Southbend GFS35, GFS45, GFS65 User Manual

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this

manual for the life of the equi pment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

OPERATOR’S MANUAL

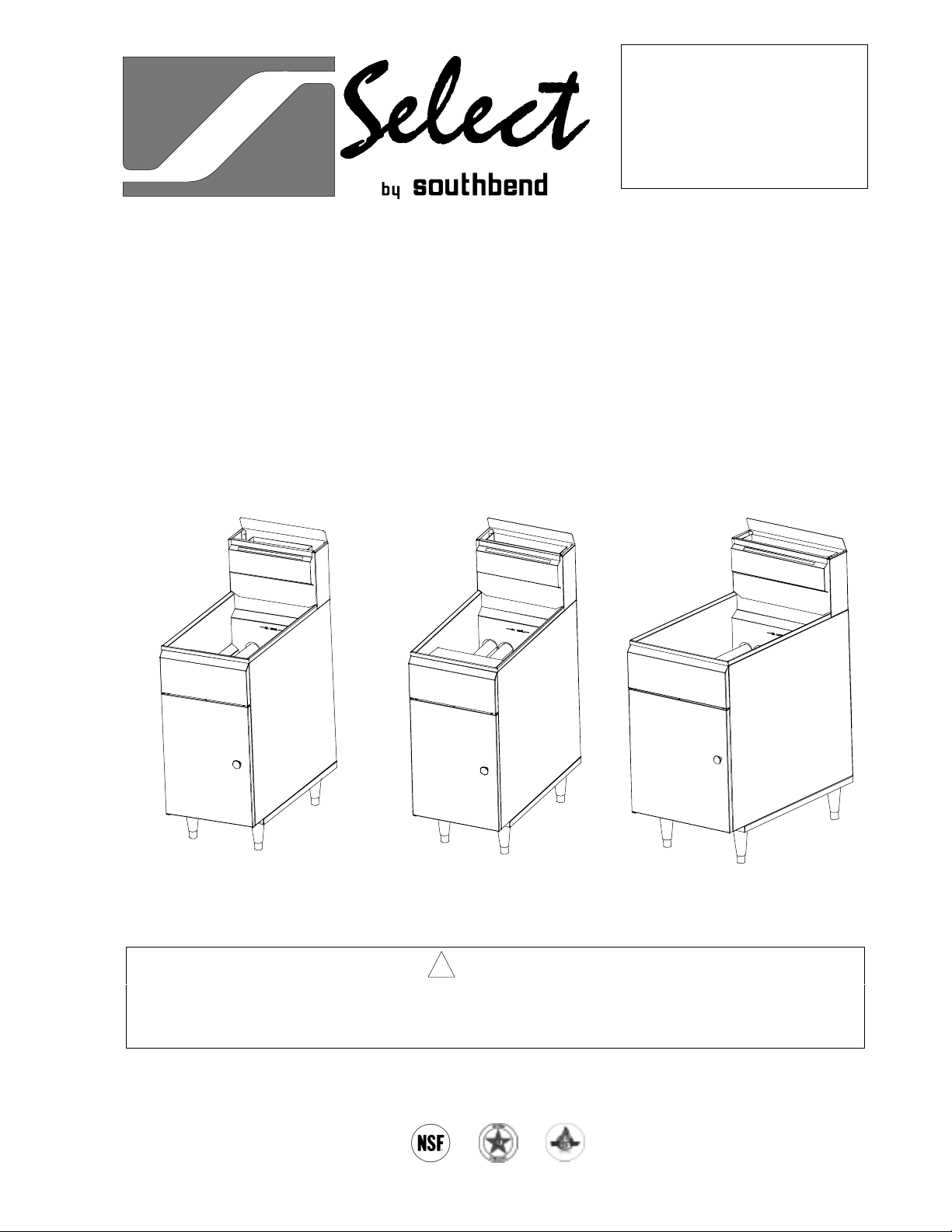

Free-Standing, Floor Model

GFS Series Tube Fryers

Model GFS35 Model GFS45 Model GFS65

! WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(800) 348-2558 or (919) 552-9161 • FAX (800) 348-2558 or (919) 552-9798

