3D Sensor

Installation Guide

Version 4.10.3

Terms of Use Applicable to the User Documentation

The legal notices, disclaimers, terms of use, and other information contained herein (the “terms”) apply only to

the information discussed in this documentation (the “Documentation”) and your use of it. These terms do not

apply to or govern the use of websites controlled by Sourcefire, Inc. or its subsidiaries (collectively,

“Sourcefire“) or any Sourcefire-provided products. Sourcefire products are available for purchase and subject

to a separate license agreement and/or terms of use containing very different terms and conditions.

Terms of Use and Copyright and Trademark Notices

The copyright in the Documentation is owned by Sourcefire and is protected by copyright and other intellectual

property laws of the United States and other countries. You may use, print out, save on a retrieval system, and

otherwise copy and distribute the Documentation solely for non-commercial use, provided that you (i) do not

modify the Documentation in any way and (ii) always include Sourcefire's copyright, trademark, and other

proprietary notices, as well as a link to, or print out of, the full contents of this page and its terms.

No part of the Documentation may be used in a compilation or otherwise incorporated into another work or with

or into any other documentation or user manuals, or be used to create derivative works, without the express

prior written permission of Sourcefire. Sourcefire reserves the right to change the terms at any time, and your

continued use of the Documentation shall be deemed an acceptance of those terms.

SOURCEFIRE®, SNORT®, CLAMAV®, SOURCEFIRE DEFENSE CENTER®, SOURCEFIRE 3D®, RNA®, RUA®,

SECURITY FOR THE REAL WORLD®, the Sourcefire logo, the Snort and Pig logo, the ClamAV logo, Sourcefire

IPS, RAZORBACK, Sourcefire Master Defense Center, DAEMONLOGGER, and certain other trademarks and

logos are trademarks or registered trademarks of Sourcefire, Inc. in the United States and other countries. Other

company, product and service names may be trademarks or service marks of others.

© 2004 - 2013 Cisco and/or its affiliates. All rights reserved.

Disclaimers

THE DOCUMENTATION AND ANY INFORMATION AVAILABLE FROM IT MAY INCLUDE INACCURACIES OR

TYPOGRAPHICAL ERRORS. SOURCEFIRE MAY CHANGE THE DOCUMENTATION FROM TIME TO TIME.

SOURCEFIRE MAKES NO REPRESENTATIONS OR WARRANTIES ABOUT THE ACCURACY OR SUITABILITY OF

ANY SOURCEFIRE-CONTROLLED WEBSITE, THE DOCUMENTATION AND/OR ANY PRODUCT INFORMATION.

SOURCEFIRE-CONTROLLED WEBSITES, THE DOCUMENTATION AND ALL PRODUCT INFORMATION ARE

PROVIDED “AS IS” AND SOURCEFIRE DISCLAIMS ANY AND ALL EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO WARRANTIES OF TITLE AND THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL SOURCEFIRE BE

LIABLE TO YOU FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, PUNITIVE, OR

CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT LIMITED TO PROCUREMENT OF SUBSTITUTE GOODS OR

SERVICES, LOSS OF DATA, LOSS OF PROFITS, AND/OR BUSINESS INTERRUPTIONS), ARISING OUT OF OR IN

ANY WAY RELATED TO SOURCEFIRE-CONTROLLED WEBSITES OR THE DOCUMENTATION, NO MATTER HOW

CAUSED AND/OR WHETHER BASED ON CONTRACT, STRICT LIABILITY, NEGLIGENCE OR OTHER TORTUOUS

ACTIVITY, OR ANY OTHER THEORY OF LIABILITY, EVEN IF SOURCEFIRE IS ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. BECAUSE SOME STATES/JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATIONS MAY NOT APPLY TO

YOU.

The Documentation may contain “links” to websites that are not created by, or under the control of Sourcefire.

Sourcefire provides such links solely for your convenience, and assumes no responsibility for the availability or

content of such other sites.

2014-Jan-15 12:06

Table of Contents

Chapter 1: Before You Begin......................................................................... 7

IPS Installation Considerations ............................................................................. 8

RNA Installation Considerations ........................................................................... 9

RUA Installation Considerations ......................................................................... 10

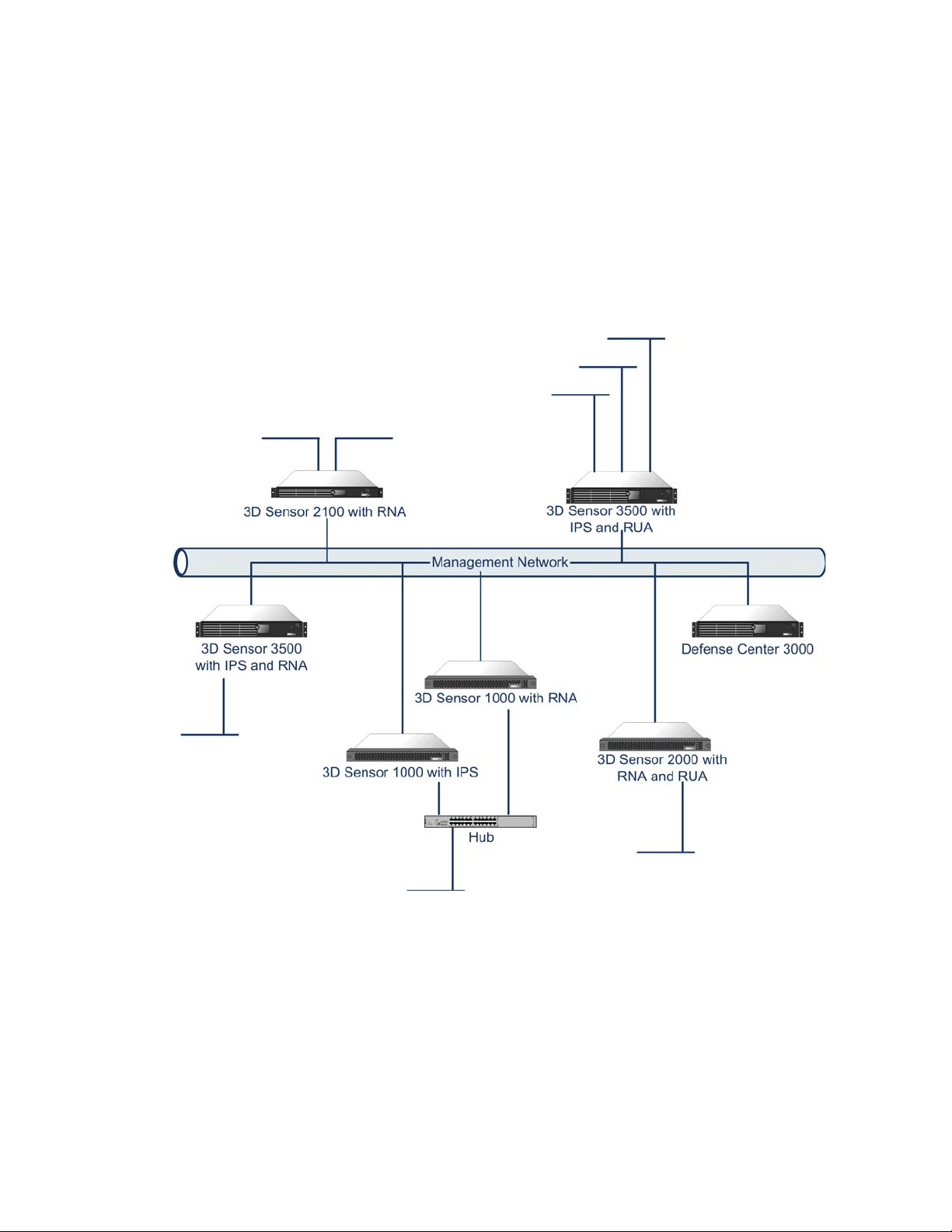

Typical 3D Sensor Deployments ......................................................................... 11

Deploying a Multi-Port 3D Sensor.......................................................... 15

Other Deployment Options ................................................................................ 18

Integrating with VPNs ............................................................................ 18

Detecting Intrusions on Other Points of Entry ....................................... 18

Deploying in Multi-Site Environments.................................................... 20

Integrating 3D Sensors with RNA within Complex Networks ............... 21

Understanding Detection Engines and Interface Sets........................................ 22

Understanding Detection Resources and 3D Sensor Models ............... 23

Comparing Inline and Passive Interface Sets......................................... 25

Connecting Sensors to Your Network................................................................. 25

Using a Hub ........................................................................................... 26

Using a Span Port .................................................................................. 26

Using a Network Tap.............................................................................. 26

Issues for Copper Cabling in Inline Deployments .................................. 27

Special Case: Connecting 8000 Series Devices .................................... 29

Using a Sourcefire Defense Center .................................................................... 29

Communication Ports ......................................................................................... 31

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 3

Table of Contents

Chapter 2: Installing a 3D Sensor .............................................................. 33

Included Items .................................................................................................... 34

Security Considerations ...................................................................................... 34

Identifying the Management and Sensing Interfaces......................................... 35

Sourcefire 3D Sensor 500/1000/2000 ................................................... 35

Sourcefire 3D Sensor 2100/2500/3500/4500......................................... 36

Sourcefire 3D Sensor 6500.................................................................... 38

Sourcefire 3D Sensor 7010/7020/7030 .................................................. 42

Sourcefire 3D Sensor 7110/7120 ........................................................... 42

Sourcefire 3D Sensor 8120/8130/8140 .................................................. 45

Sourcefire 3D Sensor 8250/8260/8270/8290......................................... 48

Sourcefire 3D Sensor 9900.................................................................... 53

Using 3D Sensors in a Stacked Configuration .................................................... 55

Connecting 3D9900 Sensors................................................................. 56

Connecting 3D8140 Sensors ................................................................. 58

Connecting 3D8250/8260/8270/8290 Sensors ...................................... 58

Using the 8000 Series Stacking Cable................................................... 62

Installing the 3D Sensor in a Rack ...................................................................... 62

Configuring the Management Interface.............................................................. 64

Using the Management Interface .......................................................... 65

Using a Monitor and Keyboard............................................................... 66

Using the LCD Panel.............................................................................. 68

Using the Command Line Interface ....................................................... 71

Performing the Initial Setup ................................................................................ 72

Redirecting Console Output ............................................................................... 75

Testing an Inline Fail-Open Interface Installation ................................................ 76

Checking for Updates ......................................................................................... 78

Chapter 3: Using the LCD Panel ................................................................. 79

Understanding the LCD Panel ............................................................................ 80

Understanding LCD Panel Modes ...................................................................... 80

Initial Setup/Network Configuration ....................................................... 81

Idle Display ............................................................................................ 82

Error Alert .............................................................................................. 83

System Status........................................................................................ 83

Using the Multi-Function Keys............................................................................ 85

Resetting the Network Configuration ................................................................. 87

Adjusting the Brightness and Contrast on the LCD Panel .................................. 88

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 4

Table of Contents

Chapter 4: Hardware Specifications......................................................... 89

Rack and Cabinet Mounting Options .................................................................. 89

Sourcefire 3D Sensor 500/1000/2000 Specifications ......................................... 90

Chassis Front View ................................................................................ 90

Chassis Rear View ................................................................................. 92

Physical and Environmental Parameters................................................ 93

Sourcefire 3D Sensor 2100/2500/3500/4500 Specifications .............................. 94

Chassis Front View ................................................................................ 94

Chassis Rear View ............................................................................... 100

Physical and Environmental Parameters.............................................. 102

Sourcefire 3D Sensor 6500 Specifications ....................................................... 103

Chassis Front View .............................................................................. 103

Chassis Rear View ............................................................................... 109

Physical and Environmental Parameters............................................... 111

Sourcefire 3D Sensor 7010/7020/7030 Specifications ...................................... 112

Chassis Front View .............................................................................. 113

Chassis Rear View ............................................................................... 118

Physical and Environmental Parameters.............................................. 119

Sourcefire 3D Sensor 7110/7120 Specifications ............................................... 120

Chassis Front View .............................................................................. 120

Chassis Rear View ............................................................................... 126

Physical and Environmental Parameters.............................................. 128

Sourcefire 3D Sensor 8120/8130/8140 Specifications ...................................... 130

Chassis Front View .............................................................................. 130

Chassis Rear View ............................................................................... 138

Physical and Environmental Parameters.............................................. 140

Sourcefire 3D Sensor 8250/8260/8270/8290 Specifications ............................ 142

Chassis Front View .............................................................................. 143

Chassis Rear View ............................................................................... 152

Physical and Environmental Parameters.............................................. 154

Sourcefire 3D Sensor 9900 Specifications ....................................................... 156

Chassis Front View .............................................................................. 156

