Page 1

13" HEAVY 13® GEARHEAD LATHE

MODEL SB1049 13" X 30"

MODEL SB1050 13" X 40"

OWNER'S MANUAL

© January, 2012 by South Bend Lathe Co. For Machines Mfg. Since 5/11

Page 2

Se

ce

W

Co.

.O. Bo

7

7

0

)

y)

sales@southbendlathe.com

:

.southbendlathe.co

cope of Manua

l

g op

happ

tact ou

cation

?

.

/

7

llingh

7

This manual helps the reader understand the machine, how to prepare it for operation, how to control

it durin

nderstanding of how to operate this type of machine, but that the reader is not familiar with the

ontrols and adjustments of this specific model. As with all machinery of this nature, learning the

uances of operation is a process that happens through training and experience. If you are not an

xperienced operator of this type of machinery, read through this entire manual, then learn more

from an experienced operator, schooling, or research before attempting operations. Following this

dvice will help you avoid serious personal injury and get the best results from your work.

eration, and how to keep it in good working condition. We assume the reader has a basic

Manual Feedback

We've made every effort to be accurate when documenting this machine. However, errors sometimes

en or the machine design changes after the documentation process—so

xactly match your machine. If a difference between the manual and machine leaves you in doubt,

n

We highly value customer feedback on our manuals. If you have a moment, please share your

xperience using this manual. What did you like about it? Is there anything you would change to

ake it better? Did it meet your expectations for clarity, professionalism, and ease-of-use

r

mer service for

larifi

e manual may not

South Bend Lathe, Inc

echnical Documentation Manager

Box 202

e

mail: manuals@southbendlathe.com

am, WA 9822

ates

For your convenience, any updates to this manual will be available to download free of charge

hrough our website at

www

ustomer

e stand behind our machines. If you have any service questions, parts requests or general questions

out your purchase, feel free to contact us.

h Bend Lathe

P

Bellingham, WA 9822

Phone: (360) 734-154

Fax: (360) 676-1075 (International

Fax: (360) 734-1639 (USA Onl

x 202

m

rvi

Page 3

Table of Contents

INTRODUCTION .................................................... 3

About This Machine .............................................3

Foreword ............................................................. 3

Capabilities ......................................................... 3

Features .............................................................. 3

General Identification ..........................................4

Controls & Components.......................................5

Master Power Switch ........................................... 5

Headstock ...........................................................5

Control Panel ......................................................6

Carriage .............................................................. 6

Tailstock .............................................................7

End Gears ...........................................................7

Safety Foot Brake ................................................ 7

Product Specifications .........................................8

SAFETY ................................................................12

Understanding Risks of Machinery ..................12

Basic Machine Safety ........................................12

Additional Metal Lathe Safety .......................... 14

Additional Chuck Safety....................................15

PREPARATION .................................................... 16

Preparation Overview ........................................ 16

Things You'll Need ............................................. 16

Power Supply Requirements ............................. 17

Availability ........................................................ 17

Full-Load Current Rating ..................................17

Circuit Requirements ......................................... 17

Grounding Requirements ................................... 18

Extension Cords ................................................18

Unpacking ..........................................................19

Inventory ............................................................ 19

Cleaning & Protecting .......................................20

Location .............................................................. 21

Physical Environment ........................................ 21

Electrical Installation ........................................ 21

Lighting ............................................................21

Weight Load ...................................................... 21

Space Allocation ................................................21

Lifting & Moving ................................................ 22

Leveling & Mounting ......................................... 23

Leveling ............................................................23

Bolting to Concrete Floors ..................................24

Assembly ............................................................24

Lubricating Lathe ..............................................24

Adding Coolant ..................................................25

Power Connection .............................................. 25

Test Run ............................................................. 26

Spindle Break-In ................................................ 30

Recommended Adjustments .............................. 30

OPERATION ........................................................31

Operation Overview ........................................... 31

Chuck & Faceplate Mounting ........................... 32

Installation & Removal Devices ........................32

Chuck Installation ............................................. 33

Registration Marks ............................................ 34

Chuck Removal .................................................. 34

Scroll Chuck Clamping ...................................... 35

4-Jaw Chuck ....................................................... 35

Mounting Workpiece .......................................... 35

Faceplate ............................................................36

Tailstock ............................................................. 37

Positioning Tailstock .........................................37

Using Quill ........................................................ 37

Installing Tooling ..............................................38

Removing Tooling .............................................. 39

Offsetting Tailstock ...........................................39

Aligning Tailstock to Spindle Centerline ............40

Centers ...............................................................41

Dead Centers .....................................................41

Live Centers ...................................................... 42

Mounting Dead Center in Spindle ...................... 42

Removing Center from Spindle ........................... 42

Mounting Center in Tailstock ............................. 42

Removing Center from Tailstock ........................43

Mounting Workpiece Between Centers ............... 43

Steady Rest ........................................................44

Follow Rest ......................................................... 45

Carriage & Slide Locks ...................................... 45

Compound Rest ..................................................46

Four-Way Tool Post ........................................... 46

Installing Tool ................................................... 46

Aligning Cutting Tool with Spindle Centerline ...47

Adjustable Feed Stop ......................................... 48

Micrometer Stop.................................................48

Manual Feed ......................................................49

Carriage Handwheel .......................................... 49

Cross Slide Handwheel ...................................... 49

Compound Rest Handwheel ............................... 49

Spindle Speed ..................................................... 49

Determining Spindle Speed ................................ 49

Page 4

Setting Spindle Speed ........................................ 50

Configuration Examples ..................................... 50

Power Feed ......................................................... 51

Power Feed Controls .......................................... 52

Setting Power Feed Rate ....................................53

End Gears ........................................................... 54

Standard End Gear Configuration ...................... 54

Alternate Configuration ..................................... 55

Threading ........................................................... 56

Headstock Threading Controls ........................... 56

Apron Threading Controls..................................57

Thread Dial ....................................................... 57

Thread Dial Chart .............................................58

Chip Drawer ....................................................... 59

Coolant System .................................................. 60

ACCESSORIES ...................................................61

MAINTENANCE ................................................... 64

Maintenance Schedule ....................................... 64

Cleaning & Protecting ....................................... 64

Maintenance Chart ............................................ 65

Lubrication ......................................................... 66

Headstock .........................................................66

Quick-Change Gearbox ...................................... 67

Apron ................................................................ 67

One-Shot Oiler ..................................................68

Longitudinal Leadscrew .....................................68

Ball Oilers & Oil Cup .........................................69

End Gears .........................................................70

Coolant System Service ..................................... 71

Hazards.............................................................71

Adding Fluid .....................................................72

Changing Coolant .............................................. 72

Machine Storage ................................................ 73

SERVICE .............................................................. 74

Backlash Adjustment ........................................74

Compound Rest .................................................74

Cross Slide ........................................................74

Leadscrew End Play Adjustment ......................75

Gib Adjustment .................................................. 75

Half Nut Adjustment ......................................... 77

V-Belts ................................................................ 77

Brake & Switch .................................................. 78

Leadscrew Shear Pin Replacement ..................80

Gap Insert Removal & Installation ..................82

Gap Removal ..................................................... 82

Gap Installation ................................................83

TROUBLESHOOTING .........................................84

ELECTRICAL ........................................................87

Electrical Safety Instructions ...........................87

Wiring Overview ................................................ 88

Component Location Index................................89

Electrical Cabinet Wiring ..................................90

Electrical Box ..................................................... 91

Spindle Motor ..................................................... 92

Coolant Pump Motor Wiring ............................. 92

Control Panel Wiring ......................................... 93

Spindle Switches ................................................ 93

Additional Component Wiring .......................... 94

Power Connection .............................................. 94

PARTS ..................................................................95

Headstock Cover ................................................ 95

Headstock Controls ............................................ 96

Headstock Internal Gears ................................. 98

Headstock Transfer Gears ............................... 100

Gearbox Gears .................................................. 101

Gearbox Controls ............................................. 103

Apron Front View ............................................105

Apron Rear View .............................................. 107

Compound Rest & Tool Post ............................ 109

Saddle Top View ..............................................110

Saddle Bottom View.........................................112

Micrometer Stop...............................................113

Dial Indicator ................................................... 113

Bed & Shafts .................................................... 114

End Gears ......................................................... 116

Main Motor ....................................................... 117

Stands & Panels ............................................... 119

Tailstock ........................................................... 121

Steady Rest ......................................................123

Follow Rest ....................................................... 123

Electrical Cabinet & Control Panel ................ 124

Accessories .......................................................125

Front Machine Labels ...................................... 126

Rear & Side Machine Labels ........................... 127

WARRANTY ....................................................... 129

Page 5

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

INTRODUCTION

About This Machine

Foreword

"The screw cutting engine lathe is the oldest and

most important of machine tools and from it all

other machine tools have been developed. It was

the lathe that made possible the building of the

steamboat, the locomotive, the electric motor, the

automobile and all kinds of machinery used in

industry. Without the lathe our great industrial

progress of the last century would have been

impossible." —How To Run a Lathe, 15th

Edition, South Bend Lathe.

The lathe represented in this manual is a

modern day version of the screw cutting lathes

that trace their roots back to the 1700's, which

were themselves technological improvements of

the bow lathe that can be traced back thousands

of years to the ancient Egyptians.

Now, almost 300 years later, these modern

"screw cutting" lathes are not just a piece of

refined machinery, but a culmination of human

ingenuity and knowledge embodied into the

design and synergy of thousands of interworking

parts—some of which represent the life's work

and dreams of many inventors, mechanical

engineers, and world-class machinists—including

the likes of Leonardo da Vinci, Henry Maudsley,

and the founders of South Bend Lathe, John and

Miles O'Brien.

And now the torch is passed to you—to take

the oldest and most important type of machine

tool—and carry on the tradition. As the operator

of a South Bend Lathe, you now join the ranks

of some very famous and important customers,

such as Henry Ford, who used the machines he

purchased to help him change the world.

Features

These Heavy 13® Gearhead Lathes are packed

with standard features and equipment, such

as a complete coolant system, easy-to-clean

chip drawer, one-shot way lubrication system,

included steady and follow rests, chuck guard,

adjustable work lamp, foot brake, powered

cross feed, 3- and 4-jaw chucks, faceplate, and

premium Allen-Bradley contactors, thermal

relays, and fuse system.

Spindle speeds are controlled by convenient

headstock levers, which allow the operator to

quickly set the spindle speed within the available

range of 80–2000 RPM.

The beds of these lathes are constructed with

Meehanite castings that are hardened and

precision-ground in the traditional three V-way

prismatic design—long used on South Bend

Lathes for its accuracy, durability, and rigidity.

The headstocks feature quick-change gear levers

and the carriages include an adjustable clutch

that disables automatic carriage feed when it

contacts the included feed stop or in the event of

a crash.

To further ensure a high degree of accuracy,

these lathes are equipped with Japanese spindle

bearings. The spindles are D1-5 camlock with an

MT#5 taper and 1.57" bore. The tailstocks have

an MT#3 taper and 4.5" of quill travel.

Capabilities

This Heavy 13® Gearhead Lathe is built for daily

use in a busy industrial setting. Loaded with

many nice features and high-precision parts, this

lathe excels at making fine tools, dies, thread

gauges, jigs, and precision test gauges—however,

it is by no means delicate. Thick castings, heavy

weight, and quality construction throughout

provide the necessary brawn for demanding

production and manufacturing tasks.

South Bend Precision Toolroom Lathe

(Circa 1958)

-3-

Page 6

13" Heavy 13® Gearhead Lathe

INTRODUCTION

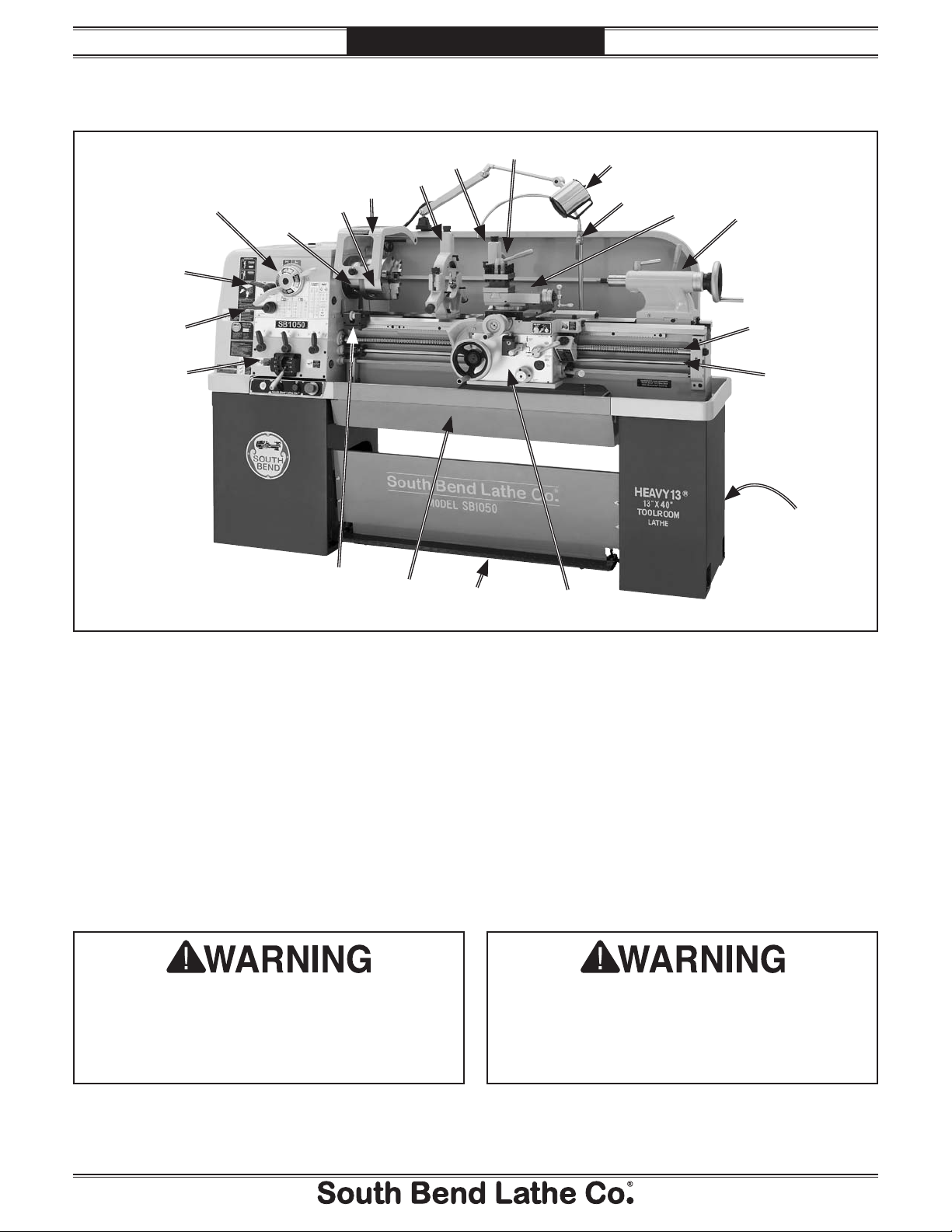

General Identification

For Machines Mfg. Since 5/11

F

E

A

B

U

T

S

D

C

R

Q

G

P

O

H

I

J

K

L

M

N

Figure 1. Identification.

