Southbend MRA-60 Owner's Manual

m southbend

A MiDDlEBY COMPANY

OWNER’S MANUAL

INSTALLATION

USER’S GUIDE

SERVICE

PARTS

IMPORTANT

FOR FUTURE REFERENCE

Please complete this information and retain this manual for

the life of the equipment.

MODEL #

SERIAL #

DATE PURCHASED

I

COMPACT

INFRA-RED BROILER

MODELS: MRA=32C, MRA-32, MRA-32W

MRA-36, MRA-60

These instructions should be read thoroughly before attempting installation. Set up,

installation and Performance Check should be performed by a qualified service

technician. The Manufacturer, Southbend (1100 Old Honeycutt Rd., Fuquay-Varina,

North Carolina 2X26), informs you that unless the installation instructions for the above

described Southbend product are followed and performed by a qualified service

technician, (a person experienced in and knowledgeable concerning the instaflation

of commercial gas and/or electrical cooking equipment) then the terms and conditions

of the Manufacturer’s Limited Warranty will be rendered void and no warranty of any

kind shall apply.

If the equipment has been changed, altered, modified or repaired by other than a

qualified service technician during or after the 12-month limited warranty period, then

the manufacturer shall not be liable for any incidental or consequential damages to

any person or to any property which may result from the use of the equipment thereafter.

Some States do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion thereto may not apply to you.

In the event you have any question concerning the installation, use, care, or service

of the product, write Customer Service Department, Southbend, 1100 Old Honeycutt

Rd., Fuquay-Varina, North Carolina 27526.

COMPACT INFRA-RED BROILER

6.00

(Manual Section BR)

Congratulations! You have just purchased one of the finest pieces of heavy-duty, commercial cooking

equipment on the market today.

You will find that your new equipment, like all Southbend equipment, has been designed and

manufactured to some of the toughest standards in the industry - those of Southbend Corporation.

Each piece of Southbend equipment has been carefully engineered and designs have been

verified through laboratory tests and field installations in some of the more strenuous commercial

cooking applications. With proper care and field maintenance, you will experience years of reliable,

trouble-free operation from your Southbend equipment. To get the best results, it’s important that

you read this manual carefully.

TABLE OF CONTENTS:

SECTION ONE - INSTALLATION

Specifications .._._...................................................... 1

Installation . . . . . . . . . . .._.............._......___................._...._. 2

SECTION TWO - USER’S GUIDE

Warranty................................................-.............. 1

Operation _......._.......__........................................~... 2

Maintenance . . __...._ . . . . . . . . . . . . . . . ..__ . . _ . .._ ._ . . . . . . . . . . . . . . . . . . . . . . . 3

SECTION THREE - SERVICE

Adjustments _...,.........................-............_................ 1

Service................................................................. 2

Trouble Shooting ._._.. Se . . . . . . . . . .._..._................................ 3

SECTION FOUR - PARTS

PartsList . . . .._......................_......_....................._.... 1

Southbend In&a-Red Broilers are unique in design. They incorporate our exclusive Schwank ceramic tile burners,

which generate i&a-red rays that provide better quality products in about one-half the usual broiling time,

with less gas input than ordinary broilers. Very little energy is wasted in heating secondary surfaces, as is

necessary in conventional-type broilers.

Since the surface of these tiles become red hot in less than one-half minute, the unit is ready to start broiling

with a very short preheat time, thereby saving

These glowing surfaces emit intense infrared rays, which are transmitted directly onto the product, thereby

yielding better tasting broiled food in less time.

Use of 100% clean primary air, which is constantly conveyed to these burners, insures efficient combustion and

maintains full production capacity and maximum recovery, even in the most severe conditions of

and smoke atmospheres, which

The Southbend I&a-Red Broilers provide such speed and recovery that broiling techniques may require some

modification in order to take full advantage of its productive capabilities.

CAUTION:

POSTIN PROMINENT

IN THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION

SHALL BE OBTAINED FROM LOCAL GAS SUPPLIER.

are

created during any broiling process.

time,

labor and energy.

LOCATION

grease

IlVSTRUCTIONS TO BE FOLLOWED

vapors

NOT INTENDED FOR HOUSEHOLD USE. FOR COMMERCIAL USE ONLY.

Retain this manual for future reference.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

KEEP AREA AROUND APPLIANCES FREE AND CLEAR FROM

COMBUSTIBLES.

