Page 1

Hundreds of Thousands of Lathes Sold With a Tradition of Quality Since 1906!

OWNER'S MANUAL

ROTARY TABLE

MODEL SB1363 4"

MODEL SB1364 6"

MODEL SB1367 8"

MODEL SB1368 10"

Copyright © July, 2010 For Equipment Mfg. Since 10/09

Page 2

Scope Of Manual

This manual helps the reader understand the equipment, how to prepare it

for operation, how to control it during operation, and how to keep it in good

working condition. We assume the reader has a basic understanding of how

to operate this type of equipment, but that the reader is not familiar with the

controls and adjustments of this specific model. As with all equipment of this

nature, learning the nuances of operation is a process that happens through

training and experience. If you are not an experienced operator of this type

of equipment, read through this entire manual, then learn more from an

experienced operator, schooling, or research before attempting operations.

Following this advice will help you avoid serious personal injury and get the

best results from your work.

We've made every effort to be accurate when documenting this item.

However, errors sometimes happen or the design changes after the

documentation process—so the manual may not exactly match the item you

received. If a difference between the manual and what you received leaves

you in doubt, contact our customer service for clarification.

We highly value customer feedback on our manuals. If you have a moment,

please share your experience using this manual. What did you like about

it? Is there anything you would change to make it better? Did it meet your

expectations for clarity, professionalism, and ease-of-use?

South Bend Lathe, Inc.

C

/O Technical Documentation Manager

P.O. Box 2027

Bellingham, WA 98227

Email: manuals@southbendlathe.com

For your convenience, any updates to this manual will be available to

download free of charge through our website at:

www.southbendlathe.com

We stand behind our equipment. If you have any service questions, parts

requests or general questions about your purchase, feel free to contact us.

South Bend Lathe Co. Phone: (360) 734-1540

P.O. Box 2027 Fax: (360) 676-1075 (International)

Bellingham, WA 98227 Email: cs@southbendlathe.com

Fax: (360) 734-1639 (USA Only)

Manual Feedback

Updates

Customer Service

Page 3

Table of Contents

INTRODUCTION

Identification ...................................................................................................... 2

Specifications ..................................................................................................... 2

SAFETY

Understanding Risks of Machinery .................................................................. 3

Basic Machine Safety ........................................................................................ 3

PREPARATION

Preparation Overview ....................................................................................... 5

Required for Setup ............................................................................................. 5

Inventory ............................................................................................................ 5

Cleaning & Protecting ....................................................................................... 6

Installation ......................................................................................................... 7

Horizontal Installation ...................................................................................... 7

Vertical Installation .......................................................................................... 8

Aligning to Spindle Centerline ......................................................................... 8

Horizontal Installation Alignment ...................................................................... 9

Vertical Installation Alignment ........................................................................ 10

OPERATION

Controls & Components .................................................................................. 11

Aligning Handwheel & Vernier Scales ........................................................... 12

Using Vernier Scale ......................................................................................... 12

Operational Examples ..................................................................................... 13

Five Evenly Space Holes .................................................................................. 13

Two Circular Slots ........................................................................................... 14

MAINTENANCE

Maintenance Schedule .................................................................................... 16

Cleaning & Protecting ..................................................................................... 16

Surface Care .................................................................................................... 16

Lubrication ....................................................................................................... 17

Ball Oilers ...................................................................................................... 17

Worm Gear & Shaft ......................................................................................... 17

SERVICE

Spindle Preload ................................................................................................ 19

PARTS

SB1363 ............................................................................................................. 20

SB1364 ............................................................................................................. 21

SB1367 ............................................................................................................. 22

SB1368 ............................................................................................................. 23

WARRANTY ............................................................................................................................. 25

Page 4

SB1363- 64 /SB1367-68

Identification

INTRODUCTION

Horizontal

Mounting Slot

Table

Lock

Mfg. Since 10/09

Rotation

Scale

Spindle

Bore

Adjustment Ring

Rotary

Handwheel

Backlash

Vernier

Scale

Handwheel

Scale

Figure 1. Identification (Model SB1367 shown).

Backlash

Ring Lever

Adjustment Lock

Backlash

Table

Lock

Vertical

Mounting

Holes

Specifications

Description SB1363 SB1364 SB1367 SB1368

Clamping Surface Flatness (Concave) 0.0008" 0.0008" 0.0008" 0.0008"

Spindle Bore Concentricity 0.0008" 0.0008" 0.0010" 0.0010"

Surface to Base Parallelism 0.0008" 0.0008" 0.0008" 0.0008"

Surface to Angle Face Squareness 0.0008" 0.0008" 0.0008" 0.0008"

Overall Height (Horizontal) 3.05" 3.30" 4.17" 4.50"

Height to Center of Spindle Bore 3.20" 3.94" 5.12" 6.38"

Morse Taper MT#1 MT#2 MT#3 MT#3

T-Slot Width (6 Each) 0.393" 0.433" 0.433" 0.512"

Table Diameter 3.94" 5.90" 8.03" 10.00"

Shipping Weight 16 lbs. 28 lbs. 62 lbs. 98 lbs.

-2-

Page 5

SAFETY

Operating all machinery and machining equipment can be dangerous or

relatively safe depending on how it is installed and maintained, and the

operator's experience, common sense, risk awareness, working conditions, and

use of personal protective equipment (safety glasses, respirators, etc.).

The owner of this machinery or equipment is ultimately responsible for its safe

use. This responsibility includes proper installation in a safe environment,

personnel training and usage authorization, regular inspection and

maintenance, manual availability and comprehension, application of safety

devices, integrity of cutting tools or accessories, and the usage of approved

personal protective equipment by all operators and bystanders.

The manufacturer of this machinery or equipment will not be held

liable for injury or property damage from negligence, improper training,

machinemodifications, or misuse. Failure to read, understand, and follow the

manual and safety labels may result in serious personal injury, including

amputation, broken bones, electrocution, or death.

The signals used in this manual to identify hazard levels are defined

as follows:

Death or catastrophic harm WILL occur.

Moderate injury or fire MAY occur.

Machinery or property damage may occur.

Death or catastrophic harm COULD occur.

Owner’s Manual: All machinery

and machining equipment presents

serious injury hazards to untrained

users. To reduce the risk of injury,

anyone who uses THIS item MUST

read and understand this entire

manual before starting.

Properly Functioning Equipment:

Poorly maintained, damaged, or

malfunctioning equipment has

higher risks of causing serious

personal injury compared to those

that are properly maintained. To

reduce this risk, always maintain

this item to the highest standards

and promptly repair/service

a damaged or malfunctioning

component. Always follow the

maintenance instructions included in

this documentation.