A. Spindle Speed Levers (see Page 50 for

details)

B. D1-5 Camlock MT#5 Spindle

C. 3-Jaw Chuck 8"

D. Chuck Guard w/Safety Switch

E. Steady Rest

F. Follow Rest

G. 4-Way Tool Post

H. Halogen Work Lamp

I. Coolant Nozzle & Valve

J. Compound Rest

K. Tailstock (see Page 7 for details)

Serious personal injury could occur if

you connect the machine to power before

completing the setup process. DO NOT

connect power until instructed to do so later

in this manual.

L. Longitudinal Leadscrew

M. Feed Rod

N. Coolant Reservoir & Pump Access

O. Carriage (see Page 6 for details)

P. Safety Foot Brake

Q. Chip Drawer

R. Micrometer Stop

S. Quick-Change Gearbox Controls

(see Page 5 for details)

T. Headstock Feed Direction Lever

U. Gearbox Range Lever

Untrained users have an increased risk

of seriously injuring themselves with this

machine. Do not operate this machine until

you have understood this entire manual and

received proper training.

-4-

Page 7

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

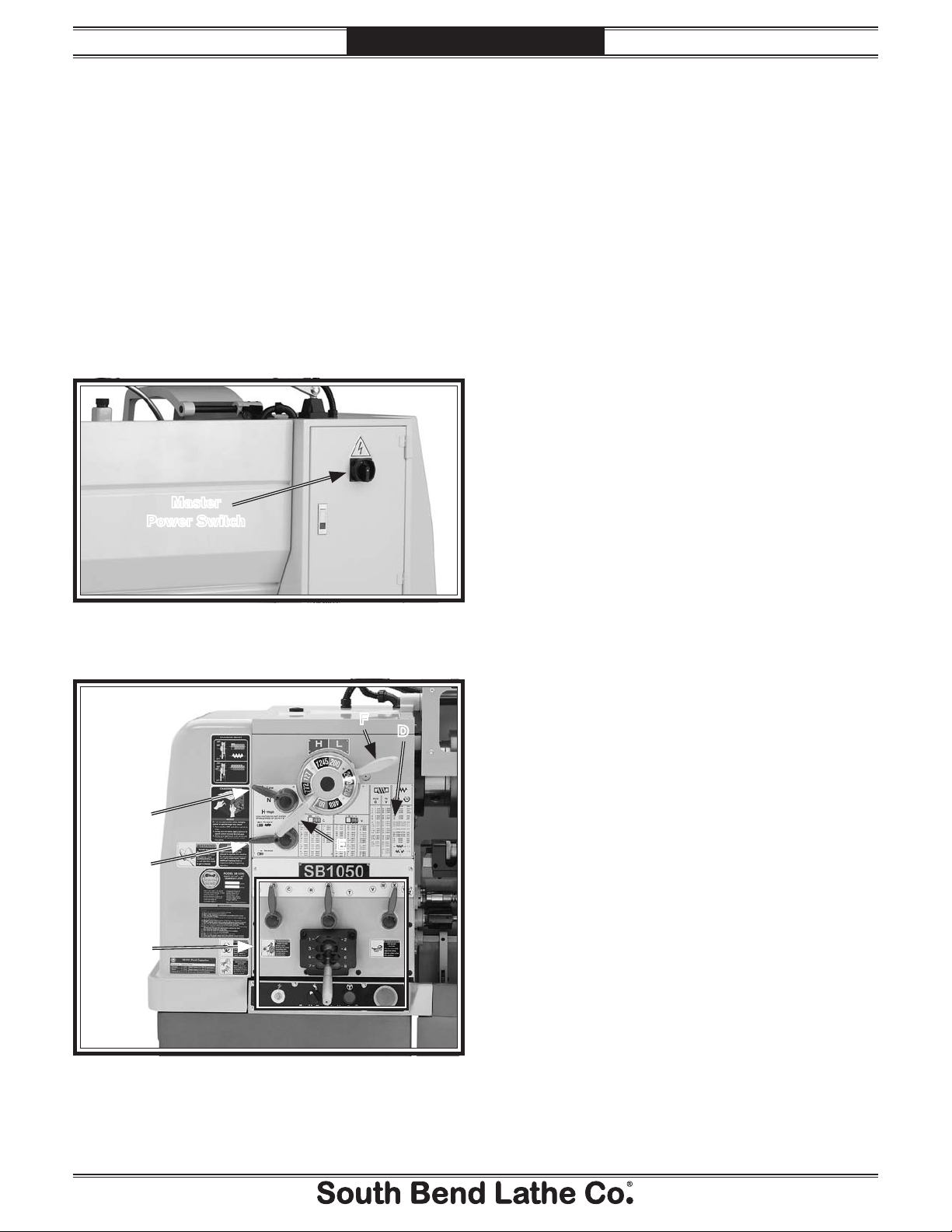

Controls &

INTRODUCTION

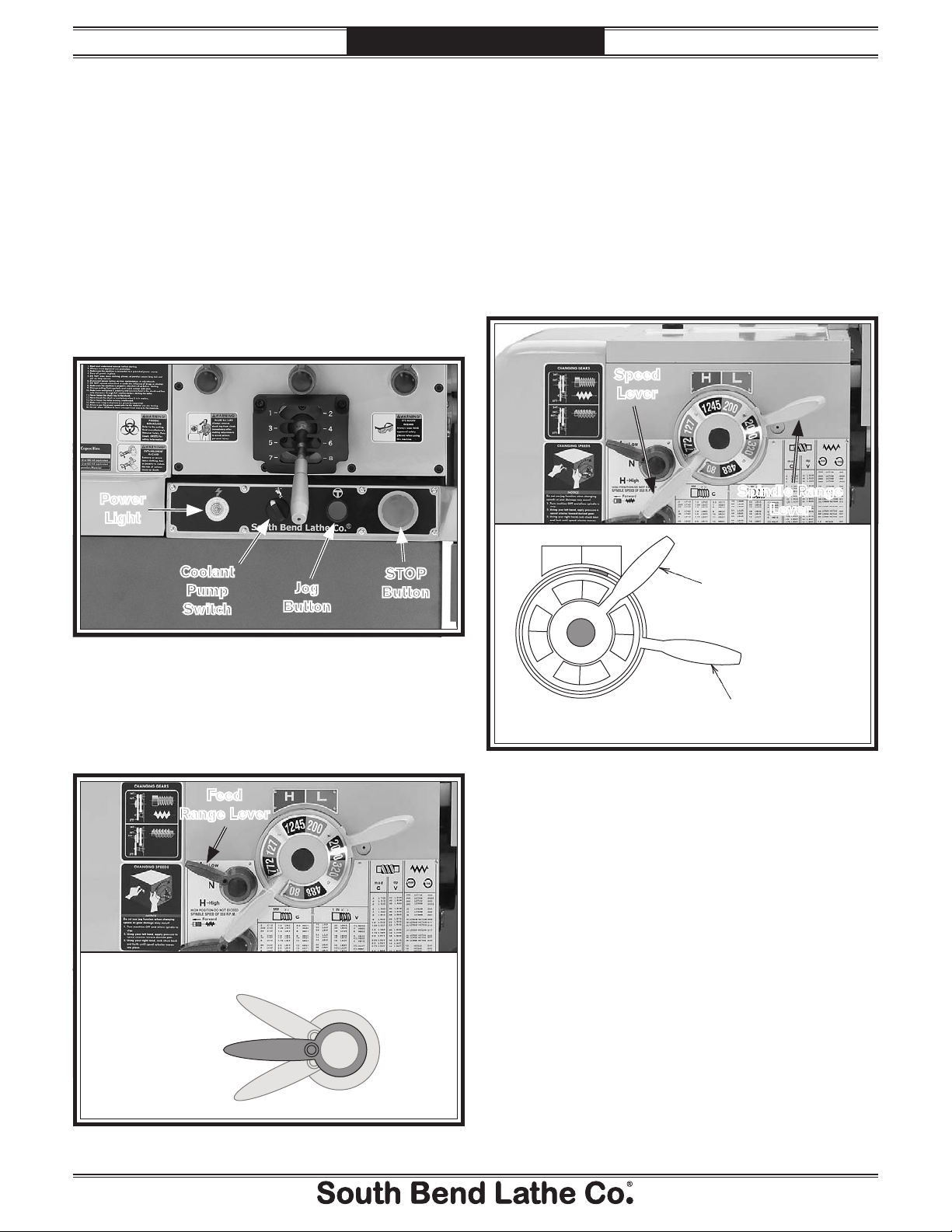

A. Quick-Change Gearbox Levers: Control the

leadscrew and feed rod speed for threading

and feed operations.

Components

Refer to Figures 2–6 and the following

descriptions to become familiar with the basic

controls of this lathe.

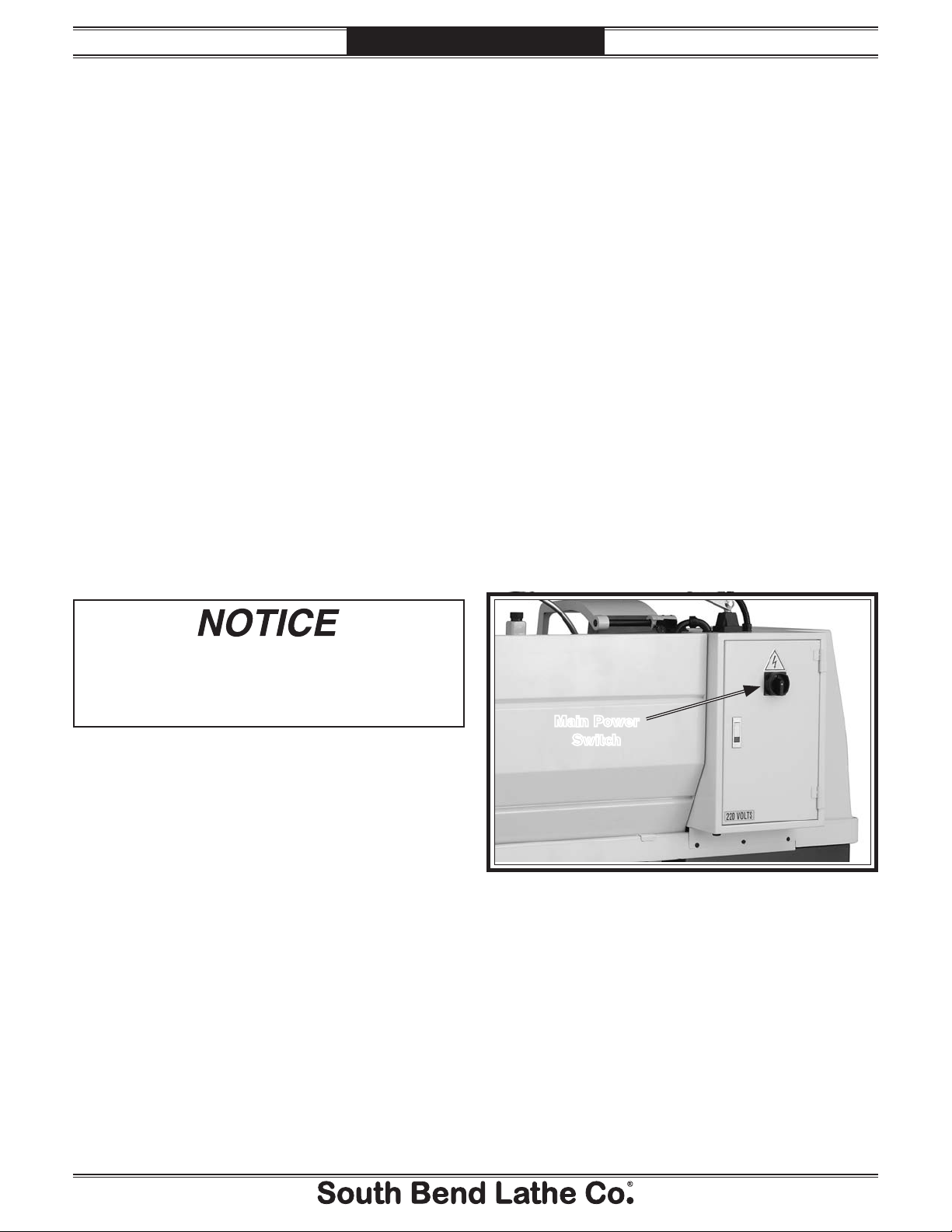

Master Power Switch

The rotary switch shown in Figure 2 toggles

incoming power ON and OFF to the lathe

controls. It also prevents the electrical cabinet

door from being opened when the switch is ON.

Master

Power Switch

B. Headstock Feed Direction Lever: Controls

the direction that the leadscrew and feed rod

rotate.

C. Gearbox Range Lever: Shifts the quick-

change gearbox into low range, neutral, or

high range.

D. Threading and Feed Charts: Display the

necessary configuration of the gearbox levers

and end gears for different threading or

feeding options.

E. Spindle Speed Lever: Selects one of the four

available spindle speeds within the selected

speed range.

F. Spindle Range Lever: Selects the spindle

speed high range (to the left) or the low

range (to the right).

Figure 2. Location of the master power switch.

Headstock

F

C

E

B

A

D

Figure 3. Headstock controls.

-5-

Page 8

13" Heavy 13® Gearhead Lathe

INTRODUCTION

For Machines Mfg. Since 5/11

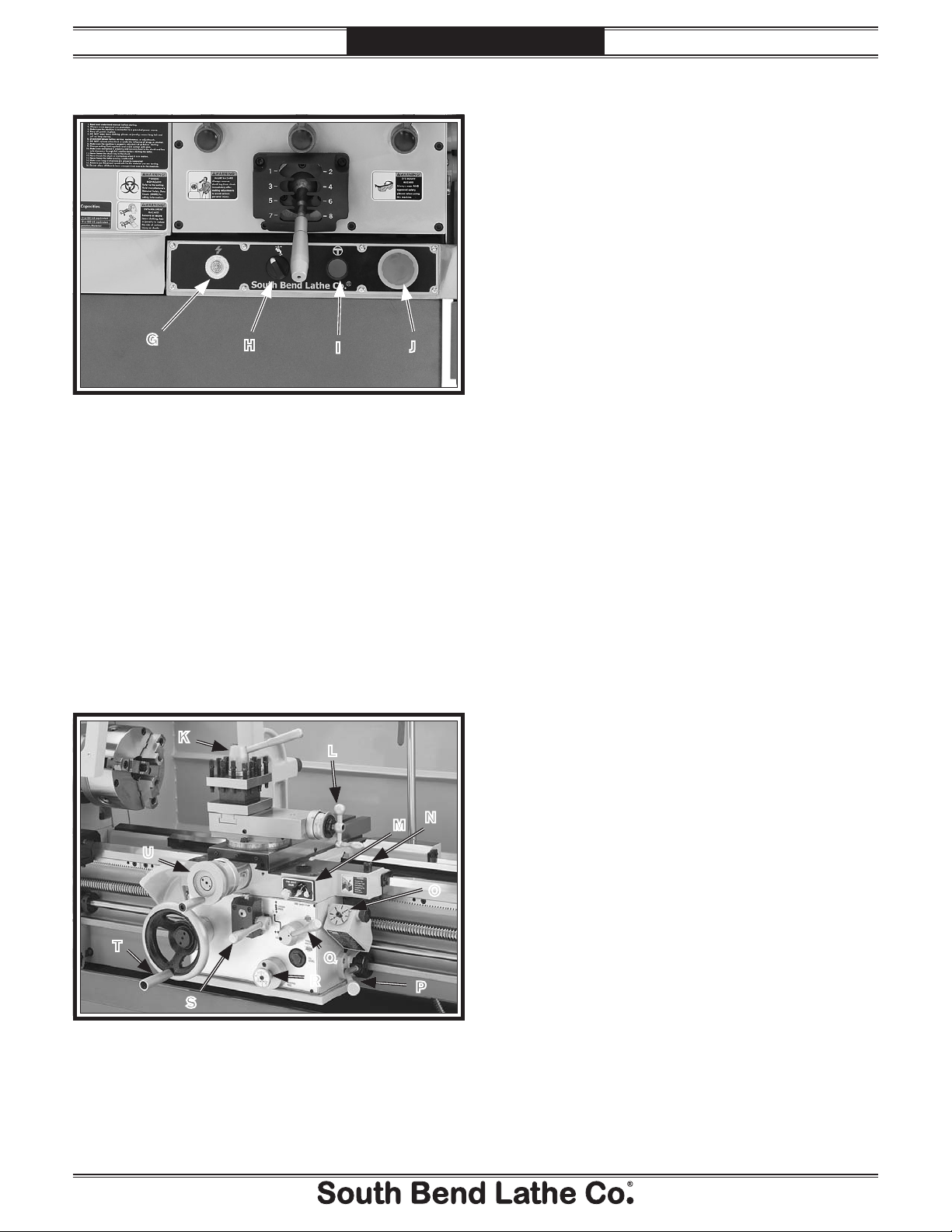

Control Panel

G

Figure 4. Control panel.