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN EQUIP-

MENT AT THE MAIN SHUTOFF VALVE AND CONTACT THE LOCAL

GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

m southbend

A mDDlE$Y

CouPAnY

1100 Old Honeycutt Road

Fuquay-Varina. NC 27526

(919) 552-9161

FAX (919) 552-9798

(600) 346-2666

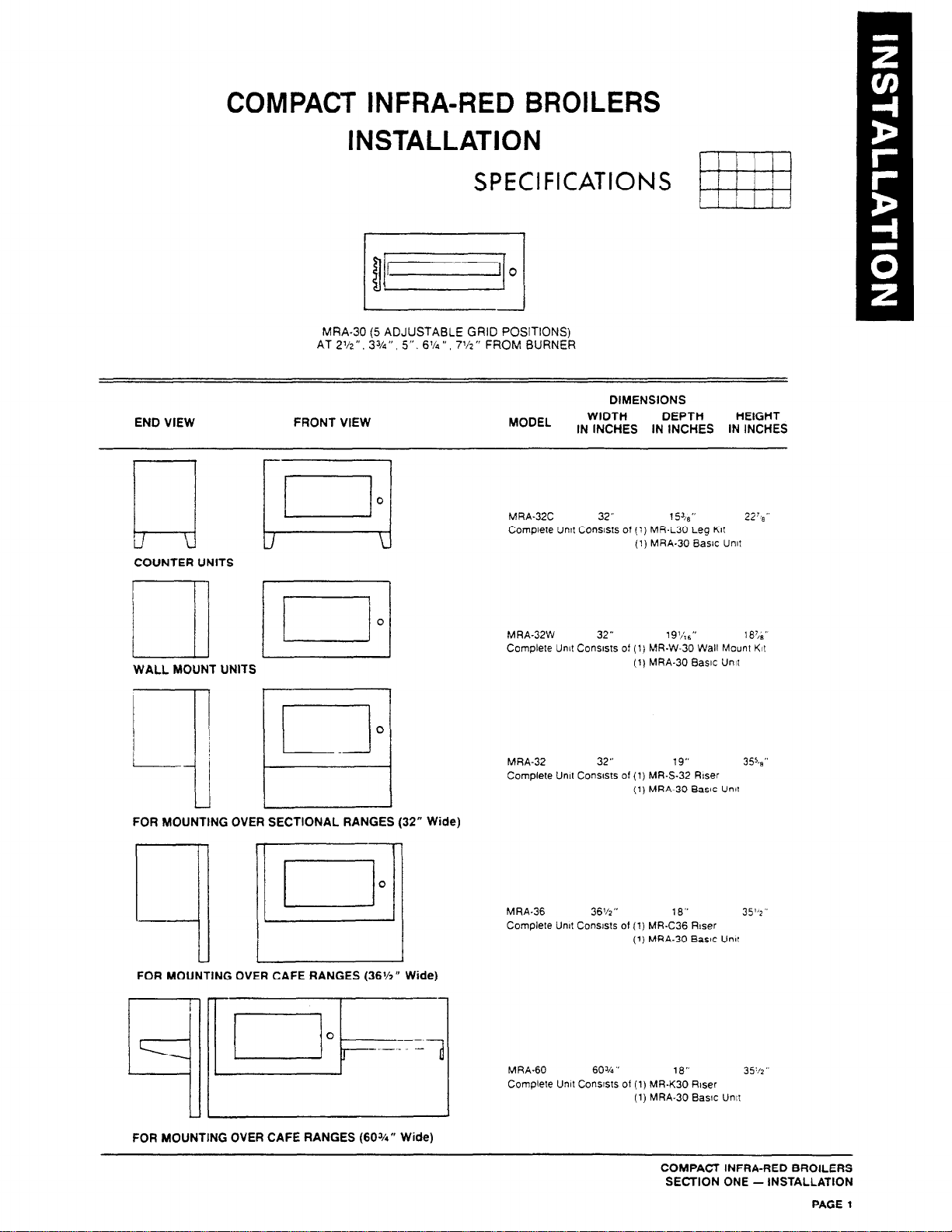

END VIEW

MR:SiOagasic

COUNTER UNITS

COMPACT INFRA-RED BROILERS

INSTALLATION

SPECIFICATIONS

MRA-30 (5 ADJUSTABLE GRID POSITIONS)

AT 2’/2”. 3%“. 5”. 6%“. 7%” FROM BURNER

DIMENSIONS

FRONT VIEW

MODEL

MRA-32C

Complete untt Consists of (1) MR.L30 Leg Kit

WIDTH

IN INCHES IN INCHES IN INCHES

32” (1)

