Page 1

Owner’s Manual

IMPORTANT FOR FUTURE REFERENCE

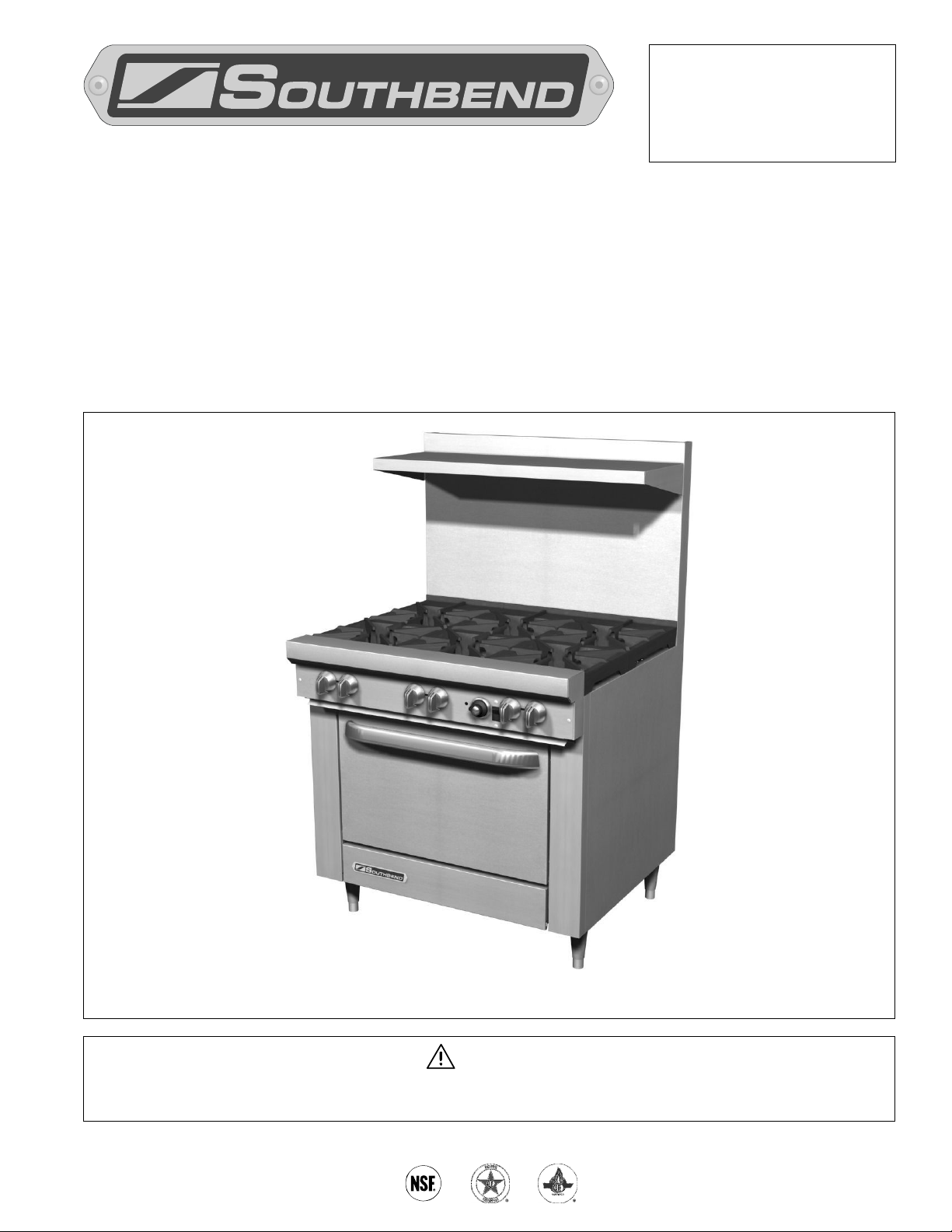

Restaurant Ranges

S Series

Please complete this information and retain

this manual for the life of the equipment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

Improper installation, adjustment, alteration, service, or maintenance can cause property damage, injury, or death.

Read installation, operation, and maintenance instructions thoroughly before installing or servicing this equipment.

O

WNER’S MANUAL

$30.00

Model S36D

WARNING

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526 USA • www.southbendnc.com

1191904 REV 1 (11/10)

S S

ERIES RESTAURANT RANGES

M

ANUAL SECTION

RR

Page 2

S

AFETY PRECAUTIONS

S S

ERIES RESTAURANT RANGES

SAFETY PRECAUTIONS

Before installing and operating this equipment, be sure everyone involved in its operation is fully trained and aware of

precautions. Accidents and problems can be caused by failure to follow fundamental rules and precautions.

The following symbols, found throughout this manual, alert you to potentially dangerous conditions to the operator,

service personnel, or to the equipment.

DANGER

WARNING

CAUTION

NOTICE

This symbol warns of immediate hazards that will result in severe injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in injury or

death.

This symbol refers to a potential hazard or unsafe practice that could result in injury,

product damage, or property damage.

This symbol refers to information that needs special attention or must be fully understood,

even though not dangerous.

WARNING

FIRE HAZARD

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of cooking appliances.

Keep area around cooking appliances free and clear of combustibles.

Purchaser of equipment must post in a prominent location detailed instructions to be followed in the event the

operator smells gas. Obtain the instructions from the local gas supplier.

WARNING

BURN HAZARD

Contact with hot surfaces will cause severe burns. Always use caution when operating cooking appliances.

WARNING

EXPLOSION AND ASPHYXIATION HAZARD

In the event a gas odor is detected, shut down equipment at the main gas shut-off valve and immediately call

the emergency phone number of your gas supplier.

Improper ventilation can result in headaches, drowsiness, nausea, and could result in death. Do not obstruct the

flow of combustion and ventilation air to and from cooking appliances.

WARNING

ELECTRIC SHOCK HAZARD

For appliances that use electric power, disconnect the power to the appliance before cleaning. Do not remove

panels that require tools to remove. Disconnect power before opening kick panel below oven.

NOTICE

This appliance is intended for commercial use, and is only for professional use. It shall be used by trained,

qualified people.

Warranty will be void if service work is performed by other than a qualified technician, or if other than genuine

Southbend replacement parts are installed.

Give this Owner’s Manual and important papers to the proper authority to retain for future reference.

Copyright © 2010 by Southbend. All rights reserved. Published in the United States of America.

P

AGE 2 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 3

S S

ERIES RESTAURANT RANGES

I

NTRODUCTION

Congratulations! You have purchased one of the finest pieces of heavy-duty commercial cooking equipment on the

market.

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to meet

the toughest standards in the industry. Each piece of Southbend equipment is carefully engineered and designs are

verified through laboratory tests and field installations. With proper care and field maintenance, you will experience

years of reliable, trouble-free operation. For best results, read this manual carefully.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

This manual is divided into six sections:

Introduction........................................... 3

Specifications........................................ 4

Operation.............................................. 8

Cleaning & Maintenance....................... 12

Installation ............................................ 14

Service.................................................. 20

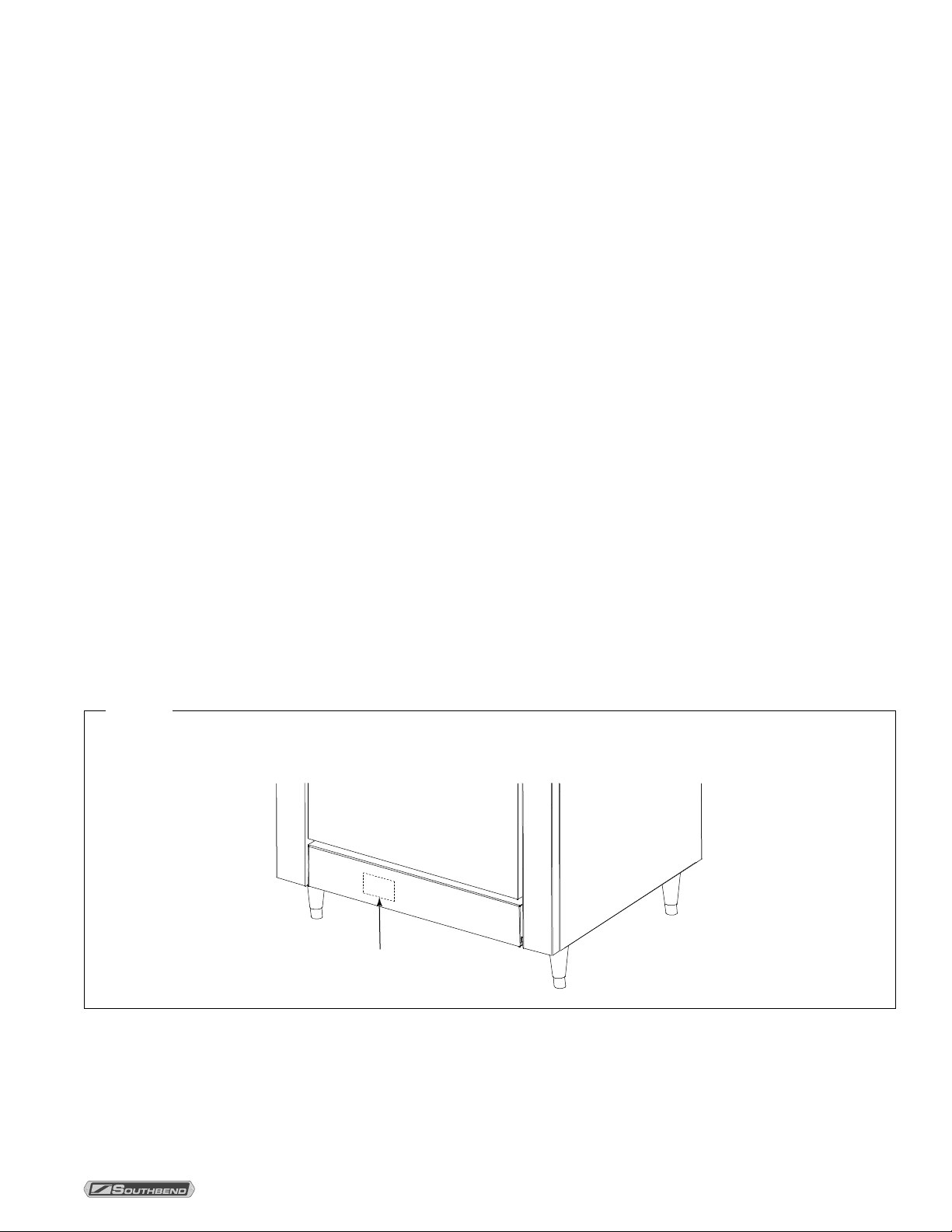

The serial plate is located on the inside surface of the kick panel (see Figure 1 below).