Chassis Rear View ............................................................................... 162

Physical and Environmental Parameters.............................................. 165

Chapter 5: Restoring a 3D Sensor to Factory Defaults......................... 166

Using an ISO File to Restore Your System ....................................................... 167

Obtaining the Restore ISO File ............................................................ 168

Using a Restore USB Drive.................................................................. 168

Using an Internal Flash Drive ............................................................... 170

Completing the Restore Process ......................................................... 171

Updating the Restore USB Drive ...................................................................... 175

Scrubbing the Contents of the Hard Drive........................................................ 176

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 5

Table of Contents

Chapter 6: Safety and Regulatory Information ...................................... 177

General Safety Guidelines ................................................................................ 177

Safety Warning Statements.............................................................................. 179

Regulatory Information ..................................................................................... 182

Sourcefire 3D Sensor 500/1000/2000 Information .............................. 183

Sourcefire 3D Sensor 2100/2500/3500/4500 Information ................... 184

Sourcefire 3D Sensor 6500/9900 Information ..................................... 185

Sourcefire 3D Sensor 7000 Series Information ................................... 186

Sourcefire 3D Sensor 8000 Series Information ................................... 189

Waste Electrical and Electronic Equipment Directive (WEEE) .......................... 193

Chapter 7: Power Requirements for Sourcefire 3D Sensors............... 194

Warnings and Cautions..................................................................................... 194

Interface Connections.......................................................................... 194

Static Control ....................................................................................... 195

3D7010/7020/7030............................................................................................ 195

Installation ........................................................................................... 195

Grounding/Earthing Requirements ..................................................... 196

3D7110/7120..................................................................................................... 197

Installation ........................................................................................... 197

Grounding/Earthing Requirements ..................................................... 198

3D8120/8130/8140 and 3D8250/8260/8270/8290 ............................................ 199

AC Installation ..................................................................................... 199

DC Installation...................................................................................... 201

Grounding/Earthing Requirements ..................................................... 202

For Assistance .................................................................................................. 204

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 6

Chapter 1

Before You Begin

This guide describes how to install and set up the Sourcefire 3D Sensor.

Depending on which Sourcefire 3D System products you have licensed, a

Sourcefire 3D Sensor can include:

• IPS, the intrusion detection and prevention component

• RNA, the Real-time Network Awareness component

• RUA, the Real-time User Awareness component

• any two components, or all three

Each of the components is described in detail in the Sourcefire 3D System User

Guide. You can install a 3D Sensor with the IPS component as a standalone

appliance, but if you want to use RNA or RUA, you must use the 3D Sensor with

a Defense Center. Note that some models of the 3D Sensor do not support every

combination of components. See Understanding Detection Resources and

3D Sensor Models on page 23 for more information.

Before you install a Sourcefire 3D Sensor, you should consider how your network

is configured and how you want to deploy the various components of the

Sourcefire 3D System within it.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 7

Before You Begin

IPS Installation Considerations

This chapter describes some of the considerations for deploying a 3D Sensor,

including:

• the concept of the detection engine and the modes in which you can deploy

detection engines on the 3D Sensor: passive or inline

• your goals in deploying sensors that use RNA to perform network discovery

and vulnerability assessment, as well as your goals in deploying sensors

that use IPS to detect and prevent attacks on your network assets

• deployment issues, such as which network segments you want to monitor

with your 3D Sensors, and why

• how you will physically connect the sensors to your network, taking into

account any special network configuration factors, such as firewall

placement, VPN deployments

• whether you will use a Sourcefire Defense Center to aggregate and

correlate RNA and intrusion events

See the following sections for more information:

• IPS Installation Considerations on page 8

• RNA Installation Considerations on page 9

• RUA Installation Considerations on page 10

• Typical 3D Sensor Deployments on page 11

• Other Deployment Options on page 18

• Understanding Detection Engines and Interface Sets on page 22

• Connecting Sensors to Your Network on page 25

• Using a Sourcefire Defense Center on page 29

Chapter 1

IPS Installation Considerations

IPS is the intrusion prevention and detection component of the Sourcefire 3D

System. Before you install a 3D Sensor with IPS, you should consider how your

network is configured and how you want to deploy the various components of the

Sourcefire 3D System within it.

Every network architecture is different, and every enterprise has different security

needs. This section lists some of the factors you should consider as you

formulate your deployment plans and includes a description of how the Sourcefire

3D System can help you meet common network security goals.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 8

Before You Begin

RNA Installation Considerations

Your deployment decisions for 3D Sensors with IPS will be based on a variety of

factors. Answering these questions can help you understand the vulnerable areas

of your network and clarify your intrusion detection and prevention needs:

• Will you be deploying your 3D Sensor with passive or inline interface sets?

Does your 3D Sensor support multiple detection engines with a mix of

interface sets, some passive and others inline? See Understanding

Detection Engines and Interface Sets on page 22 for more information

about detection engines and interface sets and how they influence your

sensor deployment.

• How will you connect the 3D Sensors to the network? Hubs? Taps?

Spanning ports on switches? See Connecting Sensors to Your Network on

page 25 for more information about methods for connecting the sensing

interfaces on your sensor to your network.

• Do you want to detect every attack on your network, or do you only want to

know about attacks that penetrate your firewall? Do you have specific

assets on your network such as financial, accounting, or personnel records,

production code, or other sensitive, protected information that require

special security policies? See Typical 3D Sensor Deployments on page 11

for more information.

• Do you provide VPN or modem access for remote workers? Do you have

remote offices that also require an IPS deployment? Do you employ

contractors or other temporary employees? Are they restricted to specific

network segments? Do you integrate your network with the networks of

other organizations such as customers, suppliers, or business partners? See

Other Deployment Options on page 18 for more information.

Chapter 1

RNA Installation Considerations

RNA is the Real-time Network Awareness component of the Sourcefire 3D

System. Before you install a 3D Sensor with RNA, you should first consider your

goals in deploying network discovery and vulnerability assessment sensors. Next,

consider deployment issues, such as which network segments you want to

monitor with RNA (and why), and how you will physically connect these

appliances to your network. Finally, you should take into account any special

network configuration factors, such as firewall placement, VPN deployments, and

how you will use a Sourcefire Defense Center to aggregate and correlate RNA

events.

Monitoring network changes with RNA can help you realize a variety of goals.

Clarifying your network discovery and vulnerability assessment goals can guide

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 9

Before You Begin

RUA Installation Considerations

your deployment choices. This section examines some general goals that can

influence a deployment of 3D Sensors with RNA, such as:

• gaining a more thorough understanding of your current network

infrastructure

• learning when network change occurs and how it affects your network’s

susceptibility to compromise

• using RNA data to refine your intrusion rules and firewall rules

RUA Installation Considerations

RUA is the Real-time User Awareness component of the Sourcefire 3D System.

RUA allows your organization to correlate threat, endpoint, and network

intelligence with user identity information. 3D Sensors with RUA allow you to

identify the source of policy breaches, attacks, or network vulnerabilities. By

linking network behavior, traffic, and events directly to individual users, RUA helps

to mitigate risk, block users or user activity, and take action to protect others from

disruption. These capabilities also significantly improve audit controls and

enhance regulatory compliance.

Chapter 1

You can deploy RUA in two ways: as a component on a 3D Sensor or as an agent

on a Microsoft Active Directory server. The implications of each deployment

method are described in “Using Real-time User Awareness” in the Sourcefire 3D

System User Guide.

3D Sensors with RUA use detection engines to passively analyze the traffic that

travels through your network. An RUA detection engine collects user login events

by passively monitoring traffic. Refer to “Setting up Sourcefire 3D Sensors with

RUA” in the Sourcefire 3D System User Guide for more information.

The Sourcefire RUA Agent on a Microsoft Active Directory (AD) server detects all

AD server logins and reports them to the Defense Center as RUA events. Only

usernames and IP addresses associated with RUA events are collected in this

manner. Information about loading the RUA Agent on a Microsoft Active Directory

server is provided in “Installing an RUA Agent on an Active Directory Server” in

the Sourcefire 3D System User Guide.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 10

Before You Begin

Typical 3D Sensor Deployments

Typical 3D Sensor Deployments

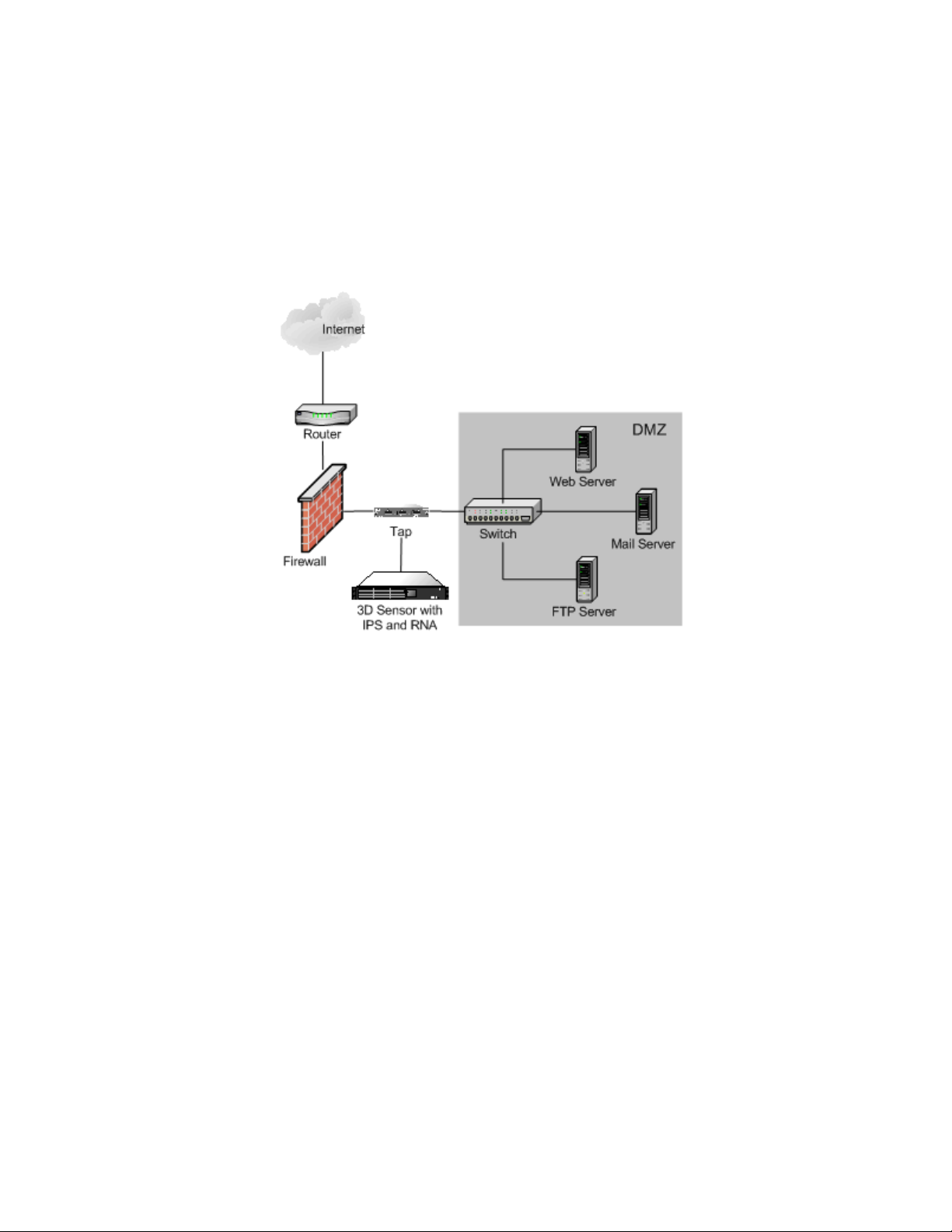

In the following simple network architecture diagram, the network has three

areas with three different security policies:

• between the border router and the firewall

• in the demilitarized zone, or DMZ

• in the internal, protected network

Chapter 1

Deploying your 3D Sensors in each of these locations serves different purposes.

Security requirements vary, so the following are typical location

recommendations:

• Placement outside the firewall gives you a clear picture of all the traffic

traversing your network via this gateway. This location is appropriate for IPS

only. Most enterprises would not need to identify user identities or employ

host and vulnerability detection capabilities in this area.

• Placement in the DMZ provides you with useful information about attacks

on outward-facing servers. This location is appropriate for IPS and RNA,

although some enterprises would want to add the user identification

capabilities of RUA here as well.

• Placement on the internal network monitors inbound traffic for firewall

misconfiguration and detects attacks that originate from hosts on the

internal network. All internal networks are ideal locations for the combined

capabilities of IPS, RNA, and RUA.

