Page 1

$6.00

southbend

A MIDDLEBY COMPANY

OWNER'S MANUAL

INSTALLATION

USER'S GUIDE

SERVICE

PARTS

IMPORTANT

FOR FUTURE REFERENCE

Please complete this

information and retain this

manual for the life of the

equipment.

MODEL #__________________

SERIAL #__________________

DATE PURCHASED__________

COUNTER TOP

CONVECTION STEAMER

MODELS: 2001 / DUAL POWER

SINGLE POWER SOURCE UNITS

These instructions should be read thoroughly before attempting installation. Installation and

Start Up should be performed by a qualified service technician. The Manufacturer,

Southbend (Head Office: 1100 Old Honeycutt Rd., Fuquay-Varina, North Carolina 27526),

informs you that unless the installation instructions for the above described Southbend

product are followed and performed by a qualified service technician, (a person experienced

in and knowledgeable concerning the installation of commercial gas and/or electrical cooking

equipment) then the terms and conditions of the Manufacturer's Limited Warranty will be

rendered void and no warranty of any kind shall apply.

If the equipment has been changed, altered, modified or repaired by other than a qualified

service technician during or after the 12-month limited warranty period, then the

manufacturer shall not be liable for any incidental or consequential damages to any person

or to any property which may result from the use of the equipment thereafter. Some States

do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion thereto may not apply to you.

In the event you have any questions concerning the installation, use, care, or service of the

product, write Customer Service Department, Southbend, 1100 Old Honeycutt Rd., Fuquay Varina, North Carolina 27526.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

COUNTER TOP

CONVECTION STEAMER

(Manual Section CS)

Page 2

1100 Old Honeycutt Road

Congratulations! You have just purchased one of the finest pieces of heavy-duty, commercial cooking equipment on the market

today.

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to some of the

toughest standards in the industry — those of Southbend. Each piece of Southbend equipment has been carefully engineered and

designs have been verified through laboratory tests and field installations in some of the more strenuous commercial cooking

applications. With proper care and field maintenance, you will experience years of reliable, trouble -free operation from your

Southbend equipment. To get the best results, it's important that you read this manual carefully.

TABLE OF CONTENTS:

SECTION ONE - INSTALLATION

Specifications ......................................…………...... 1

Installation .....................................……………........ 2

Performance Check………………………………… 5

SECTION TWO - USER'S GUIDE

Warranty.........................................…………….......

Operation....................................……………............

Cooking Hints.........................…………........... . ....

Maintenance............................…………........... . ....

SECTION THREE - SERVICE

1

2

3

7

Adjustments ..................................……............ .... .. 1

Troubleshooting .............................…....................... 5

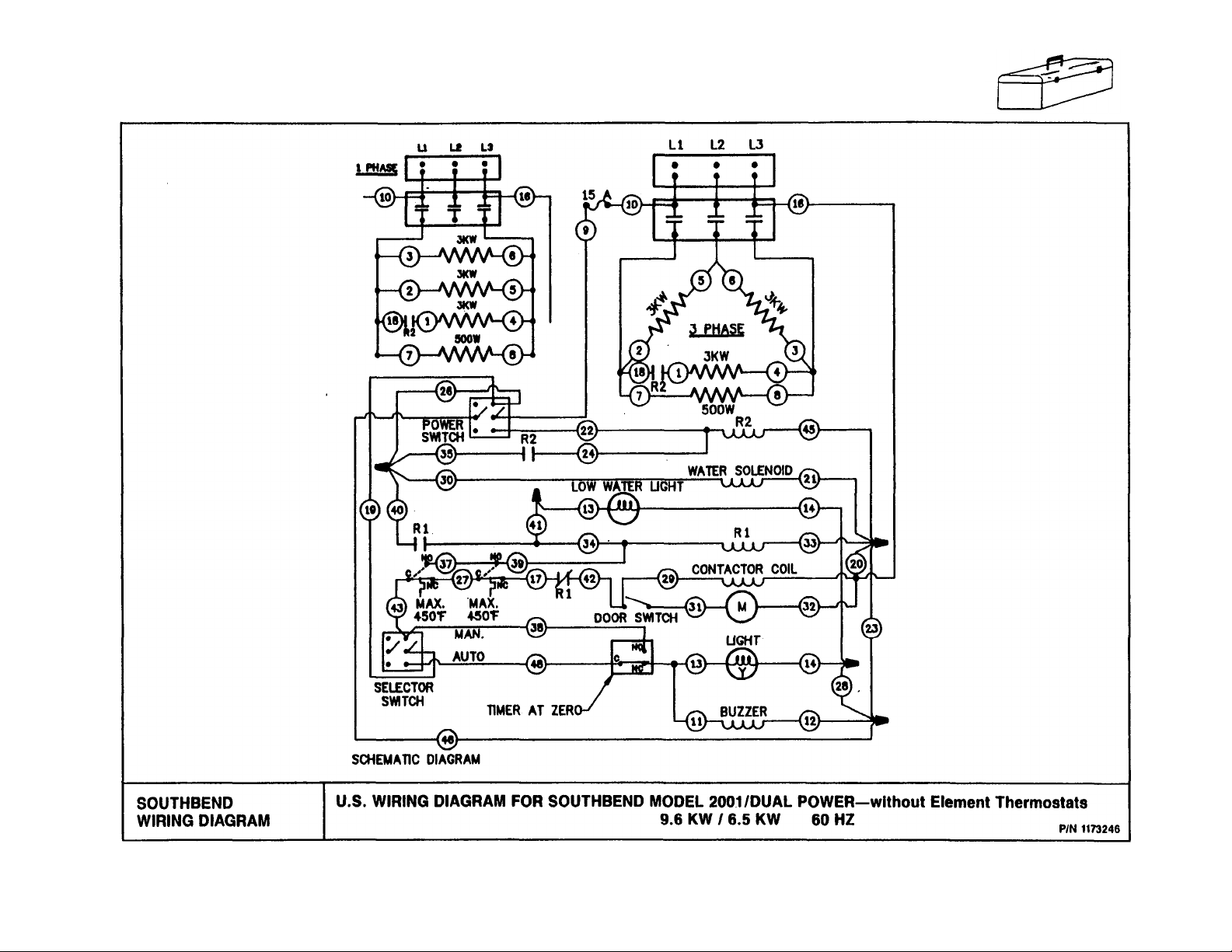

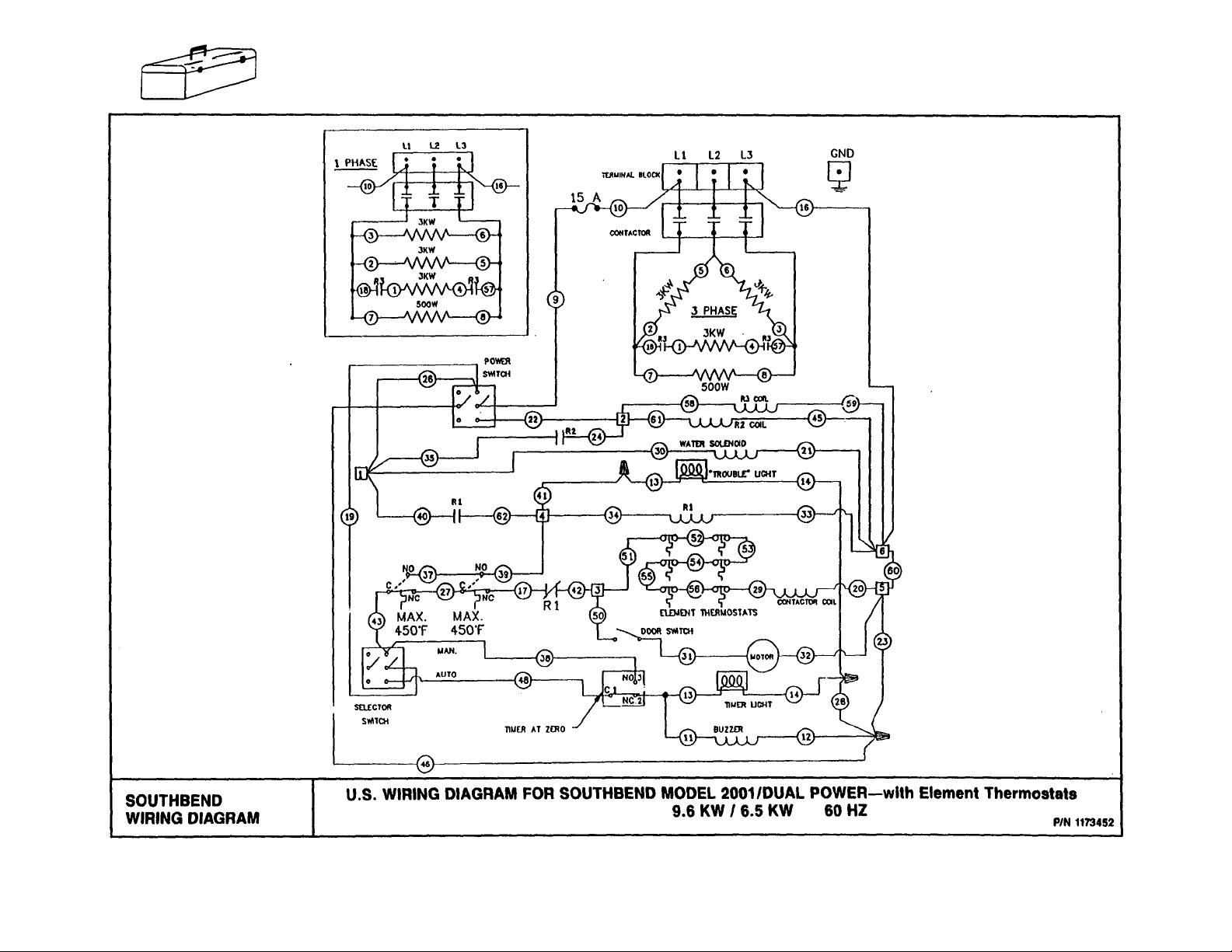

Schematic Drawings……………………………….. 7

SECTION FOUR - PARTS

Parts List.......................................……..................... 1

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

INTENDED FOR COMMERCIAL USE ONLY. NOT FOR HOUSEHOLD USE.

