Page 1

Tsunami2™ Digital Sound Decoder

Steam User’s Guide

Software Release 1.0

Rev. A 06/27/16

Page 2

Notice

The information in this document is subject to change without notice.

SoundTraxx (Throttle Up! Corp.) shall not be liable for technical or editorial errors or omissions contained

herein, nor for incidental or consequential damage resulting from the furnishing, performance or use of

this material.

This document contains information protected by copyright. No part of this document may be photocopied

or reproduced in any form without the prior written consent of Throttle Up! Corp.

Product names mentioned herein may be trademarks and/or registered trademarks of their respective

companies.

SoundTraxx, Econami, Tsunami, Tsunami2, SoundTraxx DCC, Dynamic Digital Exhaust, Auto-Exhaust,

Hyperlight, Hyperdrive2, SoundCar, and Intelligent Consisting are trademarks of Throttle Up! Corp.

Page 3

Contents

All Aboard! ...................................................................................... 4

Overview .............................................................................................................. 4

Using Tsunami2 .................................................................................................... 5

CV Programming Tutorial ................................................................................... 11

Introduction to Programming .............................................................................. 13

Basic Programming ....................................................................... 18

Configuring the Address ..................................................................................... 18

Configuring the Decoder ..................................................................................... 19

Configuring Throttle and Braking ........................................................................ 21

Configuring Lighting Outputs .............................................................................. 27

Configuring Sound Effects .................................................................................. 32

Configuring Automatic Sounds ........................................................................... 40

Advanced Programming ................................................................ 46

Configuring Audio Control .................................................................................. 46

Configuring Dynamic Digital Exhaust ................................................................. 52

Configuring Function Mapping ............................................................................ 55

Configuring Hyperdrive2 ..................................................................................... 61

Configuring Advanced Consist Operation ........................................................... 65

Miscellaneous Features ................................................................. 69

Configuring Analog Mode Operation .................................................................. 69

Troubleshooting ............................................................................ 73

Sorting Out Decoder Difficulties .......................................................................... 73

Appendix A: Decimal-Hex-Binary Conversions ............................. 76

Appendix B: Tsuami2 Steam CV Reference ................................... 77

Appendix C: License Agreement ................................................... 78

Appendix D: Service and Warranty Policy .................................... 79

Appendix E: Declaration of Conformity ......................................... 80

Page 4

All Aboard!

All Aboard!

Overview

Congratulations on purchasing your SoundTraxx Tsunami2 Digital Sound Decoder

steam locomotives! Tsunami2 is the newest wave of SoundTraxx innovation and builds upon

the previous generation of Tsunami to offer the highest quality sound for model railroading. This

user’s guide shows you how to operate Tsunami2 and customize each decoder setting to fit

your preferences, while providing some helpful troubleshooting tips along the way.

We suggest referring to the user documents listed below as you read this user’s guide.

Tsunami2 Installation Guide

Provides instructions and strategies for

successful sound installations.

Tsunami2 Steam Quick Start Guide

Gives an overview of the decoder’s default

settings and highlights some of the features.

Tsunami2 Steam Technical Reference

Offers a list of all included CVs and details

making adjustments to settings.

Tsunami2 Steam Sound Selection Reference

Lists each included sound effect for configuring

a prototypical operating experience.

(DSD) for

These documents can be downloaded from our website at www.soundtraxx.com.

Tsunami2 Steam User’s Guide 4

Page 5

All Aboard!

Using Tsunami2

The Tsunami2 Digital Sound Decoder is designed to enhance your model railroading

experience by giving you a wide variety of innovative features and incredibly realistic sound for

your models. Some of the features discussed in this user’s guide include Dynamic Digital

Exhaust, Hyperdrive2 advanced motor control, Flex-Map function mapping technology, two

volume mixers, exhaust cutoff control, independent and train brake functions, and Fireman Fred

sound effects. Tsunami2 also provides selectable whistles, bells, exhaust chuffs, airpumps, and

couplers to allow more versatility in creating your ideal model railroading experience.

You can start using Tsunami2 right out of the package without making any adjustments.

However, you may adjust settings at any time by making changes to Configuration Variables

(CVs). Most DCC decoder and command station manuals call this “programming”, though this is

misleading and sounds scarier than it is. At no point are you required to learn programming!

This user’s guide will walk you through operating and programming Tsunami2 to its full capacity.

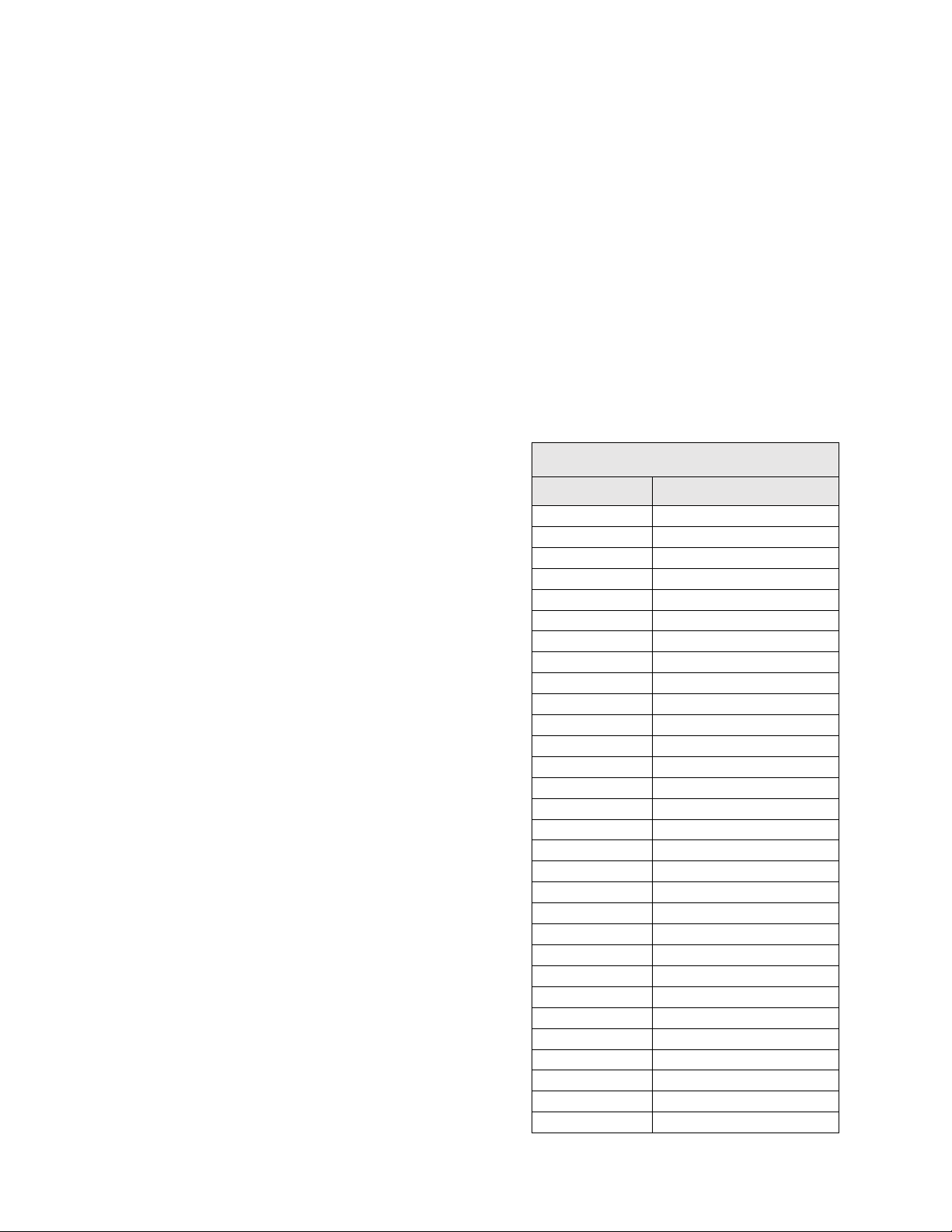

Default Function Assignments

The first time you operate your Tsunami2 decoder,

you will be able to activate features and sound effects

by simply pressing the appropriate key on your cab or

command station console. These are “default”

function assignments. The effects listed in Table A

are assigned to function keys F0-F28 by default. This

section describes how to activate each effect with

function keys.

Note: You can assign any effect to function keys

labeled as “Not Assigned” in Table A with Flex-Map

function mapping CVs. Refer to “Configuring Function

Mapping” for more information about customizing

function assignments.

Note: Pressing function keys F0-F28 will toggle

functions “on” and “off” and activate effects.