DEPTH

HEIGHT

““llZi’s”

WALL MOUNT UNITS

FOR MOUNTING OVER SECTIONAL RANGES (32” Wide)

T1: c

FOR MOUNTING OVER CAFE RANGES (36%” Wide)

u I

-.-._

I

--a

MRA-32W

Complete Unit Consists of (1) MR.W-30 Wall Mount Kit

MRA-32 32”

Complete Umt Consists of (1) MR-S-32 Riser

MRA.36

Complete Untt Consists of (1) MR.C36 Riser

MRA.60 603% ”

Complete Unit Conststs of (1) MR-K30 her

32 ”

36’h ‘I 16”

1 9% 6"

(1)

MRA-30 Basic Untr

19”

(1) MRA-30 Basic Umt

(1) MRA-30 Basic Umr

i a-'

(1) MRA-30 Bas!c Unit

18Si'

355.8“

35’,2 ”

35V2”

FOR MOUNTING OVER CAFE RANGES (60%” Wide)

COMPACT INFRA-RED BROILERS

SECTION ONE - INSTALLATION

PAGE 1

1

INSTALLATION

THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL OR

WARRANTY WILL BE VOIDED.

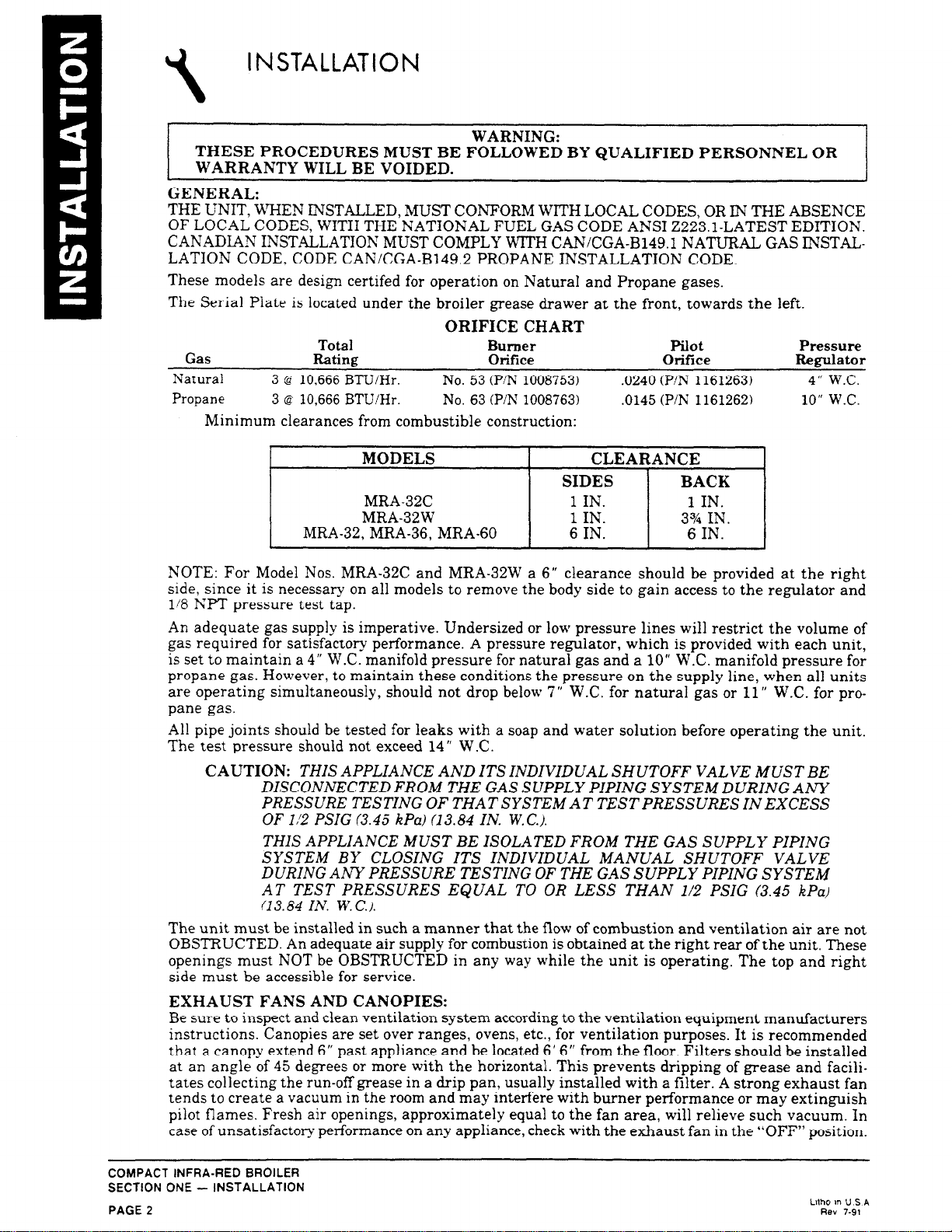

GENERAL:

