Southbend R-1QC Installation Manual

IMPORTANT

FOR FUTURE REFERENCE

Please complete this information and

retain this manual for the life of the

equipment.

MODEL #

SERIAL #

DATE PURCHASED

OWNER’S MANUAL

INSTALLTION

USER’S GUIDE

SERVICE

PARTS

COUNTER TOP

CONVECTION STEAMER

MODEL R-1: STEAMMASTER

These instructions should be read thoroughly before attempting installation.

Installation and Start Up should be performed by a qualified service

technician. The Manufacturer, Southbend (1100 Old Honeycutt Rd., Fuquay Varina, North Carolina 27526), informs you that unless the installation

instructions for the above described Southbend product are followed and

performed by a qualified service technician, (a person experienced in and

knowledgeable concerning the installation of commercial gas and/or

electrical cooking equipment) then the terms and conditions of the

Manufacturer's Limited Warranty will be rendered void and no warranty of any

kind shall apply.

If the equipment has been changed, altered, modified or repaired by other than a

qualified service technician during or after the 12-month limited warranty period,

then the manufacturer shall not be liable for any incidental or consequential

damages to any person or to any property which may result from the use of the

equipment thereafter. Some States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion thereto

may not apply to you. In the event you have any questions concerning the

installation, use. care, or service of the product, write Customer Service

Department, Southbend, 1100 Old Honeycutt Rd., Fuquay -Varina, North

Carolina 27526.

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read the

installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

Congratulations! You have just purchased one of the finest pieces of heavy-duty, commercial cooking equipment

on the market today.

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to

some of the toughest standards in the industry — those of Southbend Corporation. Each piece of Southbend

equipment has been carefully engineered and designs have been verified through laboratory tests and field

installations in some of the more strenuous commercial cooking applications. With proper care and field

maintenance, you will experience years of reliable, trouble -free operation from your Southbend equipment. To get

the best results, it's important that you read this manual carefully.

TABLE OF CONTENTS:

SECTION ONE - INSTALLATION

SECTION TWO - USER'S GUIDE

SECTION THREE – SERVICE

SECTION FOUR – PARTS

Specifications............................................................................................................................................1

Installation .................................................................................................................................................3

For Sectional Battery Assembly Instruction See ATTENTION INSTALLER MANUAL, Part No. 1165403/1

Warranty ...................................................................................................................................................1

Operation ..................................................................................................................................................2

Cooking Hints ...........................................................................................................................................6

Maintenance .............................................................................................................................................8

Adjustments ..............................................................................................................................................1

Service .....................................................................................................................................................6

Troubleshooting ........................................................................................................................................6

Schematic Drawings .................................................................................................................................9

Parts List ...................................................................................................................................................1

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

INTENDED FOR COMMERCIAL USE ONLY. NOT FOR HOUSEHOLD USE.

WARNING-WARRANTY WILL BE VOID IF

A. SERVICE WORK IS PERFORMED BY OTHER THAN A QUALIFIED TECHNICIAN.

B. OTHER THAN GENUINE SOUTHBEND REPLACEMENT PARTS ARE INSTALLED.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

KEEP AREA AROUND APPLIANCES FREE AND CLEAR FROM COMBUSTIBLES.

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN EQUIPMENT AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