Turn On the Lights

Ensure your locomotive is in the forward direction,

then turn on F0 to illuminate the headlight and spool

up the dynamo. Reverse the locomotive direction to

turn off the headlight and turn on the backup light.

Pressing F0 a second time will turn off the dynamo,

headlight, and backup light.

Turn on F7 to dim the headlight or backup light before

passing oncoming trains, or while waiting on a siding.

Press F7 again to return the headlight and backup

light outputs to full brightness.

Table A. Default Functions

Function Key Effect

F0(f) Headlight, Dynamo

F0(r) Backup Light, Dynamo

F1 Bell

F2 Whistle

F3 Short Whistle

F4 Cylinder Cocks

F5 Cutoff+

F6 CutoffF7 Dimmer

F8 Mute

F9 Grade-Crossing Signal

F10 Blowdown

F11 Independent/Train Brake

F12 Brake Select

F13 Couple/Uncouple

F14 Switching Mode

F15 Wheel Chains

F16 Water Stop

F17 Fuel Loading

F18 Ash Dump

F19 Wheel Slip

F20 Injector

F21 Sander Valve

F22 Cab Chatter

F23 All Aboard/Coach Doors

F24 FX3 Function Output

F25 FX4 Function Output

F26 FX5 Function Output

F27 FX6 Function Output

F28 Not Assigned

Tsunami2 Steam User’s Guide 5

Page 6

All Aboard!

Ring the Bell

Turn on F1 to ring the bell. Press F1 again to stop ringing the bell. The bell is generally rung

before moving the locomotive, when approaching crossings, to alert people or equipment near

the track, and as a warning signal when necessary.

Blow the Whistle

Signaling can make your operating sessions more fun! Engineers signal to notify passengers,

crew, and other trains of common locomotive movements, such as stopping, moving forward,

backing up, and approaching grade crossings. Tsunami2 provides three functions for signaling.

Use F2, F3, and F9 to signal prototypically while you operate, as described below.

Press and release F2 to blow the “long” whistle. Contrary to most function keys, the duration of

the whistle blast is determined by how long you press F2. In other words, the whistle blast will

start when you press F2, and stop when you release F2. Press F3 to issue the single “toot” of

the “short” whistle. The short whistle will be the same length every time you press F3, unlike the

long whistle.

Note: Function key F2 on the NCE Power Cab command station is on/off or “latching”, i.e.,

pressing F2 to turn on the function will start the whistle blast, and pressing F2 again to turn off

the function will stop the whistle blast. To issue momentary whistle blasts with the NCE Power

Cab, press and release the “Horn/Whistle” button instead of using F2.

To issue the long-long-short-long grade-crossing signal automatically, turn on F9 as your

locomotive approaches a grade crossing. Refer to Table B to view some more common signals.

Table B. Whistle Signals

Long = –

Short = ●

Signal Description

– – ● –

●

– –

● ● ●

● ● ● ●

– ● ● ●

– ●

–

Approaching a grade crossing: hold final blast until crossing is occupied

Applying brakes

Releasing brakes, proceeding forward

When moving, stop; when stopped, back up

Request signal from trainman

Signal flagman to protect rear

Warning signal: use when approaching areas with obstructed views and when

approaching/passing passenger/freight trains

Approaching stations, junctions, and railroad crossings at grades

Activate Cylinder Cocks

As you begin to accelerate from a stop, turn on F4 to purge the condensed water from the

cylinder. The sound of the condensed water in the cylinder being expelled outwards with the

steam, can be heard (“swish-swoosh”) as the engine moves.

Adjust the Exhaust Cutoff

As the locomotive continues to accelerate, less steam is needed in the cylinders to keep the

train moving. The engineer moves the power reverse lever or Johnson bar closer to the center

of the quadrant to shorten the amount of time steam is emitted into the cylinders.

Tsunami2 Steam User’s Guide 6

Page 7

All Aboard!

You can shorten the exhaust cutoff of the locomotive by turning on F5. The cutoff can be

shortened three times to replicate various operating conditions. Each time it is shortened the

exhaust chuff will change in both pitch and length to replicate a lighter load on the locomotive.

As the engine crests a grade, shorten the cutoff a fourth time to simulate drifting. The

locomotive will begin to drift and the exhaust chuff will fade as the engineer closes the throttle.

The snifter valve will drop and the sound of air being sucked through leaky valve packings will

start.

As the engine approaches the bottom of the hill, more steam is needed to keep the train

moving. Turn on F6 to decrease the cutoff and exit drifting. The snifter valve will lift and the

exhaust chuff will return as the engineer slowly opens the throttle. As more steam is needed,

decrease the cutoff even further by turning on F6 again. The cutoff can be lengthened three

times. Each time the cutoff is decreased, the chuff will change in both pitch and length to

replicate a harder working locomotive.

Apply the Independent Brake

The engineer generally applies the brakes on the locomotive during switching operations and to

control slack between units. You can use the independent brake function to simulate applying

the locomotive brake independently from the rest of the train.

Turn on F11 to apply the independent brake before bringing your locomotive to a stop. The

locomotive brakes typically squeal just before the wheels stop turning. You can simulate

applying the independent brake prototypically by turning on F11 as your locomotive decelerates

to a stop. Press F11 again to release the independent brake before departing. Refer to

“Configuring Throttle and Braking” to set the independent brake rate and allow the independent

brake function to reduce speed when activated.

Apply the Train Brake

You can apply the brakes on all locomotives and cars at the same time to control the speed of

the entire train at a consistent rate. On the prototype, air hoses are fastened to each piece of

equipment to form a single braking system, referred to as the “train brake” or “automatic brake.”

The train brake function allows you to simulate applying each unit’s brake at once to reduce

train speed.

First turn on F12 to select the train brake in place of the independent brake. The air compressor

will cycle on to simulate charging the train line, and indicate that the train brake is selected.

Next, turn on F11 to simulate applying the train brake. While the train brake function is turned

on, pressing F11 again will release the train brakes and turn the air compressor back on to

recharge the train line.

You can use F11 to activate the train brake only when the F12 brake select function is turned

on. Turn off F12 to reselect the independent brake for F11 and disable the train brake. Refer to

“Configuring Throttle and Braking” to set the train brake rate and allow the train brake function to

reduce speed when activated.

Mute Sound Effects

Turn on F8 to mute all sound effects when you need to silence your train. The mute function

allows a quick way to turn off sound effects for a phone call, for instance. Press F8 again to

return all sound effect volume levels to their prior settings.

Tsunami2 Steam User’s Guide 7

Page 8

All Aboard!

Blow Down the Boiler

There’s sure to be particle buildup in the boiler of your engine. To clean the boiler’s mud ring,

turn on F10 to open the blowdown valve and blow out the sediment. Turn off F10 to close the

valve.

Couple and Uncouple

Turn on F13 to engage the sound of the coupler as you add cars to your train. When you

uncouple, press F13 a second time to open the knuckle and separate the glad hands.

Use Switching Mode

To improve throttle control for switching operations, turn on F14 to override all momentum CVs

and reduce the current throttle setting by 50%. Press F14 again to reset locomotive speed to the

prior speed step and reactivate all momentum CV settings. For more information about

momentum CVs, refer to “Configuring Throttle and Braking.”

Apply Wheel Chains

Turn on F15 to place chains around the locomotive wheels. Press F15 again to remove the

chains from the wheels.

Activate Water Stop

When your locomotive is stopped, turn on F16 to open the water hatch and fill the tender. Turn

off F16 to stop filling the tender and close the hatch before departure.

Refuel the Locomotive

While your locomotive is stopped, turn on F17 to open the coal chute doors and begin loading

coal into the tender. Press F17 again before departing to stop loading coal into the tender and

close the coal chute doors. These sounds can also be configured for oil fired, wood fired and

coal stoker fired locomotives. For more information about selecting the fuel type, refer to

“Configuring Sound Effects.”

Ash Dump

Turn on F18 to clean out the firebox and ash pan after running your locomotive for a while.

Press F18 again to stop the cleaning sequence.

Activate Wheel Slip

While the locomotive is moving, turn on F19 to play the wheel slip effect. The sound of the

wheel slip can be heard as short staccato bursts of exhaust chuffs, followed by the sound of the

engineer backing off the throttle to regain traction. Press F19 again to stop the wheels from

slipping.

Operate the Injector

Turn on F20 to turn on the injector and fill the boiler with water. Press F20 again to stop the

injector fill sequence.

Open the Sander Valve

In the real world, wet rails can cause wheels to slip. When extra traction is needed, turn on F21

to open the sander valve. You will hear the quiet sound of sound being deposited onto the rails.

Press F21 again to close the sander valve.

