Page 1

400 SERIES

RESTAURANT RANGE

4 Open Burners, 36” Griddle, Double Ovens or 2 Open Burners, 48” Griddle, Double Ovens

Standard Features

- 33,000 BTU NAT Burners (24,000 BTU LP)

- 4”Stainless steel front rail

- Commercial gas range 36-1/2” wide with a 37” cooking top

(including 6” high adjustable legs)

- 4 patented, clog free, cast iron burners

- Cast iron grate top will hold a 14” stock pot

- Removable one-piece drip tray under burners

- Heat resistant door handle

- Stainless steel front, sides and removable shelf

- Porcelain enamel, lift-out oven bottom

- Hinged lower valve panel

- One year Parts and Labor Warranty

Griddle

- 36” griddle with 1/2” polished steel plate

- 48” griddle with 1/2” polished steel plate

Standard Oven (D suffix)

- 45,000 BTU NAT (40,000 BTU LP)

- Single rack per oven

- Large 26” wide x 26-1/2” deep oven - full size sheet pans fit

both ways

- Equipped with a flame failure safety device

- Thermostat range from 250°- 500°F (121°- 260°C) with low

setting

Convection Oven (A suffix)

- 32,000 BTU NAT (30,000 BTU LP)

- Three racks per oven

- Energy efficient flue design

- Fully front serviceable

- Manual pilot ignition, enamel bottom and door linings

- On/Off switch to allow CO base to operate as Standard oven

Standard Oven Std/Conv. Oven Convection Oven

460DD-3G 460AD-3G 460AA-3G

(not shown)

460DD-4G 460AD-4G 460AA-4G

(shown with optional casters)

Job Item#

CONSTRUCTION SPECIFICATIONS

Exterior Finish: Stainless steel front,sides and shelf standard.

RangeTop:- 33,000 BTU NAT (24,000 BTU LP) each cast iron

burners round, non-clogging design, Center-to-center measurements between burners not less than 12”, side-to-side or front-toback. A removable one piece drip tray is provided under burners

to catch grease

drippings. 4 burners on model 3G, 2 burners on model 4G.

Griddle: Smooth, polished, 1/2” thick steel plate with raised sides,

36” or 48”wide x 24-3/4” deep. Available on Right or Left.

Optional: Thermostat griddle control with 1 throttling-type

thermostats. Temperature range of 100° to 450°F (add prefix T).

Back Shelf: Rigid, single deck stainless steel.

Door: Constructed with heavy duty hinges and unbreakable

quadrants and heat resistant handle.

Legs: 6” black, adjustable

Pressure Regulator: Factory installed.

Standard Models (460DD-3G/460DD-4G)

Interior: Cavity sides, top and back -aluminized steel. Oven

bottom and door lining porcelain enamel finish. Four sides and top

of oven insulated with heavy, self-supporting block type rock wool

with oven baffle assembly constructed of Aluma-Ti steel.

Rack and Rack Guides: 2-postion rack guides with one

removable rack

Controls: Oven thermostat temperature type adjustable for 250° 500° F with a low setting.

Convection Models (460AA-3G/460AA-4G)

Interior: Cavity, bottom and door porcelain enamel finish. Back, top

and sides aluminized steel. Four side and top of oven insulated with

heavy, self-supporting, block type rock wool.

Rack and Rack Guides: Heavy duty, 5 sets of rack guides on 2-3/

8” centers with 3 removable plated racks. ( For best results, no

more than 3 racks should be used)

Blower Fan and Motor: 1/3 hp, 1725 rpm, 60 cycle, 115V AC, high

efficiency, permanent split phase motor with permanent lubricated

ball bearings, overload protection and Class “B” insulation. Motor

mounted to rear of oven. Motor serviceable from front of oven

through oven cavity.

Electrical System: Wired for single phase, 115V AC with 6’ cord

and 3-prong plug supplied with each deck.

Gas Control System: Includes pressure regulator, flame switch

safety, pilot filter, pilot adjustment

Oven Heating: Aluminized steel bar burner. Dual flow fan recirculates heat directly from combustion area and within oven cavity.

Controls: Oven thermostat temperature type adjustable for 250° 500° F with a low setting.