MANUAL 1182026 REV 2

$10.00

GFS SERIES TUBE FRYERS

MANUAL SECTION SR

Safety Precautions

PAGE 2OPERATOR’S MANUAL 1182026 REV 2

GFS SERIES TUBE FRYERS TABLE OF CONTENTS

OPERATOR’S MANUAL 1182026 REV 2PAGE 3

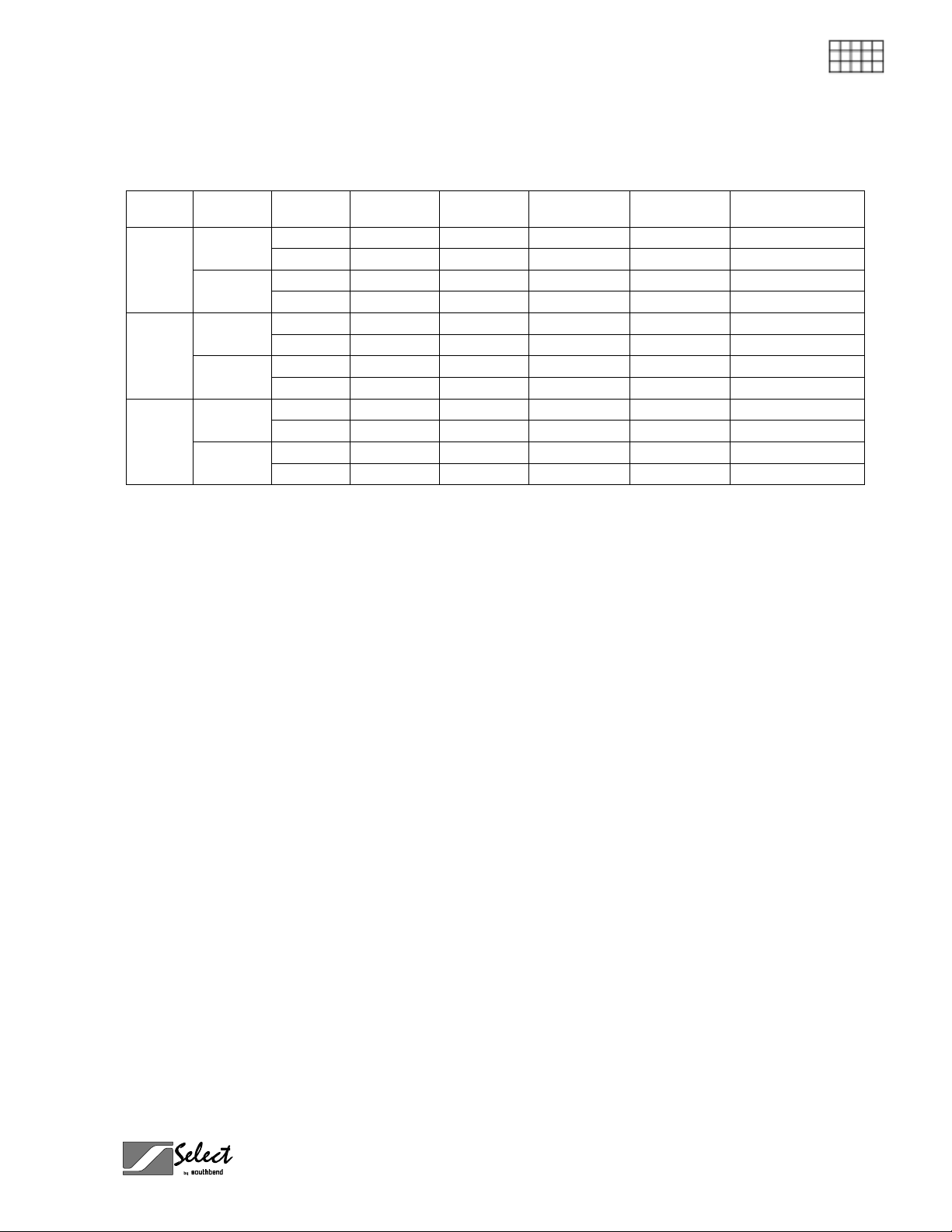

SPECIFICATIONS GFS SERIES TUBE FRYERS

SPECIFICATIONS

SPECIFICATIONS

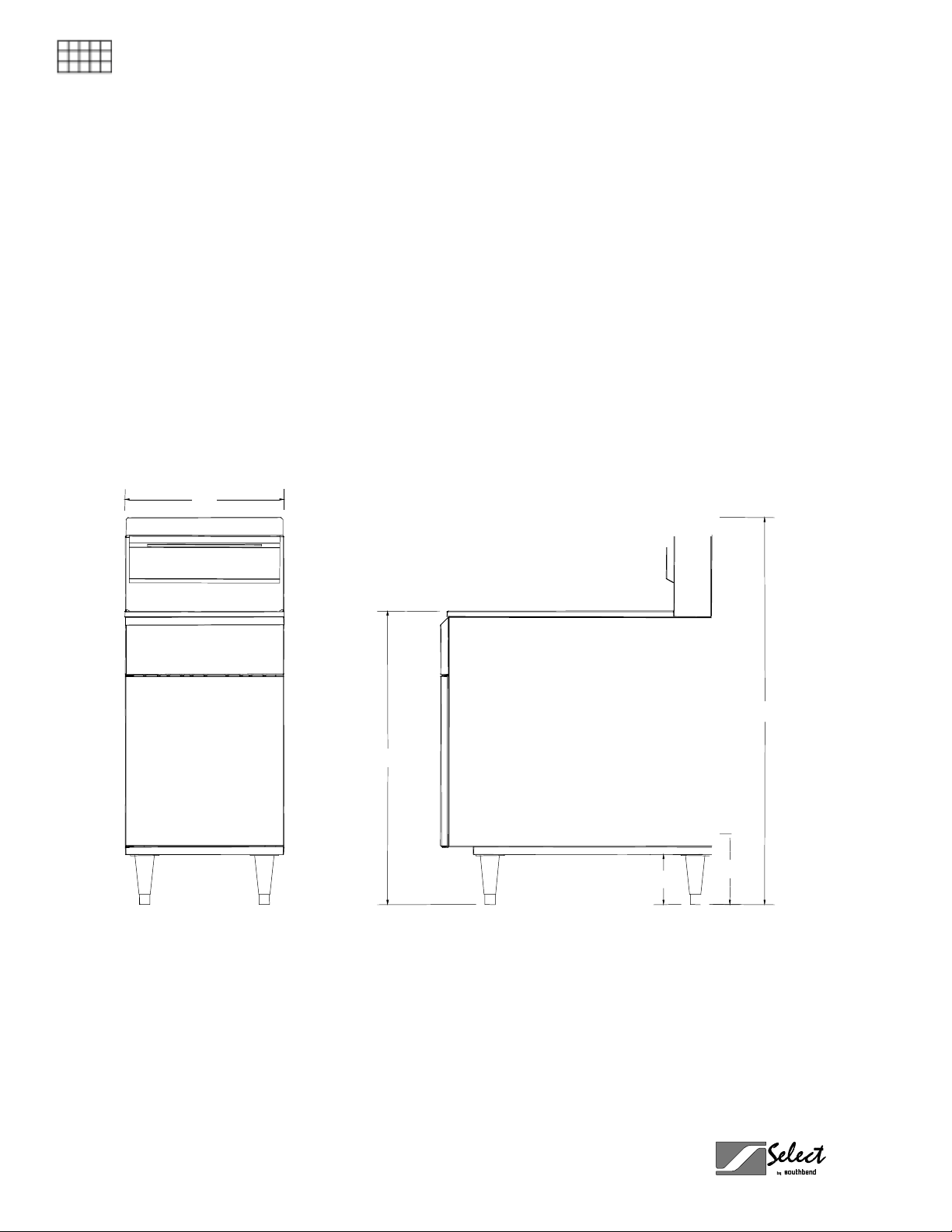

Dimensions

PAGE 4OPERATOR’S MANUAL 1182026 REV 2

GFS SERIES TUBE FRYERS SPECIFICATIONS

Gas Supply Requirements and Burner Information

Supply pressure should be greater t han 7" W.C. for natural gas or greater than 11" W .C. for propane. One

3/4" NPT male connector located on back (see illustrations on pages 4 and 7).

SPECIFICATIONS

Model Burners Gas Type

Main

GFS35

Pilot

Main

GFS45

Pilot

Main

GFS65

Pilot

Natural 4" W.C. 3 35,000 105,000 #36 - 0.1065" dia.

Propane 10" W.C. 3 30,000 90,000 #52 - 0.0635" dia.

Natural 4" W.C. 1 900 900 #77 - 0.0180" dia.

Propane 10" W.C. 1 900 900 0.0110" dia.

Natural 4" W.C. 4 35,000 140,000 #36 - 0.1065" dia.