WARNING – WARRANTY WILL BE VOID IF

A. SERVICE WORK IS PERFORMED BY OTHER THAN A QUALIFIED TECHNICIAN

B. OTHER THAN GENUINE SOUTHBEND REPLACEMENT PARTS ARE INSTALLED.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

KEEP AREA AROUND APPLIANCES FREE AND CLEAR FROM COMBUSTIBLES.

IN THE EVENT A GAS ODOR IS DETECTED. SHUT DOWN EQUIPMENT AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

southbend

A MIDDLEBY COMPANY

Fuquay, NC 27526

(919) 552-9161

FAX (919) 552-9798

(800) 348-2558

Page 3

COUNTER TOP

CONVECTION STEAMER

USER'S GUIDE

LIMITED WARRANTY

Southbend warrants that the equipment, as supplied by the factory to the original purchasers, is free from defects in materials

and workmanship. Should any part thereof become defective as a result of normal use within the period and limits defined

below, then at the option of Southbend such parts will be repaired or replaced by Southbend or its Authorized Service Agency.

This warranty is subject to the following conditions:

If upon inspection by Southbend or its Authorized Service Agency it is determined that this equipment has not been used in an

appropriate manner, has been modified, has not been properly maintained, or has been subject to misuse or misapplication,

neglect, abuse, accident, damage during transit or delivery, fire, "flood, riot or Act of God, then this warranty shall be void.

Specifically excluded under this warranty are claims relating to installation; examples are improper utility connections and

improper utilities supply. Claims relating to normal care and maintenance are also excluded; examples are calibration of

controls, and adjustments to pilots and burners.

Equipment failure caused by inadequate water quality is not covered under warranty. WATER QUALITY must not exceed the

following limits: Total Dissolved Solids (TDS) - 60 PPM (Parts Per Million). Hardness - 2 Grains or 35 PPM, PH Factor

- 7.0 to 7.5. Water pressure 30 PSI minimum, 60 PSI maximum. Boiler maintenance is the responsibility of the owner and is not

covered by warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial

application.

Repairs under this warranty are to be performed only by a Southbend Authorized Service Agency. Southbend can not be

responsible for charges incurred from other than Authorized Southbend Agencies. THIS WARRANTY MUST BE SHOWN TO AN

AUTHORIZED SERVICE AGENCY WHEN REQUESTING IN-WARRANTY SERVICE WORK. THE AUTHORIZED SERVICE

AGENCY MAY AT HIS OPTION REQUIRE PROOF OF PURCHASE. This warranty does not cover services performed at

overtime or premium labor rates nor does Southbend assume any liability for extended delays in replacing or repairing any items

in the equipment beyond the control of Southbend. "Southbend shall not be liable for consequential or special damages of any

nature that may arise in connection with such product or part." Should service be required at times which normally involve

overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such premium

rates. In all circumstances, a maximum of one hundred miles in travel and two and one half hours (25) travel time shall be

allowable. In all cases the closest Southbend Authorized Agency must be used. The actual warranty time periods and exceptions

are as follows:

This warranty only covers product shipped into the 48 contiguous United States and Hawaii, one year labor, one year parts

effective from the date of original purchase. There will be no labor coverage for equipment located on any island not connected

by roadway to the mainland. Exceptions to standard warranty, effective within above limitations:

Glass Windows, Door Gaskets, Rubber Seals, Light Bulbs, Ceramic Bricks,

Sight Glasses, Cathodic Descalers or Anodes ..…......………………………………………...................... 90 days material and labor

Stainless Steel Fry Pot.....................…………….…………………... .4 years extended material warranty on fry pot only — no labor

Stainless Steel Open Top Burners..………….………………...........4 years extended material warranty on burners only — no labor

Pressure Steam Boiler Shell .......…………………………........ Prorated 4 years extended warranty on boiler shell only — no labor

In all cases parts covered by a five year warranty will be shipped FOB the factory after the first year. Our warranty on all

replacement parts which are replaced in the field by our Authorized Service Agencies will be limited to three months on labor, six

months on materials (parts) effective from the date of installation. See LIMITED WARRANTY

- REPLACEMENT PARTS for conditions and limitations.

If the equipment has been changed, altered, modified or repaired by other than a qualified service technician during

or after the one year limited warranty period, then the manufacturer shall not be liable for any damages to any person

or to any property which may result from the use of the equipment thereafter.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS, AND CONSTITUTES THE ENTIRE

LIABILITY OF SOUTHBEND. IN NO EVENT DOES THE LIMITED WARRANTY EXTEND BEYOND THE DURATION

OF ONE YEAR FROM THE EFFECTIVE DATE OF SAID WARRANTY."

Boiler shells which have not been properly maintained will not be covered by warranty.

COUNTER TOP CONVECTION STEAMER

SECTION TWO — USER'S GUIDE

PAGE 1

Page 4

Litho in U.S.A.

OPERATION

THEORY OF OPERATION:

Compared to other steam cookers with complicated boilers, the Southbend 2001 is a very simple machine. The

bottom, or floor, of the compartment is heated. Water flows onto this heated surface, boils, and turns to steam. A fan

circulates the steam in the compartment when the door is closed. There is no pressure.

All equipment must be installed correctly to insure proper operation and reliable service. Installation instructions

must be followed by a qualified technician.

Before you turn the unit on, be sure that you have: POWER to unit, WATER to unit, and OPEN DRAIN. NOTE:

Your Southbend Convection Steamer must be thoroughly cleaned every day.

CAUTION: DO NOT USE VINEGAR OR ANY CORROSIVE CLEANER. USE ONLY CLEANERS

APPROVED FOR STAINLESS STEEL.

Before starting the unit, review the following:

A. Be sure overflow pipe in back right hand comer of the cooking compartment is in position.

B. Be sure the drain outlet is not blocked in any way. (The Southbend 2001 drain line must be free venting.)

C. Be sure the pan supports and fan guard are well secured.

D. Be sure the drip pan is in proper position with the drain hole located above the drain outlet.

CONTROL INSTRUCTIONS:

1. For manual operation, press right-hand rocker switch to "MANUAL" and select your choice on left-hand rocker

switch, "HI or LO." Red and amber lights on switch turn on when it's "HI" power and amber light only when

it's "LO" power. Unit is now in operation and will be generating steam in a few minutes (approximately 4

minutes from a cold start).

2. For automatic timed operation, press right-hand rocker switch to "AUTOMATIC" and select your choice on

left-hand rocker switch "HI" or "LO." Set timer by positioning knob pointer to desired time. When time elapses,

buzzer will sound. Buzzer may be shut off by moving selector switch to "MANUAL," shutting unit off,

resetting to a new time, or turning knob counter clock-wise past "0" time to Hold/Off position.

3. To restart timer, set to new time marking.

NOTE: For short time settings (under 20 minutes) first turn knob past "30" setting then back to desired time.

INSTRUCTIONS FOR TURNING OFF BUZZER:

The Southbend Steamer is supplied with a continuous ring buzzer. This buzzer is activated automatically in the

automatic mode of operation when the cooking cycle is complete. This buzzer can be turned off by:

1. Resetting to a new time.

2. Shut unit off (left hand switch to middle position).

3. Set the right-hand rocker switch to manual.

4. Turn knob full counterclockwise past "0" time to Hold/Off position.

COUNTER TOP CONVECTION STEAMER

SECTION TWO — USER'S GUIDE

PAGE 2

Rev. 12-92

Page 5

MAINTENANCE

Southbend equipment is sturdily constructed of the best quality materials and is designed to provide durable service when treated

with ordinary care. To expect the best performance, your equipment must be maintained in good condition and cleaned daily.

Naturally, the periods for this care and cleaning depend on the amount and degree of usage.

DAILY CLEANING:

Following daily and periodic maintenance procedures will enhance long-life for your equipment. Climatic conditions —

salt air — may require more thorough and frequent cleaning or the life of the equipment could be adversely affected.

As with any cooking utensil, the unit should be thoroughly washed with a mild detergent and warm water every day.

Remove the pan supports, drip pan, fan guard, and overflow pipe. Wash separately.

All water will drain out of the compartment. Clean all interior surfaces, including the fan and heating element with a food equipment

cleansing and de-liming solution. Rinse with clean water.

Return all cleaned parts to the unit to make ready for the next day's operation.

It is advisable to leave door open when the unit is not in use. This allows the unit to dry thoroughly after cleaning and also prolongs

the life of the door seal.

CAUTION: DO NOT USE ANY CORROSIVE CLEANER. USE ONLY CLEANERS APPROVED FOR

STAINLESS STEEL.

STAINLESS STEEL: To remove normal dirt, grease or product residue from stainless steel, use ordinary soap and

water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with a clean cloth. Never use

vinegar or any corrosive cleaner.

To remove grease and food splatter or condensed vapors that have baked on the equipment, apply cleanser to a damp

cloth or sponge and rub cleanser on the metal in the direction of the polishing lines on the metal. Rubbing cleanser as

gently as possible in the direction of the polished lines will not mar the finish of the stainless steel. NEVER RUB

WITH A CIRCULAR MOTION. Soil and burnt deposits which do not respond to the above procedure can usually be

removed by rubbing the surface with SCOTCH-BRTTE scouring pads or STAINLESS scouring pads. DO NOT USE

ORDINARY STEEL WOOL as any particles left on the surface will rust and further spoil the appearance of the

finish. NEVER USE A WIRE BRUSH, STEEL SCOURING PADS (EXCEPT STAINLESS), SCRAPER, FILE OR

OTHER STEEL TOOLS. Surfaces which are marred collect dirt more rapidly and become more difficult to clean.

Marring also increases the possibility of corrosive attack. Refinishing may then be required.