These three locations indicate where you may want to connect the 3D Sensor’s

sensing interfaces. Regardless of where you connect the sensing interfaces,

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 11

Before You Begin

Typical 3D Sensor Deployments

make sure you connect the 3D Sensor’s management interface to a secure

internal network that is protected from unauthorized access.

Outside the Firewall

Outside the firewall, the router provides the first line of defense. Although you

can configure most routers to block unwanted packets, this is not typically used

to secure the network segment between the router and the firewall. Placing the

3D Sensor here can help you detect attacks made against your network as well as

attacks from your network to another.

Chapter 1

Deploying the 3D Sensor on this segment of your network for a week or two can

help you understand what kinds of attacks reach your firewall and where they

originate. Although you can readily inspect all traffic traversing your network,

considerable resources are required to prioritize, investigate, and respond to

events that may be blocked by your firewall. Your enterprise’s ability to gain

knowledge from this approach depends on the amount of traffic traversing your

network and your security analyst resources. Gaining this kind of information can

help you tune your firewall rules to be as effective as possible.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 12

Before You Begin

Typical 3D Sensor Deployments

In the DMZ

In this simple network architecture, the DMZ contains outward-facing servers

(web, FTP, DNS, mail, and so on). The hosts in the DMZ provide services to

external users and are at a greater security risk than those inside the firewall.

Chapter 1

In this network configuration, the servers in the DMZ also provide services such

as mail relay and web proxy to users on the internal network. A 3D Sensor with

IPS on this segment can provide useful information about the kinds of attacks on

outward facing servers as well as detect attacks directed to the Internet that

originate from a compromised server in the DMZ. Adding RNA to the sensor on

this segment can help you monitor these exposed servers for changes (for

example, a new unknown service suddenly appearing) that could indicate a

compromised server in the DMZ.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 13

Before You Begin

Typical 3D Sensor Deployments

On the Internal Side of Redundant Firewalls

Many network environments implement a redundant data path for Internet

connectivity. These secondary links may also require monitoring in situations

when the primary, or active, links go offline. Two options are available for ensuring

continuous monitoring during a primary link outage:

• A single 3D Sensor can monitor both the active (primary) and passive

(secondary) links over multiple inline links passing through the single

sensor. Built-in fail-open bypass capabilities ensure that traffic is always

moving through the appliance, and any traffic that moves to the secondary

link is still monitored by the sensor appliance as if nothing had failed.

• Two 3D Sensor appliances may be placed on the network. One can monitor

the active (primary) link and one the passive (secondary) link, with both

sensors up and continuously monitoring the specified link. If a condition

causes traffic to move from the primary to the secondary link, the

3D Sensor on the secondary link automatically takes over all monitoring

responsibilities.

Chapter 1

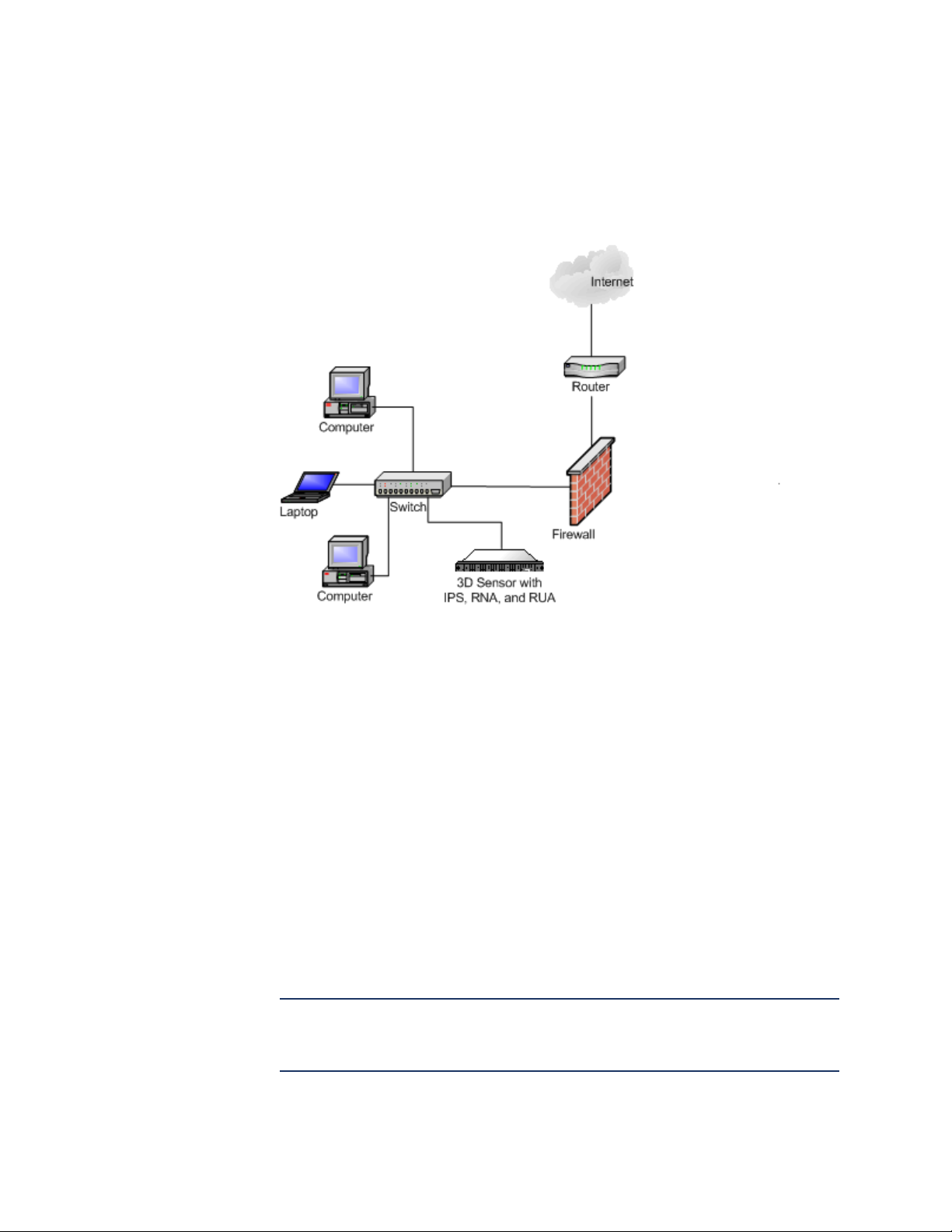

On the Internal Network

Although the sample network includes a firewall configured to provide security to

the servers and workstations on the internal network, 3D Sensors on this

segment can monitor traffic that is allowed inbound by the firewall by choice or

due to firewall misconfiguration. For example, if you have a security policy that

prohibits FTP connections to any host on the internal network, you can create a

rule on the 3D Sensor that will trigger when it detects traffic directed to port 21

on any IP address in the segment. A 3D Sensor on this segment can also detect

attacks that originate from hosts on the internal network. For instance, attaching

one 3D Sensor to a mirror or span port on a switch helps you identify attacks from

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 14

Before You Begin

Typical 3D Sensor Deployments

one computer on the internal network directed against other computers on the

internal network if the attack traffic traverses the switch.

Chapter 1

Similarly, if a host on your network is compromised from within, RNA can

immediately identify both unauthorized changes on hosts. For example, a

Microsoft shop can use RNA to identify in real time a rogue Linux or FreeBSD

system that mysteriously appears on their network segment. RNA on a switched

network segment can monitor all the hosts and services on the segment for

changes and vulnerabilities. For example, attaching an 3D Sensor to a mirror or

SPAN port on the switch allows you to monitor the entire network segment, as

long as all traffic to and from all hosts on the segment traverses the switch.

In either case, by adding RUA to the 3D Sensor, you can immediately identify the

user who is logged into the host that is running the rogue operating system or

launching the internal attack.

Deploying a Multi-Port 3D Sensor

Selected models of the 3D Sensor offer multiple sensing ports on an adapter

card. You can use the multi-port 3D Sensors in either of two ways:

• to recombine the separate connections from a network tap

• to capture and evaluate traffic from different networks

IMPORTANT! Although each port is capable of receiving the full throughput for

which the sensor is rated, the total traffic on the 3D Sensor cannot exceed its

bandwidth rating without some packet loss.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 15

Before You Begin

Typical 3D Sensor Deployments

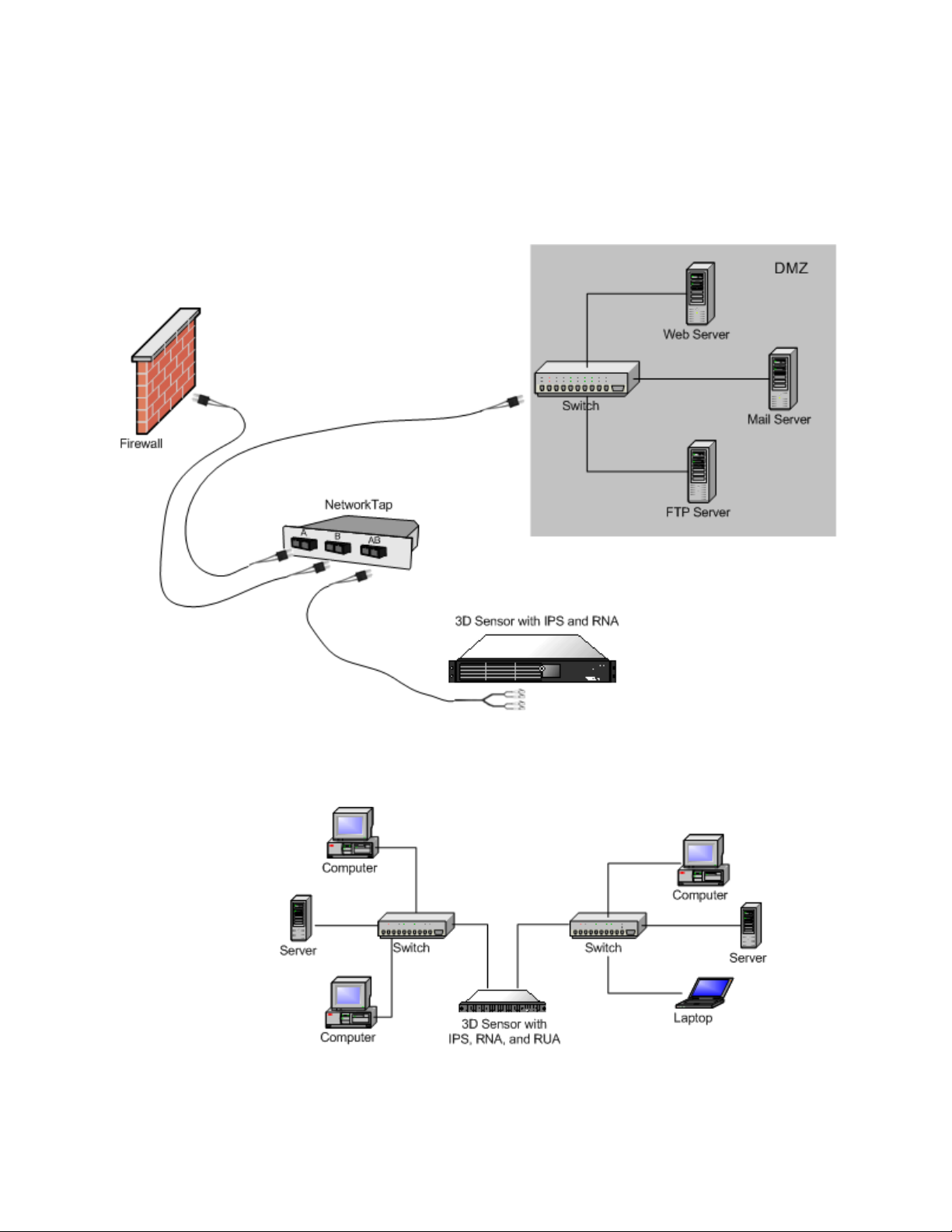

Deploying a multi-port 3D Sensor with a network tap is a straightforward process.

The following diagram shows a network tap installed on a high-traffic network

segment.

Chapter 1

In this scenario, the tap transmits incoming and outgoing traffic through separate

ports. When you connect the multi-port adapter card on the 3D Sensor to the tap,

the 3D Sensor is able to combine the traffic into a single data stream so that it

can be analyzed.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 16

Before You Begin

Typical 3D Sensor Deployments

Note that with a gigabit optical tap, as shown in the illustration below, both sets

of ports on the 3D Sensor are used by the connectors from the tap.

