Page 1

TM

gy

s

s

New Dimensions in Digital Sound Technolo

USA Trains PA-1

Sierra Sound System Installation Notes

Overview

This application note describes how to install your Sierra

sound system in the USA Trains PA-1. Please read through

the entire document to become comfortable with the

steps involved before beginning the installation. No major

mechanical modifications are required and the entire

process can be completed in a few hours.

Tools You Will Need

■ #2 Phillips Screw Driver with 4” shank

■ Wire cutters

■ Wire strippers

■ 25W Solder Iron

■ Rosin core solder

■ 1/4” Drill Bit

■ Electric Hand Drill or equivalent

■ Superlock Fastener Radio Shack #64-2360

■ 2 Sided Foam Tape Radio Shack #64-2343

■ Heat Shrink Tubing SoundTraxx P.N. 810037

INSTALLATION GUIDE

Installation

1. Locomotive Disassembly

Use a foam pad or thick towel to support the

locomotive body and turn it upside down. Be

careful of the horns and other details atop the

locomotive.

2. Remove the two screws securing the fuel tank

to the locomotive frame. Remove the fuel tank

and side ‘skirts’ (Figure 1).

3. Remove the four screws securing the pilot to

the locomotive frame as shown in Figure 2.

Remove the pilot to expose two screws

underneath.

4. Pop the lower ends of the handrails from the

step ladders on each side of the locomotive.

See Figure 3. You may also wish to remove the

step ladders from the locomotive frame to

prevent them from accidentally breaking off

while completing this installation.

Figure 1

Remove (4) Screw

Figure 2

Remove Hand-rails from step ladder

Figure 3

Page 2

5. Remove the ten screws securing the

n

locomotive frame to the body shell as shown in

Figure 4. The screws near the truck side frames

will be most easily removed using a #2 Philips

screw-driver with a long shank. Carefully

separate the body shell from the frame.

Top View of Locomotive Floor

(rear)

1/4"

Drill 1/4" hole

for Charging Jack

(optional)

Mounting

Post

Remove (10) Screws at Locations show

Figure 4

6. There is an unused plug on the USA PC board at

the center of the locomotive labeled “SPEAK1”.

Cut a 9” length from the supplied red wire. Strip

and tin the ends. Solder one end directly to the

left plug post. Cut a 14” length from the

supplied green wire. Strip and tin the ends.

Solder one end to the right plug post. Insulate

the connections with heat shrink tubing (See

Figure 5).

2-1/8"

Figure 6

1/2"

Mounting

Post

5/8"

Control Switch (optional)

Drill 1/4" hole

for Remote Volume

Drill 1/4" hole for

Power Switch

1/2"

5/8"

10. Cut two 1”x1-1/2” strips of double-sided foam

tape and place them on one side of the battery.

Snugly press the battery against the floor close

to the coupler spring wire screw as shown in

Figure 7.

