Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this

manual for the life of the equi pment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

OPERATOR'S MANUAL

FOR MODEL EZ-3 and EZ-5

Simple Steam

COUNTERTOP STEAMERS

Model EZ-3 Model EZ-5

! WARNING

Improper installation, operation, service, or maintenance can cause property damage, injury, or death.

Read this manual thoroughly before installing and operating this equipment.

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(800) 348-2558 or (919) 552-9161 • FAX (800) 348-2558 or (919) 552-9798

MANUAL 1178387 REV 2 COUNTERTOP STEAMER

$18.00 MANUAL SECTION ST

Page 2

SAFETY PRECAUTIONS

Before installing a nd opera ting this equipm ent, be sure e ver yone involv ed in its operat ion is f ully tr ained and

aware of precautions. Accidents and problems can be caused by failure to follow fundamental rules and

precautions.

The following s ymbols, found throughout this manual, alert you to potentially dangerous conditions to the

operator, service personnel, or to the equipment.

! DANGER

! WARNING

! CAUTION

NOTICE

This symbol warns of im mediate hazards which will result in severe injury or

death.

This symbol refers to a p otential hazard or uns afe practice wh ich could result in

injury or death.

This symbol refers to a p otential hazard or uns afe practice wh ich could result in

injury, product damage, or property damage.

This symbol refers to information that needs special attention or must be fully

understood, even though not dangerous.

! WARNING

FIRE HAZARD

For your safety, do n ot store or use gasol ine or other flamm able vapors and liquids in the vicinit y of

this or any other appliance.

Keep area around appliances free and clear of combustibles.

! WARNING

SHOCK HAZARD

Do not open panels that require use of tools.

Unit must be cleaned daily and properly maintained to reduce chances of unsafe operating

conditions.

! WARNING

BURN HAZARD

Watch for clogged drain - can crate burn hazard when door is opened.

Stand back when opening doors - hot steam or hot water may escape from steamer.

NOTICE

Be sure this Operator's Manual and important papers are given to the proper author ity to retain for

future reference.

PAGE 2OPERATOR’S MANUAL 1178387 REV 2

Page 3

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TABLE OF CONTENTS

Congratulations! You have purchased on e of the finest p ieces of heav y-duty comm ercial cook ing equipm ent

on the market.

You will find that your new equipm ent, like all Southbend equipment, has been desig ned and m anufactured

to meet the toughest standards in the indus try. Each piece of Southbend equipm ent is carefully eng ineered

and designs are verified through laboratory tests and field installations. With proper care and field

maintenance, you will experience years of reliable, trouble-free operation. For best results, read this

manual carefully.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Table of Contents

Specifications..........................................................................................................................4

Installation...............................................................................................................................5

Operation ................................................................................................................................9

Cooking Hints........................................................................................................................10

Cleaning................................................................................................................................13

Troubleshooting ....................................................................................................................15

Parts......................................................................................................................................37

Limited Warranty...................................................................................................................41

Read these instructions carefully before attempting installation. Installation and initial startup should be

performed by a qualified installer. Unless the installation instructions for this product are followed by a

qualified service tech nician (a person experienced in and knowledge able with the insta llation of comm ercial

gas an/or electric cooking equipm ent) then the terms and conditi ons on the Ma nufactur er's Lim ited W arranty

will be rendered void and no warranty of any kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, write to:

Technical Service Department

Southbend

1100 Old Honeycutt Road

Fuquay-Varina, North Carolina 27526 USA

The serial plate is located on the right side of the unit near the back and top (see Figure 2 on page 7).

OPERATOR’S MANUAL 1178387 REV 2PAGE 3

Page 4

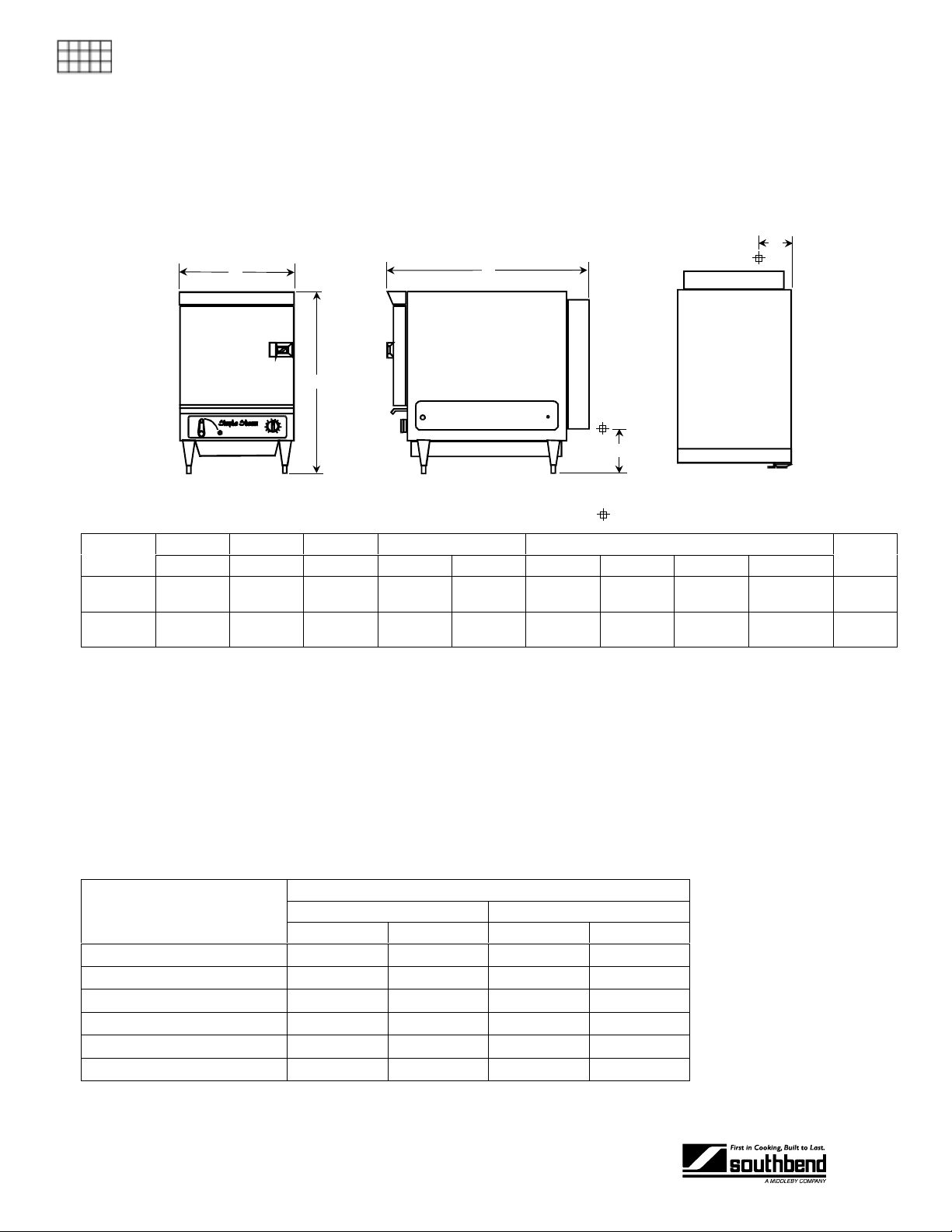

SPECIFICATIONS MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

SPECIFICATIONS

SPECIFICATIONS

DIMENSIONS

E

A

B

FRONT VIEW

Model

EZ-3

EZ-5

Internal Dimensions: EZ-3: 13.5" W x 22" D x 9.5" H; EZ-5: 13.5" W x 22" D x 15.5" H

Width Height Depth Electrical Connection Crate Size

A B C D E Width Depth Height Volume

16.375"

416 mm

16.375"

416 mm

24.25"

616 mm

30.25"

762 mm

30.25"

768 mm6"153 mm

30.25"

768 mm6"153 mm

C

SIDE VIEW

2.44"

62 mm

2.44"

62 mm

508 mm

508 mm

20"

20"

D

TOP VIEW

= Electrical Connection Terminal Block

34"

864 mm

34"

864 mm

37"

940 mm

37"

940 mm

14.6 cu. ft.

0.41 cu. m.

14.6 cu. ft.

0.41 cu. m.

Crated

Weight

150 lbs.

68 kg.

175 lbs.

79 kg.

UTILITY INFORMATION

One electric connection is required.

IMPORTANT: UNIT MUST BE LEVEL FOR PROPER O PERATION. W ARRANTY WILL BE VOID ED FOR

IMPROPER INSTALLATION.

All units shipped per customer order, three phase or single phase.

Kit available for field conversion to three phase or single phase.

Max. Amps per Line

Total Connected Amps

1 Phase 3 Phase 1 Phase 3 Phase

208 V 60 Hz 40 24 57 33

220 V 50/60 Hz 38 23 54 31

240 V 60 Hz 35 21 49 29

380/220 V 50 Hz 23 14 31 19

415/240 V 50 Hz 21 13 29 17

480 V 60 Hz 18 13 25 15

Circuit must be wired for maximum amps at required voltage.