Entanglement: Loose clothing, gloves,

neckties, jewelry or long hair may

get caught in moving parts, causing

entanglement, amputation, crushing,

or strangulation. Reduce this risk

by removing/securing these items so

they cannot contact moving parts.

Trained/Supervised Operators Only:

Untrained users can seriously injure

themselves or bystanders. Only allow

trained and properly supervised

personnel to operate this item. Make

sure safe operation instructions are

clearly understood. If machine is

electrically powered, use padlocks

and master switches, or remove start

switch keys to prevent unauthorized

use or accidental starting. If machine

cannot be locked out, restrict access

to the shop.

Understanding Risks of Machinery

SB1363- 64 /SB1367-68Mfg. Since 10/09

Basic Machine Safety

-3-

Page 6

SB1363- 64 /SB1367-68

Personal Protective Equipment:

Operating or servicing this item

may expose the user to flying debris,

dust, smoke, dangerous chemicals,

or loud noises. These hazards can

result in eye injury, blindness, longterm respiratory damage, poisoning,

cancer, reproductive harm or hearing

loss. Reduce your risks from these

hazards by wearing approved eye

protection, respirator, gloves, or

hearing protection.

Safe Environment: Operating

electrically powered equipment in

a wet environment may result in

electrocution; operating near highly

flammable materials may result in

a fire or explosion. Only operate this

item in a dry location that is free

from flammable materials.

Unattended Operation: Electrically

powered equipment that is left

unattended while running cannot

be controlled and is dangerous to

bystanders. Always turn the power

OFF before walking away.

Guards/Covers: Accidental contact

with moving parts during operation

may cause severe entanglement,

impact, cutting, or crushing injuries.

Reduce this risk by keeping any

included guards/covers/doors

installed, fully functional, and

positioned for maximum protection.

Difficult Operations: Attempting

difficult operations with which you

are unfamiliar increases the risk of

injury. If you experience difficulties

performing the intended operation,

STOP! Seek an alternative method

to accomplish the same task, ask a

qualified expert how the operation

should be performed, or contact our

Technical Support for assistance.

Chuck Keys or Adjusting Tools: Tools

used to adjust spindles, chucks,

or any moving/rotating parts will

become dangerous projectiles if left

in place when the machine is started.

Reduce this risk by developing the

habit of always removing these tools

immediately after using them.

Secure Workpiece/Tooling: Loose

workpieces, cutting tools, or rotating

spindles can become dangerous

projectiles if not secured or if they

hit another object during operation.

Reduce the risk of this hazard by

verifying that all fastening devices

are properly secured and items

attached to spindles have enough

clearance to safely rotate.

Disconnect Power: Adjusting or

servicing electrically powered

equipment while it is connected to

the power source greatly increases

the risk of injury from accidental

startup. Always disconnect power

BEFORE any service or adjustments,

including changing blades or other

tooling.

Electrical Connection: With

electically powered equipment,

improper connections to the power

source may result in electrocution or

fire. Always adhere to all electrical

requirements and applicable codes

when connecting to the power

source. Have all work inspected by a

qualified electrician to minimize risk

of electrocution or fire.

Mental Alertness: Operating this

item with reduced mental alertness

increases the risk of accidental

injury. Do not let a temporary

influence or distraction lead to a

permanent disability! Never operate

when under the influence of drugs/

alcohol, when tired, or otherwise

distracted.

Health Hazards: Certain cutting

fluids and lubricants, or dust/

smoke created when cutting,

may contain chemicals known to

the State of California to cause

cancer, respiratory problems, birth

defects, or other reproductive

harm. Minimize exposure to these

chemicals by wearing approved

personal protective equipment and

operating in a well ventilated area.

Work Area: Clutter and dark

shadows increase the risk of

accidental injury. Only operate this

item in a clean, non-glaring, and

well-lighted work area.

SAFETY

Mfg. Since 10/09

-4-

Page 7

PREPARATION

This item was carefully packaged to

prevent damage during transport.

If you discover any damage, please

immediately call Customer Service

at (360) 734-1540 for advice. You

may need to file a freight claim, so

save the containers and all packing

materials for possible inspection by

the carrier or its agent.

The purpose of the preparation

section is to help you prepare your

rotary table for operation. The list

below outlines the basic process.

Specific steps for each of these

points will be covered in detail later

in this section.

The typical preparation process is as

follows:

1. Unpack the tool and inventory

the contents.

2. Clean the tool and its

components.

3. Install the rotary table on

the mill table horizontally or

vertically.

SB1363- 64 /SB1367-68Mfg. Since 10/09

InventoryPreparation Overview

Description (Figure 2) Qty

A. Rotary Table . . . . . . . . . . . . . . 1

B. Handwheel Handle . . . . . . . . . 1

A

4. Align the rotary table with the

mill spindle centerline.

Required for Setup

The items listed below are required

to successfully set up and prepare

this tool for operation.

• Safetyglasses

• Cleaner/degreaser(seePage 6)

• Clampinghardwareandtools

• Customkeysforhorizontal

installation (see Page 7)

(Optional)

• Machinist'ssquare

• Testindicator

• Edgefinder(Optional)

B

Figure 2. Shipping inventory.

-5-

Page 8

SB1363- 64 /SB1367-68

The unpainted surfaces are coated

at the factory with a heavy-duty

rust preventative that prevents

corrosion during shipment and

storage.The benefit of this rust

preventative is that it works very

well. The downside is that it can

be time-consuming to thoroughly

remove.

Be patient and do a careful job when

cleaning and removing the rust

preventative. The time you spend

doing this will reward you with

smooth-sliding parts and a better

appreciation for the proper care of

the unpainted surfaces.

Although there are many ways

to successfully remove the rust

preventative, we have cleaned

thousands of machines and found

the following process to be the best

balance between efficiency and

minimized exposure to toxic fumes

or chemicals.

Before cleaning, gather the

following:

• Disposablerags

• Cleaner/degreaser (certain

citrus-based degreasers work

extremely well and they have

non-toxic fumes)

• Safetyglasses&disposable

gloves

Note: Automotive degreasers,

mineral spirits,orWD•40canbe

used to remove rust preventative.

Before using these products, though,

test them on an inconspicuous area

of a painted area to make sure they

will not damage it.

Basic steps for removing rust

preventative:

1. Put on safety glasses and

disposable gloves.

