Southbend GDA-2S, GC-3S, GC-2S, CQ-325S User Manual

COMPARTMENT STEAMER

GAS BOILER

(Manual Section CS)

OWNER’S MANUAL

INSTALLATION

USER'S GUIDE

SERVICE

PARTS

COMPARTMENT STEAMER

GAS BOILER

MODELS: GC-2S; GC-3S; GDA-2S; CQ-325S

(250,000 BTU BOILER)

These instructions should be read thoroughly before attempting installation.

Set up, installation and Performance Check should be performed by a

qualified service technician. The Manufacturer, Southbend (1100 Old

Honeycutt Rd., Fuquay-Varina, North Carolina 27526), informs you that

unless the installation instructions for the above described Southbend product

are followed and performed by a qualified service technician, (a person

experienced in and knowledgeable concerning the installation of commercial

gas and/or electrical cooking equipment) then the terms and conditions of the

Manufacturer's Limited Warranty will be rendered void and no warranty of any

kind shall apply.

If the equipment has been changed, altered, modified or repaired by other

than a qualified service technician during or after the 12-month limited

warranty period, then the manufacturer shall not be liable for any incidental or

consequential damages to any person or to any property which may result

from the use of the equipment thereafter. Some States do not allow the

exclusion or 'imitation of incidental or consequential damages, so the above

limitation or exclusion thereto may not apply to you.

In the event you have any question concerning the installation, use, care, or

service of the product, write Customer Service Department, Southbend

Corporation, 1100 Old Honeycutt Rd., Fuquay-Varina, North Carolina 27526.

A MIDDLEBY COMPANY

Warranty

............................... . ............... ..……………….......

1

Dimensions

..................................................…………............

2

SECTION SIX

— SERVICE

A MIDDLEBY COMPANY

Congratulations! You have just purchased one of the finest pieces of heavy-duty, commercial cooking equipment on

the market today.

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to some of

the toughest standards in the industry - those of Southbend Corporation. Each piece of Southbend equipment has

been carefully engineered and designs have been verified through laboratory tests and field installations in some of the

more strenuous commercial cooking applications. With proper care and field maintenance, you will experience years of

reliable, trouble-free operation from your Southbend equipment. To get the best results, it's important that you read this

manual carefully.

TABLE OF CONTENTS:

SECTION ONE — INSTALLATION

SECTION TWO — STEAM FUNCTION

SECTION THREE — COOKING CHART

SECTION FOUR — MAINTENANCE

SECTION FIVE — OPERATION

SECTION SEVEN — PARTS

SECTION EIGHT — WIRING

CAUTION: WATER QUALITY IS THE MAJOR FACTOR AFFECTING THE PERFORMANCE OF YOUR

APPLIANCE. INCOMING WATER HARDNESS SHOULD NOT EXCEED 2.0 PPM GRAINS AND

THE pH SHOULD NOT EXCEED 7.5. IF YOU ARE UNSURE OF WATER CONDITIONS, HAVE

IT ANALYZED. CONSULT YOUR LOCAL WATER DEPARTMENT OR A COMPETENT WATER

CONDITIONER AGENCY. FAILURE OR MALFUNCTION OF THIS APPLIANCE DUE TO POOR

QUALITY OF WATER IS NOT COVERED UNDER THE WARRANTY.

Retain this manual for future reference.

Service Connections ........................................……............... 3

Start Up…………………………………………………………… 3

Functioning Mode ...................................................………..... 5

Time Schedules ................................................………........... 6

Periodic Maintenance .........................................…................ 8

Operating Instructions..........................................……............ 15

Service Information .........................................……............ ... 16

Parts List .........................................................…………......... 23

Wiring Diagrams ..............................................………........... 37

WARNING — WARRANTY WILL BE VOID IF

A. SERVICE WORK IS PERFORMED BY OTHER THAN A QUALIFIED TECHNICIAN.

B. OTHER THAN GENUINE SOUTHBEND REPLACEMENT PARTS ARE INSTALLED.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

KEEP AREA AROUND APPLIANCES FREE AND CLEAR FROM COMBUSTIBLES.

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN EQUIPMENT AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER

FOR SERVICE.

southbend

1100 Old Honeycutt Road

Fuquay –Varina, NC 27526

(919) 552-9161

FAX (919) 552-9798

(800) 348-2558

COMPARTMENT STEAMER

GAS BOILER

USER'S GUIDE

LIMITED WARRANTY

Southbend warrants that the equipment, as supplied by the factory to the original purchasers, is free from defects in materials

and workmanship. Should any part thereof become defective as a result of normal use within the period and limits defined

below, then at the option of Southbend such parts will be repaired or replaced by Southbend or its Authorized Service Agency.

This warranty is subject to the following conditions:

If upon inspection by Southbend or its Authorized Service Agency it is determined that this equipment has not been used in an

appropriate manner, has been modified, has not been properly maintained, or has been subject to misuse or misapplication,

neglect, abuse, accident, damage during transit or delivery, fire, "flood, riot or Act of God, then this warranty shall be void.