G. Power Light: Illuminates when lathe controls

are receiving power.

H. Coolant Pump Switch: Controls the coolant

pump motor.

I. Jog Button: Starts forward spindle rotation

as long as it is pressed.

J. STOP Button: Stops all machine functions.

Twist clockwise to reset.

H

I

J

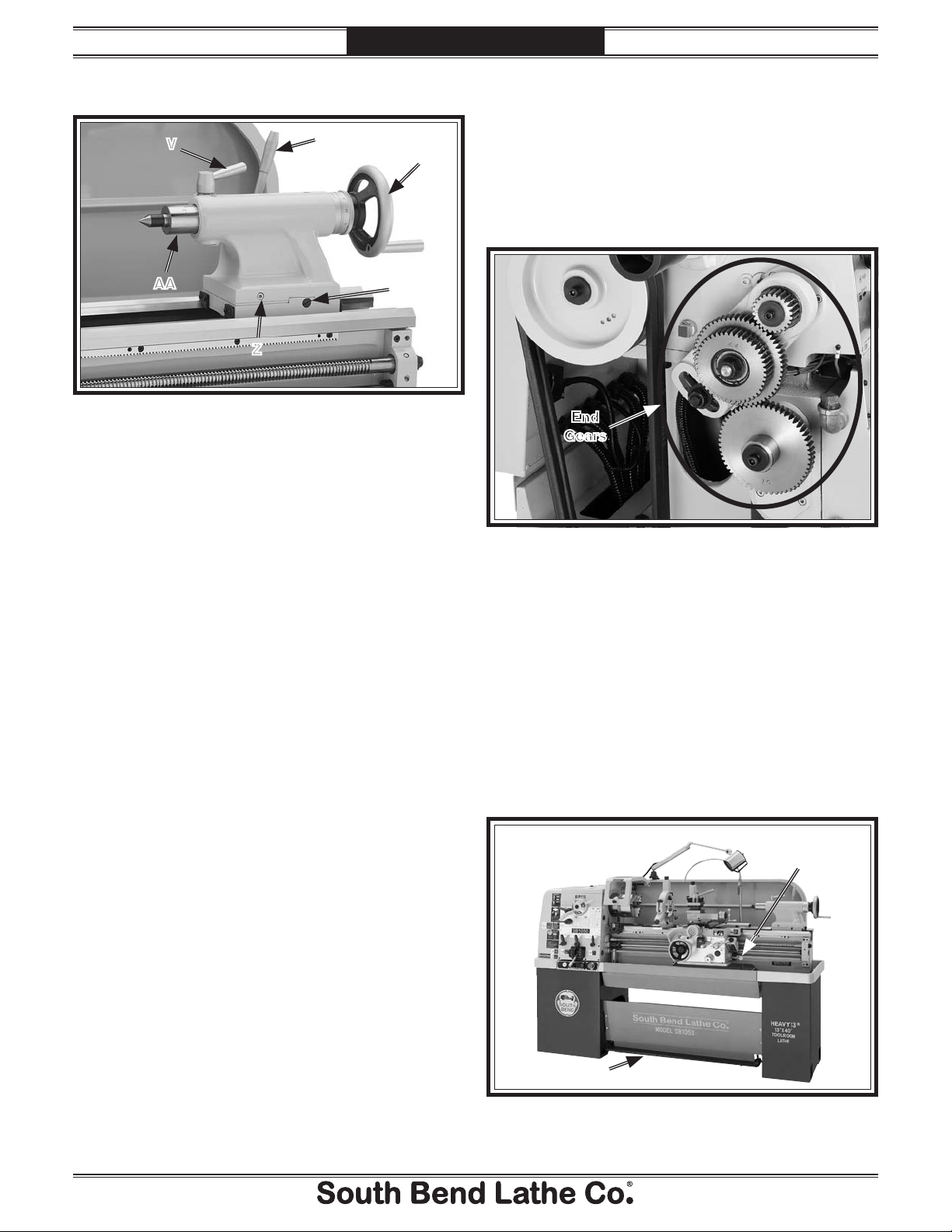

Carriage

K

L

K. 4-Way Tool Post: Mounts up to four cutting

tools at once that can be individually indexed

to the workpiece.

L. Compound Rest Handwheel: Moves the tool

toward and away from the workpiece at the

preset angle of the compound rest.

M. One-Shot Oiler: Draws oil from the apron

reservoir to lubricate the carriage ways

through various oil ports.

N. Carriage Lock: Secures the carriage in place

when to ensure accuracy during operations

where it should not move.

O . Thread Dial and Chart: Dial indicates when

to engage the half nut during inch threading

operations. Chart indicates which thread

dial reading to engage the half nut for

specific inch thread pitches.

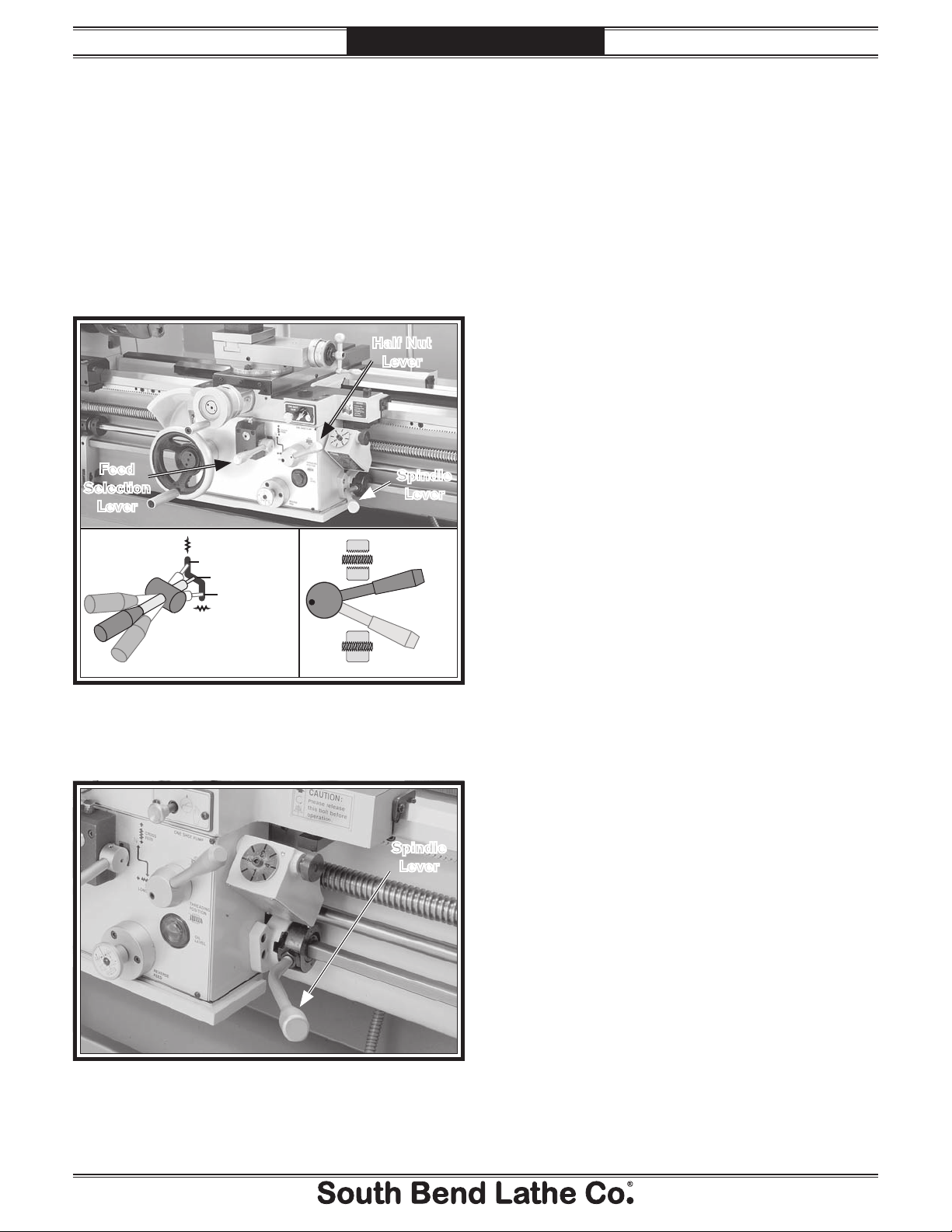

P. Spindle Lever: Starts and stops spindle

rotation in either direction.

Q . Half Nut Lever: Engages/disengages the half

nut for threading operations.

R. Apron Feed Direction Knob: Changes

direction of the carriage or the cross slide

feed without having to stop the lathe and

move the headstock feed direction lever.

S. Feed Selection Lever: Selects the carriage or

cross slide for power feed operations.

-6-

M

N

T. Carriage Handwheel: Moves the carriage

along the bed.

U

O

T

S

Figure 5. Carriage controls.

Q

R

P

U. Cross Slide Handwheel: Moves the cross

slide toward and away from the workpiece.

Page 9

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

INTRODUCTION

Tailstock

V

AA

Z

Figure 6. Tailstock controls.

V. Quill Lock Lever: Secures the quill in

position.

W. Tailstock Lock Lever: Secures the tailstock in

position along the bedway.

W

X

Y

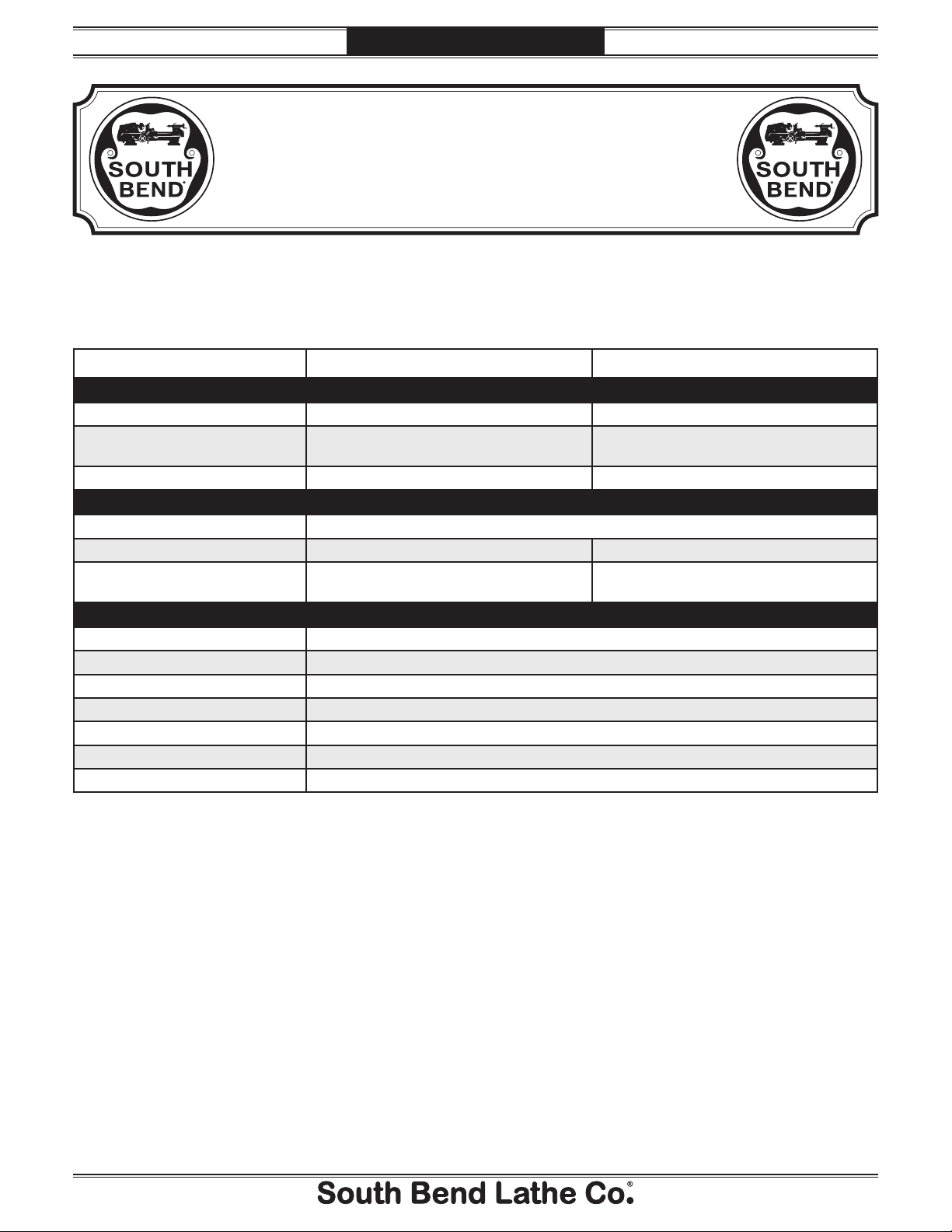

End Gears

Configuring the end gears shown in

Figure 7 will control the speed of the leadscrew

for threading or the feed rod for power feed

operations. The rotational speed of these

components depends not only on the end gear

configuration, but the spindle speed as well.

End

Gears

Figure 7. End gear components.

X. Quill Handwheel: Moves the quill toward or

away from the spindle.

Y. Gib Adjustment Screw: Adjusts the tapered

gib to control tailstock offset accuracy

(1 of 2).

Z. Tailstock Offset Screw: Adjusts the tailstock

offset left or right from the spindle centerline

(1 of 2).

AA. Quill: Moves toward and away from the

spindle and holds centers and tooling.

Safety Foot Brake

This lathe is equipped with a foot brake (see

Figure 8) to quickly stop the spindle instead of

allowing the spindle to coast to a stop on its own.

Pushing the foot brake while the spindle is ON

cuts power to the motor and stops the spindle.

After the foot brake is used, the spindle lever

must be returned to the OFF (middle) position

to reset the spindle switches before re-starting

spindle rotation.

Spindle

Lever

Foot Brake

Figure 8. Foot brake and spindle lever.