PAGE 4OPERATOR’S MANUAL 1178387 REV 2

EZ-3 EZ-5

Page 5

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS INSTALLATION

INSTALLATION

! WARNING

DO NOT CONNECT 3/4” ID GREY HOSE IN R EAR OF UNIT TO ANYTHING. T HESE ARE VENT

HOSES AND MUST BE ALLOWED TO DRAIN INT O PAN. FAILURE T O COMPLY COULD CAUSE

A DANGEROUS PRESSURE RISE INSIDE OF THE STEAMER.

! CAUTION

Do not locate unit adjacent t o any high heat or greas e pr od uc in g p iece of eq ui pment, such as a range

top, griddle, fryer, etc., that could allo w radiant heat to raise th e exterior temperature of the steam

body above 130°F (54°C). DO NOT MOUNT ABOVE OTHER COOKING EQUIPMENT.

NOTICE

These installation procedures must be followed by qualified personnel or warranty will be void.

Local codes regarding install ation var y greatly from one area to an other. T he National F ire Protec tion

Association, Inc. states in its NFPA 96 latest edition that local codes are the “authority having

jurisdiction” when it com es to installation r equirements for equipment. Theref ore, installations shou ld

comply with all local codes.

The unit, when installed, must be electrically grounded and comply with local codes, or in the

absence of local codes with the National El ec tr ical Code ANSI /NF P A 70-latest edition.

INSTALLATION

Canadian installation must comply with CSA-Standard (C22.2 No. 109-M1981 General

Requirements-Canadian Electrical Code, Part II. 109-M1981) Commercial Cooking Appliances.

Step 1: Unpacking

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers shou ld be examined for dam age before and during unlo ading. The freight car rier has

assumed responsibility for its safe transit and delivery. If damaged equipment is received, either

apparent or concealed, a claim must be made with the delivering carrier.

Apparent damage or l oss m u st be noted on the freight b ill at the t im e of deliver y. T he f reight bi ll m ust

then be signed by the c arrier representative (Dr iver). If the bill is not signed, the carrier ma y refuse

the claim. The carrier can supply the necessary forms.

A request for insp ection must be m ade to the carrier within 15 da ys if there is concea led damage or

loss that is not apparent until after the equipment is uncrated. The carrier should arrange an

inspection. Be certain to hold all contents plus all packing material.

OPERATOR’S MANUAL 1178387 REV 2 PAGE 5

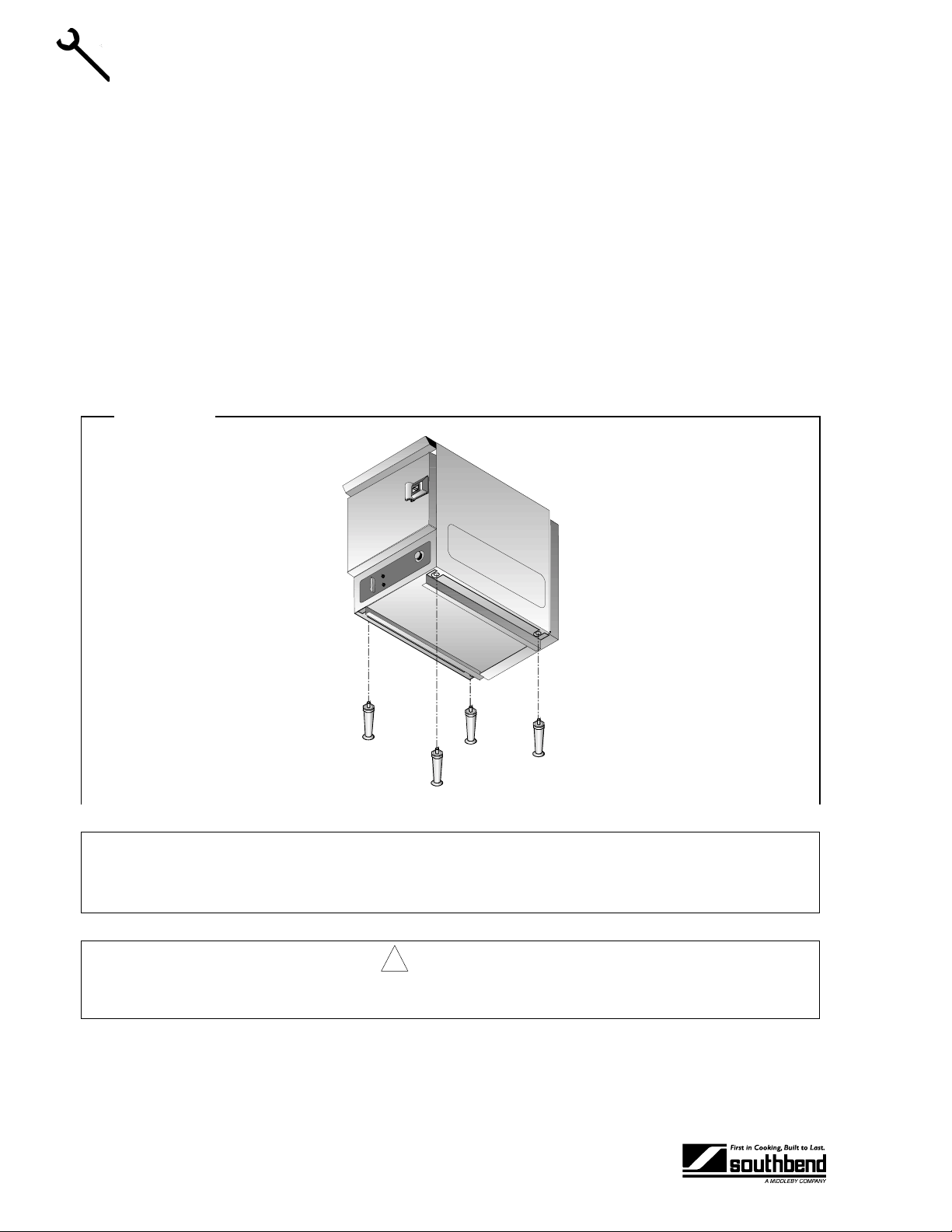

Page 6

INSTALLATION MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

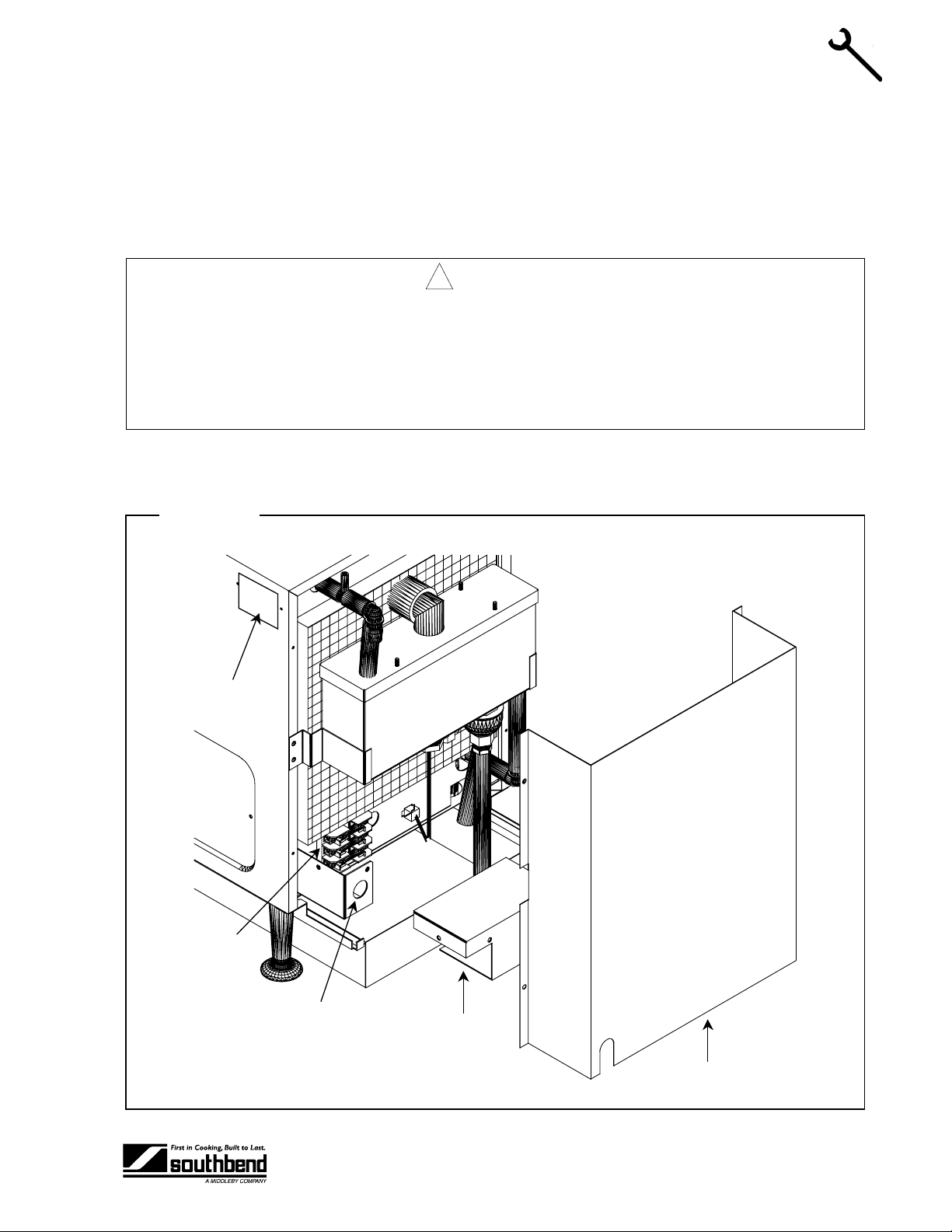

Step 2: Install the Legs

1. Uncrate carefully. Report any hidden damage to the freight carrier IMMEDIATELY.

2. Do not remove any tags or labels until unit is installed and working properly.

3. Remove placeholder bolts holding bottom cover onto unit and discard.

4. Screw legs into the bottom of the unit until approxim ately 1/4 " of thre ad is sho wing. T he legs wit h rubber

suction cups go on the back of unit.