Specifically excluded under this warranty are claims relating to installation; examples are improper utility connections and

improper utilities supply. Claims relating to normal care and maintenance are also excluded; examples are calibration of

controls, and adjustments to pilots and burners.

Equipment failure caused by inadequate water quality is not covered under warranty. WATER QUALITY must not exceed the

following limits: Total Dissolved Solids (TDS) - 60 PPM (Parts Per Million). Hardness - 2 Grains or 35 PPM, PH Factor

- 7.0 to 7.5. Water pressure 30 PSI minimum, 60 PSI maximum. Boiler maintenance is the responsibility of the owner and is not

covered by warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial

application.

Repairs under this warranty are to be performed only by a Southbend Authorized Service Agency. Southbend can not be

responsible for charges incurred from other than Authorized Southbend Agencies. THIS WARRANTY MUST BE SHOWN TO AN

AUTHORIZED SERVICE AGENCY WHEN REQUESTING IN-WARRANTY SERVICE WORK. THE AUTHORIZED SERVICE

AGENCY MAY AT HIS OPTION REQUIRE PROOF OF PURCHASE. This warranty does not cover services performed at

overtime or premium labor rates nor does Southbend assume any liability for extended delays in replacing or repairing any items

in the equipment beyond the control of Southbend. "Southbend shall not be liable for consequential or special damages of any

nature that may arise in connection with such product or part." Should service be required at times which normally involve

overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such premium

rates. In all circumstances, a maximum of one hundred miles in travel and two and one half hours (25) travel time shall be

allowable. In all cases the closest Southbend Authorized Agency must be used. The actual warranty time periods and exceptions

are as follows:

This warranty only covers product shipped into the 48 contiguous United States and Hawaii, one year labor, one year parts

effective from the date of original purchase. There will be no labor coverage for equipment located on any island not connected

by roadway to the mainland. Exceptions to standard warranty, effective within above limitations:

Glass Windows, Door Gaskets, Rubber Seals, Light Bulbs, Ceramic Bricks,

Sight Glasses, Cathodic Descalers or Anodes ..…......………………………………………...................... 90 days material and labor

Stainless Steel Fry Pot.....................…………….…………………... .4 years extended material warranty on fry pot only — no labor

Stainless Steel Open Top Burners..………….………………...........4 years extended material warranty on burners only — no labor

Pressure Steam Boiler Shell .......…………………………........ Prorated 4 years extended warranty on boiler shell only — no labor

Boiler shells which have not been properly maintained will not be covered by warranty.

In all cases parts covered by a five year warranty will be shipped FOB the factory after the first year. Our warranty on all

replacement parts which are replaced in the field by our Authorized Service Agencies will be limited to three months on labor, six

months on materials (parts) effective from the date of installation. See LIMITED WARRANTY

- REPLACEMENT PARTS for conditions and limitations.

If the equipment has been changed, altered, modified or repaired by other than a qualified service technician during

or after the one year limited warranty period, then the manufacturer shall not be liable for any damages to any person

or to any property which may result from the use of the equipment thereafter.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS, AND CONSTITUTES THE ENTIRE

LIABILITY OF SOUTHBEND. IN NO EVENT DOES THE LIMITED WARRANTY EXTEND BEYOND THE DURATION

OF ONE YEAR FROM THE EFFECTIVE DATE OF SAID WARRANTY."