THE UNIT, WHEN INSTALLED, MUST CONFORM WITH LOCAL CODES, OR IN THE ABSENCE

OF LOCAL CODES, WITH THE NATIONAL FUEL GAS CODE ANSI Z223.1-LATEST EDITION.

CANADIAN INSTALLATION MUST COMPLY WITH CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE, CODE CAN/CGA-B149.2 PROPANE INSTALLATION CODE.

These models are design certifed for operation on Natural and Propane gases.

The Serial Plate is located under the broiler grease drawer at the front, towards the left.

Gas

Natural

Propane

Minimum clearances from combustible construction:

NOTE: For Model Nos. MRA-32C and MRA-32W a 6” clearance should be provided at the right

side, since it is necessary on all models to remove the body side to gain access to the regulator and

118 NPT pressure test tap.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of

gas required for satisfactory performance. A pressure regulator, which is provided with each unit,

is set to maintain a 4” W.C. manifold pressure for natural gas and a 10” W.C. manifold pressure for

propane gas. However, to maintain these conditions the pressure on the supply line, when all units

are operating simultaneously, should not drop below 7” W.C. for natural gas or 11” W.C. for propane gas.

All pipe joints should be tested for leaks with a soap and water solution before operating the unit.

The test pressure should not exceed 14 ’ W .C.

CAUTION:

Total

Rating

3 @ 10,666 BTU/Hi-. No. 53 (P/N 1008753) .0240 (P/N 1161263)

3 @ 10,666 BTU/Hi-. No. 63 (P/N 1008763) .0145 (P/N 1161262)

MODELS

MRA-32C 1 IN.

MRA-32W 1 IN. 3% IN.

MRA-32, MRA-36, MRA-60 6 IN.

THIS APPLIANCE AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE

WARNING:

ORIFICE CHART

Burner

Orifice

!

SIDES BACK

Pilot Pressure

Orifice Regulator

4” W.C.

10” W.C.

CLEARANCE

1 IN.

6 IN.

DISCONNECTED FROM THE GAS SUPPLY PIPING SYSTEM DURING ANY

PRESSURE TESTING OF THAT SYSTEM AT TEST PRESSURES IN EXCESS

OF l/2 PSIG (3.45 kPd (13.84 IN. W.C.).

THIS APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING

SYSTEM BY CLOSING ITS INDIVIDUAL MANUAL SHUTOFF VALVE

DURING ANY PRESSURE TESTING OF THE GAS SUPPLY PIPING SYSTEM

AT TEST PRESSURES EQUAL TO OR LESS THAN 112 PSIG (3.45 kPa)

(13.84 IN. W. C./.

The unit must be installed in such a manner that the flow of combustion and ventilation air are not

OBSTRUCTED. An adequate air supply for combustion is obtained at the right rear of the unit. These

openings must NOT be OBSTRUCTED in any way while the unit is operating. The top and right

side must be accessible for service.

EXHAUST FANS AND CANOPIES:

Be sure to inspect and clean ventilation system according to the ventilation equipment manufacturers

instructions. Canopies are set over ranges, ovens, etc., for ventilation purposes. It is recommended

that a canopy extend 6” past appliance and be located 6’ 6” from the floor. Filters should be installed

at an angle of 45 degrees or more with the horizontal. This prevents dripping of grease and facilitates collecting the run-off grease in a drip pan, usually installed with a filter. A strong exhaust fan

tends to create a vacuum in the room and may interfere with burner performance or may extinguish

pilot flames. Fresh air openings, approximately equal to the fan area, will relieve such vacuum. In

case of unsatisfactory performance on any appliance, check with the exhaust fan in the “OFF” position.