Read these instructions carefully before attempting installation. Installation and initial startup should be performed by

a qualified installer. Unless the installation instructions for this product are followed by a qualified service technician (a

person experienced in and knowledgeable with the installation of commercial gas and/or electric cooking equipment)

then the terms and conditions on the Manufacturer’s Limited Warranty will be rendered void and no warranty of any

kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, contact:

Figure 1

I

Southbend Technical Service

1100 Old Honeycutt Road

Fuquay-Varina, North Carolina 27526 USA

www.southbendnc.com

NTRODUCTION

Location of Serial Plate

Serial Plate is Located on

Inside Surface of Kick Panel

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 3 OF

40

Page 4

S

PECIFICATIONS

S

PECIFICATIONS

S S

ERIES RESTAURANT RANGES

NOTICE

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association,

Inc., states in its NFPA 96 latest edition that local codes are the “authority having jurisdiction” when it comes to

installation requirements for equipment. Therefore, installations should comply with all local codes.

Southbend reserves the right to change specifications and product design without notice. Such revisions do not

entitle the buyer to corresponding changes, additions, or replacements for previously purchased equipment.

Southbend appliances are intended for commercial use only, not for household use.

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGAB149.2, as applicable, including:

1. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psi (3.45 kPa).

2. The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.45

kPa).

C

LEARANCES

WARNING

MINIMUM CLEARANCES FROM COMBUSTIBLE CONSTRUCTION

There must be adequate clearance between ranges and combustible construction. Clearance must also be

provided for servicing and for operation.

Minimum Clearances for ranges with ovens:

Standard Oven Convection Oven Double Oven Base

Sides 10 inches 10 inches 10 inches

Back 10 inches 10 inches 10 inches

Floor zero zero zero

Ranges are suitable for installation on combustible floors.

Adequate clearance must be provided in the aisle and at the side and rear to allow the door to open sufficiently to

permit the removal of the racks and for serviceability.

On ranges with a convection-type oven, a minimum of 2 inches clearance must be allowed behind the motor and

the rear non-combustible enclosure. Care must be taken to provide adequate air circulation to prevent the motor

from overheating.

E

LECTRICAL REQUIREMENTS

Ranges with a convection oven require connection to a supply of electricity. The appliance, when installed, must be

electrically grounded in accordance with local codes, or in the absence of local codes, with the National Electric Code,

ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.2, as applicable. An electrical diagram is located on the

rear of the range.

The range may be furnished with one or two power cords (one for each oven), each with a standard 115V, 60Hz,

single-phase prong plug. Some ranges instead have terminal connections. See the serial plate for maximum

amperage requirements.

P

AGE 4 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 5

S S

ERIES RESTAURANT RANGES

G

AS REQUIREMENTS

S

PECIFICATIONS

The total BTU gas requirement for the range varies depending on the ordered options. The gas requirement and type

of gas the range is configured for (natural gas or propane) is stated on the serial plate.

A 3/4" female NPT gas connection is located on the rear of the range (see Figure 2).

The serial plate is located inside the oven kick panel (see Figure 1). The serial plate indicates the type of gas the

range is equipped to burn, and the total gas supply requirement (in BTUs). All Southbend equipment is adjusted at

the factory.

These models are design-certified for operation on natural or propane gases. A kit for conversion to a different type of

gas is available from Southbend.

For natural gas, the regulator is set to 4" W.C. (0.99 kPa). For propane gas, it is set to 10" W.C. (2.48 kPa). If

applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in accordance

with local codes, or in the absence of local codes, with the applicable national codes.

This appliance should be connected ONLY to the type of gas for which it is equipped.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas required for

satisfactory performance. A 1/8" pressure tap is located on the manifold to measure the manifold pressure.

An adequate gas supply line to the range should be no smaller than the inside diameter of the pipe from the range to

which it is connected.

Purge the supply line to clean out dust, dirt, or other foreign matter before connecting the line to the range.

All pipe joints and connections must be tested thoroughly for gas leaks. Use only soapy water for testing on all gases.

NEVER use an open flame to check for gas leaks. All connections must be checked for leaks after the range has

been put into operation. Test pressure should not exceed 14" W.C. (3.47 kPa).

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 5 OF

40

Page 6

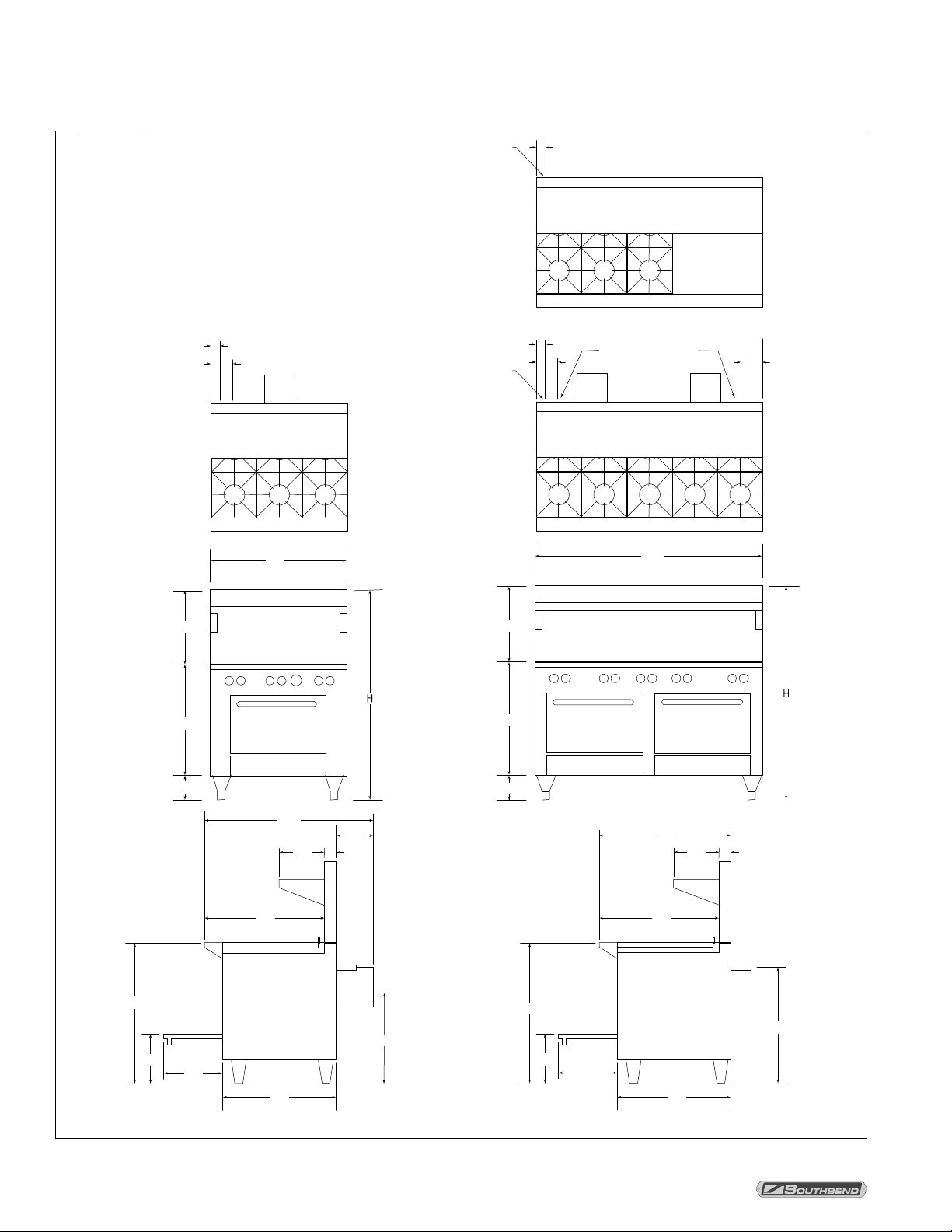

S

Gas Connection

PECIFICATIONS

D

IMENSIONS

S S

The dimensions of the restaurant range are shown in Figure 2 below and on the next page.

