Page 1

southbend

A MIDDLEBY COMPANY

OWNER'S MANUAL

INSTALLATION

USER'S GUIDE

ELECTRIC TRI-LEG FULL JACKET KETTLE

KELS-20F, KELS-30F, KELS-40F MODELS:

KELS-60F, KELS-80, KELS-100

ELECTRIC PEDESTAL KETTLE

KEPS-20, KEPS-30, KEPS-40 MODELS:

KEPS-60, KEPS-80, KEPS-100

These instructions should be read thoroughly before attempting installation. Set up, installation and

Performance Check should be performed by a qualified service technician. The Manufacturer.

Southbend (1100 Old Honeycutt Rd., Fuquay-Varina, North Carolina 27526), informs you that

unless the installation instructions for the above described Southbend product are followed and

performed by a qualified service technician, (a person experienced in and knowledgeable

concerning the installation of commercial gas and/or electrical cooking equipment) then the terms

and conditions of the Manufacturer's Limited Warranty will be rendered void and no warranty of any

kind shall apply.

If the equipment has been changed, altered, modified or repaired by other than a qualified service

technician during or after the 12-month limited warranty period, then the manufacturer shall not be

liable for any incidental or consequential damages to any person or to any property which may result

from the use of the equipment thereafter. Some States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion thereto may not apply to

you.

In the event you have any question concerning the installation, use. care. or service of the product,

write Customer Service Department, Southbend Corporation. 1100 Old Honeycutt Rd., FuquayVarina. North Carolina 27526.

Page 2

INSTALLATION AND OPERATION

MODELS

EP-100

1100

Old Honeycutt Road

Fuquay

-

Varina, NC

27526

(

919) 552

-

9161 FAX (919) 552

-

9798 (800) 348

-

2558

MANUAL

SELF-GENERATING STEAM JACKETED KETTLES

MODELS

EL-20

EL-30

EL-40

EL-60

EL-80

EL-100

EP-20

EP-30

EP-40

EP-60

EP-80

southbend

A MIDDLEBY COMPANY

Page 3

INSTALLATION AND OPERATION

It is recommended that this manual be read thoroughly and that all instructions be followed carefully. This

manual should be retained for future reference.