Listen to Cab Chatter

Turn on F22 to hear railroad radio transmissions being exchanged from inside the cab. The

radio will continue to play messages at random while F22 is turned on. Press F22 again to turn

Tsunami2 Steam User’s Guide 8

Page 9

All Aboard!

off the function. The current message will finish and radio will be silent. To manually issue a new

radio message, toggle the cab chatter function from off to on by pressing F22 twice.

Announce “All Aboard!”

Turn on F23 before leaving the station to issue the conductor’s “all aboard!” announcement.

After the coach doors slam shut, increase the throttle and depart the station.

Turn On FX3-FX6 Lighting

If you have additional lights wired to the FX3-FX6 function outputs, use function keys F24-F27

to activate them. Depending on board format, Tsunami2 offers up to six lighting outputs to

support Hyperlight effects. To select Hyperlight effects for lighting outputs, refer to “Configuring

Lighting Outputs.”

Make an Emergency Stop

Press the emergency stop button to issue the emergency brake application and bring your train

to an immediate stop.

Automatic Sound Effects

Tsunami2 plays a variety sound effects automatically. Automatic sound effects respond

prototypically to aspects of operation, such as certain functions, speed settings, and motor load

changes.

Power Reverser or Johnson Bar

Changing the direction of the locomotive will automatically play the sound of the power reverser

being moved forward or backward. Each time you increase or decrease the exhaust cutoff with

F5 and F6, the power reverser can be heard adjusting the position of the valves.

The locomotive can also be configured with a manual reverse lever, also known as a Johnson

bar. Refer to the “Configuring Sound Effects” section for more information.

Auto-Exhaust

2-cylinder exhaust for a light steam locomotive is the decoder’s default setting, and the chuff

rate is automatically regulated by the back-EMF sensor in response to the demand on the

motor. For example, the chuff volume and timbre will respond to changes in grade; the chuff

becomes more rapid when the motor is spinning faster, and less rapid when the motor is

impeded. To adjust the Auto-Exhaust chuff rate which synchronizes the chuff with the motion of

the wheels, refer to “Configuring Sound Effects.”

The Dynamic Digital Exhaust (DDE) processor will automatically adjust the exhaust volume and

timbre to simulate the engine working under varying load conditions. You can also use F5 and

F6 to manually adjust the exhaust cutoff if desired, as mentioned on page 6. Refer to

“Configuring Throttle and Braking” to set acceleration and deceleration rates, and refer to

“Configuring Dynamic Digital Exhaust” to adjust a given parameter of the DDE processor.

Furthermore, you can select 3-cylinder or articulated type exhaust in place of 2-cylinder exhaust

for a range of exhaust chuff sound effects. Refer to “Configuring Sound Effects” for details

regarding exhaust selections.

Snifter Valve

Just as you start to move the locomotive, you’ll hear the Pffffffft! of the snifter valve opening. As

you come to a stop, you’ll hear the clink! of the snifter valve dropping.

Tsunami2 Steam User’s Guide 9

Page 10

All Aboard!

Side Rod Clank

The “clanks” and “clunks” of the side rod occur with the exhaust chuff. You can use exhaust

cutoff control to mute the exhaust chuff and elevate the volume of the side rod clank if desired.

Airpumps

The airpump maintains air pressure during operation. To simulate charging the train line, the

pump cadence will revert to its most rapid setting when the coupler function is turned on, when

the train brake function is turned off, and every third time the independent brake function is

turned on.

Blower

The blower simulates draft being maintained near the exhaust nozzle in the smokebox during

operation.

Clickety-Clack

The “clickety-clack” of the locomotive running across rail joints is synchronized in proportion to

locomotive speed. To adjust the clickety-clack sound effect, refer to “Configuring Sound

Effects.”

Fireman Fred

Each time the engine is brought to a stop, Fireman Fred may attend to a randomly selected task

(or tasks), including shoveling coal, oiling the side rods, checking the frame and more.

Tsunami2 Steam User’s Guide 10

Page 11

All Aboard!

CV Programming Tutorial

Configuration Variable (CV) is the industry-adopted and NMRA Standard term for a decoder’s

user-adjustable parameters of the decoder. CVs allow you to adjust various decoder properties

and customize your operating experience. The address, audio settings, motor control, lighting

effects, and function assignments are just some of the properties you can adjust with CVs. You

can modify CVs at any time and the decoder will save your settings even when the power is

turned off. If reading about CV programming already has your head spinning, this tutorial will

help you understand how CVs work.

At first glance, you may feel overwhelmed by the large number of CVs offered by Tsunami2.

Don’t worry! You don’t need an engineering degree to customize your decoder’s settings.

Making adjustments is easy, and you can customize settings one CV at a time by referring to

this user’s guide and the Tsunami2 Steam Technical Reference. When in doubt, you can always

reset the decoder to factory defaults. Refer to “Resetting CVs” for more information.

Bits and Bytes

All the bits, bytes, and other symbols used in decoder manuals, and differences between

command stations can make CV programming difficult to understand. Put simply, each CV

contains a value that can be changed, and changing the value of a CV will modify a specific

decoder setting. However, knowing a little more about how CV values are represented will help

you make the right adjustments. CV values can be represented in the three numeric formats

listed below:

Decimal

Decimal representation is the format you will probably use most often. Decimal values are

represented using numerals 0-9. Each CV contains a decimal value from 0 to 255.

Binary

Like computers, binary is the numbering system used in Digital Sound Decoders. Binary values

are called “bits” and can be represented as either 0 or 1. Each CV contains eight bits, or one

“byte.” Each CV contains a binary value from 00000000 to 11111111, which easily converts to

decimal form.

Hexadecimal

Referred to as “hex,” hexadecimal values are represented using characters A-F and numerals

0-9. Each CV contains a hex value from 00 to FF. Hex allows you to represent decimal numbers

using fewer digits if your command station has a limiting interface.

Programming by the Bits

Each CV is made up of eight bits and can be set to decimal values from 0 to 255 or binary

values from 00000000 to 11111111. Most CVs contain a single piece of data easily represented

in decimal, binary, or hex.

Some CVs use individual bits to control specific features, allowing up to eight features to be

controlled using a single CV. You can set each bit to a binary input of 0 or 1 to modify a specific

setting. For this reason, “programming by the bits” allows you to make basic adjustments that

are on/off, disabled/enabled, etc. Because most DCC systems don’t use binary representation,

programming by the bits requires you to convert binary values into decimal (or hex) values.

Tsunami2 Steam User’s Guide 11

Page 12

All Aboard!

This user’s guide represents CV values in decimal form to expedite programming. However,

binary is occasionally used to represent CV values in the Tsunami2 Steam Technical Reference

for CVs that are programmed by the bits. For instance, CV 29 (Configuration Data 1) is

programmed by the bits and controls important decoder settings, such as the locomotive

direction, the decoder’s speed step mode, alternate power source, and speed table setting.