SOUTHBEND – Effective February 1, 1990

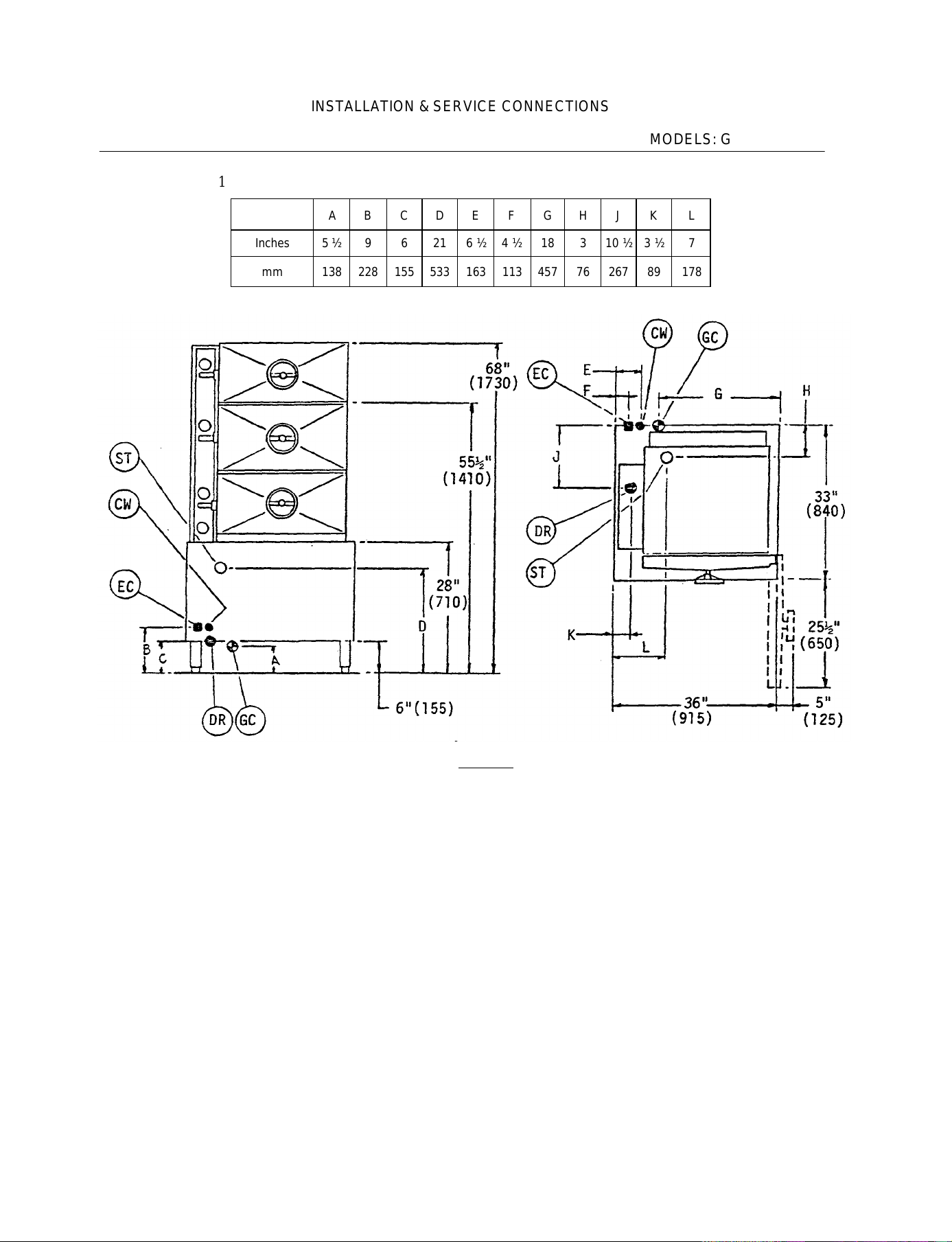

INSTALLATION & SERVICE CONNECTIONS

SECTION 1: MODELS: GC-2 & GC-3

FIG. 1

Inches 5 ½ 9 6 21 6 ½ 4 ½ 18 3 10 ½ 3 ½ 7

mm 138 228 155 533 163 113 457 76 267 89 178

A B C D E F G H J K L

LEGEND

GC Supply gas through 3/4" pipe with pressure of approx. 7" W.C. For propane use IT'

W.C. pressure. A gas shut off valve must be installed in supply piping convenient

and adjacent to appliance.

EC Unless otherwise specified. Field Wire Electrical Connection to be 120 Volts, 60

Hertz single phase with grounding wire.

DR Appliance drain is 2" pipe size. Provide open air gap type drain.

CW Cold Water supply to Boiler. Provide 3/8" copper tube. A Backflow Prevention Device

acceptable to BOCA Code or equivalent must be installed in this line.

ST Steam take-off locations to supply steam to adjacent units if desired.

2

INSTALLATION

&

SERVICE CONNECTIONS

SECTION 1: MODELS: GC-2 & GC-3

INSTALLATION INSTRUCTIONS

Cooker location should have an exhaust system provided directly above the appliance to exhaust

combustion gases generated by the Gas Boiler.

APPLIANCE IS INTENDED FOR USE ON NONCOMBUSTIBLE FLOORS. MINIMUM CLEARANCE FROM COMBUSTIBLE

CONSTRUCTION, 3" ON SIDES AND 2" FROM BACK.

Ascertain that adequate clearance of left side of appliance is available for servicing components

contained in Cooker Control Enclosure.

Set Cooker in place and "level appliance using spirit level. Mark hole locations on floor through anchoring

holes provided in flanged adjustable feet.

Remove appliance and drill holes into locations marked on floor and insert proper anchoring devices. Set

Cooker back in proper position.

Re-level the appliance, leveling the unit left to right and front to back. Appliance should be elevated on

the right 1/16" to 1/8" to assure proper compartment drainage.

Bolt and anchor appliance securely to the floor. Seal bolts and flanged feet with Silastic or equivalent

compound.

SERVICE CONNECTIONS

Make service connections as indicated in LEGEND (Fig. 1).

GAS INSTALLATION TO CONFORM TO LOCAL CODES OR IN THE ABSENCE OF LOCAL CODES TO NATIONAL FUEL

GAS CODE - ANSI Z223.1 - 1980. FURTHER NOTE THAT:

1. THE APPLIANCE AND ITS INDIVIDUAL- SHUTOFF VALVE MUST BE DISCONNECTED FROM THE GAS SUPPLY

PIPING SYSTEM DURING ANY PRESSURE TESTING OF THAT SYSTEM AT TEST PRESSURES IN EXCESS OF 1/2 PSIG

(3.45kPa).