TO REMOVE HEAT TINT: Darkened areas sometimes appear on stainless steel surfaces where the area has been

subjected to excessive heat. These darkened areas are caused by a thickening of the protective surface of the stainless

steel and are not harmful. Heat tint can normally be removed by the foregoing, but tint which does not respond to this

procedure calls for a vigorous scouring in the direction of the polish lines using SCOTCH-BRITE scouring pads or a

STAINLESS scouring pad in combination with a powdered cleanser. Heat tint action may be lessened by not

applying or by reducing heat to equipment during slack periods.

COUNTER TOP CONVECTION STEAMER

SECTION TWO — USER'S GUIDE

PAGE 7

Page 6

SERVICE

COUNTER TOP CONVECTION STEAMER

SECTION THREE – SERVICE

PAGE 7

Page 7

SERVICE

Litho in U.S.A

COUNTER TOP CONVECTION STEAMER

SECTION THREE – SERVICE

PAGE 8

Rev. 12-92

Page 8

southbend

A MIDDLEBY COMPANY

Convection Ovens Ranges Steam Kettles Under Fired Broilers

Cook & Hold Convection Ovens Fryers Tilting Braising Pans Salamander Broilers

Bake & Roast Ovens Special & Custom Equipment Cooker/Mixer Kettles Cheese Melters

Pizza Ovens Convection Steamers Floor Model Broilers Counter Top Broilers & Griddles

Page 9

COUNTER TOP

CONVECTION STEAMER

9161

A MIDDLEBY COMPANY

A product with the Southbend name incorporates the best in durability and low

maintenance. We all recognize however, that replacement parts and occasional

professional service may be necessary to extend the useful life of this unit. When

service is needed, contact a Southbend Authorized Service Agency, or your dealer.

To avoid confusion, always refer to the model number, serial number, and type of

your unit.

southbend

1100 Old Honeycutt Road

Fuq Fuquay-Varina. NC 27526

PART NUMBER 1173012

(919)552FAX (919) 552-9798

(800) 348-2558

Page 10

TO: Southbend Parts & Service Distributors

FROM: Thomas S. Enyeart

Manager, Technical Services

DATE: February 11, 1991 BULLETIN #9105

SUBJECT: Model 2001 and R-1 In Line Water Strainer

Please insert this bulletin in your roaster Southbend manual in Section ST behind the

2001 manual.

A new improved in line water strainer is now being supplied on all Model 2001 and R-1

Convection Steamers. This is a Y type which incorporates a clean out screen.

The Part number is 1173428 and it replaces #PP-629.

Part number 1173428 is on units manufactured January 2, 1991 and after; serial numbers

beginning with 91A and up. Part Number PP-629 was discontinued at the end of December

1990; serial numbers beginning with 90L and before.

Although #1173428 replaces #PP-629, it is not a direct replacement. For the first change

over, you need to use Kit #4440329. After using this kit one time, you then will then just use

#1173428.

A replacement strainer screen is available for this new strainer; Part # 1173429.

Recap:

#PP-629 No longer available - use 173428 or 4440329

1991 List Price

#1173428 In Line Strainer $32.50

#1173429 Replacement Screen $ 3.50

for 1173428

#440329 Replacement Strainer $44.50

Kit to Convert from #PP-629 to 1173428

TE/dy

1100 Old Honeycutt Rd.

Fuquay-Varina, NC 27526

(919) 552-9161

FAX (919) 552-9798

Page 11

TO: Southbend Parts & Service Distributors

FROM: Thomas S. Enyeart

Manager, Technical Services

DATE: June 10, 1991 BULLETIN #9122

SUBJECT: Model 2001 - New Improved Door Latch/Catch

Please insert this bulletin behind the 2001 owners manual in the ST-Steamer section

of your master Southbend manual.

Effective May, 1991, serial number 91C46648 and all there after.

A new improved door latch and door catch are now being supplied on model 2001

steamers. This new design allows for improved latching action and easier, more

positive alignment adjustment.

Old style parts are no longer available. The first time a change of these parts is

made, you must use part #4440334 Door Latch/Catch Improvement Kit.

New Parts:

#1173531 Door Handle Assembly (replaces #6600376)

#1173530 Door Latch (replaces #6600434)

#1173529 Door Catch (replaces #132125)

#4440334 Door Latch/Catch Improvement Kit

Contains one each #1173531 Door Handle Assembly, one #1173530

Door Latch, one #1173529 Door Catch and one #1173536

Instruction sheet. These parts replace old style #6600376

Handle, 6600434 Latch and 132125 Catch.

Discontinued Parts* -- No longer available

#6600376 Door Handle Assembly (replaced by #1173531)

#6600434 Door Latch (replaced by #1173530)

#132125 Door Catch (replaced by #1173529)

* As stated before, when first changing any of these three parts,

they all have to be changed by using the replacement kit or :the

individual parts.

TE/dy

1100 Old Honeycutt Rd.

Fuquay-Varina, NC 27526

(919) 552-9161

FAX (919) 552-9798

Page 12

TO: SOUTHBEND PARTS & SERVICE DISTRIBUTORS

FROM: THOMAS S. ENYEART

MANAGER, TECHNICAL SERVICES

DATE: AUGUST 1, 1990 Bulletin 9012

SUBJECT: 2001 CONVECTION STEAMER

SPORADIC LOW WATER LIGHT

OVERHEATING ELEMENTS-POSSIBLE ELEMENT MELTDOWM

Please insert this bulletin in the ST-Steamer section of your master Southbend

manual behind 2001 Convection Steamer Manual #1173012.

We have had some units where the electric elements actually melt down. In all

cases the high limit control had either been adjusted or the unit had been

miss-wired. If you have problems with the low water light coming on and the

unit shutting down, please check, the following: DO NOT ADJUST THE HIGH LIMIT

CONTROLS.

1. Check the interior cavity bottom for lime/mineral build up. If

lime/mineral build up exists, clean following the instructions in the

manual. Note: Lime build up acts as an insulator.

2. Be sure that during operation-the water level is at the top of the

stopper to the overflow point, and of uniform depth throughout the

cavity. If water level is uneven, level the unit. If the water level

is not -at the top of the stopper check the following:

a. Be sure there is no lime build up on the stopper or the drain

opening. If there is, clean following the instructions in the

manual.

b. Be sure the stopper fits properly so the water is forced to drain

over the top and not around the stopper.

c. Be sure water flow into the unit is sufficient to provide the

proper water level. If not take what ever steps are necessary

to assure same.

1100 Old Honeycutt Rd.

Fuquay-Varina, NC 27526

(919) 552-9161

FAX (919) 552-9798

Page 13

August 1, 1990

Page 2

3. Check the boiling pattern of the water on the interior cavity bottom.

The pattern should be in the shape of the 3 elements. If the boiling

pattern is good this means the heat transfer is good. If the boiling

pattern is not good there is bad heat transfer - you will probably

have to remove the elements, apply a new coat of thermal grease, and

then reinstall the elements. Note:' The bottom must be flat to

assure a good contact. Please refer to the manual.

4. The high limit is set to shut down the unit when the element reaches

450 degrees. (The normal operating element temperature is

approximately 370 degrees). You can check the element temperature by

using a temperature probe (remove element cover and go through the

rear of the unit). Sense the element where the high limit bulb

contacts the element.

5. Be sure the high limit sensing bulb is secure to the element.

Performing these checks should eliminate any problems and assure the unit

is operating as designed.

AS previously Stated. DO NOT UNDER ANY CIRCUMSTANCES ADJUST THE HIGH LIMIT

CONTROLS. Not only can this result in destruction of the unit, it nay

create unsafe conditions for the user. Any person who adjusts this control

will be solely responsible!

TSE/tws

Page 14

S E R V I C E

southbend B•U•L•L•E•T•I•N

TO: Southbend Parts & Service Distributors

FROM: Thomas S. Enyeart- CFSP

Director Product Service

DATE: February 7, 1994 BULLETIN #9433

SUBJECT: Availability of Stainless Steel Water Jet Nozzle

Model 2001

Effective Date: Special Part in now available

Please insert this bulletin with #1173012 Counter Top Convection Steamer

owners manual in the ST-Steamers-Pressure less & Pressure section of your

master Southbend manual.

This new part is not a replacement of existing 6600241 Nozzle in standard

production. It is a special Stainless Steel Jet Nozzle to be used where water

conditions dictate, and is available on special request only.

New Part:

6600241-SS Stainless Steel Full Jet Nozzle

List Price – effective 1-15-94

TE/dy

1100 Old Honeycutt Rd. • Fuquay-Varina, NC 27526 • (919) 552-9161 • (800) 348-2558 • Fax (919) 552-9798

Parts Service Hotline (800) 54 RANGE (800-547-2643)

Page 15

BULLETIN # 9502

1

FIGURE

2

FIGURE

4

TO: Southbend Parts & Service Distributors

FROM: Roscoe Hester

Service Administrator

DATE: June 28,1995

SUBJECT: Door Spring Tool (Model 2001)

We now supply a door spring tool to assist in installing handle springs on model 2001

(Part numbers 6600396 and 6600398).

Part Number for door spring tool: 4440366

List Price: $ 8.40

If you have questions, please contact the Service Department at (800) 348-2558.

FIGURE

FIGURE 3

1100 Old Honeycutt Rd. • Fuquay-Varina, NC 27526 • (919) 552-9161 • (800) 348-2558 • Fax (919)

552-9798 Parts Service Hotline (800) 54 RANGE (800-547-2643)

Page 1 of 1

Page 16

TO: Southbend Parts & Service Distributors

FROM: Thomas S. Enyeart

Manager, Technical Services

DATE: September 20, 1991 BULLETIN# 9126

SUBJECT: 2001 Convection Steamer

a) Addition of element thermostats

b) Low water light changed to trouble light

Please insert the attached revised 7 manual pages into your 2001

Counter Top Convection Steamer Owners Manual -Pt #1173012 in the STSteamer Section of your master Southbend manual.