Form 460-3G4G Rev 4 (04/07)

www.yatesgd.com www.yatesgraphicdesign.com

Printed in USA

Page 2

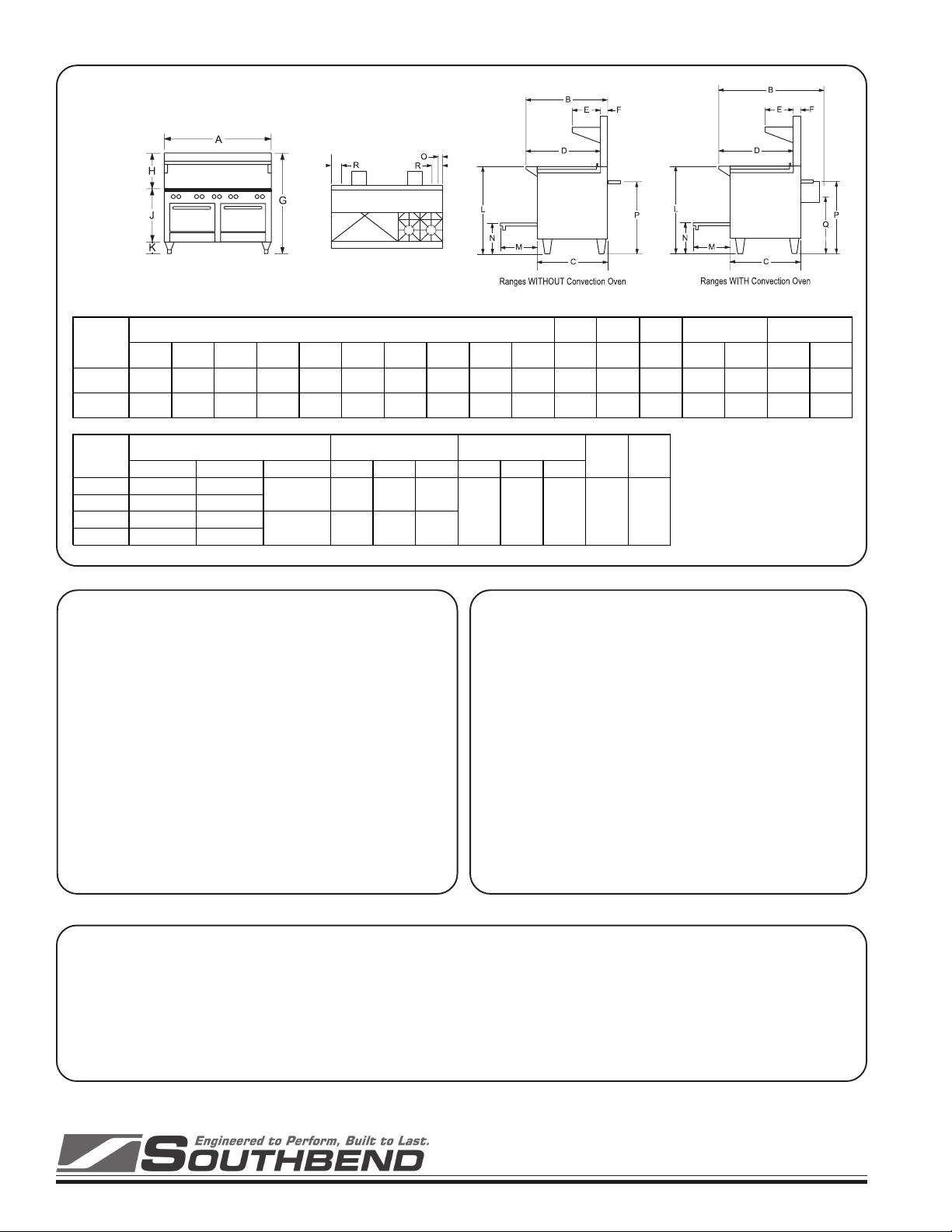

Models:

460DD-3G 460AD-3G 460AA-3G

460DD-4G 460AD-4G 460AA-4G

Dimensions -in (mm)

MODE LS

460DD-3G/3T

460DD-4G/4T

460AA-3G/3T

460AA-4G/4T

WIDTH

A

60.75"

(1543)

60.75"

(1543)

EPTH

D

B

34.00"

(864)

44.50"

(1130)

COOK

DOOR

15.50"

(394)

15.50"

(394)

OVEN

BOTTOM

13.00"

(330)

13.00"