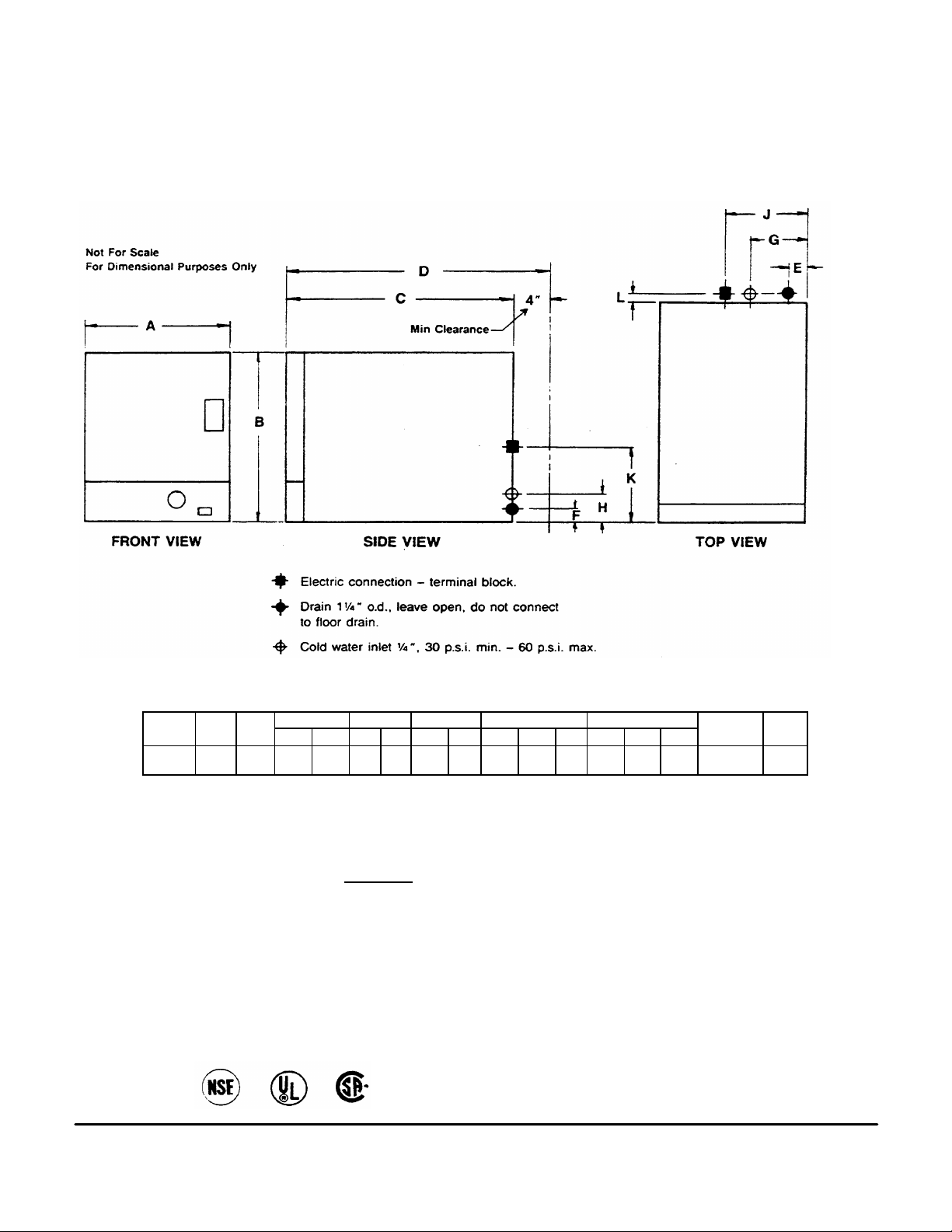

COUNTER TOP CONVECTION STEAMER

E F G H J K L

STEAM

16" 19" 24%" 28%" 2" W 6%" 374" 9%" 8V7

- 1" 19" 30" 22" 7.25

cu. U.

90

lbs. MASTER

(406) (482) (625) (727) (51) (38) (158) (82) (235) (216) (25) (482) (762) (559) .20

cu. m.

41kg.

208/240

V

208/60/1

44

208/60/3

25

240/60/1

38

240/60/3

22

INSTALLATION

SPECIFICATIONS

DIMENSIONS: ( ) = Millimeters

MODEL

Width A Width

B

DEPTH

C 0

DRAIN WATER

ELECTRIC CONN. CRATE SIZE

Width Depth Heigh

UTILITY INFORMATION:

ELECTRIC: One electric connection required. Controls on all units and, elements 208/60/1, 240/60/1, 208/60/3, or

240/60/3.