Figure 2

O

ERIES RESTAURANT RANGES

24" Griddle

Gas Connection

O

Electrical Connection

R

A

I

J

K

Gas Connection

I

J

K

O

Electrical Connections

(for ranges with convection ovens)

R R

A

P

AGE 6 OF

B

E

L

M

D D

Side View of Ranges WITH Convection Oven Side View of Ranges WITHOUT Convection Oven

C

Electrical

Connection

Q

40 O

L

NN

M

WNER’S MANUAL

B

FF G

E

1191904 REV 1 (11/10)

G

Gas Connection

P

Page 7

S S

ERIES RESTAURANT RANGES

E

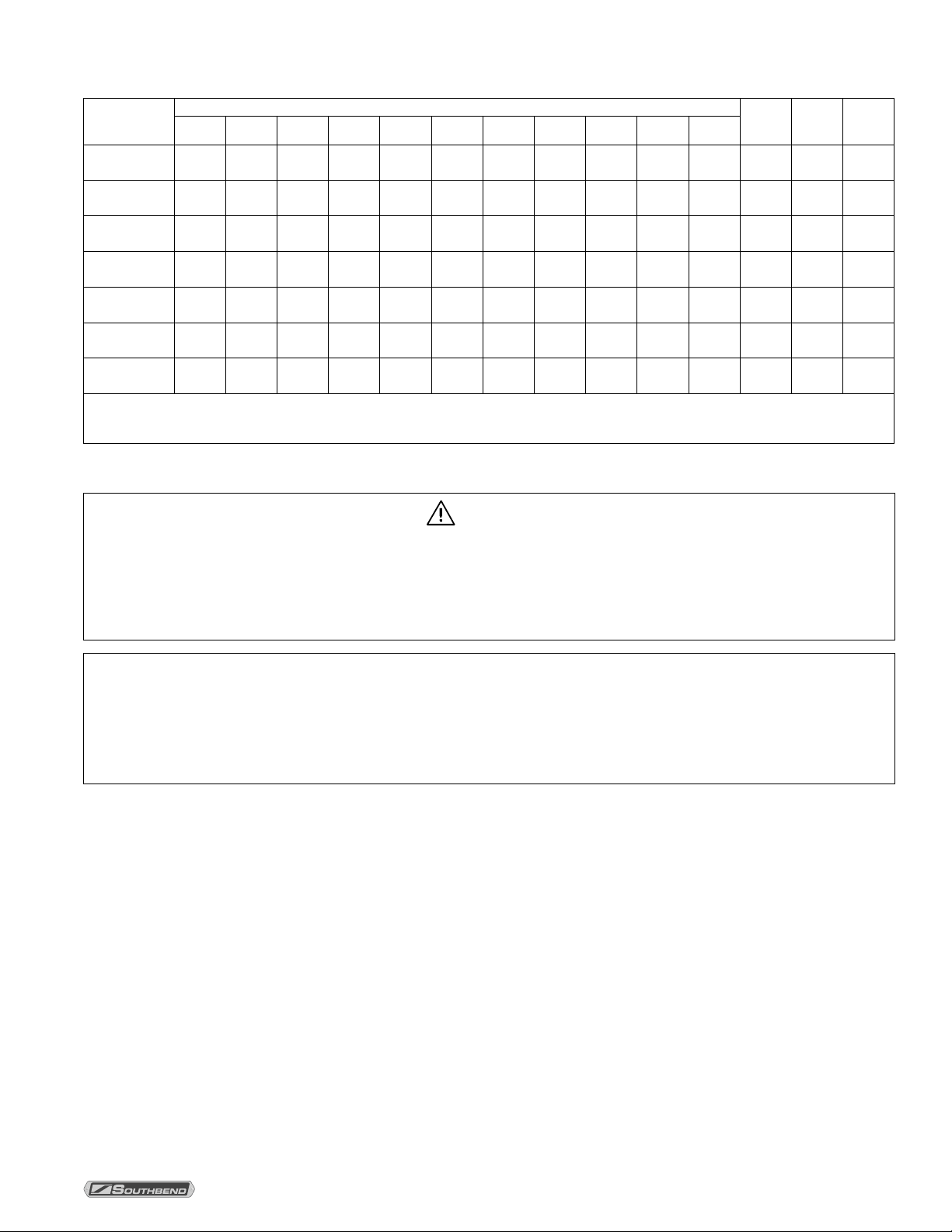

XTERIOR DIMENSIONS

S

PECIFICATIONS

6"

(152)

6"

(152)

6"

(152)

6"

(152)

6"

(152)

6"

(152)

6"

(152)

Cook Top

Height

37.0"

(914)

37.0"

(914)

37.0"

(914)

37.0"

(914)

37.0"

(914)

37.0"

(914)

37.0"

(914)

Model Number

S24…

S36…

with convection oven

S36…

with standard oven

S48…

with convection oven

S48…

with standard oven

S60…

with convection oven(s)

S60…

with standard oven(s)

Dimensions O & P: Gas connection is on rear of range and is 3.25” (82mm) from left side and 30.25” (768mm) above the floor.

Dimensions Q & R: Electric connection is on rear of range and is 6” (152mm) from left side and 24” (610mm) above the floor. Ranges with dual ovens have two electric connections with the second

connection 6” (152mm) from right side.

V

ENTILATION

A B C D E F G H I J K

24.5"

(622)

36.5"

(927)

36.5"

(927)

48.5"

(1232)

48.5"

(1232)

60.75"

(1543)

60.75"

(1543)

34"

(864)

44"

(1118)

34"

(864)

44"

(1118)

34"

(864)

44"

(1118)

34"

(864)

-

10"

(254)

-

10"

(254)

-

10"

(254)

-

Exterior Dimensions in Inches and (Millimeters)

30"

(762)

30"

(762)

30"

(762)

30"

(762)

30"

(762)

30"

(762)

30"

(762)

31.25"

(794)

31.25"

(794)

31.25"

(794)

31.25"

(794)

31.25"

(794)

31.25"

(794)

31.25"

(794)

11"

(279)

11"

(279)

11"

(279)

11"

(279)

11"

(279)

11"

(279)

11"

(279)

2.75"

(70)

2.75"

(70)

2.75"

(70)

2.75"

(70)

2.75"

(70)

2.75"

(70)

2.75"

(70)

WARNING

59.5"

(1511)

59.5"

(1511)

59.5"

(1511)

59.5"

(1511)

59.5"

(1511)

59.5"

(1511)

59.5"

(1511)

22.5"

(587)

22.5"

(587)

22.5"

(587)

22.5"

(587)

22.5"

(587)

22.5"

(587)

22.5"

(587)

31.0"

(787)

31.0"

(787)

31.0"

(787)

31.0"

(787)

31.0"

(787)

31.0"

(787)

31.0"

(787)

Door

Depth

L

M

- -

15.5"

(394)

15.5"

(394)

15.5"

(394)

15.5"

(394)

15.5"

(394)

15.5"

(394)

Improper ventilation can result in personal injury or death. Ventilation which fails to properly remove flue products

can cause headaches, drowsiness, nausea, or could result in death.

Oven

Bottom

N

13"

(318)

13"

(318)

13"

(318)

13"

(318)

13"

(318)

13"

(318)

All ranges must be installed in such a manner that the flow of combustion and ventilation air are not obstructed.

Provisions for adequate air supply must be provided. Do not obstruct the front of the range at the top by the control

panel, or the bottom just below the oven compartment, as combustion air enters through these areas.

NOTICE

Proper ventilation is the owner’s responsibility. Any problem due to improper ventilation will not be covered by the

warranty.

Be sure to inspect and clean the ventilation system according to the ventilation equipment manufacturer’s

instructions.

Canopies are set over ranges, ovens, etc., for ventilation purposes. It is recommended that a canopy extend 6" past

the appliance and the bottom edge be located 78" above the floor. Filters should be installed at an angle of 45° or

more from the horizontal. This position prevents dripping grease and facilitates collecting the run-off grease in a drip

pan, unusually installed with a filter.

A strong exhaust fan tends to create a vacuum in the room and may interfere with burner performance or may

extinguish pilot flames. Fresh air openings approximately equal to the fan area will relieve such a vacuum.

The exhaust fan should be installed at least 2" above the vent opening at the top of the range.

If the range is connected directly to an outside flue, a CSA design-certified down draft diverter must be installed at the

flue outlet of the oven and connected to the flue.

In case of unsatisfactory performance on any appliance, check the appliance with the exhaust fan in the OFF position.

Do this only long enough to check equipment performance. Then turn hood back on and let it run to remove any

exhaust that may have accumulated during the test.

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 7 OF

40

Page 8

O

PERATION

O

S S

PERATION

DANGER

ERIES RESTAURANT RANGES

EXPLOSION AND ASPHYXIATION HAZARD

In the event a gas odor is detected, shut down equipment at the main gas shut-off valve and immediately call

the emergency phone number of your gas supplier.

Improper ventilation can result in headaches, drowsiness, nausea, and could result in death. Do not obstruct the

flow of combustion and ventilation air to and from cooking appliances.

CAUTION

If top-burner pilots go out, the flow of gas to the burners is NOT interrupted (unless the range is equipped with

the optional flame-failure safety valves). Consequently, it is the responsibility of the operator to check the

ignition of the burners, immediately after burner value has been turned ON. Should ignition fail after 10 seconds,

turn off burners, wait 5 minutes, and then check the pilots and try again.

The controls for the burners and oven(s) are located on the control panel on the front of the range.

If the pilots need to be lit, follow the steps listed in each section below.

L

IGHTING AFTER GAS HAS BEEN SHUT OFF

When turning the main gas supply on after the gas supply has been shut off, do the following:

1. Make sure all of the control knobs are in the OFF position.

2. Turn on the incoming gas supply.

3. Light the pilots as described below.

4. Light the oven first and then wait six minutes before lighting top burners to purge all air from the range.

O

PERATION OF TOP BURNERS

To operate a top burner, turn the corresponding control knob on the front panel to the desired flame level.

Each top burner has its own pilot. If a top-burner pilot needs to be lit, do the following:

1. Turn all the top-burner control knobs to the OFF position.

2. On ranges with standard pilots, use a match or lighter to light all the pilots.

O

PERATION OF GAS OVEN

To operate a gas oven, turn the oven-thermostat knob on the front panel to the desired temperature. On convection

ovens, the blower is controlled by an ON-OFF switch.