2. Coatallsurfacesthathave

rust preventative with a liberal

amount of your cleaner or

degreaser and let them soak for

a few minutes.

3. Wipe off the surfaces. If your

cleaner or degreaser is effective,

the rust preventative will wipe

off easily.

Note: To clean off thick coats of rust

preventative on flat surfaces,

such as beds or tables, use

aPLASTICpaintscraperto

scrape off the majority of the

coating before wiping it off with

yourrag.(Donotuseametal

scraper or it may scratch the

surface.)

4. Repeat Steps 2–3 as necessary

until clean, then coat all

unpainted surfaces with a

quality metal protectant or light

oil to prevent rust.

Gasoline and petroleum

products have low flash points

and can explode or cause fire if

used for cleaning. Avoid using

these products to remove rust

preventative.

Many cleaning solvents are toxic

if inhaled. Minimize your risk by

only using these products in a

well ventilated area.

Cleaning & Protecting

PREPARATION

Mfg. Since 10/09

-6-

Page 9

PREPARATION

Installation

Before installing the rotary

table, make sure that the spindle

centerline is properly aligned or

"trammed" with the mill table. Also,

remove any burrs or scratches from

the mating surfaces of the rotary

and mill table by "stoning" them,

then thoroughly wipe them clean

and dry (refer to the Surface Care

section on Page 16 for detailed

instructions).

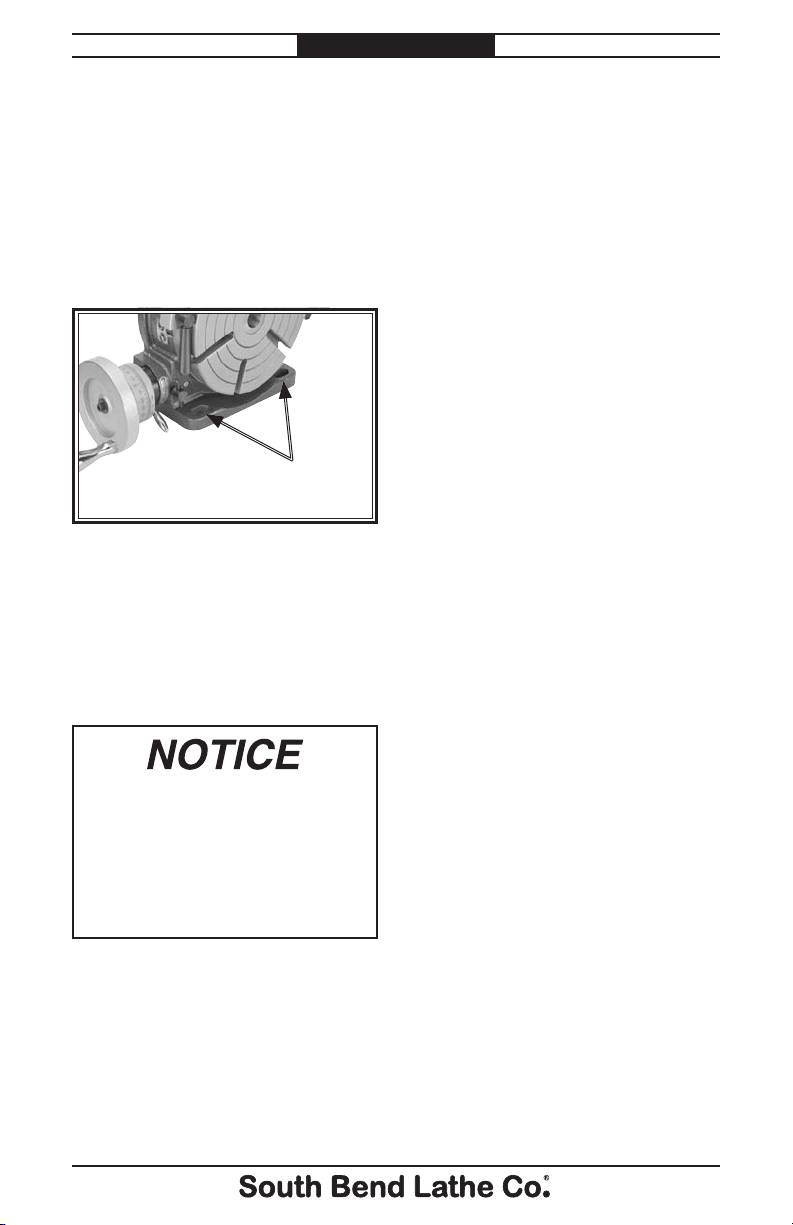

Horizontal Installation

The horizontal base has slots (see

Figure 3) that accept keys for

quick alignment with the mill table.

Because of the many variations in

mill table T-slots, these keys are not

provided with the rotary table. If

you choose to use keys for alignment

when installing the rotary table

horizontally, you will have to

machine them to fit the rotary table

and your mill table.

Mounting

Slots

Key Slots

SB1363- 64 /SB1367-68Mfg. Since 10/09

To mount the rotary table

horizontally:

1. DISCONNECT MILL FROM

POWER!

2. Position the rotary table

horizontally on the mill table so

that the mounting slots shown

in Figure 3 are aligned with the

mill table center T-slot.

Make sure the rotary

table handwheel is free of

obstructions. Depending on your

setup, the rotary table may need

to be blocked up or mounted so

the handle is hanging over the

edge of the mill table.

3. Attach the rotary table to the

mill table with the clamping

hardware, but leave the

fasteners loose for now.

4. Placethemachinist'ssquare

along the front edge of the mill

table and the machined foot

of the rotary table, square the

rotary table to the mill table,

then fully tighten the clamping

fasteners.

Figure 3. Locations of the horizontal

base key slots and mounting slots

(Model SB1363 shown).

You MUST properly secure the

rotary table to the mill table to

prevent unexpected movement

of the rotary table and workpiece

during operation, which could

result in personal injury or

workpiece damage.

5. Perform the Horizontal

Installation Alignment

procedure as instructed on

Page 9.

-7-

Page 10

SB1363- 64 /SB1367-68

PREPARATION

Mfg. Since 10/09

Vertical Installation

Compare the center to center

distance between the mill table

T-slots to the vertical mounting

holes on the rotary table foot (see

Figure 4). If the mounting holes do

not intersect the mill table T-slots

with sufficient space for T-bolts, use

step blocks and clamps in place of

one of the T-bolts.

Vertical

Mounting Holes

Figure 4. Locations of the vertical

mounting holes.

To mount the rotary table vertically:

1. DISCONNECT MILL FROM

POWER!