DO NOT ATTEMPT TO OPERATE THIS UNIT IN THE EVENT OF A POWER FAILURE

ADEQUATE CLEARANCES MUST BE MAINTAINED FOR SAFE AND PROPER OPERATION

I N D E X

DESCRIPTION PAGE

INDEX 1

INSTALLATION AND SERVICE CONNECTIONS 2

INSTALLATION INSTRUCTIONS 4

INTRODUCTION 5

OPERATION INSTRUCTIONS 7

CLEANING INSTRUCTION 8

TROUBLESHOOTING 9

Page 4

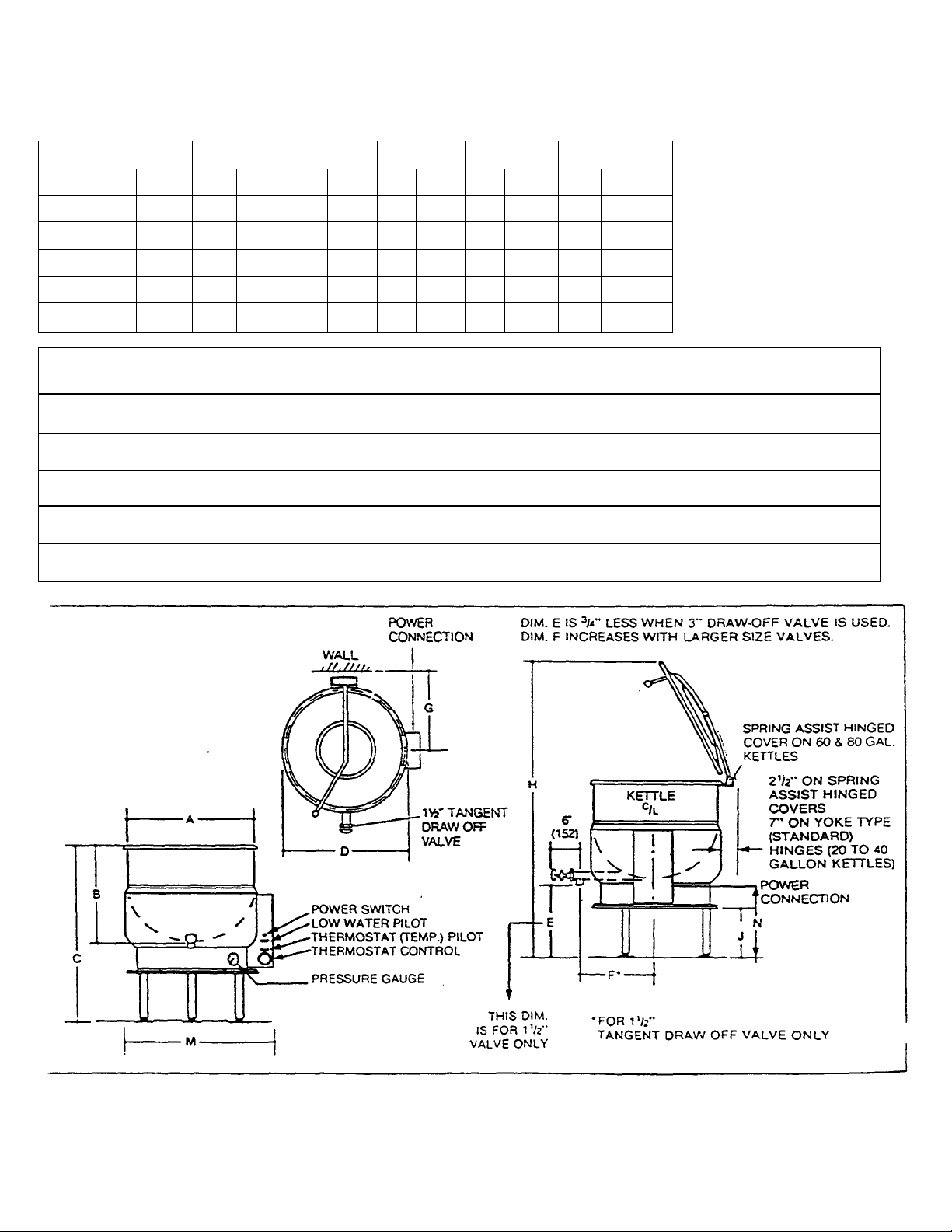

INSTALLATION AND SERVICE CONNECTIONS

Model 208V 230V 240V 380V 415V 480V

KW AMP KW AMP KW AMP KW AMP KW AMP KW AMP

EL-20 12 33.4 12 30.1 12 28.9 12 18.3 12 16.7 12 14.5

EL-30 15 41.7 15 37.7 15 36.1 15 22.8 15 20.8 15 18

EL-40 18 50 18 45.2 18 43.4 18 27.4 18 25 18 21.7

EL-60 18 50 18 45.2 18 43.4 18 27.4 18 25 18 21.7

EL-80 18 50 18 45.2 18 43.4 18 27.4 18 25 18 21.7

Model Capacity A B C D E F G H J M N

EL-20

EL-30

EL-40

EL-60

EL-80

20 U.S. gal.

76 liter

30 U.S. gal.

174 lifer

40 U.S. gal.

752 liter

60 U.S. gal.

227 liter

80 U.S. gal.

303 liter

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

21

533

24

670

26

660

29-1/2

749

33

838

18

457

20

508

22-1/2

572

26

660

28

777

38

965

38

965

38

965

42

1067

45

7743

22-3/4

578

25-3/4

654

27-3/4

705

31-1/4

1029

34-3/4

883

18

457

16

406

13-1/2

343

14

356

15

387

13-3/4

350

15

387

16

406

17

432

18-1/2

470

18-1/2

470

20

508

21

533

19

483

20-1/2

527

60-1/2

7537

63-1/2

7673

65

7657

75

7905

81

2058

14

356

12-1/2

378

9

229

11

250

123/4

324

24-3/4

629

27-3/4

705

29-3/4

756

33-3/4

857

36-3/4

933

21

533

19

483

17

432

171/4

438

18

458

As continued product improvement is a policy of Crown. specifications are subject to change without notice