Each oven has its own pilot. If an oven pilot needs to be lit, do the following:

1. Turn the oven thermostat to the OFF position.

2. For convection ovens, turn the fan switch to the OFF position.

3. Open the oven door and remove the oven bottom and fire plate to expose pilot and burner.

4. Open the kick panel below the oven door, turn the knob on the safety valve to the PILOT position, and depress

the button on oven safety valve.

5. Light the pilot while continuing to depress the button on the safety valve. Wait 30 seconds, then release the

button. The pilot should remain lit.

6. Turn the knob on the safety valve to the ON position.

7. Close the kick panel.

8. Replace the fire plate and oven bottom.

P

AGE 8 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 9

S S

ERIES RESTAURANT RANGES

O

PERATION OF NON-THERMOSTATIC GRIDDLES

Ranges can be ordered with a non-thermostatic griddle that is controlled by knobs on the front control panel.

At the end of each use, allow griddle to cool normally. After griddle has cooled, coat griddle surface with a light film of

cooking oil to protect surface from moisture.

If a non-thermostatic griddle pilot needs to be lit, do the following:

1. Raise griddle at front so it is approximately 8" (200 mm) high and prop it up with two blocks of wood. On some

models, the pilots can instead be lit by inserting a long match or lighter through a hole on the front control panel.

2. Ignite pilot tube located under all burners with port at each side of burners. Pilots are supplied and adjusted by a

common valve located below the filter on the manifold.

3. Carefully lower the griddle into position, use the griddle control knob to turn on the griddle, and observe the

griddle burners through holes in control panel. When operating, the burners should have a 1/4" to 5/8" (13 to 16

mm) high steady blue flame. Adjust if necessary.

O

PERATION OF THERMOSTATIC GRIDDLES

Ranges can be ordered with a thermostatic griddles that is controlled by a knob on the front control panel.

At the end of each use, allow griddle to cool normally. After griddle has cooled, coat griddle surface with a light film of

cooking oil to protect surface from moisture.

If a thermostatic griddle pilot needs to be lit, do the following:

1. Raise griddle at front so it is approximately 8" (200 mm) high and prop it up with two blocks of wood. On some

models, the pilots can instead be lit by inserting a long match or lighter through a hole on the front control panel.

2. The thermostat sensing bulbs must be fully inserted into their tubular holders, which are welded to the underside

of the griddle.

3. One pilot tube is located under all burners with ports at each side of the burners. Pilots are supplied and adjusted

by a common valve on the manifold. Light the pilots.

4. Carefully lower the griddle into position taking extreme care that capillary tubes are coiled under manifold in

control panel compartment. NEVER leave any part of the capillary tube in the burner compartment.

5. Set the griddle thermostat dials to maximum, one at a time, and observe the griddle burners through holes in

control panel. When operating, the burners should have a 1/4" to 5/8" (13 to 16 mm) high steady blue flame.

After operating the griddle for ten minutes with the thermostat dial set at maximum, turn the dial to “LOW” and

again observe the burners through the holes in the control panel. When the thermostat knob is set “LOW” the

burners should have a 1/8" to 1/4" (3 to 6 mm) high steady blue flame. Adjust if necessary.

O

PERATION

R

AISED-GRIDDLE BROILER

Ranges can be ordered with a raised-griddle broiler that has three separately controlled burners.

At the end of each use, allow griddle to cool normally. After griddle has cooled, coat griddle surface with a light film of

cooking oil to protect surface from moisture.

To light the pilots of a raised-griddle broiler, do the following:

1. Remove griddle from unit.

2. Position ceramics on burners with projections pointing downward.

3. Light pilot tube ports (2 at each burner). Adjust pilot flame to be large enough to effect ignition.

4. Place griddle in position on range.

5. Turn control knobs completely on.

6. Burner should have 1/2" to 5/8" steady blue flame. Adjust if necessary.

H

OT TOP SECTIONS

The range can be ordered with a hot-top section replacing one or more open-top burner sections. Each hot-top is

controlled by a knob on the front control panel.

To light the pilots of a hot-top section, do the following:

1. Raise or remove hot-top plate. Every two burners have one pilot located at the front and in between burners.

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 9 OF

40

Page 10

O

PERATION

S S

ERIES RESTAURANT RANGES

2. Light the pilot.

3. Pilot flame should be steady blue, large enough to effect ignition.

4. Turn burner control knob completely on. The sharp blue flame should be approximately 1/4" to 3/8" high.

5. Replace hot top plate.

6. Adjust the burner control knob to the desired setting.

S

HUTDOWN OF ENTIRE RANGE

To completely shut down the range for an extended period (or prior to disconnecting the gas supply), do the following:

1. Turn all burner control knobs to OFF.

2. Turn the oven thermostat knob(s) to OFF.

P

AGE 10 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 11

S S

ERIES RESTAURANT RANGES

T

ROUBLESHOOTING BY OPERATOR

The following table lists the possible causes and solutions of problems that may occur during operation.

Problem Possible Causes and Solutions

A top burner will not light. – Check pilot position.

Oven will not heat up. – Check and light the oven pilot.

Blower of convection oven is not running. – Check that the oven’s blower control switch is in ON position.

Pilot(s) will not remain lit. – Check gas supply to range.

If other appliances connected to the same source of gas or electricity are also not operating correctly, the problem is

likely not within the range.

If the problem only occurs for the range, and if the above solutions to do not solve the problem, call for repair service.

O

– Check and light the burner’s pilot.

– Check gas supply to range.

– Check gas supply to range.

– Check electricity supply to range.

– Check pilot adjustment.

PERATION

T

ROUBLESHOOTING CONVECTION-OVEN COOKING PROBLEMS

If… then…

Cakes are dark on the sides and not done in the center… lower oven temperature.

Cake edges are too brown… reduce number of pans or lower oven temperature.

Cakes have light outer color… raise temperature.

Cake settles slightly in the center… bake longer or raise oven temperature slightly. Do not

open doors too often for long periods.

Pies have uneven color… reduce number of pies per rack.

Meats are browned and not done in center… lower oven temperature and roast longer.

Meats are well done and not browned… raise temperature. Limit amount of moisture.

Cakes ripple… overloading pans or batter is too thin.

There is excessive meat shrinkage… lower oven temperature.

Cakes are too coarse… lower oven temperature.

WARNING

THE USE OF ALUMINUM FOIL CAN CAUSE HEAT DISTRIBUTION PROBLEMS IN OVENS. EXTREME

CARE MUST BE USED WHEN PLACING ALUMINUM FOIL IN THE OVEN TO ENSURE THAT IT DOES NOT

BLOCK OR CHANGE THE AIR FLOW. THE USE OF ALUMINUM FOIL MAY VOID THE PRODUCT

WARRANTY IF ITS USE IS ASCERTAINED TO BE A PROBLEM.

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 11 OF

40

Page 12

C

LEANING & MAINTENANCE

C

LEANING &

Shut off the range and allow time for it to cool before cleaning or performing maintenance.

Southbend appliances are sturdily constructed of the best materials and are designed to provide durable service when

treated with ordinary care. To expect the best performance, your equipment must be maintained in good condition and

cleaned daily. Naturally, the periods for this care and cleaning depend on the amount and degree of usage.

Following daily and periodic maintenance procedures will enhance long life for your equipment. Climatic conditions

(such as salt air) may require more thorough and frequent cleaning or the life of the equipment could be adversely

affected.

Keep exposed, cleanable areas clean at all times.

D

AILY CLEANING

1. Turn all controls to OFF and allow time for the range to cool.

2. Remove, empty, and clean drip trays.

3. Wipe clean all cooking surfaces.

S S

M

AINTENANCE

WARNING

ERIES RESTAURANT RANGES

P

ERIODIC CLEANING AND MAINTENANCE

At least monthly, clean around burner air mixers and orifices if lint has accumulated and visually check proper pilot

operation.

At least twice a year, examine and clean the range hood and venting system.

C

LEANING OVEN INTERIOR

FOR YOUR SAFETY, BEFORE CLEANING A CONVECTION OVEN DISCONNECT THE POWER SUPPLY.

WHEN CLEANING THE BLOWER WHEEL, BE SURE THAT THE POWER SWITCH IN THE “OFF” POSITION.

Allow oven to cool. Remove porcelain enameled oven bottom. Clean by rubbing with strong detergent and Brillo pad

or similar scrubber. “Spill-overs” should be cleaned from the bottom as soon as possible to prevent carbonizing and a

“burnt-on” condition. For stubborn accumulations, commercial oven cleaners are recommended.

The porcelain oven lining can be cleaned in a similar manner.

Avoid using excessive amounts of water, as this may drip into burner compartment and deteriorate the metal in that

area.

B

AKED-ENAMEL SURFACES

Wash interior baked-enamel surfaces with a hot, mild detergent or soap solution to clean off all grease deposits. Dry

thoroughly with a dry cloth.

WARNING

S

TAINLESS-STEEL SURFACES

To remove normal dirt, grease and product residue from stainless steel surfaces that operate at LOW temperature,

use ordinary soap and water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with a clean

cloth.

To remove BAKED-ON grease and food splatter, or condensed vapors; apply cleanser to a damp cloth or sponge and

rub cleanser on the metal in the direction of the polishing lines on the metal. Rubbing cleanser, as gently as possible,

in the direction of the polished lines will not mar the finish of the stainless steel. NEVER RUB WITH A CIRCULAR

MOTION. Soil and burnt deposits which do not respond to the above procedure can usually be removed by rubbing

P

AGE 12 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 13

S S

ERIES RESTAURANT RANGES

the surface with SCOTCH-BRITE scouring pads or STAINLESS scouring pads. DO NOT USE ORDINARY STEEL

WOOL as any particles left on the surface will rust and further spoil the appearance of the finish. NEVER USE A

WIRE BRUSH, STEEL SCOURING PADS (EXCEPT STAINLESS), SCRAPER, FILE OR OTHER STEEL TOOLS.