Propane 10" W.C. 4 30,000 120,000 #52 - 0.0635" dia.

Natural 4" W.C. 1 900 900 #77 - 0.0180" dia.

Propane 10" W.C. 1 900 900 0.0110" dia.

Natural 4" W.C. 5 35,000 175,000 #36 - 0.1065" dia.

Propane 10" W.C. 5 30,000 150,000 #52 - 0.0635" dia.

Natural 4" W.C. 1 900 900 #77 - 0.0180" dia.

Propane 10" W.C. 1 900 900 0.0110" dia.

Manifold

Pressure

Electrical Requirement

No external electric power is required.

Clearances

See page 9.

Number

per Unit

Rate Each

BTUs/Hour

Total Rate

BTUs/Hour

Orifice Size

OPERATOR’S MANUAL 1182026 REV 2PAGE 5

INSTALLATION GFS SERIES TUBE FRYERS

INSTALLATION

Installation mu st conform with local codes, or in the absence of local codes , with the National Fue l

Gas Code, ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane

Installation Code, CAN/CGA-B149.2, as applicable.

INSTALLATION

These installation procedures must be followed by qualified personnel or warranty will be void.

Local codes regarding install ation var y greatly from one area to an other. T he National F ire Protec tion

Association, Inc. states in its NFPA 96 latest edition that local codes are the “authority having

jurisdiction” when it comes to installation requirements for equipment.

NOTICE

NOTICE

Step 1: Unpack

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers shou ld be examined for dam age before and during unlo ading. The freight car rier has

assumed responsibility for safe transit and delivery. If damaged equipment is received, either

apparent or concealed, a claim must be made with the delivering carrier.

Apparent damage or l oss m u st be noted on the freight b ill at the t im e of deliver y. T he f reight bi ll m ust

then be signed by the c arrier representative (Dr iver). If the bill is not signed, the carrier ma y refuse

the claim. The carrier can supply the necessary forms.

A request for insp ection must be m ade to the carrier within 15 da ys if there is concea led damage or

loss that is not apparent until after the equipment is uncrated. The carrier should arrange an

inspection. Be certain to hold all contents plus all packing material.