TOTAL CONNECTED AMPS

9KW

'Circuit must be wired for maximum 9 KW at required voltage.

WATER USAGE: 0.12 gallons per minute at 45 p.s.i. water pressure in cavity.

0.16 gallons per minute at 45 p.s.i. water pressure in condenser.

APPROVALS:

Cubic

Volume

Crated

Weight

COUNTER TOP CONVECTION STEAMER

SECTION ONE — INSTALLATION

PAGE1

INSTALLATION

Litho in

GENERAL:

THE UNIT WHEN INSTALLED MUST BE ELECTRICALLY GROUNDED AND COMPLY

WITH LOCAL CODES, OR IN THE ABSENCE OF LOCAL CODES, WITH THE

NATIONAL ELECTRICAL CODE ANSI NFPA 70-1990.

CANADIAN INSTALLATION MUST COMPLY WITH CSA STANDARD C22.2 No. 0M1982 -General Requirements - Canadian Electrical Code, Part II. 109-M1981 - Commercial

Cooking Appliances

CLEARANCES:

Allow at least a four inch (4") 102 mm. clearance between the back of the unit and any wall

obstruction for proper ventilation of the unit, and room for plumbing and electrical connections.

Do not locate the STEAMMASTER adjacent to any high heat[producing piece of equipment,

such as a range top, griddle, fryer, etc., that could allow radiant heat to raise the exterior

temperature of the STEAMMASTER above 130T (54°C).

DO NOT MOUNT ABOVE OTHER COOKING EQUIPMENT.

WARNING:

THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL OR

WARRANTY WILL BE VOIDED.

TO INSTALL:

1. Uncrate carefully. Report any hidden freight damage to the freight company immediately.

2. Do not remove any tags or labels until the unit is installed and working properly.

3. Set unit in place.

4. Counter Model — Set on non-flammable surface and shim to make level. Seal to counter top with

sealer such as G .E. or DOW Corning RTV type sealant. (Consult local code for exact

requirements.)

LEVELING:

Unit must be level to assure maximum performance. Improper leveling may void warranty.

WATER CONNECTION:

Connect cold water line, 1/4" (6 mm.) pipe. Water line pressure should be 30 psi (205 Kpa) minimum

— 60 psi (410 Kpa) maximum.

NOTE: Tb facilitate cleaning, plus allowing access to rear of unit, flexible connections are recommended.

WATER SPECIFICATION:

To meet warranty requirement, supply water must be as follows:

Pressure: 30 to 60 psi

Total dissolved solids (TDS) — 60 PPM

Hardness: 2 grains or 35 PPM

PH factor: 7.0 to 7.5

WATER LEVEL SWITCH FLOAT INSTALLATION:

See page 5 SERVICE.