5. Slip drain pan guides in to p lace between legs and bo ttom of steamer, as s ho wn in Figure 1, making sure

that pan stops are toward the rear of the unit.

6. Tighten legs, making sure that the pan guides stay seated against the leg threads.

INSTALLATION

7. To level the unit, adjust the base of unit’s legs.

8. Place custom drain pan under unit.

Figure 1

NOTICE

Unit must be level to assure maximum performance. Improper leveling may void warranty.

! CAUTION

WATER FROM A FULL CAVITY CANNOT BE HELD IN A 12" x 20" X 2½" PAN..

PAGE 6OPERATOR’S MANUAL 1178387 REV 2

Page 7

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS INSTALLATION

Step 2: Electric Connection

A field connection Fus e Block is located at the rear of the unit, lo wer left side. A hole is provided for a 3/4”

conduit fitting (solid or flex). Rear cover and fuse block cover m ust be rem oved to ga in acces s to fus e block.

Refer to Figure 2.

Be sure that the input voltage matches the requirement on the serial plate. The unit is factory wired per

customer order.

! WARNING

A POSITIVE GROUND CONNECTION IS ESSENTIAL. DO NOT ALLOW ANY TAMPERING OR

ADJUSTMENT OF ANY CONTROL OR WIRING. T HE UNIT IS FACTORY SET. ADJUSTING ANY

INTERNAL COMPONENT OTHER THAN THE MAIN FUSE BLOCK CAN VOID THE WARRANTY.

THIS UNIT REQUIRES A KIT TO BE FIELD CONVERTED FROM THREE-PHASE TO SINGLEPHASE OR VICE-VERSA. CONSULT FACTORY FOR PHASE CHANGES.

All 208-220-240 and 480 volt units will h ave three fuse bl ock sections , “L1-L2-L3”, for us e with either 3-wir e

3-phase or 2-wire, single-phase, 50 or 60 Hz. All 380V and 415V units will have four fuse block sections, “L1L2-L3-N,” for use with European style 4-wire 3-phase with neutral.

Figure 2

INSTALLATION

Serial

Plate

Fuse Block

3/4" Conduit

Fitting Hole

Fuse Block Cover

(shown removed)

Rear Cover

OPERATOR’S MANUAL 1178387 REV 2 PAGE 7

Page 8

INSTALLATION MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Step 3: Optional Floor Drain

The drain valve is 1/2’’ NPT. Posi tion the unit near, but not on top of, an ope n floor drain. Allow at le ast a 1"

air gap.

DO NOT directly plumb to the unit unless you also insta ll an “ope n funne l” downstr eam of this connect ion in

the drain system. The “open funnel” is int end ed t o eliminate an y water f r om entering the steamer because of

a blocked drain. An y connection that allows the build- up of back pressure in the unit (such as a reduct ion in

pipe size to a line smaller than 1/2’’or a 9 0 degree angle in the line pr ior to the “open f unnel” dr ain d ischarge

point) may cause personal or property damage and will therefore void the warranty. (See Figure 3)

Figure 3

INSTALLATION

PERFORMANCE CHECK

The following items should be checked within the first 30 days of operation by a qualified service technician.

1. Check doors for proper alignment.

2. Ensure proper opening and closing of doors.

3. Open door and remove cavity bottom cover, if present.

4. Ensur e that the li ght com es on when le ver is set to the ‘’ON” pos it ion.

5. An audible ‘’click” should be heard when the door switch actuator rod is depressed and held. This

indicates proper func tioning of the contactor as it closes. You should hear a sec ond audible ‘’click” (in

less than 75 seconds) as the contactor opens. Release rod.

6. Pour approximately 2 gallons of water into trough, ensuring that the cavity bottom is covered.

7. Depress and hold the door switch for 2 minutes. The contactor should close when the switch is first

depressed and stay closed during this period.

8. Close the door and wait approximately 12 minutes until the contactor closes, indicating the unit has

reached operating tem per ature.

PAGE 8OPERATOR’S MANUAL 1178387 REV 2

Page 9

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS OPERATION

OPERATION

STARTUP

1. If the cavity bottom cover is present, open door and remove.

2. Turn lever to ‘’ON’’ position with door open.

3. Important: Pour water into trou gh above the door until water is obs erved pass ing through t he fill / drain

opening at left rear corner of cavity bottom.

4. Add additional water through trough or through door up to ‘’-WATER LEVEL-’’ mark.

NOTICE: WATER SPECIFICATION

To meet warranty requirements, supply water must meet the following specification:

Total Dissolved Solids (TDS)........... 60 PPM

Hardness.......................................... 2 Grains or 35 PPM

pH Factor ......................................... 7.0 to 7.5

5. Replace cavity bottom cover (if present).

6. Unit will be ready for cooking in approximately 12 minutes.

OPERATION

1. Suggested cooking times for various foods are shown in the table in the following section.

2. Pan specifications are shown on specifications page (page 4).

3. The door may be opened or closed at any time.

4. Unit will automatically idle at operatin g tem per ature when and if the door is c l os ed a nd there is no food in

the cavity.

5. Timer can be used as desired. However, it has no effect on unit operation.

6. Add proper am ount of water thr ough t he trough (abo ve the door) or direc tl y through the door when water

level is low.

7. If unit runs out of water the ‘’CHECK WATER LEVEL’’ light will illuminate. Follow step # 6, above.

SHUTDOWN

OPERATION

1. The custom drain pan or a 12” x 20”x 4” non-perfor ated stainless steel pan should be loc ated under the

unit at all times.

2. Turn lever to the “OFF” position.

3. Empty drain pan after allowing water to cool.

4. Remove pan guides and cavity bottom cover (if present).

5. Wipe out steamer (with Lime-A-Way or equivalent deliming solution as necessary), RINSE

THOROUGHLY WITH CLEAN WATER.

6. Ensur e drai n open ing is clear .

7. Replace pan guides and cavity bottom cover (if present).

8. Leave the door ope n at night af ter clean in g.

9. DO NOT USE high-chlorine or bleach solution for cleaning the door gasket.

10. DO NOT USE steel wool or other metallic pads in the steamer.

OPERATOR’S MANUAL 1178387 REV 2PAGE 9

Page 10

COOKING HINTS MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

COOKING HINTS

COOKING TIPS

Schedule cooking of fresh vegetables so that they will be served soon after they are cooked. If it is

necessary to prepare t hem in advance, they can be plun ged into cold water, dr ained thoroughly and hel d

under refrigeration until needed for service.

Five pounds of c old cooked vege tables can be r eheated in the steam er in 5 to 10 m inutes, depe nding upo n

the variety.

SUGGESTED COOKING TIMES

Timer settings are for general gu idance only. Differenc es in food quality, size, sha pe, freshness, load si ze,

and desired degree of doneness must be taken into consideration and adjustments made in time, if

necessary.

Cooking Time

Product Weight Portions

(minutes) Pan Used

Asparagus

Fresh

Frozen Spears (Thawed)

Beans

COOKING HINTS

Green - Frozen, Cut

Green - Fresh

Wax - Frozen

Lima - Frozen

Broccoli

Spears -Fresh

Spears - Frozen (Thawed)

Brussel Sprouts

Fresh

Fresh

Carrots

Frozen - Whole Baby

Fresh - ¼-inch Bias Cut

Cabbage

Green, Cut Into Wedges

Red, Cut Into Wedges

Cauliflower

Fresh, Whole

Fresh, Whole

Frozen, Flowerettes

3½ lbs.

5 lbs.

5 lbs.

5 lbs.

5 lbs.

5 lbs.

4 lbs.

5 lbs.

5 lbs.

5 lbs.

5 lbs.

5 lbs.

2 lbs.

2 lbs. 12 oz.

5 lbs.

14 (4 oz.)

20 (4 oz.)

20 (4 oz.)