1. Uncrate carefully. Report any hidden damage to the freight carrier IMMEDIATELY.

2. Do not remove any tags or labels until unit is installed and working properly.

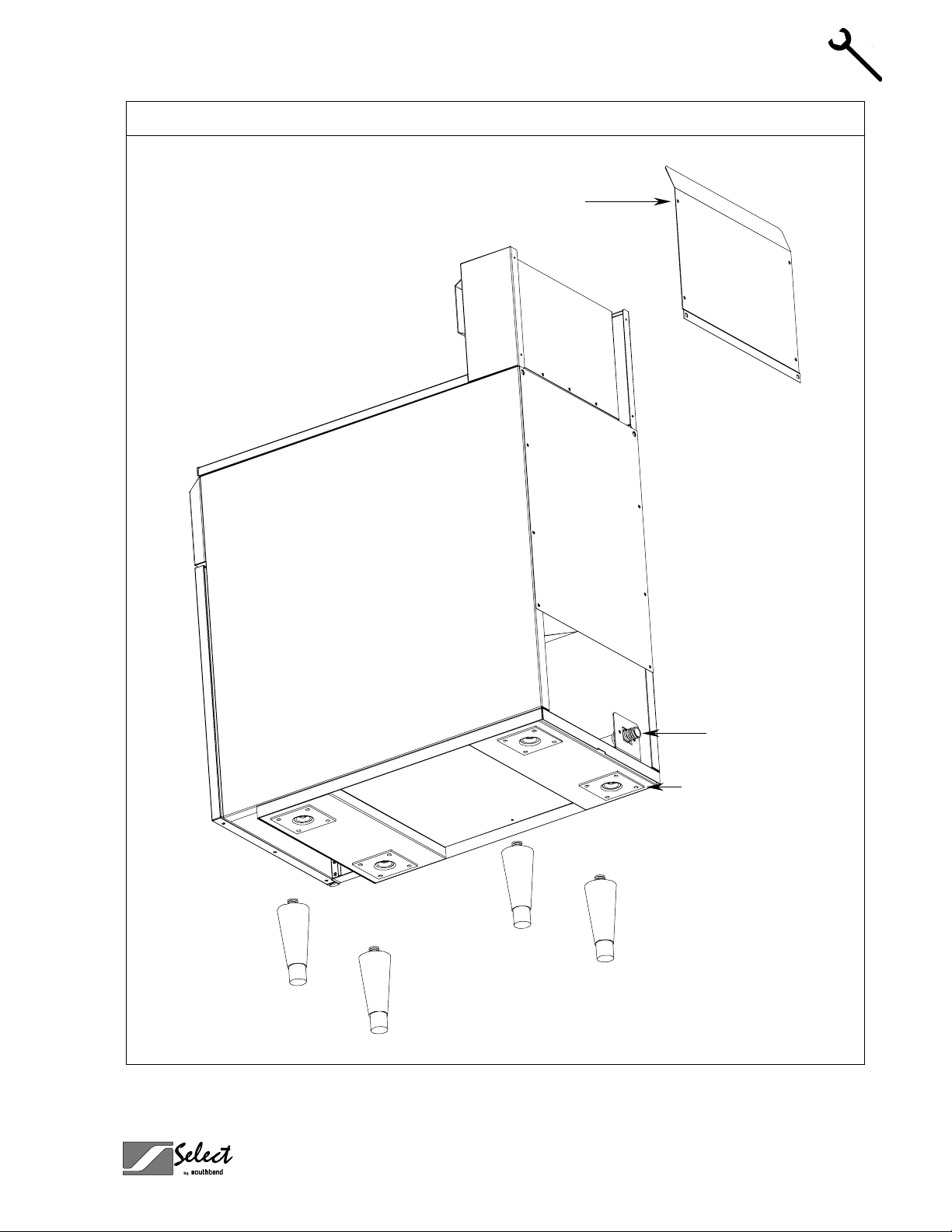

Step 2: Install Flue Riser

The flue riser assembl y is packed separately in the f ryer shipping crate. Att ac h t he f lue ris er to the top rear of

the fryer (see illustration on page 7).