Surfaces which are marred collect dirt more rapidly and become more difficult to clean. Marring also increases the

possibility of corrosive attack. Refinishing may then be required.

“Heat tint” is darkened areas that sometimes appear on stainless steel surfaces where the area has been subjected to

excessive heat. These darkened areas are caused by thickening of the protective surface of the stainless steel and

are not harmful. Heat tint can normally be removed by the foregoing, but tint which does not respond to this procedure

calls for a vigorous scouring in the direction of the polish lines using SCOTCH-BRITE scouring pads or a STAINLESS

scouring pad in combination with a powered cleanser. Heat tint may be lessened by reducing heat to equipment

during slack periods.

C

ARE OF GRIDDLES

New griddles should be carefully tempered and cared for in order to avoid possible damage. To break in a new

griddle, first wipe it clean. Next, light all the griddle burners and turn them to low for one hour. Then gradually bring

each griddle up to frying temperature. Next, spread three or four ounces of beef suet, or as a substitute, baking soda,

to season it. Never allow water on a hot griddle and never wash it with soap and water.

Use a Norton Alundum Griddle Brick to clean the griddle. Always remember to heat griddle slowly because quick heat

may cause costly damage. Griddle plates cannot be guaranteed against damage due to carelessness. Never place

utensils on griddle. Do not overheat griddle above 550°F (288°C), as this will cause warpage or breakage.

Do not use any type of steel wool. Small particles may be left on the surface and get into food products. Do not clean

spatula by hitting the edge on the griddle plate. Such action will only cut and pit the griddle plate, leaving it rough and

hard to clean.

Do not waste gas or abuse equipment by leaving control knobs at “Full On” position or thermostat at a high

temperature if not required. During idle periods, set control knobs at “Low” position or thermostats to low temperature

settings to keep griddle warm. Reset control knobs or thermostats, as required, for periods of heavy load. Turn control

knobs or thermostats to OFF at end of daily operation.

C

LEANING & MAINTENANCE

H

OT TOPS

Allow range to cool. If water is used on tops while still hot, they may crack. Avoid this practice. Remove tops from

range and clean surfaces with hot water and detergent. A wire brush may be used on the underside of the hot top

plate. It is recommended not to clean tops while still on range, even if cooled, as excessive water will drip into the

burner box and deteriorate the metal.

Do not waste gas and abuse equipment by leaving all burners “Full On,” if not required. During idling periods, adjust

burner control knobs to keep top warm. Re-adjust burner control knobs as required for periods of heavy loads.

T

OP BURNERS

Little attention is needed, but if spillage should occur, it may be necessary to clean around pilot areas, air mixer and

under burners. Use a wire brush if necessary.

Periodically, burners (particularly open top type) should be removed and cleaned. Allow interior to drain. Dry

thoroughly before replacing.

Burner grates can be lifted out for cleaning. Clean them with a solution of hot water and strong soap or detergent.

The flash tubes must be clean and properly aligned with the pilot housing to insure good top burner ignition. Pilots

should have a 1/2" to 5/8" blue flame. Avoid carbon producing tip or unstable blowing or lifting of flame.

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 13 OF

40

Page 14

I

NSTALLATION

I

NSTALLATION

S S

ERIES RESTAURANT RANGES

NOTICE

These installation procedures must be followed by qualified personnel or warranty will be void.

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association,

Inc., states in its NFPA 96 latest edition that local codes are the “authority having jurisdiction” when it comes to

installation requirements for equipment. Therefore, installations should comply with all local codes.

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGAB149.2, as applicable, including:

1. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psi (3.45 kPa).

2. The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.45

kPa).

NOTICE

EXHAUST FANS AND CANOPIES: It is recommended that the range be installed under a ventilation hood.

Consult local codes for proper installation of hoods. Proper ventilation is the owner’s responsibility. Any problem

due to improper ventilation will not be covered by warranty.

NOTICE

In the Commonwealth of Massachusetts all gas appliances vented by either mechanical systems or ventilation

hoods shall comply with 248 CMR interlocking requirements.

S

TEP 1: UNPACKING

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has assumed

responsibility for its safe transit and delivery. If damaged equipment is received, either apparent or concealed, a

claim must be made with the delivering carrier.

Apparent damage or loss must be noted on the freight bill at the time of delivery. The freight bill must then be

signed by the carrier representative (Driver). If the bill is not signed, the carrier may refuse the claim. The carrier

can supply the necessary forms.

A request for inspection must be made to the carrier within 15 days if there is concealed damage or loss that is not

apparent until after the equipment is uncrated. The carrier should arrange an inspection. Be certain to hold all

contents plus all packing material.

Do the following:

1. Cut the banding straps and remove the corrugated cardboard surrounding the range. If legs were shipped in the

same container, set them aside for installation in later steps of this procedure. Do not remove any tags or labels

attached to the range until the range is installed and working properly.

2. Lift the flue riser and shelf (if applicable) off the range and set it aside for installation later in this procedure.

3. Unbolt the shipping hold-down brackets from the skid, then remove the brackets from the range. Replace the

bolts back into the threaded holes in the range.

4. If the range is to be installed on legs, go to Step 2a.

If the range is to be installed on casters, go to Step 2b.

P

AGE 14 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 15

S S

ERIES RESTAURANT RANGES

S

TEP 2A: ATTACH LEGS

I

NSTALLATION

A set of four legs is packed with ranges ordered with legs. (For ranges ordered with casters, go to Step 2b.)

A threaded leg pad is fastened to the base frame at each corner. Each leg has a corresponding mating thread. The

legs can be adjusted to overcome a slightly uneven floor.

1. Raise range sufficiently to allow legs to be attached. For safety, “shore up” and support the range with an

adequate blocking arrangement strong enough to support the load.

2. Screw the legs into the holes in the centers of the leg pads. The legs should be fully screwed into the leg pads.

3. Lower range gently onto a level surface. Never drop or allow the range to fall.

4. Use a level to make sure that the range surface is level. The foot of each leg can be screwed in or out to lower or

raise each corner of the range.

5. Go on to Installation Step 3.

Figure 3

Installation of Legs

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 15 OF

40

Page 16

I

NSTALLATION

S

TEP 2B: ATTACH CASTERS AND RESTRAINT

S S

ERIES RESTAURANT RANGES

NOTICE

For an appliance equipped with casters, (1) the installation shall be made with a connector that complies with

the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 or Connectors for Moveable Gas

Appliances, CAN/CGA-6.16, and a quick-disconnect device that complies with the Standard for QuickDisconnect Devices for Use With Gas Fuel, ANSI Z21.41, or Quick Disconnect Devices for Use with Gas Fuel,

CAN1-6.9, (2) adequate means must be provided to limit the movement of the appliance without depending on

the connector and the quick-disconnect device or its associated piping to limit the appliance movement, and (3)

the restraining means should be attached to a frame member on the back of the unit.

A set of four casters is packed with ranges ordered with casters (instead of legs).

A threaded leg pad is fastened to the base frame at each corner. Each caster has a corresponding mating thread. The

casters can be adjusted to overcome a slightly uneven floor. Casters are provided with a fitting for proper lubrication

when required.

1. Raise range sufficiently to allow the casters to be attached. For safety, “shore up” and support the range with an

adequate blocking arrangement strong enough to support the load.

2. Screw the casters into the holes in the centers of the leg pads. Install the casters that have a locking brake under

the front of the range.

3. Lower range gently onto a level surface. Never drop or allow the range to fall.

4. Use a level to make sure that the range surface is level. The casters can be screwed in or out slightly to lower or

raise each corner of the range.

Figure 4

Installation of Casters

5. Secure the restraining-device bracket (item “B” in the following illustration) to a wall stud located as close as

possible to the appliance connector inlet and outlet connections. Use four #12 screws (items “C”) and plastic

anchors (items “A”) if necessary.

6. Install eye-bolt (item “F”) to a frame member on the rear of the equipment. After checking carefully behind the

frame member for adequate clearance, drill a 1/4" (6 mm) hole through the frame member.

7. Thread hex nut (item “G”) and slide the washer (item “H”) onto the eye-bolt. Insert the eye-bolt through the 1/4"

(6 mm) drilled hole and secure with a washer (item “H”) and nylon lock nut (item “I”).

8. Using the spring-loaded snap hooks, attach the restraining device to the bracket and the eye-bolt.

9. Using the cable clamp (item “D”), adjust the restraining device extended length to prevent over-bending or

kinking of the appliance connector.

P

AGE 16 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 17

S S

ERIES RESTAURANT RANGES

Figure 5

Installation of Restraint

I

A

D

E

NSTALLATION

H

F

C

G

I

B

Be sure all controls are turned off prior to disconnecting. After reconnecting, be sure all controls are turned off and all

pilots are lit.

NOTICE

Adequate means must be provided to limit the movement of the appliance without depending on the connector

and the quick-disconnect device or its associated piping to limit the appliance movement.

The restraining means should be attached to a frame member on the back of the range.

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 17 OF

40

Page 18

I

NSTALLATION

S

TEP 3: ATTACH FLUE RISER AND SHELF ASSEMBLY

Place the flue riser assembly on the range as shown on the appropriate diagram below.

1. Slide the flue riser assembly over the bayonets until it bottoms out, as shown below.

2. Secure ends of flue riser assembly with two (2) 1/4-20 x 3/4 hex head bolts, flat washers and lockwashers.

3. Attach the shelf assembly (if ordered) to the flue riser assembly with 1/4-20 x 3/4 hex head bolts, flat washers

and lockwashers.