20 (4 oz.)

20 (4 oz.)

20 (4 oz.)

16 (4 oz.)

20 (4 oz.)

20 (4 oz.)

20 (4 oz.)

20 (4 oz.)

20 (4 oz.)

24

16

8 (4 oz.)

11 (4 oz.)

20 (4 oz.)

8-10

9

12

15-17

13

10

10-12

8

15-17

13

12

12

15

18-20

9-10

15

10-12

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Corn

Fresh, Cob, 4-5 Inch Ears

Frozen - Whole Kernel

Frozen - Cob, 6 Inch Ears

Table continues on next page.

PAGE 10 OPERATOR’S MANUAL 1178387 REV 2

5½ lbs.

5 lbs.

9 lbs.

15

20 (4 oz.)

14

13-15

8

12-14

Full/Perforated

Full/Perforated

Full/Perforated

Page 11

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS COOKING HINTS

Table continuing from previous page.

Cooking Time

Product Weight Portions

Mixed Vegetables

Frozen 5 lbs. 20 (4 oz.) 12 Full/Perforated

Peas

Frozen 5 lbs. 20 (4 oz.) 8 Full/Perforated

Potatoes

Red Bliss - Whole

Russetts - Whole

Russetts - Peeled

Russetts 1-Inch Cubes

Spinach

Fresh, Leaf

Frozen, Chopped

Zucchini

Fresh - Slices ¼-inch Thick 5 lbs. 20 (4 oz.) 6-8 Full/Perforated

7 lbs.

8 lbs.

5 lbs.

5 lbs.

2½ lbs.

6 lbs.

28

20

12

20 (4 oz.)

10 (4 oz.)

24 (4 oz.)

(minutes) Pan Used

35

25-35

20

17

5

35

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Full/Perforated

Broccoli

Spears -Fresh

Spears - Frozen (Thawed)

Eggs

Large - Hard Cooked 12 lbs. 12 15-16 ½ Perforated

Meats

Corned Beef

Hot Dogs, Thawed

Hot Dogs, Frozen

Fowl

Boneless Chicken Breast 4½ lbs. 12 (6 oz.) 15 Full/Perforated

Tamales, Frozen

Tortilla, Frozen 8-Inch

Beef Ravioli, Frozen 48 Ravioli

Elbow Macaroni 2 lbs.

Spaghetti

Egg Noodles 2 lbs.

4 lbs.

5 lbs.

6¾ lbs.

5 lbs.

5 lbs.

3 lbs.

4 Tortillas

(1 lb. 8 oz.)

Uncooked

2 lbs.

Uncooked

Uncooked

16 (4 oz.)

20 (4 oz.)

18 (6 oz.)

40 (2 oz.)

40 (2 oz.)

12 (4 oz.)

4

8 5-6 Full/Perforated

32 (2 oz.) 7 In Perforated Pan

32 (2 oz.) 14

32 (2 oz.) 10 Full/Perforated

10-12

8

2 hours

5

10

20

45 Seconds

Full/Perforated

Full/Perforated

Full

Full/Perforated

Full/Perforated

Full/Perforated

Half/Perforated

Nested in Solid Pan

In 4-Inch

Full/Perforated

COOKING HINTS

Converted Rice 2 lbs.

2½ Qts. Water

+ Oil & Salt

Navy Beans

Place beans in pan and cover with 3-quarts hot tap

water. Steam for 2 minutes; remove from steamer

and cover for 1 hour. Remove cover and place back

in steamer for 40 minutes.

Table continues on next page.

OPERATOR’S MANUAL 1178387 REV 2 PAGE 11

2 lbs. Full/Perforated

25 Full/Perforated

Page 12

COOKING HINTS MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Table continuing from previous page.

Cooking Time

Product Weight Portions

(minutes) Pan Used

Black Eyed Peas

Place beans in pan and cover with 3-quarts hot tap

water. Steam for 2 minutes; remove from steamer

and cover for 1 hour. Remove cover and place back

in steamer for 35 minutes.

Oysters 5 lbs. 16 Count 12 Perforated Pan

Shrimp, Fresh, Medium, Heads Removed 5 lbs. 6-7 Full/Perforated

Shrimp, Frozen, Large, Peeled & Deveined 5 lbs. 8 Full/Perforated

Lobster 1¾ lbs. 8 Full/Perforated

Alaskan King Crab Legs 1 lb. 4-5 Full/Perforated

Cherrystone Clams 5 lbs. 12 7 Full/Perforated

Fish Fillets 7½ lbs. 12 (10 oz.) 18 Full/Perforated

• For eggs cooked in the shell, adding salt to the cooking water increases cooking efficiency and decreases cooking

time. If the egg cracks, the white is cooked at the crack and is sealed right away.

• To avoid green yolk (which is a deposit of iron sulfide) chill the eggs immediately after removing from the steamer by

COOKING HINTS

plunging them into a cold water bath (preferably containing ice).

• A quick and easy way to cook eggs for a salad mixture is to crack them directly into a solid steam table pan which has

been lightly coated with salad oil. Do not mix. Steam until they are hard cooked. Remove and chop as you would for

egg salad. The job of peeling is eliminated.

• Transfer steamed hot chicken to deep pan, cover with Cacciatore Sauce and finish in oven. Bake 20 to 30 minutes.

May be held on steam table.

• Chicken, sausage, and/or fish may be browned in Infra-Red or Radiant Broiler after steaming by brushing with melted

margarine mixed with salad oil to give a golden brown color.

• Save juices from steamed chicken or turkey to make soups, sauces, or casserole dishes.

• Chicken may be steamed in advance and refrigerated for next day’s use. Be sure to bring product back to 180°F

before serving.

• Save the juice from the corned beef. After the cabbage has been steamed, place it in a solid pan and add the juice for

flavoring and holding on a steam table.

• Steaming brisket is a definite time saver. Boiling in water takes 40 to 50 minutes per pound. Using the Simple Steam

can save 50% in cooking time.

• Cabbage, when steamed, retains its color and wedge identity. It will not break apart as it does when boiled in an open

pot.

• When removing items prepared in a perforated pan, place a solid pan underneath the perforated pan with the cooked

food in order to prevent dripping on the floor.

• The Simple Steam is designed to accept standard 12 x 20 pans. Fractional size pans and dishes can be used as well

with the optional perforated shelf.

• For stirring, the pan does not have to be removed from the steamer. Pull pan 1/3 way out of the cavity and the entire

surface is accessible.

• The door may be opened at any time during operation to remove or add food.

2 lbs. Full/Perforated

Nested in Full Pan

2½-Inch Deep

Nested in Full

Hotel Pan

PAGE 12 OPERATOR’S MANUAL 1178387 REV 2

Page 13

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS CLEANING

CLEANING

Southbend equipment is constructed with the best quality materials and is designed to provide durable

service when properl y maintained. To expect the b est performance, your equipment must be m aintained in

good condition and cleaned dail y. Naturally, the frequenc y and extent of cleaning depends on the amount

and degree of usage.

Following daily and more extensi ve peri odic maintenance proced ur es will incr e as e th e l if e of your equ ipment.

Climatic conditions (i.e., salt air, seasonings, and water quality) may result in the need for more thorough and

more frequent cleaning in order to keep equipment performing at optimal levels.

! WARNING: BURN HAZARD

For proper and safe operation, this steamer must be cleaned daily as described in this manual.

Failure to do so could result in serious injury or damage.

Drains must be kept clean and clear of debris.

! WARNING: SHOCK HAZARD

DO NOT GET WATER IN THE CONTROLS.

This could result in expensive repairs and/or electrical shock.

De-energize all power to equipment before cleaning the equipment.

DAILY CLEANING

• Remove pan guides and cavity bottom cover (if present).

• Wipe out steamer (with Lime- A-Way or equivalent delim ing solution as nec essary) and rinse t horoughly

with clean water.

• Make sure drain opening is clear.

• Replace pan guides and cavity bottom cover (if present).

• Leave the door open at night after cleaning.

• Do not clean the door gasket with a high-chlorine solution or bleach.

• Do not use steel wool or other metallic pads in the steamer.

PERIODIC CLEANING

• If lime or mineral deposit starts to buil d up in th e interi or, cle an the u nit b y using Sou thbend “desc aler” or

other non-caustic de liming solution. Fol low manufacturer’s r ecommended procedures. T horoughly rinse

out unit with clean water.

CLEANING

• To remove normal dirt, grease, or product residue from stainless steel, use ordinary soap and water

applied with a sponge or cloth. Dr y thoroughly with a clean cloth. Nev er use vinegar o r any corrosiv e

cleaner.

• Occasionally drain rear water box. T o remove grease and f ood splatter or condense d vapors that have

baked on the equipment, apply cleans er to a dam p cloth or s ponge a nd rub cle anser on th e metal i n the

direction of the polishing lines on the metal. Rub bi ng cleans er as gently as possible in t he d irec ti on of the

polished lines will not mar the finish of the stainless steel. NEVER RU B WITH A CIRCULAR MOTION.