Figure 5

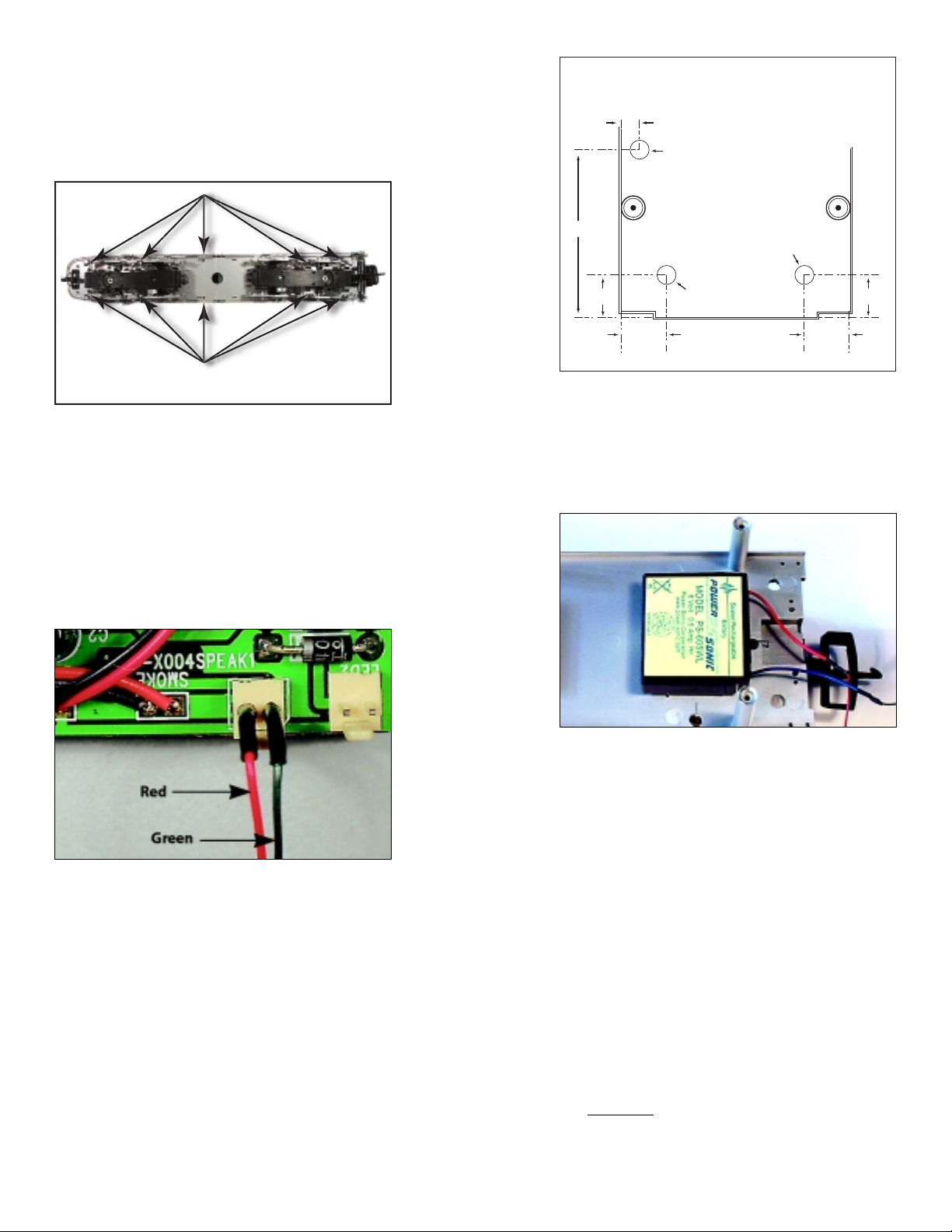

7. Locating the Switches

Mark and drill a 1/4” hole for the power switch

in the rear of the locomotive floor using Figure

6 as a guide.

8. If you are installing the optional Battery

Charging Kit (PN 810076), mark and drill a 1/4”

hole for the charging jack as shown in Figure 6.

9. If you are installing the optional Remote

Volume Control Switch (P.N. 810073), mark and

drill a 1/4" hole for the charging jack as shown

in Figure 6.

Figure 7

11. Installing both the Power Switch and

Battery Charging Jack

(Skip to Step 12 if you are not installing the

Battery Charging Kit.)

The following steps describe the installation of

both the Power Switch and the optional

Charging Jack. Insulate the soldered

connections with shrink tubing to prevent

accidental shorts.

n Cut the battery wire harness in half and strip

3/16” of the insulation from the ends of each

wire. Twist the ends of the (-) negative black

wire together and solder them to the Charging

Jack’s A terminal. Insulate the connection with

heat shrink tubing.

CAUTION: It is very easy to get the terminals A,

B, and C of the charging jack confused. Refer to

the drawing and make sure the correct

terminals are used.

Page 3

BLACK

d

ed

C

e

SA

'

t

al

e

s

g

a

ot Used

d

2

356

d

d

of

)

e

SA

'

t

al

s

g

a

ot Used

d

356

RED

- +

6V Battery

Battery

Charging Jack

Green Wir

from U

'SPEAK1

ermin

To Sierr

Terminal 7

Not Use

Figure 8

B

To Right

Track Pickup

To Terminal 7 on

Sierra board

A

BLACK

RED

C

To r

wire of

Charging Jack

Terminal

To red wir

f Sierra'

battery plu

N

Sierra Battery

Connector Plug

Power

Switch

Not use

n Solder the positive (+) red wire from the battery

to the Charging Jack’s B terminal and insulate

the connection with heat shrink tubing.

n Cut a 5” length from the remaining supplied red

wire. Strip and tin the ends. Solder one end to

terminal C of the Charging Jack. Solder the

other end to terminal #4 of the Power Switch.

Insulate both connections.

n Solder the positive (+) red wire from Sierra’s

Battery Connector Plug to terminal #5 of the

Power Switch and insulate the connection.

n Cut a 9” length from the remaining supplied

green wire. Strip and tin the ends. Solder one

end to terminal #2 of the Power Switch and

insulate the connection.

n Solder the free end of the green wire from the

‘Speak1’ plug (Step 6) to terminal #1 of the

Power Switch and insulate the connection.

n Install the charging jack in the hole you drilled

in Step 8. The threaded shank of the battery

charging jack may not be long enough to go

through the thick plastic of the frame and have

room for the nut. We suggest using epoxy to

glue the jack in place. Be careful to not get any

glue inside the jack’s opening or barrel.

n Install the Power Switch in the hole you drilled

in Step 7.

n After completing Step 11, skip to Step 13.

12. Installing Only the Power Switch

Since you are not installing the Battery

Charging Jack, wire the power switch as in

Figure 9. Insulate the soldered connections

with heat shrink tubing to prevent accidental

shorts.

n Cut the positive (+) red battery wire in half and

strip 3/16” of the insulation from the ends of

each wire.

n Connect the wire from the (+) battery terminal

to terminal #4 of the Power Switch and insulate

the connection..

n Connect the remaining wire to terminal #5 of

the Power Switch and insulate the connection.

n Cut a 9” length from the remaining supplied

green wire. Strip and tin the ends. Solder one

end to terminal #2 of the Power Switch and

insulate the connection.

n Solder the free end of the green wire from the

‘Speak1’ plug (Step 6) to terminal #1 of the

Power Switch and insulate the connection.

n Install the Power Switch in the hole you drilled

in Step 7.