PAGE 6OPERATOR’S MANUAL 1182026 REV 2

GFS SERIES TUBE FRYERS INSTALLATION

Installation

Flue Riser

INSTALLATION

Gas Connection

Leg Attachment Pad

OPERATOR’S MANUAL 1182026 REV 2PAGE 7

INSTALLATION GFS SERIES TUBE FRYERS

Step 3: Install the Legs (or Casters) and Restraints

A set of legs or casters is packed with the fryer. A threaded pad is fastened to the base frame at each corner

(see illustration on page 7). Each leg or caster has a similar mating thread. When casters have been

ordered, the casters are provided with a Zerk fitting for proper lubrication when required.

1. Raise fryer sufficientl y to allow legs or cas ters to be screwed into the pads. For s afety, “shore up” an d

support the fryer with an adequate blocking arrangement strong enough to support the load.

2. Screw the four legs or caster s to the pads o n the bottom of the f ryer. W hen cas ters have bee n ordered,

the casters having a locking-brake should be attached under the front of the fryer.

3. Lower the fryer gently. Never drop or allow the fryer to fall.

4. Use a level to make sure that the fryer is level. Each caster, or the tubular-end of each leg, can be

INSTALLATION

screwed in or out to lower or raise each c orner of the fryer. For f ryers having casters, t ighten the lock

nuts after the unit has been leveled.

5. Attach r est raints as requir ed b y loca l code s.

NOTICE

Unit must be level to assure maximum performance. Improper leveling may void warranty.

NOTICE

Adequate restraining means must be attached to rear of appliance when installed. Installation must

conform to local codes as applicable.

! WARNING

If disconnection of the restraint is necessar y to move the appliance for cleaning, etc., reconnect it

when the appliance is moved to its original installed position.

! WARNING

For an appliance e quipp ed with cas ter s, the ins tall ation sh all b e m ade with a co nnector that com plies

with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 or Connectors for

Moveable Gas Appliances, CAN/CGA-6.16, and a quick-disconnect device that complies with the

Standard for Quick-Disconnect Devices for Use With Gas Fuel, ANSI Z21.41, or Quick Disconnect

Devices for Use with Gas Fuel, CAN1-6.9. Adequate means must be provid ed to lim it the m ovement

of the appliance without depending on the connector and the quick-disconnect device or its

associated piping to limit the appliance movement.

! WARNING

All GFS Series Fryers must be restrained to prevent t ipping in order to a void the splashing of hot

liquid. The means of restraint m ay be the manner of installat ion, such as connection to a battery of

appliances or installing the fryer in an alcove, or by separate means, such as adequate ties.

PAGE 8OPERATOR’S MANUAL 1182026 REV 2

GFS SERIES TUBE FRYERS INSTALLATION

Step 4: Check Clearances and Ventilation

Select a firm, level loc ation for your Southb end fryer. Leave clear ance, whenever possible, s o that access

from the rear is possible to permit clean ing. If the unit is to be s et on non-combustible floor ing, such as a

concrete slab, 3 inches minim um toe room must be provided t o prevent restriction of t he air opening in the

bottom of the unit.

! WARNING

There must be adequate clearance between fryer(s) and construction. Clearance must also be

provided in front for servicing and for operation.

Minimum Clearances:

From Combustible Construction From Non-Combustible Construction

Sides 7" 0"

Rear 7" 0"

ALL GFS SERIES FRYERS SHALL BE INSTALLED WITH AT LEAST A 16 INCH SPACE BETWEEN

THE FRYER AND SURFACE FLAMES FROM ADJACENT EQUIPMENT.

No additional side and rear clearance is required for service as the fryer is serviceable from the front.

INSTALLATION

! WARNING

Improper ventilation can result in personal injury or death. V ent il ation that fails to properly remove flue

products can cause headaches, drowsiness, nausea, or could result in death.

