Page 1

Direct Steam Kettle on

48” G

Model description

GMT-6-6

Two 6 gallon kettle on

48’ gas boiler base

aS Boiler BaSe

capacity (per Kettle)

G

allon liter

6 23

OPERATION SHALL BE BY:

Gas operated 15 psi (103 kPa) steam boiler operating on

115 VAC, 1 phase, 50/60 Hz rated at 250,000 BTU.

Natural gas

L.P. gas

STANDARD FEATURES:

Electronic ignition

CSD-1

Automatic blowdown

Split water lines (boiler feed and condensate)

Job Item#

SPECIFICATIONS:

Shall be a Southbend Model GMT-6-6 , consisting of two

direct connected steam, tilting kettles, 6 gallon (23 litre). A

double wall kettle interior shall form a steam jacket around

the lower 2/3 of the kettle. The bottom of the kettle shall be

of hemispherical design for superior heat circulation. The

liner shall be of 316 stainless steel for high acid content

products. The stainless steel mounting legs shall have the

steam supply and condensate within the legs and the right

leg tted with a steam control valve for the kettle. Each

kettle shall be tted with a tilt handle and heat proof knob,

allowing the kettles to be tilted forward 90 for complete

emptying.

The kettles mounted on a cabinet base with full perimeter

angle frame, reinforced counter, hot and cold water faucet

with control valves, 3” (76 mm) deep sinks with drain and

splash guard grates, boiler mountings, gas boiler with

controls, hinged doors with magnetic catches, removable

side panels and 6” (152 mm) stainless steel legs tted with

adjustable bullet feet on front and anged adjustable feet on

rear for securing to the oor, all #4 stainless steel exterior.

Steam manifold canceled within cabinet tted with steam

trap and safety relief valve.

OPTIONAL ITEMS AT EXTRA COST:

208-240 VAC specify voltage

300,000 BTU boiler

California code

Etched gallon markings

Etched liter markings

Correctional package

Stainless steel frame (SSF-42)

OPTIONAL ITEMS AT EXTRA COST:

One piece stainless steel lift off cover

Lift-out stainless steel basket strainer

Graduated measuring strip

Steam take off kit

De-lime kit DPA-1(not available with CSD-1)

Form GMT2-6 Rev 1 (October/2015)