2. Insert the clamping hardware

into the outer mill table T-slots.

3. Place the rotary table on the

mill table so that you can use

the clamping hardware to secure

it in the next step.

4. Placethemachinist'ssquare

along the front of the mill table

and the machined side of the

rotary table foot, square the

rotary table to the mill table,

then fully tighten the clamping

hardware.

5. Perform the Vertical

Installation Alignment

procedure as instructed on

Page 10.

Aligning to Spindle

Centerline

Whether the rotary table is mounted

horizontally or vertically, you must

align the rotary table centerline

to the mill spindle centerline to

achieve quality results. Also, the

spindle centerline must first be

properly aligned to mill table in both

the X- and Y- axis (this procedure

is generally called "tramming the

spindle").

Make sure the rotary

table handwheel is free of

obstructions. Depending on your

setup, the rotary table may need

to be blocked up or mounted so

the handle is hanging over the

edge of the mill table.

-8-

There are many methods for

aligning the centerlines, and it

is up to the machinist and their

capabilities to decide which

approach is best.

Page 11

PREPARATION

Horizontal Installation

Alignment

Two methods are described below

for aligning the mill spindle and

rotary table centerlines when the

rotary table is mounted horizontally.

To use a test indicator to align the

rotary table:

1. DISCONNECT MILL FROM

POWER!

2. Mount the test indicator to the

mill spindle offset from the

spindle centerline by the radius

of the rotary table spindle bore,

then position the tip on the

inside vertical surface of the

rotary table spindle bore (see

Figure 5 for an example).

SB1363- 64 /SB1367-68Mfg. Since 10/09

6. Repeat Step 5 until the test

indicator reads zero deviation in

all four directions.

Tip: Use a mirror to read the

indicator when it is facing away

from you.

To use an edge finder to align the

rotary table:

1. Mount an edge finder into the

mill spindle, then position it

roughly in the center of the

rotary table spindle bore and

below the rotary table surface.

2. Set the mill spindle speed to

800–1000 RPM, then turn the

mill ON.

3. Slowly move the mill table along

the X-axis in one direction until

the edge finder meets the edge

of the rotary table spindle bore,

then note the position of the

table on the handwheel dial.

Figure 5. Example of using a test

indicator to align a rotary table.

3. Turn the mill spindle by hand so

that the test indicator is aligned

to the X-axis of the mill table.

Note: For best results, turn the mill

spindle in only one direction.

4. Slowly move the mill table until

the test indicator reads zero

deviation.

5. Rotate the mill spindle and

test indicator 90°, then repeat

Step 4.

Note: When recording the mill table

position, take into account the

backlash that is usually present

in the leadscrew.

4. Slowly move the mill table in

the opposite direction until

you again find the edge of the

spindle bore, then note the table

position on the handwheel dial.

5. Calculate the difference of

the mill table positions from

Steps 3–4.

6. Move the mill table

1

⁄2 the

amount calculated in Step 5

along the X-axis. Be sure to take

into account any backlash.

-9-

Page 12

SB1363- 64 /SB1367-68

1

2

3

4

5

6

Edge

Finder

Lathe

Center

Rotary

Table

Top View

PREPARATION

Mfg. Since 10/09

7. Repeat the above steps for the

mill table Y-axis.

Note: Use the pattern illustrated in

Figure 6 to aid in positioning

the edge finder for the above

procedure.

Figure 6. Pattern of positioning the edge

finder to the rotary table spindle bore.

Vertical Installation

Alignment

In these procedures, you will verify

the rotary table alignment with the

mill spindle from front to back and

to its centerline.

4. Repeat Step 3 until the entire

rotary table surface is correctly

aligned with the mill spindle.

To center the rotary table with the

mill spindle centerline:

1. DISCONNECT MILL FROM

POWER!

2. Fully seat a lathe center into the

rotary table spindle.

Note: Any center runout will have to

be determined and accounted for

in the following steps.

3. Use an edge finder mounted in

the mill spindle to find the edge

of the center, as illustrated in

Figure 7.

To verify the front-to-back alignment

of the rotary table to the mill

spindle:

1. DISCONNECT MILL FROM

POWER!

2. Mount a test indicator to the

mill spindle and position the

indicator tip on one end of the

rotary table face.

3. Move the mill table along the

Y-axis and note any deviations

in the test indicator.

— If a deviation is found, loosen

the rotary table mounting

fasteners, tap the rotary

table into the proper position,

then re-tighten the mounting

fasteners.

-10-

Figure 7. Using an edge finder and center

to align the rotary table (top view).

4. Measure the diameter of the

center where the edge finder

makes contact, divide this

number in half, then add half of

the edge finder diameter. The

result is the amount you need

to move the mill table along the

Y-axis to center the rotary table

with the mill spindle centerline.

Note: Be sure to take into account

any backlash and any rounout

of the center when moving the

table.

Page 13

OPERATION

To reduce the risk of serious

injury when using this

equipment, read and understand

this entire manual before

beginning any operations.

Controls & Components

Refer to Figure 8 and the following

descriptions to become familiar with

the controls and components used to

operate the rotary table.

D

C

B

A

Figure 8. Rotary table controls and

components (Model SB1367 shown).

G

H

A. Handwheel: Rotates the table

when the gears are engaged.

B. Handwheel Scale: Displays the

amount of the table rotation

witharesolutionof1'(onearc

minute) and also in 1° marks.

One complete revolution of the

handwheel rotates the table 4°.

E

F

SB1363- 64 /SB1367-68Mfg. Since 10/09

C. Vernier Scale: Displays the

amount of table rotation with

a resolution of 10" (ten arc

seconds).

D. Rotation Scale: Displays the

table position in whole degrees.

E. Table Locks: When fully

tightened, keep the table from

rotating to reduce the strain

on the gears during operation.

When cutting circular slots, a

slight drag can be applied with

the table locks to help reduce

chatter caused by gear backlash.

F. Spindle Bore: Holds a center to

support a workpiece for dividing

work. Also, used in rotary table

alignment with the mill spindle

centerline.

G. Backlash Adjustment

Lock: Secures the backlash

adjustment ring in place.

H. Backlash Adjustment Ring

Lever: Conveniently controls the

backlash adjustment ring for

adjusting the backlash between

the gears.

When rotated completely

clockwise, the backlash

adjustment ring disengages the

gears so that the table can be

rotated by hand.

Note: The Model SB1368 uses

a knurled ring instead of a

lever.