All units must be installed in such a manner that the flow of combustion and ventilation air is not

obstructed. Provisions for adequate air supply must also be provided. Do NOT obstruct the bottom

front of the unit, as combustion air enters through this area. Be sure to inspect and clean the

ventilation system according to the ventilation equipment manufacturer’s instructions.

NOTICE

Proper ventilation is t he owner’s responsibility. An y problem due to improper venti lation will not be

covered by the warranty.

Due to the variety of problems that c an be ca us ed b y outside weather condit io ns , ve nt ing by canopies or wall

fans is preferred over any type of direct venting. It is recommended that a canopy extend 6" past the

appliance and the bottom edge be located 6'6" from the floor. Filters should be installed at an angle of 45° or

more from the horizontal. This position prevents dripping of grease and facilitates collecting the run-off

grease in a drip pan, unusually install ed with a filter. A strong exha ust fan tends to creat e a vacuum in the

room and may interfere with burner performance or may extinguish pilot flames. Fresh air openings

approximately equal to the fan area will relieve such a vacuum . In case of unsatisfactor y performance on

any appliance, chec k the appliance with the exhaust f an in the “OFF” position. Do th is only long enough to

check equipment perform ance, then turn hood bac k on and let it run to remove any exhaus t that may have

accumulated during the test.

The exhaust fan should be installed at least 2 feet above the vent opening at the top of the fryer.

This unit is not intended to be connected directly to an outside flue.

OPERATOR’S MANUAL 1182026 REV 2PAGE 9

INSTALLATION GFS SERIES TUBE FRYERS

Step 5: Gas Connection

A 3/4" male NPT line for the gas connection is located near the lower left rear corner of the fryer (see

illustration on page 7). T he ser i al pla te (l oc ate d i nsid e th e f r ont do or of the f ryer) indicates the type of gas th e

unit is equipped to burn (natural gas or propa ne). The f ryer shou ld be c onnec ted O NLY t o the t ype of gas f or

which it is equipped.

A millivoltage circuit diagram is located inside the front door of the fryer.

All Southbend equ ipment is adjusted at the f actory; however, pilot he ight should be c hecked at instal lation

and adjusted, if necessary (see page 22).

For orifice sizes and pressure regulator settings, see the chart on page 5. If the fryer is being installed at over

2,000 feet altitude and that inform ation was not specified when order ed, contact the appropr iate authorized

Southbend Service Representative or the Southbend Service Department. Failure to install with proper

orifice sizing will result in poor performance and may void the warranty.

INSTALLATION

If applicable, the ven t line from the gas appliance pressure regulator shall be installed to the outdoors in

accordance with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code, CAN/CGAB149.2, as applicable.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas

necessary for satisfac tory performance. A com bination gas valve an d pressure regulator, which is provide d

with each unit, is set to maintain a 4 " W.C. manifold press ur e f or natur al gas or 1 0.0 " W.C. manifold press ur e

for propane gas. However, to mainta in these conditions the press ure on the supply line, wh en all units are

operating simultaneously, should not drop below 7" W.C. for natural gas or 11" W.C. for propane gas.

Fluctuations of m ore than 25% on nat ural gas or 1 0% on pr opan e gas will cr eate pro blem s and aff ect bur ner

operating characteristics. A 1/8" tap to measure the manifold pressure is located on the combination gas

valve, which is on the burner manif old loca ted dir ectly below the burners inside t he cabin et.

Purge the supply line to clean out dust, dirt, or other foreign matter before connecting the line to the unit.

It is recommended that an individual manual shutoff valve be installed in the gas supply line to the unit.

Use pipe joint compound that is suitable for use with both natural and LP gas on all threaded connections.

! CAUTION

ALL PIPE JOINTS AND CONNECTIONS MUST BE TESTED THOROUGHLY FOR GAS LEAKS.