Page 5

INSTALLATION AND SERVICE CONNECTIONS

227

liter

mm

660

7067

356

349

483

280

303 liter

mm

838

711

7743

387

363

Model 208V 230V 240V 380V 415V 480V

KW AMP KW AMP KW AMP KW AMP KW AMP KW AMP

EP20 12 33.4 12 30.1 12 28.9 12 18.3 12 16.7 12 14.5

EP30 15 41.7 15 37.7 15 36.1 15 22.8 15 20.8 15 18

EP40

EP60 18 50 18 45.2 18 43.4 18 27.4 18 25 18 21.7

EP80 18 50 18 45.2 18 43.4 18 27.4 18 25 18 21.7

Model Capacity

EP-20

EP-30

EP-40

EP-60

EP-80

18 50 18 45.2 18 43.4 18 27.4 18 25 18 21.7

20 U.S. gal.

76 liter

30 U.S. gal.

114 liter

40 U.S. gal.

752 liter

60 U.S. gal.

80 U.S. gal.

inches

mm

inches

mm

inches

mm

inches

inches

A B C D E F G H J M

21

533

24

670

26

660

29-1/2

749

33

18

457

20

508

22-1/2

572

26

28

38

965

38

965

38

965

42

45

22-3/4

578

25-3/4

654

27-3/4

705

31-1/4

7029

42-1/2

7080

18

457

16

406

13-1/2

343

14

15

12

305

12-3/4

324

13-1/4

337

13-3/4

14-1/2

16-1/2

479

16-1/2

479

17

432

19

20-1/2

527

60-1/2

7537

63-1/2

7673

64-1/2

7638

72-1/2

7842

79-1/2

2020

14

356

12-3/8

374

10

254

11

12-5/8

327

17-1/4

438

17-1/4

438

17-1/4

438

17-1/4

438

19-1/4

489

As continued product improvement is a policy of Crown, specifications are subject to change without notice

Page 6

INSTALLATION INSTRUCTIONS

SELF-GENERATING STEAM JACKETED TILTING FLOOR

MOUNTED KETTLES

a) Select a location to provide drainage directly below the tangent Draw-Off. Allow sufficient rear clearance from wall

for kettle cover to lift upright freely and completely without obstructions.

b) Mark hole locations through flanged adjustable feet on ELT models. Remove kettle.

c) On hole locations marked, drill holes and insert expansion shields to accommodate 5/16" size lag bolts.

d) Reposition kettle. On EL models level by making necessary adjustments on flanged feet.

e) Bolt down kettle and seal with Silastic or other equivalent sealing compound. Sealant must be applied not only to

bolt heads but also around flanges or pedestal base making contact with floor surface to fulfill NSF requirements.

Wipe off excess sealant immediately.

g) A Control Box with power supply equivalent to Electrical Rating of kettle should be located conveniently nearby.

h) A water proof electrical connection for power supply to rear of control housing must be provided.

i) Ground kettle to terminal provided inside control housing.

j) Turn power ON and check for proper operation.

Page 7

INTRODUCTION

SELF-GENERATING STEAM JACKETED TILTING FLOOR

MOUNTED KETTLES

DESCRIPTION

All electrically power kettles described and referred to in this Manual are pressure vessels of a double-wall stainless steel

construction forming a sealed jacket (chamber) enveloping the lower two thirds of the kettle bowl surface.

The kettle bowl is the container for the food product which ideally should be a liquid or semi-liquid consistency to achieve

complete contact with the bowl surface and thus fully absorb the heat transmitted through that surface from the

pressurized steam generated in the kettle jacket.

The jacket is intended to function as a self contained sealed chamber with a permanent solution of water and anti-freeze

sufficient not only to immerse and thereby protect replaceable electric heating elements but also provide the steam source

during the steam generating process.

The heating elements are thermostatically dial controlled to provide precise temperatures throughout the range from slow

simmer to rolling boil.