-7-

Page 10

13" Heavy 13® Gearhead Lathe

Product Specifications

INTRODUCTION

For Machines Mfg. Since 5/11

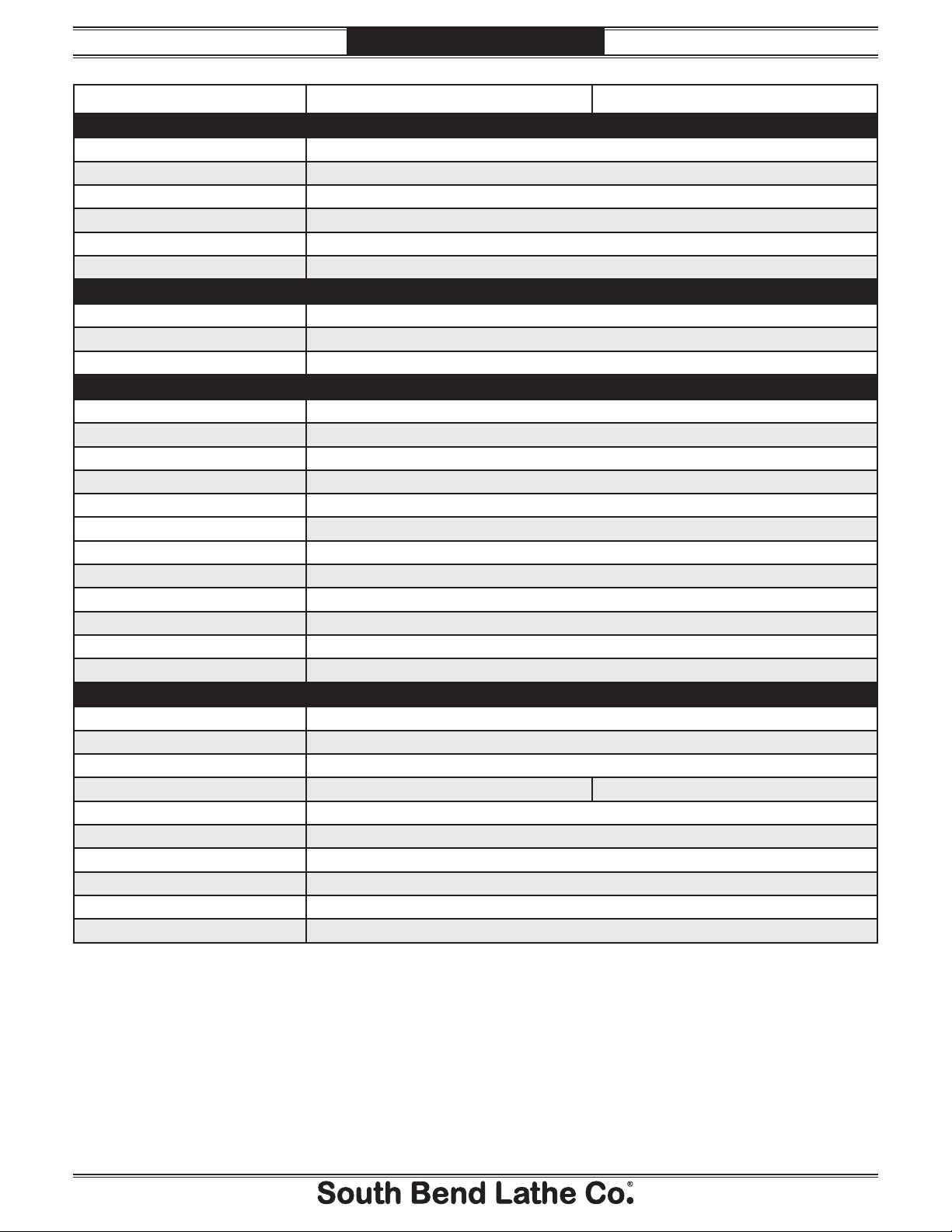

Product Specifications

P.O. Box 2027, Bellingham, WA 98227 U.S.A.

0(/.%s© South Bend Lathe Co.

www.southbendlathe.com

MODEL SB1049 & SB1050

®

13" HEAVY 13

Model Number SB1049 SB1050

Product Dimensions

Weight 1870 lbs. 2205 lbs.

Width (side-to-side)/Depth

(front-to-back)/Height

Foot Print (Width/Depth) 69

Shipping Dimensions

Type Wood Slat Crate

Weight 2090 lbs. 2469 lbs.

Width (side-to-side)/Depth

(front-to-back)/Height

Electrical

Power Requirement 220V, Single-Phase, 60Hz

Full-Load Current Rating 19.5A

Minimum Circuit Size 30A

Switch Magnetic with Thermal Protection

Switch Voltage 220V

Plug Included No

Recommended Plug/Outlet Type NEMA L6-30

GEARHEAD LATHES

79" x 38" x 69" 90" x 38" x 69"

3

⁄4" x 19 1⁄2" 80 3⁄4" x 19 1⁄2"

79 x 38 x 69 79" x 45" x 69"

-8-

Page 11

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

INTRODUCTION

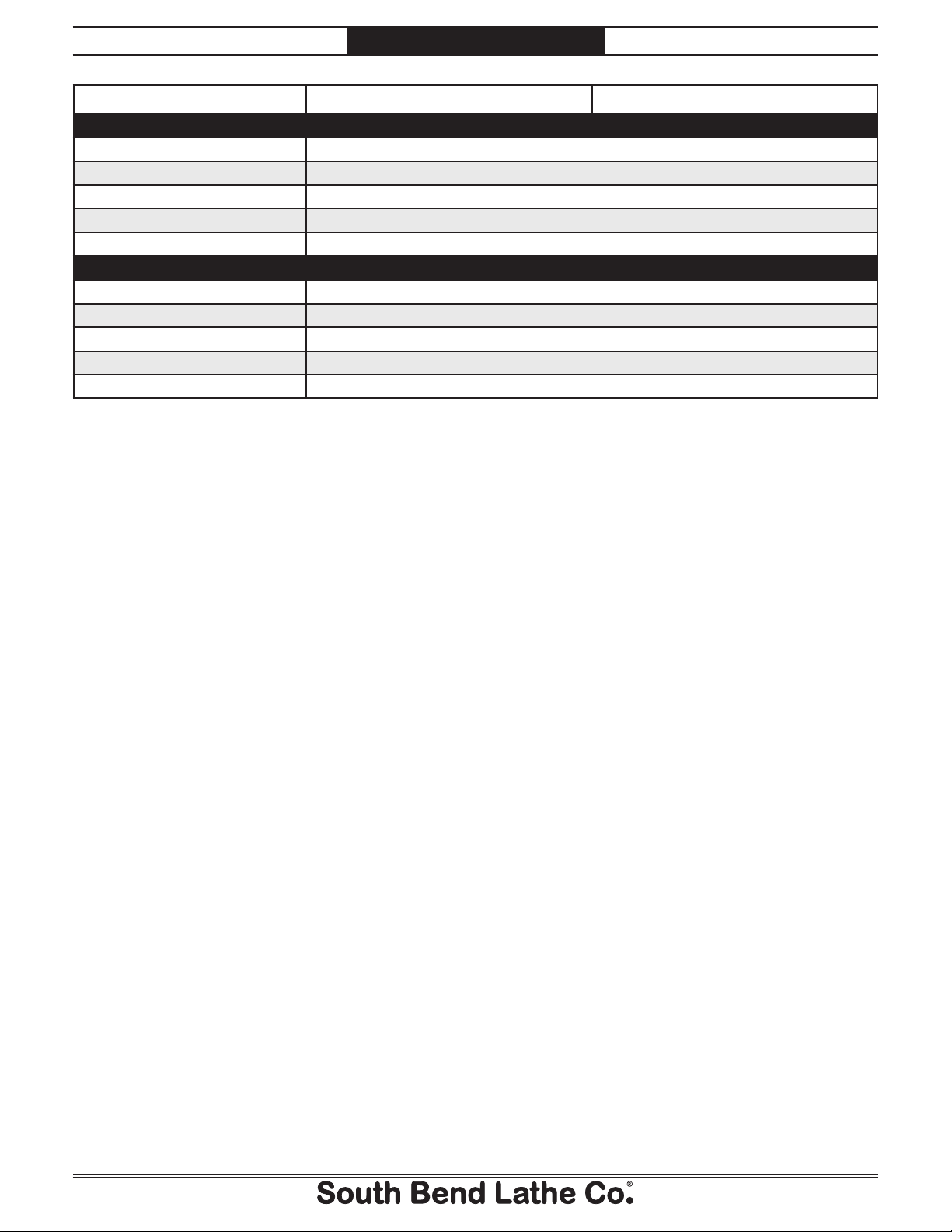

Model Number SB1049 SB1050

Main Motor

Type TEFC Induction

Horsepower 3 HP

Voltage 220V

Phase Single-Phase

Amps 19A

Speed 1720

Cycle 60 Hz

Power Transfer V-Belt & Gear

Bearings Shielded & Permanently Sealed

Coolant Motor

Type TEFC Induction

1

Horsepower

Voltage 220V

Phase Single-Phase

Amps 0.45A

Speed 3450 RPM

Cycle 60 Hz

Power Transfer Direct Drive

Bearings Shielded & Permanently Sealed Shielded & Permanently Sealed

Operation Information

Swing Over Bed 13.38"

Distance Between Centers 30" 40"

Swing Over Cross Slide 8.26"

Swing Over Saddle 11.02"

Swing Over Gap N/A 20"

Maximum Tool Bit Size 0.75"

Compound Travel 4"

Carriage Travel 36.5"

Cross Slide Travel 7"

⁄8 HP

-9-

Page 12

13" Heavy 13® Gearhead Lathe

INTRODUCTION

For Machines Mfg. Since 5/11

Model Number SB1049 SB1050

Headstock Information

Spindle Bore 1.57"

Spindle Taper MT#5

Number of Spindle Speeds 8

Range of Spindle Speeds 80–2000 RPM

Spindle Type D1-5 Camlock

Spindle Bearings Tapered Roller

Tailstock Information

Tailstock Quill Travel 4.5"

Tailstock Taper MT#3

Tailstock Barrel Diameter 1.968"

Threading Information

Number of Longitudinal Feeds 17

Range of Longitudinal Feeds 0.002"–0.067"

Number of Cross Feeds 17

Range of Cross Feeds 0.001"–0.034"

Number of Inch Threads 45

Range of Inch Threads 2–72 TPI

Number of Metric Threads 39

Range of Metric Threads 0.2–14 mm

Number of Modular Pitches 18

Range of Modular Pitches 0.3–3.5 MP

Number of Diametral Pitches 21

Range of Diametral Pitches 8–44 DP

Dimensions

Bed Width 9"

1

Leadscrew Diameter 1

Leadscrew TPI 4 TPI

Leadscrew Length 47" 59"

Steady Rest Capacity

Follow Rest Capacity

Faceplate Size 10"

Feed Rod Diameter

Floor to Center Height 42.2"

Height With Leveling Jacks 59.06"

⁄8"

5

⁄16"–4 5⁄16"

5

⁄8"–3 1⁄8"

3

⁄4"

-10-

Page 13

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

INTRODUCTION

Model Number SB1049 SB1050

Construction

Headstock Cast Iron

Headstock Gears Flame-Hardened Steel

Bed Meehanite Castings with Precision Hardened-and-Ground Ways

Stand Cast Iron

Paint Urethane

Other

Country of Origin Taiwan (Some Components Made in USA & Japan)

Warranty 1 Year

Serial Number Location ID Label on Front of Headstock

1

Assembly Time Approximately 1

Sound Rating at Idle 71 dB

⁄2 Hours

-11-

Page 14

13" Heavy 13® Gearhead Lathe

SAFETY

For Machines Mfg. Since 5/11

Understanding Risks of Machinery

Operating all machinery and machining equipment can be dangerous or relatively safe depending

on how it is installed and maintained, and the operator's experience, common sense, risk awareness,

working conditions, and use of personal protective equipment (safety glasses, respirators, etc.).

The owner of this machinery or equipment is ultimately responsible for its safe use. This

responsibility includes proper installation in a safe environment, personnel training and usage

authorization, regular inspection and maintenance, manual availability and comprehension,

application of safety devices, integrity of cutting tools or accessories, and the usage of approved

personal protective equipment by all operators and bystanders.

The manufacturer of this machinery or equipment will not be held liable for injury or property

damage from negligence, improper training, machine modifications, or misuse. Failure to read,

understand, and follow the manual and safety labels may result in serious personal injury, including

amputation, broken bones, electrocution, or death.

The signals used in this manual to identify hazard levels are as follows:

Death or catastrophic

harm WILL occur.

Death or catastrophic

harm COULD occur.

Basic Machine Safety

Owner’s Manual: All machinery and machining

equipment presents serious injury hazards

to untrained users. To reduce the risk of

injury, anyone who uses THIS item MUST

read and understand this entire manual

before starting.

Personal Protective Equipment:

servicing this item may expose the user

to flying debris, dust, smoke, dangerous

chemicals, or loud noises. These hazards

can result in eye injury, blindness, longterm respiratory damage, poisoning,

cancer, reproductive harm or hearing loss.

Reduce your risks from these hazards

by wearing approved eye protection,

respirator, gloves, or hearing protection.

Operating or

Moderate injury or fire

MAY occur.

Machine or property

damage may occur.

Trained/Supervised Operators Only: Untrained

users can seriously injure themselves

or bystanders. Only allow trained and

properly supervised personnel to operate

this item. Make sure safe operation

instructions are clearly understood. If

electrically powered, use padlocks and

master switches, and remove start switch

keys to prevent unauthorized use or

accidental starting.

Guards/Covers:

moving parts during operation may cause

severe entanglement, impact, cutting,

or crushing injuries. Reduce this risk by

keeping any included guards/covers/doors

installed, fully functional, and positioned

for maximum protection.

Accidental contact with

-12-

Page 15

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

SAFETY

Entanglement: Loose clothing, gloves, neckties,

jewelry or long hair may get caught in

moving parts, causing entanglement,

amputation, crushing, or strangulation.

Reduce this risk by removing/securing

these items so they cannot contact moving

parts.

Mental Alertness: Operating this item with

reduced mental alertness increases the

risk of accidental injury. Do not let a

temporary influence or distraction lead to a

permanent disability! Never operate when

under the influence of drugs/alcohol, when

tired, or otherwise distracted.

Safe Environment:

powered equipment in a wet environment

may result in electrocution; operating near

highly flammable materials may result in a

fire or explosion. Only operate this item in

a dry location that is free from flammable

materials.

Electrical Connection: With electically powered

equipment, improper connections to the

power source may result in electrocution

or fire. Always adhere to all electrical

requirements and applicable codes when

connecting to the power source. Have all

work inspected by a qualified electrician to

minimize risk.

Disconnect Power: Adjusting or servicing

electrically powered equipment while it

is connected to the power source greatly

increases the risk of injury from accidental

startup. Always disconnect power

BEFORE any service or adjustments,

including changing blades or other tooling.

Operating electrically

Chuck Keys or Adjusting Tools:

adjust spindles, chucks, or any moving/

rotating parts will become dangerous

projectiles if left in place when the machine

is started. Reduce this risk by developing

the habit of always removing these tools

immediately after using them.

Work Area:

the risks of accidental injury. Only operate

this item in a clean, non-glaring, and welllighted work area.

Properly Functioning Equipment:

maintained, damaged, or malfunctioning

equipment has higher risks of causing

serious personal injury compared to

those that are properly maintained.

To reduce this risk, always maintain

this item to the highest standards and

promptly repair/service a damaged or

malfunctioning component. Always follow

the maintenance instructions included in

this documentation.

Unattended Operation:

equipment that is left unattended while

running cannot be controlled and is

dangerous to bystanders. Always turn the

power OFF before walking away.