www.yatesgd.com www.yatesgraphicdesign.com

Page 2

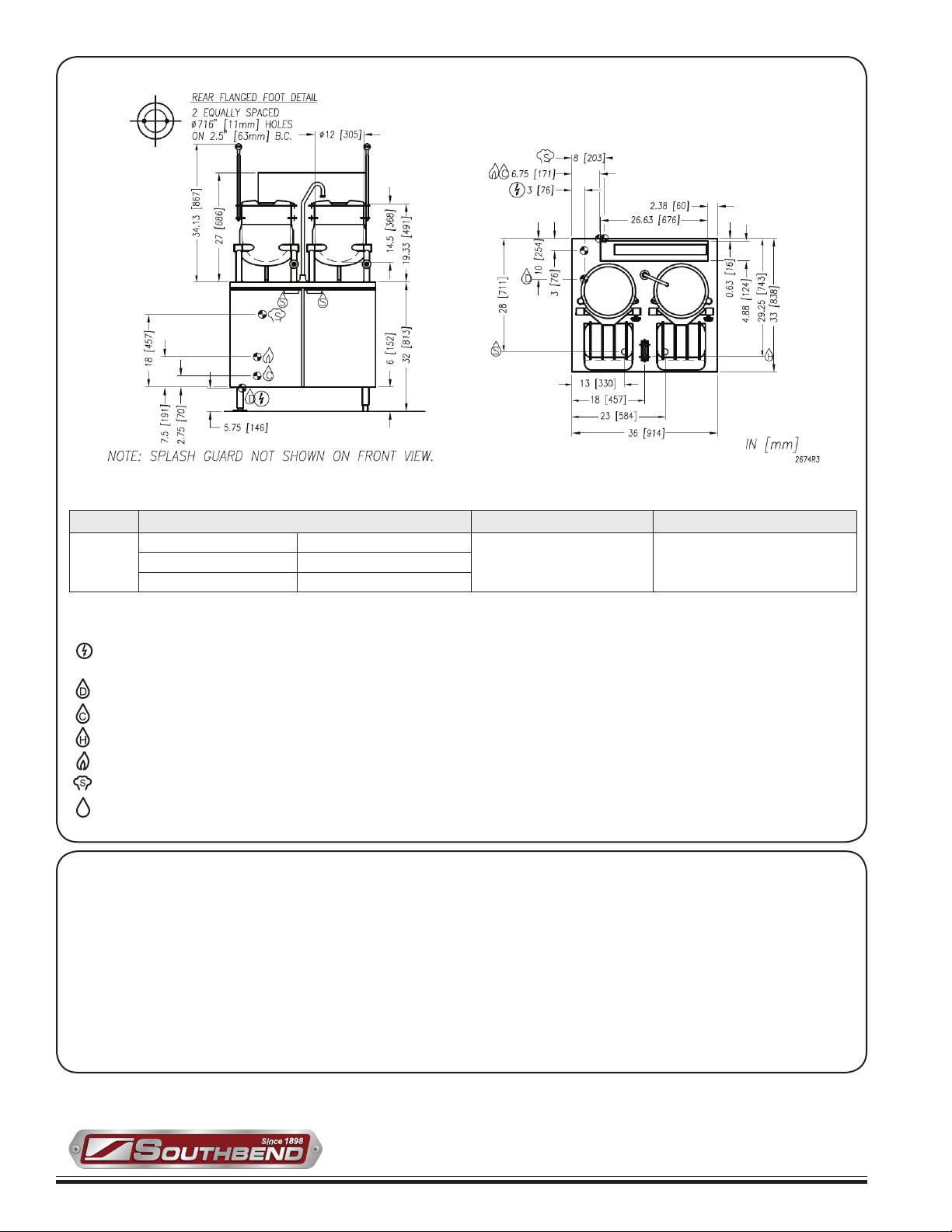

Models:

GMT-6-6

Model Boiler inpUt sHippinG WeiGHt MiniMUM clearance

BTU/HOUR kW/HOUR

GMT-6-6

– ELECTRICAL CONNECTION: 1/2” (13 mm) conduit connection to controls. 120 VAC-60Hz-1PH.

2 Amps per compartment or as specied on data plate.

– DRAIN: 2” (51 mm) IPS piped to open oor drain. No solid connection.

– COLD WATER: 3/8” (10 mm) O.D. tubing at 25-50 PSI (170-345 kPa). (OPTIONAL)

– HOT WATER: 3/8” (10 mm) O.D. tubing at 25-50 PSI (170-345 kPa)

– GAS CONNECTION: 3/4” (19 mm) IPS supply line required.

– STEAM TAKE-OFF CONNECTION: 3/4” (19 mm) IPS optional to operate adjacent equipment.

s

– SINK DRAIN: 1 1/8” O.D. tubing

Water quality is the major factor affecting the performance of your appliance. If you are unsure of water quality, consult a local water

treatment specialist and have the water analyzed. Your water supply must be within these general guidelines:

Total dissolved solids .................... Less than 60 PPM

Total alkalinity ................................ Less than 20 PPM

Silica ...............................................Less than 13 PPM

Chlorine .........................................Less than 1.5 PPM

pH Factor ......................................7.0 - 8.5

250,000 73.3

300,00 87.9

WATER QUALITY STATEMENT

450 lbs. (204 kg)

SIDES 3 (76mm)

BACK 6 (152mm)

Water which fails to meet these standards should be treated by installation of water conditioner.

FAILURE OR MALFUNCTION OF THIS APPLIANCE DUE TO POOR WATER QUALITY IS NOT COVERED UNDER WARRANTY.

CONTACT SOUTHBEND FOR WATER QUALITY SOLUTIONS.

INTENDED FOR COMMERCIAL USE ONLY.

NOT FOR HOUSEHOLD USE

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(919) 762-1000 www.southbendnc.com

Form GMT2-6 Rev 1 (September/2015)

.

Loading...

Loading...