Also, please correct your price list, showing the new part numbers

- prices remain the same.

Effective date - August 1991 - Unit serial numbers beginning with

"91H".

A major improvement has been made to the 2001 Steamer, adding disctype fixed thermostats to the heating elements and changing the amber

"low water" light to a red "Trouble" light. This change makes the

unit more forgiving. The thermostats will control the element

temperature still using the high limit control for a safety backup.

This change will help compensate for improper installations, guards

against low water almost entirely, eliminating the chance of element

meltdown and warped bottoms. The new trouble light indicates a

problem with the unit and that the operator should call the authorized

service agency. Installation should still be made as instructed in

the manual.

New parts are:

#1174302 Disc-type thermostat for element

#1174299 Wire routing support

#1174301 Wiring shield

#1174300 Wiring routing channel

#1174306 Element insulation

#1174307 Insulation cover

#1161675 Bushing

#1173537 Polypanel

#6600028 Red trouble light

#1174320 Control panel

#1174309 Relay mounting bracket

1100 Old Honeycutt Rd.

Fuquay-Varina, NC 27526

(919) 552-9161

FAX (919) 552-9798

Page 17

Bulletin #9126

Page 2

#1170335 Terminal strip

#1174308 Retainer - High limit bulb

#1174304 Element 208V

#1174305 Element 240V

Discontinued parts are:

#6600030 Low water light - amber - still available

#1170008 Relay bracket - still available

#1168029 Element 208V - Discontinued - use 1174304

#1168028 Element 240V - Discontinued - use 1174305

#132282 Control panel - still available

#1167592 Polypanel - still available

#A19-00011Element insulation - still available

Please note new elements #1174304 S 1174305 can be used on both models

using cast aluminum elements, either with or without thermostats. Old

style elements 1168029 & 1168028 can only be used on units without the

thermostats. The difference is the new elements are drilled and tapped

to accept the thermostats, whereas the discontinued elements are not.

RECAP: The new revised steamer (Ser. 91H & up) is being manufactured

with protective thermostats installed on the element body. There

are 2 thermostats per element for a total of 6. These units can

be easily identified in the field by the following:

1. Red "trouble" light in place of amber "low water" light.

2. Terminal strip and 3 relays in rear component area on right

side of motor. Previously, no terminal strip was used and

there were two relays - mounted to the left of the motor.

Under normal operating conditions, the steamer will operate with the

elements on continuously. They will not cycle "off" and "on". If the

interior bottom of the cooking cavity space becomes unclean due to lime

or other deposits, or if the water supply to the unit is stopped or

diminished, the elements may begin to cycle off and on. This condition

may be recognized by reduced performance of the unit. Check and clean

the interior bottom, if necessary, and check to make sure that the

water supply is not restricted or turned off.

Page 18

Bulletin #9126

Page 3

The “trouble” light illuminated indicates that there may be severe

lime/deposits and/or restricted water supply to unit. However, this

condition can only occur if the element thermostats all fail in the

"on" (normally closed - "untripped" state) position.

If "trouble" light is on, a thorough investigation must be done to

determine the cause of the problem. Please consult a Southbend service

representative at the factory if you need assistance in determining the

problem.

TE/dy

Page 19

Date: September 22, 1988

To: Southbend Authorized Service Representatives And Parts

Distributors

Subject: 2001 Steamer Door Slide Pivot Kit

Please insert in the CS-Convection Steamer section of your Master Southbend

Manual

A major improvement that has been made on the door slide pivot. The old

style clip has been eliminated by the use of a pivot and a screw. These

are in production and field use has proven very satisfactory. To improve

the older units and to reduce inventories Part #132-312 door slide pivot

kit is now available (Instruction sheet reprinted on rear of this bulletin).

This parts kit #132-312 replaces any and all of the following:

Pivots #132-238

132-027-2

132-309

A81-00049

1167264

6600404

Clips #PH-301

PH-307

PH-317

1167265

6600402

Screw #PH095

This is a Mandatory Distributor Stock Item

T5. Enyeart

Manager - Parts & Service

TSE/kj

Southbend Sales Representatives

Internal Distribution

1100 Old Honeycutt Rd.

Fuquay-Varina, NC 27526

(919) 552-9161

FAX (919) 552-9798

Page 20

PIVOT

IMPORTANT;

1167264

(6600404)

P.N. 132-312 " DOOR SLIDE PIVOT KIT

OLD STYLE REPLACE WITH NEW STYLE

Screw on slide is placed to

Inside. Screw on door Is

placed to outside. USE

"LOCTITE" on threads of

screw.

RETAINING RING

1167265

(6600402)

Old styles using Pivot and Retaining Ring

are replaced by #132-312 Door Slide Pivot

Kit.

INSTRUCTION P/N 1170041

NOTE: For units with Serial numbers before 807-18 enlarge

holes with 21/64th drill.

Page 21

Date: August 29. 1988

To: ALL SOUTHBEND AUTHORIZED SERVICE AGENCIES AND

PARTS DISTRIBUTORS

Subject: 2001 Dual Power Steamers

Intermittent Element Drop Out, Low Water Light Coming On

Please insert in the CS-Convection Steamer Section of your Master Southbend

Manual.

On a few 2001 New Style Dual Power Steamer we have had sporatic reports

of the high limit control switching on causing the Elements to drop out and the

low water light to come on.

If you encounter these symptoms on this unit, the following will normally

solve the problem. Complete steps as necessary to eliminate the problem.

1. Check the high limit control.

2. Check the physical condition of the elements. Make certain they are

intact and in good array.

3. Make certain that all nuts that hold the elements in position are tight.

Care should be taken not to break the weld stud (Do Not tighten over

75 inch lbs.)

4. Remove the elements and make sure there is no weld splatter around

the studs to hold elements from fitting flush to the bottom plate of

the steamer - If there is splatter then carefully remove before

replacing elements.

IF ELEMENTS HAVE TO BE REMOVED FOLLOW THE ATTACHED- INSTRUCTIONS.

PART NO. PN-126 Thermo Coat may be ordered thru our Parts Department.

1100 Old Honeycutt Rd.

Fuquay-Varina, NC 27526

(919)552-9161

FAX (919) 552-9798

Page 22

THERMOCOAT INSTRUCTIONS - 2001 DUAL POWER STEAMER

READ THE ENTIRE PROCEDURE CAREFULLY BEFORE

STARTING ANY WORK

1. Disconnect all power, water and drain lines to the unit.

2. Turn unit upside down.

3. Remove bottom aluminized panel and aluminum back.

4. Make a general inspection of this area looking for any heat damage or

lime deposits from leaky inlet water connections.

5. Carefully start to un-tighten the 1/4-20 nuts which hold Item 3 in place.

6. Disconnect and remove the copper water line to the condenser.

7. Item 3 can now be removed, however caution should be used here

because the insulation underneath is brittle and can be damaged.

8. Remove the insulation surrounding the healing elements Items 4, 8, and

9. Here again be very gentle considering the brittleness of the insulation.

9. The heating elements are now exposed inspect elements and wiring for

damage.

10. Remove high limit thermostats very carefully taking eztra care not to put

any crimps in the bulb or tube.

11. Carefully remove the nuts and washers. Note that washers are

cupped. The application of some lubricate like penetrating oil before

untightening is advisable.

12. If any of the studs have broken away from the bottom carefully

reinstall all parts and return to factory.

13. Remove heating elements, being careful not to use the portion of the

element extending from the aluminum casting as a hand hold. (Note

present position of elements.)

Page 23

14. Thoroughly clean the heat conducting paste from the heater and its

mating surface. Inspect the element and mating surface for flatness using

a good straight edge. If when checking the flatness of the mating surface

a gap greater than 1/16 in depth and 2 inches long is detected consult the

factory for additional instructions.

15. Coat the underside of the heating element with a coat of heat conducting

paste approximately 1/32 to 1/16 in depth across the entire surface

making sure there are no voids or air pockets.

16. Reinstall the heating elements in the same position they were removed.

Install washers so cups are facing each other leaving a small gap in center

of washers. Refer to drawing one. When tightening, tighten diagonally to

no more than 50 in-lbs on the first pass. On the second pass tighten

diagonally to 75 in-lbs then go back over each nut in reverse order.

17. After all heating elements have been installed go back over each nut and

tighten to 75 in-lbs.

18. Reconnect wiring to heating elements per wiring diagram.

19. Reinstall high limit thermostat making sure that the bulb is laying flat on

the heater and is securely fastened. It may be necessary to bend slightly

the washer which holds the bulb down. The bulb should not be loose in

its holder.

20. Reinstall insulation again being very careful not to damage it. Replace

any broken pieces.

21. Reinstall cover Item 3. The nuts which hold the cover on also hold the

heating element in place and should be tightened as described earlier.