COUNTER TOP CONVECTION

STEAMER SECTION O NE — INSTALLATION

Page 2

U.S.A. 4-92

INSTALLATION

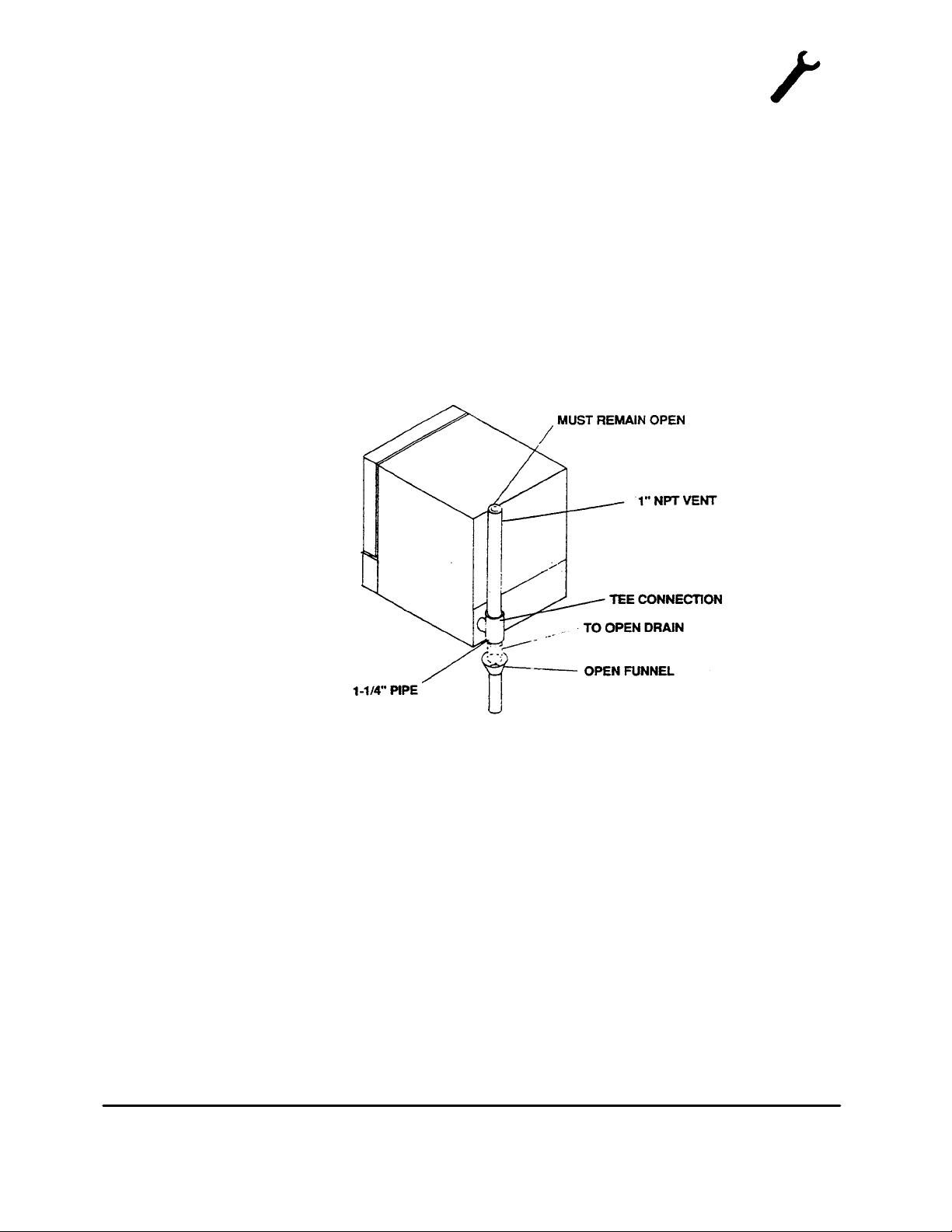

DRAIN LINE:

The drain line connection size from the unit is 1-1/4" NPT (32 mm). Position the unit near, but not on top of,

an open floor drain. DO NOT directly plumb to the unit unless you also install an "open funnel" downstream

of this connection in the drain system. Make the drain line from the unit to the air gap above the "open

funnel" as short as possible. There should be no horizontal piping between the unit and the air gap above the

"open funnel". The "open funnel" is intended to elim inate any water from entering the steamer because of a

blocked drain and it also prevents any back pressure within the steamer cavity. The unit must be free-venting

to atmosphere. Any connection that allows the build-up of back pressure in the unit such as a reduction in

pipe size to a line smaller than 1-1/4" or a 90 degree angle in the line prior to the "open funnel" drain

discharge point will void the warranty. This is a pressureless, free-venting steam cooker and will not operate

properly unless the drain line is short, at a steep angle, and open!