2. THE APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY CLOSING ITS INDIVIDUAL

MANUAL SHUTOFF VALVE DURING ANY PRESSURE TESTING OF THE GAS SUPPLY PIPING SYSTEM AT TEST

PRESSURES EQUAL TO OR LESS THAT 1/2 PSIG (3.45kPa).

ELECTRICAL GROUNDING MUST BE PROVIDED IN ACCORDANCE WITH LOCAL CODES, OR IN THE ABSENCE OF

LOCAL CODES, WITH THE NATIONAL ELECTRIC CODE, ANS1/NFPA 70 - 1981.

3

INSTALLATION & SERVICE CONNECTIONS

SECTION 1: MODELS: GC-2 & GC-3

START UP TEST RUN

Open manual gas shut off supply valve and if the appliance has a manual Blow Down Valve, close

it. Open left cabinet door and turn ON power switch. Pilot light will come on (green) and water will

begin to enter Boiler and required water level will be reached in about 3 minutes. Observe water

gauge glass to verify.

The Dial on the gas combination control valve has 3 positions (ON-PILOT-OFF) for manual gas

control of main burners and pilot. Turn Dial on gas combination valve to PILOT. Depress Dial and

light Pilot Burner located on centre main burner of Boiler. Maintain Dial in depressed position for

about 30 seconds and release. Observe that Pilot Burner flame stays on. If at any time the flame

should become extinguished, a 5 minute period for complete shut off of Gas Supply is required

before relighting.

Turn Dial to ON and burners will ignite. Steam generation will now commence and be completed in

about 15 minutes. Observe that Boiler Pressure Gauge indicates steam pressure in range of 9 - 12

psi. The Pressure Gauge on the face of the Cooker Control Panel should indicate pressure of 5 to 6

psi.

Open Cooker compartment door. Dial Timer to 5 minutes and pull out Operating Handle and

observe that steam enters compartment.

With Operating Handle pulled out, dial Timer back to "O". The buzzer will now be audible and must

be silenced by releasing Operating handle. Check each compartment in a similar manner.

Close compartment door and turn Handwheel clockwise sufficiently to provide a good seal on door

gasket. Dial Timer to 5 minutes. Pull out Operating Handle and set in position. Steam entry into

compartment will be audible and Compartment Vent, located at rear left side of Cooker

compartment, will exhaust air (hissing noise) trapped in the compartment until replaced by steam.

Observe that door gasket seals properly and no leaks are evident.

After 5 minutes the Timer will read "0", Buzzer will come on, steam will cease to enter

compartment and drain valve will open to exhaust steam and condensate from compartment.

Release Operating Handle to silence Buzzer.

Observe Appliance Drain that live steam from compartment is being cooled by cold water from Cold

Water Solenoid Valve (thermostatically controlled). Turn Handwheel fully counter-clockwise to

avoid pressure on door gasket when not in use. Check each compartment in a similar manner.

During simulation of the cooking cycle, the Burners will cycle on and off to maintain steam

pressure in Boiler between 9 to 12 psi range.

Turn OFF power switch. Observe that Burners go off and if the appliance is equipped with

Automatic Blow Down Solenoid Valve, the Boiler contents water and steam, will be blown out and

exhausted through the appliance Drain. The Cold Water Solenoid Valve will now be activated as

well. If the appliance is equipped with a manual Blow Down Valve, open it.

4

INSTALLATION & SERVICE CONNECTIONS

SECTION 2: MODELS: GC-2 & GC-3

Steamers are made of two sections, the Cooker and the Cabinet. These Steamers are

intended for use in commercial establishments. They are floor supported, are steam

heated and incorporate steel enclosures to contain live electrical parts.

Gas, Power, hot and cold water, must be supplied to these Steamers. Refer to Section 1,

Service Connections.

The Cooker consists of two or three compartments and is the upper portion of the Steamer. Each

compartment is provided with its own Solenoids, Interlock Switches, Timer, Pilot Light, Operating

Handle and Door. When a compartment is off, or de-energized, the Exhaust Solenoid Valve is

open and the inlet Steam Solenoid Valve is closed. Pans, containing food properly portioned, are

placed into guided racks or unto wire shelves provided in each compartment. When the door is

closed, the Timer dialed and the Operating Handle is pulled out to the locked position, (which also

locks the door and engages the Interlock Switches), the valves are energized. Steam reduced to

maximum 6 psi pressure by the Pressure Regulating Valve will then be permitted to enter the

compartment but not exit. Air, captured in the sealed compartment is allowed to exhaust through

the Compartment Vent which will close at approximately 180°F, whence the compartment becomes

an entirely sealed chamber. The duration of the cooking cycle is controlled by the Timer and when

desired time has elapsed. Timer will read '0' and will set off an audible Buzzer and de-energize

valves. Buzzer must be silenced by releasing the Operating Handle and presumably door opened

to remove cooked food. -

The Cabinet is the lower portion of the Steamer and contains components which control the

functioning of the Gas Boiler. A switch located on the front face of the Generator Control Box, when

turned ON will provide power for the appliance and also initiate the Gas Burners to maintain steam

generation in the boiler which in turn supplies steam to the compartment.

