Southbend GC-2S User Manual

SPECIFICATIONS:

Shall be a Model __________________________________

_, pressure compartment cooker with gas steam boiler. The

cooker shall be constructed of all-welded satin nish stainless

steel, type 304. The doors shall have a removable inner liner

of aluminum plate with full perimeter gasket seal, an outer liner

of one-piece all-welded stainless steel, and a wheel-and-screw

closing mechanism. The doors, with a clear opening of 10-1/4”

x 26-3/8”, shall latch upon closing and shall open 15° upon

latch release. Compartment operation shall be at a maximum

pressure of 6 psi (0.42 kg/cm2).

The control housing shall be constructed of stainless steel with

a full-access removable panel. The timing of each compartment

shall be independently controlled by:

Automatic timer controls with visible and audible signals. At

the end of the cooking cycle, the controls automatically shut

off and exhaust the incoming steam, drain the condensate

from the compartment, and sound a continuous signal until

turned off manually.

Each cooking compartment shall have either removable shelf

supports with two slide-out shelves (third shelf optional) or

removable universal pan supports. The capacities shall range

as follows:

Shelf supports: Four full size (1/1 gastronorm) pans, 2-1/2”

or 4” (64 mm or 100 mm) deep.

Universal supports: Eight full size (1/1 gastronorm) pans,

2-1/2” (64 mm) deep, or four full size (1/1 gastronorm) pans,

4” (100 mm) deep.

Gas steam

C

ompartment Cooker

with Cabinet base

Model CoMpartMents CapaCity

GC-2S 2 8-16 Pans

GC-3S 3 12-24 Pans

The compartment cooker shall be mounted on a cabinet

base with full perimeter angle frame, reinforced counter

and boiler mountings, gas boiler with controls, all stainless

steel exterior, hinged doors and 6” (152 mm) stainless steel

legs with adjustable bullet feet.

OPERATION SHALL BE BY:

Gas heated steam boiler operating at 15 psi (1 kg/cm2)

and rated at:

250,000 BTU (standard)

Electronic ignition

The steam boiler shall be equipped for operation on:

Natural gas

Propane gas

The controls shall be equipped for operation on 115VAC,

1 Phase, 60 Hz

OPTIONAL ITEMS AT EXTRA COST:

Extra shelf

12" x 20" x 2-1/2" perforated stainless steel pan

12" x 20" x 2-1/2" solid stainless steel pan

12" x 20" x 4" perforated stainless steel pan

12" x 20" x 4" solid stainless steel pan

Spray and rinse assembly

Steam take-off kit

Automatic boiler blowdown

220 or 240 VAC, 1 Phase, 50 Hz

Job Item#

Form GC Rev 2 (March/2015)

www.yatesgd.com www.yatesgraphicdesign.com

Models:

GC-2S GC-3S

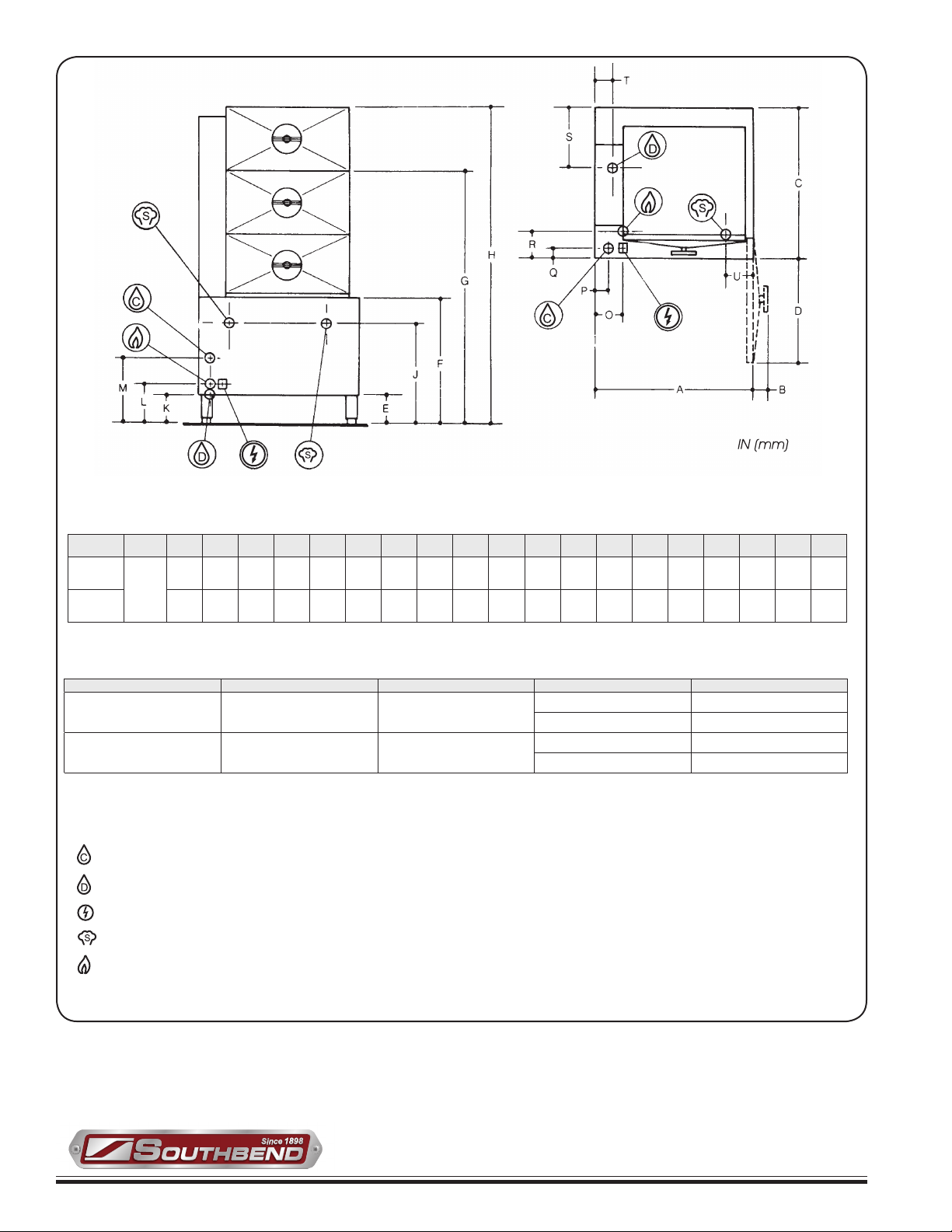

DIMENSIONS

Model Units A B C D E F G H J K L M O P Q R S T U

GC-2S

GC-3S

in

(mm)

36”

(914)6”(152)

36”

(914)6”(152)

33”

(838)

33”

(838)

23”

(597)6”(152)

23”

(597)6”(152)

28”

(711)

28”

(711)

55”

(1397)

-

22”

(559)6”(152)8”(203)

68”

(1727)

13”

(330)4”(102)2”(51)2”(51)3”(76)

11”

(279)3”(76)5”(127)

Model BtU/HoUr kCal/HoUr FUel Water ColUMn pressUre

GC-2S 250,000 63,291

GC-3S 250,000 63,291

Natural 4” (102 mm)

Propane 11” (279 mm)

Natural 4” (102 mm)

Propane 11” (279 mm)

SERVICE CONNECTIONS

- COLD WATER: 1/2” (13 mm)

– DRAIN: 2” (51 mm) IPS piped to open oor drain. No solid connection.

ELECTRICAL CONNECTIONS: 1/2” (13 mm) conduit connection to controls. 2 Amps per compartment, 120-60-1, 220-50-1.

–

– STEAM TAKE-OFF CONNECTION: 3/4” IPS optional to operate adjacent equipment.

- GAS CONNECTION: 3/4” (19 mm) IPS

Form GC Rev 2 (March/2015)

INTENDED FOR COMMERCIAL USE ONLY.

NOT FOR HOUSEHOLD USE

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(919) 762-1000 www.southbendnc.com

.

Loading...

Loading...