ELECTRICAL CONNECTION:

For proper connection of field wiring to terminal block, see Wiring Diagram, Section 3, Page 6. Be sure

that the input voltage and phase match the requirements shown on the serial plate located on the left rear

side of each piece of equipment.

NOTE: This unit has one power supply for controls and elements, as well as one (1) ground wire. A

POSITIVE GROUND CONNECTION IS ESSENTIAL.

DO NOT ALLOW ANY TAMPERING OR ADJUSTMENT OF ANY CONTROL OR WIRING. THE

UNIT IS FACTORY SET. ADJUSTMENT OF ANY INTERNAL COMPONENT OTHER THAN THE

FIELD TERMINAL BLOCK CAN VOID THE WARRANTY.

FINAL:

5. Open water valve to full open position.

CHECK:

a. Power to unit.

b. Water to unit.

c. Open drain.

Unit is now ready for initial start-up.

COUNTER TOP CONVECTION STEAMER

SECTION ONE — INSTALLATION

PAGE 3

INSTALLATION

Litho in U.S.A.

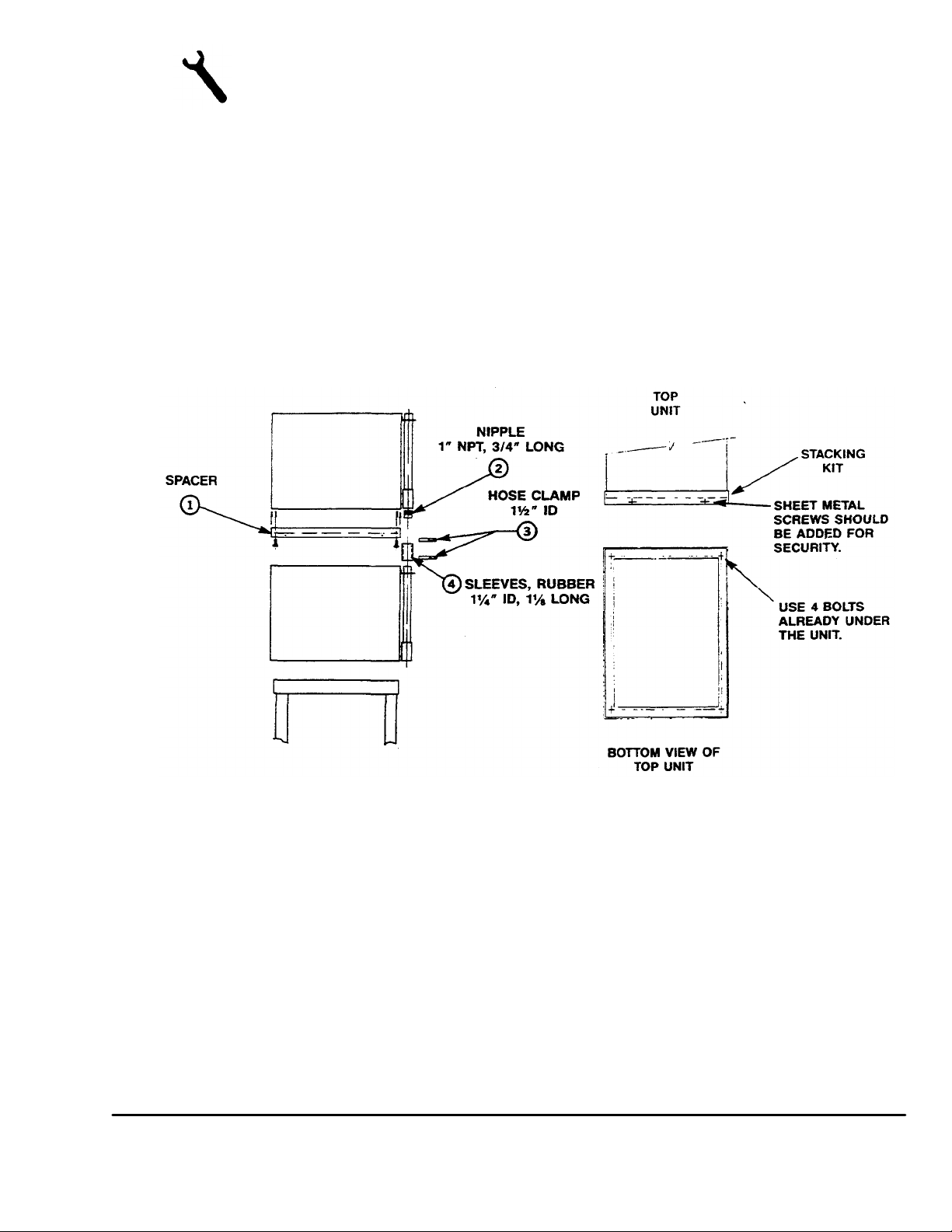

STEAMMASTER STACKING INSTRUCTIONS:

1. Bolt spacer (Item 1) to bottom of top unit, using the 3/8" bolts holding the lower cover on. Cover

remains on.

2. Attach nipple (Item 2) to lower threads of drain "tee" at rear of top unit.

3. Place rubber sleeve (Item 4) on lower portion of just installed nipple (top unit).

4. Carefully lower top unit onto lower unit, lining up sleeve with top of vent pipe on lower unit. Secure

with clamps.

5. It is recommended to drill (2) 3/32" holes in each side through the spacer bracket holes and secure in

place with #10 sheet metal screws.

PERFORMANCE CHECK:

The following items should be checked before or within the first 30 days of operation by a qualified

service technician.

1. Check doors for proper alignment.

2. Check door gaskets for wear and sealing ability.

3. Check spray tubes or nozzles for cleanliness and/or leakage.

4. Check all gauges, timers, valves and switches for proper operation.

5. Visually check control compartment wiring for burned or loose connections.