Chapter 1

If your 3D Sensor supports multiple detection engines, you can also create

interface sets to capture data from separate networks. The following diagram

shows a single sensor with a dual-port adapter and two interface sets connected

to two networks.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 17

Before You Begin

Other Deployment Options

Other Deployment Options

The following sections describe other installation scenarios that may affect your

enterprise’s deployment of the Sourcefire 3D System:

• Integrating with VPNs on page 18

• Detecting Intrusions on Other Points of Entry on page 18

• Deploying in Multi-Site Environments on page 20

• Integrating 3D Sensors with RNA within Complex Networks on page 21

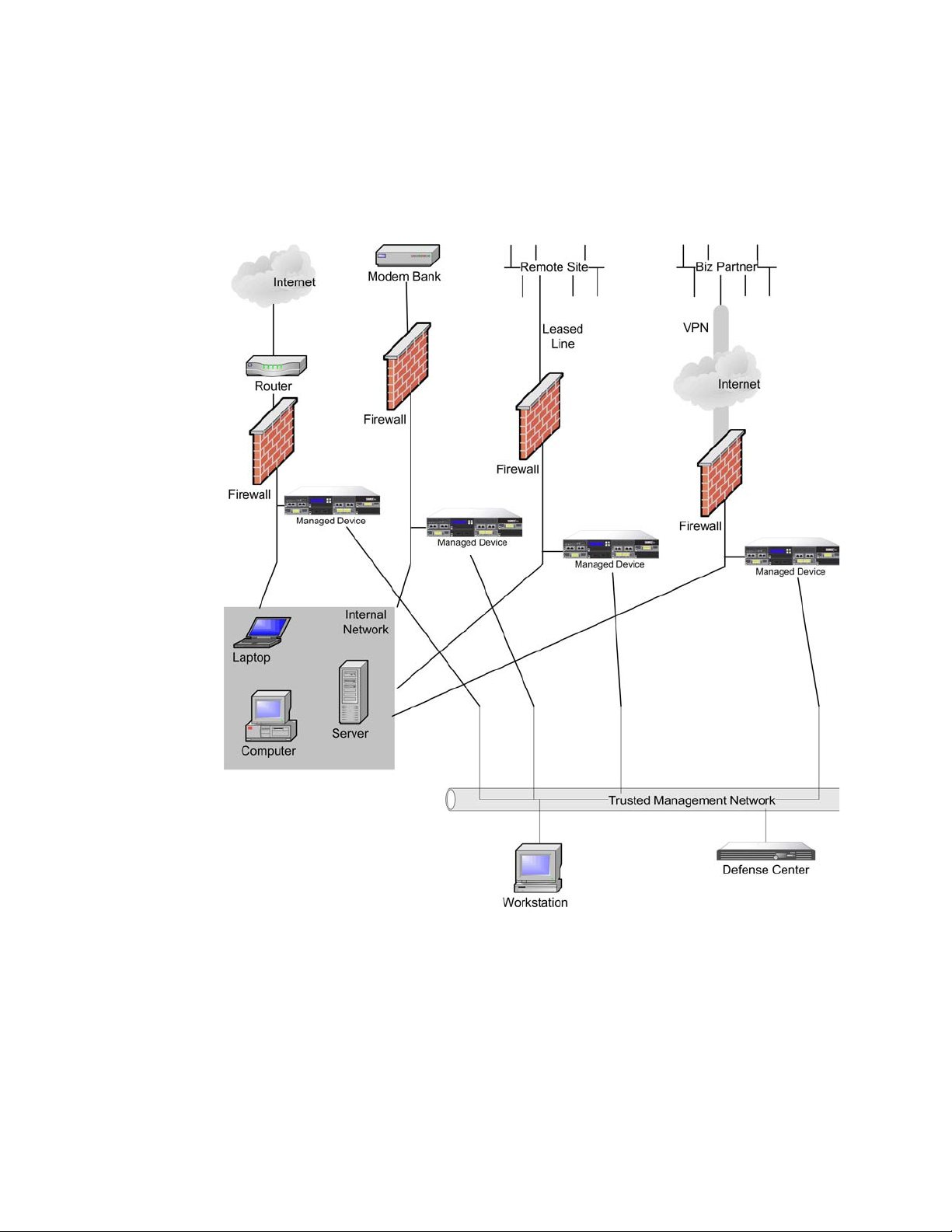

Integrating with VPNs

Virtual private networks, or VPNs, use IP tunneling techniques to provide the

security of a local network to remote users over the Internet. In general, VPN

solutions encrypt the data payload in an IP packet. The IP header is unencrypted

so that the packet can be transmitted over public networks in much the same way

as any other packet. When the packet arrives at its destination network, the

payload is decrypted and the packet is directed to the proper host.

Because network appliances cannot analyze the encrypted payload of a VPN

packet, placing 3D Sensors outside the terminating endpoints of the VPN

connections ensures that all packet information can be accessed. The following

diagram illustrates how 3D Sensors can be deployed in a VPN environment.

Chapter 1

Detecting Intrusions on Other Points of Entry

Many networks include more than one access point. Instead of a single border

router that connects to the Internet, some enterprises use a combination of the

Internet, modem banks, and direct links to business partner networks. In general,

you should deploy 3D Sensors near firewalls (either inside the firewall, outside

the firewall, or both) and on network segments that are important to the integrity

and confidentiality of your business data. The following diagram shows how

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 18

Before You Begin

Other Deployment Options

3D Sensors can be installed at key locations on a complex network with multiple

entry points.

Chapter 1

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 19

Before You Begin

Other Deployment Options

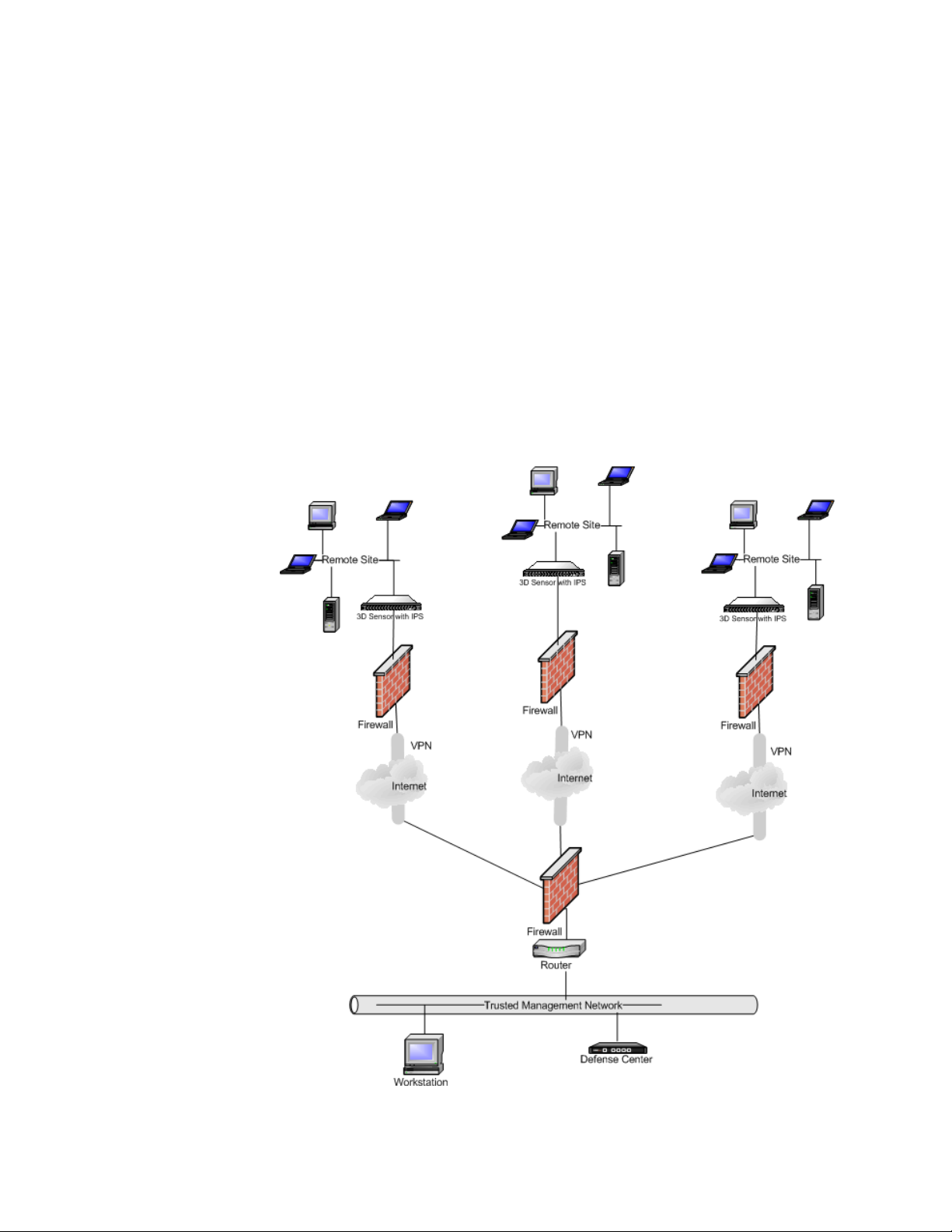

Deploying in Multi-Site Environments

Many organizations want to extend intrusion detection across a geographically

disparate enterprise and then analyze all the IPS data from one location. The

Sourcefire 3D System supports this by offering the Defense Center, which

aggregates and correlates events from 3D Sensors deployed throughout the

organization’s many locations. Unlike deploying multiple 3D Sensors and Defense

Centers in the same geographic location on the same network, when deploying

3D Sensors in disparate geographic locations, you must take precautions to

ensure the security of the 3D Sensors and the data stream. To secure the data,

you must isolate the 3D Sensors and Defense Center from unprotected

networks. You can do this by transmitting the data stream from the 3D Sensors

over a VPN or with some other secure tunneling protocol as shown in the

following diagram.

Chapter 1

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 20

Before You Begin

Other Deployment Options

Integrating 3D Sensors with RNA within Complex Networks

You can deploy 3D Sensors with RNA in more complex network topologies than a

simple multi-sector network. This section describes the issues surrounding

network discovery and vulnerability analysis when deploying RNA in

environments where proxy servers, NAT devices, and VPNs exist, in addition to

information about using the Sourcefire Defense Center to manage multiple

3D Sensors and the deployment and management of 3D Sensors in a multi-site

environment.

Integrating with Proxy Servers and NAT

Network address translation (NAT) devices or software may be employed across a

firewall, effectively hiding the IP addresses of internal hosts behind a firewall. If

3D Sensors with RNA are placed between these devices or software and the

hosts being monitored, RNA may incorrectly identify the hosts behind the proxy

or NAT device. In this case, Sourcefire recommends that you position 3D Sensors

with RNA inside the network segment protected by the proxy or NAT device to

ensure that hosts are correctly detected.

Chapter 1

Integrating with Load Balancing Methods

In some network environments, “server farm” configurations are used to

perform network load balancing for services such as web hosting, FTP storage

sites, and so on. In load balancing environments, IP addresses are shared

between two or more hosts with unique operating systems. In this case, RNA

detects the operating system changes and cannot deliver a static operating

system identification with a high confidence value. Depending on the number of

different operating systems on the affected hosts, RNA may generate a large

number of operating system change events or present a static operating system

identification with a lower confidence value.

Other RNA Detection Considerations

If an alteration has been made to the TCP/IP stack of the host being identified,

RNA may not be able to accurately identify the host operating system. In some

cases, this is done to improve performance. For instance, administrators of

Windows hosts running the Internet Information Services (IIS) Web Server are

encouraged to increase the TCP window size to allow larger amounts of data to

be received, thereby improving performance. In other instances, TCP/IP stack

alteration may be used to obfuscate the true operating system to preclude

accurate identification and avoid targeted attacks. The likely scenario that this

intends to address is where an attacker conducts a reconnaissance scan of a

network to identify hosts with a given operating system followed by a targeted

attack of those hosts with an exploit specific to that operating system.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 21

Before You Begin

Understanding Detection Engines and Interface Sets

Understanding Detection Engines and Interface Sets

A detection engine is the mechanism on a 3D Sensor that is responsible for

analyzing the traffic on the network segment where the sensor is connected.

Depending on which components are licensed on the sensor, 3D Sensors can

support three types of detection engines: IPS, RNA, and RUA.

A detection engine has two main components:

• an interface set, which can include one or more sensing interfaces

• a detection resource, which is a portion of the sensor’s computing

resources

3D Sensor models have at least three detection resources available and can

support at least three detection engines: one for IPS, one for RNA, and the third

for RUA.

An interface set refers to a grouping of one or more sensing interfaces on a

sensor; a sensing interface can belong to only one interface set at a time. The

Sourcefire 3D System supports three types of interface sets, but the interface

options available to you depend on the type of sensor and the capabilities of its

sensing interfaces.