(330)

3/4" GAS CONN.ELECTRI C

3.25"

(83)

3.25"

(83)

30.25"

(768)

30.25"

(768)

--

24.00"

(610)

6.00"

(152)

EXTERIOR

CDEFGH J KL MNOPQR

29.75"

31.00"

12.00"

2.75"

59.50"

22.50"

(756)

29.75"

(756)

(787)

31.00"

(787)

(305)

12.00"

(305)

(70)

2.75"

(70)

(1511)

59.50"

(1511)

(572)

22.50"

(572)

31.00"

(787)

31.00"

(787)

6.00"

(152)

6.00"

(152)

TOP

37.00"

(940)

37.00"

(940)

OPENING

M ODELS

460DD-3G/3T 4@ (16K/16K) 4@(33K/30K)

460DD-4G/4T 5@ (16K/16K) 2@(33K/30K)

460AA-3G/3T 4@(16K/16K ) 4@(33K/ 30K)

460AA-4G/4T 5@(16K/16K ) 2@(33K/ 30K)

B URNERS (B TU EACH NAT/LP) OVEN INTERIOR CRATE S IZE

G RIDDLE O PEN O VEN W IDTH DEPTH HEIGHT WID T H DEPTH HEIGHT

26.00"

26.50"

2@(45K/40K )

2@(32K/30K )

(660)

26.00"

(660)

(673)

24.00"

(610)

14.00"

(356)

14.00"

(356)

GAS:

- 460DD-3G/T Total BTU NAT: 286,000; LP: 264,000

- 460AD-3G/T Total BTU NAT: 273,000; LP: 254,000

- 460AA-3G/T Total BTU NAT: 260,000; LP: 244,000

- 460DD-4G/T Total BTU NAT: 236,000; LP: 220,000

- 460AD-4G/T Total BTU NAT: 223,000; LP: 210,000

- 460AA-4G/T Total BTU NAT: 210,000; LP: 200,000

- Required minimum inlet pressure

- Natural gas 4” W.C.

- Propane gas 10” W.C.

- Pressure regulator is supply with unit

- Required supply line size to the regulator is 3/4” NPT.

ELECTRICAL:

- Standard -115/60/1 furnished with 6’ cord with 3-prong plug.

Total max amps 4.8

- Optional -208/60/1, 50/60/1 or 3 phase. Supply must be wired to

junction box with terminal block located at rear. Total max amps

2.6

CUB IC

V OLUME

NOTES:

CRA TE D

1. Optional -Hot Plate in lieu of 2

W EIGHT

open top burners at 12,000 BTU/

burner (24,000 BTU total NAT or LP)

67.00"

(1118)

45.50"

(1702)

75.00"

(1905)

132.3 cu. ft

3.75 cu.m.

2. Thermostat griddle control with 1

860 lbs.

throttling-type thermostats.

390.1kg.

Temperature range of 100° to 450°F

(add prefix T).

MISCELLANEOUSUTILITY INFORMATION

- If using Flex-Hose, the I.D. should not be smaller than 3/4”

and must comply with ANSI Z 21.69

- If casters are used with flex hose, a restraining device should

be used to eliminate undue strain on the flex hose

- For installation on combustible floors (with 6” high legs) and

adjacent to combustible walls, allow 6” clearance.

- Install under vented hood

- Check local codes for fire, installation and sanitary regulations.

NOTICE:

Southbend has a policy of continuous product research and

improvement. We reserve the right to change specifications

and product design without notice. Such revisions do not

entitle the buyer to corresponding changes, improvements,

additions or replacements for previously purchased

equipment.

OPTIONS AND ACCESSORIES

10” Flue Riser

3/4” quick disconnect with flexible hose complies with

ANSI Z 21.69 (specify 3ft, 4ft, 5ft)

Casters-all swivel-front with locks

Hot Top plates - each plate replaces 2 Open burner section

Form 460-3G4G Rev 4 (04/07)

www.yatesgd.com www.yatesgraphicdesign.com

Various salamander & cheesemelter mounts

available. (Please refer to the price list)

Auxillary griddle plates

Extra Oven Racks

Cabinet Base

INTENDED FOR COMMERCIAL USE ONLY.

NOT FOR HOUSEHOLD USE

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(919) 762-1000 www.southbendnc.com

.

Loading...

Loading...