22. Reinstall copper water line to condenser.

23. Replace bottom return unit to normal operating position.

24. Hooking water, power and drain lines install back.

25. Turn unit on and check for proper operation.

HUSSMANN/SOUTHBEND 8/88

Page 24

PARTS

-SET Of

4

Litho in U.S.A

CONDENSOR

KEY NO. PART NO. DESCRIPTION

1 130-283 CONOENSOR - COMPLETE (A12-0027)

2 130-225 HOLDING RING - NOZZLE <6600325)

3 PP-632 SPRAY JET NOZZLE (6600241)

4 PP-247 COUPLING (A98-00003)

5 PH-003 SCREW (6600540)

6 PH.277 LOCKWASHER (6600541)

7 130-169 TEFLON GASKET - DRAIN (6600316)

MOUNTING VIEW - ELEMENTS

(208V,220V,240V)

KEY NO. PART NO. DESCRIPTION

1 PH-202 NUT- ¼ -20 (1146413)

2 PH-251 LOCKWASHER - 1/4- (1146500)

3 132-295 COVER - INSULATION ELEMENT (A14-00026)

4 132-294-1 INSULATION - ELEMENT (A19-00011)

5 1-0574 SPRING WASHER (A60-00004)

6 132-296 WASHER - LIMIT THERMOSTAT (A60.00005)

7 132-264-1 HEATING ELEMENT (208V) (1168029)

132-264-2 HEATING ELEMENT (240V) (1168028)

8 132.294-3 INSULATION - FRONT & REAR (A19-00012)

9 132-294-2 INSULATION - SIDE (A19-00013)

PM-140

THERMO JOINT COMPOUND FOR

ELEMENTS (202)

COUNTER TOP CONVECTION STEAMER

SECTION FOUR — PARTS

PAGE 4

MISCELLANEOUS PARTS NOT SHOWN IN

PHOTOS OR DRAWINGS

KEY NO. PART NO. DESCRIPTION

132-105-1 DOOR CATCH SPACER (6600509)

132-033 DRAIN PAN (6600454)

STEEL LEG ASSY - (OPTIONAL)

PM-015

6600362

- ONE (6600361)

6.88

Page 25

Clip over

Body of

Hold Slide Clip with

Side View

AUTHORIZED PARTS DISTRIBUTORS & SERVICE September 30, 1986

AGENCIES

2001RL DOOR SLIDE CLIPS

Please insert in the CS - Convection Steamer Section of the master Southbend Service

Manual. Replaces Bulletin dated 7-16-86. Destroy 7-16 bulletin.

Due to heavy usage the slide clip which is welded to the slide arm can become damaged. In

the past it was suggested that the slide arm assembly he cut off and a new assembly be

welded to the unit.

Effective immediately a new clip is available that can be slipped on over the slide arm.

It is necessary to cut the old clip off with a

hacksaw.

Once the new clip is in place squeeze the clip together with a pair of vise grips and

assemble to the slide arm with a 10-24 pan head bolt and nut. Be sure to use a jam nut to

ensure that the nut remains in place.

Also the head of the bolt should face the interior of the unit to minimize damage

to the gasket. See Below.

Top View

Kit Part No. A81-00004 - Slide Clip Kit (consists of

slide clip #A34-00001, one 10-24 pan head bolt

Snap Slide

Slide Rod

#1146238, two 10-24 nuts #1146412). Current list

price $5.00.

Unit

Patton G. Philotoff

Regional Service Manager

cc. Sales Directors

Sales Representatives

Internal Distribution

Vise Grips here

1100 Old Honeycutt Rd.

Fuquay-Varina, NC 27526

(919)552-9161

FAX (919) 552-9798

Page 26

COUNTER TOP CONVECTION STEAMER

208/240

V

9.5

KW*

208/60/3

30

240/60/3

25

FRONT VIEW

APPROVALS:

Not For Scale

For Dimensional Purposes Only

INSTALLATION

SIDE VIEW TOP VIEW

SPECIFICATIONS

Electric connection - terminal block.

Drain 1 ¼” o.d., leave open, do not connect

to floor drain.

Cold water inlet ¼”, 30 p.s.i. min. - 60 p.s.i. max.

DIMENSIONS: ( ) = Millimeters

MODEL

2001

Width

A

24"

(610)

HEIGHT DEPTH ELECTRIC CONN.

B C D E F G H I

5.5"

(140)

18.3"

(465)

21.5"

(546)

23.8"

(605)

25.25"

(610)

3.5"

(89)

13"

(330)

1.5"

(38)

Drain J Water

3.5"

(89)

K

10"

(254)

CRATE SIZE

Width Depth Height

26.5"

29.5"

(749)

26.5"

(673)

(673)

Cubic

Volume

12 cu. ft.

.34 cu.

Crated

Weight

155 Ibs.

70.3 kg.

UTILITY INFORMATION:

ELECTRIC: 208/60/1, 240/60/1, 208/60/3, or 240/60/3.

TOTAL CONNECTED AMPS

208/60/1 46

240/60/1 41

*Circuit must be wired for maximum 9.5 KW at required voltage.

WATER USAGE: 0.20 gallons per minute at 45 p.s.i. water pressure.

COUNTER TOP CONVECTION STEAMER

SECTION ONE — INSTALLATION

PAGE 1

Page 27

INSTALLATION

Litho in U.S.A.

GENERAL:

THE UNIT WHEN INSTALLED MUST BE ELECTRICALLY GROUNDED AND COMPLY WITH LOCAL

CODES, OR IN THE ABSENCE OF LOCAL CODES, WITH THE NATIONAL ELECTRICAL CODE

ANSI/NFPA 70-Latest Edition.

CANADIAN INSTALLATION MUST COMPLY WITH Canadian Electrical Code, Parts I and II.

CLEARANCES:

Allow at least a three inch (3") 76 mm. clearance between the back of the unit and any wall obstruction for proper

ventilation of the motor compartment, and room for plumbing and electrical connections.

Do not locate the Southbend Steamer adjacent to any high heat-producing piece of equipment, such as a range top,

griddle, fryer, etc., that could allow radiant heat to raise the exterior temperature of the Southbend Steamer above

130T (54'C).

WARNING:

THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL OR WARRANTY

WILL BE VOIDED.

TO INSTALL:

1. Uncrate carefully. Report any hidden freight damage to the freight company immediately.

2. Do not remove any tags or labels until the unit is installed and working properly.

3. Set unit in place.

4. Counter Model — Set on non-flammable surface and shim to make level. Seal to counter top with sealer such

as G. E. or DOW Coming RTV type sealant. (Consult local code for exact requirements.)

LEVELING:

1. Unit must be level to assure maximum performance. Improper leveling may void warranty.

WATER CONNECTION:

Connect cold water line, 1/4( (6mm.) pipe. Do not connect to hot water source. (Connecting hot water may void the

warranty.) Water line pressure should be 30 psi (205 Kpa) minimum — 60 psi (410

Kpa) maximum.

NOTE: To facilitate cleaning, plus allowing access to the rear of unit, flexible connections are recommended.

COUNTER TOP CONVECTION STEAMER

SECTION ONE — INSTALLATION

PAGE 2

Rev. 12-92

Page 28

INSTALLATION

DRAIN LINE:

Type A: Drain line to unit requires 1 ¼” (32 mm.) pipe. Unit should be positioned near an open floor drain. There

must be no plumbing connection to a drain system. The unit must be free-venting to atmosphere. The drain

line should be as short as possible (no longer than 40" (1016 mm.) to the "FUNNEL," and at a slope of at

least 15°. Any connection that allows the build-up of back pressure in the unit will void the warranty. This

is a pressureless, free-venting steam cooker and will not operate properly unless the drain line is short, at a

steep angle, and open!

Type B: Drain line to unit requires 1" (25 mm.) pipe. Unit should be positioned near drain. The drain line can be

connected to drain, but must have a vent pipe extending upward from the "T" connection.

ELECTRICAL CONNECTION:

For proper connection of field wiring to terminal block, see Wiring Diagram, Section 3, Page 7. Be sure that the

input voltage and phase match the requirements shown on the serial plate (located on each piece of equipment).

NOTE: A POSITIVE GROUND CONNECTION IS ESSENTIAL.

NOTE: ALL Steamers are shipped wired for three phase. To convert to single phase see Section One, Page 4.

DO NOT ALLOW ANY TAMPERING OR ADJUSTMENT OF ANY CONTROL OR WIRING. THE UNIT IS

FACTORY SET. ADJUSTMENT OF ANY INTERNAL COMPONENT OTHER THAN THE FIELD TERMINAL

BLOCK CAN VOID THE WARRANTY.

1. Open water valve to full open position.

CHECK:

a. Power to unit.

b. Water to unit.

c. Open drain.

COUNTER TOP CONVECTION STEAMER

SECTION ONE — INSTALLATION

PAGE 3

Page 29

INSTALLATION

Litho in U.S.A.

NOTE: ALL Steamers are shipped three phase. If it becomes necessary to convert from three phase to single phase

follow instructions below.

1. Remove louver panel from rear of steamer

2. Locate contactor in right hand side of rear control compartment and loosen wire terminals on the output side of

contactor.

3. Move wire number 3 from A3 to Al. Refer to diagram below.

4. Move wires number 5 and 6 from A2 to A3. Refer to diagram below.

5. Tighten all wire terminals and replace louver panel. The unit is now converted from three phase to single phase.

COUNTER TOP CONVECTION STEAMER

SECTION ONE - INSTALLATION

PAGE 4

Rev. 12-92

Page 30

INSTALLATION

INSTRUCTIONS FOR STACKING THE 2001:

1. Center one of the 2001s on top of the other, making sure the back bottom comers of the top unit line up with the

back top comers of the bottom unit.

2. Using a felt tip pen, trace around the top unit.

3. Remove the top unit. Spread a bead of high temperature silicone, about the diameter of a pencil, inside the line

drawn in No. 2.

4. Carefully place the top unit on the bottom unit. Seal around edges with silicone to comply with NSF requirements.

5. To install brackets, remove the screws that fasten the bottom plate to the back of the unit. These screws are 3"

from each comer. The hook on the bracket should slide over the lip on the very top of the bottom unit. It may be

necessary to push in slightly on the back louvered panel to allow room for the brackets. Reinstall the screws

through the bracket.

6. Allow 24 hours for silicone to dry before using units.

PERFORMANCE CHECK:

The following items should be checked before or within the first 30 days of operation by a qualified service technician.

1. Check doors for proper alignment and tension.

2. Check door gaskets for wear and sealing ability.

3. Check spray tubes or nozzles for cleanliness and/or leakage.

4. Check all gauges, timers, valves, switches, and motors for proper operation.

5. Visually check control compartment wiring for burned or loose connections.

6. Is user keeping compartment clean?

7. Check electrical load on elements, where applicable, for proper wattage.

COUNTER TOP CONVECTION STEAMER

SECTION ONE — INSTALLATION

PAGE 5

Page 31

COOKING HINTS

Red -

shredded

5lbs. 18-20

27

SPINACH

cut side down

halves

Zucchini, sliced,

5lbs.