USE ONLY SOAPY W ATER FOR TESTING O N ALL GASES. NEVER USE AN O PEN FLAME T O

CHECK FOR GAS LEAK S. ALL CONNECTIONS MUST BE CHEC KED FOR LEAKS AFTER T HE

UNIT HAS BEEN PUT INTO OPERATION. TEST PRESSURE SHOULD NOT EXCEED 14" W.C.

! CAUTION

THIS APPLIANCE AND ITS INDIVIDU AL COMBINATION GAS VALV E MUST BE DISCONNE CTED

FROM THE GAS SUPPLY PIPING SYSTEM DURING ANY PRESSURE TESTING OF THAT

SYSTEM AT TEST PRESSURES IN EXCESS OF 1/2 PSIG (3.45 kPa).

The appliance must be isola ted from the gas supply pipin g system by closing its individ ual manual

shutoff valve during any pressur e testing of the gas suppl y piping system at test pres sur es eq ua l to or

less than 1/2 psi (3.45 kPa).

Connect the gas suppl y direc tly to th e 3/4" m ale NPT connector locat ed near the lower left r ear corn er of the

fryer. When tighten ing the s u pp l y pipe, be s ure to hol d th e mating connector exten din g from the unit sec ure ly

with a wrench. This will prevent any damage or distortion to the internal piping and controls of the unit.

After connecting the gas suppl y, check again that the fryer is level. Use a long spirit lev el four ways; ac ross

the front and rear of the frypot, and along each edge.

PAGE 10 OPERATOR’S MANUAL 1182026 REV 2

GFS SERIES TUBE FRYERS INSTALLATION

! CAUTION

IF YOU SMELL GAS DURING THE LIGHTING PROCE DURE, I MMEDIAT ELY SHUT OFF THE GAS

INSTALLATION

OPERATOR’S MANUAL 1182026 REV 2PAGE 11

OPERATION GFS SERIES TUBE FRYERS

OPERATION

NOTICE

These procedures mus t be followed b y qual if ied pers onn el or warranty will be voided.

All Southbend GFS Series Tube Fryers are immersion tube fryers. This is the most efficient method of

transmitting heat int o the oil. T he tubes are actu ally large h eat exc hangers. Eac h tub e is heated by a burner

at its front that propels its flame and heat into the tube , toward the rear, where it is vented into a flue box .

The combined heat tr ansfer area of the tubes is m uch greater than the other t ypes using element c oils or

under-fired pots. Consequent ly, heat transf er per square inch is lower, as is the tem perature, but beca use of

the increased surf ace area, immers ion tube fryers transf er more heat into the oil. The lo wer temperature of

the heating surfac e prevents scorching and carbonizatio n of the oil. Higher heat trans fer rate gives faster

recovery between loads.

Another advantage of immersion tube fryers is the cold zone. As oil is heated it passes between and over the

tubes and rises int o the frying zone, where it imparts heat into the pr oduct. After gi ving up heat , it des cends

to the cooler zone be low the tub es. Foo d particl es and cr umbs are dropped and trap ped in the cold zone as

the oil awaits to be recirculated. The cold zone concept helps keep the oil circulating and clean of debris.

OPERATION

! WARNING

BURN HAZARD

Contact with hot oil will cause sever e b urns . Al ways use caution. Oil at 2 00 °F is more dangerous than

boiling water.

! CAUTION

NEVER OPERATE THE FRYER WITHOUT SUFFICIENT OIL TO COVER THE TUBES.

Lighting

! CAUTION

IF YOU SMELL GAS DURING THE LIGHTING PROCE DURE, I MMEDIAT ELY SHUT OFF THE GAS

SUPPLY UNTIL THE LEAK HAS BEEN CORRECTED.

Open the burner compartment door and do the following:

1. Turn thermostat to “OFF” (lowest position).

2. Press down the knob of the combination gas

valve, turn it counterclockwise to the “PILOT”

position, and continue to press the knob down.

PAGE 12 OPERATOR’S MANUAL 1182026 REV 2

Loading...

Loading...