All stationary kettles are intended to be permanently floor mounted on legs with adjustable flanged feet (EL models) or

pedestals (EP Models).

All kettles are equipped with a hinged counterbalanced stainless steel lid covering the kettle bowl opening, a sanitary

stainless steel tangent draw-off valve for the removal of the food product from the kettle bowl, and a safety relief valve

plumbed to the kettle jacket.

CAPACITIES

All models are suffixed with either -20, -30, -40, -60, -80 or 100 to indicate the capacity of that kettle in US gallons. Thus

an EL-40 indicates a two thirds jacketed electrically powered steam kettle mounted on legs with a capacity of 40 gallons

(US). If the letter F is added to the suffix, this then indicates that the kettle is full jacketed as averse to two thirds jacketed.

Thus an EP-30F indicates a full jacketed electrically powered steam kettle mounted on a pedestal with a capacity of 30

gallons.

FUNCTIONING MODE

All electrically powered self steam generating kettles consist of a jacket containing a permanent solution of water and antifreeze sufficient to completely immerse and protect replaceable electric heating elements.

Page 8

To minimize tampering, the Safety Valve is plumbed towards the rear the kettle jacket. Should any component

malfunction and cause the pressure in the jacket to reach the rated pressure of the kettle this protective device will open

automatically and release excessive pressurized steam.

When the Power Switch is turned ON and the Temperature Control (Thermostat) Knob dialed, simultaneously

TEMPERATURE pilot light will glow and contactors will close to allow power to elements and steam generation will

commence and continue until the water contained in the jacket reaches the thermostatic temperature manually preselected, at which point the Temperature (thermostat) Control will de-energize and open the contactors cutting of power

to heating elements and TEMPERATURE pilot light will go off. When the temperature of the water in the jacket drops

slightly, the cycle will repeat itself thus making it possible to maintain any selected precise cooking mode temperature.

The temperature required for the cooking process to function adequately must be greater than the boiling point of the

liquid food product, viz. water. Further, the higher the temperature, the greater the steam pressure attained in the jacket

and consequently the quicker the cooking process. For example, steam pressurized at 30 p.s.i. attains a temperature of

274 degrees fahrenheit.

Since air is an unsuitable media through which heat may be transferred, it has been removed from the kettle jacket during

testing at Crown. The Pressure Gauge should indicate vacuum in the jacket of approximately 20-25 inches HG when the

kettle is cold or has been inoperative for sometime. The kettle jacket is intended to function at all times as a completely

sealed self contained chamber and it is especially advisable not to trip the safety relief valve during inoperative periods

since this will break the vacuum seal and allow air to enter the kettle jacket.

It should be noted that Temperature Controls (thermostats) used on these particular kettles have an ultimate high limit

temperature and this setting will prevent the heating elements from ever generating steam pressure to reach or exceed

the rated working pressure of these kettles. Further should the Temperature Control fail, an unlikely condition, and

consequently the circuit to the heating elements remain energized, the Safety Valve will blow and release steam (i.e.

water) from the self contained sealed kettle jacket and consequently lower the water level in the jacket (but still maintain

elements in an immersed condition), whence the Safety Probe sensing depletion of the water level in the kettle jacket will

not only activate the LOW WATER level indicator pilot light but also signal the Liquid Level Control to switch off power

and de-energize the circuit to the heating elements (preventing element burn outs) until the water level is adequately

replenished.

Page 9

OPERATING INSTRUCTIONS

SELF-GENERATING STEAM JACKETED

TILTING FLOOR MOUNTED KETTLES

OPERATING INSTRUCTIONS

a) Check kettle Pressure Gauge that reading indicates 20-25 vacuum for a cold kettle. If vacuum is insufficient, Air

Venting Instructions must be followed. If equipped with Draw Off Valve ensure Valve is closed.

b) Place Kettle Power Switch in ON position.

