Southbend 3230 Installation Manual

$4.00

southbend

A MIDDLEBY COMPANY

OWNER'S MANUAL

INSTALLATION

USER'S GUIDE

SERVICE

PARTS

SALAMANDAR

IMPORTANT

FOR FUTURE REFERENCE

Please complete this

information and retain this

manual for the life of the

equipment.

MODEL #__________________

SERIAL #__________________

DATE PURCHASED__________

RADIANT BROILERS

MODELS: S-36, S-36A, S-60, S-60A, 3230, 3230A

S-36W, S-36AW, 3230W, 3230AW

These instructions should be read thoroughly before attempting installation. Installation and

Start Up should be performed by a qualified service technician. The Manufacturer,

Southbend (Head Office: 1100 Old Honeycutt Rd., Fuquay-Varina, North Carolina 27526),

informs you that unless the installation instructions for the above described Southbend

product are followed and performed by a qualified service technician, (a person experienced

in and knowledgeable concerning the installation of commercial gas and/or electrical cooking

equipment) then the terms and conditions of the Manufacturer's Limited Warranty will be

rendered void and no warranty of any kind shall apply.

If the equipment has been changed, altered, modified or repaired by other than a qualified

service technician during or after the 12-month limited warranty period, then the

manufacturer shall not be liable for any incidental or consequential damages to any person

or to any property which may result from the use of the equipment thereafter. Some States

do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion thereto may not apply to you.

In the event you have any questions concerning the installation, use, care, or service of the

product, write Customer Service Department, Southbend, 1100 Old Honeycutt Rd., Fuquay Varina, North Carolina 27526.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

SALAMANDER

RADIANT BROILERS

(Manual Section BR)

Congratulations! You have just purchased one of the finest pieces of heavy-duty, commercial cooking equipment on the market

A MIDDLEBY COMPANY

1100 Old Honeycutt Road

today.

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to some of the

toughest standards in the industry — those of Southbend. Each piece of Southbend equipment has been carefully engineered and

designs have been verified through laboratory tests and field installations in some of the more strenuous commercial cooking

applications. With proper care and field maintenance, you will experience years of reliable, trouble -free operation from your

Southbend equipment. To get the best results, it's important that you read this manual carefully.

TABLE OF CONTENTS:

SECTION ONE - INSTALLATION

Specifications ......................................…………...... 1

Installation .....................................……………........ 2

SECTION TWO - USER'S GUIDE

Warranty.........................................…………….......

Operation....................................……………............

Maintenance............................…………........... . .... 3

SECTION THREE - SERVICE

Adjustments ..................................……............ .... .. 1

Troubleshooting .............................…....................... 2

SECTION FOUR - PARTS

Parts List.......................................……..................... 1

1

2

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

CAUTION

POST IN PROMINENT LOCATION INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION SHALL BE

OBTAINED FROM LOCAL GAS SUPPLIER.

INTENDED FOR COMMERCIAL USE ONLY. NOT FOR HOUSEHOLD USE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

KEEP AREA AROUND APPLIANCES FREE AND CLEAR FROM COMBUSTIBLES.

IN THE EVENT A GAS ODOR IS DETECTED. SHUT DOWN EQUIPMENT AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

southbend

Fuquay, NC 27526

(919) 552-9161

FAX (919) 552-9798

(800) 348-2558

SALAMANDER

RADIANT BROILER

USER'S GUIDE

LIMITED WARRANTY

Southbend warrants that the equipment, as supplied by the factory to the original purchasers, is free from defects in materials

and workmanship. Should any part thereof become defective as a result of normal use within the period and limits defined

below, then at the option of Southbend such parts will be repaired or replaced by Southbend or its Authorized Service Agency.

This warranty is subject to the following conditions:

If upon inspection by Southbend or its Authorized Service Agency it is determined that this equipment has not been used in an

appropriate manner, has been modified, has not been properly maintained, or has been subject to misuse or misapplication,

neglect, abuse, accident, damage during transit or delivery, fire, "flood, riot or Act of God, then this warranty shall be void.

Specifically excluded under this warranty are claims relating to installation; examples are improper utility connections and

improper utilities supply. Claims relating to normal care and maintenance are also excluded; examples are calibration of

controls, and adjustments to pilots and burners.