Soil and burnt deposits which do not r esp ond to the above procedur e c an usually be rem oved by rubbing

OPERATOR’S MANUAL 1178387 REV 2 PAGE 13

Page 14

CLEANING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

the surface with SCOTCH-BRITE scouring pads. DO NOT USE ORDINARY STEEL WOOL, as any

particles left on the sur face will r ust and f urther sp oil the appe arance of the finish . NEVER U SE A W IRE

RUSH, STEEL SCOURING PAD, SCRAPER, FILE OR OTHER STEEL TOOLS. Surfaces which are

marred collect dirt more rapidl y and bec om e mor e diff icult to cl ean. M arring also increas es t he poss ibilit y

of corrosive attack. Refinishing may then be required.

SEMIANNUAL CLEANING

At least twice a year, have your Southbend Authorized Service Agency or another qualified service

technician clean and adjust the unit for maximum performance. Semiannual cleaning should include the

following:

1. Remove rear cover.

2. Place a (1) gallon container under the water seal box drain valve (see Figure 12 on page 29).

3. Open drain v al ve, and clos e va lve when box is fin ished dra ining.

4. Add one gallon of deliming solution to the trough above the door.

5. Add two gallons of deliming solution through the door into the cavity

6. Turn unit on, let run for 30 minutes.

7. Turn unit off and drain all solution from the cavity.

8. Drain solution from water seal box as in steps 2 and 3.

9. Fill unit with clean water THROUGH THE TROUGH and drain. Repeat 2 times.

Consult the Southbend Authorized P arts/Servic e Distributor list for th e Authorized Service Representat ive in

your area or contact Southbend at 1-800-348-2558 for this information.

CLEANING

PAGE 14 OPERATOR’S MANUAL 1178387 REV 2

Page 15

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TROUBLESHOOTING

TROUBLESHOOTING

This section contai ns a troub les hootin g k ey and ref erenced f lowcharts to ass ist a qual ifie d serv ice tech nic ian

in the servicing of a EZ-3 or EZ-5 Countertop Steamer.

TROUBLESHOOTING KEY

Find the symptom below that corresponds to the malfunction, then tur n to t he c orr esponding figure and pag e.

Follow the flowchart on that page until the problem is solved.

Symptom Page

Unit Not Heating Up, "ON" Light Not Lit 16

Unit Not Heating Up Properly or Not Cooking As Fast, "ON" Light Lit 17

Unit Using Excessive Amount of Water and/or Excessive Steam Coming from Vent Tube 18

"Check Water Level" Light Does Not Come On When Unit Runs Out of Water 19

Buzzer Does Not Come On 20

TROUBLESHOOTING FIGURES AND PROCEDURES

Figure and/or Procedure Page

Voltage Check at Control Panel Fuse Block 21

Heating Element Resistance Check (at contactor) 22

Main Fuse Replacement 23

Power Switch Continuity Check 24

Contactor Coil and MOV Check 25

Idle Element Resistance Check 26

Timer and Buzzer Check 27

Door Switch Continuity Check 28

Float Switch Continuity Check 29

High Limit Continuity Check 30

Time Delay Relay Check (EZ-3 only) 31

Controller Check (EZ-5 only) 32

Electric Schematic for 208-240 Volt 60 Hz or 220 Volt 50 Hz Model EZ-3 33

TROUBLESHOOTING

Electric Schematic for 480 Volt Model EZ-3 34

Electric Schematic for 208-240 Volt 60 Hz or 220 Volt 50 Hz Model EZ-5 35

Electric Schematic for 480 Volt Model EZ-5 36

OPERATOR’S MANUAL 1178387 REV 2PAGE 15

Page 16

TROUBLESHOOTING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Unit Not Heating Up, "ON" Light Not Lit

Unit not heating up, "ON" light not lit.

Check that circuit breaker is ON and that proper voltage is

DISCONNECT POWER AT CIRCUIT BREAKER.

Remove control panel without disconnecting plug.

Check voltage between A and B on control panel fuse

No Yes

DISCONNECT POWER AT CIRCUIT BREAKER.

Check resistance between contactor terminals

(see Figure 5 on page 22).

No Yes

Replace elements and

(see Fig. 6 on page 23).

Is measured resistance

consistent with th e table in

Figure 5 (see page 22)?

main fu se s

Check main fuses and

replace as needed

(see Fig. 6 on page 23).

available at main fuse block.

Turn le ver to "ON " po sitio n.

Reconnect power.

(see Figure 4 on page 21).

Does voltage

meet specifications?

Check voltage across

terminals 1 and 6 of

terminal block

(see Fig. 4 on page 21).

Check voltage on side C and D on control panel

fuse block (see Fig. 4 on page 21).

Does voltage

meet specifications?

Che ck for sh ort circuit in

power switch (see Fig. 7

on page 24), contactor coil

and MOV (see Fig. 8 on

page 25), idle element

(see Fig. 9 on page 26),

and buzzer (see Fig. 10

on page 27). Replace as

nece ssa ry.

NoYes

No Yes

Test power switch or

adjust so that it is

actuated properly by cam

on valve shaft. Replac e

TROUBLESHOOTING

switch a s n e ce s s a ry

(see Fig. 7 on page 24).

Does volta ge

meet specifications?

PAGE 16 OPERATOR’S MANUAL 1178387 REV 2

Replace control panel

fuses.

Replace "ON" light;

continue on next page.

Page 17

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TROUBLESHOOTING

y

Unit Not Heating Up Properly or Not Cooking A s Fast, "ON" Light Lit

Unit not heating up properly, or not

cooking as fast, "ON" light lit.

Check all three main fuses, replace as necessary.

No Yes

Drain unit. Turn unit on with door open.

Add two gallons of water THROUGH

TROUGH. Close door, wait 10 minutes.

Does unit heat up?No Yes

Open door, depress

and hold switch

Does constactor

No Yes

"click" on and stay on for at

least 2 minutes?

Check and replace time

delay relay as necessary

(EZ-3 only, see Fig. 14

on page 31).

Remind operator of

proper filling procedure.

Is "CHECK WATER LEVEL"

light on with door closed?

Add water according to

start up instru ctions on

door. Wait 5 minutes,

light should go off.

No Yes

DISCONNECT POWER

AT CIRCUIT BREAKER

Check high limits and

replace as necessary

(see Fig. 13 on page 30).

Does unit have water?No Yes

Is bo ttom

of unit covered with

deposits?

Clean unit

(see page 13)

DISCONNECT POWER

AT CIRCUIT BREAKER

Remove control panel. Remove control panel.

Rem o ve do o r sw itch lead

wires f rom t e rminal block

positions 2 and 3.

Depress door switch and

check door switch lead

wires for continuit

(see Fig. 11 on page 28).

Replace door switch.

DISCONNECT POWER

AT CIRCUIT BREAKER

Check resistance between

contactor terminals and

replace any bad elements

(see Fig. 5 on page 22).

Continuity?No Yes

OPERATOR’S MANUAL 1178387 REV 2PAGE 17

Reconnect door switch

lead wires.

Remove rear cover.

Che ck flo a t switch for

continuity and clean

openings in float tube

(see Fig. 12 on page 29).

No Yes

Replace float switch

and clean tube.

Float

switch and float tube

OK?

Check and replace contactor

(see Fig. 8 on page 25) and

controller (EZ-5 only, see

Fig. 15 on page 32).

TROUBLESHOOTING

Page 18

TROUBLESHOOTING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Unit Using Excessive Amount of Water and/or Excessive Steam Coming from Vent Tube

Unit using excessive amount of water

and/or excessive steam coming from

vent tube behind the unit.

DISCONNECT POWER

AT CIRCUIT BREAKER

Remove control panel,

but leave plug connected.

Disconnect wire C23 from term inal block position 3

(EZ-3) or wire C98 from controller (EZ-5), reconnect

power, turn unit on, wait 12 minutes.

Yes No

DISCONNECT POWER AT

CIRCUIT BREAKER

C heck tim e delay relay (EZ-3

only, see Figure 14 on pag e 31)

or controller (EZ-5 only, see

Figure 15 on pa ge 32). Replace

if necessary

Reconnect power.

Wait 12 minutes.

Yes No

Excessive steam?

DISCONNECT POWER AT

CIRCUIT BREAKER

Check float switch and float tube.

Replace float switch and c lean

float tube as nece ssary

(see Figure 12 on pag e 29).

Excessive stea m?

TROUBLESHOOTING

PAGE 18 OPERATOR’S MANUAL 1178387 REV 2

Che c k contactor and

replace as necessary

(see Figure 8 on page 25).

Reinstall control panel,

reconnect power.

Page 19

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TROUBLESHOOTING

"Check Water Level" Light Does Not Come On When Unit Runs Out of Water

"CHECK WATER LEVE L" light does not

come on when unit runs out of water.

Remove wire C17 (EZ-3) or C53 (EZ-5)

from "CH ECK WAT ER LE VEL " light a nd

check resistanc e acro ss light terminals.

Check High Limits

(se e Figure 13 on

Page 30) an d

replace as needed.