Chapter 1

Interface Set Types

Type Description

Passive Use a passive interface set if you deployed the sensor out of

band from the flow of network traffic.

Inline Use an inline interface set if you deployed the sensor inline on

your network and the sensing interfaces do not support

automatic fail-open capabilities. Note that you can use any

two of the non-fail-open interfaces on the sensor’s network

interface cards as part of an inline interface set.

Inline with

Fail Open

The typical scenario for deploying 3D Sensors across your network infrastructure

calls for installing a different sensor in each location where you want to enforce a

security policy. In other words, you may want to install one 3D Sensor in the DMZ

and others on each internal network segment. If you have a network segment

with hosts that are likely to be targets of specialized attacks (for example, a web

host farm), you would deploy another 3D Sensor there.

Use an inline with fail-open interface set if you deployed the

sensor inline on your network and the sensing interfaces do

support automatic fail-open capabilities. Note that you must

use paired fail-open interfaces on the sensor’s network

interface cards for an inline with fail-open interface set.

Multiple IPS detection engines on a single 3D Sensor can provide you with more

flexibility in deploying 3D Sensors throughout your network. A detection engine is

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 22

Before You Begin

Understanding Detection Engines and Interface Sets

like a virtual sensor within a sensor. When you create a detection engine on a

3D Sensor, you specify which of the sensor’s sensing interfaces it uses and what

portion of the sensor’s detection resources it can use. You can then create and

apply an intrusion policy that is tuned especially for the network attacks that are

likely to be seen on the segment of the network that the detection engine

monitors. See the “Using Detection Engines and Interface Sets” chapter in the

Sourcefire 3D System User Guide for more information about creating and using

detection engines.

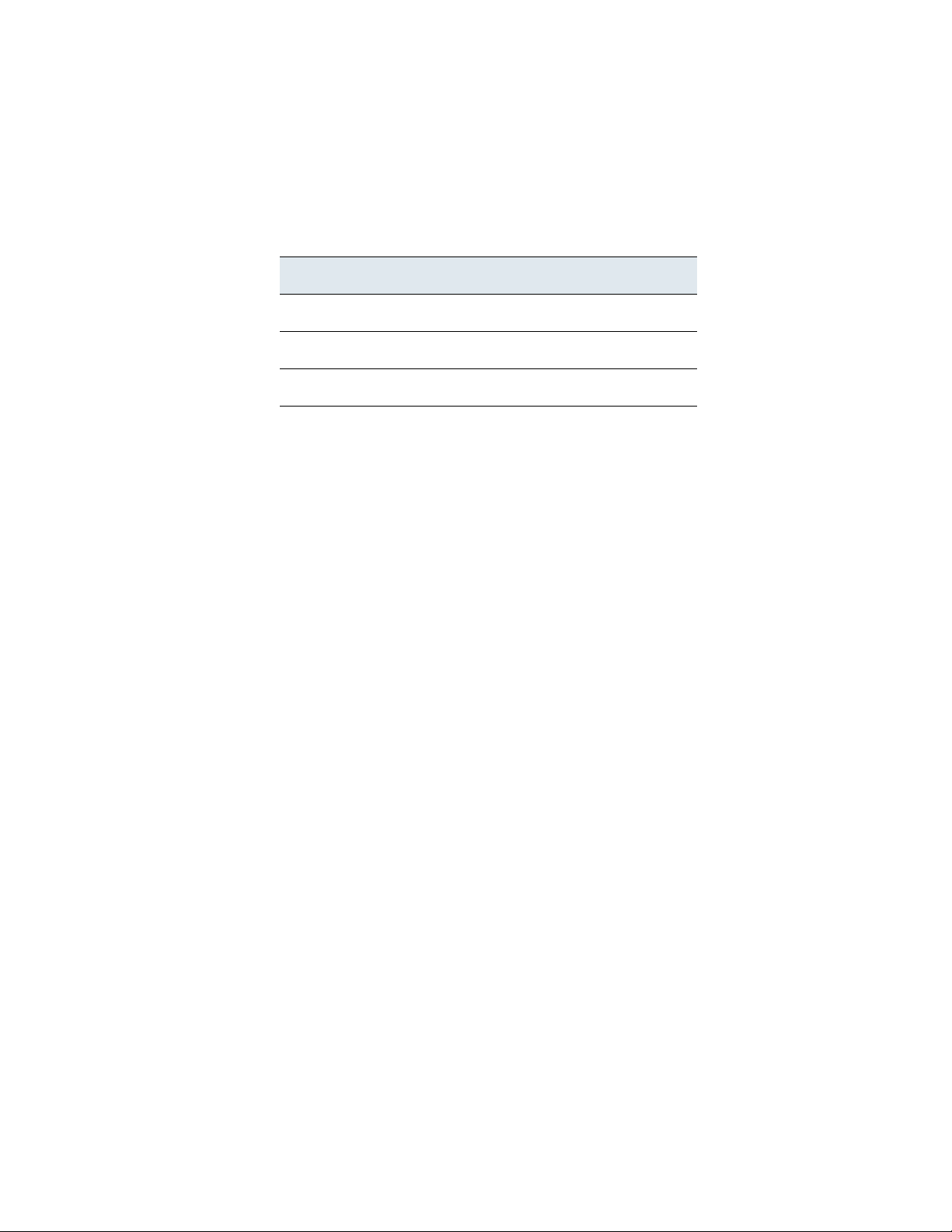

Understanding Detection Resources and 3D Sensor Models

3D Sensor with IPS can use multiple detection resources per detection engine,

which allows you to use more computing resources when network traffic is high.

For example, if you plan to use the 3D3500 sensor in inline mode, you could

assign two detection resources to your detection engine to allow processing of

more events per second. As a best practice, use one detection resource per

application per core on your appliance. Different sensor models have different

numbers of detection resources as shown in the Detection Resources by Model

table on page 23:

Chapter 1

• The Optimal column indicates the per sensor total number of detection

resources you should use if you want to maximize the performance of the

sensor. It also indicates the maximum number of detection resources you

can assign a single detection engine.

• The Maximum column indicates the total number of detection resources

available on the sensor.

• The Combination Restrictions column indicates the permitted combinations of

detection resources that you can allocate to detection engines on the same

sensor; 3D Sensors can run combinations of IPS, RNA, and RUA.

Note that for some sensor models, the availability of detection resources

depends on the amount of RAM on the sensor, which you can determine using

the Memory Usage field on the Statistics page (Operations > Monitoring > Statistics).

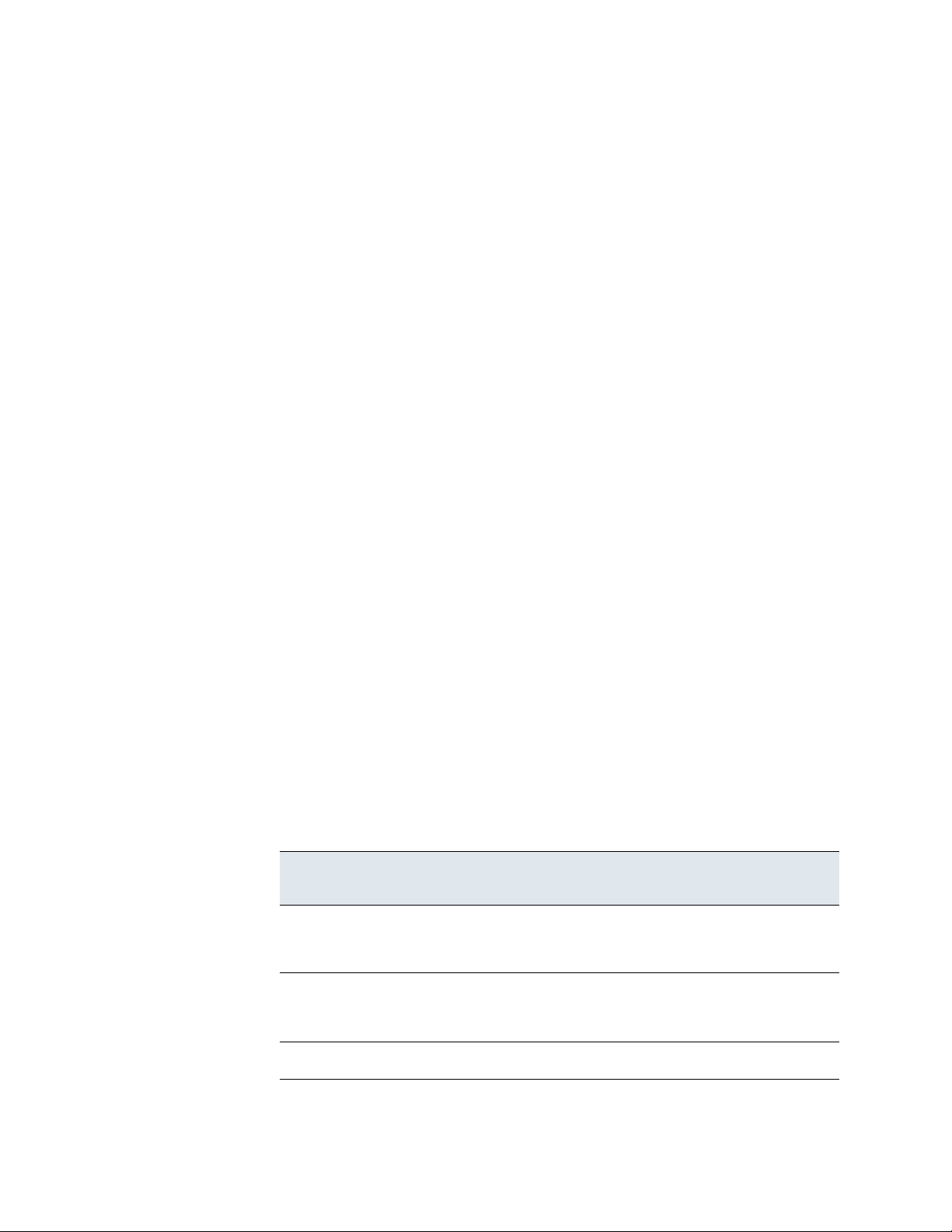

Detection Resources by Model

Model Optimal

per Sensor

3D500 1 2 Maximum of one IPS

3D1000 (512MB RAM) 1 2 Maximum of one IPS

Maximum

per Sensor

Combination

Restrictions

and either one RNA or

one RUA

and either one RNA or

one RUA

3D1000 (1GB RAM) 1 2 No restrictions

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 23

Before You Begin

Understanding Detection Engines and Interface Sets

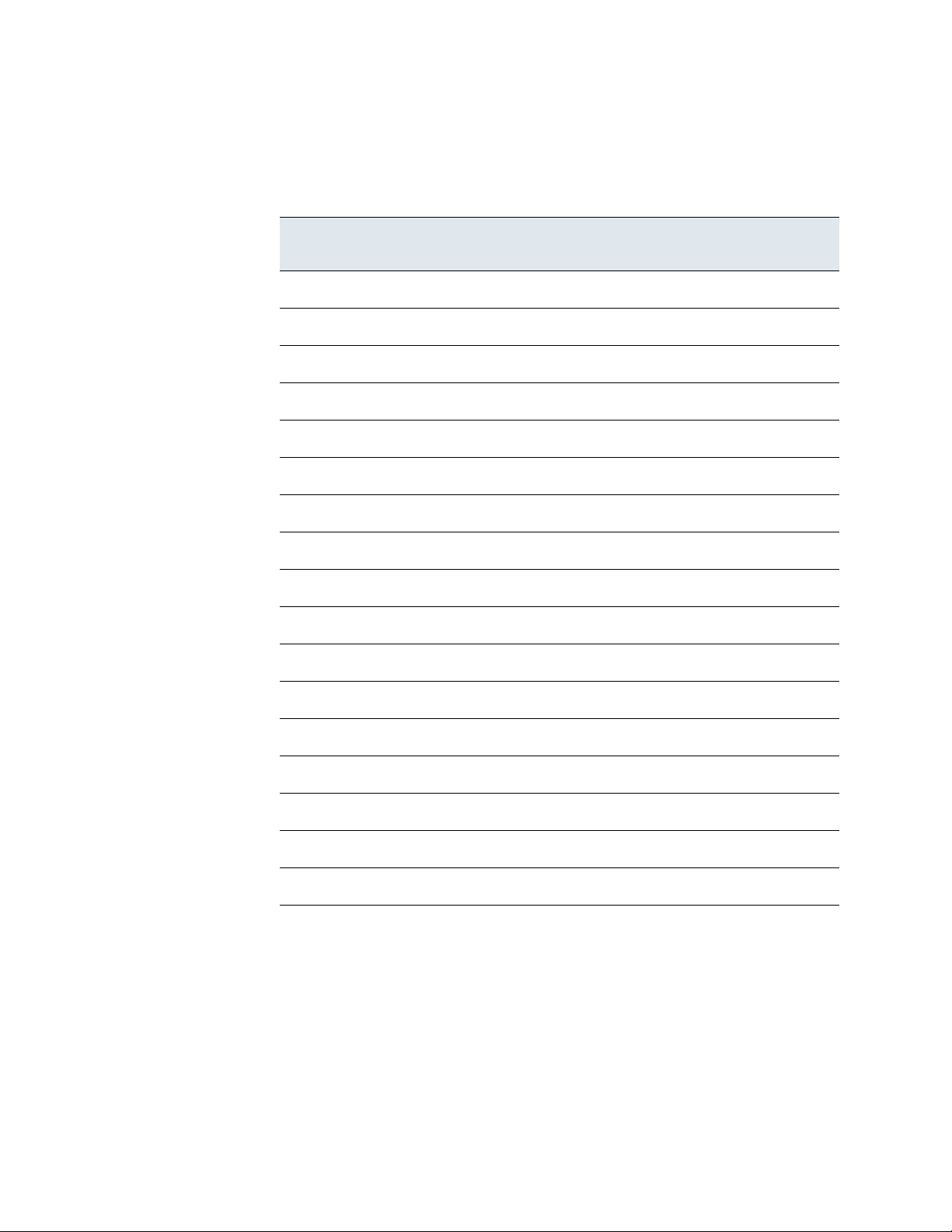

Detection Resources by Model (Continued)