6. Is user keeping compartment clean?

7. Check electrical load on elements, where applicable, for proper wattage.

8. Check hoses at clamped connections, it is particularly important to ensure that the hose connected to

front panel drain tube is securely attached.

COUNTER TOP CONVECTION STEAMER

SECTION ONE — INSTALLATION

PAGE 4

4-92

COUNTER TOP CONVECTION

STEAMER

USER'S GUIDE

LIMITED WARRANTY

Southbend warrants that the equipment, as supplied by the factory to the original purchasers, is free from defects in materials and

workmanship. Should any part thereof become defective as a resu lt of normal use within the period and limits defined below, then at

the option of Southbend such parts will be repaired or replaced by Southbend or its Authorized Service Agency. This warranty is

subject to the following conditions:

If upon inspection by Southbend or its Authorized Service Agency it is determined that this equipment has not been used in an

appropriate manner, has been modified, has not been properly maintained, or has been subject to misuse or misapplication, neglect,

abuse, accident, damage during transit or delivery, fire, flood, riot or Act of God, then this warranty shall be void.

Specifically excluded under this warranty are claims relating to installation; examples are improper utility connections and improper

utilities supply. Claims relating to normal care and maintenance are also excluded; examples are calibration of controls, and

adjustments to pilots and burners.

Equipment failure caused by inadequate water quality is not covered under warranty. WATER QUALITY must not exceed the

following limits: Total Dissolved Solids (TDS) - 60 PPM (Parts Per Million). Hardness - 2 Grains or 35 PPM, PH Factor

- 7.0 to 7.5. Water pressure 30 PSI minimum, 60 PSI maximum. Boiler maintenance is the responsibility of the owner and is not

covered by warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial application.