Preheat kettle by turning Thermostat Knob to '8' and wait until Temperature pilot light goes off. c)

NOTE: Food products with milk or egg base should be placed into cold kettle and then the cooking

operation begun. Avoid sudden contact of these food products to hot kettle bowl surface

since caking/adhering will occur.

d) Place food product into kettle bowl. Close kettle cover.

e) Adjust Thermostat Knob to temperature cooking mode. Setting of 6-7 will provide simmer and 8-10 low to rolling

boil.

f) Turn both kettle Power Switch and Thermostat Knob OFF when cooking has been completed.

g) Remove food product by ladling out of kettle bowl or by opening Draw-Off Valve and pouring into a suitable

container,

Page 10

CLEANING INSTRUCTIONS

CLEANING PROCEDURE

Your kettle should be cleaned immediately after each use to prevent- food residue from drying and adhering to kettle bowl

and valve surfaces.

a) Turn power supply OFF to kettle.

b) Rinse inside of Kettle thoroughly. Drain kettle by tilting or if equipped with drain valve, open valve and remove all

food particles. Close drain valve.

c) Using nylon brush, clean kettle with a mild detergent and warm water rinse. Never use steel wool or scouring

powder as they will scratch stainless steel. Food adhering excessively to bowl surface may be loosened by

allowing water to soak in a bowl at a low temperature setting.

d) Open the Draw-Off to allow soap and water solution to drain.

e) By hand, turn large hex nut oh Draw-Off Valve counter clockwise until completely disengaged from thread. Grasp

Valve knob and pull out valve steam and disc slowly. Avoid contact of Valve disc with hard surfaces since

damage to disc may occur and result in valve leakage. Wash the valve stem. disc and handles. Insert nylon

brush with detergent into interior of valve body and tangent draw-off tube and brush vigorously.

f) Replace valve stem assembly and engage hex nut fully by hand. Flush kettle with clean warm water and leave

Valve open when kettle is not in use.

g) Wipe down exterior of kettle with clean damp cloth.

WARNING

It is NOT RECOMMENDED to use cleaning agents that are corrosive.

Use of cleaning agents that contain chloride, acids or salts are corrosive and may cause pitting and corrosion when used

over a period of time; this will reduce the life of the appliance.

Should pitting or corrosion occur this is not covered by warranty.

Follow the recommended cleaning instructions. Use a mild detergent, warm water and rinse thoroughly.

NEVER SPRAY WATER INTO ELECTRIC CONTROLS

Page 11

TROUBLESHOOTING

EL-60 and EP

-

60 Models add

250

ozs.

SELF-GENERATING STEAM JACKETED TILTING

FLOOR MOUNTED KETTLE

GENERAL MAINTENANCE

No general maintenance is required other than adhering to the Cleaning Procedure instructions.

LOW WATER LEVEL

Proper water level must be maintained within the jacket for the kettle to operate. Depletion of water may occur from

excessive opening of, or leakage through the safety relief valve.

If water is below required operating level, either initially at start-up or during use, the kettle will automatically shut off,

refuse to operate and the LOW WATER signal light will come on.

In order for the kettle to operate, the following procedure must be followed:

a) Trip the safety relief valve lever to relieve all pressure from the kettle jacket.

b) At exterior rear of kettle jacket remove nut from Air Vent.

c) Insert funnel into Air Vent opening and slowly add the indicated amount of clean water for:

EL-20 and EP-20 Models add 140 ozs.

EL-30 and EP-30 Models add 150 ozs.

EL-40 and EP-40 Models add 220 ozs.

EL-80 and EP-80 Models add 330 ozs.

EL-100 and EP-100 Models add 420 ozs.

d) Replace Air Vent nut.

e) Follow Air Venting Instructions below.

f) Continue normal Operating Procedure of kettle.

Page 12

AIR VENTING INSTRUCTIONS

Periodically check Pressure Gauge when the kettle is cold. Reading should be in (green) VACUUM zone between 20 to

25, otherwise air is present and efficient heating will not occur.

To remove air, set Thermostat Knob at 8 and heat empty kettle until TEMPERATURE pilot light goes off.

Open Air Vent nut one full turn for 10 seconds to exhaust air from kettle jacket. Close Air Vent nut.

Loading...

Loading...