Is resistance over

100 Kohm?

YesNo

Replace light

OPERATOR’S MANUAL 1178387 REV 2PAGE 19

TROUBLESHOOTING

Page 20

TROUBLESHOOTING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Buzzer Does Not Come On

Buzzer doe s not come on.

DISCONNECT POWER

AT CIRCUIT BREAKER

Remove co n trol panel.

Set time r for five minu tes.

Yes No

Remove buzzer

le ad wires

from time r.

Check timer

(see Fig ure 10

on page 27 ).

Yes No

Continuity?

Does timer

time down?

Replace

timer.

TROUBLESHOOTING

Replace

timer.

PAGE 20 OPERATOR’S MANUAL 1178387 REV 2

Replace

buzzer

(see Fig ure 10).

Page 21

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TROUBLESHOOTING

g

Figure 4

Voltage Check at Control Panel Fuse Block

Power Switch

"ON" Light

"CHECK WATER

LEVEL" Li

ht

C

Control

Panel

Fuse

Block

A

D

B

1. Disconnect power at circuit breaker.

2. Remove control panel without disconnecting plug.

3. Turn lever to “on” position.

4. Reconnect power.

5. Place leads as shown.

6. Check voltage.

Terminal Block

Door Switch

TROUBLESHOOTING

OPERATOR’S MANUAL 1178387 REV 2PAGE 21

Page 22

TROUBLESHOOTING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Figure 5

Heating Element Resistance Check (at contactor)

C

B

A

Contactor

(top view)

1. Disconnect power at circuit breaker.

2. Remove control panel.

3. Place test leads between terminals A and C on left side of contactor.

4. Check the resistance and compare to the allowable range in the following table:

Model EZ-3

Voltage

208 8 to 16 6 to 12

220 9 to 18 7 to 13

240 11 to 21 8 to 15

380 28 to 53 21 to 39

415 34 to 63 24 to 46

480 45 to 84 33 to 61

Allowable Resistance (Ohms)

Model EZ-5

Allowable Resistance (Ohms)

5. Check resistance between terminals A and B and between terminals B and C similarly.

TROUBLESHOOTING

PAGE 22 OPERATOR’S MANUAL 1178387 REV 2

Page 23

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TROUBLESHOOTING

Figure 6

Main Fuse Replacement

Fuse Block

1. Disconnect power at circuit breaker.

2. Remove rear cover from unit.

3. Remove fuse block cover.

4. Check fuses for continuity.

5. Replace as necessary.

Fuse Block Cover

(shown removed)

Rear Cover

TROUBLESHOOTING

OPERATOR’S MANUAL 1178387 REV 2PAGE 23

Page 24

TROUBLESHOOTING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Figure 7

Power Switch Continuity Check

Power Switch

"NO" Lead

1. Disconnect power at circuit breaker.

2. Remove control panel.

3. Turn Lever to ‘’ON’’ from ‘’OFF’’ and to ‘’OFF’’ from ‘’ON’’ ensuring that the power switch is

properly actuated.

4. Remove power switch lead wires from fuse block (note wire locations).

5. Place test leads on ‘’C’’ and ‘’NO’’ lead wires as shown.

"C" Lead

Fuse Block

6. Check for continuity with lever in ‘’OFF’’ position (there should be no continuity).

7. Check for continuity with lever in ‘’ON’’ posit io n (there should be continuity).

8. Repeat steps 5 - 7 with test leads between other pair of ‘’C’’ and ‘’NO’’ lead wires.

9. Place test lead on “NO” lead wire and other test lead on other “NO” lead wire.

10. Check for continuity with lever in “ON” position (there should be no continuity).

11. Reconnect wires or replace switch as necessary.

TROUBLESHOOTING

PAGE 24 OPERATOR’S MANUAL 1178387 REV 2

Page 25

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TROUBLESHOOTING

Figure 8

Contactor Coil and MOV Check

Actuator

C

B

A

TOP VIEW

1. Disconnect power at circuit breaker.

2. Remove control panel and disconnect nine-pin plug PL1.

3. Depress actuator on top of contactor. Actuator should travel freely and spring back when released.

4. Check for continuity between contacts A and D as shown in top view. There should be no

continuity.

5. Repeat Step 4 for contacts B and E and for contacts C and F.

F

E

D

MOV

LEFT SIDE VIEW

6. Place test leads on contactor coil terminal as shown in left side view.

7. Check resistance.

8. If resistance is not approximately 390 (+/- 40) ohms, remove MOV and recheck coil resistance. If

resistance is now approximately 390 (+/-40) ohms, replace MOV, otherwise replace contactor.

9. Reconnect all wires.

OPERATOR’S MANUAL 1178387 REV 2PAGE 25

TROUBLESHOOTING

Page 26

TROUBLESHOOTING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Figure 9

Idle Element Resistance Check

Model EZ -3

Model EZ -5

High Limit

Idle Element Plug

1. Disconnect power at circuit breaker.

2. Remove control panel.

3. Disconnect idle element plug (PL3).

4. Place test leads as shown above.

5. Check to see if resistance is within +/- 10% of values in the following table:

Model EZ-3

Voltage

208 115 87

220 129 97

240 154 115

380 385 289

415 459 344

480 614 461

TROUBLESHOOTING

6. Remove one test lead, place on ground, check for short circuit.

Resistance (Ohms)

Model EZ-5

Resistance (Ohms)

PAGE 26 OPERATOR’S MANUAL 1178387 REV 2

Page 27

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TROUBLESHOOTING

Figure 10

Timer and Buzzer Check

Timer

Buzzer

1. Disconnect power at circuit breaker.

2. Remove control panel.

3. Set timer for one minute and allow to time out. If timer does not run, then replace.

4. Remove buzzer lead wires from timer and terminal block position 6, as shown.

5. Place test leads between positions 1 and 3 on the timer.

6. Check for continuity. If no continuity, replace timer.

7. Place test leads in terminals of buzzer lead wires.

8. Check physical condition of buzzer.

9. Check that resistance is approximately 3.4Kohms. Otherwise, replace buzzer.

TROUBLESHOOTING

OPERATOR’S MANUAL 1178387 REV 2PAGE 27

Page 28

TROUBLESHOOTING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Figure 11

Door Switch Continuity Check

Model EZ-3

Terminal Block

1. Disconnect power at circuit breaker.

Model EZ-5

Door Switch

2. Remove control panel.

3. Depress and release door switch actuator rod to make sure door switch is properly actuated.

4. EZ-3: Remove door switch lead wires from terminal block positions 2 and 3, or

EZ-5: Remove door switch lead wires from terminal block position 1 and terminal 2 of the controller.

5. Place test lead as shown inside the terminal connectors of the lead wires.

6. Check for continuity - (there should be NO continuity).

7. Depress door switch actuator rod and check for continuity - (there should be continuity).

TROUBLESHOOTING

PAGE 28 OPERATOR’S MANUAL 1178387 REV 2

Page 29

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TROUBLESHOOTING

Figure 12

Float Switch Continuity Check

Coupling

Water Seal Box

Float Switch

Drain Valve

Rear View of Unit with Back Cover Removed

1. Disconnect power at circuit breaker.

2. Remove rear cover from unit.

3. Disconnect 2 pin float switch plug from mating plug on back of unit (PL2).

4. Drain water seal box by opening 3/8’’ drain valve on box.

5. Remove float switch from box by removing float switch fitting from coupling on box.

6. Make sure float travels freely along stem.

7. Place test leads in float switch connector as shown.

8. Hold float switch in same orientation as when installed.

9. Check continuity. There should not be continuity.

10. Flip float switch over.

11. Check for continuity. There should be continuity. Replace as necessary.

12. Check 0.060 passages in float tube. Clean if necessary.

TROUBLESHOOTING

OPERATOR’S MANUAL 1178387 REV 2PAGE 29

Page 30

TROUBLESHOOTING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Figure 13

High Limit Continuity Check

Model EZ-3

C16

C19

Terminal Block

Model EZ-5

C58

C59

1. Turn unit off.

2. Wait for cavity bottom to cool to touch.

3. Disconnect power at circuit breaker.

4. Remove control panel without disconnecting plug.

5. EZ-3: Remove wires C16 and C19 from terminal block positions 1and 2, as shown; or

EZ-5: Remove wires C58 and C59 from terminal block positions 5 and 6, as shown.

6. EZ-3: Place test leads as shown inside the terminal connectors of wires C16 and C19, or

EZ-5: Place test leads as shown inside the terminal connectors of wires C58 and C59.

7. Check for continuity.

8. If no continuity, disconnect each high limit switch individually and check for continuity. Replace

switches that do not have continuity. (See Figure 9 for typical high limit switch location).

9. EZ-3: Reco nn ec t wires C16 and C19; or

EZ-5: Reconnect wires C58 and C59.

10. Reconnect power at circuit breaker.

11. Dry cavity bottom with cloth.

12. Turn unit on with door closed.

13. Wait 6 minutes.

TROUBLESHOOTING

14. Disconnect power at circuit breaker.

15. EZ-3: Remove wires C16 and C19; or

EZ-5: Remove wires C58 and C59.