SUGGESTED COOKING TIMES:

Timer settings are for general guidance only. Differences in food quality, size, shape, freshness, load size and degree of

cook desired must be considered and adjustments made in time if necessary.

PRODUCT

BATCH

SIZE

APPROX.

COOKING

TIME (MIN)

PRODUCT

BATCH

SIZE

APPROX.

COOKING

TIME (MIN)

FROZEN VEGETABLES* FRESH VEGETABLES*

ASPARAGUS

Cuts and tips 5 IDS. 8-10 Spears 4 Ibs. 12-14

Spears

BEANS

Green or wax - cut 1"

Green - French cut

Lima - Fordhook 5lbs. 16-18 Small 5lbs. 12-14

BROCCOLI

Chopped - tempered 4 IDS. 8-10 CABBAGE

Cut - tempered

Spears 4 IDS. 10-12 Green - wedges, 1/6 cut 5lbs. 20-22

BRUSSEL SPROUTS 4 IDS. 8-10

CARROTS

Sliced

Whole, baby 5lbs. 14-16 CAULIFLOWER

CAULIFLOWER

Flowerettes 4 IDS. 8-10 CELERY

CORN

Cobettes - 3"

Whole Kernel

MIXED VEGETABLES 5lbs. 16-18 On the cob

PEAS

POTATOES

White, whole, small 5 Ibs. 18-20 PEPPERS

Chopped - tempered 6 IDS. 8-10

Leaf - tempered

SUCCOTASH 5lbs. 16-18 peeled, 1 "-3" 7 Ibs. 25-30

ZUCCHINI

Sliced - tempered

*Prepare in 12 x 20 x 2 ½” perforated pan.

5 IDS.

5 IDS.

5lbs.

5lbs.

4 IDS.

5lbs.

5lbs.

6 Ibs.

6 Ibs.

10-12

14-16

20-22

8-10

10-12

14-16

10-12

10-12

- 5"-7" length, 2 pans e ea. pan

18-20

8-10

BROCCOLI

BEANS

Green, 1 "-2" cut 5lbs. 13-15

BRUSSEL SPROUTS

Large 5lbs. 16-18

Green - shredded

CARROTS

Sliced – ½” 7 Ibs. 17-19

Flowerettes

1 "-2" cuts

3"-4" cuts in solid pan 5lbs. 14-16

w/chicken broth added

CORN

5"-7" length 1 14 ears

On the cob 1

Green, large, 14

POTATOES

Red boilers, whole,

Red boilers, whole,

peeled, 1"-3", 3 pans ea. pan

SPINACH

Leaf 2 Ibs. 4-5

SQUASH

Zucchini, sliced, 3/16” 5lbs. 7-8

3/16” - 2 pans ea. pan

COUNTER TOP CONVECTION STEAMER

5lbs.

6 Ibs.

5lbs.

14 ears

7 Ibs.

SECTION TWO — USER'S GUIDE

12-14

14-16

14-16

13-15

18-20

5-7

45-50

12-13

PAGE 3

Page 32

COOKING HINTS

Semolina

2lbs. 18-22

WILD EXTRA FANCY

Litho in

U.SA.

PRODUCT

BATCH

SIZE

FRUIT

CRANBERRIES

Fresh-12 x 20 x 2 ½” solid pan - use

3 cups water and 5 cups sugar

PRUNES

Dried and pitted - 12 x 20 x 2 ½” solid

pan - add 4 cups hot water and sugar

to taste

4 lbs. 8-10

halfway through cooking cycle.

4lbs. 8-10

APPROX.

COOKING

TIME (MIN)

PRODUCT

PASTA

Prepare in 2 ½” deep perforated pan nested inside solid 12" x

20" x 4" pan. Cover with hot tap water. Add salt and oil if

desired and stir. Stir again

SPAGHETTI

Semolina 2lbs. 12-14

MACARONI

BATCH

SIZE

APPROX.

COOKING

TIME (MIN)

RICE AND DRIED BEANS

Prepare in 12" x 20" x 2 ½” solid pan unless otherwise indicated.

Add hot tap water; salt and oil as desired. Stir before placing in

steamer. Do not cover.

WHITE LONG GRAIN CONVEF TTED

2 ½ quarts water, salt, oil 2 lbs. 30-35

6" deep pan, 6 ½ lbs. 40-45

6 ½ quarts water (1 gal)

WHITE MEDIUM GRAIN

1 ¾ quarts water 2 lbs. 22-25

BROWN LONG GRAIN PARBO ILED

1 ½ quarts water 1 ¾ Ibs. 25-30

1 ½ quarts water, 2 pans 1 ¾ Ibs. 30-35

5 cups water 1 Ib. 60-65

KIDNEY BEANS

4 quarts hot water. Steam 4

minutes. Remove; cover; let stand

one hour. Remove cover.

Continue steaming.

NAVY BEANS

3 quarts hot water. Steam 2

minutes. Remove; cover; let stand

1 hour. Remove cover. Continue

steaming.

NOODLES

Egg, Semolina 2lbs. 12-14

Lasagna, Semolina 2lbs. 15-18

EGGS

Prepare in 12" x 20" x 2 ½” perforated pan, unless indicated.

Remove eggs from refrigerator 1 hour prior to cooking.

SOFT COOKED

Large

HARD COOKED

Large, in shell Large, cracked

into oiled solid pan - for salad

SCRAMBLED

Add margarine and spices if

ea. pan

2lbs. 2-50 CHICKEN

4-50

desired. Stir with wire whip after

15 minutes. 4" solid pan. Mixture

in 5-lb. poly film bag, frozen.

Cover with hot water in 4" pan.

Stir after 25 min.

POACHED

In poaching pan or water 8 3-4

POULTRY

Prepare in 12" x 20" x 2 ½” perforated pan. Place solid pan

underneath to catch juice.

4 doz. 8-10

4 doz. 12-14

4 doz. 10-12

6 doz.

2 bags

18-20

45-50

COUNTER TOP CONVECTION STEAMER

SECTION TWO — USER'S GUIDE

PAGE 4

Whole, as purchased 4lbs. 40

Quarters, 8-9 oz. 14 pcs. 18-20

Quarters, 8-9 oz., 2 pans 14 pcs. 24-27

ea. pan

Rev. 12-92

Page 33

APPROX.

APPROX.

BATCH

COOKING

BATCH

COOKING

Frozen,

12" x 20" x 6" Two

1"

water. Cook to

180°

per Ib.

Steam in solid pan with

Stir at

30

minutes.

10

Ibs. 40

DINNER ROLLS

per Ib.

HOT DOGS

TORTILLAS

thawed

5

Ibs. 5 perforated pan or on

8oz. 1-2

COOKING HINTS

PRODUCT SIZE TIME (MIN) PRODUCT SIZE TIME (MIN)

MEAT

MISCELLANEOUS

Prepare in 12" x 20" pan - depth as indicated. CHEESE SOUP

BEEF

Clod - 4" solid pan; add

pan. Water or milk added. 4-lb. tubs 40

Stir at 15 and 30 minutes.

internal temperature 15-17 Ibs. 13-15 BLANCHING NUTS

Ground - 4" solid pan.

CORNED BEEF BRISKET

Raw - cured, 2 ½” solid

1 cup water.

Pre-baked, frozen. Reheat

in perforated pan or on

pan; add ½” water. 9 Ibs. 18-22 pan shelf, uncovered.

2 ½” perforated pan,

2 ½ ‘ perforated pan,

FISH

Prepare in 12" x 20" x 2 ½” perforated pan.

Place solid pan underneath to catch juice.

COD PORTIONS

Thawed - 4 oz. size 3 Ibs. 8-10

OYSTERS

In shell - 18-20 per pan 1 pan 12

In shell - 18-20 per pan 3 pans 15-20

Slightly overlap on

pan shelf. 6-8 1-2

Cooked. To reheat place in

perforated pan or strainer.

4-5

3-4

COUNTER TOP CONVECTION STEAMER

SECTION TWO — USER'S GUIDE

PAGE 5

Page 34

COOKING HINTS

END USER TIPS:

Litho in U.S.A.

Schedule cooking of fresh vegetables so that they will be served soon after they are cooked. If it is necessary to

prepare them in advance, they can be plunged into cold water, drained thoroughly and held under refrigeration until

needed for service.

Five pounds of cold cooked vegetables can be reheated in the steamer in 5 to 10 minutes, depending upon the

variety.

Adding salt to the water for eggs cooked in the shell makes the cooking water more efficient and faster at its job. If

the egg cracks, the white is cooked at the crack and is sealed right away.

To avoid the dreaded green yolk (which is a deposit of iron sulfide) chill the eggs immediately after removing from

the steamer by plunging them into a cold water bath (preferably containing ice).

A quick and easy way to cook eggs for a salad mixture is to crack them directly into a solid steam table pan which

has been lightly coated with salad oil. Do not mix. Steam until they are hard cooked. Remove and chop as you would

for egg salad. The job of peeling has been eliminated.

Transfer steamed hot chicken to deep pan, cover with Cacciatore Sauce and finish in Marathoner oven. Bake 20 to

30 minutes. May be held on steam table.

After cooking, chicken may be browned in Infra-Red or Radiant Broiler. Brush with melted margarine mixed with

salad oil to give a golden brown color.

Use juice saved from steamed chicken to make soups, sauces, or casserole dishes.

Chicken may be steamed in advance and held under refrigeration for next day's use. Be sure to bring product back to

180 °F before serving.

Save the juice from the corned beef. After the cabbage has been steamed, place it in a solid pan and add the juice for

flavoring and holding on a steam table.

Steaming brisket in the 2001 Steamer is a definite time saver. Boiling in water takes 40 to 50 minutes per pound.

Using the 2001 can save 50% in cooking time.

Cabbage when steamed, retains its color and wedge identity. It will not break apart as it does when boiled in an open

pot.

When open, the door can be used as a convenient pan holder while seasoning, loading or unloading.