Equipment failure caused by inadequate water quality is not covered under warranty. WATER QUALITY must not exceed the

following limits: Total Dissolved Solids (TDS) - 60 PPM (Parts Per Million). Hardness - 2 Grains or 35 PPM, PH Factor

- 7.0 to 7.5. Water pressure 30 PSI minimum, 60 PSI maximum. Boiler maintenance is the responsibility of the owner and is not

covered by warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial

application.

Repairs under this warranty are to be performed only by a Southbend Authorized Service Agency. Southbend can not be

responsible for charges incurred from other than Authorized Southbend Agencies. THIS WARRANTY MUST BE SHOWN TO AN

AUTHORIZED SERVICE AGENCY WHEN REQUESTING IN-WARRANTY SERVICE WORK. THE AUTHORIZED SERVICE

AGENCY MAY AT HIS OPTION REQUIRE PROOF OF PURCHASE. This warranty does not cover services performed at

overtime or premium labor rates nor does Southbend assume any liability for extended delays in replacing or repairing any items

in the equipment beyond the control of Southbend. "Southbend shall not be liable for consequential or special damages of any

nature that may arise in connection with such product or part." Should service be required at times which normally involve

overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such premium

rates. In all circumstances, a maximum of one hundred miles in travel and two and one half hours (25) travel time shall be

allowable. In all cases the closest Southbend Authorized Agency must be used. The actual warranty time periods and exceptions

are as follows:

This warranty only covers product shipped into the 48 contiguous United States and Hawaii, one year labor, one year parts

effective from the date of original purchase. There will be no labor coverage for equipment located on any island not connected

by roadway to the mainland. Exceptions to standard warranty, effective within above limitations:

Glass Windows, Door Gaskets, Rubber Seals, Light Bulbs, Ceramic Bricks,

Sight Glasses, Cathodic Descalers or Anodes ..…......………………………………………...................... 90 days material and labor

Stainless Steel Fry Pot.....................…………….…………………... .4 years extended material warranty on fry pot only — no labor

Stainless Steel Open Top Burners..………….………………...........4 years extended material warranty on burners only — no labor

Pressure Steam Boiler Shell .......…………………………........ Prorated 4 years extended warranty on boiler shell only — no labor

In all cases parts covered by a five year warranty will be shipped FOB the factory after the first year. Our warranty on all

replacement parts which are replaced in the field by our Authorized Service Agencies will be limited to three months on labor, six

months on materials (parts) effective from the date of installation. See LIMITED WARRANTY

- REPLACEMENT PARTS for conditions and limitations.

If the equipment has been changed, altered, modified or repaired by other than a qualified service technician during

or after the one year limited warranty period, then the manufacturer shall not be liable for any damages to any person

or to any property which may result from the use of the equipment thereafter.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS, AND CONSTITUTES THE ENTIRE

LIABILITY OF SOUTHBEND. IN NO EVENT DOES THE LIMITED WARRANTY EXTEND BEYOND THE DURATION

OF ONE YEAR FROM THE EFFECTIVE DATE OF SAID WARRANTY."

Boiler shells which have not been properly maintained will not be covered by warranty.

SALAMANDER RADIANT BROILER

SECTION TWO — USER'S GUIDE

PAGE 1

SALAMANDER RADIANT BROILER

SERVICE

ADJUSTMENTS

WARNING:

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

TECHNICIAN WHO IS EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE

OPERATION OF COMMERCIAL GAS COOKING EQUIPMENT. HOWEVER, TO ASSURE

YOUR CONFIDENCE, CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR

RELIABLE SERVICE, DEPENDABLE ADVICE OR OTHER ASSISTANCES, AND FOR

GENUINE FACTORY PARTS.

WARNING:

DISCONNECT POWER FROM APPLIANCE EQUIPPED WITH CONVECTION-TYPE OVEN

HAVING A RADIANT BROILER MOUNTED TO APPLIANCE BEFORE CLEANING OR

SERVICING, IF APPLICABLE.

In case of problems in operation at initial installation, check type of gas and manifold pressure and compare with

information listed on the serial plate, located on interior bottom, at center towards front under grease pan.