-11-

Page 14

SB1363- 64 /SB1367-68

OPERATION

Mfg. Since 10/09

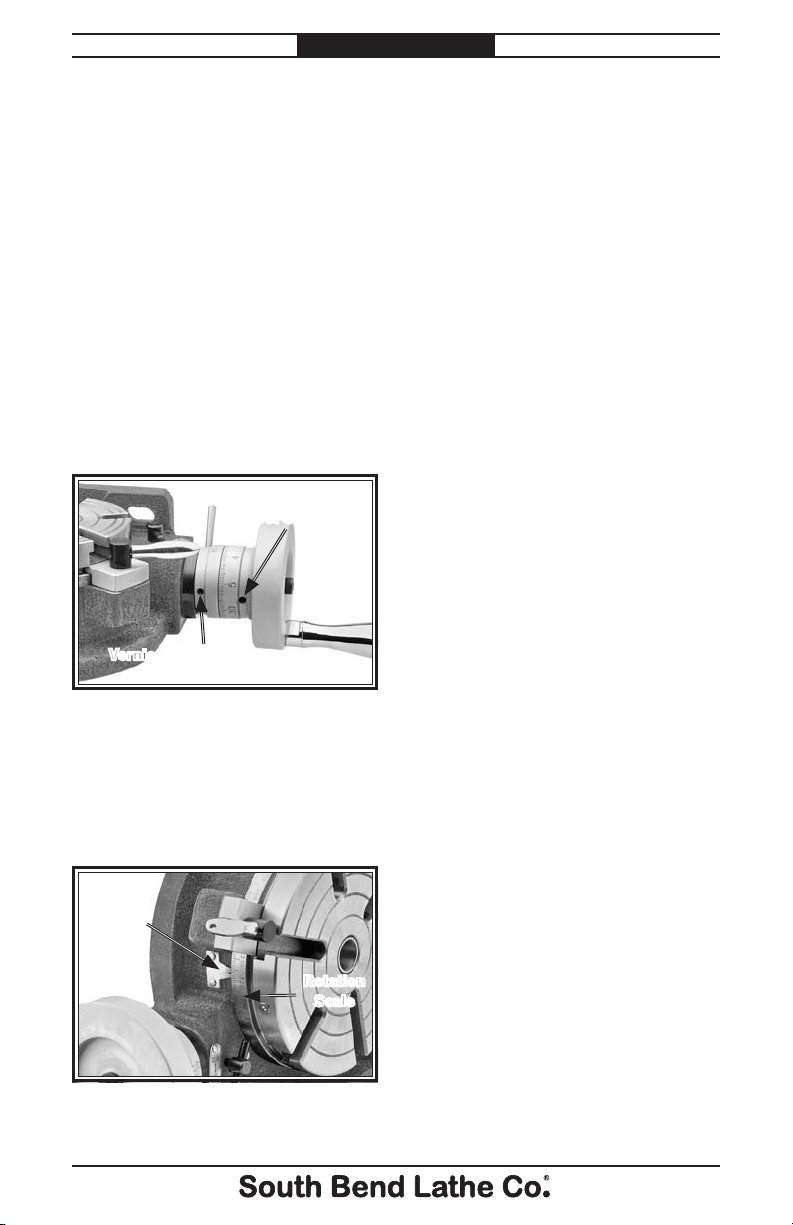

Aligning Handwheel &

Vernier Scales

The handwheel scales can be

easily aligned with each other and

adjusted for easy viewing.

Tools Needed Qty

Hex Wrench 5mm. . . . . . . . . . . . . . 1

To align and adjust the handwheel

and vernier scales:

1. Loosen the two set screws on

the vernier scale (see Figure 9),

rotate the vernier scale so that

it is in a convenient viewing

position, the re-tighten the set

screws.

Handwheel Scale

Set Screw

Vernier Scale Set Screw

(1 of 2)

Figure 9. Locations of the handwheel and

vernier scale set screws

2. Use the handwheel to rotate the

table until the 0° on the table

rotation scale aligns with the

center mark on the pointer (see

Figure 10).

Pointer

3. Loosen the set screw on the

handwheel (see Figure 9),

rotate the handwheel scale until

the 0° mark aligns with the 0°

mark on the vernier scale, then

re-tighten the set screw.

Using Vernier Scale

The vernier scale is used to measure

table rotation by 10" (ten arc

seconds) at a time.

Use your rotary table to follow along

with the example below to better

understand how to use the vernier

scale.

Note: This example assumes the

table rotation position is at 0°, and

the handwheel and vernier scales

are aligned at 0°.

To set the table at 16° 32' 20":

1. With the table at 0°, rotate the

handwheel clockwise four full

turns, which will rotate the

table 16°.

— If you go past the handwheel

scale 0° mark on the fourth

turn, rotate the table

counterclockwise

then start again.

Note: When changing direction

with the handwheel, take into

account any backlash.

1

⁄2 turn,

Rotation

Scale

Figure 10. Location of the rotation scale

-12 -

pointer.

Page 15

OPERATION

0

60

40

30

20

10

0

50

10

20

5

0

1

32 Arc Minutes

20 Arc Seconds

Vernier Scale

Handwheel Scale

72º

SB1363- 64 /SB1367-68Mfg. Since 10/09

2. Slowly continue to turn the

handwheeluntilthe32'markon

the handwheel scale aligns with

the 0° mark on the vernier scale

(see the illustrated example in

Figure 11).

Note: Figure 11 may not agree

with the layout of the scales on

your model. However, the use of

these scales as instructed here

is the same.

Figure 11. Handwheel and vernier

scales aligned so that the table is at

16° 32' 20".

3. Identify the mark on the vernier

scale that is two marks (20") to

the left of the vernier scale 0°

mark.

Important: When the handwheel

is turned clockwise, the marks

to the left of the vernier scale

0° mark are used, and when

the handwheel is turned

counterclockwise, the marks on

the right are used.

Operational Examples

Use your rotary table and mill to

follow along with the operational

examples below to better

understand how to use the rotary

table.

Note: For both examples, the

following statements are assumed to

be true:

• Therotarytableisproperly

secured to the mill in the

horizontal position.

• Therotarytableisproperly

centered with the mill spindle

centerline.

• Theworkpieceiscenteredand

properly clamped on the rotary

table, and elevated for proper

machining clearances.

• The0°marksofthehandwheel

and vernier scales are aligned.

Five Evenly Space Holes

In this example, you will make

five holes spaced 72° apart in a

circular workpiece, as illustrated in

Figure 12.