COMPACT INFRA-RED BROILER

SECTION ONE - INSTALLATION

PAGE 2

LIthO m U S A

Rev 7.91

INSTALLATION

t

WARNING:

FOR AN APPLIANCE EQUIPPED WITH CASTERS, THE INSTALLATION SHALL

BE MADE WITH A CONNECTOR THAT COMPLIES WITH THE STANDARD FOR

CONNECTORS FOR MOVABLE GAS APPLIANCES, ANSI Z21.69ANSI 221.691987,

AND ADDENDA, Z21.69a-1963, AND A QUICK-DISCONNECT DEVICE THAT COMPLIES WITH THE STANDARD FOR QUICK-DISCONNECT DEVICES FOR USE

WITH GAS FUEL, ANSI 221.41-1978, AND ADDENDA, Z21.41a-1981 AND

Z21.41b-1983. ADEQUATE MEANS MUST BE PROVIDED TO LIMIT THE MOVEMENT OF THE APPLIANCE WITHOUT DEPENDING ON THE CONNECTOR AND

THE QUICK-DISCONNECT DEVICE OR ITS ASSOCIATED PIPING TO LIMIT THE

APPLIANCE MOVEMENT.

,

IF DISCONNECTION OF THIS RESTRAINT IS NECESSARY TO REMOVE THE

APPLIANCE FOR CLEANING, ETC., RECONNECT IT WHEN THE APPLIANCE

IS MOVED TO ITS ORIGINALLY INSTALLED POSITION.

GAS CONNECTION:

1. All MRA- Series broilers are factory equipped with a pressure regulator which is set for the type

of gas denoted on the serial plate.

2. If applicable, the vent line from the gas appliance pressure regulator shall be installed to the

outdoors in accordance with local codes or, in the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1-Latest Edition.

3. Gas supply connection is made on the right side. Remove the right body side for complete

accessibility to connection.

4. Gas supply connection can be made:

a. Rear:

Connection can be made by going directly into the pressure regulator (female connection

3/S NET).

b. Top:

Connection can be made by:

1. Removing knockout hole in top partition.

2. Screwing elbow into inlet end of regulator.

3. Cut access hole through expanded metal top.

4. Screwing supply pipe into elbow.

c. Bottom:

Connection can be made by:

1. Removing knockout hole in bottom.

2. Removing knockout hole in bottom cover (not supplied in counter units).

3. Screwing elbow into inlet end of pressure regulator.

4. Screwing supply pipe into elbow.

CAUTION:

BE SURE TO HOLD PRESSURE REGULATOR WITH A WRENCH WHEN

TIGHTENING SUPPLY PIPE TO AVOID DAMAGE TO REGULATOR,

VALVE,

AND OTHER COMPONENTS.

5. The unit should be connected only to the type of gas for which it is equipped. Check type of gas

on rating plate. On all threaded connections, the pipe compound must be approved for use with

natural and propane gas.

6. Make sure burner valve is in the “OFF” position before connecting gas to unit. Test pipe connections thoroughly for gas leaks. Use soapy water only.

7. Turn on burners and bleed supply line, then turn burners off.

8. Light pilots and adjust so that flame comes out the ends of the pilot flame carriers and extends

to the burner tile surface. PILOTS ARE ADJUSTABLE THROUGH THE HOLE ABOVE THE

VALVE KNOB.

NOTE: The six burner shipping screws located at each end of the three burners must be removed

after installation.