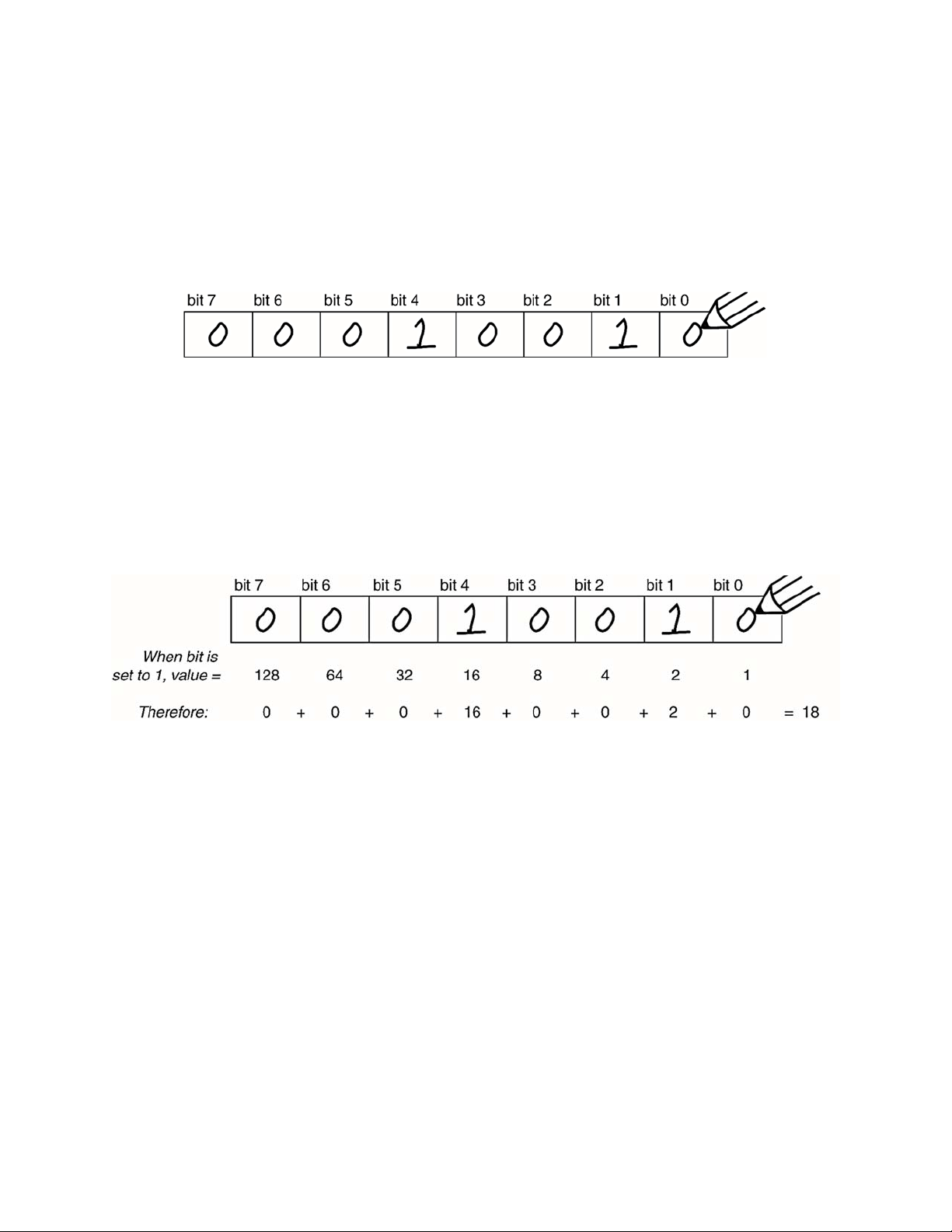

A CV is illustrated below and shows a binary value for each bit. Bits 1 and 4 are set to 1, and

bits 0, 2, 3, 5, and 6 are set to 0, which is a binary value of 00010010.

Refer to Appendix A to locate the binary value 00010010 and convert it to a decimal value of 18

(0x12 in hex). Entering a value of 18 into the CV would then adjust the settings contained by

each bit according to the binary input 00010010.

Binary-Decimal Conversions

You can convert binary values into decimal form without the conversion chart as well. It helps to

know the decimal value contained in each bit set to 1. The decimal value of each bit doubles

sequentially (1, 2, 4, 8, 16, etc.) from bit 0 to bit 7. Add the decimal values together for each bit

set to 1. The sum is the total decimal value of the CV.

Tsunami2 Steam User’s Guide 12

Page 13

All Aboard!

Introduction to Programming

This section details CV programming modes, reading CVs,

accessing indexed CVs, resetting CVs to factory defaults,

and locking and unlocking CVs. Due to the varying CV

programming methods used by DCC systems, we cannot

provide comprehensive instructions that address every

command station and must assume you understand the

capabilities of your system on some level. Consult your

DCC system manual or contact the manufacturer if you

need more detailed programming instructions.

The sections of this user’s guide are categorized according to each part of decoder operation,

from basic to advanced programming, and allows you to configure one group of CVs at a time.

When you’re comfortable programming one set of CVs, move on to the next category and

explore each setting Tsunami2 has to offer. Refer to the Tsunami2 Steam Technical Reference

for a list of CVs detailing each adjustable setting.

Programming Modes

Tsunami2 supports Operations Mode and Service Mode programming.

Operations Mode

Referred to as “Ops Mode” or “programming on the main,” Operations Mode allows you to

program CVs during operation even when other locomotives and rolling stock are present.

Being able to program during operation is especially helpful when making adjustments to sound

effects since you can hear the results of the changes you’ve made. However, because data

cannot be read back from the decoder, programming on the main will not allow you to verify CV

values.

Service Mode

Service Mode programming usually requires connecting the model to a dedicated programmer

or placing it on a separate programming track. Tsunami2 supports four types of Service Mode

instructions:

Configuration Variable Control CVs

CV 8: Manufacturer ID

CV 15: CV Unlock Code

CV 16: CV Lock ID

CV 30: Error Information

CV 31: CV Index 1

CV 32: CV Index 2

CVs 1.257-1.512: Indexed CV Page 1

CVs 2.257-2.512: Indexed CV Page 2

Address Mode: CV 1 may be modified

Register Mode: CVs 1, 2, 3, 4, 7, 8, and 29 may be modified

Paged Mode: A page register is used to modify any CV indirectly

Direct Mode: All CVs may be directly modified

Reading CVs

Some command stations permit you to read the value of a CV and verify its setting during

Service Mode programming. If you have trouble reading or verifying CVs, there may be a

problem within the command station’s design rather than with the decoder.

Try another programming mode if you experience difficulties programming or reading CVs.

Many of the newer DCC systems automatically select the appropriate programming mode and

only require you to enter the CV number and desired value. However, some DCC systems may

restrict the number of available CVs. If you’re having difficulty determining the programming

modes supported by your DCC system, refer to the manual or contact the manufacturer.

Note: Tsunami2 does not require a programming track booster, such as the PTB-100.

Tsunami2 Steam User’s Guide 13

Page 14

All Aboard!

Indexed CVs

The term “indexed CVs” tends to cause confusion and consternation. Simply put, indexed CVs

are located on ‘pages’ to help manage the total number of CVs. This is required by the NMRA

DCC Standard and works like this:

The standard (S-9.2.2) requires that CVs exceeding CV 256 be contained within “indexed CV

pages”. An individual set of CVs from 257-512 is contained within each indexed CV page.

Pages are indicated in user documentation by a preceding number. For example, CV 257 on

indexed page 1, would be represented as 1.257. CV 257 on indexed page 2 would be

represented as 2.257 and so on. This preceding number is also the value to enter into CV 32 to

select that page.

Indexed CVs are accessed with the use of two CVs: CV 31 enables indexing when set to a

value of 16 (the default value) and CV 32 selects the desired indexed page.

Because of the number of features and options contained within Tsunami2 decoders, three

pages of indexed CVs are provided:

To access CVs 1.257-1.512:

1. Ensure CV 31 is set to a value of 16.

2. Enter a value of 1 into CV 32 to select Indexed CV Page 1.

3. Access CVs 257-512 from your command station.

To access CVs 2.257-2.512:

1. Ensure CV 31 is set to a value of 16.

2. Enter a value of 2 into CV 32 to select Indexed CV Page 2.

3. Access CVs 257-512 from your command station.

To access CVs 3.257-3.512:

1. Ensure CV 31 is set to a value of 16.

2. Enter a value of 3 into CV 32 to select Indexed CV Page 3.

3. Access CVs 257-512 from your command station.

To make things easier, Tsunami2 CVs are grouped by like function as follows:

CVs 1.257-1.512 are used for configuring Flex-Map function mapping CVs. Access CVs 1.257-

1.384 for function mapping CVs and CVs 1.385-1.512 for automatic effect configuration. Refer

to “Configuring Function Mapping” for more information.

CVs 2.257-2.512 are used for adjusting alternate mixer channel volume levels and configuring

Dynamic Digital Exhaust CVs. Access CVs 2.289-2.320 for alternate mixer CVs and CVs 2.503-

2.512 for DDE control CVs. Refer to “Configuring Throttle and Braking,” “Configuring Sound

Effects” and “Configuring Dynamic Digital Exhaust” for more information.

CVs 3.257-3.512 are used for adjusting the clickety-clack rate of the clickety-clack and rail joints

sound effects. Refer to “Configuring Sound Effects” for more information.

Tsunami2 Steam User’s Guide 14

Page 15

All Aboard!

Resetting CVs (Starting Over)

Occasionally, something goes wrong and Tsunami2 will not respond as expected. Usually, this

is caused by one or more CVs inadvertently being programmed to the wrong value. The CVs

can be quickly reset to their factory default values. Follow the steps below to perform either a

full or partial CV reset:

1. Turn on track power to the decoder. If you have a SoundTraxx CurrentKeeper

another device that maintains power, allow at least one minute before turning the power

back on.

2. Enter one of the following values into CV 8 (Manufacturer ID) to perform a full or partial

CV reset:

CV 8: Manufacturer ID

8 = Reset All CVs

9 = Reset CVs 1-128

10 = Reset CVs 129-256

11 = Reset CVs 1.257-1.512

12 = Reset CVs 2.257-2.512

13 = Reset CVs 3.257-3.512

3. Wait about 10 seconds after returning power to the decoder. The headlight and/or

backup light will flash 16 times to indicate CVs have been successfully reset. Tsunami2

will respond to primary address 3 after all CVs, or CVs 1-128 have been reset.