4. Identify the mark on the

handwheel scale that is

immediately to the left of the

vernier scale 20" mark, then

slowly rotate the handwheel

clockwise until the this mark

and the vernier scale 20" mark

are aligned. The table is now set

at16°32'20".

Figure 12. Five hole layout spaced 72°

apart.

-13 -

Page 16

SB1363- 64 /SB1367-68

92º

0.25"

1.125"

Start

Here

Radius

OPERATION

Mfg. Since 10/09

Tip: When using the rotary table

to machine several locations or

with a complicated pattern, make a

drawing with measurement details

to help visualize the operation. This

will reduce the risk of making errors

during the operation.

To make five evenly spaced holes:

1. Use the handwheel to rotate the

rotary table to the 0° mark on

the rotation scale, then tighten

both table locks.

2. Drill the first hole.

3. Unlock the table, then turn

the handwheel 18 full turns.

This will rotate the rotary table

to 72°, as displayed on the

rotational scale.

Important: Be careful not to pass the

handwheel scale 0° mark on the

last turn. If you go past the 0°

mark, reverse the handwheel

one full turn, then try again.

This will eliminate any backlash

error that occurs when reversing

the handwheel direction.

4. Lock the table in place and drill

the hole.

5. Repeat Steps 3–4 to produce

the third hole at 144°, the fourth

hole at 216°, and the fifth hole

at 288°.

Two Circular Slots

In this example, you will cut two 92°

circular slots in a round workpiece,

as illustrated in Figure 13.

Figure 13. Layout for creating two

To make two circular slots:

1. Use the handwheel to rotate

the rotary table to the 0° mark

on the rotational scale, then

tighten the table locks.

2. Move the mill table to the left

1.125" along the X-axis so that

the spindle is at the starting

point above the lower end of the

upper slot.

3. Install a

spindle, then make a 0.083"

deep hole (approximately

cutter diameter).

circular slots.

1

⁄4" end mill in the mill

1

⁄3 the

-14-

Page 17

OPERATION

SB1363- 64 /SB1367-68Mfg. Since 10/09

4. With the end mill continuing

to cut, turn the rotary table

handwheel clockwise 23 full

turns (92°), using care not to

pass the handwheel scale 0°

mark on the last turn.

5. Raise the end mill from the

workpiece, then rotate the

handwheel clockwise 45 full

turns (180°), making sure not

to pass the 0° mark. This will

bring the cutter to the starting

point of the second slot.

Note: Rotating the rotary table in

only one direction throughout

the operation will remove any

error from backlash.

6. Make a 0.083" deep hole, then

with the end mill continuing

to cut, turn the rotary table

handwheel clockwise 23 full

turns to begin the second 92°

slot.

7. Raise the end mill, rotate the

rotary table clockwise back to

the 0° mark on the rotational

scale, then take an additional

0.083" deep cut.

8. Repeat Steps 4–7, increasing

the depth of cut by 0.083" each

time, until the final depth of cut

is reached for each slot.

-15 -

Page 18

SB1363- 64 /SB1367-68

MAINTENANCE

Mfg. Since 10/09

Maintenance Schedule

For optimum performance from

your rotary table, follow this

maintenance schedule and refer to

any specific instructions given in

this section.

Daily Before Use

• Lubricatetheballoilers

(Page 17).

• Check/resolveanyunsafe

condition.

Daily After Use

• Cleantherotarytable.

• Dressthemachinedsurfaces.

• Lubricatethemachinedsurfaces

to prevent rust.

Semi-Annually

• Disassembleandcleanthe

internal cavity of the rotary

table, then lubricate the worm

gear and shaft (Page 17).

Cleaning & Protecting

It is essential that the rotary table

be cleaned after every use. DO

NOT use compressed air to clean

your rotary table. Chips or debris

may become lodged between the

moving parts, reducing the life and

accuracy of the tool. Instead, use a

stiff-bristled brush to remove the

chips and swarf, then wipe down

the machined surfaces with a clean

shop rag before applying a thin

coat of light machine oil to prevent

corrosion.

Surface Care

Nicks, dings, and scratches on the

machined surfaces of the rotary

table can have an adverse effect

on accuracy and may damage the

workpiece or mill table.

Prior to use, dress or "stone" these

machined surfaces with a fine

sharpening stone. A few strokes

of the stone on the rotary table

surface, the machined base and

back, and the mill table will help

to ensure longevity and accuracy.

Make sure to thoroughly wipe these

surfaces clean to remove any dust

generated from the process, then

apply a thin coat of light machine oil

to prevent corrosion.

-16-

Tip: After stoning and wiping down

the surfaces, run your fingers lightly

across the surfaces to detect any

irregularities.

Page 19

MAINTENANCE

Lubrication

The recommended schedule

on the previous page for the

lubrication tasks is based on

light-to-medium usage. Keeping

in mind that lubrication helps to

protect the value and operation

of the rotary table, these

lubrication tasks may need to be

performed more frequently than

recommended, depending on

usage.

Failure to follow reasonable

lubrication practices as

instructed in this manual could

lead to premature failure of the

rotary table components and will

void the warranty.

Ball Oilers

There are two ball oilers (see

Figure 14) that must be lubricated

before daily use, or more often with

heavy use.

SB1363- 64 /SB1367-68Mfg. Since 10/09

Important: Use an oil can or gun

that has a plastic or rubber tip.

Metal tips can damage the ball and

spring inside the oilers.

Clean away debris and grime from

around the ball oilers, then depress

the ball with the oil can tip to add

oil until it is seen exiting between

the parts. Clean away any excess

lubricant, then rotate the table at

least one full revolution to evenly

disperse the lubricant.

Worm Gear & Shaft

To gain access to the worm gear and

shaft for cleaning and lubrication,

you need to remove the table from

the cast iron housing.

Items Needed Qty

Hex Wrench 3mm. . . . . . . . . . . . . . 1

Dead Blow Hammer ............1

Stiff-Bristled Brush . . . . . . . . . . . . 1

Shop Rags ............ As Needed

Mineral Spirits ........ As Needed

MP Gear Grease ....... As Needed

To remove the table and clean/

lubricate the worm gear and shaft:

1. Remove the table lock

assemblies, as shown in

Figure 15.

Ball Oilers

Figure 14. Locations of the two ball

oilers.

Figure 15. Table lock assemblies

removed (Model SB1364 shown).

-17-

Page 20

SB1363- 64 /SB1367-68

MAINTENANCE

Mfg. Since 10/09

2. Use the backlash adjustment

ring to disengage the gears from

the handwheel so that the table

rotates freely by hand.