The Gas Boiler is designed to ASME Code and approved as a steam heating boiler restricted

to operate at pressures not to exceed 15 psi and the burner system is UL tested and Certified.

Refer to Periodic Maintenance, Section 4, for detailed version of components and controls.

5

PAN SELECTION & TIME SCHEDULES

SECTION 3: MODELS: GC-2 & GC-3

COMPARTMENT CAPACITIES

The Cooker compartments are provided with either removable shelf supports with slide out shelves OR

universal pan supports. The following capacities for each compartment are based on full size, 12" x 20",

pans and depths indicated.

Shelf supports with shelving can accommodate:

6 - 2-1/2" deep full size pans or

4 - 4" deep full size pans or

2 - 6" deep and 2 - 2-1/2" deep full size pans.

Universal pan supports can accommodate:

8 - 2-1/2" deep full size pans or

4 - 4" deep full size pans or

2 - 6" deep and 2 - 2-1/2" deep full size pans.

Food placed in pans must, where possible, be evenly spread out and not protrude above pans since

steam circulation between pans in the compartment will be impeded.

Always preheat compartments for satisfactory results.

When a11 compartments are to be used at the same time, allow one compartment to recover steam

pressure (approx. 4-1/2 p.s.i.) before commencing cooking operation on next compartment.

When time does not allow for defrosting of frozen vegetables such as loose pack peas. corn, diced

carrots, etc., they may be cooked at once provided half suggested portions in Cooking Chart are used.

COOKING CHART

ITEM PAN DEPTH

(FULL SIZE) IN MINUTES PER PAN OF PANS

TIMER SETTING

WEIGHT LBS NUMBER

Beans 2-1/2" 10 - 12 5 1 - 3

Lima & Reg. Perforated 13 - 15

4-6

Beans 2-1/2" 15-20 6 1 - 3

Waxed Perforated 20 - 25

4-6

Broccoli 2-1/2" 8-10 6 1 - 3

Waxed Perforated 10 - 12

4-6

Broccoli 2-1/2" 10 - 15 6 1 - 3

1/2" - 3/4" Perforated 15-20 4-6

Stalks

Canned 2-1/2" 4-5 7 1 - 3

Vegetables Solid 5-8

4-6

6

PAN SELECTION & TIME SCHEDULES

SECTION 3: MODELS: GC-2 & GC-3

COOKING CHART - cont'd

ITEM

(FULL SIZE)