Note: Continue cycling power to the decoder if the CV reset is unsuccessful. If you are unable

to reset CV values, continue to “Locking and Unlocking CVs” to verify the decoder is not locked.

Locking and Unlocking CVs

The CV Lock/Unlock feature allows you to program a decoder without the danger of overwriting

the programming in another. This is especially useful in installations where multiple decoders

are used. For example, if you have installed a function decoder in addition to the sound

decoder, you may wish to lock the CVs after programming to prevent accidentally programming

one decoder or the other.

CV 15, CV Unlock Code

CV 16, CV Lock Code

CV 30, Error Information

To use the CV Lock feature implemented in CVs 15 and 16, bit 0 of CV 30 must first be set to 1

(the default value is 0). This is to avoid inadvertently locking the decoder when the CV Lock

feature is not needed.

CVs 15 and 16 are used for locking and unlocking the decoder. CV 15 is the Unlock Code and

may be programmed to any value from 0 to 255 regardless of whether the decoder is locked or

unlocked. CV 16 is the Lock Code and may be set to any value from 0 to 7, but only when the

decoder is unlocked. Attempts to program CV 16 with a value greater than 7 will be ignored.

The decoder is unlocked when the value in CV 15 matches the value in CV 16. Otherwise the

decoder is locked and cannot be programmed in either Operations Mode or Service Mode.

Further, a locked decoder cannot be reset to its factory defaults until it is unlocked. Tsunami2

decoders are shipped from the factory with all CVs unlocked, that is, CV 15 and 16 are both set

to 0.

™

or

Tsunami2 Steam User’s Guide 15

Page 16

All Aboard!

Note that if the decoder is unlocked, changing the value in CV 16 will instantly lock the decoder.

You must then set CV 15 to the same value as was just programmed into CV 16 to unlock the

decoder again. If you use the CV Locking feature for a multi-decoder installation in one model,

each decoder must first have its Lock Code set in CV 16 prior to the installation of any other

decoders. Otherwise, all the decoders will have the same Lock Code and the feature will not

work. First install one decoder and program its Lock Code. Then install the next decoder and

program its Lock Code. Since the first decoder is now locked, it will be unaffected by the

programming of the second decoder (unless you accidentally set the Lock Code of the two

decoders to the same value. If this happens you will need to disconnect one decoder and start

over). Continue in this manner until all decoders have been installed and their Lock Codes have

been set.

Follow the steps below to lock and unlock CVs:

1. Enter a value of 1 into CV 30 (Error Information) to enable the CV lock/unlock feature.

2. Enter a value from 0 to 7 into CV 16 to set the lock code.

3. To unlock CVs, set CV 15 to the same value as CV 16.

4. To lock CVs, set CV 15 to a different value than CV 16 to unlock CVs.

Note: CV 8 (Manufacturer ID) cannot be used to reset CVs to factory defaults when CVs are

locked, i.e., when CV 30 is set to 1 and CVs 15 and 16 are not set to the same value.

It is a good idea to set up a standardized system so you don’t forget the Lock Code settings.

You might, for example, set all motor decoders to a CV Lock Value of 1, sound decoders to a

value of 2, and function decoders to a value of 3. Keeping CV 15 set to 0 will guarantee the

decoder stays locked until you are ready to begin programming.

Example: Using CV Lock/Unlock

Let’s say you will be installing motor decoder, a sound decoder, and a function decoder in one

locomotive. Using the previously described system, you would first install the motor decoder and

set its Lock Code by programming CV 16 to 1. Since CV 15 (CV Unlock Code) is currently set to

0 (the default value), the decoder is immediately locked. Now install the sound decoder and set

its Lock Code by programming CV 16 to 2. Since CV 15 is still set to 0, this decoder is also

immediately locked. Now install the function decoder and set its Lock Code by programming CV

16 to 3. At this point, all three decoders are installed and locked. Starting with the motor

decoder, set CV 15 to 1 to unlock and program the motor decoder. When you are finished, set

CV 15 to 2 and program the sound decoder. Finally, set CV 15 to 3 and program the function

decoder. When you are done, set CV 15 back to 0 to lock all the decoders.

If You Forget the Lock Code

As there are only eight possible combinations, you can easily determine a forgotten Lock Code

using trial and error with the following procedure:

Place the locomotive on the Programming Track and set CV 15 to 0. Then try to read the value

in CV 16. If CV 16 does not read back, the decoder is locked. Set CV 15 to 1 and try reading CV

16 once more. Again, if CV 16 does not read back, the decoder is still locked. Program CV 15 to

2 and try reading CV 16 again. Continuing in the manner, you should eventually find the value

stored in CV 16 as it can only be programmed from 0 to 7. If you have tried setting CV 15 to all

eight values from 0 to 7 and the decoder still does not respond, there may be a problem with the

installation, the program track, or the decoder itself and further investigation will be required.

To reiterate, follow the steps below to unlock CVs and determine the lock code:

Tsunami2 Steam User’s Guide 16

Page 17

All Aboard!

1. Place the model on the programming track and enter a value of 0 into CV 15.

2. Try reading the value of CV 16. If the value is not read back, CVs are locked.

3. Enter a value of 1 into CV 15 and try reading the value of CV 16 again.

4. If the value is not read back, enter a value of 2 into CV 15 and try again.

5. Enter values 3-7 into CV 15 until the value of CV 16 is read back and CVs are unlocked.

If you still can’t identify the lock code, there may be a problem with the installation, programming

track, or decoder. Contact SoundTraxx customer support if this occurs.

If you do not have access to a programming track with read-back capabilities (or are uncertain

as to whether it is working properly), you can also use Operations Mode to discover the Lock

Code by alternately programming CV 15 and setting another CV to a value where there is a

known response. For example, changing CV 128 (Master Volume Control) will provide auditory

feedback as to whether the decoder is unlocked by virtue of a change in sound level. Thus, you

would begin by setting CV 15 to 0 and then setting CV 128 to 0. If the volume does not fall to 0,

the decoder is locked. Then set CV 15 to 1 and try programming CV 128 again. Repeat this

process until you find a value for CV 15 that results in a change in sound volume as you change

CV 128.

Troubleshooting Tip: Even if you are not planning to use the CV Lock feature, it can still be

accidentally activated by inadvertently programming CV 15 or 16 with a non-default value. If you

have a decoder that is otherwise working properly (i.e., making sound and responding to throttle

commands) but has suddenly stopped accepting CV changes, then first run through the

procedure under “If you Forget the Lock Code” to determine if the decoder has been locked.

Tsunami2 Steam User’s Guide 17

Page 18

Basic Programming

Basic Programming

Configuring the Address

Like all DCC decoders, Tsunami2 responds to primary address 3

right out of the package. Address control CVs allow you to set

primary and extended addresses or your choice, which can be

useful when matching the decoder’s address with the number on

the locomotive, for instance.

Setting Addresses

Tsunami2 recognizes either the primary address (also known as the short address) in CV 1 or

the extended (long) address in CVs 17-18 (Extended Address). Whether you use the primary or

extended address will first depend on whether or not your DCC system uses extended

addressing (not all of them do, so if in doubt, see your command station owner’s manual.)

Second, it will depend on your preferences and the numbering scheme you use for setting your

decoder addresses. The extended address has the advantage that you can use all four digits of

a locomotive’s road number for the decoder address making it easy to remember. Be aware that

some DCC systems do not support the full range of available addresses.

Programming Notes: You can set the primary and extended addresses in Service Mode at any

time. Some DCC systems also allow you to set the address in Operations Mode according to

the following restrictions:

Address Control CVs

CV 1: Primary Address

CVs 17-18: Extended Address

If the decoder’s primary address is enabled (bit 5 of CV 29 set to 0), only the extended

address can be changed in Operations Mode.

If the decoder’s extended address is enabled (bit 5 of CV 29 set to 1), only the primary

address can be changed in Operations Mode.

Primary Address

Enter a value from 1 to 127 into CV 1 to set the primary address. All SoundTraxx decoders are

set to primary address 3 by default.

Extended Address

The extended address is actually made up of two CVs, 17 and 18. Unless you are an

experienced user, you should not try to program these CVs individually as a specific protocol is

required in order for the decoder to accept the new data (see the Tsunami2 Steam Technical

Reference for details). Since most command stations that support extended addressing will

automatically generate the correct protocol, simply follow their instructions for setting the

extended address.

After setting the extended address, set bit 5 of CV 29 (Configuration Data 1) to 1 to enable its

usage. If bit 5 of CV 29 is set to 0, the decoder will continue to respond to the primary address.