Figure 6

S S

ERIES RESTAURANT RANGES

Installation of Flue Riser and Shelf Assembly

Single-Oven Models Dual-Oven Models

S

TEP 4: ELECTRICAL CONNECTION

Wiring diagrams are located on the rear of the range. Be sure that the input voltage and phase match the

requirements shown on the serial plate (see Figure 1 on page 3).

Ranges are factory-equipped either with a power cord or with one or two two-pole terminal blocks (one for each oven),

located behind cover plate(s) located on the rear of the range. To connect the supply wires, remove the appropriate

cover plate. Route the supply wires and the grounding wire through the strain relief fitting to the terminal block. Insert

the supply wires, one each, into the two poles of the terminal block and tighten the screws. Insert the ground wire into

the grounding lug and tighten the screw. Re-attach the cover plate.

Three phase ranges are wired as above, using only two supply wires. The third wire is not used and must be properly

terminated.

All ranges are shipped wired as specified by factory order. Conversion between single-phase and three-phase can be

accomplished by referring to phase loading and line amperes chart on wiring diagram for wire size and ampere

requirements.

S

TEP 5: GAS CONNECTION

If this equipment is being installed at over 610 meters altitude and that information was not specified when ordered,

contact the appropriate authorized Southbend Service Representative or the Southbend Service Department. Failure

to install with proper orifice sizing will result in poor performance and may void the warranty.

P

AGE 18 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 19

S S

ERIES RESTAURANT RANGES

The serial plate is located on the interior side of the kick panel below the oven. It indicates the type of gas the range is

equipped to burn. All Southbend equipment is adjusted at the factory. Check type of gas on serial plate.

These models are design-certified for operation on natural or propane gases. For natural gas, the regulator is set to

deliver gas at 0.99 kPa (4" W.C.) pressure to the manifold. For propane gas, it is set to 2.48 kPa (10" W.C.).

This appliance should be connected ONLY to the type of gas for which it is equipped.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas required for

satisfactory performance. A 1/8" pressure tap is located on the manifold to measure the manifold pressure.

The gas supply line to the range should be no smaller than the inside diameter of the pipes to which it is connected.

Purge the supply line to clean out dust, dirt, or other foreign matter before connecting the line to the range.

I

NSTALLATION

CAUTION

ALL PIPE JOINTS AND CONNECTIONS MUST BE TESTED THOROUGHLY FOR GAS LEAKS. USE ONLY

SOAPY WATER FOR TESTING ON ALL GASES. NEVER USE AN OPEN FLAME TO CHECK FOR GAS

LEAKS. ALL CONNECTIONS MUST BE CHECKED FOR LEAKS AFTER THE RANGE HAS BEEN PUT INTO

OPERATION. TEST PRESSURE SHOULD NOT EXCEED 14" W.C. (3.47 kPa).

S

TEP 6: CHECK THE INSTALLATION

Check the installation of the range, as follows:

1. Check that all screws and bolts are tightened.

2. Check that the electrical and gas connections have been made correctly.

3. With the range in the position that it will be operated, check that the range is level. If not, adjust the legs or

casters.

4. Check that the appropriate minimum clearances are satisfied (see page 4).

5. Check that the oven door(s) open and close properly.

6. Check that there is sufficient clearance in front of the range to open the oven door.

7. Wipe clean all surfaces.

S

TEP 7: CHECK OPERATION

Check the operation of the range, as follows:

1. Turn on the gas supply and, for convection-oven models, the electric power supply.

2. Light the burner pilots and oven pilot(s), starting with the top burner farthest from the gas input in order to purge

the system of air. Check for proper pilot-flame height and adjust pilots, if necessary.

3. Turn on the oven and all burners at the same time. Check for correct burner operation and adjust the air

shutters, if necessary.

4. On convection-oven models, turn on the blower(s) and check for proper operation.

5. Turn off the burners and oven.

S

TEP 8: SHUT-DOWN AND WIPE-CLEAN RANGE

Complete the installation by leaving the range ready for customer use:

1. Allow the range to cool.

2. Wipe clean all surfaces.

3. Unless the range is to be placed in service immediately, turn off the gas supply and (for convection-oven models,

the electricity supply.

4. Make sure that a copy of this manual will be available to the people who will operate and maintain the range.

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 19 OF

40

Page 20

S

ERVICE

S S

S

ERVICE

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED TECHNICIAN WHO IS

EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE OPERATION OF COMMERCIAL COOKING

EQUIPMENT. TO ASSURE YOUR CONFIDENCE, CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR

RELIABLE SERVICE, DEPENDABLE ADVICE OR OTHER ASSISTANCE, AND FOR GENUINE FACTORY

PARTS.

WARNING

ERIES RESTAURANT RANGES

NOTICE

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID THE WARRANTY ON THIS

EQUIPMENT.

The serial plate are located on the right side of the range (see Figure 1 on page 3).

Replacement parts (including parts not listed in this manual) may be ordered either through a Southbend Authorized

Parts Distributor or a Southbend Authorized Service Agency.

When ordering parts, please supply the Model Number, Serial Number, Part Number, and Part Description.

In case of problems in operation at initial installation, check type of gas and manifold pressure and compare with

information listed on the serial plate.

This section contains troubleshooting flowcharts, procedures, and electric schematics to assist a qualified service

technician in the servicing of a Southbend S Series Restaurant Range.

T

ROUBLESHOOTING FLOWCHARTS, PROCEDURES, AND WIRING DIAGRAMS

Find the symptom below that corresponds to the malfunction, then turn to the corresponding page. Follow the

flowchart on that page until the problem is solved.

Troubleshooting Flowchart, Procedure, or Wiring Diagram Page

Troubleshooting Open-Top Burners 21

Troubleshooting Base Oven 22

Troubleshooting Convection-Oven Blower 23

Adjustment of Gas Pressure Regulator 25

Adjustment of Open-Top Pilots 26

Adjustment of Open-Top Burners 26

Adjustment of Oven Standing Pilot 26

Adjustment of Oven Burner 26

Calibration of Oven Thermostat 26

Adjustment of Thermostatic Griddle Bypass Flame Level 27

Calibration of Thermostatic Griddle Thermostat 27

Conversion from One Type of Gas to Another 28

Wiring Diagram for Gas Oven 29

P

AGE 20 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 21

S S

ERIES RESTAURANT RANGES

T

ROUBLESHOOTING OPEN-TOP BURNERS

S

ERVICE

Each open-top burner should have a steady blue flame on each port of the burner. Propane burners may have a small

amount of yellow tipping, and may make a slight popping noise when turned off.

If the flame is rising up off of the ports, adjust the burner shutter so it is more closed. If the flame is long and yellow

adjust the burner shutter so it is more open.

Consult the following table and the flowchart on this page.

Problem Look for -

No burners or pilots in the range will turn on. – Main gas supply to range is OFF.

Spark electrode does not spark (to light pilot). – Battery (inside corresponding spark module on rear of

of range) needs replacement.

All burners produce excessive carbon deposits. – Incorrect gas type supplied to range.

– Incorrect supply pressure.

Only some burners in a range produce excessive carbon

deposits.

– Incorrect orifices or orifice alignment.

– Primary air not adjusted properly.

Only some pilots produce excessive carbon deposits. – Pilot gas not adjusted properly.

– Incorrect pilot orifice.

Top burner will not come on, but oven will come on. – Control knob for top burner is in OFF position.

– Pilot out.

Open-top burner pilot will not stay ignited. – Pilot gas not adjusted properly.

– Clogged orifice.

– Draft condition.

– Improper ventilation system.

– Air in gas line.

– Thermocouple bad.

Figure 7

Troubleshooting Open-Top Burners

Open-top burners are not working correctly.

Check that the burners are set level in their support brackets.

Check that the burners are clean and that their ports are clear.

Remove each burner and check that the venturi is clean and free of buildup and debris. Also check that the

Remove the burner control knobs and carefully lower the control panel. CAUTION! Convection oven models

Check the pressure of the gas supply with all the gas appliances connected to the supply turned fully on. The

inlet pressure (before entering the pressure regulator for the range) must be a minimum 7" W.C. for natural

gas, or a minimum 11" W.C. for propane but no more than 14” H2O for either gas typ. Adjust the pressure

Check the pressure of the gas manifold of the range (after the gas leaves the pressure regulator for the

O

WNER’S MANUAL

orifice size is correct and that it is clean and free of buildup and debris.

have wiring attached behind the panel.

Check that each burner valve and orifice is in alignment with the corresponding burner.

and/or capacity of the gas supply, if necessary.

range). See page 25.

1191904 REV 1 (11/10) P

AGE 21 OF

40

Page 22

S

ERVICE

S S

T

ROUBLESHOOTING BASE OVEN

ERIES RESTAURANT RANGES

CAUTION

Proper and efficient operation of oven is dependent on correct installation and function of components. Always

verify that components are in place and functioning as intended.

Consult the following table and the flowchart that begins on the following page.

Problem Look for -

Oven will not come on. – Oven pilot is out.

Oven pilot will not stay ignited – Pilot gas not adjusted properly.

– Bad thermopile.

– Bad thermopile connections at safety valve.

– Bad safety valve.

– Clogged orifice.

– Dirty pilot

– Draft condition.

– Improper ventilation system.

– Air in gas line.

Figure 8

Troubleshooting Oven Pilot

Oven pilot does not work.

Check whether the pilot flame is lit by looking through the hole in

the bottom of the oven. Leave the oven door open for five minutes

If the pilot is not lit, attempt to light the pilot by raising the kick panel

slightly and rotating its top edge outward. Press and hold the button

on the oven safety valve and put a flame to the pilot.

No

Check that the oven pilot adjustment on the manifold is open. Continue to hold the button for 30 seconds. The pilot should remain

If the pilot still will not light, do the following: Remove the oven

bottom. Loosen the pilot nut on the burner bracket. Remove the

pilot tube from the safety valve. Remove the pilot orifice from the

pilot or end of the tube and check for debris.