Chapter 1

Model Optimal

per Sensor

3D2000 1 2 No restrictions

3D2100 2 3 No restrictions

3D2500 2 4 No restrictions

3D3000 2 4 No restrictions

3D3500 2 6 No restrictions

3D4500 4 8 No restrictions

3D6500 8 12 No restrictions

3D7010 Auto 6 No restrictions

3D7020 Auto 6 No restrictions

3D7030 Auto 6 No restrictions

3D7110 Auto 6 No restrictions

Maximum

per Sensor

Combination

Restrictions

3D7120 Auto 6 No restrictions

3D8120 Auto 16 No restrictions

3D8130 Auto 22 No restrictions

3D8140 Auto 22 No restrictions

3D8250 Auto 22 No restrictions

3D9900 7 12 No restrictions

Note that disabling hyperthreading on 3D7010/7020/7030 and 8000 Series

sensors reduces the maximum number of detection engines you can create. If

you disable hyperthreading after creating more than the allowable number of

detection engines for a sensor with disabled hyperthreading, you are prohibited

from creating additional detection engines. For information on hyperthreading,

see “Command Line Reference” in the Sourcefire 3D System User Guide.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 24

Before You Begin

Connecting Sensors to Your Network

Comparing Inline and Passive Interface Sets

An interface set is comprised of one or more sensing interfaces on the

3D Sensor. Each detection engine is assigned to an interface set and uses those

interfaces to monitor the traffic on specific network segments. Interface sets can

be one of the following types:

• passive

• inline

• inline with fail open

If you create an IPS detection engine that uses either type of the inline interface

set, you can deploy your detection engine inline. This allows you to take

advantage of drop rules that prevent suspicious traffic from reaching a potentially

vulnerable host. You can also use replace rules that substitute malicious content

with a benign alternative. You can also create RNA and RUA detection engines for

inline or inline with fail open interface sets.

A detection engine that uses an inline with fail open interface set has the same

properties as an inline interface set with one exception. You can only use an inline

with fail open interface set with fail-open network interface cards (NICs). If a

3D Sensor with a fail-open card should fail for some reason (power failure, hard

drive failure, and so on), traffic is not blocked by the sensor and your network

continues to function.

On the 3D9900 model of the 3D Sensor, you can also take advantage of a feature

called tap mode. Tap mode allows you to use interface sets to passively monitor

traffic when your sensor is deployed inline on your network.

Chapter 1

Connecting Sensors to Your Network

There are several ways to connect 3D Sensors to your network. The following

sections outline the supported connection methods:

• Using a Hub on page 26

• Using a Span Port on page 26

• Using a Network Tap on page 26

Additionally, Issues for Copper Cabling in Inline Deployments on page 27 explains

some of the guidelines for using straight-through or crossover cables in your

deployment and Special Case: Connecting 8000 Series Devices on page 29

describes how to configure stable network links for Series 3 devices.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 25

Before You Begin

Connecting Sensors to Your Network

Using a Hub

An Ethernet hub is an inexpensive way to ensure that the detection engine on a

3D Sensor can see all the traffic on a network segment. Most hubs of this type

take the IP traffic meant for any of the hosts on the segment and broadcast it to

all the devices connected to the hub. Connect the interface set to the hub to

monitor all incoming and outgoing traffic on the segment. Using a hub does not

guarantee that the detection engine sees every packet on a higher volume

network because of the potential of packet collision. For a simple network with

low traffic, this is not likely to be a problem. In a high-traffic network, a different

option may provide better results. Note that if the hub fails or loses power, the

network connection is broken. In a simple network, the network would be down.

IMPORTANT! Some devices are marketed as hubs but actually function as

switches and do not broadcast each packet to every port. If you attach your

3D Sensor to a hub, but do not see all the traffic, you may need to purchase a

different hub or use a switch with a Span port.

Chapter 1

Using a Span Port

Many network switches include a span port that mirrors traffic from one or more

ports. By connecting an interface set to the span port, you can monitor the

combined traffic from all ports, generally both incoming and outgoing. If you

already have a switch that includes this feature on your network, in the proper

location, then you can deploy the detection on multiple segments with little extra

equipment cost beyond the cost of the 3D Sensor. In high-traffic networks, this

solution has its limitations. If the span port can handle 200 Mbps and each of

three mirrored ports can handle up to 100 Mbps, then the span port is likely to

become oversubscribed and drop packets, lowering the effectiveness of the

3D Sensor.

Using a Network Tap

Network taps allow you to passively monitor traffic without interrupting the

network flow or changing the network topology. Taps are readily available for

different bandwidths and allow you to analyze both incoming and outgoing

packets on a network segment. Unfortunately, you can monitor only a single

network segment with most taps, so they are not a good solution if you want to

monitor, for example, the traffic on two out of the eight ports on a switch.

Instead, you would have to install the tap between the router and the switch and

access the full IP stream to the switch.

By design, network taps divide incoming and outgoing traffic into two different

streams over two different cables. 3D Sensors offer multi-port options that

recombine the two sides of the conversation so that the entire traffic stream is

evaluated by the decoders, the preprocessors, and the detection engine.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 26

Before You Begin

Connecting Sensors to Your Network

Issues for Copper Cabling in Inline Deployments

If you are deploying your sensor inline on your network, and you are taking

advantage of your sensor’s fail open capabilities to maintain network connectivity

even if the sensor goes down, there are a few important points to keep in mind.

If you are deploying a sensor with fiber fail-open interfaces, there are no special

cabling issues beyond ensuring that the connections are securely fastened and

the cables are not kinked. However, if you are deploying sensors with copper

rather than fiber network interfaces, then you must be aware of the sensor model

that you are using, because different sensor models use different network cards.

The network interface cards (NICs) in the sensor support a feature called

Auto-Medium Dependent Interface Crossover (Auto-MDI-X), which allows

network interfaces to configure automatically whether you are using a

straight-through or crossover Ethernet cable to connect to another network

device. However, the network cards in the sensor can act in a different manner

when the sensor loses power and the NICs fail open. Some of the cards will fail

open as a straight-through connection, others as crossover. This has implications

for you as you choose cables to connect a sensor to each endpoint. The Sensor

Models and Fail Open Characteristics table lists the various sensor models and

whether they fail open as crossover or straight-through devices.

Chapter 1

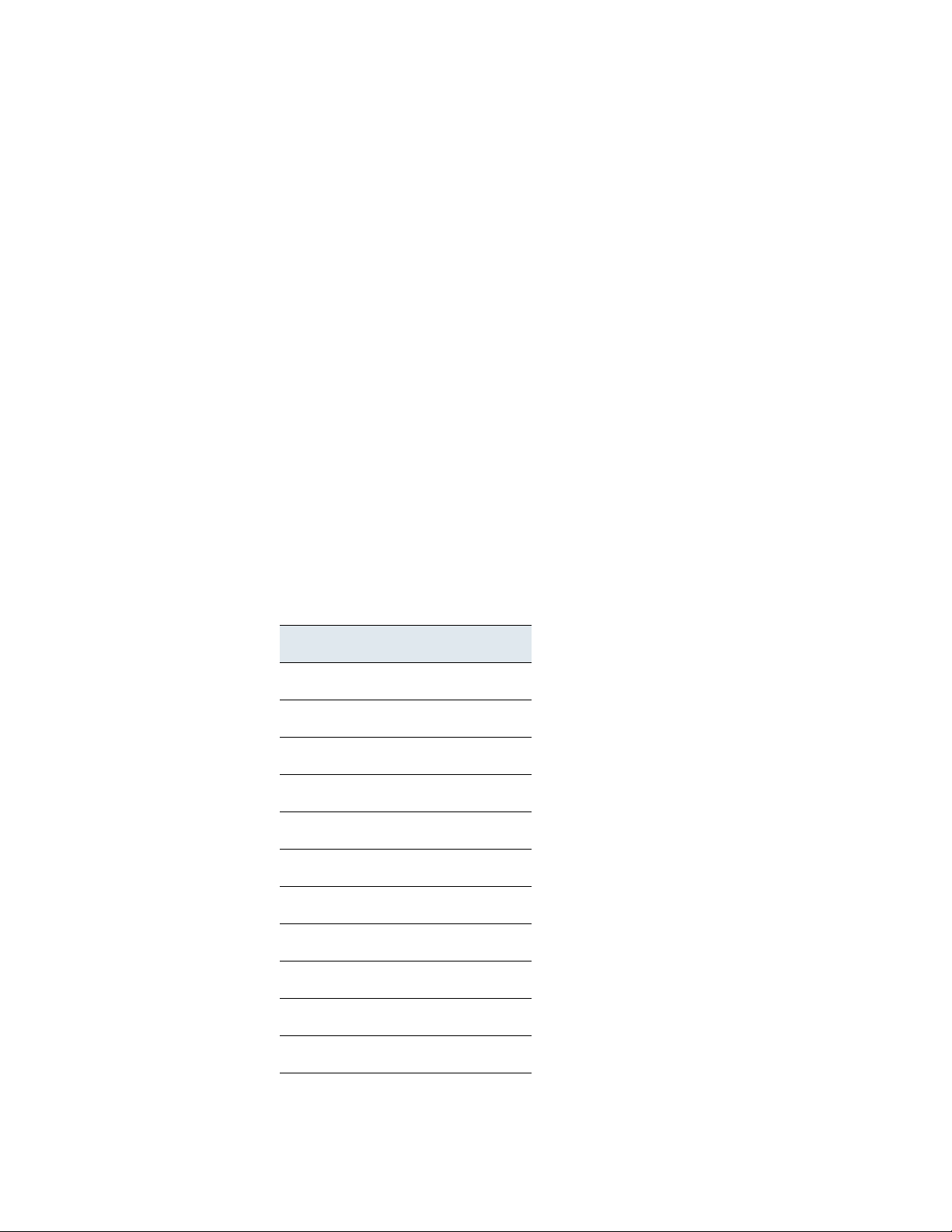

Sensor Models and Fail Open Characteristics

Model Fails open as...

3D500 straight-through

3D1000 straight-through

3D2000 straight-through

3D2100 straight-through

3D2500 straight-through

3D3500 straight-through

3D4500 straight-through

3D6500 crossover

3D9900 crossover

7000 Series crossover

8000 Series crossover

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 27

Before You Begin

Connecting Sensors to Your Network

For sensor models that fail open as straight-through, wire the device as you

would for normal operation without a sensor deployed. The link should work with

power to the sensor removed. In most cases you should use one crossover cable

and one straight-through cable to connect the sensor to the two endpoints.

For sensor models that fail open as crossover, wire the device as would normally

be done with the 3D Sensor live on the network. In most cases you should use

two straight-through cables to connect the sensor to the two endpoints.