Repairs under this warranty are to be performed only by a Southbend Authorized Service Agency. Southbend can not be responsible

for charges incurred from other than Authorized Southbend Agencies. THIS WARRANTY MUST BE SHOWN TO AN AUTHORIZED

SERVICE AGENCY WHEN REQUESTING IN-WARRANTY SERVICE WORK. THE AUTHORIZED SERVICE AGENCY MAY AT HIS

OPTION REQUIRE PROOF OF PURCHA SE. This warranty does not cover services performed at overtime or premium labor rates nor

does Southbend assume any liability for extended delays in replacing or repairing any items in the equipment beyond the control of

Southbend. "Southbend shall not be liable for consequential or special damages of any nature that may arise in connection with such

product or part." Should service be required at times which normally involve overtime or premium labor rates, the owner shall be

charged for the difference between normal service rates and such premium rates. In all circumstances, a maximum of one hundred

miles in travel and two and one half hours (2.5) travel time shall be allowable. In all cases the closest Southbend Authorized Agency

must be used. The actual warranty time periods and exceptions are as follows:

This warranty only covers product shipped into the 48 contiguous United States and Hawaii, one year labor, one year parts effective

from the date of original purchase. There will be no labor coverage for equipment located on any island not connected by roadway to

the mainland. Exceptions to standard warranty, effective within above limitations:

Glass Windows, Door Gaskets, Rubber Seals, Light Bulbs, Ceramic Bricks, Sight Glasses, Cathodic Descalers or A nodes

................................... 90 days material and labor

Stainless Steel Fry Pot .........................4 years extended material warranty on fry pot only — no labor

Stainless Steel Open Top Burners...............4 years extended material warranty on burners only — no labor

Pressure Steam Boiler Shell ................ Prorated 4 years extended warranty on boiler shell only — no labor

parts covered by a five year warranty will be shipped FOB the factory after the first year. Our warranty on all replacement parts which

are replaced in the field by our Authorized Service Agencies will be limited to three months on labor, six months on materials (parts)

effective from the date of installation. See LIMITED WARRANTY

- REPLACEMENT PARTS for conditions and limitations.

If the equipment has been changed, altered, modified or repaired by other than a qualified service technician during

or after the one year limited warranty period, then the manufacturer shall not be liable for any damages to any person

or to any property which may result from the use of the equipment thereafter.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS, AND CONSTITUTES THE ENTIRE

LIABILITY OF SOUTHBEND. IN NO EVENT DOES THE LIMITED WARRANTY EXTEND BEYOND THE DURATION

OF ONE YEAR FROM THE EFFECTIVE DATE OF SAID WARRANTY."

Boiler shells which have not been properly maintained will not be covered by warranty. In all cases

COUNTER TOP CONVECTION STEAMER

SECTION TWO — USER'S GUIDE

PAGE 1

OPERATION

Litho in U.S.A.

THEORY OF OPERATION:

Compared to other steam cookers with complicated boilers, the STEAMMASTER is a very simple

machine. Immersion elements are installed on the left side of the cavity and when water covers the

elements, water starts to boil and turn to steam. There is no pressure in this unit.

All equipment must be installed correctly to ensure proper operation and reliable service. Installation

instructions must be followed by a qualified technician.

Before you turn the unit on, be sure that you have: POWER to unit, WATER to unit, and OPEN DRAIN.

NOTE: Your STEAMMASTER must be thoroughly cleaned every day.

CAUTION: DO NOT USE ANY CORROSIVE CLEANER. USE ONIV CLEANERS APPROVED

FOR STAINLESS STEEL.

Before starting the unit, review the following:

A. Be sure overflow pipe in back right hand corner of the cooking compartment is in position.

B. Be sure the drain outlet is not blocked in any way. (The STEAMMASTER drain line must be free

venting.)

C. Be sure the pan supports and steam deflector are well secured.

CONTROL INSTRUCTIONS:

1. For manual operation, press right-hand rocker switch to "MANUAL" and the light will turn on. The

unit is now in operation and will be generating steam in a few minutes (approximately 9 minutes

from a cold start).