Health Hazards: Certain cutting fluids and

lubricants, or dust/smoke created when

cutting, may contain chemicals known to

the State of California to cause cancer,

respiratory problems, birth defects,

or other reproductive harm. Minimize

exposure to these chemicals by wearing

approved personal protective equipment

and operating in a well ventilated area.

Clutter and dark shadows increase

Electrically powered

Tools used to

Poorly

Secure Workpiece/Tooling:

cutting tools, or rotating spindles can

become dangerous projectiles if not

secured or if they hit another object during

operation. Reduce the risk of this hazard

by verifying that all fastening devices are

properly secured and items attached to

spindles have enough clearance to safely

rotate.

Loose workpieces,

Difficult Operations:

operations with which you are unfamiliar

increases the risk of injury. If you

experience difficulties performing the

intended operation, STOP! Seek an

alternative method to accomplish the

same task, ask a qualified expert how the

operation should be performed, or contact

our Technical Support for assistance.

Attempting difficult

-13 -

Page 16

13" Heavy 13® Gearhead Lathe

SAFETY

Additional Metal Lathe Safety

For Machines Mfg. Since 5/11

Speed Rates. Operating the lathe at the wrong

speed can cause nearby parts to break or the

workpiece to come loose, which will result in

dangerous projectiles that could cause severe

impact injuries. Large or non-concentric

workpieces must be turned at slow speeds.

Always use the appropriate feed and speed

rates.

Chuck Key Safety. A chuck key left in the chuck

can become a deadly projectile when the

spindle is started. Always remove the chuck

key after using it. Develop a habit of not

taking your hand off of a chuck key unless it

is away from the machine.

Safe Clearances. Workpieces that crash into

other components on the lathe may throw

dangerous projectiles in all directions,

leading to impact injury and damaged

equipment. Before starting the spindle,

make sure the workpiece has adequate

clearance by hand-rotating it through its

entire range of motion. Also, check the tool

and tool post clearance, chuck clearance, and

saddle clearance.

Clearing Chips. Metal chips can easily cut bare

skin—even through a piece of cloth. Avoid

clearing chips by hand or with a rag.Use a

brush or vacuum to clear metal chips.

Stopping Spindle by Hand. Stopping the spindle

by putting your hand on the workpiece

or chuck creates an extreme risk of

entanglement, impact, crushing, friction, or

cutting hazards. Never attempt to slow or

stop the lathe spindle with your hand. Allow

the spindle to come to a stop on its own or

use the brake.

Crashes. Aggressively driving the cutting tool

or other lathe components into the chuck

may cause an explosion of metal fragments,

which can result in severe impact injuries

and major damage to the lathe. Reduce

this risk by releasing automatic feeds after

use, not leaving lathe unattended during

operation, and checking clearances before

starting the lathe. Make sure no part of the

tool, tool holder, compound rest, cross slide,

or carriage will contact the chuck during

operation.

Long Stock Safety. Long stock can whip violently

if not properly supported, causing serious

impact injury and damage to the lathe.

Reduce this risk by supporting any stock

that extends from the chuck/headstock more

than three times its own diameter. Always

turn long stock at slow speeds.

Securing Workpiece. An improperly secured

workpiece can fly off the lathe spindle with

deadly force, which can result in a severe

impact injury. Make sure the workpiece is

properly secured in the chuck or faceplate

before starting the lathe.

Chucks. Chucks are very heavy and difficult to

grasp, which can lead to crushed fingers or

hands if mishandled. Get assistance when

handling chucks to reduce this risk. Protect

your hands and the precision-ground ways

by using a chuck cradle or piece of plywood

over the ways of the lathe when servicing

chucks. Use lifting devices when necessary.

Coolant Safety. Coolant is a very poisonous

biohazard that can cause personal injury

from skin contact alone, especially when it

gets old or has been well-used. Incorrectly

positioned coolant nozzles can splash on

the operator or the floor, resulting in skin

exposure or a slipping hazard. To decrease

your risk, change coolant regularly and

position the nozzle where it will not splash

or end up on the floor.

Tool Selection. Cutting with an incorrect or

dull tool increases the risk of accidental

injury due to the extra force required for

the operation, which increases the risk of

breaking or dislodging components that

can cause small shards of metal to become

dangerous projectiles. Always select the

right cutter for the job and make sure it is

sharp. Using a correct, sharp tool decreases

strain and provides a better finish.

-14-

Page 17

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

SAFETY

Additional Chuck Safety

Entanglement. Entanglement with a rotating

chuck can lead to death, amputation, broken

bones, or other serious injury. Never attempt

to slow or stop the lathe chuck by hand,

and always roll up long sleeves, tie back

long hair, and remove any jewelry or loose

apparel BEFORE operating.

Chuck Speed Rating. Excessive spindle speeds

greatly increase the risk of the workpiece or

chuck being thrown from the machine with

deadly force. Never use spindle speeds faster

than the chuck RPM rating or the safe limits

of your workpiece.

Using Correct Equipment. Many workpieces can

only be safely turned in a lathe if additional

support equipment, such as a tailstock or

steady rest, is used. If the operation is too

hazardous to be completed with the lathe or

existing equipment, the operator must have

enough experience to know when to use a

different machine or find a safer way. If you

do not have this experience, seek additional

training (outside of this manual) from

experienced lathe operators, books, or formal

classes

Trained Operators Only. Using a chuck

incorrectly can result in workpieces coming

loose at high speeds and striking the

operator or bystanders with deadly force.

To reduce the risk of this hazard, read

and understand this document and seek

additional training from an experienced

chuck user before using a chuck.

Chuck Capacity. Avoid exceeding the capacity

of the chuck by clamping an oversized

workpiece. If the workpiece is too large to

safely clamp with the chuck, use a faceplate

or a larger chuck if possible. Otherwise, the

workpiece could be thrown from the lathe

during operation, resulting in serious impact

injury or death.

Clamping Force. Inadequate clamping force

can lead to the workpiece being thrown

from the chuck and striking the operator

or bystanders. Maximum clamping force

is achieved when the chuck is properly

maintained and lubricated, all jaws are

fully engaged with the workpiece, and the

maximum chuck clamping diameter is not

exceeded.

Proper Maintenance.

maintained and lubricated to achieve

maximum clamping force and withstand

the rigors of centrifugal force. To reduce

the risk of a thrown workpiece, follow all

maintenance intervals and instructions in

this document.

Disconnect Power. Serious entanglement or

impact injuries could occur if the lathe is

started while you are adjusting, servicing, or

installing the chuck. Always disconnect the

lathe from power before performing these

procedures.

All chucks must be properly

-15 -

Page 18

13" Heavy 13® Gearhead Lathe

PREPARATION

For Machines Mfg. Since 5/11

Preparation Overview Things You'll Need

The purpose of the preparation section is to help

you prepare your machine for operation. The list

below outlines this basic process. Specific steps

for each of these points will be covered in detail

later in this section.

The typical preparation process is as follows:

1. Unpack the lathe and inventory the contents

of the box/crate.

2. Clean the lathe and its components.

3. Identify an acceptable location for the lathe

and move it to that location.

4. Level the lathe and either bolt it to the floor

or place it on mounts.

5. Assemble the loose components and make

any necessary adjustments or inspections to

ensure the lathe is ready for operation.

6. Check/lubricate the lathe.

To complete the preparation process, you will

need the following items:

For Lifting and Moving

s !FORKLIFTOROTHERPOWERLIFTINGDEVICE

rated for at least 25% more than the

shipping weight of the lathe (see Product

Specifications beginning on Page 1)

s ,IFTINGstraps, each rated for at least 25%

more than the shipping weight of the lathe

s 'UIDERODSFORSTEADINGTHELOADWHENLIFTING

s Two other people for assistance when moving

machine

s Hardwood blocks (see Page 22)

For Power Connection

s !POWERSOURCETHATMEETSTHEMINIMUM

circuit requirements for this machine (review

Power Supply Requirements on the next

page for details)

s !NELECTRICIANORQUALIFIEDSERVICEPERSONNEL

to ensure a safe and code-compliant

connection to the power source

7. Connect the lathe to the power source.

8. Test run the lathe to make sure it functions

properly.

9. Perform the spindle break-in procedure to

prepare the lathe for operation.

For Cleaning & Assembly

s Cotton rags

s Mineral spirits

s Quality metal protectant oil

s 3AFETYglasses

s Wrench or socket 21mm

s Wrench or socket 19mm

s &LOORmounting hardware as needed

s 0RECISIONLEVEL

s Standard screwdriver #2

-16 -

Page 19

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

A

Power Supply

Requirements

PREPARATION

The full-load current is not the maximum

amount of amps that the machine will draw. If

the machine is overloaded, it will draw additional

amps beyond the full-load rating.

Availability

Before installing the machine, consider the

availability and proximity of the required power

supply circuit. If an existing circuit does not meet

the requirements for this machine, a new circuit

must be installed.

To minimize the risk of electrocution, fire,

or equipment damage, installation work and

electrical wiring must be done by an electrician

or qualified service personnel in accordance with

all applicable codes.

Serious injury could occur if you connect

the machine to power before completing the

setup process. DO NOT connect to power until

instructed later in this manual.

Full-Load Current Rating

The full-load current rating is the amperage

a machine draws at 100% of the rated output

power. On machines with multiple motors, this is

the amperage drawn by the largest motor or sum

of all motors and electrical devices that might

operate at one time during normal operations.

If the machine is overloaded for a sufficient

length of time, damage, overheating, or fire may

result—especially if connected to an undersized

circuit. To reduce the risk of these hazards,

avoid overloading the machine during operation

and make sure it is connected to a power supply

circuit that meets the requirements in the

following section.

Circuit Requirements

This machine is prewired to operate on a 220V

power supply circuit that has a verified ground

and meets the following requirements:

Nominal Voltage ...............................220V/240V

Cycle .............................................................60 Hz

Phase ..............................................Single-Phase

Circuit Rating....................................... 30 Amps

Cord ........."S" Type, 3-Wire, 12 AWG, 300 VAC

Plug/Receptacle ............................NEMA L6-30

power supply circuit includes all electrical

equipment between the main breaker box or fuse

panel in your building and the incoming power

connections inside the machine. This circuit

must be safely sized to handle the full-load

current that may be drawn from the machine for

an extended period of time. (If this machine is

SB1049 Full-Load Rating ................ 19.5 Amps

SB1050 Full-Load Rating ................ 19.5 Amps

For your own safety and protection of property,

consult an electrician if you are unsure about

wiring practices or applicable electrical codes.

Note: The circuit requirements in this manual

are for a dedicated circuit—where only one

machine will be running at a time. If this

machine will be connected to a shared circuit

where multiple machines will be running at

the same time, consult a qualified electrician to

ensure the circuit is properly sized.

-17-

Page 20

13" Heavy 13® Gearhead Lathe

PREPARATION

This machine must be grounded! In the event

of certain types of malfunctions or breakdowns,

grounding provides a path of least resistance

for electric current in order to reduce the risk of

electric shock.

Improper connection of the equipment-grounding

wire can result in a risk of electric shock. The

wire with green insulation (with or without

yellow stripes) is the equipment-grounding

wire. If repair or replacement of the power cord

is necessary, do not connect the equipmentgrounding wire to a live (current carrying)

terminal.

Check with an electrician or qualified service

personnel if you do not understand these

grounding requirements, or if you are in doubt

about whether the machine is properly grounded.

If you ever notice that a cord is damaged or

worn, disconnect it from power, and immediately

replace it with a new one.

For Machines Mfg. Since 5/11

Extension CordsGrounding Requirements

We do not recommend using an extension cord

with this machine. If you must use an extension

cord, only use it if absolutely necessary and only

on a temporary basis.

Extension cords cause voltage drop, which may

damage electrical components and shorten motor

life. Voltage drop increases as the extension cord

size gets longer and the gauge size get smaller

(higher gauge numbers indicate smaller sizes).

Any extension cord used with this machine

must contain a ground wire, match the required

plug and receptacle, and meet the following

requirements:

Minimum Gauge Size ...............................12 AWG

Maximum Length (Shorter is Better) ........... 50 ft.

The power cord and plug specified under Circuit

Requirements section on the previous page has

an equipment-grounding wire and a grounding

prong. The plug must only be inserted into a

matching receptacle (outlet) that is properly

installed and grounded in accordance with all

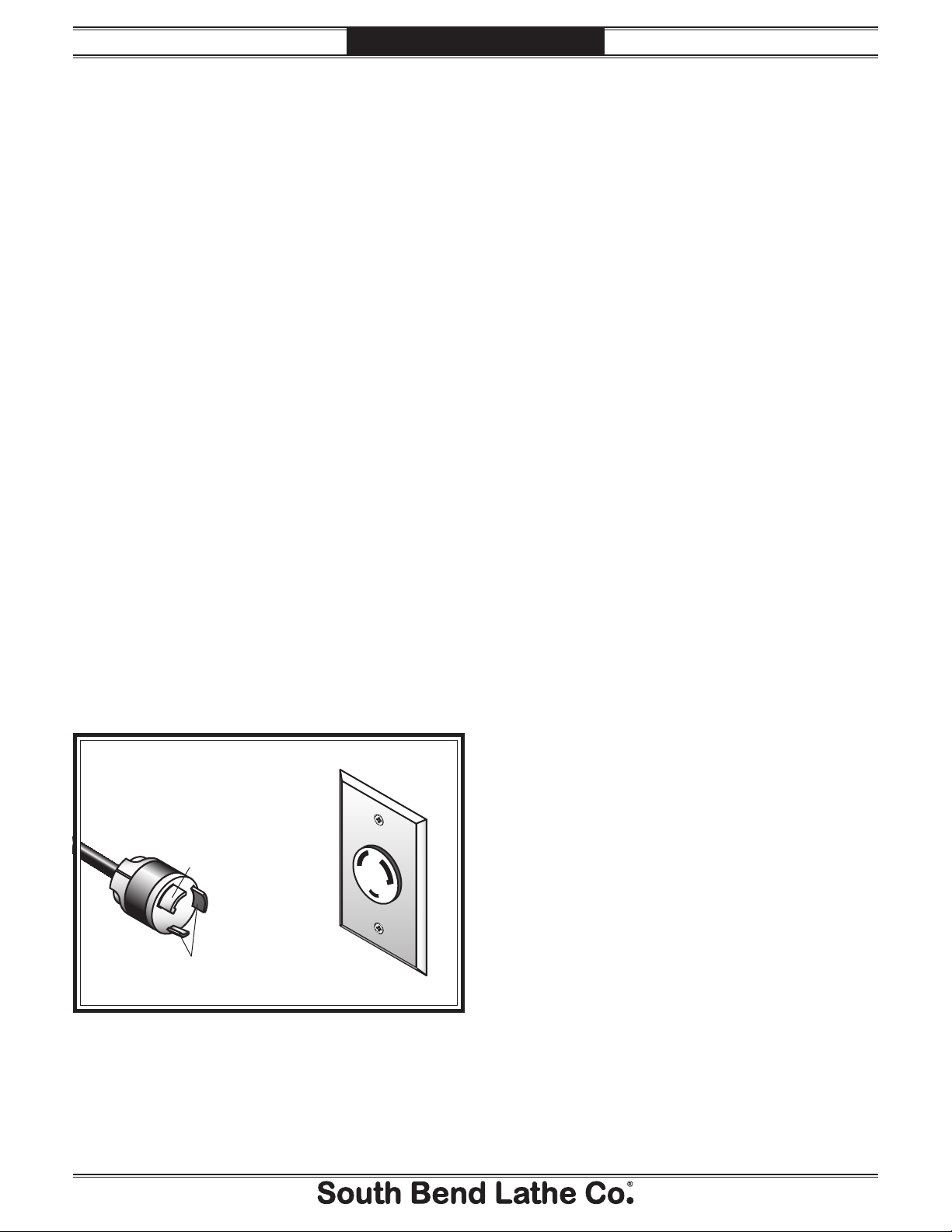

local codes and ordinances (see Figure 9).