COMPACT INFRARED BROILER

SECTION ONE - INSTALLATION

PAGE 3

INSTALLATION

\

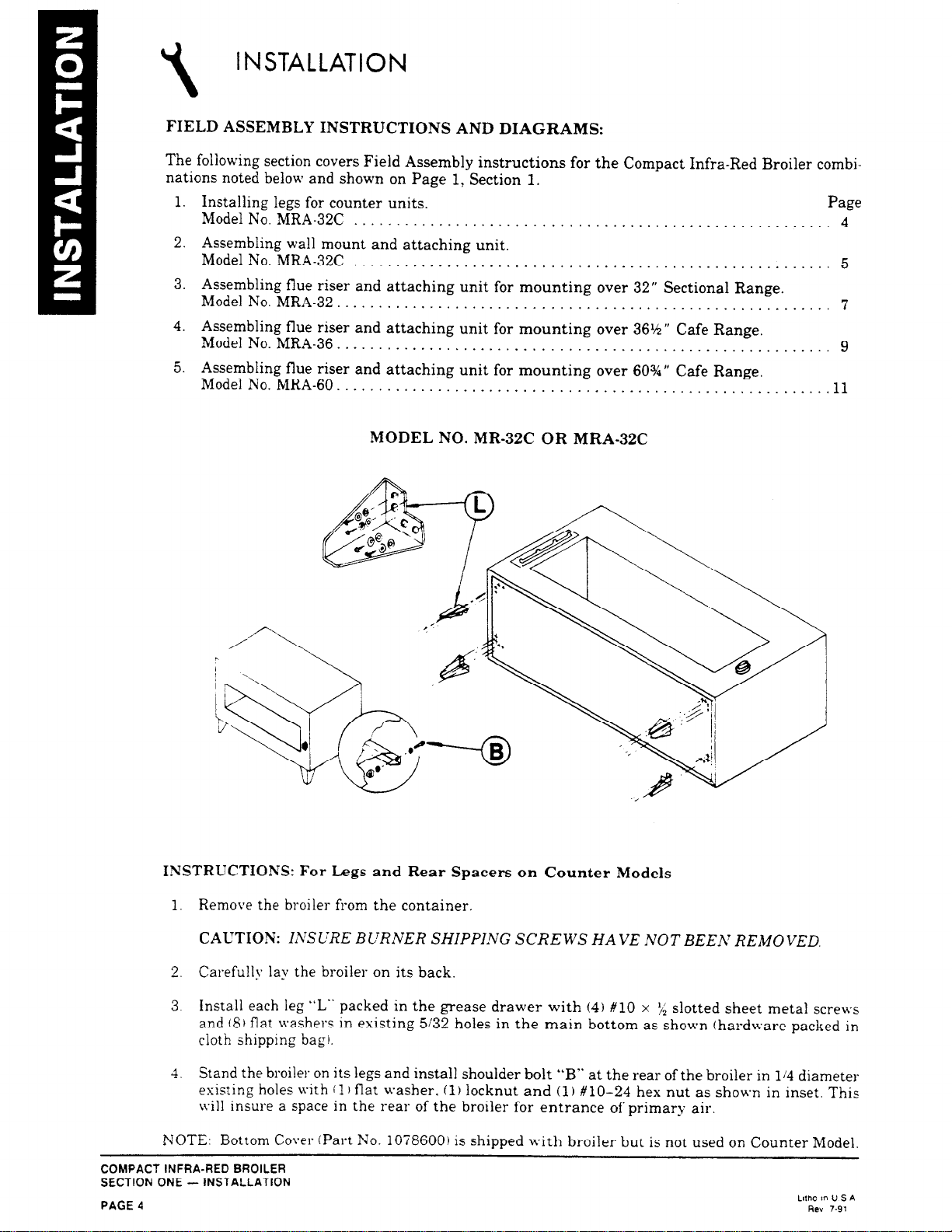

FIELD ASSEMBLY INSTRUCTIONS AND DIAGRAMS:

The following section covers Field Assembly instructions for the Compact Infra-Red Broiler combi-

nations noted below and shown on Page 1, Section 1.

1. Installing legs for counter units.

ModelNo.MRA-32C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Assembling wall mount and attaching unit.

ModelNo.MRA-32C . . . . . . . . . . . . . . .._....................................... 5

3. Assembling flue riser and attaching unit for mounting over 32” Sectional Range.

ModelNo.MRA-32............................,............................. 7

4. Assembling flue riser and attaching unit for mounting over 36ih” Cafe Range.

ModelNo.MRA-36.......................................................... 9

5. Assembling flue riser and attaching unit for mounting over 60%” Cafe Range.

Model No. MRA-60. . . . . . . . . . . . . . . _ . _ . . , . . . _ _ . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

MODEL NO. MR-3X OR MRA-32C

Page

INSTRUCTIONS: For Legs and Rear Spacers on Counter Models

1. Remove the broiler from the container.

CAUTION: INSURE BClRNER SHIPPING SCREWS HAVE NOT BEEN REMOVED.

2. Carefully lay the broiler on its back

3. Install each leg “L” packed in the grease drawer with (4) #lO x

and (81 flat washers in existing 5132 holes in the main bottom as shown (hardware packed in

cloth shipping bag’.

4. Stand the broiler on its legs and install shoulder bolt “B” at the rear of the broiler in 114 diameter

existing holes with ‘1 I flat washer. (1) locknut and (1) #lo-24 hex nut as shown in inset. This

\vill insure a space in the rear of the broiler for entrance of primary air.

NOTE: Bottom Cover (Part No. 1078600) is shipped xvith broiler but is not used on Counter Model.