When removing items prepared in a perforated pan put a solid pan on the door shelf to hold the pan of cooked food.

This will prevent dripping on the floor.

The 2001 is designed to accept standard 12 x 20 pans the way you naturally carry them. Fractional size pans can be

used as well with the optional perforated shelf.

For stirring, the pan does not have to be removed from the steamer. Pull pan 1/3 way out of the cavity and the entire

surface is accessible.

The door may be opened at any time during operation to remove or add food.

Possibility of overcooking is eliminated during the automatic cycle because the elements shut off when the buzzer

sounds.

COUNTER TOP CONVECTION STEAMER

SECTION TWO — USER'S GUIDE

PAGES

Rev. 12-92

Page 35

COUNTER TOP CONVECTION STEAMER

SERVICE

ADJUSTMENTS

WARNING:

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

TECHNICIAN WHO IS EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE OPERATION

OF COMMERCIAL COOKING EQUIPMENT, HOWEVER, TO ASSURE YOUR CONFIDENCE,

CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR RELIABLE SERVICE,

DEPENDABLE ADVICE OR OTHER ASSISTANCES, AND FOR GENUINE FACTORY PARTS.

The following is a brief explanation of the operation of your Southbend Series 2001 Electric Convection Steamer.

The unique design of the Southbend Convection Steamer allows you to cook with steam without the problems of

bulky, troublesome steam boilers. The Southbend 2001 Dual Power Series uses 9.5 KW or 6.5 KW (your choice).

The Southbend Steamer generates its own steam on the bottom of the cooking compartment.

With the selector switch in the "OFF" position, you should have AC across selector switch. If not, check fuse.

When selector switch is placed in the "LO" or "HI" position and second one to "MANUAL" position, voltage is

applied to the coil of contactor from line 4 at terminal block; through fuse; through both selector switches; through

safety thermostats; through relay. Voltage is also applied to water solenoid. Solenoid furnishes 3/8" water

(overflow drain installed) to the floor of the cooking compartment, which turns to steam when heating elements get

hot. Heating elements are fastened directly under the floor of the cooking compartment and heat the water through

direct conduction.

NOTE: From a cold start, the unit should be up to temperature within 4 to 5 minutes.

When contactor energizes, the higher rated voltage is applied to heating elements through the closure of contactor

contacts L1, L2, and L3; from the LINE voltage at terminal block.

NOTE: Interior element also cycles in parallel with heating elements.

Interior element super-heats and dehumidifies the steam in the cooking compartment.

NOTE: The fan will not operate if the door is open, due to safety interlock door switch.

Anytime the unit is turned "ON," a small amount of water will be noticed coming out of the drain-line. This is due

to a "water mist," which is sprayed across the exhaust of the cooking compartment. This eliminates any possibility

of "live" steam ever reaching a drain line. This feature is required by law on ALL pressure less, atmospheric

steamers.

NOTE: The water connection into any Southbend Steamer must be cold water.

FOR REPLACEMENT OF HEATING ELEMENTS (See Drawing on Parts Page 4):

For units without thermostatic element control — Serial Number 91G and before.

A. REMOVAL OF ELEMENTS:

1. Close water valve and remove power to the unit.

2. Disconnect field connection to unit.

3. Remove bolts holding unit to table or stand.

4. Turn the unit on its side and remove bottom cover by sliding it toward the rear.

5. To facilitate work, unscrew control panel and electric box and pull out from their position with

disconnecting any wire. Then disconnect 1/8" copper tubing from condenser.

6. Remove the four nuts, lockwashers, element cover and insulation.

7. Remove all nuts, spring washers and bulbs between elements.

8. Disconnect and remove defective elements. Note carefully where each element is connected.

COUNTER TOP CONVECTION STEAMER

SECTION THREE — SERVICE

PAGE 1

Page 36

ADJUSTMENTS

Litho in U.S

-A-

FOR REPLACEMENT OF HEATING ELEMENTS (See Drawing on Parts Page 5):

For units with thermostatic element control — Serial Number 91H and after.

A. REMOVAL OF ELEMENTS;

1. Close water valve and remove power to the unit.

2. Disconnect field connection to unit.

3. Remove bolts holding unit to table or stand.

4. Turn the unit on its side and remove bottom cover by sliding it toward the rear.

5. To facilitate work, unscrew control panel and electric box and pull out from their position with

disconnecting any wire. Then disconnect 1/8" copper tubing from condenser.

6. Disconnect wires from thermostats and set loose wires aside.

7. Remove the four nuts, lockwashers, element cover and insulation.

8. Remove all nuts, spring washers and bulbs between elements.

B. INSTALLATION OF NEW ELEMENTS (See Drawing on Parts Page 4):

For units without thermostatic element control — Serial Number 91G and before.

9. Make sure the new elements are of correct voltage. Voltage marked on elements must be exactly the

same as marked on the nameplate of the unit.

10. Completely coat the machined side of the element with #PN-126 thermal grease. (Failure to do so will

result in inadequate heat transfer from the element into the steamer bottom plate, causing the low water

light to come on.)

11. Before installing elements make sure to have clean surfaces (on stud plate and elements) except the white

thermo grease.

12. Reinstall elements. Markings should be visible.

13. Install bulbs, flat washers, spring washers and nuts. A maximum of 70 inch/pounds torque should be on

nuts.

14. Connect the new elements in accordance with the wiring diagram.

15. Place the insulation over and around. Use a new insulation if the original one is broken.

16. Place the element cover over the insulation plate with lockwashers and four nuts.

17. Install the bottom cover and turn the unit on its base.

18. Fasten the unit to stand or counter top and seal to the counter top.

19. Connect field wiring and water line and open water valve.

20. Connect drain extension if so equipped, making sure that drain vents freely.

21. Reset power to the unit, turn unit ON and test amperage on each phase and each element. R

INSTALLATION OF NEW ELEMENTS (See Drawing on Parts Page 5):

For units with thermostatic element control — Serial Number 91H and up.

9. Disconnect and remove defective elements. Note locations of wires.

10. Make sure the new elements are of the correct voltage. Voltage marked on elements must be the same as

marked on unit serial plate.

11. Completely coat the machined side of the element with PN-126 thermal grease. Failure to do so will

cause inadequate heat transfer and may severely damage unit.

12. Before installing elements, make sure bottom surface is clean.

13. Reinstall elements. Markings should be visible, (rough side).

14. Install hi-limit bulbs, flat washers, spring washers and nuts. Torque securing nuts to 70 in/lbs.

15. Install (2) new thermostats on new element, tighten snug to casting surface.

16. Reinstall the element insulation board. Use new insulation if broken.

17. Connect the wires back to the elements per the wiring diagram.

18. Reinstall the sheet metal insulation cover and securing nuts.

19. Reinstall thermostat wires to thermostats. Refer to wiring diagram or sticker inside lower side panel.

20. Install the bottom cover and turn unit on its base.

21. Fasten unit to stand or countertop.

22. Connect field wiring and waterline. Open water valve.

23. Connect drain piping.

24. Reset power to unit. Turn unit on and check amperage on each leg of supply wires.

COUNTER TOP CONVECTION STEAMER

SECTION THREE — SERVICE

PAGE 2

Rev. 12-S2

Page 37

ADJUSTMENTS

FOR REPLACEMENT OF MOTOR (Disconnect Electric Field Connections):

A. REMOVAL OF FAN:

1. Remove plastic plug and set screw on the fan hub. An adhesive (LOCTITE or equivalent) may have been

used to prevent loosening of set screw. In such case, the set screw may have to be heated to soften the

adhesive and allow removal. An electric soldering iron or gas soldering torch may be used.

2. Insert a bolt one inch (25 mm) or longer into the threaded hole at the end of the fan hub. Tighten the bolt

against the end of the motor shaft until fan slips off.

Caution: If fan does not move on shaft while tightening the bolt against the end of the motor shaft, spray

penetrating oil (WD-40 or equal) into plug and set screw holes every few minutes until fan can be removed

without damage.

R REMOVAL OF MOTOR:

3. Remove seal and clean shaft.

4. Remove electric wires from motor. Note which terminals the wires were attached to. Incorrect wiring could

damage the motor.

5. Remove motor assembly.

6. Undo the four lockouts holding the motor to the motor support.

C. INSTALLATION OF NEW MOTOR (See Drawing on Parts Page 2):

7. Fasten the new motor to the support with four locknuts,

8. Install nylon washer between cavity and motor support.

9. Place the new motor assembly in position until the motor shaft is exactly centered in the hole where it

penetrates the cooking compartment; check from the front side.

10. Reconnect wiring to the motor.

11. Place the seal on motor shaft (without grease); thin lip of seal in direction of cavity. Seal should make a good

contact on cavity.

D. INSTALLATION OF FAN (See Drawing on Parts Page 2):

12. Before installing the fan check the following points:

a. The motor assembly must be secure.

b. The motor shaft must be centered in the hole.

c. The motor must turn freely.

d. The seal must be in place on the shaft inside the cooking compartment.

13. Coat the inside of the fan hub and the motor shaft with a high-temperature, waterproof anti-seize compound

(LOCTITE 771 or equivalent).

14. Position fan in place. Apply suitable grade adhesive on set screw threads (LOCTITE or equivalent),

position set screw in place and tighten to secure fan on shaft. Place plastic plug in front hole.

15. Rotate the fan by hand to see if everything is smooth. The fan should rotate freely, not rubbing against

anything.

16. Reassemble interior components and place switch in "MANUAL" position. Within five (5) minutes steamer

should be up to temperature and fan should be running. Check for proper rotation (CCW).

COUNTER TOP CONVECTION STEAMER

SECTION THREE - SERVICE

PAGE 3

Page 38

ADJUSTMENTS

REPLACEMENT OF DOOR GASKET (See Drawing on Parts Page 2):

REMOVAL OF INNER PANEL ASSEMBLY (DETAIL)

Litho in U.S.A.

