to the power source.

Use the information in this section to determine

the power source requirements needed to operate

this machine. If your existing power source does

not meet the stated requirements, consult with a

qualified electrician about running a new circuit.

Note About Extension Cords: Using an

incorrectly sized extension cord may decrease the

life of electrical components on your machine.

Note About 3-Phase Power (SB1022 Only):

DO NOT use a static phase converter to create

3-phase power—it can quickly decrease the life

of electrical components on your machine. If you

must use a phase converter, only use a rotary

phase converter and connect the wild wire to the

correct power connection terminal, shown in the

wiring diagram on Page 47.

220V Conversion for SB1021

Wiring diagrams are provided on Pages 44 and

46 in this manual, showing the Model SB1021

wired for both 110V and 220V. Refer to these

diagrams when following this procedure.

4. Turn the dial on the overload relay (see

Page 48, Figure 50) from 14A for 110V to

7A for 220V.

5. Locate the welding transformer in the

control panel (see Page 48, Figure 49).

Remove the wire connected to the #2

terminal and move it to the #5 terminal;

remove the wire connected to the #4 terminal

and move it to the #7 terminal.

6. The machine is now wired for 220V.

SB1021 110V (Prewired) Power

Source

Full Load Amp Draw ............................ 13.6 Amps

Permissible Voltage Range ....................99V–121V

Phase ................................................. Single-Phase

Frequency ...................................................... 60 Hz

Minimum Circuit Size ............................. 20 Amps

Included Plug ...................................... NEMA 5-15

Minimum Extension Cord Size ................14 AWG

Maximum Extension Cord Length ................ 50 ft.

SB1021 (220V) Power Source

Full Load Amp Draw .............................. 6.8 Amps

Permissible Voltage Range ..................198V–242V

Phase ................................................. Single-Phase

Frequency ...................................................... 60 Hz

Minimum Circuit Size ............................. 15 Amps

Recommended Plug/Receptacle .......... NEMA 6-15

Minimum Extension Cord Size ................14 AWG

Maximum Extension Cord Length ................ 50 ft.

SB1022 (220V 3-Phase) Power

To convert the Model SB1021 to operate on

220V:

1. DISCONNECT BANDSAW FROM POWER!

2. Rewire the motor for 220V, as shown in the

diagram on the inside of the motor junction

box. If there is not a diagram in the junction

box, use the motor wiring diagram in this

manual (see Page 46).

-16 -

Source

Full Load Amp Draw .............................. 3.6 Amps

Permissible Voltage Range ..................198V–242V

Phase ..........................................................3-Phase

Frequency ...................................................... 60 Hz

Minimum Circuit Size ............................. 15 Amps

Recommended Plug/Receptacle ......NEMA L15-15

Minimum Extension Cord Size ................16 AWG

Maximum Extension Cord Length ................ 50 ft.

For Machines Mfg. Since 8/09 Model SB1021/SB1022

PREPARATION

4. Connect the machine to the power source.

Test Run

After all preparation steps have been completed,

the machine and its safety features must be

tested to ensure correct operation. If you discover

a problem with the operation of the machine or

its safety components, do not operate it further

until you have resolved the problem.

Note: Refer to Troubleshooting on Page 38 for

solutions to common problems that occur with

all metal bandsaws. If you need additional help,

contact our Tech Support at (360) 734-1540.

To reduce the risk of

serious injury when using

this machine, read and

understand this entire

manual before beginning

any operations.

5. Push the ON button. The green motor light

will illuminate and the motor will start.

6. Verify that the machine is operating

correctly. When operating correctly, the

machine runs smoothly with little or no

vibration or rubbing noises.

Note: For three phase-models, verify that the

blade is moving downward toward the table.

If so, the motor is running in the correct

direction. Proceed to Step 7.

s If the blade is moving in the upward

direction out of the table, stop the

machine immediately. It is likely wired

"out of phase." To correct this problem,

disconnect the machine from the power

source, and switch any two incoming

power wires at the main terminal block

(refer to Figure 50 on Page 48).

To test run your machine:

1. Read and follow the safety instructions at

the beginning of the manual, take required

safety precautions, and make sure the

machine is set up and adjusted properly

2. Clear away all tools and objects used during

assembly and preparation.

3. Make sure the blade is properly tensioned

and the blade guides are positioned correctly

(for detailed instructions, refer to Blade

Tensioning on Page 23, and Adjusting

Blade Guides on Page 26).

7. Adjust the blade speed through the full

range of operation. The speed should change

as you make the adjustments.

8. Press the STOP button, the green motor

light will go out, and the bandsaw will stop.

9. Turn the work lamp and the welding lamp

ON and OFF.

10. Turn the grinder ON and OFF.

-17-

Model SB1021/SB1022

OPERATION

For Machines Mfg. Since 8/09

OPERATION

Operation Overview

The purpose of the operation section is to

familiarize you with the basic controls,

terminology, capabilities, and adjustments that

are necessary to use this machine.

To better understand the remaining parts of

this section, please take a moment to read this

overview.

To reduce the risk of

serious injury when using

this machine, read and

understand this entire

manual before beginning

any operations.

To complete a typical operation, the operator

does the following:

1. Examines the workpiece to make sure it is

suitable for cutting.

4. Adjusts the upper blade guide height to

approximately

for maximum blade support.

5. Puts on safety glasses, and rolls up sleeves

or secures any clothing or hair that could get

entangled with moving parts.

1

⁄8"–1⁄4" above the workpiece

Loose hair, clothing, or

jewelry could get caught

in machinery and cause

serious personal injury.

Keep these items away

from moving parts at all

times to reduce this risk.

During operation, small

metal chips may become

airborne, leading to serious

eye injury. Wear safety

glasses to reduce this risk.

2. Checks to make sure blade tension is correct,

and the blade guides are positioned correctly.

3. Marks the cut line on the workpiece.

Workpieces that cannot be stabilized from

unexpected movement should not be cut with

a vertical metal bandsaw due to the increased

risk of the operator's hands slipping into the

blade. Examples are chains, cables, balls, or

workpieces with built-in moving parts.

6. Turns the bandsaw ON, and adjusts blade

speed for the type of material being cut.

7. Presses the workpiece against the blade,

using light and even pressure and following

the cut line with the blade.

Depending on the workpiece material, the

operator may squirt a small amount of

cutting fluid at the cutting area to keep it

from overheating and smoking.

8. Turns the bandsaw OFF.

-18 -

Loading...

Loading...