COMPACT INFRA-RED BROILER

SECTION ONE - INSTALLATION

PAGE 4

‘/; slotted sheet metal screws

INSTALLATION

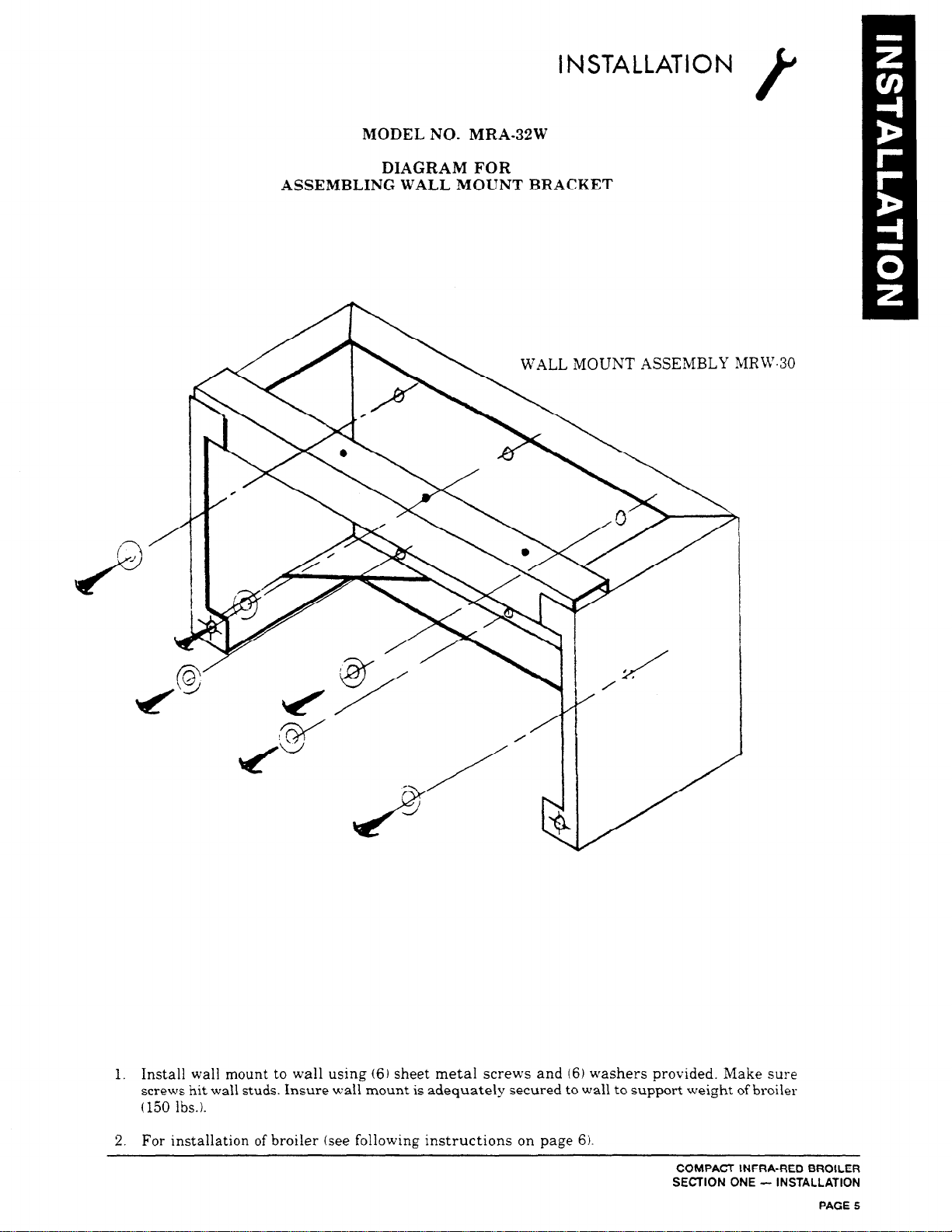

MODEL NO. MRA-32W

DIAGRAM FOR

ASSEMBLING WALL MOUNT BRACKET

WALL MOUNT ASSEMBLY MRW-30

t

1. Install wall mount to wall using (6) sheet metal screws and (6) washers provided. Make sure

screws hit wall studs. Insure wall mount is adequately secured to wall to support weight of broiler

(150

lbs.).