PAN DEPTH

TIMER SETTING

IN MINUTES

WEIGHT LBS

PER PAN

NUMBER

OF PANS

Carrots (sliced) 2-1/2" 18 - 21 9 1 - 3

Perforated 21 - 25

4-6

Corn 2-1/2" 9-10 5 1 - 3

Perforated 11 - 13

4-6

Chicken 2-1/2" 18 - 25 8 1 - 3

Blanched-Cut Perforated 25 - 30

4-6

Eggs - out of 2-1/2" 6-7 4 dozen 1 - 3

Shell Solid 7-8

4-6

Eggs - in 2-1/2" 2-3 3 dozen 1 - 3

Shell Perforated 4-6

4-6

Fish-Fillets 2-1/2" 8-12 3 1 - 3

Perforated 10 - 15

4-6

Meatloaf 2-1/2" 35 - 40 15 1 - 3

Solid for Broth 40 - 45

4-6

Peas 2-1/2" 6-7 5 1 - 3

Perforated 8-9

4-6

Potatoes cut 2-1/2" 20 - 25 10 1 - 3

Regular Perforated 25 - 30

4-6

Potatoes cut 2-1/2" 15 - 18 10 1 - 3

French Fry Perforated 18 - 20

4-6

Spinach 4" 3-5 3 1 - 2

cut, cleaned Perforated 4-6

3-4

Rice 4" 22 - 24 4 1 - 2

1 Gallon Water Solid -,25-27

3-4

Spaghetti 4" 20 - 22 3 1 - 2

1-3/4 Gal. Water Solid 23 - 26

3-3

Turkey 2-1/2" 50 - 60 10 - 12 1 - 3

Perforated 60 - 75

4-6

7

PERIODIC MAINTENANCE

SECTION 4: MODELS: GC-2 & GC-3

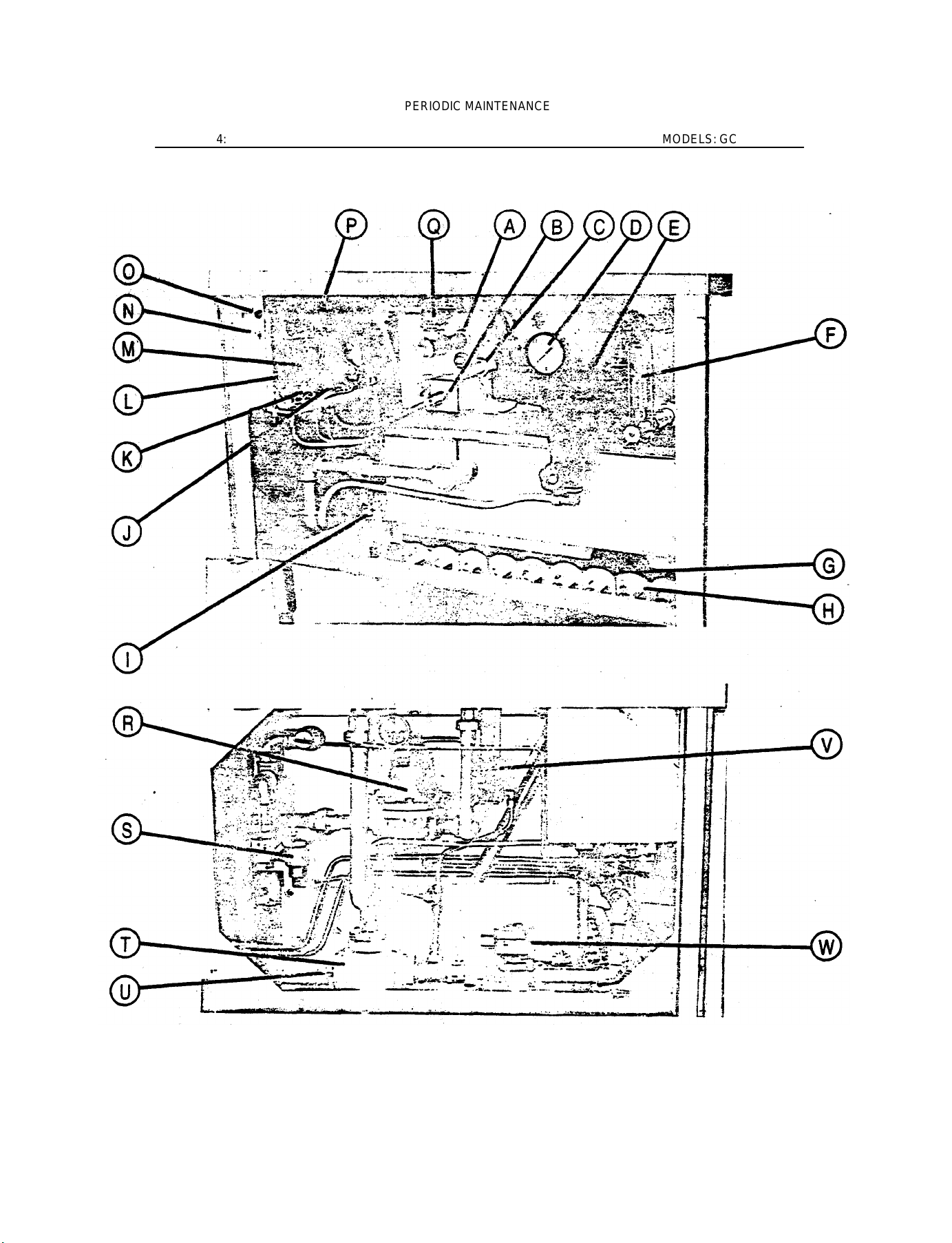

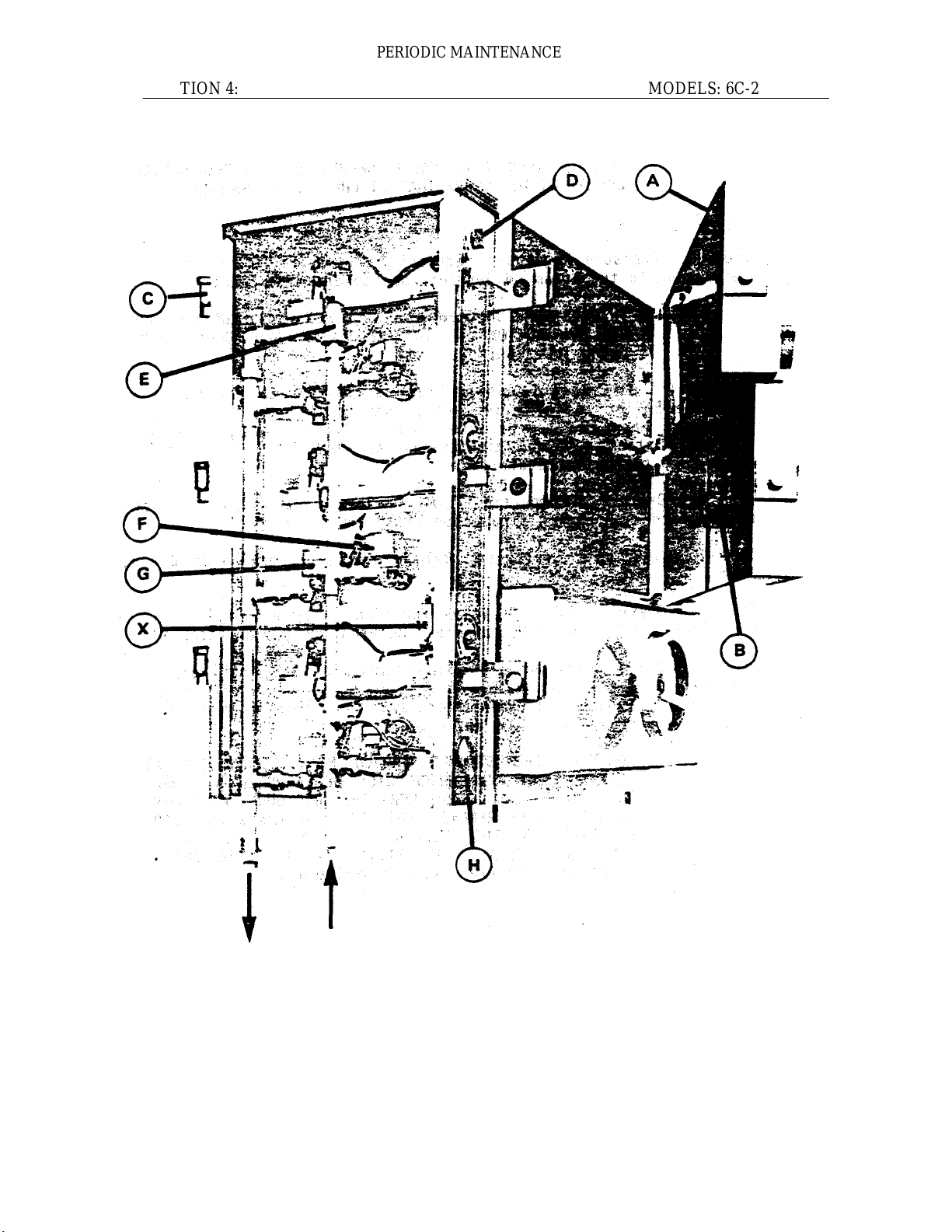

FIG. 2

SIDE VIEW

8

PERIODIC MAINTENANCE

SECTION 4: MODELS: GC-2 & GC-3

Fig. 2: The Cabinet is the lower section of the Steamer providing not only a base for the Cooker to be positioned at a

proper working height but also the enclosure for the Gas Boiler and Controls.

THE APPLIANCE AREA MUST BE KEPT FREE AND CLEAR FROM

COMBUSTIBLES. DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATION AIR.

FRONT VIEW

Item A: Gas Boiler weldment assembly.

Item B: Safety Sensor, enclosed by the Sensor Cover Box, is a Boiler protective device which will shut off the Main

Burners when excessive heat occurs should the water level in the Boiler drop below a level sufficient to immerse and