GROUNDED

L6-30 LOCKING

RECEPTACLE

Grounding Prong

is Hooked

L6-30

LOCKING

PLUG

Current Carrying Prongs

Figure 9. Typical NEMA L6-30 plug and receptacle.

-18 -

Page 21

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

PREPARATION

Unpacking

This item was carefully packaged to prevent

damage during transport. If you discover any

damage, please immediately call Customer

Service at (360) 734-1540 for advice. You may

need to file a freight claim, so save the containers

and all packing materials for possible inspection

by the carrier or its agent.

Inventory

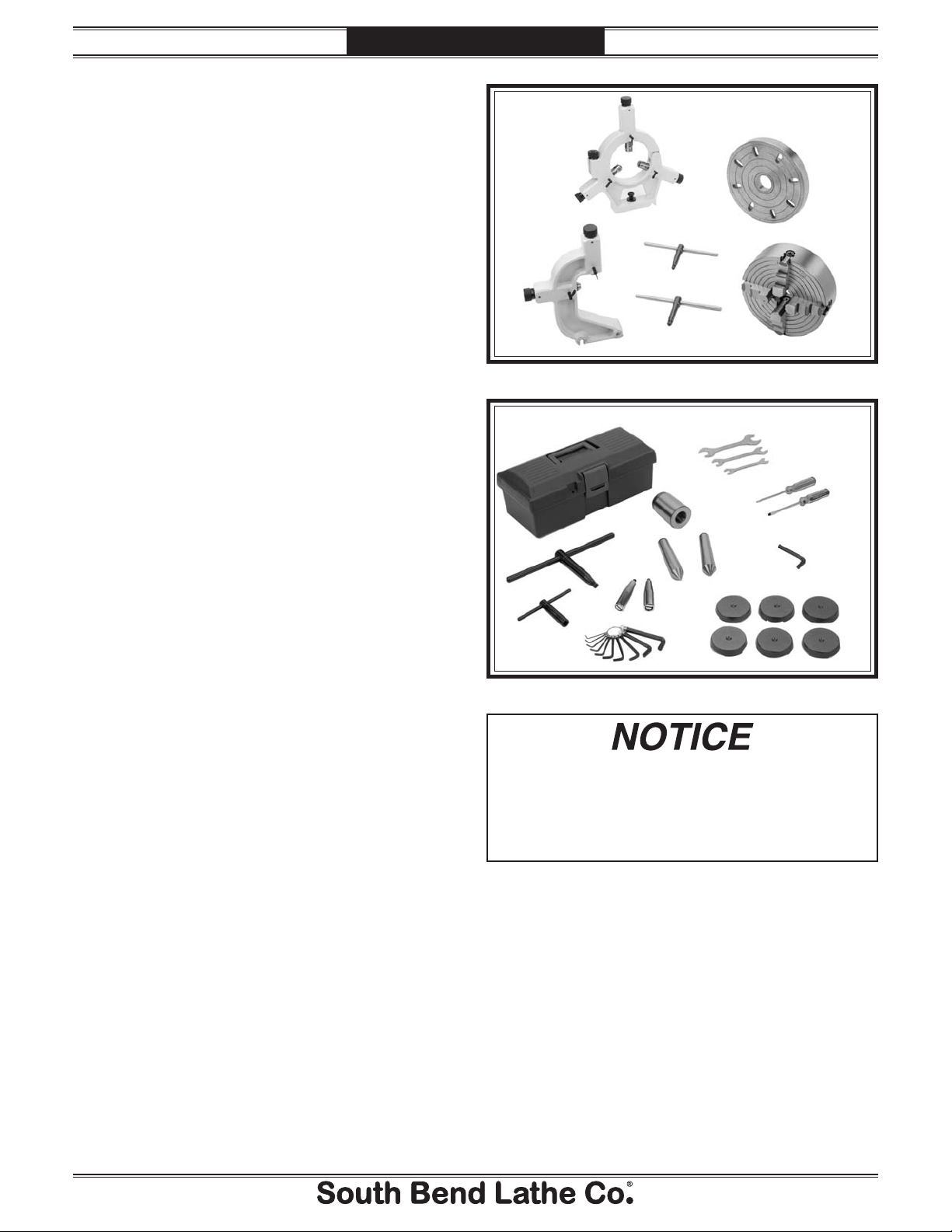

Main Inventory 1: (Figure 10) Qty

A. Steady Rest Assembly (Installed) .................1

B. 10" Faceplate w/D1-5 Camlock Stud Set ...... 1

C. 8" 4-Jaw Chuck w/Combo Jaws (SB1226) ....1

D. 3-Jaw Chuck Key ...........................................1

E. 4-Jaw Chuck Key ........................................... 1

F. Follow Rest Assembly (Installed) .................. 1

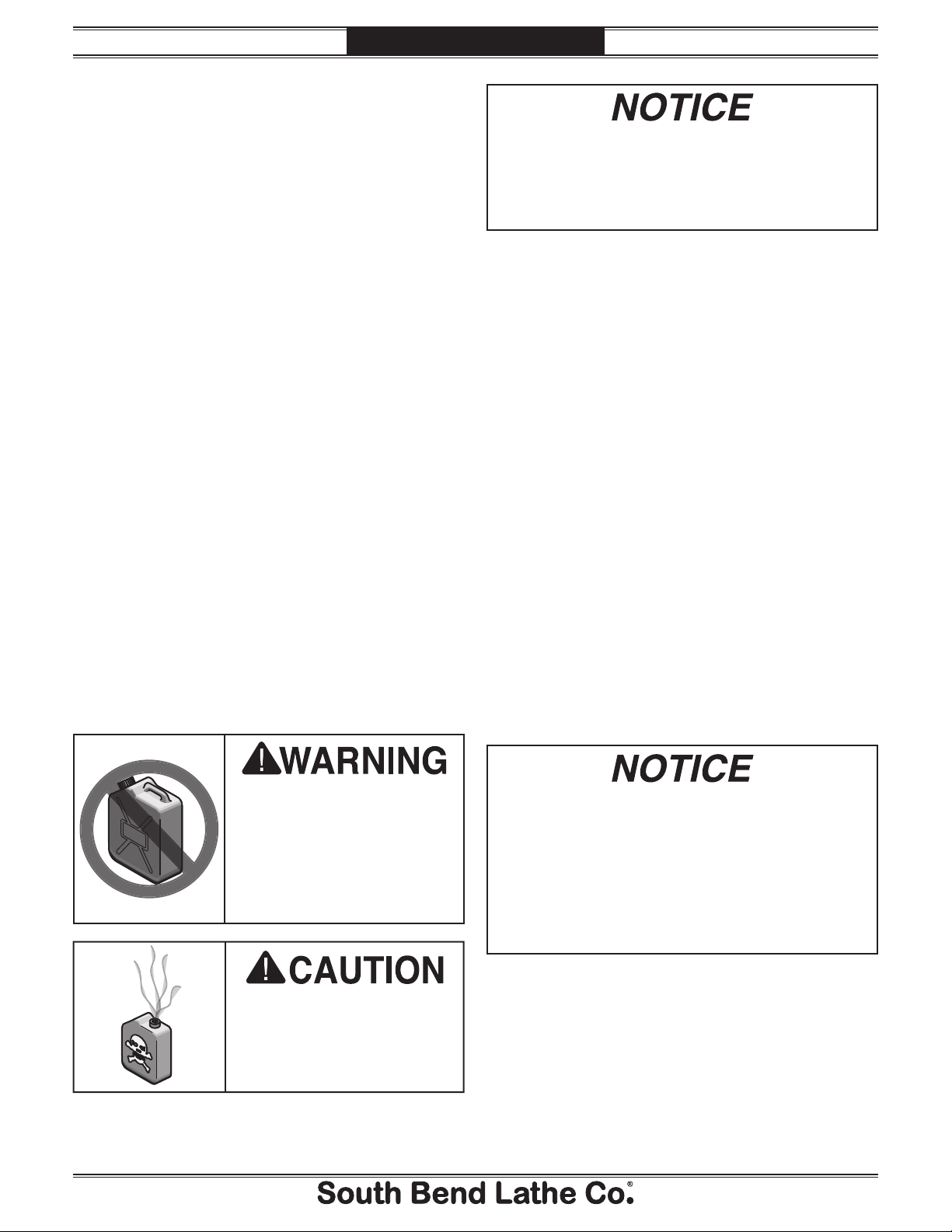

Tool Box Inventory: (Figure 11) Qty

G. Tool Box .......................................................... 1

H. Open End Wrench 22/24mm .........................1

I. Open End Wrench 14/17mm .........................1

J. Open End Wrench 10/12mm .........................1

K. Phillips Screwdriver #2 .................................1

L. Standard Screwdriver #2 ............................... 1

M. Hex Wrench 8mm ..........................................1

N. Tapered Spindle Sleeve MT#5-#3 .................1

O. Dead Center MT#3 .........................................1

P. Carbide-Tipped Dead Center MT#3 .............. 1

Q. Camlock Key D1-5 ......................................... 1

R. Tool Post T-Wrench (Clamped on Tool Post) 1

S. Hex Wrench Set 1.5-10mm ............................ 1

T. Carriage Handwheel Handle .........................1

U. Cross Slide Handwheel Handle ..................... 1

V. Cast Iron Leveling Pads ................................6

A

D

F

E

Figure 10. Main inventory.

G

Q

R

If you cannot find an item on this list, check

the mounting location on the machine or the

packaging materials. Sometimes parts are

pre-installed for shipping, or they become

hidden by packaging materials.

T

S

Figure 11. Toolbox inventory.

H

N

O

U

B

C

I

J

P

K

L

M

V

Pre-Installed (Not Shown) Qty

s 7" 3-Jaw Chuck (SB1308) .............................. 1

1

s 8

Note: Some inventory components may be

shipped inside of the lathe electrical box. These

items MUST be removed before connecting the

lathe to the power source.

⁄4" Back Plate D1-5 (SB1399) ...................... 1

-19 -

Page 22

13" Heavy 13® Gearhead Lathe

A

PREPARATION

Cleaning & Protecting

For Machines Mfg. Since 5/11

The unpainted surfaces are coated at the factory

with a heavy-duty rust preventative that

prevents corrosion during shipment and storage.

The benefit of this rust preventative is that it

works very well. The downside is that it can be

time-consuming to thoroughly remove.

Be patient and do a careful job when cleaning

and removing the rust preventative. The time

you spend doing this will reward you with

smooth-sliding parts and a better appreciation

for the proper care of the unpainted surfaces.

lthough there are many ways to successfully

remove the rust preventative, the following

process works well in most situations.

Before cleaning, gather the following:

s $ISPOSABLErags

s #LEANERDEGREASER (certain citrus-based

degreasers work extremely well and they

have non-toxic fumes)

s 3AFETYGLASSESDISPOSABLEGLOVES

Note: Automotive degreasers, mineral spirits, or

7$sCANBEUSEDTOREMOVERUSTPREVENTATIVE

Before using these products, though, test them

on an inconspicuous area of a painted surface to

make sure they will not damage it.

Avoid chlorine-based solvents, such as

acetone or brake parts cleaner that may

damage painted surfaces. Always follow the

manufacturer’s instructions when using any

type of cleaning product.

Basic steps for removing rust preventative:

1. Put on safety glasses and disposable gloves.

2. #OATALLSURFACESTHATHAVERUSTPREVENTATIVE

with a liberal amount of your cleaner or

degreaser and let them soak for a few

minutes.

3. Wipe off the surfaces. If your cleaner or

degreaser is effective, the rust preventative

will wipe off easily.

Note: To clean off thick coats of rust preventative

on flat surfaces, such as beds or tables, use

A0,!34)#PAINTSCRAPERTOSCRAPEOFFTHE

majority of the coating before wiping it off

WITHYOURRAG$ONOTUSEAMETALSCRAPEROR

it may scratch the surface.)

4. Repeat Steps 2–3 as necessary until clean,

then coat all unpainted surfaces with a

quality metal protectant or light oil to

prevent rust.

-20-

GAS

Gasoline and petroleum

products have low flash

points and can explode

or cause fire if used for

cleaning. Avoid using these

products to remove rust

preventative.

Many cleaning solvents are

toxic if inhaled. Minimize

your risk by only using

these products in a well

ventilated area.

Remove the end gear cover and end gears,

and use a stiff brush with mineral spirits

to clean the rust preventative from the

gears and shafts. DO NOT get any cleaner

or rust preventative on the V-belts, as it

could damage them or make them slip

during operations. If the belts do become

contaminated, replace them.

Page 23

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

PREPARATION

LocationLocation

Physical Environment

The physical environment where your machine

is operated is important for safe operation and

longevity of parts. For best results, operate this

machine in a dry environment that is free from

excessive moisture, hazardous or flammable

chemicals, airborne abrasives, or extreme

conditions. Extreme conditions for this type

of machinery are generally those where the

ambient temperature is outside the range of 41°–

104°F; the relative humidity is outside the range

of 20–95% (non-condensing); or the environment

is subject to vibration, shocks, or bumps.

Electrical Installation

Place this machine near an existing power source

that meets the minimum circuit requirements.

Make sure all power cords are protected from

traffic, material handling, moisture, chemicals,

or other hazards. Leave access to disconnect the

power source or engage a lockout/tagout device.

Weight Load

Refer to the Machine Specifications for the

weight of your machine. Make sure that the

surface upon which the machine is placed will

bear the weight of the machine, additional

equipment that may be installed on the machine,

and the heaviest workpiece that will be used.

Additionally, consider the weight of the operator

and any dynamic loading that may occur when

operating the machine.