PILOTS:

1. Locate pilot valve on bottom of unit near the front edge. It is inside the unit and can be seen through a small hole.

2. Turn slotted screw on valve until pilot achieves ignition of both burners. If pilots are turned to high, soot will

begin to form on ceramics above pilot flames. Pilot flames should be approximately 3/4" in length.

BURNERS:

1. To adjust burner air shutters, first observe burner flames:

A. If flames are lifting off the burner ports, air shutter must be closed.

B. If flames have large yellow tips or are sooting ceramic tiles, air shutter must be opened.

2. Turn off burners and allow to cool.

3. Remove ceramic tiles around burner requiring adjustment.

4. Remove burner.

5. Loosen air shutter screw and adjust air shutter as per Step 1 above.

6. Tighten screw.

7. Re-install burner.

8. Replace ceramic tiles.

9. Light burner and observe flame.

10. Repeat this procedure, as necessary, to obtain a stable blue flame with a slight yellow tip.

SALAMANDER RADIANT BROILER

SECTION THREE — SERVICE

PAGE 1

ADJUSTMENTS

TROUBLE SHOOTING:

—

incorrect orifices.

—

draft condition.

Litho in U.S.A.

PRESSURE REGULATOR:

1. Turn off main gas to unit.

2. Remove broiler bottom (6 sheet metal screws).

3. Remove pilot line valve from manifold.

4. Install a fitting appropriate to connect a manometer.

5. Be sure both valves are in the "OFF" position and turn on main gas.

6. Ignite rear burner by hand and then front burner.

7. With burners full on, read manometer. It should read 4" W.C. for natural gas and 10" W.C. for

propane gas. (If pressure is satisfactory, go to Step 10.)

8. Remove cap from top of regulator.

9. With a screwdriver, rotate adjustment screw "clockwise" to increase, or "counterclockwise" to

decrease, pressure until manometer shows correct reading.

10. Turn burner valves to "OFF" position.

11. Turn main gas off.

12. Remove manometer fitting.

13. Replace pilot valve in manifold.

14. Put bottom on.

15. Turn on main gas.

16. Light pilot.

17. Verify proper burner ignition.

Problem Look for —

Unit will not turn on

main gas supply "OFF."

— pilot out.

Burners produce excessive — incorrect gas type.

carbon deposits — incorrect supply pressure.

— primary air not adjusted properly.

Pilot produces excessive — pilot gas not adjusted properly.

carbon deposits — incorrect gas type.

— incorrect supply pressure.

Pilot will not stay ignited — pilot gas not adjusted properly.

— clogged orifice.

— improper ventilation system.

— air in gas line.

SALAMANDER RADIANT BROILER

SECTION THREE — SERVICE

PAGE 2

2-94

southbend

A MIDDLEBY COMPANY

Convection Ovens Ranges Steam Kettles Under Fired Broilers

Cook & Hold Convection Ovens Fryers Tilting Braising Pans Salamander Broilers

Bake & Roast Ovens Special & Custom Equipment Cooker/Mixer Kettles Cheese Melters

Pizza Ovens Convection Steamers Floor Model Broilers Counter Top Broilers & Griddles

SALAMANDER

9161

A MIDDLEBY COMPANY

RADIANT BROILERS

A product with the Southbend name incorporates the best in durability and low

maintenance. We all recognize however, that replacement parts and occasional

professional service may be necessary to extend the useful life of this unit. When

service is needed, contact a Southbend Authorized Service Agency, or your dealer.

To avoid confusion, always refer to the model number, serial number, and type of

your unit.