protect the Boiler tubes, heads and shell that come in contact with direct heat from the Burners.

Item C: Handhole Cover Assembly when unbolted and removed allows internal examination and cleaning of Boiler if

required.

AT LEAST TWICE A YEAR REMOVE HANDHOLE COVER ASSEMBLY.

INSPECT BOILER INTERIOR FOR SCALANT AND LIME BUILD UP.

Item D: The Pressure Gauge is directly above and threaded to the Water Level Control. It should read '0' during shut

down and function in a range of approximately 9 to 13 p.s.i. during operation of the appliance.

Item E: The Water Level Control is a mechanical switch intended to maintain proper water level in the Boiler. A Float is

contained within the chamber of the Water Level Control and when it drops, it will trip the switch in the control and

demand sufficient water to replenish it to the proper level.

A MANUAL VALVE LOCATED DIRECTLY BELOW THE WATER LEVEL

CONTROL CHAMBER MUST BE OPENED BRIEFLY AT LEAST ONCE A WEEK

TO BLOWDOWN SEDIMENT AND SCALANT THAT MAY BE LODGED IN THE

CHAMBER. FAILURE TO DO SO MAY CAUSE EXCESSIVE

ACCUMULATION, SEIZURE OF THE FLOAT AND EVENTUAL MALFUNCTION

OF THE WATER LEVEL CONTROL.

Item F: The Water Gauge assembly has a glass tube for visual verification that water level is being maintained in the

Boiler during operation. The manual valves at the top and the bottom of this assembly must be fully open and only

closed if damage should occur to the glass tube.

OBSERVE THAT THE WATER IS CLEAN AND CLEAR IN THE GLASS TUBE.

THE APPEARANCE OF EXTREME MURKINESS IN THE WATER

INDICATES INADEQUATE WATER QUALITY AND WILL CAUSE FAILURE

OF CONTROLS AND THE APPLIANCE. WARRANTY DOES NOT COVER

MALFUNCTION DUE TO POOR WATER CONDITIONS.