Re-install the pilot orifice and tubing.

to allow gas fumes to clear.

Does the pilot light?

lit after the button is released. If it does not, wait five minutes and

If the pilot will not remain lit, do the following: Remove the

thermocouple from the safety valve. Install a thermocouple adapter

between the safety valve and the thermocouple to measure the

direct-current millivoltage produced by the thermocouple. While

holding the button, light the pilot and measure the voltage produced

by the thermocouple. If the voltage does not rise above 10

millivolts, adjust the pilot valve and retest. If the voltage still does

not quickly rise above 10 millivolts, replace the thermocouple.

If instead the thermocouple is working properly, replace the safety

Yes

try again.

valve.

P

AGE 22 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 23

S S

DISCONNECT POWER AT CIRCUIT BREAKER.

Check that there are no ai

r-flow obstructions around the range.

motor, replace the blower motor.

ERIES RESTAURANT RANGES

T

ROUBLESHOOTING CONVECTION-OVEN BLOWER

S

ERVICE

WARNING

Before attempting to service or replace any electrical component, make sure power source has been

disconnected.

CAUTION

When changing motor or servicing range, always verify that blower wheel rotation is clockwise when looking into

the oven cavity.

If the blower does not run at all, consult the flowchart that begins on the next page. If the blower runs intermittently,

consult the flowchart on this page.

The appropriate wiring diagram for the oven can be found on the rear of the oven (as well as at the end of this section

of this manual).

Figure 9

Convection-Oven Blower Runs Intermittently

Convection-oven blower runs intermittently.

No

Check all wiring for loose connections or breaks.

Remove the cover from the junction box on the back of the range.

Disconnect the black wire and place an ammeter in the circuit.

CAUTION: Check that the ammeter is rated for at least 40

amperes! Reconnect the power to the range and turn on the

blower switch while watching the ammeter. The reading should

surge and then return to the rated current of the motor when

running at high speed. If the measured current exceeds the motor

rating, replace the blower motor.

Does the problem

occur only when the oven

is hot?

Check that the blower motor is not pressing against the wall

Check that the blower motor air vents are not obstructed.

Check for excessive grease and dust buildup on the motor.

Check for sources of excessive heat behind the range.

With the blower turned ON, turn the oven thermostat to OFF and

allow the oven to cool. If the blower motor runs continuously

when the oven is cool, turn the oven thermostat to the highest

setting. If the blower motor shuts off when the oven becomes hot,

and if there are no sources of excessive heat around the blower

Yes

behind the range.

Check for hot-air leaks around the motor pocket.

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 23 OF

40

Page 24

S

DISCONNEC

T POWER AT CIRCUIT BREAKER

.

DISCONNECT PO

WER AT CIRCUIT BREAKER

.

from the blower control switch.

No

DISCONNECT POWER AT CIRCUIT BREAKER

.

Replace door switch.

Continue on next page.

ERVICE

S S

Figure 10

Convection-Oven Blower Does Not Run

Convection-oven blower does not run.

Remove the control knobs from the front of the range. Remove the

screws that secure the top of the control panel and carefully tilt the

panel forward to expose the back of the blower switch that is

mounted in the front panel. CAUTION: Be careful not to damage

the wiring behind the control panel. Remove the protective cover

Check that the switch wires and terminals are secure.

Use a multimeter to check the continuity across the terminals of

blower-switch wires 1 and 3 (refer to the appropriate wiring diagram

in this manual or on the range). With the switch in the ON position,

there should be continuity.

ERIES RESTAURANT RANGES

No

Replace the blower control switch.

Re-assemble the switch cover and control panel. Turn on the

blower-control switch and open the oven door.

No

Open the kick panel below the oven door by raising it slightly and

tilting the top edge outward. Locate the door switch and check for

continuity across the wired switch terminals while pressing the

switch actuator lever.

Is there continuity?

Does the blower

run with the oven door

Yes

Reconnect the power supply. Use a voltmeter to measure the

voltage across the center terminals of switch wires 1 and 2.

Yes

open?

Open the kick panel below the oven door by raising it slightly and

tilting the top edge outward. Locate the door switch and check that

one wire is connected to the common (90° bottom) terminal of the

switch. Move the other wire to the normally open (lower leg)

terminal on the side of the door switch.

Does the measured

voltage match the rated voltage

of the range?

Check power supply to range.

Yes

No

Loosen the two screws on the door switch bracket and adjust it so

that the door switch is pressed when the oven door is closed.

P

AGE 24 OF

40 O

Is there continuity?

No

Yes

Close the oven door (which should

press the door-switch actuator lever).

Is there continuity?

Yes

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 25

S S

DISCONNECT POWER AT CIRCUIT BREAKER

.

the white wire.

DISCONNECT POWER

AT CIRCUIT BREAKER

.

ERIES RESTAURANT RANGES

Figure 11

S

Convection-Oven Blower Does Not Run, Continued

(Continuing from previous page.)

ERVICE

CHECK THAT POWER IS DISCONNECTED

Remove the wire terminal cover from the blower motor.

Check that the red wire is capped off.

Remove the wire nuts from the black and the white wires. Check

that in each case the wires are twisted together securely.

Check that the common wire is connected to the motor black wire.

Check that the neutral wire is connected to the white wire.

Reconnect the power supply and turn on blower-control switch.

Use a voltmeter to measure the voltage between the black wire and

No

Check all wiring for loose terminals or breaks.

AT CIRCUIT BREAKER.

Is there voltage?

Remove the wire nuts from the red, white, and black wires.

Check that the resistance across the white and black wires is

approximately 1.9 ohms. Check that the resistance across the

white and red wires is also approximately 1.9 ohms. If either

Yes

resistance is incorrect, replace the blower motor.

A

DJUSTMENT OF GAS PRESSURE REGULATOR

The pressure regulator is factory set at 4" W.C. (0.99 kPa) for natural gas and 10" W.C. (2.48 kPa) for propane gas.

To check the manifold pressure:

1. Turn all thermostats and burner control knobs to OFF position.

2. Turn main gas valve to entire range off.

3. Remove control panel and locate the small plug in the manifold.

4. Remove plug and install a fitting appropriate to connect a manometer.

5. Turn on main gas to range and light pilots.

6. Turn all burners and ovens to full ON position and read manometer.

7. If manometer does not read 4" W.C. (0.99 kPa) for natural gas, or 10" W.C. (2.48 kPa) for propane gas, adjust

regulator (if gas pressure is correct go to Step 10).

8. Remove cap from top of regulator.

9. With a screwdriver rotate regulator adjustment screw clockwise to increase, or counterclockwise to decrease,

pressure until manometer shows correct reading.

10. Repeat steps 1 and 2.

11. Remove manometer fitting and replace plug in manifold.

12. Turn on main gas to range and light pilots.

13. Replace control panel.

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 25 OF

40

Page 26

S

ERVICE

S S

A

DJUSTMENT OF OPEN-TOP PILOTS

The open-top pilots are the non-aerated (yellow-tipped flame) type. One is located beside each open-top burner.

Pilot outage is often caused by an unstable flame due to over-adjustment to the point where the flame is leaving its

port, or “blowing off.” Often, in an effort to improve ignition, the pilots are increased too much and result in this

unstable condition.

The pilots are adjusted by inserting the blade of a screwdriver into the slot on the small valve, located on the manifold.

The maximum flame size is approximately 3/4" (19 mm) with a slight yellow tip. The first indication of over-adjustment

is evident when the yellow tip begins to stream into black streaks and generate carbon. Continued over-adjustment

leads to the unstable lifting and blowing condition.

A

DJUSTMENT OF OPEN-TOP BURNERS

All open-top burners are primarily adjusted by means of an air shutter on the mixer face.

To adjust a burner, loosen the screw that holds the air shutter in position and rotate the mixer cap until a clear, stable

blue flame is obtained. The flame should not be yellow tipped nor should it blow off the burner ports.

All orifice sizes and burner rate are properly set at the factory and should not be altered.

Over-rated burners cause poor burner and pilot performance, resulting in less heat, and wasted gas.

A

DJUSTMENT OF GAS OVEN STANDING PILOT

The standing oven pilot flame can be adjusted by turning the adjusting screw on the pilot line valve with a screwdriver.

The pilot line valve is located behind the kick panel below the oven door. Remove the kick panel to gain access. The

pilot flame is properly adjusted when it is just large enough to maintain a glowing red color of the thermopile capillary

bulb.

ERIES RESTAURANT RANGES

A

DJUSTMENT OF GAS OVEN BURNER

The oven burner orifice is of the fixed type, sized for the specified gas supply. The burner flame characteristics are

controlled by varying the primary air mixer cap. There should be a clear blue flame with a distinct inner cone at each

port. Excessive primary air can result in “blowing” or the flames leaving the ports. Lack of primary air causes soft or

yellow tipped flame.

C

ALIBRATION OF GAS OVEN THERMOSTAT

The oven thermostat control is carefully calibrated at the factory so that its dial settings closely match actual oven

temperatures. Field recalibration is seldom necessary, and should not be resorted to unless considerable experience

with unexpected cooking results definitely proves that the control is not maintaining the temperatures to which the dial

is set.

When checking the oven temperature, use a test instrument or a reliable mercury thermometer positioned in the

center of the oven. The oven bottom must be in place. For convection ovens, the blower baffle must be in place.

Proceed as follows:

1. Light the oven pilot, set the oven thermostat to 350°F, and, if the oven is a convection oven, turn on the fan.

2. After burner has been on about 15 minutes, check the oven temperature. The oven door should be open for as

short a time as possible. Use a flashlight, if necessary, to see the thermometer clearly.