southbend

1100 Old Honeycutt Road

PART NUMBER 1164373

Fuquay-Varina. NC 27526

(919)552-

FAX (919) 552-9798

(800) 348-2558

SERVICE

AUGUST

5, 1986

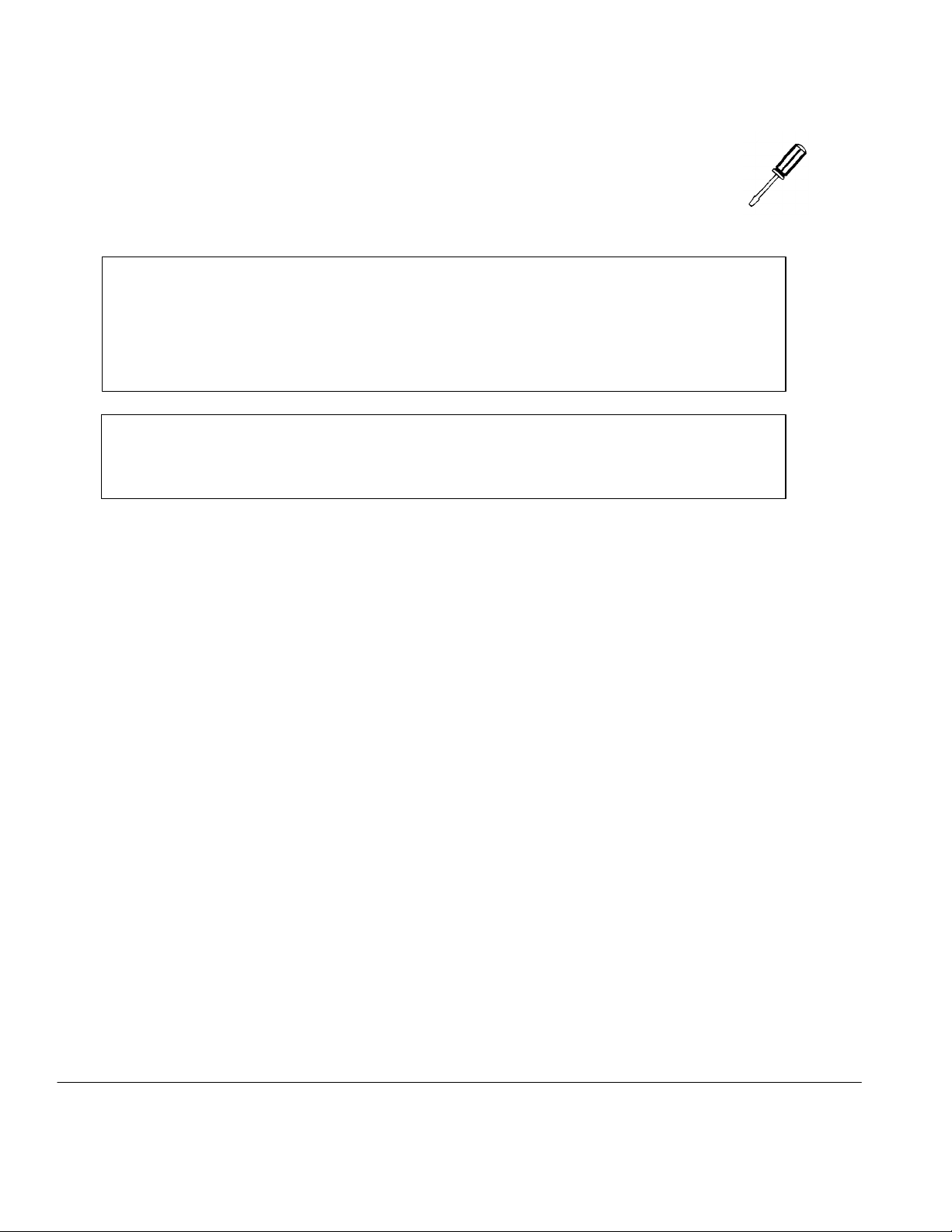

Orifice Nut

southbend

ALL SOUTHBEND AUTHORIZED SERVICE AGENCIES AND

PARTS DISTRIBUTORS

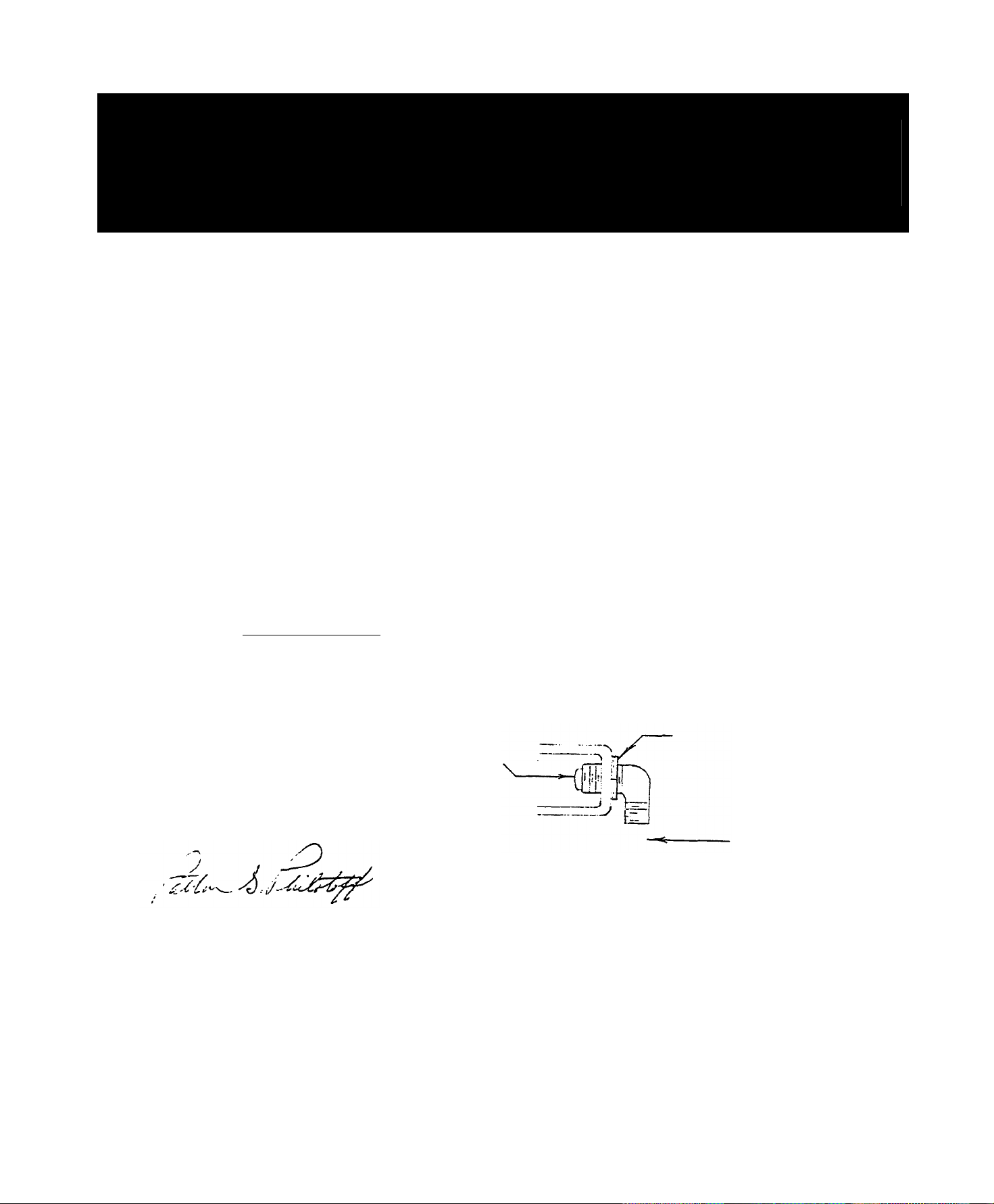

ORIFICE ALIGNMENT ON INFRA-RED BROILERS

MODELS: 170, 171, 270, 171-40

Please insert in the BR - Broiler and Cheese Melter Section of your master

Southbend Service Manual.

In the past it was concluded that it was not required to use an orifice

elbow "nut" in the installation of the orifices on Infra-Red Broilers. This

conclusion was made in error. Without the nut in place there is not enough thread

surface on the elbow to maintain good orifice alignment.

Symptoms are poor combustion or blue haze on the burner, it would not be

possible to properly adjust the unit with the air and/or low setting adjustments on

valve.

BULLETIN

To correct this situation order and install:

Orifice Elbow Nut - Part Number 58-00002 - List Price $.50

For assembly, see Fig. 1.

Patton G. Philotoff

Regional Service Manager

cc. Sales Directors

Sales Representatives

Internal Distribution

Orifice

Supply Tube

Figure 1

1100 Old Honeycutt Rd.

Fuquay-Varina, NC 27526

(919) 552-9161

FAX (919) 552-9798

Loading...

Loading...