Chapter 1

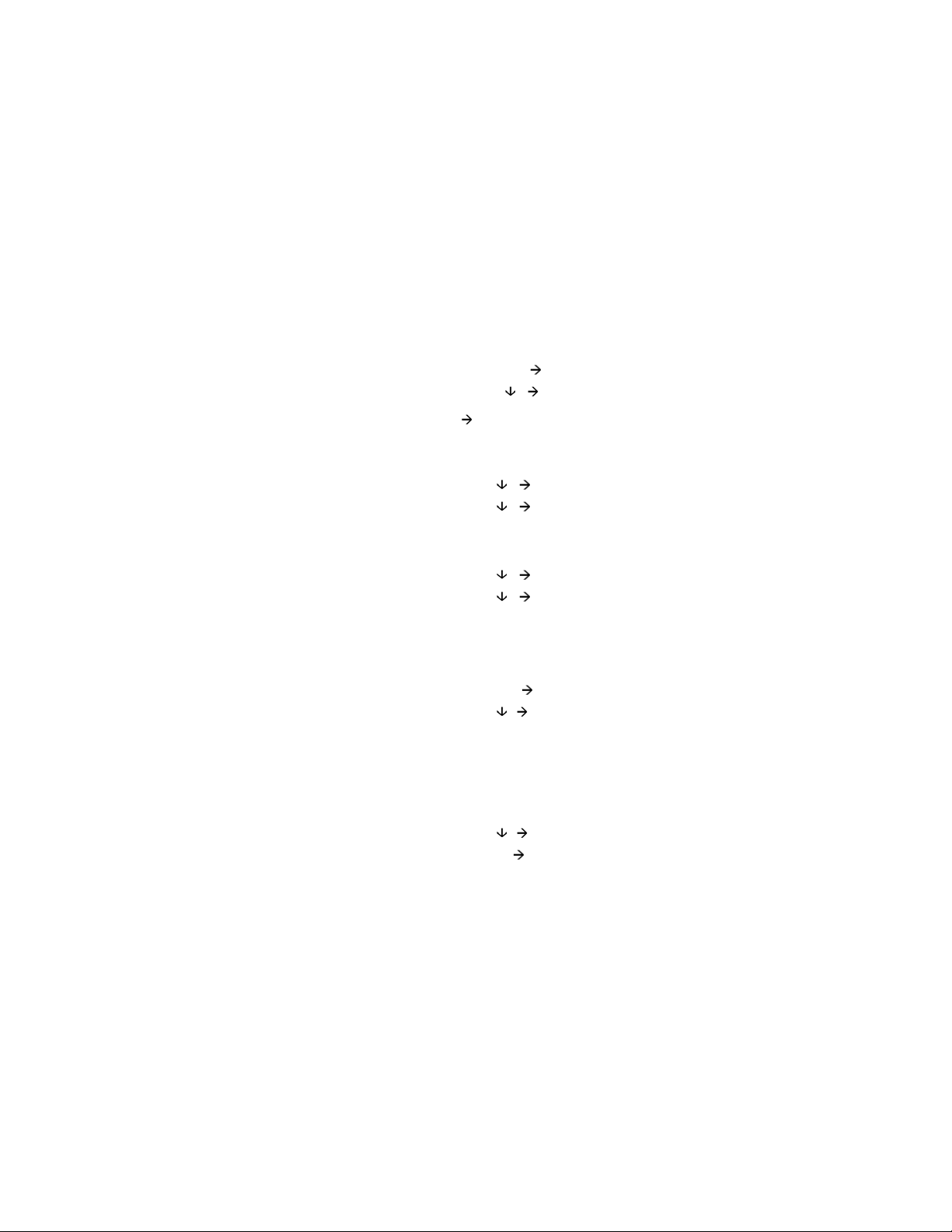

The following table indicates where you should use crossover or straight-through

cables in your hardware bypass configurations.

Valid Configurations for Hardware Bypass

Endpoint 1 Cable Sensor Cable Endpoint 2

MDIX===MDI

MDIX==MDI

MDI = = X MDI

MDI===MDIX

MDIX=X=MDIX

MDI = X = MDI

MDIXXXMDI

MDIX X X = MDI

= indicates a straight-through cable or sensor bypass connection

X indicates a crossover cable or sensor bypass connection

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 28

Before You Begin

Using a Sourcefire Defense Center

Note that every network environment is likely to be unique, with endpoints that

have different combinations of support for Auto-MDI-X. The easiest way to

confirm that you are installing your sensor with the correct cabling is to begin by

connecting the sensor to its two endpoints using one of the cabling scenarios

shown in the illustration, but with the sensor powered down. Ensure that the two

endpoints can communicate. If they cannot communicate, then one of the cables

is the incorrect type. Switch one (and only one) of the cables to the other type,

either straight-through or crossover.

After the two endpoints can successfully communicate with the inline sensor

powered down, power up the sensor. The Auto-MDI-X feature ensures that the

two endpoints will continue to communicate. Note that if you have to replace an

inline sensor, you should repeat the process of ensuring that the endpoints can

communicate with the new sensor powered down to protect against the case

where the original sensor and its replacement have different fail-open

characteristics.

The Auto-MDI-X setting functions correctly only if you allow the network

interfaces to auto-negotiate. If your network environment requires that you turn

off the Auto Negotiate option on the Network Interface page, then you must

specify the correct MDI/MDIX option for your inline network interfaces. See

“Editing Network Interface Configurations” in the Sourcefire 3D System User

Guide for more information.

Chapter 1

Special Case: Connecting 8000 Series Devices

8000 Series managed devices do not support half duplex network links; they also

do not support differences in speed or duplex configurations at opposite ends of a

connection. To ensure a stable network link, you must either auto-negotiate on

both sides of the connection, or set both sides to the same static speed.

Using a Sourcefire Defense Center

You must manage 7000 Series and 8000 Series 3D Sensors with a Sourcefire

Defense Center. The Defense Center aggregates and correlates events

generated by multiple 3D Sensors on different segments of your network. You

can also use the Defense Center to manage, change, and standardize the

intrusion policies on 3D Sensors.

In addition to running Series 2 3D Sensors with IPS as standalone appliances, you

can manage 3D Sensors with the Sourcefire Defense Center. The Defense

Center aggregates and correlates events generated by multiple 3D Sensors on

different segments of your network. You can also use the Defense Center to

manage, change, and standardize the intrusion policies on 3D Sensors.

To safeguard the Defense Center, it must be installed on a protected internal

network. Although the Defense Center is configured to have only the necessary

services and ports available, you must make sure that attacks cannot reach it from

outside the firewall.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 29

Before You Begin

Using a Sourcefire Defense Center

If the 3D Sensor and the Defense Center reside on the same network, you can

connect the management interface on the 3D Sensor to the same protected

internal network as the Defense Center. This allows you to securely control the

sensor from the Defense Center and aggregate the event data generated on the

3D Sensor’s network segment. By using the Defense Center’s filtering

capabilities, you can analyze and correlate data from attacks across your network

to evaluate how well your security policies are being implemented.

Chapter 1

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 30

Before You Begin

Communication Ports

Chapter 1

Communication Ports

The Sourcefire 3D System uses ports 443 and 8305 to communicate internally

and externally between the Defense Center and sensors. Open other ports to

enable optional functionality within your deployment.

Communication Ports

Ports Description Protocol Direction Open the port to...

22 ssh/ssl TCP Bidirectional allow a secure remote connection to the

appliance. SSH version 2 is supported

for command-line connections; TLS

version 1 and SSL version 3 are

supported for HTTPS connections.

25 smtp TCP Outbound send email notices and alerts from the

appliance.

53 dns TCP Outbound use DNS.

67, 68 dhcp UDP Outbound use DHCP. Default is disabled.

80 http TCP Outbound allow the RSS Feed dashboard widget to

162 snmp UDP Bidirectional provide access if you enabled SNMP

389, 636 ldap TCP Outbound use RUA and for authentication.

443 https TCP Inbound

Bidirectional

514 syslog UDP Outbound use for remote syslog server.

623 SOL/LOM UDP Bidirectional allow a Serial Over LAN connection to

1500, 2000 database access TCP Inbound access the Defense Center or Master

connect to a remote web server; use for

auto-update.

polling (inbound) and SNMP traps

(outbound).

access the appliance. Required.

Add outbound access to allow

appliances to download software

updates.

use Lights Out Management.

Defense Center if external database

access is enabled.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 31

Before You Begin

Communication Ports

Communication Ports (Continued)

Ports Description Protocol Direction Open the port to...

Chapter 1

1812, 1813 RADIUS UDP Outbound use RADIUS. Open both ports to ensure

3306 RUA Agent TCP Inbound allow communication between the

8301 Intrusion Agent TCP Bidirectional allow communication between the

8302 eStreamer TCP Bidirectional use for an eStreamer client.

8305 sensor

management

8307 Host Input

Client API

18183 OPSEC SAM TCP Outbound use OPSEC for remediations.

TCP Bidirectional communicate between the Defense

TCP Bidirectional communicate with the Defense Center

that RADIUS functions correctly.

Ports 1812 and 1813 are the default, but

you can configure RADIUS to user other

ports instead. For more information, see

the Sourcefire 3D System User Guide.

Defense Center and RUA Agents.

Defense Center and Intrusion Agents.

Center and 3D Sensors. Required.

during client/server authentication.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 32

Chapter 2

Installing a 3D Sensor

Depending on what you have licensed and which sensor model you are using, the

Sourcefire 3D Sensor can host the RNA component, the IPS component, the

RUA component, or any combination of the three. The IPS component requires

that you install a license on the sensor itself during the initial setup process. The

RNA and RUA components require that you manage the sensor with a Defense

Center and that you install an RNA host or RUA user license on the Defense

Center.

TIP! You can also install an RUA Agent on a Microsoft Active Directory server to

take advantage of RUA features. The RUA Agent installation process is explained

in the Sourcefire 3D System User Guide.

You can install the 3D Sensor as part of a larger Sourcefire 3D System

deployment or, if you are licensing the IPS component, as a standalone network

monitoring appliance. You can also manage multiple 3D Sensors using the

Defense Center, which allows for data correlation and display for IPS, RUA, and

RNA.

See the following sections for more information about installing a 3D Sensor:

• Included Items on page 34

• Security Considerations on page 34

• Identifying the Management and Sensing Interfaces on page 35

• Installing the 3D Sensor in a Rack on page 62

• Configuring the Management Interface on page 64

• Performing the Initial Setup on page 72

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 33

Installing a 3D Sensor

Included Items

Included Items

Chapter 2

• Redirecting Console Output on page 75

• Testing an Inline Fail-Open Interface Installation on page 76

• Checking for Updates on page 78

The following is a list of components that ship with Sourcefire appliances. As you

unpack the system and the associated accessories, check that your package

contents are complete as follows:

• one Sourcefire 3D Sensor

• power cord (two power cords are included with appliances that include

redundant power supplies)

• two Category 5e Ethernet straight-through cables

• one rack-mounting kit (not applicable to the 3D500; available separately for

the 3D7010/7020/7030)

IMPORTANT! Remove all factory packaging from delivered appliances and cables

before installation. Do not cover the vents or enclose the appliance; there must be

ample clearance on all sides of the chassis. Restricting the airflow may cause the

appliance to overheat.

Security Considerations

Sourcefire 3D System appliances are hardened to ensure secure operation. In

accordance with security best practices, before you install your appliance,

Sourcefire recommends that you consider the following:

• Locate your Sourcefire 3D System appliance in a lockable rack within a

secure location that prevents access by unauthorized personnel. If you are

installing a desktop model, make sure you place it within a secure location

that prevents access by unauthorized personnel.

• Allow only trained and qualified personnel to install, replace, administer, or

service the Sourcefire appliance.

• Always connect the management interface to a secure internal

management network that is protected from unauthorized access.

• Identify the specific workstation IP addresses that can be allowed to access

appliances. Restrict access to the appliance to only those specific hosts,

using the Access List within the appliance’s System Policy. For more

information, see the Sourcefire 3D System User Guide.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 34

Installing a 3D Sensor

Management Interface Sensing Interfaces

eth0 eth1 eth2 eth3 eth4

Identifying the Management and Sensing Interfaces

Identifying the Management and Sensing Interfaces

The Sourcefire 3D Sensor is delivered on different hardware appliances. Make

sure you refer to the correct illustration for your appliance as you follow the

installation procedure:

• Sourcefire 3D Sensor 500/1000/2000 on page 35

• Sourcefire 3D Sensor 2100/2500/3500/4500 on page 36

• Sourcefire 3D Sensor 6500 on page 38

• Sourcefire 3D Sensor 7010/7020/7030 on page 42

• Sourcefire 3D Sensor 7110/7120 on page 42

• Sourcefire 3D Sensor 8120/8130/8140 on page 45

• Sourcefire 3D Sensor 8250/8260/8270/8290 on page 48

• Sourcefire 3D Sensor 9900 on page 53

• Using 3D Sensors in a Stacked Configuration on page 55

Chapter 2

Sourcefire 3D Sensor 500/1000/2000

The 3D500, 3D1000, and 3D2000 models are Series 2 sensors, available on the

desktop appliance. The following illustration indicates the locations of the

management and sensing interfaces.