Continue to “Configuring the Decoder” for more information about CV 29.

Tsunami2 Steam User’s Guide 18

Page 19

Basic Programming

Configuring the Decoder

After setting the address, we recommend you adjust the settings of

CV 29 (Configuration Data 1). CV 29 controls a variety of important

settings. It determines locomotive direction, speed-step mode,

alternate power source, speed tables, and the decoder address.

Configuring CV 29

Add the values of all bits set to 1 in CV 29 and enter the sum into the CV to adjust settings. For

information about CVs and entering CV values, refer to “CV Programming Tutorial.”

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 EAM STE 0 APS F0 DIR

DIR: Locomotive Direction

Bit 0 (DIR) is used to determine locomotive direction. Setting bit 0 to 1 will invert direction

commands, and the decoder will interpret forward as reverse, and reverse as forward. This

operating mode is most useful for setting up diesel engines that ran with the long hood section

forward. However, it is also useful for electronically correcting installations where the motor

wires were accidentally reversed and avoids dismantling the locomotive a second time.

F0: F0 Location (Speed-Step Mode Select)

Bit 1 (F0) is used to determine the number of speed steps within the throttle range. 14, 28, and

128 speed-step modes are available, and 28/128 speed-step mode has been enabled by

default. Select the highest number of speed steps supported by your command station for the

most refined throttle operation.

APS: Alternate Power Source (Analog Mode)

Setting bit 2 (APS) to 1 will allow the decoder to use an analog power source when a DCC

signal is not present. Entering a value of 1 into CV 12 (Alternate Power Source) will enable

analog mode (disabled by default). Refer to “Configuring for Analog Mode Operation” for more

information.

STE: Speed Table Enable

Setting bit 4 (STE) to 1 will select a linear or 28-point custom speed table in place of the 3-point

speed table. Refer to “Configuring Throttle and Braking” for more information.

EAM: Primary or Extended Address

Bit 5 (EAM) is used for selecting the active address. Setting bit 5 to 0 will enable the primary

address. Set the primary address with CV 1 (Primary Address). CVs 17 and 18 (Extended

Address) are used to set the extended address. Set bit 5 of CV 29 to 1 to enable the extended

address. Refer to the previous section, “Configuring the Address,” for more information about

setting the extended address.

Refer to Table C on the following page to view decimal values for CV 29.

Decoder Configuration CVs

CV 29: Configuration Data 1

+1 = Bit 0 (DIR) set to 1

+2 = Bit 1 (F0) set to 1

+4 = Bit 2 (APS) set to 1

+16 = Bit 4 (STE) set to 1

+32 = Bit 5 (EAM) set to 1

Tsunami2 Steam User’s Guide 19

Page 20

Basic Programming

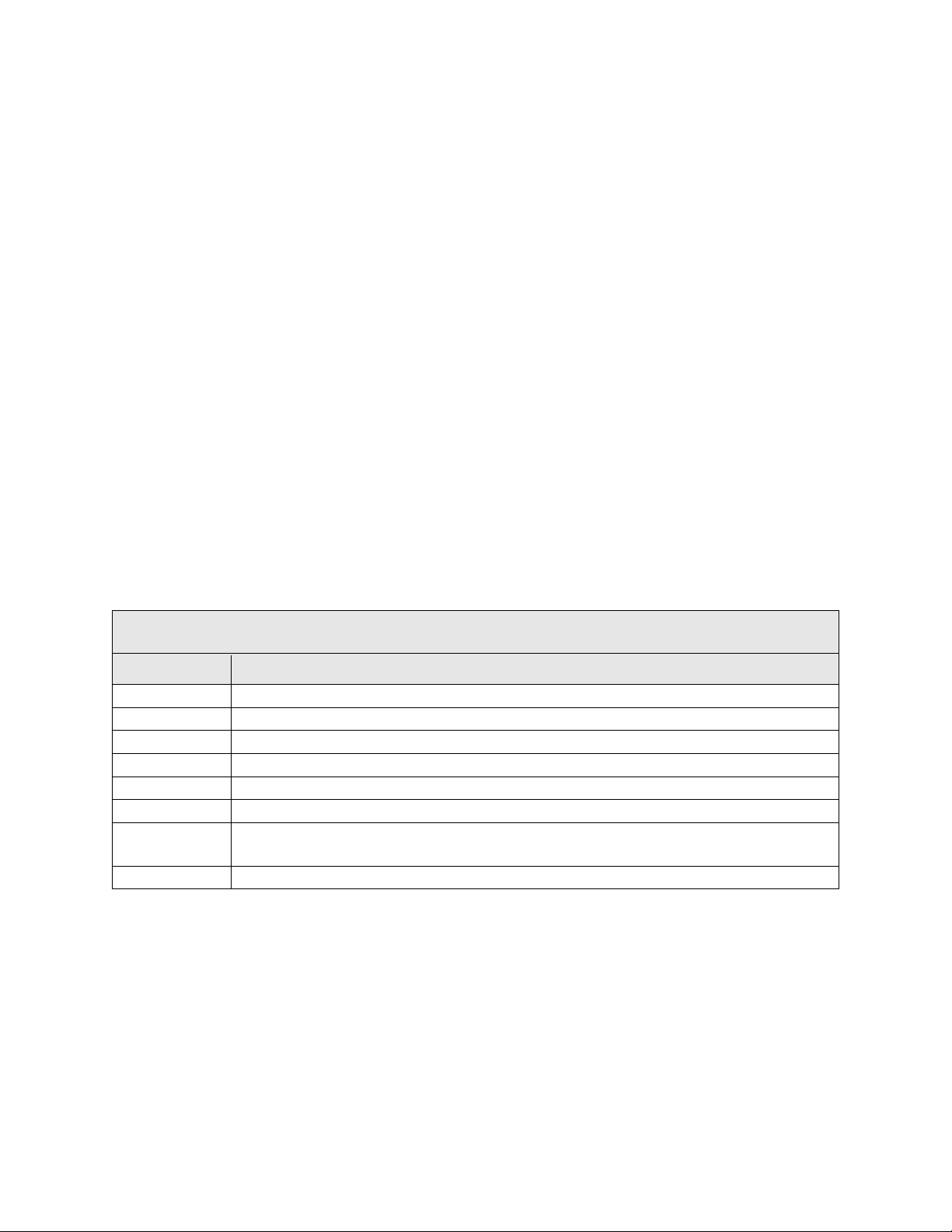

Table C. CV 29 Reference

Address Type Speed Table Analog Mode Speed Steps Direction CV Value

Primary (CV1) No No 14 Normal 0

Primary (CV1) No No 14 Reversed 1

Primary (CV1) No No 28/128 Normal 2

Primary (CV1) No No 28/128 Reversed 3

Primary (CV1) No Yes 14 Normal 4

Primary (CV1) No Yes 14 Reversed 5

Primary (CV1) No Yes 28/128 Normal 6

Primary (CV1) No Yes 28/128 Reversed 7

Primary (CV1) Yes No 14 Normal 16

Primary (CV1) Yes No 14 Reversed 17

Primary (CV1) Yes No 28/128 Normal 18

Primary (CV1) Yes No 28/128 Reversed 19

Primary (CV1) Yes Yes 14 Normal 20

Primary (CV1) Yes Yes 14 Reversed 21

Primary (CV1) Yes Yes 28/128 Normal 22

Primary (CV1) Yes Yes 28/128 Reversed 23

Extended (CV 17:18) No No 14 Normal 32

Extended (CV 17:18) No No 14 Reversed 33

Extended (CV 17:18) No No 28/128 Normal 34

Extended (CV 17:18) No No 28/128 Reversed 35

Extended (CV 17:18) No Yes 14 Normal 36

Extended (CV 17:18) No Yes 14 Reversed 37

Extended (CV 17:18) No Yes 28/128 Normal 38

Extended (CV 17:18) No Yes 28/128 Reversed 39

Extended (CV 17:18) Yes No 14 Normal 48

Extended (CV 17:18) Yes No 14 Reversed 49

Extended (CV 17:18) Yes No 28/128 Normal 50

Extended (CV 17:18) Yes No 28/128 Reversed 51

Extended (CV 17:18) Yes Yes 14 Normal 52

Extended (CV 17:18) Yes Yes 14 Reversed 53

Extended (CV 17:18) Yes Yes 28/128 Normal 54

Extended (CV 17:18) Yes Yes 28/128 Reversed 55

Note: Values in Table C are shown in decimal format. If your command station requires hex

inputs, you will need to convert. Refer to Appendix A for conversions.