3. Continue to check temperature noting the minimum and maximum "swing" variation in temperature until two

successive readings are within 5 degrees of each other. The oven temperature is the midpoint of the "swing"

range.

The control should be recalibrated if your reading is not within 20 degrees of the dial setting (350°F). If calibration is

required, the additional steps to be taken are these:

4. Insert a flat screwdriver through the center of the thermostat stem and then turn the adjustment screw clockwise

to decrease the oven temperature and counterclockwise to increase the oven temperature. Do not allow the stem

to turn. Turn the adjustment screw only 5 degrees of rotation in the appropriate direction, then repeat Steps 2

and 3 to check the temperature. Repeat until the temperature is within 10 degrees of 350°F.

5. Set the oven thermostat to 400°F. Check oven temperature again, as instructed in Steps 2 and 3. If the oven

temperature is not within 20 degrees of the dial setting (400°F) it means that the sensing element is inoperative

and the control should be replaced.

P

AGE 26 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 27

S S

ERIES RESTAURANT RANGES

A

DJUSTMENT OF THERMOSTATIC GRIDDLE BYPASS FLAME LEVEL

When the griddle reaches the temperature at which the dial is set, the control cuts down the flow of gas to the amount

required to keep the griddle at that temperature. Always, however, the control must bypass enough gas to keep the

entire burner lit. To maintain this minimum flame, the bypass must be set carefully and accurately, as follows (see

Figure 12 on page 28):

1. Light the burner, then turn dial FULL ON.

2. After 5 minutes, turn dial clockwise to point slightly beyond first mark on dial.

3. Remove dial and bezel.

4. With a screwdriver, turn Bypass Adjustor (counterclockwise to increase the flame, clockwise to decrease it) until

there is a minimum flame over the entire burner.

5. Replace bezel and dial, turning the dial clockwise until it locks in the OFF position.

C

ALIBRATION OF THERMOSTATIC GRIDDLE THERMOSTAT

The griddle temperature control is carefully calibrated at the factory—that is, it is so adjusted that dial settings match

actual temperatures. Field recalibration is seldom necessary, and should not be resorted to unless considerable

experience with cooking results definitely proves that the control is not maintaining the temperatures to which the dial

is set.

Recalibration should not be undertaken, however, until the griddle bypass flame has been adjusted (see previous

subsection).

To check temperatures when recalibrating, use a test instrument with a DISC type thermocouple for surface

temperature checking. Drop a couple of drops of oil on griddle surface plate and place thermocouple disc flat into the

oil.

Proceed as follows (see Figure 12):

1. Remove dial and push out metal insert.

2. Replace dial, turn to 350°F (175°C) mark, and light burner.

3. After burner has been on about 15 minutes check temperature.

4. Continue to check temperature, at 5-minute intervals, until two successive readings are within 5°F (3°C) of each

other.

The control should be recalibrated if your reading is not within 20°F (11°C) of the dial setting (350°F or 175°C). If

calibration is required, the additional steps to be taken are these:

5. Hold dial firmly, insert screwdriver through center of dial, and push calibration stem inward. DO NOT TURN THIS

STEM.

6. While holding calibration stem in firmly with screwdriver, turn dial until it is set at the actual oven temperature as

shown by your test instrument. Release pressure on calibration stem. Replace dial insert.

7. Set dial at 400°F (205°C) mark. Check temperature again, as instructed in steps 3 and 4. If the temperature is

not within 20°F (11°C) of the dial setting (400°F or 205°C), it means that the sensing element is inoperative and

the control should be replaced.

S

ERVICE

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 27 OF

40

Page 28

S

D

ERVICE

S S

Figure 12

Thermostat Calibration and Bypass Flame Adjustment

ERIES RESTAURANT RANGES

Bypass Adjuster

Calibration Stem

ial Insert

Dial

C

ONVERSION FROM ONE TYPE OF GAS TO ANOTHER

Bezel

Each range is shipped adjusted and equipped for a specific type of gas (either natural gas or propane). To convert a

range from one type of gas to another, do the following:

1. Refer to service procedures to access all burner orifices.

2. Refer to instructions included with conversion kit.

3. Follow all steps as indicated in the conversion kit.

4. Check for leaks and proper manifold pressure (the procedure is on page 25).

5. Re-light all pilots and check for proper operation.

Note: A kit for conversion to a different type of gas may be purchased from Southbend.

P

AGE 28 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 29

S S

ERIES RESTAURANT RANGES

Figure 13

S

Wiring Diagram for Gas Oven

ERVICE

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 29 OF

40

Page 30

S

P/N 1172650

ERVICE

P

ARTS

S S

ERIES RESTAURANT RANGES

NOTICE

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID THE WARRANTY ON THIS

EQUIPMENT.

The following parts diagrams list and show serviceable parts. For parts not listed, contact a Southbend Authorized

Parts Distributor or a Southbend Authorized Service Agency.

Parts Diagram Page

Leg and Caster Parts 30

Control, Top Burner, and Oven Door Parts 31

Oven Parts 32

Griddle Parts 33

Raised Griddle Broiler Parts 34

Hot Top Parts 35

Figure 14

Leg and Caster Parts

Leg Pad

Leg Package, SS

P/N 1174260

(set of four legs)

Caster Package

P/N 1174265

(includes two with brake

and two without brake)

Not Shown:

Earthquake Legs P/N 1174262

(set of four legs)

P

AGE 30 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 31

S S

Grate, Rear P/N 1180405

P

/N 1177111

ERIES RESTAURANT RANGES

Figure 15

S

Control, Top Burner, and Oven Door Parts

Oven Thermostat Control

P/N 1191727

Grate, Front P/N 1180781

ERVICE

Burner Knob

P/N 1184192

Oven Thermostat Knob Parts:

Knob P/N 1190573

Bezel P/N 1190574

Screw, Thermostat P/N 6600334

Screw, Bezel P/N 1146303

Door Switch

P/N 1177567

#10 Shoulder Screw

P/N 1077800

Switch, On/Off

Non-Clog Burner (front & rear)

P/N 1179949

Pilot Assembly, Front P/N 1177447

Pilot Assembly, Back P/N 1177448

Kick Panel

P/N 1180783

O

WNER’S MANUAL

Pilot Adjust (Single)

P/N 1179451

Valve (Burner Control)

P/N 1178202 (Nat & LP)

Pilot Adjust (Double)

P/N 1166004

1191904 REV 1 (11/10) P

AGE 31 OF

40

Page 32

S

P/N 1177520

P/N 1173545

P/N 1163870 (LP)

240V P/N 1179688

60" Wide Units, LP P/N 1181077

ERVICE

S S

Figure 16

Oven Parts

ERIES RESTAURANT RANGES

Blower Wheel

Rack Guide, Convection Oven

P/N 1180528

Rack, Convection Oven

P/N 1179920

Gas Safety Valve

P/N 1190648

Rack, Standard Oven

Rack Guide, Standard Oven

P/N 1187571

Flex Gas Tube

P/N 1187477

Oven Burner

P/N 1190568

Thermopile

P/N 1182154

Pilot Assembly

P/N 1163869 (Nat)

Gas Regulator

24", 36", and 48" Wide Units, Nat & LP P/N 1178815

60" Wide Units, Nat P/N 1181076

P

AGE 32 OF

40 O

Convection Oven Motor

120V P/N 1188523

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 33

S S

P/N 1182285

P/N 1042980

P/N 1178202

P/N 118

4192

ERIES RESTAURANT RANGES

Figure 17

Griddle Parts

S

Burner, Bar Assembly

Burner Support

Gas Valve, Hi-Off (for non-thermostatic griddles)

Burner Knob

ERVICE

Not Shown:

Pilot Adjustment Valve (for 12" griddle) P/N 1099002

Pilot Adjustment Valve (for 24", 36", and 48" griddles) P/N 1163844

Grease Drawer Assembly P/N 1186275

Thermostat (for thermostatic griddles) P/N 1174709

Thermostat Knob (for thermostatic griddles) P/N 1179997

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 33 OF

40

Page 34

S

P/N 1042980

P/N P3111

P/N 1162925

P/N P3112

P/N 1162924

P/N 1178204

P/N

1184192

P/N 1173554

P/N 1173555

P/N 1161636

P/N 1189600

P/N 1178204

P/N 1173556

ERVICE

S S

Figure 18

Raised Griddle Broiler Parts

Griddle Burner

Ceramic (side)

ERIES RESTAURANT RANGES

Broiler Rack Support

Gas Valve, Hi-Off

Burner Knob

Broiler Burner (center)

Ceramic (center)

Broiler Burner (side)

Gas Valve, Hi-Off

Burner Knob

Broiler Rack

P

AGE 34 OF

Not Shown:

Pilot Adjustment Valve P/N 1163844

Grease Chute P/N 1043699

40 O

Broiler Rack Pan

Broiler Dirt Tray

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 35

S S

P/N 11

80877

P/N

1022994

P/N 1178202

P/N

1184192

ERIES RESTAURANT RANGES

Figure 19

Hot Top Parts

S

Top Plate Assembly

ERVICE

Hot Top Burner

Gas Valve, Hi-Off

Burner Knob

Not Shown:

Pilot Adjustment Valve P/N 1099002

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 35 OF

40

Page 36

S S

Notes:

ERIES RESTAURANT RANGES

P

AGE 36 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 37

S S

ERIES RESTAURANT RANGES

Notes:

O

WNER’S MANUAL

1191904 REV 1 (11/10) P

AGE 37 OF

40

Page 38

S S

Notes:

ERIES RESTAURANT RANGES

P

AGE 38 OF

40 O

WNER’S MANUAL

1191904 REV 1 (11/10)

Page 39

S S

ERIES RESTAURANT RANGES

Notes:

O