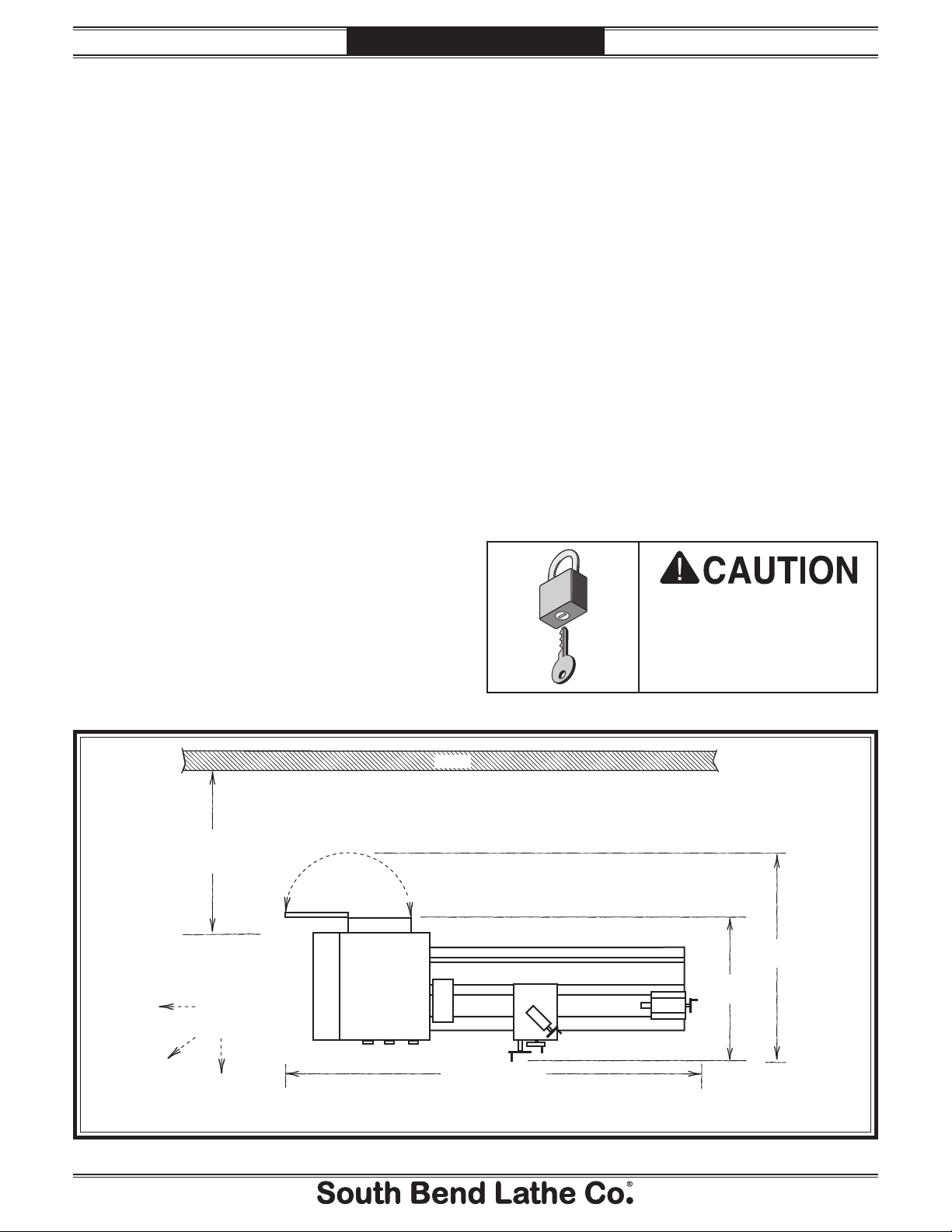

Space Allocation

Consider the largest size of workpiece that will

be processed through this machine and provide

enough space around the machine for adequate

operator material handling or the installation

of auxiliary equipment. With permanent

installations, leave enough space around

the machine to open or remove doors/covers

as required by the maintenance and service

described in this manual.

Lighting

Lighting around the machine must be adequate

enough that operations can be performed

safely. Shadows, glare, or strobe effects that

may distract or impede the operator must be

eliminated.

Wall

Electrical

Min. 30"

for Maintenance

Keep

Workpiece

Loading Area

Unobstructed

Cabinet

Lathe

Children or untrained

people may be seriously

injured by this machine.

Install machine in an

access restricted location.

54"

38"

(Drawing Not To Scale)

Figure 12. Space required for full range of movement.

79" (SB1049)

90" (SB1050)

-21-

Page 24

13" Heavy 13® Gearhead Lathe

Lifting & Moving

PREPARATION

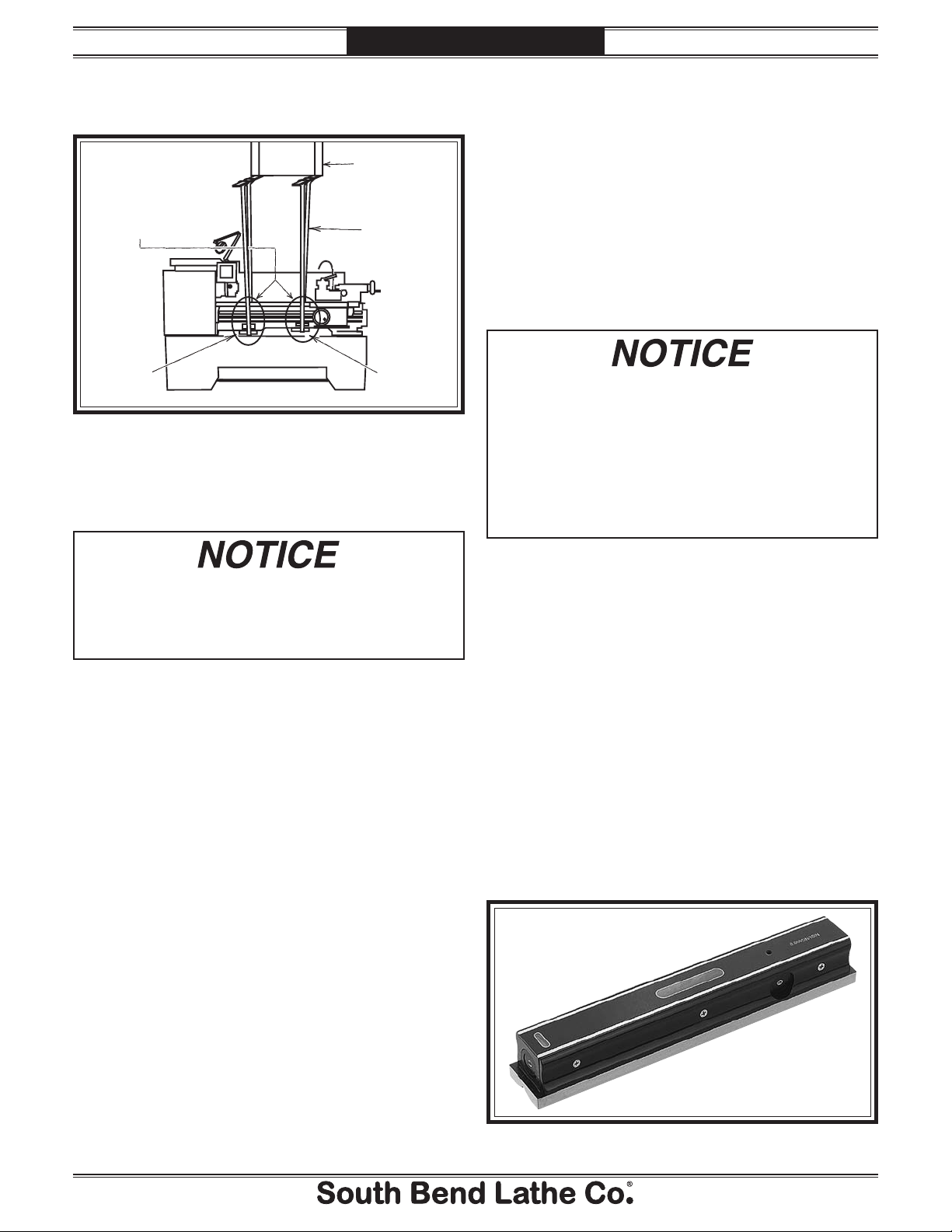

5. Position hardwood blocks under each end

of the bed as shown in Figure 13. This

will keep the lifting straps away from the

leadscrew, feed rod, and spindle rod to

prevent bending them during lifting.

(Looking at Lifting Setup from Tailstock End)

Leadscrew

Feed Rod

For Machines Mfg. Since 5/11

To Power Lifting Equipment

Control

Rod

Lifting

Strap

Lathe

Bed

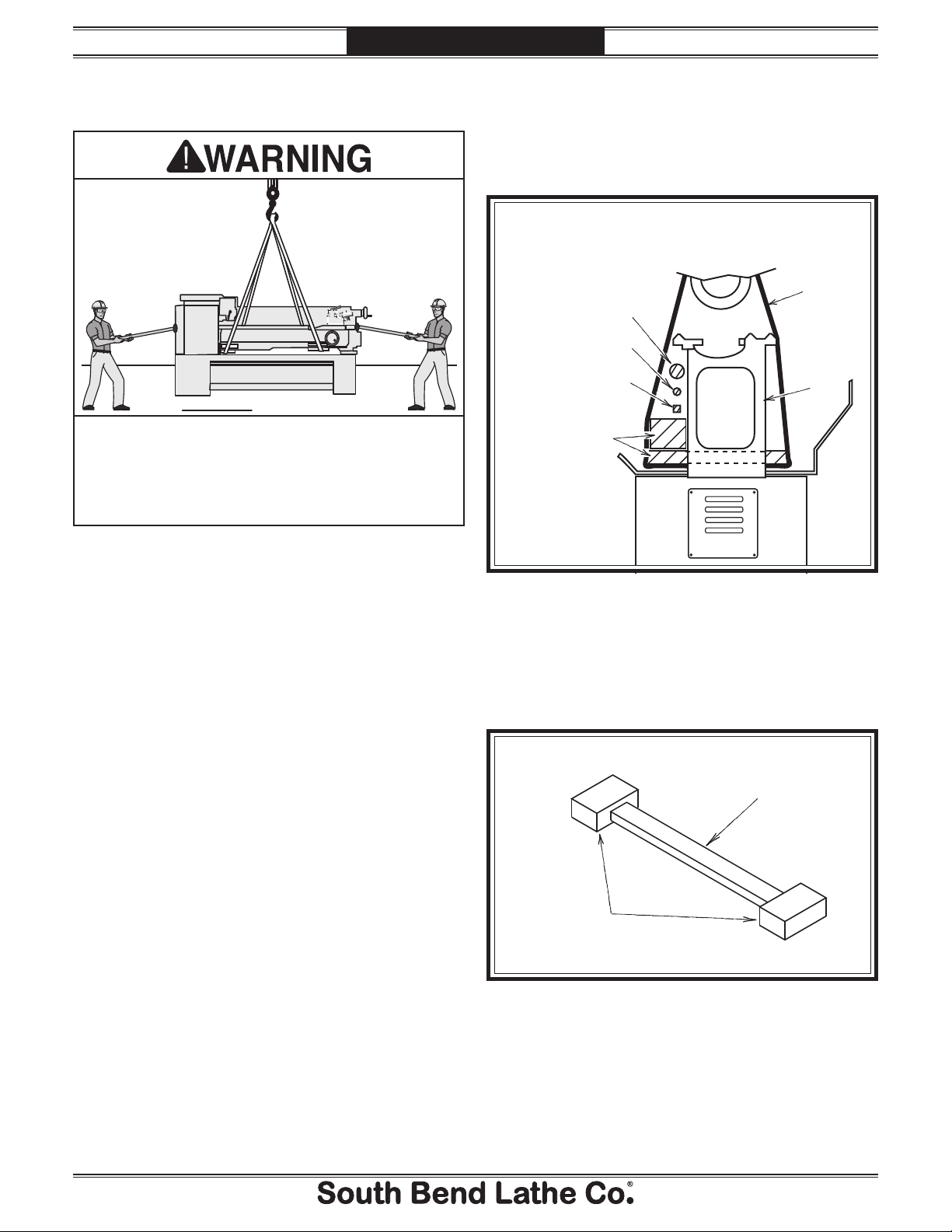

This machine and its parts are heavy! Serious

personal injury may occur if safe moving

methods are not used. To reduce the risk of a

lifting or dropping injury, ask others for help,

and use power equipment and guide rods.

Do not attempt to lift or move this lathe without

using the proper lifting equipment (such as

forklift or crane) or the necessary assistance from

other people. Each piece of lifting equipment

must be rated for at least 25% more than the

shipping weight of your lathe to support dynamic

loads that may be applied while lifting. Refer to

Things You'll Need on Page 16 for details.

To lift and move the lathe:

1. Remove the shipping crate top and sides,

then remove the small components from the

shipping pallet.

2. Move the lathe to its prepared location while

it is still attached to the shipping pallet.

Hardwood Blocks

and Planks

Positioned as

Required to

Prevent Lifting

Straps from

Bending

Leadscrew

Figure 13. Lifting setup to keep straps from bending

leadscrew or rods.

Note: Fasten a center support between the

hardwood blocks so that they will stay

spread apart and in place when lifting (see

the example in Figure 14).

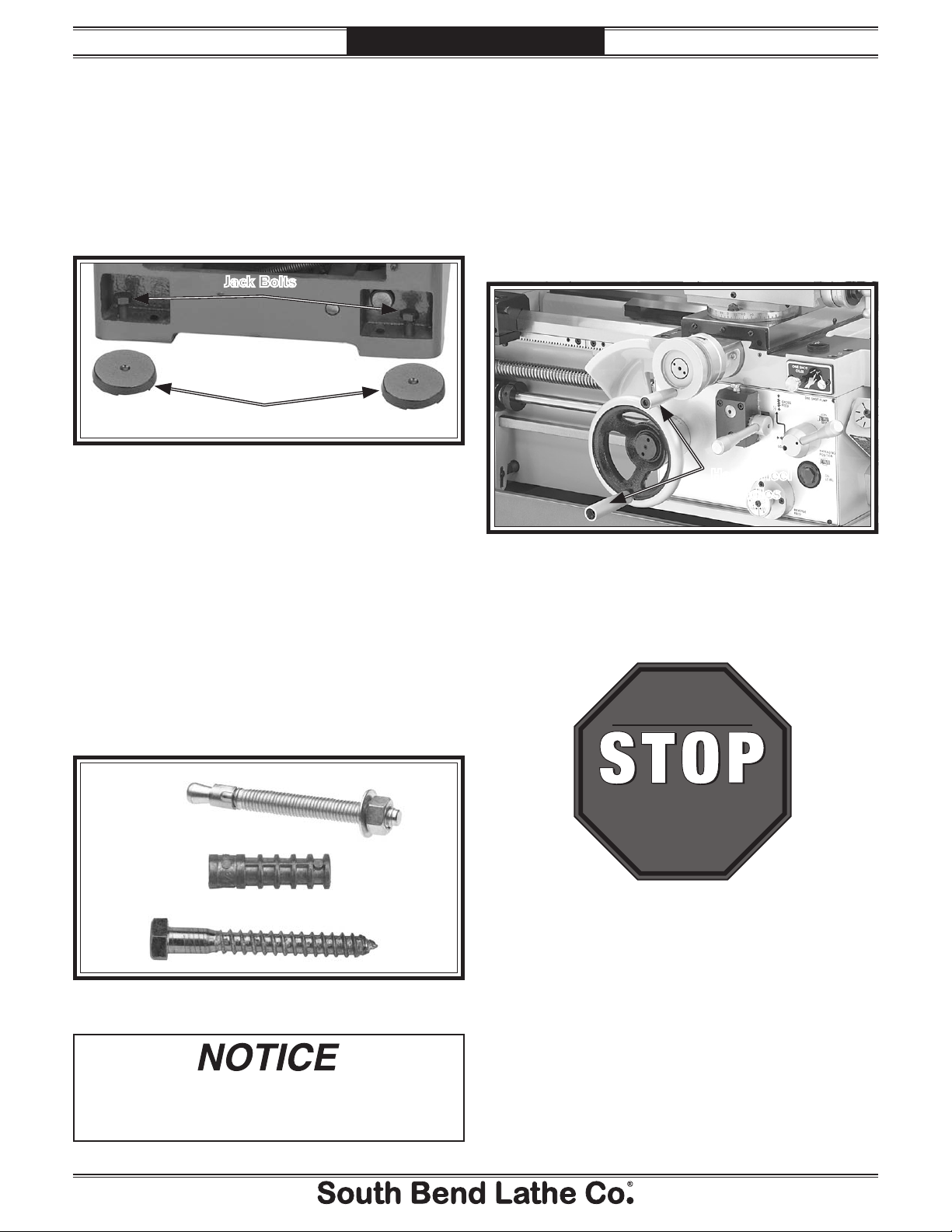

Center

Support

3. Unbolt the lathe from the shipping pallet

4. To balance the load for lifting, move the

tailstock and carriage to the extreme right

end of the bedway, then lock them in place.