You can use the sensing interfaces to passively sense up to four separate

network segments.

You also can use paired interfaces in inline or inline with fail-open mode, which

allows you to deploy the 3D Sensor as an intrusion prevention system. The

3D500 can monitor one network when deployed inline, while the 3D1000 and

3D2000 can monitor two networks inline.

If you want to take advantage of the sensor’s automatic fail-open capability, you

must connect either the two interfaces on the left or the two interfaces on the

right to a network segment. This allows traffic to flow even if the sensor fails or

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 35

Installing a 3D Sensor

paired

interfaces

paired

interfaces

(eth1 and eth2) (eth3 and eth4)

Management interface (eth0)

eth1 (Do not use)

Identifying the Management and Sensing Interfaces

loses power. You must also use the web interface to configure the interface set

as inline with fail open.

If you configure the interfaces as inline without using the fail-open capability, you

can use any two of the interfaces on the sensor as an inline pair.

IMPORTANT! By default, the initial setup process supports one inline fail-open

interface pair for

single interface sets by default: eth1:eth2, and eth3:eth4. For more information,

see “Using Detection Engines and Interface Sets” in the Sourcefire 3D System

User Guide.

eth1 and eth2. For the 3D1000 or 3D2000, the pairs are in

Chapter 2

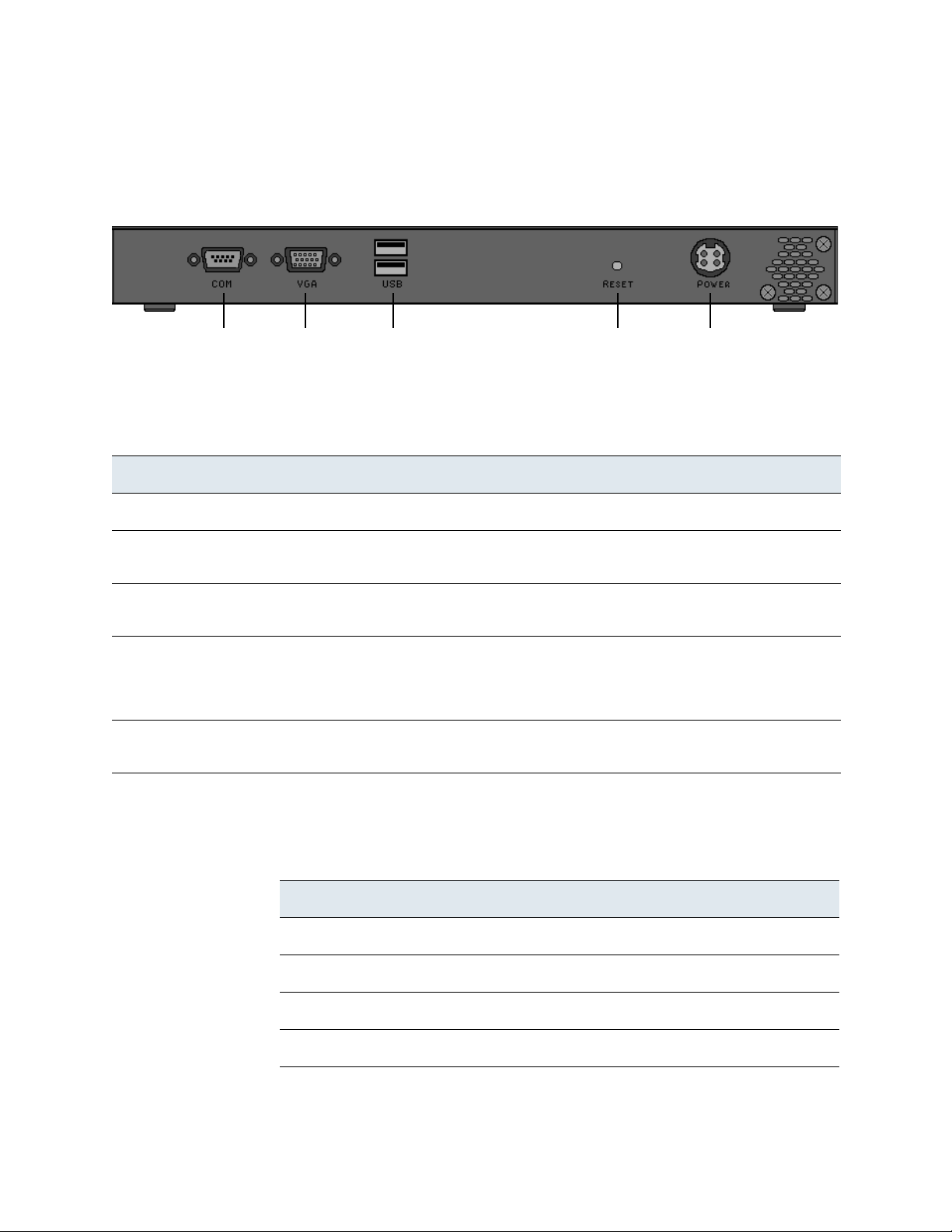

Sourcefire 3D Sensor 2100/2500/3500/4500

The 3D2100, 3D2500, 3D3500, and 3D4500 models are Series 2 3D Sensors, and

are available on a 1U appliance.

The following illustration of the 3D3500/4500 indicates the location of the

management interface, which is on the rear of the chassis of these Sourcefire

appliances.

Note that the 3D2100 and 3D2500 sensors do not have a redundant power

supply. Otherwise, the rear of the Sourcefire appliance chassis are identical.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 36

Installing a 3D Sensor

NIC 1

eth4

eth2

eth3

eth5

eth8

eth6

eth7

eth9

Sensing Interfaces

NIC 2

Sensing Interfaces

paired interfacespaired interfaces

(eth2 and eth3) (eth4 and eth5)

Identifying the Management and Sensing Interfaces

The following illustration indicates the locations of the sensing interfaces, which

are on the front of the chassis.

The Sourcefire appliance can be delivered with two different network interface

cards (NICs), depending on the model:

• NIC 1: a quad-port copper bypass NIC, which contains four 10/100/1000

copper Ethernet interfaces.

• NIC 2: either a quad-port fiber bypass NIC, which contains four gigabit fiber

interfaces, or a duplicate of NIC 1 (quad-port copper bypass).

The 3D2100 sensor contains only NIC 1. The 3D2500, 3D3500, and 3D4500

sensor models contain both NIC 1 and NIC 2, in either the quad-port copper or the

quad-port fiber configuration. Note that the fiber NIC accepts LC-type (Local

Connector) optical transceivers.

Chapter 2

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 37

You can use each NIC to passively monitor up to four separate network

segments. You also can use paired interfaces in inline or inline with fail open

mode, which allows you to deploy the 3D Sensor as an intrusion prevention

system on up to four networks, depending on the sensor model.

If you want to take advantage of a NIC’s automatic fail-open capability, you must

connect the two interfaces on the left or the two interfaces on the right (top and

bottom on the same NIC) as paired interfaces to a network segment. The

fail-open mode allows traffic to flow even if the sensor fails or loses power. You

must use the sensor’s or the Defense Center’s web interface to configure the

interface set as inline with fail open. The web interface ensures the correct

pairing.

Installing a 3D Sensor

Management Interface (eth0)

Sensing Interfaces

Identifying the Management and Sensing Interfaces

If you configure the interfaces as inline without using the fail-open capability, you

can use any two of the interfaces on the same NIC as an inline pair.

IMPORTANT! By default, the initial setup process supports one inline fail-open

interface pair for

3D4500, the initial setup process supports two inline fail-open interface pairs, one

for

eth2 and eth3 and another for eth6 and eth7. If you want to use additional

inline fail-open pairs, see “Using Detection Engines and Interface Sets” in the

Sourcefire 3D System User Guide.

eth2 and eth3 on the 3D2100. On the 3D2500, 3D3500, and

Sourcefire 3D Sensor 6500

The 3D6500 model is a Series 2 3D Sensor, and is available as a 2U appliance.

The following illustration of the 3D6500 indicates the location of the management

interface, which is on the rear of the chassis.

Chapter 2

The following illustration indicates the location of the sensing interfaces, which

are on the front of the chassis.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 38

Installing a 3D Sensor

eth2 eth13eth3 eth4 eth5 eth6 eth7 eth8 eth9 eth10 eth11 eth12

Identifying the Management and Sensing Interfaces

The 3D6500 appliance can be delivered with four different sensing interface

configurations:

• twelve 10/100/1000 copper interfaces with bypass capability; see

Twelve-Port Copper Configuration on page 39 for more information.

• four 10Gb fiber interfaces with bypass capability; see Quad-Port 10Gb Fiber

Configuration on page 40 for more information

• a combination of six 10/100/1000 copper Ethernet interfaces and two 10Gb

fiber bypass interfaces; see Dual-Port 10Gb Fiber with Six Copper Interfaces

on page 40 for more information

• a combination of six 10/100/1000 copper Ethernet interfaces and four 1Gb

fiber bypass interfaces; see Quad-Port 1Gb Fiber with Six Copper Interfaces

on page 41 for more information

Twe lv e-Port Copper Configuration

The 3D6500 sensor 12-port configuration provides for 1Gb copper

connections.The following illustration indicates the interface numbering.

Chapter 2

You can use these connections to passively monitor up to 12 separate network

segments. You also can use paired interfaces in inline or inline with fail-open

mode, which allows you to deploy the 3D Sensor as an intrusion prevention

system on up to six networks.

If you want to take advantage of a NIC’s automatic fail-open capability, you must

connect adjacent interfaces (

network segment. The fail-open mode allows traffic to flow even if the sensor

fails or loses power. You must use the sensor’s or the Defense Center’s web

interface to configure the interface set as inline with fail open. The web interface

ensures the correct pairing.

If you configure the interfaces as inline without using the fail-open capability, you

can use any two sensing interfaces (even nonconsecutive interfaces) as an inline

pair.

By default, the initial setup process supports six inline fail-open interface pairs. If

you want to use passive or other configurations, see Using Detection Engines

and Interface Sets in the Sourcefire 3D System User Guide.

IMPORTANT! When using NetOptics copper taps with 3D6500 sensor 1Gb

copper interfaces, you must keep the cable length between the tap and sensor to

no more than 25 feet.

eth2 with eth3, eth4 with eth5, and so on) to a

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 39

Installing a 3D Sensor

eth2 eth3 eth4 eth5

eth2 eth4 eth9eth3 eth5 eth6 eth7 eth8

Identifying the Management and Sensing Interfaces

Quad-Port 10Gb Fiber Configuration

The 3D6500 sensor can be shipped with a quad-port 10Gb fiber bypass

configuration. It uses LC-type (Local Connector) optical transceivers. Note that

these are SR interfaces. The following illustration indicates the interface

numbering.

You can use this configuration to passively monitor up to four separate network

segments. You also can use paired interfaces in inline or inline with fail open

mode, which allows you to deploy the 3D Sensor as an intrusion prevention

system.

If you want to take advantage of a sensor’s automatic fail-open capability, you

must connect the two interfaces on the left or the two interfaces on the right to a

network segment. This allows traffic to flow even if the sensor fails or loses

power. You must also use the web interface to configure the interface set as

inline with fail open.

If you configure the interfaces as inline without using the fail-open capability, you

can use any two of the interfaces as an inline pair.

Chapter 2

Dual-Port 10Gb Fiber with Six Copper Interfaces

The 3D6500 sensor can be shipped with dual 10Gb fiber interfaces and six 1Gb

copper interfaces. The fiber portion of the configuration uses LC-type (Local

Connector) optical transceivers. Note that these are SR interfaces. The following

illustration indicates the interface numbering.

Version 4.10.3 Sourcefire 3D Sensor Installation Guide 40

Installing a 3D Sensor

eth2 eth5 eth6 eth11eth3 eth4 eth7 eth8 eth9 eth10

Identifying the Management and Sensing Interfaces

You can use the copper interfaces to passively monitor up to six separate network

segments. You can also use paired interfaces in inline or inline with fail open

mode, which allows you to deploy the 3D Sensor as an intrusion prevention

system on up to three networks.

IMPORTANT! When using NetOptics copper taps with 3D6500 sensor 1Gb

copper interfaces, you must keep the cable length between the tap and sensor to

no more than 25 feet.

If you want to take advantage of the automatic fail-open capability, you must

connect interfaces

eth9 as paired interfaces to a network segment. This allows traffic to flow even if

the sensor fails or loses power. You must also use the web interface to configure

the interface set as inline with fail open.

WARNING! You must use two of the same type of interfaces as a pair. You cannot

pair a fiber with a copper interface.

eth2 and eth3, eth4 and eth5, eth6 and eth7, or eth8 and

Chapter 2