16. Remove wires from each high limit switch individually and check for continuity. Replace switches

that have continuity.

PAGE 30 OPERATOR’S MANUAL 1178387 REV 2

Page 31

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TROUBLESHOOTING

Figure 14

Time Delay Relay Check (EZ-3 only)

1. Disconnect power at circuit breaker.

2. Remove control panel, but leave plugged in.

3. Disconnect wire C23 from terminal block position 3.

4. Reconnect power.

5. Depress and hold door switch. Contactor should actuate and then deactuate in approximately 60

seconds.

6. If contactor fails to actuate or actuates but fails to deactuate, check potentiometer on top of time

delay relay. Make sure potentiometer is seated properly on time delay relay terminal and make sure

it is set to 60.

7. Depress door switch again. If contactor still fails to actuate and deactuate properly, replace time

delay relay.

TROUBLESHOOTING

OPERATOR’S MANUAL 1178387 REV 2PAGE 31

Page 32

TROUBLESHOOTING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Figure 15

Controller Check (EZ-5 only)

C98

1. Disconnect power at circuit breaker.

2. Remove control panel, but leave plugged in.

3. Disc onnect wir e C98 fr om controller.

4. Reconnect power.

5. Use a spacer to hold door switch in closed position. Contactor should actuate and then deactuate

in less than 60 seconds.

6. If contactor fails to actuate (or actuates but fails to deactuate), replace controller.

7. With spacer still in place and door open, momentarily reconnect wire C98 and then disconnect.

8. Controller should actuate, then deactuate 10 seconds after C98 is disconnected.

9. If contactor fails to actuate (or actuates but fails to deactuate), replace controller.

TROUBLESHOOTING

PAGE 32 OPERATOR’S MANUAL 1178387 REV 2

Page 33

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TROUBLESHOOTING

Figure 16

Electric Schematic for 208-240 Volt 60 Hz or 220 Volt 50 Hz Model EZ-3

OPERATOR’S MANUAL 1178387 REV 2PAGE 33

TROUBLESHOOTING

Page 34

TROUBLESHOOTING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Figure 17

Electric Schematic for 480 Volt Model EZ-3

TROUBLESHOOTING

PAGE 34 OPERATOR’S MANUAL 1178387 REV 2

Page 35

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS TROUBLESHOOTING

Figure 18

Electric Schematic for 208-240 Volt 60 Hz or 220 Volt 50 Hz Model EZ-5

OPERATOR’S MANUAL 1178387 REV 2PAGE 35

TROUBLESHOOTING

Page 36

TROUBLESHOOTING MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Figure 19

Electric Schematic for 480 Volt Model EZ-5

TROUBLESHOOTING

PAGE 36 OPERATOR’S MANUAL 1178387 REV 2

Page 37

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS PARTS

PARTS

NOTICE

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID T HE WARRANTY

ON THIS EQUIPMENT.

The serial plate with volta ge, model, an d serial inform ation is locate d on the right sid e of the steam er cavity

on the upper rear cor ner. On single units a sec ond tag is located on t he face of the door which will show

only model and serial number. On tandem units, a second ta g is on t he r i ght s ide of the r i ght un it a nd t he lef t

side of the left unit.

Replacement parts may be ordered either thr ough a Southbend Auth orized Parts Dis tributor or a S outhbend

Authorized Service Agency.

When ordering parts, please suppl y the Model Number, Serial Number, Part Num ber, Description, Finish,

and Electrical Character istic s as appl icab le.

For parts not listed, consult a Southbend Authorized Parts Distributor or Southbend Authorized Service

Agency. Consult the Southbend Authori zed Parts/Servic e Distributor list f or the Authorized P arts supplier in

your area. If this list is not available, call Southbend at 1-800-348-2558 to obtain this list.

Parts for Simple Steam Countertop Steamer

EZ-3 Part Number EZ-5 Part Number Description

PH-422 PH-422 BELLEVILLE WASHER, 1/4 ID

1332076 1332076 BLANK, DOOR HINGE

1178266 1178266 BOX WELD ASM.,REAR

1178651 1178651 BRACKET, COMPONENT SIMPLE

1178534 1178534 BRACKET, ON/OFF SWITCH

1178525 1178525 BRACKET, VENT TUBE

1178411 1178411 BRACKET,WIRE HANGER

1177770 1177770 BUSHING, VALVE LEVER MOUN

1178389 BUSSMAN FUSE BLOCK,30A

1178494 1178494 BUSSMAN FUSE BLOCK,60A 48

1175708 1175708 BUZZER, ADJUSTABLE, 220V,

1178276 1178276 CAM ACTUATOR, STEAMER

1178370 CAVITY INSULATION

1178299 1181019 CAVITY WELD ASM

1178256 1178256 CLAMP, HEATER

1176561 CLEANING INSTRUCTIONS,RS1161525 1161525 CONTACTOR, 2-POLE,240V,30

1173448 CONTACTOR, 63A,240V COIL

1181032 CONTACTOR, DP, 60 FLA

1178397 1181042 CONTROL PANEL S/A

1178311 1178311 CONTROL PANEL W/A

1181038 CONTROLLER, EZ-5

1178442 1178442 COVER ASM.,POOL

1178524 1178524 COVER W/A, DRAIN BOX

1178552 1178552 COVER W/A, DRAIN

PARTS

OPERATOR’S MANUAL 1178387 REV 2PAGE 37

Page 38

PARTS MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Parts for Simple Steam Countertop Steamer

EZ-3 Part Number EZ-5 Part Number Description

1178265 1178265 COVER, BOTTOM

1178527 1181000 COVER, REAR STEAMER

1178255 1181009 COVER,EXTERIOR

1178657 COVER,EXTERIOR,STACKED

1179962 1179962 COVER,REMOVABLE BUSS

1176797 DESCALER, 3.5OZ PKG (100G)

1178167 1181015 DOOR ASSEMBLY COMPLETE

1178171 DOOR INSUL.BLOCK

1178522 1178522 DRAIN BOX WELD ASM.

1178410 1178410 DRAIN PAN WELD ASM.

1333045 DRAIN VENT TUBE ( AIR VEN

1178353 DUAL HEATING ELEMENT

1178359 DUAL HEATING ELEMENT

1178526 ELBOW, 90 DEG. 1 "NPT FEM,

1178656 1178670 ELBOW, 90 DEG, STR. 1/2"

1178354 ELEMENT BLO CK, 220V,CENTE

1178360 ELEMENT BLO CK, 220V,OUTER

1178355 ELEMENT BLO CK, 240V,CENTE

1178361 ELEMENT BLO CK, 240V,OUTER

1178358 ELEMENT BLO CK, 480V,CENTE

1178364 ELEMENT BLO CK, 480V,OUTER

1178332 1178332 FITTING,3/4 HOSE ID X 1/2

1178423 FITTING,3 /4" KYNAR HOSE,E

1178422 1178422 FITTING,FLOAT SWITCH

PH-423 PH-423 FLANGE BUSHING, 1/4ID BRO

1178318 1181020 FRONT FRAME WELD ASM

1178317 1178317 FRONT TOP CROSSMEMBER W/A

1178545 1178545 FUSE, 10 AMP

1178392 FUSE, 2.5 AMP

1178390 FUSE, 30 AMP

1181024 FUSE, 35 AMP

1178495 FUSE, 50 AMP, CLASS G

1181026 FUSE, 60 AMP

1178391 1178391 FUSEBLOCK, CONTROLS

1178096 1181010 GASKET, DOOR

1178227 GASKET, SIDE PANEL

1178325 1178325 GASKET,CONTROL PANEL

1180953 1180953 HANGER,HOSE

1332048-1 1332048-1 HINGE, LT DOOR

1332048-2 1332048-2 HINGE, RT DOOR

1181041 HARNESS, WIRE, EZ-5

1178560 HEAT ELEMENT,DUAL COIL, 20

1178561 HEAT ELEMENT,DUAL COIL, 22

1178565 HEAT ELEMENT,DUAL COIL, 48

1178562 HEAT/ELEMENT,240V,DUAL CO

1178554 HEATING ELEMENT, 208V, EZ

1178555 HEATING ELEMENT, 220V, EZ

PARTS

1178556 HEATING ELEMENT, 240V

1178559 HEATING ELEMENT, 480V, EZ

PAGE 38 OPERATOR’S MANUAL 1178387 REV 2

Page 39

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS PARTS

Parts for Simple Steam Countertop Steamer

EZ-3 Part Number EZ-5 Part Number Description

1178483 HOSE, 1 1/2"ID,SILCONE

1178386 1178386 HOSE,3/4" ID SILCONE

1178685 HOS E, OVERF LO W, 28"

1178369 1181021 INSULATION, BACK PANEL

1178371 1178371 INSULATION, BOTTOM

1181022 INSULATION,CAVITY,EZ-5

1181018 INSULATION, DOOR, EZ-5

1178418 1178418 INSULATION,FRONT CAVITY

4440478 4440480 KIT, DRAIN BOXES,STACK

1170337 1170337 KNOB

1175168 1175168 KNURLED INSERT, 3/8"