2. For timed operation, press right-hand rocker switch to " ." Set timer by positioning knob

pointer to desired time marking. When time elanses buzzer will sound. Buzzer may be shut off by

opening door, moving selector switch to " ," shutting unit off, resetting to a new time or

turning knob counterclockwise to the Hold/Off position (counterclockwise past "0" time).

3. To restart timer, set to new time marking.

NOTE: Timer is an audible time reminder only. It does not control cook time or shut off elements.

HEATING ELEMENTS REMAIN ON.

4. The STEAMMASTER is designed to accept standard 12" x 20" pans (305 x 508 mm.). Fractional

size pans can be used as well with optional stainless steel perforated shelf.

INSTRUCTIONS FOR TURNING OFF BUZZER:

The STEAMMASTER is supplied with a continuous ring buzzer. This buzzer is activated automatically

in the automatic mode of operation when the cooking cycle is complete. This buzzer can be turned off by:

1. Reset timer to begin a new time cycle.

2. Set the three position rocker switch to or to off position.

3. Open the door of the unit

4. Turn knob counterclockwise past "0" time.

COUNTER TOP CONVECTION STEAMER

SECTION TWO — USER'S GUIDE

PAGE 2

4-92

COOKING HINTS

SUGGESTED COOKING TIMES:

Timer settings are for general guidance only. Differences in food quality, size, shape, freshness, load size and degree of

cook desired must be considered and adjustments made in time if necessary.

Product

ASPARAGUS

Fresh

Frozen Spears (Thawed)

BEANS

Green — Frozen, Cut

Green — Fresh

Wax — Frozen

Lima — Frozen

BROCCOLI

Spears — Fresh

Spears — Frozen (Thawed)

BRUSSEL SPROUTS

Fresh

Fresh

CARROTS

Frozen — Whole Baby

Fresh — V4-lnch Bias Cut

CABBAGE

Green, Cut Into Wedges

Red, Cut Into Wedges

CAULIFLOWER

Fresh, Whole

Fresh, Whole

Frozen, Flowerettes

CORN

Fresh — Cob, 4-5 Inch Ears

Frozen — Whole Kernel

Frozen — Cob, 6 Inch Ears

MIXED VEGETABLES

Weight P ortions Cooking Time

3'/2 Ibs. 14(40Z.) 8-10 Full/Perforated

5 IDS. 20 (4 oz.) 9 Full/Perforated

5 Ibs. 20 (4 oz.) 12 Full/Perforated

5 Ibs. 20 (4 oz.) 15-17 Full/Perforated

5 Ibs. 20 (4 oz.) 13 Full/Perforated

5 Ibs. 20 (4 oz.) 10 Full/Perforated

4 Ibs. 16(4oz.) 10-12 Full/Perforated

5 Ibs. 20 (4 oz.) 8 Full/Perforated

5 Ib. 20 (4 oz.) 15-17 Full/Perforated

5 Ibs. 20 (4 oz.) 13 Full/Perforated

5 Ibs. 20 (4 oz.) 12 Full/Perforated

5 Ibs. 20 (4 oz.) 12 Full/Perforated

2 Ibs. 8 (4 oz.) 9-10 Full/Perforated

2 Ibs. 12oz. 11 (4 oz.) 15 Full/Perforated

5 Ibs. 20 (4 oz.) 10-12 Full/Perforated

5V2 Ibs. 15 13-15 Full/Perforated

5 Ibs. 20 (4 oz.) 8 Full/Perforated

9 Ibs. 14 12-14 Full/Perforated

24 15 Full/Perforated

16 18-20 Full/Perforated

(minutes)

Pan Used

Frozen

PEAS

Frozen

5 Ibs. 20 (4 oz.) 12 Full/Perforated

5 Ibs. 20 (4 oz.) 8 Full/Perforated

COUNTER TOP CONVECTION STEAMER

SECTION TWO — USER'S GUIDE

PAGE 3

Loading...

Loading...