3. Turn the rotary table upside

down on a protective surface.

4. Loosen the cap screw that

secures the spindle lock collar,

then unthread and remove the

collar (see Figure 16).

Lock

Collar

Figure 16. Loosening the spindle lock

collar cap screw.

5. Lift the edge of the cast iron

housing with one hand, and tap

the back end of the spindle with

the dead blow hammer until the

table assembly breaks free from

the housing.

7. Use the stiff-bristled brush,

shop rags, and mineral spirits

to clean grime and debris from

inside the housing cavity, the

worm shaft, and the worm gear.

8. When these parts are dry, apply

a medium coat of multi-purpose

gear grease to the teeth of the

worm shaft and gear.

9. Use a clean shop rag and

mineral spirits to wipe clean

the mating surfaces of the

housing and table, then apply

a thin coat of light machine

oil to the housing oil grooves

and surrounding surface (see

Figure 17).

10. Re-install the table, the spindle

lock collar, and the table lock

assemblies, then perform the

Spindle Preload procedure as

instructed on the next page.

6. Remove the table from the

housing, as shown in Figure 17.

Oil

Grooves

Worm Gear

Figure 17. Locations of worm gear and

shaft with the table removed.

-18 -

Worm Shaft

Page 21

SERVICE

SB1363- 64 /SB1367-68Mfg. Since 10/09

Spindle Preload

Setting the spindle preload on the

rotary table affects the accuracy and

ease of use during operation.

Keep in mind, that too much preload

will make table rotation difficult

and will cause pre-mature wear of

the gears and mating surfaces of

the table. Conversely, not enough

preload may result in reduced

accuracy. Use your best judgment

when setting the spindle preload on

the rotary table.

Tool Needed Qty

Hex Wrench 3mm. . . . . . . . . . . . . . 1

To set the rotary table spindle

preload:

1. Make sure the table locks are

loose.

2. Use the backlash adjustment

ring to disengage the worm

shaft from the worm gear so

that the table can be freely

rotated by hand and not the

handwheel.

4. From the back of the rotary

table, loosen the spindle lock

collar cap screw (see Figure 16

on the previous page).

5. Loosen the lock collar at least

two full turns to remove any

preload.

6. Rotate the table by hand as you

re-tighten the lock collar. When

it becomes difficult to turn the

table, back off the lock collar

slightly until the table rotates

freely again, then, while keeping

the lock collar from rotating, retighten the lock collar cap screw.

7. Use the backlash adjustment

ring to re-engage the worm

shaft and gear, then test the

table rotation by using the

handwheel.

— If you are not satisfied with

the table rotation, repeat

this procedure to re-adjust

the preload until you are

satisfied with the results.

3. Position the table in a vertical

position so that both the front

and the back are accessible.