1. Open door and remove inner panel assembly by sliding panel toward you and lifting out of door.

2. Place panel assembly facing down on a flat surface.

3. Remove the two (2) nuts holding two (2) retaining panels and gasket.

4. Install new gasket around inside panel.

5. Two spacers must be installed on studs inside of panel. Front panel inside of gasket.

6. Install flange deflector down, opposite to the turn-down edge panel and then install two nuts.

7. Place panel assembly in door with turn-down edge of panel nearest you. Slide panel toward you, push

downward and secure turn-down edge by sliding panel toward unit.

8. Close door, turn on unit and test for leaks around the door.

9. If required, door can be adjusted by means of the four screws holding the door to the hinges.

To adjust door, loosen the four screws, position door to obtain light pressure on gasket and tighten the four

screws. Make sure the two comers of the door are in

line with the comers of the unit.

10. Further adjustment is possible by adding or removing

shims under the door catch plate. Removing shims

will increase pressure on top edge of gasket.

If these instructions are followed carefully, door

should be easy to operate and without steam or water

leaks.

NOTE: This unit must be free-venting through the drain.

Any restriction at drain outlet or failure to install drain ac-

cording to installation instructions will cause the steam to

escape around door due to excessive backpressure in the

unit

DOOR HINGE TUBING ASSEMBLY (See Drawing on Parts Page 2):

TO REMOVE:

1. Open door and unscrew (4) #10-32 screws.

2. Remove door hinge each side, freeing the door hinge tubing assembly.

3. Remove torsion springs, inspect for damage; replace if defective.

TO REASSEMBLE:

1. Insert door hinge tubing assembly in between tabs on front frame.

2. Install #10-32 screws, being sure to apply thread sealer.

3. Reinstall door; check for smooth operation.

COUNTER TOP CONVECTION STEAMER

SECTION THREE — SERVICE

PAGE 4

Rev. 12-92

Page 39

building.

KPA)

SERVICE

TROUBLE SHOOTING:

FIRST — CHECK THE BASICS. The unit needs power, water, and an open drain to operate properly.

BASIC #1 — POWER: Is there power to the unit of the proper voltage and phase?

BASIC #2 — LOW WATER: Is there water flowing into the compartment? Be sure all water valves are open.

BASIC #3 — DRAIN: Is the drain line open (no solid connection), short (about three feet), and without

obstructions?

Check the BASICS. Then, and only then, can malfunction of controls be considered.

Refer to "INSTALLATION INSTRUCTIONS" section of this service manual to make sure the unit was installed

properly. After all previous steps have been complied with, proceed with this trouble shooting guide. Carefully check

all symptoms listed to find the one closest to the actual malfunction of your steamer.

NOTE: Improper installation may void warranty.

TROUBLE SHOOTING GUIDE: (Always Press Power Off)

Problem:

Steam leaks around the door. —

No water in the cooking

compartment (or very little

water). Non thermostat element

type: Yellow-Low water light

on or thermostat element type:

Bed—Trouble light on

Look For: Correction:

BASIC #3 - DRAIN The drain either

wasn't installed properly or has developed

an obstruction of some sort, causing a back

pressure in the cooking compartment.

— Worn door gasket. Replace gasket.

—

BASIC #2 - WATER Drain overflow not in

place.

— Water valve shut off. Check any water valves to the unit.

— Water may be shut off elsewhere in

— Waterstrainer may be plugged. Clean as necessary.

— Flow control valve may be plugged. Clean as necessary.

— Tank solenoid may be plugged or not

operating.

— Inlet to cooking compartment may be

plugged.

— Low water pressure. Water pressure must be 30 P.S.I. (207

Check drain line installation. The drain line

must be short, at a slope, not physically

connected to any drain system and without

restrictions. (No drain traps.)

Drain overflow should be inserted in drain

of cooking compartment.

Make sure cold water line to unit is on.

Check tank solenoid.

Clean as necessary.

minimum.

COUNTER TOP CONVECTION STEAMER

SECTION THREE — SERVICE

PAGE 5

Page 40

NOTE: Before fan motor will turn on, door switch must be energized. (Check fuse and Master

SERVICE

Litho in U.S.A.

TROUBLE SHOOTING GUIDE: (Continued)

Problem:

No steam. — BASIC #1 - POWER Is there power to the unit? Does the

Look For: Correction:

supply match the rating on the nameplate?

BASIC #2 - WATER There must be at least 1/4" (6 mm) of

water covering floor of cooking

compartment. (If no water on floor of

cooking compartment, SEE SYMPTOM

#2).

— No power to the contactor coil or defective

contactor.

See Wiring Diagram and trace voltages

through proper circuits.

Check element thermostats.

If Contactor is operating properly, check

both sides of contactor to make certain all

phases are going to the elements.

— Defective heating elements. Check all elements. Replace if necessary.

Defective element thermostats. Check thermostat — contacts should be

NOTE: If elements are replaced, check

Section 3-Page 1 for service procedure.

closed at room temperature.

Fan Motor doesn't run. NOTE: Generally, if you can spin the fan by hand, the motor will not be defective unless it is.

overheating. See cause "E" below.

Switch also.)

— Fuse. Check — replace if necessary. Turn

master switch to manual position.

— Loose door latch. Adjust so door will close and activate

door switch.

Temperature in motor compartment is too

high. (Motor will stop automatically if

overheating — it will reset automatically

when temperature returns to normal.)

There must be at least three inches

clearance at back of unit. Unit must not be

located near high heat-producing pieces

of equipment — see installation

instructions.

Slow cooking or unit won't get

— BASIC #2 - WATER Check Symptom #2.

hot enough to make much

steam.

COUNTER TOP CONVECTION STEAMER

SECTION THREE — SERVICE

PAGE 6

Rev. 12-92

Page 41

COUNTER TOP CONVECTION STEAMER

Serial

91G

and before

PE-196

KNOB FOR TIMER

PARTS

PARTS

WARNING:

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID THE

WARRANTY ON THIS EQUIPMENT,

The serial plate is located on exterior right side at rear.

Replacement parts may be ordered either through a Southbend Authorized Parts Distributor or a Southbend

Authorized Service Agency.

When ordering parts please supply the Model Number, Serial Number, Part Number, Description, plus Finish, and

Electrical Characteristics, as applicable.

For parts not listed consult a Southbend Authorized Parts Distributor or Southbend Authorized Service Agency. If

necessary, please consult Southbend Parts Department for assistance.

NOTE: NO THERMOSTAT ELEMENT CONTROLS ON UNITS Serial Number 91G and before. Units Serial

Number 91H and up have thermostat element controls and a red trouble light replaces the amber low water

light.

CONTROL PANEL VIEW

KEY NO. PART NO. DESCRIPTION

1 1167592 POLYPANEL, Serial 91G and before

2 A93-00023 POWER SWITCH (PE-172)

3 6600030 LOW WATER LIGHT, 240V, AMBER,

4 PE.195

5 A9340025 AUTO/MANUAL SWITCH (A93-00029)

6 1109900 BUZZER,240V

1173537 POLYPANEL, Serial 91H and after

6600028 TROUBLE LIGHT, 240V, Red, Serial

Not Shown

132282

1174320 CONTROL PANEL, Serial 91H and after

91H and after

TIMER

CONTROL PANEL. Serial 91G and

before

2001 SINGLE POWER CONNECTION

COUNTER TOP CONVECTION STEAMER

SECTION FOUR — PARTS

PAGE 1

Page 42

PARTS

Litho in U.S.A

-

2001 SINGLE POWER CONNECTION

DOOR ASSEMBLY MOUNTING VIEW

KEY NO. PART NO. DESCRIPTION

1 1167325 SCREW. HINGE MOUNT (PH-158)

2 1168259 DOOR PIVOT SHAFT TUBE (132-223)

3 A11.00019 BASKET FRAME (132-305)

4 All-00018 INSIDE PANEL (132-306)

5 A16-00004 DOOR GASKET (132-255)

6 6600367 SPACER (PH-404)

7 6600430 LOCK NUT (PH-406)

8 1167344 DOOR PANEL (Exterior) (132-188)

9 132321 DOOR HINGE BLOCK (Left or Right)

10 6600416 HINGE SPRING (Left) (132-046-1)

11 6600414 HINGE SPRING (Right) (132-046-2)

12 6600412 LOCKWASHER. SS. ¼ (PH-256)

13 6600410 SCREW, HINGE BLOCK (PH-007)

14 1173531 DOOR HANDLE (132-121) (6600376)

1173530 DOOR LATCH

15 6600396 SPRING, HANDLE (Left Hand) (132-018-1)

16 6600398 SPRING. HANDLE (Right Hand) (132-018-2)

17 6600402 SPRING CLIP (PH-307)

18 6600400 PIVOT PIN, HANDLE (132-027-1)

19 11-00029 HOLDING PLATE (132-307)

MOTOR AND FAN

MOUNTING

KEY NO. PART NO. DESCRIPTION

1 132-320 MOTOR. 208-240V

2 1167330 BRACKET. MOTOR (132-013)

3 6600430 LOCK NUT (132-200)

4 1168255 BLOWER WHEEL (132-233, 1167331)

5 A16-00005 SHAFT SEAL - CAVITY (PM-122)

6 A60-00003 WASHER, NYLON (130-135)

7 1167332 SET SCREW (PH-172)

8 A59-00020 HOLE PLUG BUTTON (PM-005)

Kit A03-00030 includes items 3. 4. 5,6 & 7 (132-304)

Kit A03-00054 includes items 8 thru 19 (132-303)

Kit 4440334 Door Latch/catch Improvement Kit includes 1 each:

1173531.1173530.1173529

Kit 6600370 includes items 3 thru 19

2001 SINGLE POWER CONNECTION

COUNTER TOP CONVECTION STEAMER

SECTION FOUR — PARTS

PAGE 2

Rev. 12-92

Page 43

10 1173293

SOLENOID 208

-

240V

PARTS

2001

SINGLE POWER CONNECTION

BACK VIEW OF STEAMER

KEY

NO.