RED

- +

To Right

To Terminal 7 on

Green Wir

from U

'SPEAK1

ermin

To Sierr

Terminal 7

Not Use

Track Pickup

Sierra board

6V Battery

Figure 9

13. Installing the Remaining Switches

If you have purchased a Remote Volume

Control Switch (P.N. 810073), install this switch

in the hole you drilled in Step 9.

14. If you plan to install an optional Coupler Clank

Sensor Switch (P.N. 810072) install it now using

the directions that come with the switch.

15. Trigger switches can be used to activate some

of Sierra’s sound effects by way of magnets

embedded in the roadbed. If you wish to use

this method of activating your sound effects

you will need to purchase P.N. 810074. Included

is one trigger switch and one magnet. One

trigger switch is required per effect and one

magnet per location. If you plan to use trigger

reed switches, install them according to the

instructions that came with them.

16. Cut a piece of double-sided foam tape (or

Superlock fastener) approximately 2” long. Peel

the backing off and place on the Sierra board

on top of the large chips on the side opposite

the terminal blocks. Peel the remaining

backing off of the tape and place on the floor of

the locomotive in front of the battery as shown

in Figure 10. Be sure to allow enough clearance

for the body shell.

BLACK

To re

wire

Battery (+

To red wire

f Sierra'

battery plu

N

Sierra Battery

Connector Plug

Power Switch

Not use

Page 4

- +

terminal 1, the black wire to terminal 2 and the

green wire to terminal 3.

21. Connect any other accessories you’ve installed,

including trigger reed switches, lights and

coupler clank sensor switches, following the

directions provided with the accessory.

22. Plug the battery harness plug into the socket at

the middle of the Sierra circuit board.

Figure 10

17. Installing the Speaker

Place the speaker in the fuel tank as shown in

Figure 11. Ensure that the speaker is flat on the

grill. Use the screws and clamps provided to

secure the speaker to the tank interior. Feed the

speaker wires through the large hole in the

floor of the locomotive above the fuel tank.

Figure 11

18. Make connections to the Sierra circuit board.

Use Figure 12 to guide you in making your

connections.

n Connect the speaker leads to terminals 9 and

10 on the Sierra circuit board.

19. Connect the green power lead from terminal #2

of the Power Switch (Figures 8 and 9) to

terminal 7 on the Sierra board. Connect the red

wire from the USA circuit board ‘SPEAK1’ plug

(Step 6) to terminal 8 of the Sierra board.

Caution: Use your finger to hold the socket firmly

against the circuit board when plugging in the

connector to prevent the socket from ripping off the

circuit board. The connector only goes in one way. It

is a snug fit and once plugged in, it is difficult to

remove. If you need to unplug the battery later, use

your thumb and forefinger to hold the socket firmly

against the circuit board, while using your other

hand to grasp the connector (NOT THE WIRES) and

gently wiggle it from side to side as you pull the

connector straight out. Excessive force may pull out

the wires or rip the mating connector off of the

circuit board.

23. Attach the body shell to the frame, ensuring

that all wires are inside the frame’s edge and

replace the screws. Re-install the pilot.

Re-install the hand-rails and the step ladders

you removed in Step 4.

24. Make sure the speaker wires are tucked inside

the fuel tank and there is nothing “pinched.”

Replace the fuel tank with the securing screws.

25. Place the locomotive on a section of track. Turn

the power switch ‘on’. The Sound switch on the

underside of the locomotive must also be set to

ON. You should hear the engine start up. Slowly

apply power. You should hear two short horn

toots as the locomotive moves forward and

three horn toots as the locomotive moves

backward. Make certain that there are no short

circuits detected. If horn signals are reversed,

switch the wires to Sierra’s terminals 7 and 8. As

you increase the throttle, you will hear the

engine RPMs increase and the bell will come on.

Refer to your owner’s manual for programming.

20. If you have installed the Remote Volume

Control Switch, connect the yellow wire to

Figure 12

Speaker +

Speaker -

Bell Trigger Switch

Airhorn Trigger Switch

Dynamic Brake Trigger Switch

CouplerTrigger Switch

Track Pickup - USA circuit

board ‘SPEAK1’ right terminal

GREEN

Power On/Off

Switch

9

10

11

12

13

14

15

16

Not used

Optional

Recharging Jack

BLACK

6V Battery

8

7

6

5

4

3

2

1

- +

Enjoy your SoundTraxx equipped PA-1!

GREEN

To Terminal 7

Light 2Light 1

Remote

Volume

Control

RED

Track Pickup USA circuit

board ‘SPEAK1’

left terminal

030052 Rev. B 121703

Loading...

Loading...