-19 -

Page 22

SB1363- 64 /SB1367-68

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

28

29

30

31

32

7

6

5

11

36

37

REF PART # D ESCRIPTI ON REF PART # DES CRIPTION

1 PSB1363001 TABLE 18 PSB1363018 VERNIER RING

2 PSB1363002 NEEDLE ROLLER BEARING NA4904 19 PSS05M SET SCREW M5-.8 X 10

3 PSB1363003 WORM GEAR 20 PSB1363020 BACKLASH RING LEVER

4 PCAP15M CAP SCREW M5-.8 X 20 21 PSB1363021 LOCK COLLAR M14-1.25

5 PSB1363005 CLAMP BOLT M6-1 X 25 22 PSS111M SET SCREW M4-.7 X 4

6 PSB1363006 CLAMP BOLT HANDLE M6-1 X 10 23 PSB1363023 HANDWHEEL SCALE

7 PSB1363007 CLAMP 24 PSB1363024 HANDWHEEL

8 PSB1363008 MAIN CASTING 25 PSB1363025 HANDWEEL HANDLE 3/8-16 X 1/2

9 PSB1363009 THRUST NEEDLE BEARING 20 X 35 X 4 26 PWF06M FENDER WASHER 6MM

10 PSB1363010 LOCK COLLAR M20-1 28 PCAP26M CAP SCREW M6-1 X 12

11 PLUBE001 TAP-IN BALL OILER 1/4 29 PSB1363029 BACKLASH DIRECTION LABEL

12 PSB1363012 BACKLASH ADJUST LOCK M6-1 X 14 30 PK65M KEY 4 X 4 X 7

13 PSB1363013 POINTER 31 PSB1363031 TAPER SLEEVE MT#1

14 PSB1363014 WORM SHAFT 32 PCAP18M CAP SCREW M4-.7 X 8

15 PSB1363015 ECCENTRIC WORM HOUSING 36 PSS50M SET SCREW M4-.7 X 20

16 PSB1363016 BACKLASH ADJUSTMENT RING 37 PN04M HEX NUT M4-.7

17 PCAP164M CAP SCREW M3-.5 X 12

SB1363

PARTS

Mfg. Since 10/09

-20-

Page 23

SB1364

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

28

29

30

31

32

33

36

37

33

7

6

5

11

REF PART # D ESCRIPTI ON REF PART # DES CRIPTION

1 PSB1364001 TABLE 18 PSB1364018 VERNIER RING

2 PSB1364002 NEEDLE ROLLER BEARING NK3520 19 PSS05M SET SCREW M5-.8 X 10

3 PSB1364003 WORM GEAR 20 PSB1363020 BACKLASH RING LEVER

4 PCAP15M CAP SCREW M5-.8 X 20 21 PSB1363021 LOCK COLLAR M14-1.25

5 PSB1363005 CLAMP BOLT M6-1 X 25 22 PSS111M SET SCREW M4-.7 X 4

6 PSB1363006 CLAMP BOLT HANDLE M6-1 X 10 23 PSB1364023 HANDWHEEL SCALE

7 PSB1363007 CLAMP 24 PSB1364024 HANDWHEEL

8 PSB1364008 MAIN CASTING 25 PSB1363025 HANDWEEL HANDLE 3/8-16 X 1/2

9 PSB1364009 THRUST NEEDLE BEARING 25 X 42 X 4 26 PWF06M FENDER WASHER 6MM

10 PSB1364010 LOCK COLLAR M24-1.5 28 PCAP26M CAP SCREW M6-1 X 12

11 PLUBE001 TAP-IN BALL OILER 1/4 29 PSB1363029 BACKLASH DIRECTION LABEL

12 PSB1363012 BACKLASH ADJUST LOCK M6-1 X 14 30 PK65M KEY 4 X 4 X 7

13 PSB1363013 POINTER 31 PSB1364031 TAPER SLEEVE MT#2

14 PSB1364014 WORM SHAFT 32 PCAP18M CAP SCREW M4-.7 X 8

15 PSB1364015 ECCENTRIC WORM HOUSING 33 PSB1364033 BRASS WASHER

16 PSB1363016 BACKLASH ADJUSTMENT RING 36 PSS50M SET SCREW M4-.7 X 20

17 PCAP164M CAP SCREW M3-.5 X 12 37 PN04M HEX NUT M4-.7

PARTS

SB1363- 64 /SB1367-68Mfg. Since 10/09

-21-

Page 24

SB1363- 64 /SB1367-68

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

28

29

30

31

32

33

36

37

33

5

6

7

11

1

REF PART # D ESCRIPT ION REF PART # D ESCRIPT ION

1 PSB1367001 TABLE 18 PSB1367018 VERNIER RING

2 P6208-OPEN BALL BEARING 6208-OPEN 19 PSS05M SET SCREW M5-.8 X 10

3 PSB1367003 WORM GEAR 20 PSB1367020 BACKLASH RING LEVER

4 PCAP95M CAP SCREW M5-.8 X 30 21 PSB1367021 LOCK COLLAR M17-2

5 PSB1367005 CLAMP BOLT M6-1 X 32 22 PSS07M SET SCREW M5-.8 X 5

6 PSB1367006 CLAMP BOLT HANDLE M6-1 X 13 23 PSB1367023 HANDWHEEL SCALE

7 PSB1367007 CLAMP 24 PSB1367024 HANDWHEEL

8 PSB1367008 MAIN CASTING 25 PSB1367025 HANDWEEL HANDLE 3/8-16 X 1/2

9 P32007 TAPER ROLLER BEARING 32007 26 PWF06M FENDER WASHER 6MM

10 PSB1367010 LOCK COLLAR M32-1.5 28 PCAP26M CAP SCREW M6-1 X 12

11 PLUBE001 TAP-IN BALL OILER 1/4 29 PSB1367029 BACKLASH DIRECTION LABEL

12 PSB1367012 BACKLASH ADJUST LOCK 30 PK05M KEY 4 X 4 X 10

13 PSB1367013 POINTER 31 PSB1367031 TAPER SLEEVE MT#3

14 PSB1367014 WORM SHAFT 32 PCAP18M CAP SCREW M4-.7 X 8

15 PSB1367015 ECCENTRIC WORM HOUSING 33 P51103 THRUST BEARING 51103

16 PSB1367016 BACKLASH ADJUSTMENT RING 36 PSS50M SET SCREW M4-.7 X 20

17 PCAP164M CAP SCREW M3-.5 X 12 37 PN04M HEX NUT M4-.7

SB1367

PARTS

Mfg. Since 10/09

-22-

Page 25

SB1368

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

21

22

23

24

25

26

28

29

30

31

32

33

34

35

36

37

33

5

6

7

11

REF PART # D ESCRIPT ION REF PART # D ESCRIPT ION

1 PSB1368001 TABLE 19 PSS05M SET SCREW M5-.8 X 10

2 P6208-OPEN BALL BEARING 6208-OPEN 21 PSB1367021 LOCK COLLAR M17-2

3 PSB1368003 WORM GEAR 22 PSS07M SET SCREW M5-.8 X 5

4 PCAP95M CAP SCREW M5-.8 X 30 23 PSB1368023 HANDWHEEL SCALE

5 PSB1367005 CLAMP BOLT M6-1 X 32 24 PSB1368024 HANDWHEEL

6 PSB1367006 CLAMP BOLT HANDLE M6-1 X 13 25 PSB1367025 HANDWEEL HANDLE 3/8-16 X 1/2

7 PSB1367007 CLAMP 26 PWF06M FENDER WASHER 6MM

8 PSB1368008 MAIN CASTING 28 PCAP26M CAP SCREW M6-1 X 12

9 P32007 TAPER ROLLER BEARING 32007 29 PSB1367029 BACKLASH DIRECTION LABEL

10 PSB1367010 LOCK COLLAR M32-1.5 30 PK05M KEY 4 X 4 X 10

11 PLUBE001 TAP-IN BALL OILER 1/4 31 PSB1367031 TAPER SLEEVE MT#3

12 PSB1367012 BACKLASH ADJUST LOCK 32 PCAP18M CAP SCREW M4-.7 X 8

13 PSB1367013 POINTER 33 P51103 THRUST BEARING 51103

14 PSB1368014 WORM SHAFT 34 PSB1368034 KNURLED BACKLASH RING

15 PSB1368015 ECCENTRIC WORM HOUSING 35 PCAP158M CAP SCREW M3-.5 X 16

16 PSB1368016 BACKLASH ADJUSTMENT RING 36 PSS50M SET SCREW M4-.7 X 20

17 PCAP164M CAP SCREW M3-.5 X 12 37 PN04M HEX NUT M4-.7

18 PSB1368018 VERNIER RING

PARTS

SB1363- 64 /SB1367-68Mfg. Since 10/09

-23-

Page 26

Page 27

WARRANTY

This quality product is warranted by South Bend Lathe Company to the

original buyer for one year from the date of purchase. This warranty does

not apply to consumable parts, or defects due to any kind of misuse, abuse,

negligence, accidents, repairs, alterations or lack of maintenance. We do not

reimburse for third party repairs. In no event shall we be liable for death,

injuries to persons or property, or for incidental, contingent, special or

consequential damages arising from the use of our products.

We do not warrant or represent that this machine/equipment complies with

the provisions of any law, act, code, regulation, or standard of any domestic

or foreign government, industry, or authority. In no event shall South Bend’s

liability under this warranty exceed the original purchase price paid for this

machine/equipment. Any legal actions brought against South Bend Lathe

Company shall be tried in the State of Washington, County of Whatcom.

This is the sole written warranty for this machine/equipment. Any and all

warranties that may be implied by law, including any merchantability or

fitness, for any purpose, are hereby limited to the duration of this warranty.

To take advantage of this warranty, contact us by mail or phone to give us

the details of the problem you are having.

Thank you for your business and continued support.

SB1363- 64 /SB1367-68Mfg. Since 10/09

-25-

Page 28

South Bend Lathe Co.

P.O. Box 2027

Bellingham, WA 98227

PHONE: (360) 734-1540 (Administrative Offices)

FAX: (360) 676-1075 (International)

FAX: (360) 734-1639 (USA only)

southbendlathe.com

Printed In Taiwan #TS13041

Loading...

Loading...