Tsunami2 Steam User’s Guide 20

Page 21

Basic Programming

Configuring Throttle and Braking

You can use throttle and braking control CVs to customize

the decoder’s throttle and braking settings to your operating

preferences. This section details setting acceleration and

deceleration rates, automatically calibrating Dynamic Digital

Exhaust (DDE) load compensation, setting braking rates for

the independent brake and train brake functions, adjusting

speed table settings, and enabling motor trim scaling factors.

If this is overwhelming at first glance, don’t worry! It’s not

necessary to change all of them if you don’t want to. We’ve

already talked about speed step selection in CV 29.

Setting the Start Voltage

Tsunami2 provides CV 2, Vstart, to set the starting voltage

that is applied to the motor at Speed Step 1, and is used to

compensate for inefficiencies in the locomotive’s motor and driveline. CV 2 may be programmed

with any value between 0 and 255 with each step in value being about 0.5% of the maximum

available motor voltage. To calculate the value of CV 2, you can use the formula:

CV 2 = 255 x ——————————————

Maximum Motor Voltage

If your DCC system supports Operations Mode Programming, an alternative method for setting

Vstart is to turn your throttle to the first speed step and then use the operations mode

programming feature to increase the value in CV 2 until the locomotive just begins to move.

Desired Starting Voltage

Setting Momentum Rates

Tsunami2 provides two CVs to simulate the momentum due to train weight. CV 3 (Baseline

Acceleration Rate) controls how fast the locomotive responds to increases in throttle

settings. CV 4 (Baseline Deceleration Rate) controls how fast the locomotive will respond to

decreases in the throttle setting.

Both CVs can be programmed with any value from 0 to 255, with 255 corresponding to the

slowest acceleration or deceleration rate. Lower settings yield a more responsive locomotive,

which is useful for switching. When both CVs are set to 0, the locomotive will respond nearly

instantly to any throttle changes. A setting of 255, on the other hand, will require several

minutes for a locomotive to reach full speed from a standing stop. Setting acceleration and

deceleration rates can allow the speed of the locomotive to match the sound effects regulated

by Dynamic Digital Exhaust.

When using 14 or 28 speed-step mode, configuring acceleration and deceleration rates will

improve the decoder’s throttle response. This allows the locomotive to speed up and slow down

without lurching from one speed step to the next.

Calibrating DDE Load Compensation

Tsunami2 features a cutting-edge new version of our already revolutionary Dynamic Digital

Exhaust! We highly recommend you automatically calibrate Dynamic Digital Exhaust settings

Throttle and Braking Control CVs

CV 2: Vstart

CV 3: Baseline Acceleration Rate

CV 4: Baseline Deceleration Rate

CV 5: Vhigh

CV 6: Vmid

CV 25: Speed Table Enable

CV 29: Configuration Data 1

CV 32: CV Index 2

CV 66: Forward Motor Trim

CVs 67-94: Custom Speed Table

CV 95: Reverse Motor Trim

CV 117: Independent Brake Rate

CV 118: Train Brake Rate

CV 2.503: DDE Load Offset

CV 2.504: DDE Load Slope

CV 2.512: DDE Load Sensitivity

Tsunami2 Steam User’s Guide 21

Page 22

Basic Programming

before adjusting throttle and braking control CVs. This will create an amazingly accurate

representation of prototypical operation. You can automatically calibrate DDE according to the

specifics of your installation and model. This will allow the decoder to produce more prototypical

prime mover responses when encountering changes in both grade and number of cars, during

operation. To adjust all DDE settings provided by Tsunami2, refer to “Configuring Dynamic

Digital Exhaust.”

Follow the steps below to automatically calibrate DDE load compensation:

1. Ensure CV 31 (CV Index 1) is set to a value of 16 (default).

2. Enter a value of 2 into CV 32 to select Indexed CV Page 2. This allows you to adjust

DDE control CVs by accessing CVs 2.503-2.512 from your command station.

3. Set CV 512 (DDE Load Sensitivity) to a value of 16.

4. We suggest running the locomotive at a moderate speed for a minute or two before

continuing. If there is any build-up of lubrication or oil in the motor, this will provide better

results during the calibration procedure.

5. Set the throttle to speed-step 1.

6. When your locomotive is on level track, enter a value of 255 into CV 503 (DDE Load

Offset) to automatically calibrate the nominal low-speed load level.

7. Increase the throttle to an appropriate moderate speed for your layout (generally

between speed-step 25 and speed-step 40).

8. When your locomotive is on level track, enter a value of 255 into CV 504 (DDE Load

Slope) to automatically calibrate the nominal high-speed load level.

Note: If, after the calibration is complete, you feel the need to increase or decrease the

sensitivity, you can do this with CV 2.512.

Setting Braking Rates

Although you can activate the independent brake and train brake

sound effects with function keys by default, CV 117

(Independent Brake Rate) and CV 118 (Train Brake Rate) allow

you to use the independent brake and train brake functions (F11)

to reduce locomotive speed and simulate actually applying

brakes during operation. We recommend setting CV 3 (Baseline

Acceleration Rate) to a minimum value of 45 before setting

braking rates to allow for smoother operation when the brakes

are applied and released.

The values of CVs 117 and 118 are added to the value of CV 4 (Baseline Deceleration Rate)

and determine how quickly your locomotive decelerates when brakes are applied. Enter values

from 0 to 127 into CVs 117 and 118 to set longer braking rates, and enter values from 129 to

255 to set shorter braking rates. The independent brake and train brake functions will not

reduce locomotive speed when CVs 117 and 118 are set to values of 0 or 128.

Note: When consisting with active momentum and braking rates, ensure the values of CVs 3, 4,

117, and 118 are the same for all units.

Set the Independent Brake Rate

The independent brakes on prototype locomotives are applied separately from the rest of the

train, generally during switching operations and to control slack between units. CV 117

Braking Rate CV Values

0 = CV 4 + 0 (Disabled)

1 = CV 4 + 1

↓

127 = CV 4 + 127

128 = CV 4 + 0 (Disabled)

129 = CV 4 – 1

↓

255 = CV 4 – 127

Tsunami2 Steam User’s Guide 22

Page 23

Basic Programming

determines the deceleration rate that will bring the locomotive to a stop when the independent

brake function is turned on. Turning off the independent brake function will release brakes and

allow the locomotive to accelerate back to the prior throttle setting. Enter a value from 0 to 255

into CV 117 to set the independent brake rate:

Seconds/Speed Step = (CV 4 + CV 117) × 0.896 ÷ Number of Speed Steps

Note: The brake select function (F12 by default) must be turned off for the independent brake

rate to be activated with the independent brake function.

Set the Train Brake Rate

On a prototype locomotive, the train brake controls the brakes for each unit in the train and is

the braking method most commonly used to reduce speed. CV 118 determines the deceleration

rate that will bring the locomotive to a stop when the train brake function is turned on. Turning

off the train brake function will release brakes, cycle the air compressor for 15 seconds, and

allow the locomotive to accelerate back to the prior throttle setting. Enter a value from 0 to 255

into CV 118 to set the train brake rate:

Seconds/Speed Step = (CV 4 + CV 118) × 0.896 ÷ Number of Speed Steps

Note: The brake select function (F12 by default) must be turned on for the train brake rate to be

activated with the train brake function.

Example: Prototypical Braking

Tsunami2 has more ways to prototypically operate your model, and the independent and train

brake functions are a great example! The steps below will guide you through setting

recommended momentum and braking rates and using the independent brake and train brake

functions prototypically while you operate:

1. Enter a value of 45 into CV 3 to allow the locomotive to accelerate in sequence with the

exhaust chuff sound effects regulated by Dynamic Digital Exhaust.

2. Enter a value of 75 into CV 4 to set the deceleration rate that allows the locomotive to

coast to a stop without any of the brakes being applied.

3. Because independent brakes are most often applied when running only a locomotive,

you may want to set CV 117 to a value of 178 for a more rapid braking rate.

4. Because an entire train takes longer to bring to a stop than just a locomotive, you may

want to set CV 118 to a value of 100 for a more gradual braking rate.

5. When running a light locomotive or a consist of only locomotives, apply the independent

brake with the independent brake function (F11 by default). The brake select function

(F12 by default) must be turned off for the independent brake to be applied.

6. When running a complete train, apply the train brake with the train brake function (F11

by default). The brake select function must be turned on for the train brake to be applied.

Turning on the brake select function will cycle the air compressor to simulate charging

the train line.