2. For installation of broiler (see following instructions on page 6).

COMPACT INFRA-RED BROILER

SECTION ONE

- INSTALLATION

PAGE 5

INSTALLATION

\

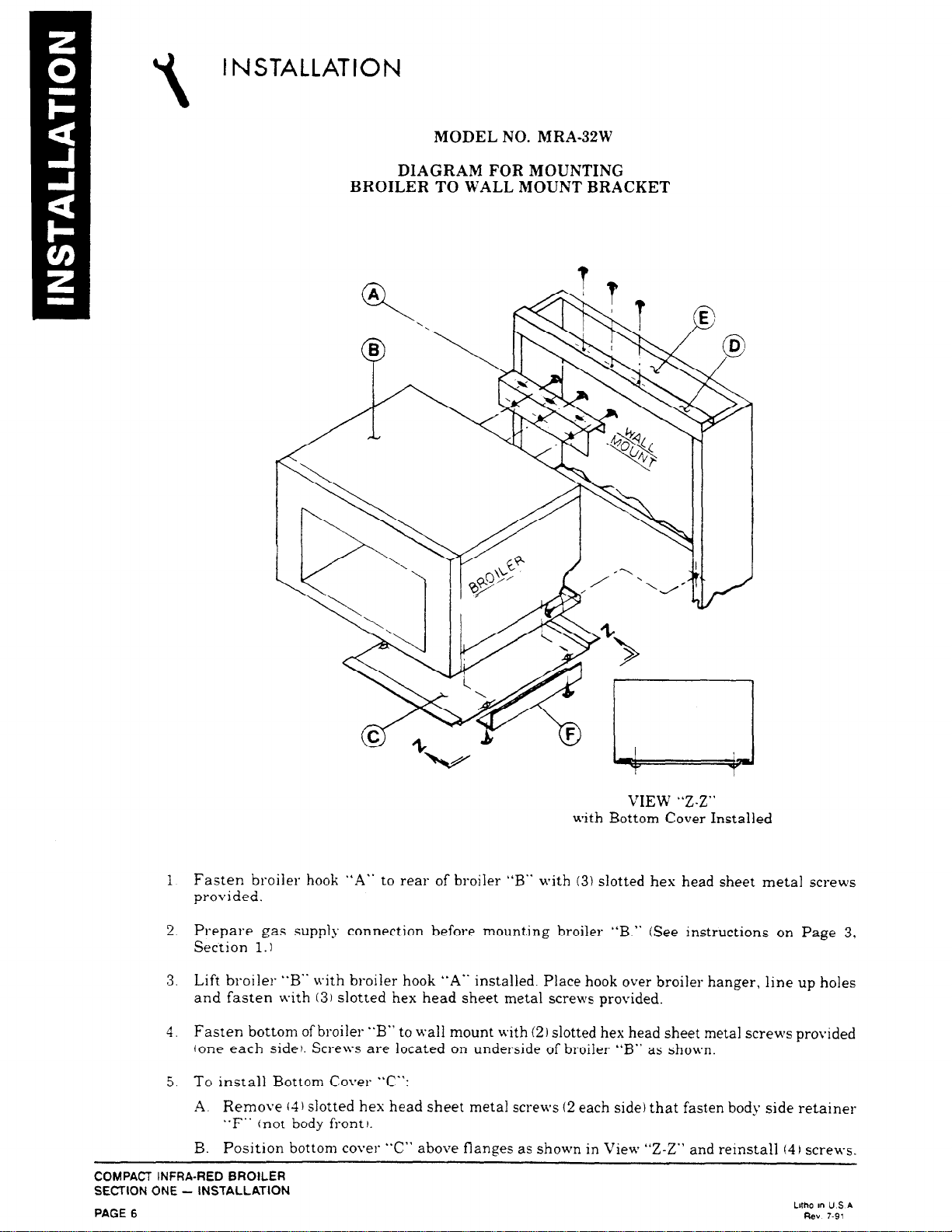

MODEL NO. MRA-32W

DIAGRAM FOR MOUNTING

BROILER TO WALL MOUNT BRACKET

1 Fasten broiler hook “A” to rear of broiler “B” with (3) slotted hex head sheet metal screws

provided.

2. Prepare gas supply connection before mounting broiler

Section 1.)

3. Lift broiler “B” with broiler hook “A” installed. Place hook over broiler hanger, line up holes

and fasten with (31 slotted hex head sheet metal screws provided.

4. Fasten bottom of broiler “B” to wall mount with (2) slotted hex head sheet metal screws provided

lone each side). Screws are located on underside of broiler “B” as shown.

5. To install Bottom Cover “C”:

Remove (3 I slotted hex head sheet metal screws (2 each side) that fasten body side retainer

A.

‘.F” (not body front,.

Position bottom cover “C” above flanges as shown in View “Z-Z” and reinstall (4) screws.

B.

COMPACT INFRA-RED BROILER

SECTION ONE - INSTALLATION

PAGE 6

VIEW “Z-Z”

with Bottom Cover Installed

“B.” (See instructions on Page 3,

LllhO I” u s A

Rev 7.91

Loading...

Loading...