Note: Before attempting to move the carriage,

make sure the carriage lock is loose, the half

nut is disengaged, and the power feed is

disengaged (feed selection lever).

-22-

Hardwood

Blocking

Figure 14. Example of blocking center support.

Page 25

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

PREPARATION

6. Attach the lifting straps to the power lifting

equipment (see Figure 15 for an example).

Leveling & Mounting

You must level your machine and either use

Use Blocks as Necessary

to Space Straps Away

from Control Rod,

Feed Rod, and Leadscrew

to Prevent Bending when

the Lathe is Lifted

Power Lifting

Equipment

Lifting

Straps

the included foot pads and leveling hardware or

bolt and shim your lathe to the floor. Because

mounting your lathe to the floor with permanent

hardware is an optional step and floor materials

may vary, floor mounting hardware is not

included.

Leveling

Hardwood

Blocking

Figure 15. Example of lathe setup for lifting.

Hardwood

Blocking

7. At each end of the lathe, have assistants

connect guide rods to safely keep the lathe

from swaying or tipping during lifting.

When lifting the lathe with straps, the load

will be top heavy. Take extra care to keep the

load balanced vertically and only lift the lathe

far enough to remove the shipping pallet.

8. Raise the lathe a couple of inches and check

the balance of the load.

— If the load is not safely balanced,

immediately lower the lathe and resolve

the issue before attempting to lift it

again.

For accurate turning results and to prevent

warping the cast iron bed and ways, the lathe

bedways MUST be leveled from side-to-side

and from front-to-back on both ends.

Re-check the bedways 24 hours after

installation, two weeks after that, and then

annually to make sure they remain level.

Leveling machinery helps precision components,

such as bedways, remain straight and flat during

the lifespan of the machine. Components on a

machine that is not level may slowly twist due to

the dynamic loads placed on the machine during

operation.

For best results, use a precision level that

is at least 12" long and sensitive enough to

show a distinct movement when a 0.003" shim

(approximately the thickness of one sheet of

standard newspaper) is placed under one end of

the level.

9. Raise the lathe enough to clear the shipping

pallet, carefully remove the pallet, then

lower the lathe into position.

See the figure below for an example of a high

precision level.

Figure 16. Example of a precision level.

-23-

Page 26

13" Heavy 13® Gearhead Lathe

PREPARATION

To level the machine, use a precision level to

make sure the bedways are level from side-toside and from front-to-back.

— If using the included leveling pads (see

Figure 17), place them under the six

leveling jack bolt locations, then adjust

the bolts to level the lathe.

Jack Bolts

Pads

Figure 17. Leveling pads and screws.

— If using mounting hardware that does not

allow for adjustment, level the lathe by

placing metal shims between the lathe

base and the floor before bolting it down.

For Machines Mfg. Since 5/11

Assembly

With the exception of the handwheel handles, the

lathe is shipped fully assembled.

To install the handwheel handles, thread the

large handle into the carriage handwheel and the

small handle into the cross slide handwheel, as

shown in Figure 19.

Handwheel

Handles

Figure 19. Handwheel handles installed.

Bolting to Concrete Floors

Lag screws and anchors, or anchor studs

(below), are two popular methods for bolting

machinery to a concrete floor. We suggest you

research the many options and methods for

mounting your machine and choose the best one

for your specific application.

Anchor

Stud

Lag Screw

and Anchor

Figure 18. Common types of fasteners for bolting

machinery to concrete floors.

Most electrical codes require that machines

connected to the power source by fixed

conduit MUST be secured to the floor.

Lubricating Lathe

GEARBOXES MUST

BE FILLED WITH OIL!

OIL MAY NOT BE

SHIPPED WITH MACHINE!

Refer to Lubrication Section

for Correct Oil Type.

The headstock, quick-change gearbox, and apron

oil reservoirs must have the proper amount of oil

in them before the lathe can be operated for the

first time.

Damage caused to the bearings and gears from

running the lathe without oil in the reservoirs

will not be covered under warranty. Refer to the

Lubrication section, beginning on Page 66, for

details on how to check, add oil, and prime the

headstock oil pump.

-24-

Page 27

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

PREPARATION

In addition to the reservoirs, we also recommend

that you lubricate all other points on the

machine at this time. This can be accomplished

by following the maintenance schedule on

Page 64.

Note: If this lathe was shipped with oil in the

reservoirs, do not change that oil until after the

test run and spindle break-in procedures.

Adding Coolant

Add the coolant of your choice now. For detailed

instructions on where the coolant tank is located

and how to add fluid, refer to Coolant System

Service on Page 71.

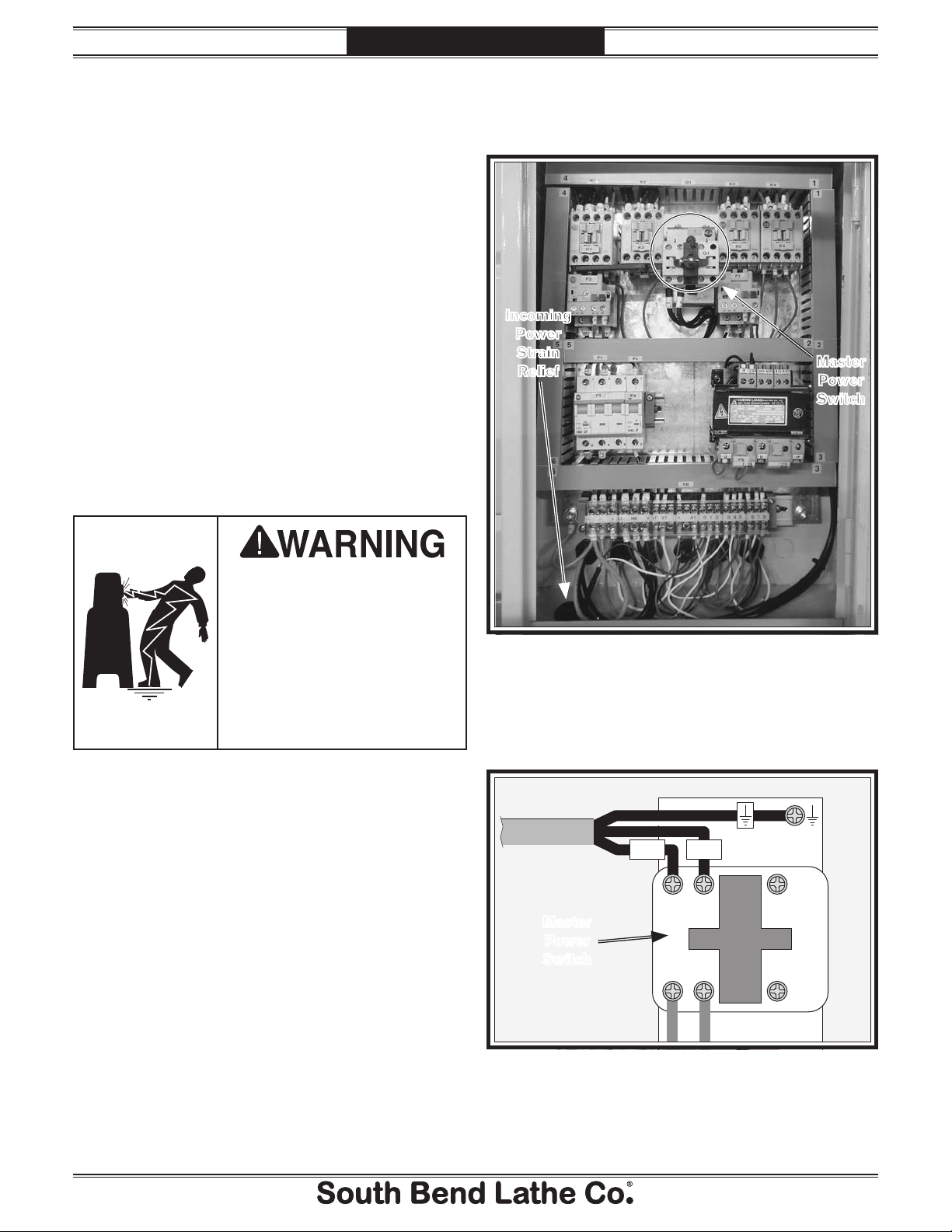

Power Connection

2. Thread the power cord through the strain

relief, and up to the master power switch

shown in Figure 20.

Incoming

Power

Strain

Relief

Master

Power

Switch

Electrocution or fire

may occur if machine is

ungrounded, incorrectly

connected to power, or

connected to an undersized

circuit. Use an electrician or

a qualified service personnel

to ensure a safe power

connection.

Once your machine is set up and assembled as

previously described in this manual, it is ready to

be connected to the power source.

Note About Extension Cords: Using an

incorrectly sized extension cord may decrease the

life of electrical components on your machine.

Refer to Extension Cords on Page 18 for more

information.

To connect the power cord to the lathe:

1. Make sure the master power switch is

turned to the OFF position, then open the

electrical cabinet door.

Figure 20. Location to connect power inside main

electrical cabinet.

3. Connect the incoming hot wires to the

upper master power switch terminals, as

illustrated in Figure 21.

To Plug

HotHot

Master

Power

Switch

Figure 21. Power connection at master power switch.

Ground

4. Connect the incoming ground wire to the

ground terminal on the switch bracket, as

illustrated in Figure 21.

-25-

Page 28

13" Heavy 13® Gearhead Lathe

5. Make sure the power cord and wires have

slack between the strain relief and terminal

connections so that they do not bind, then

tighten the strain relief to secure the cord.

Note: The strain relief must be tightened against

the outer jacket of the cord. Avoid overtightening the strain relief or it may crush

the cord and cause a short.

PREPARATION

For Machines Mfg. Since 5/11

Test Run

After all preparation steps have been completed,

the machine and its safety features must be

tested to ensure correct operation. If you discover

a problem with the operation of the machine or

its safety components, shut the machine down,

disconnect it from power, and do not operate it

until you have resolved the problem.

6. Test the strain relief to ensure it is properly

tightened by pulling the cord from outside

the box with light-to-moderate force. When

the strain relief is properly tightened, the

cord will not move inside the cabinet.

7. Install a NEMA L6-30 plug on the other end

of the power cord per the manufacturer's

instructions.

8. Close and lock the main electrical box door.

9. Connect the plug to the matching receptacle

and power source as specified in Circuit

Requirements on Page 17.

To avoid unexpected start-up of lathe

components, keep the master power switch

turned OFF until instructed otherwise in the

Test Run.

A Troubleshooting section is provided, starting

on Page 84, to assist you with solutions if a

problem occurs or if the lathe does not function

as described in this section.

If you need additional help after reviewing the

troubleshooting section, or you are not confident

troubleshooting the machine on your own,

contact our Tech Support at (360) 734-1540.

To test run your machine:

1. Make sure the master power switch (see

Figure 22) on the rear of the machine is

turned OFF.

Main Power

Switch

-26-

Figure 22. Location of the master power switch.

2. Read and follow the safety instructions

at the beginning of the manual, take all

required safety precautions, and make sure

all previous preparation steps discussed

in this manual have been followed and

completed.

Page 29

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

PREPARATION

3. Clear away all tools and objects used during

assembly, lubrication, and preparation.

4. Make sure that the chuck and jaws, if

installed, are secure (refer to Chuck and

Faceplate Mounting on Page 32).

Note: If a chuck is not installed on the lathe, you

do not need to install one for this test.

5. Push the STOP button on the control panel

(see Figure 23), and point the coolant nozzle

into the chip pan.

Power

Light

Note: During the next step, you may need to

use the chuck key rock the spindle back

and forth while attempting to shift so

the gears will mesh. If you do this, be

sure to remove the chuck key afterward.

7. Set the spindle speed to 80 RPM as follows:

a. Move the spindle range lever so the

arrow on the hub points toward the L

(low) label (see Figure 25).

Speed

Lever

Spindle Range

Lever

Coolant

Pump

Switch

Figure 23. Control panel.

Jog

Button

STOP

Button

6. Disengage the quick-change gearbox

by moving the feed range lever to the

neutral (middle) position, as illustrated in

Figure 24.

Feed

Range Lever

Feed Range Lever

Low

:>

Spindle Speed

*

*

"

*

&

"

$

%

"

"

"

$

)

)

$

#

$

)

#

$

"

&

"

'

$

Lever Set to

80 RPM

Spindle Range

Lever Set to LOW

Figure 25. Spindle speed set to 80 RPM.

b. Move the spindle speed lever so that the

80 on its hub is also pointing at the L

label.

Note: You will hear a distinct click when

the spindle speed lever is in the correct

position.

Neutral

High

Figure 24. Feed range lever.

-27-

Page 30

13" Heavy 13® Gearhead Lathe

PREPARATION

For Machines Mfg. Since 5/11

8. Turn the master power switch on the

electrical cabinet to the ON position.

9. Reset the STOP button by twisting it

clockwise until it pops out. The power lamp

on the control panel should illuminate.

10. To ensure the carriage components do not

unexpectedly move during the following

steps, disengage the half nut lever and feed

selection lever (see Figure 26).

Half Nut

Lever

Feed

Selection

Lever

Spindle

Lever

Disengaged

Cross Slide

Disengaged

Carriage

Halfnut

Lever

Feed Control

Lever

Engaged

— When operating correctly, the machine

runs smoothly with little or no vibration

or rubbing noises.

— Investigate and correct strange or

unusual noises or vibrations before

operating the machine further. Always

disconnect the machine from power when

investigating or correcting potential

problems.

12. Press the STOP button to turn the lathe

OFF, then, without resetting the STOP

button, try to restart spindle rotation. The

spindle should not start.

— If spindle rotation does start with the

STOP button pressed in, the STOP button

safety is not operating correctly. This

safety feature must operate properly

before continuing operation. Use the

spindle lever to stop the lathe, disconnect

it from power, and call Tech Support for

help.

13. Move the spindle lever to the OFF (middle)

position, reset the STOP button by twisting

it clockwise until it pops out, then restart

spindle rotation.

Figure 26. Disengaging carriage components.

11. Start the spindle by pulling the spindle lever

out and moving it down (see Figure 27).

Spindle

Lever

Figure 27. Spindle lever in down (forward) position.

14. Push the foot brake. The spindle should

come to a quick stop.

— If the brake pedal has no effect on the

lathe, push the STOP button, and refer

to Brake & Switch on Page 78 to make

any required adjustments.

-28-

Page 31

For Machines Mfg. Since 5/11 13" Heavy 13® Gearhead Lathe

PREPARATION

15. Move the spindle lever to the OFF (middle)

position. Remove the end gear cover from the

left side of the headstock. This activates a

safety switch that should prevent the spindle

from starting while this cover is removed.

16. Stand away from all the exposed gears on

the side of the headstock, and attempt to

start spindle rotation. The spindle should not

start.

— If spindle rotation does start with the end

cover removed, the safety switch is not

operating correctly. This safety feature

must operate properly before continuing

operation. Press the STOP button to turn

the lathe OFF, disconnect it from power,

and call Tech Support for help.

17. Push the STOP button in, move the spindle

lever to the OFF position, then replace the

end gear cover.

18. Lift the chuck guard up—this will activate

the chuck guard safety switch. Reset the

STOP button and attempt to start spindle

rotation. The spindle should not start.

— If spindle rotation does start with the

chuck guard in the up position, the safety

switch is not operating correctly. This

safety feature must operate properly

before continuing operation. Press the

STOP button to turn the lathe OFF,

disconnect it from power, and call Tech

Support for help.

19. Re-start spindle rotation, use the cutting

fluid pump switch on the control panel to