9

PERIODIC MAINTENANCE

SECTION 4: MODELS: GC-2 & GC-3

Item G: Pilot Burner should remain lit at all times unless appliance will not be in use for an

extended period of time.

IF AT ANY TIKE THE FLAME SHOULD BECOME

EXTINGUISHED. A 5 MINUTE PERIOD FOR COMPLETE SHUT

OFF OF GAS SUPPLY IS REQUIRED BEFORE RELIGHTING.

Item H: Main Burners of aluminized steel tube.

FLOOR AREA BENEATH BURNERS MUST BE KEPT FREE AND

CLEAR TO PROVIDE AIR FOR COMBUSTION AND

VENTILATION.

Item I: Gas Combination Control Valve regulates flow of natural gas (or propane) to Burners.

Operation is dependent on other controls. Refer to START UP TEST RUN - SECTION 1.

Item J: Cold Water Solenoid Valve fastened to the right rear bottom of Generator Control Box

supplies cold water to condense live steam before it exhausts into the drain and is controlled by the

Thermostat (Item P).

Item K: Hot Water Solenoid Valve fastened to the bottom of Generator Control Box immediately in

Front of Item J feeds hot water to the Boiler but its functioning is entirely dependent on the Water

Level Control (Item E).

Item L: Operating Pressure Switch fastened to the inside bottom front of the Generator Control

Box is plumbed to sense the pressure in the Boiler and thence control the operating cycle of the

Gas Combination Control Valve (Item I). This switch is factory set to energize the Gas Combination

Control Valve and ignite the Main Burners at 9 psi but to de-energize the Valve and turn off

Burners at 11 ½ psi thus maintaining a pressure range in the Boiler between 9 psi to

approximately 13 psi (override considered).

Item M: Override Pressure Switch similar to and located directly behind the above switch senses

steam pressure in excess of the normal operating range which occurs only at initial Start-Up of the

Boiler at approximately 13 psi and thence energizes Solenoid Valve (Item V) to open briefly to

allow for discharge of said excess pressurized steam thence the Boiler becomes stabilized.

Item N: Power Switch fastened to the front fact of the Generator Control Box when switched ON

will automatically begin the steam generating process in the Boiler.

Item O: Pilot Light is located directly above the Power Switch and when lit (green) indicates power

is ON.

Item P: A Thermostat mounted on the back wait of the Generator Control Box has its heat

sensing capillary bulb fastened to the appliance Drain. When excessive heat (i.e. steam) comes in

contact with the bulb, the Thermostat will energize the Cold Water Solenoid Valve (Item J).

10

PERIODIC MAINTENANCE

SECTION 4: MODELS: GC-2 & GC-3

Item Q: Safety Valve is a protective device set at 15 psi. Malfunction or improper setting of controls may allow the

pressure to exceed 15 psi in the Boiler and will consequently set off this valve.

ONCE A WEEK THIS VALVE SHOULD BE TRIPPED DURING OPERATION TO

ASSURE THAT IT FUNCTIONS PROPERLY.

LEFT SIDE VIEW

Item R: Pressure Regulator reduces the pressure of the steam supplied from the Boiler to the Steam Header and the

Cooker compartments.

TWICE A YEAR UNSCREW THE LARGE HEX HEAD PLUG LOCATED AT THE

BOTTOM OF THE REGULATOR AND REMOVE AND CLEAN THE STRAINER.

Item S: A Thermostatic Steam Trap is plumbed to the steam supply piping from the Boiler and is a mechanical device

that closes on high temperatures and opens when the temperature drops. This Trap allows water formed from

condensed steam to exhaust into the appliance Drain but will retain steam being of a higher temperature.

Item T: Drain for compartments and Boiler approximately 2" pipe size. Must be provided with open air gap type floor

drain.

Item U: Thermostat Capillary Bulb fastened to appliance Drain. Refer to Item P.

Item V: Override Solenoid Valve functions only briefly at initial Start-Up of Boiler and is controlled by override Pressure

Switch (Item M).

Item W: Boiler Blowdown Valve is plumbed to the drain pipe of the Boiler and when specified as automatic will be a

solenoid (electrically operated) valve which will close when energized in order to facilitate maintenance of proper water

level in the Boiler.

HOWEVER. THE STEAMER SHOULD BE SWITCHED OFF AT LEAST ONCE

DAILY WHICH WILL DE-ENERGIZE AND OPEN THE VALVE IN ORDER FOR

THE BLOKDOWN PROCEDURE TO OCCUR AND REMOVE SEDIMENTS.

SCALANTS AND LIME BUILD-UP IN THE BOILER. IF THE APPLIANCE IS

SUPPLIED WITH A MANUAL VALVE. IT SHOULD BE OPENED DAILY WHEN

THE APPLIANCE IS SHUT DOWN.

11

PERIODIC MAINTENANCE

SECTION 4: MODELS: 6C-2 &GC-3

FIG. 3

STEAM

EXHAUST

IN

TO DRAIN

12

Loading...

Loading...