1177079 1177079 LATCH ARM, CAST

1177317 1177317 LATCH ASSEMBLY, STEAMERS

1177078 1177078 LATCH COVER PLATE, CAST

1181039 LE AD, ELEMENT EZ-5

1178485 1178485 LEG,4" S/S, EZ (FRONT)

1178486 1178486 LEG,4" S/S,EZ (REAR)

1179930 LEVER, VALVE

1178329 1178329 LIGHT,INDICATING,AMBER

1178330 1178330 LIGHT,INDICATING,RED

1175547 1175547 LUG, GROUNDING

1178374 1178374 MAIN POWER LEADS

1178387 1178387 MANUAL, EZ-3&5 STEAMER

1178367 1178367 METAL OXIDE VARISTOR

1178643 1178643 NIPPLE, CLOSE, 1/2" NPT

1146402 NUT 1/4-20, HEX HEAD

1177865 NUT, HEX, 5/8 -18, BRASS

1178351 NYLON INSERT NUT

PH-292 PH-292 NYLON WASHER

1178342 1178342 O-RING, VALVE SHAFT

1178344 1178344 PAN Z-BRACKET,LEFT

1178345 1178345 PAN Z-BRACKET,RIGHT

1178169 1181017 PANEL ASM.,DOOR

1178105 1181016 PANEL ASM.,INNER DOOR

1178106 1181001 PANEL, GASKET RETAINER

1177081 1177081 PIN, .250 DIA, SS, CAST L

1178393 PIN,COTTE R,SS,1/8"X 1 1/4

1172949 PIPE ALUM,1" SCHE DULE 40

PM-141 PM-141 PLUG BUTTO N, 1/4 NYLON

1178319 1178319 POLYPANEL W/TIMER

1178684 1178684 POT FILLER

1178352 POTENTIOMETER,TDR

1333041 1333041 RACK MOUNTING STUDS,1/4-2

1178337 RELAY, TIME DELAY, 120V

1177086 1177086 RETAINER, CAST LATCH

1178338 1178338 RETAINING RING

6600402 6600402 RING,RETAINING S.S.

1178343 ROLL PIN

1175712 1175712 S/A BUZZER, 220V

PARTS

OPERATOR’S MANUAL 1178387 REV 2PAGE 39

Page 40

PARTS MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

Parts for Simple Steam Countertop Steamer

EZ-3 Part Number EZ-5 Part Number Description

1178347 1178347 SEAL,SHAFT

1178275 SHAFT, VALVE LEVER

1178373 1178373 SHIELD,HEAT TRANSFER

1177318 1177318 SHIM, CAST STRIKER

1178234 SIDE PANEL,SIMPLE STEAM

1181045 SIDE, RACK W/A

1172951 1172951 SLEEVE, RUBBER 1 1/4"ID X

1178113 SLIDE RACK, 3 PAN STEA MER

1178644 SLIDE RACK, 5 POS. 3 PAN

1179932 1179932 SPRING

1177082 1177082 SPRING, DOOR HANDLE

1178654 1178654 STAND W/DRAIN, EZ

1178655 1178655 STAND, EZ

1178379 1178379 STEAM TRAP

1177080 1177080 STRIKER, CAST

1178270 1178270 SWITCH ACTUATOR ROD

1178340 1178340 SWITCH, FLOAT

1178533 1178533 SWITCH, POWER S/A

1178430 1178430 SWITCH,DOOR S/A,SIMPLE ST

1181013 THERMOSTAT ASSEMBLY, F/F

1181012 THERMOSTAT ASSEMBLY, M/M

1174302 THERMOSTAT, E LEMENT, 2001

1178341 1178341 TIMER, MECHANICAL

1176388 1176388 TRANSFORMER, 480 TO 240,7

1178439 1178439 TROUGH SCREEN ASM.

1178261 1178261 TUBE & BOX TOP W/A

1178376 1178376 TUBE, VALVE ACTUATOR

1178388 1178388 VALVE LEVER WELD ASM

1178425 1178425 VALVE, 1/2" DRAIN,MODIFIE

1178444 1178444 VALVE, 3/8" BALL,NSF/FDA

1176878 VENT P IPE , 1" NIPPLE

1178683 VENT PIP E, 1" X 24.375"

1180460 WASHER, SEALI NG, #10

1178324 1178324 WATER TROUGH W/A

1178652 1181043 WIRE HARNESS SUPPL., 480V

1178394 WIRE HARNESS W/DISC TSTAT

1178650 1181040 WIRING, DIAGNOSTIC, 480V

1178395 1181037 WIRING, DIAGNOSTIC,208/22

PARTS

PAGE 40 OPERATOR’S MANUAL 1178387 REV 2

Page 41

MODEL EZ-3 & EZ-5 COUNTERTOP STEAMERS

LIMITED W ARRANTY

Southbend warrants that the equipment, as supplied by the factory to the original purchasers, is free from defects in

materials and workmanship. Should any part thereof become defective as a result of normal use within the period and

limits defined below, then at the option of Southbend such parts will be repaired or replaced by Southbend or its

Authorized Service Agency. This warranty is subject to the following conditions:

Repairs under this warranty are to be performed by a Southbend Authorized Service Agency. Southbend cannot be

responsible for charges incurred or service performed by non-Southbend Authorized Agencies. In all cases the closest

Southbend Authorized Service Agency must be used.

TIME PERIOD:

One year labor, one year parts effective from the date of original purchase. The authorized service agency may at his

option require proof of purchase.

Exceptions to standard warranty, effective within above limitations:

• Glass Windows, Door Seals, Rubber Seals, Light Bulbs, Ceramic Bricks,

• Sight Glasses, Cathodic Descalers or Anodes, Broiler, Briquettes and Drip Shields.......90 days material and labor

• Stainless Steel Fry Pot................................................4 years extended material warranty on fry pot on ly—no labor

• Stainless Steel Open Top Burners........................... 4 years extended material warranty on burners only—no labor

• Pressure Steam Boiler Shell.............................. Prorated 4 years extended warranty on boiler shell only—no labor

Boiler shells which have not been properly maintained will not be covered by warranty.

In all cases, parts covered by a five year warranty will be shipped FOB the factory after the first year.

EXCLUSIONS:

• Equipment failure relating to improper installation. Examples are: improper utility connection, improper utilities supply

and problems due to ventilation.

• Equipment that has not been properly maintained. Examples are: calibration of controls, adjustments to pilots and

burners, damage from improper cleaning, and water damage to controls.

• Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication,

neglect, abuse, accident, damage during transit or delivery, fire, flood, riot, or act of God.

If the equipment has been changed, altered, modified or repaired by other than a qualified service technician during or

after the one year limited warranty period, then the manufacturer shall not be liable for any damages to any person or to

any property which may result from the use of the equipment thereafter.

Equipment failure caused by inadequate water quality is not covered under warranty. WATER QUALITY must not exceed

the following limits: Tota l Dissolved Solids (TDS) - 60 PPM (Parts Per Million). Hardness - 2 Grains or 35 PPM, PH

Factor - 7.0 to 7.5. Water pressure 30 PSI minimum, 60 PSI maximum. Boiler maintenance is the responsibility of the

owner and is not covered by warranty.

This warranty does not cover services performed at overtime or premium labor rates nor does Southbend assume any

liability for extended delays in replacing or repairing any items in the equipment beyond the control of Southbend.

"Southbend shall not be liable for consequential or special damages of any nature that may arise in connection with such

product or part." Should service be required at times which normally involve overtime or premium labor rates, the owner

shall be charged for the difference between normal service rates and such premium rates.

This warranty only covers product shipped into the 48 contiguous United States and Hawaii. There will be no labor

coverage for equipment located on any island not connected by roadway to the mainland.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial

application.

Warranty on all replacement parts which are replaced in the field by Southbend Authorized Service Agencies will be

limited to three months on labor, six months on materials (parts) effective from the date of installation. See LIMITED

WARRANTY - REPLACEMENT PARTS for conditions and limitations.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS, AND CONSTITUTES THE ENTIRE

LIABILITY OF SOUTHBEND. IN NO EVENT DOES THE LIMITED WARRANTY EXTEND BEYOND THE DURATION

OF ONE YEAR FROM THE EFFECTIVE DATE OF SAID WARRANTY."

OPERATOR’S MANUAL 1178387 REV 2PAGE 41

Page 42

COUNTERTOP STEAMER

A product with the So uthbend name incor porates the best in dur ability and low m aintenance. We

all recognize, however, that replacement parts and occasional professional service may be

necessary to extend the useful life of this unit. When service is needed, contact a Southbend

Authorized Service Agenc y, or your dea ler. T o a void conf usion, alwa ys refer to the m odel num ber ,

serial number, and type of your unit.

Southbend

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(800) 348-2558 or (919) 552-9161 • FAX (800) 348-2558 or (919) 552-9798

PAGE 42 OPERATOR’S MANUAL 1178387 REV 2

Loading...

Loading...