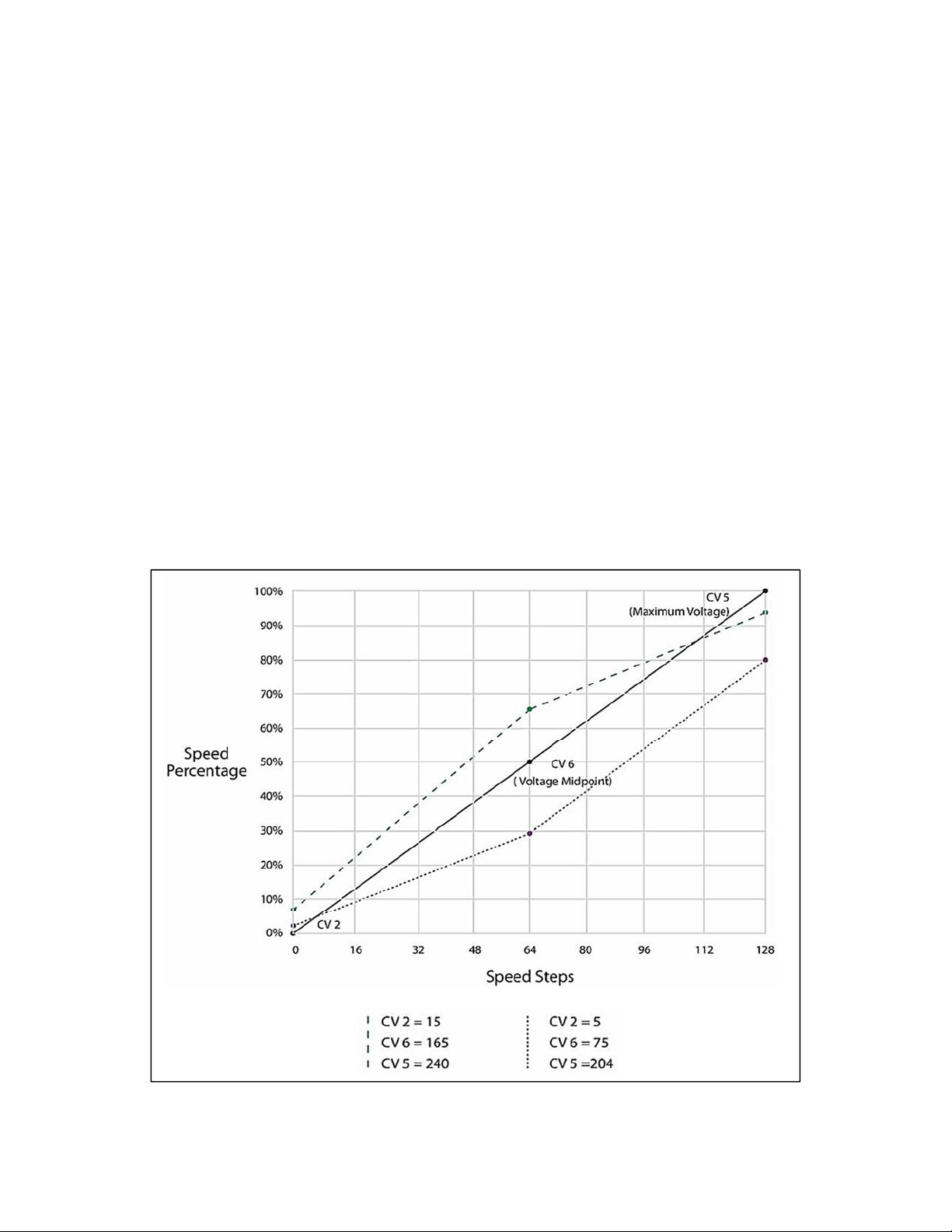

Setting the 3-Point Speed Curve

By default, track voltage is distributed to the decoder with no variation in a straight line and the

decoder responds instantly to the throttle setting. You can designate the amount of voltage

applied at the first, middle, and last speed step with CV 2 (Vstart), CV 5 (Vhigh), and CV 6

Tsunami2 Steam User’s Guide 23

Page 24

Basic Programming

(Vmid) to compensate for track power or throttle control inefficiencies. First, set bit 4 (STE) of

CV 29 to 0. Then enter values from 1 to 255 into CVs 2, 5, and 6 to set the 3-point speed curve.

Each value is equivalent to roughly 0.5% of the total supply voltage. Use the calculations below

to determine starting, mid-point, and maximum voltage settings:

Vstart, Vmid, Vhigh = Supply Voltage × CV Value ÷ 255

Note: Use CV 218 (Analog Mode Motor Start Voltage) to set the starting voltage level for analog

mode operation. Refer to “Configuring for Analog Mode Operation” for more information.

If your system supports Operations Mode, refer to the steps below for an alternative method of

setting the 3-point speed curve:

1. Place the unit on the mainline and set the throttle to speed-step 1, and then increase the

value of CV 2 until the model responds to your preferred starting voltage.

2. Set the throttle to a medium speed step, and then increase the value of CV 6 until the

model responds to your preferred mid-speed voltage.

3. Set the throttle to the maximum speed step, and then increase the value of CV 5 until

the model responds according to your preferred high-speed voltage level.

Use the 3-Point Speed Curve

The figure shown below gives an example of how CVs 2, 5, and 6 can be used to change

voltage levels during operation.

Tsunami2 Steam User’s Guide 24

Page 25

Basic Programming

Setting the Custom Speed Table

Tsunami2 offers a custom speed table with 28

adjustable speed points. The 28-point custom

speed table is disabled by default. However,

you can enable it with CV 25 (Speed Table

Enable) and CV 29 (Configuration Data 1), and

then adjust each speed point with CVs 67-94

(Custom Speed Table). This allows you to

speed-match one locomotive to another, set a

prototypical speed range, compensate for

design flaws in the driveline, or improve

switching operations by setting more speed

steps to lower speeds and fewer speed steps

to higher speeds.

CVs 67-94 correspond to speed points 1-28.

Table D shows default values for CVs 67-94,

which create a linear speed table when the

custom speed table is enabled. Enter values

from 0 to 255 into CVs 67-94 adjust each

speed point from 0% to 100% of the maximum

throttle setting.

The decoder interpolates between speed steps

for more refined throttle control when 28/128

speed-step mode is active. Each speed point

of the custom speed table corresponds to a

number of speed steps. In 14 speed-step

mode, each speed point is equivalent to 0.5

speed steps. In 28 speed-step mode, each

speed point is equivalent to one speed step. In

128 speed-step mode each speed point is

equivalent to 4.5 speed steps.

Note: All 28 speed points of the custom speed table must be set when using 14, 28, or 128

speed-step mode to prevent an unpredictable response from the motor when accelerating and

decelerating.

Follow the steps below in reference to Table D to enable the 28-point custom speed table and

adjust each speed point with CVs 67-94:

Table D. 28-Point Speed Table Settings

CV Value % of Throttle

67 9 4

68 18 7

69 27 11

70 36 14

71 45 18

72 55 22

73 64 25

74 73 29

75 82 32

76 91 36

77 100 39

78 109 43

79 118 46

80 127 50

81 137 54

82 146 57

83 155 61

84 164 64

85 173 67

86 182 71

87 191 75

88 200 78

89 209 82

90 219 86

91 228 89

92 237 93

93 246 96

94 255 100

1. Designate each speed point of the 28-point speed table as a percentage from 0% to

100% of the maximum speed.

2. Enter each speed point’s percentage into the equation below to determine values for

CVs 67-94:

CV Value = 255 × (% ÷ 100)

3. Enter CV values for speed points 1-28 into CVs 67-94 to configure the 28-point custom

speed table.

4. Set bit 4 (STE) of CV 29 to 1 to enable speed tables.

5. Enter a value of 16 into CV 25 to enable the 28-point custom speed table.

Tsunami2 Steam User’s Guide 25

Page 26

Basic Programming

Setting Motor Trim

CV 66 (Forward Motor Trim) and CV 95 (Reverse Motor Trim) are used to “trim” the forward and

reverse drive voltages when the 28-point custom speed table is enabled. Setting motor trim can

help compensate for speed differences between forward and reverse directions. For instance, if

the throttle setting is the same in both directions and the locomotive appears to be moving faster

in reverse, you can use CVs 66 and 95 to correct the speed difference.

Entering values from 0 to 255 into CVs 66 and 95 will multiply

the forward and reverse drive voltages by a scaling factor. Enter

values from 1 to 127 to decrease speed. Enter values from 129

to 255 to increase speed. Entering a value of 0 or 128 into CVs

66 and 95 will set the scaling factor to 1 and will not modify the

decoder’s drive voltage.

Note: Bit 4 (STE) of CV 29 (Configuration Data 1) must be set to

1 for the motor trim scaling factors in CVs 66 and 95 to modify

forward and reverse drive voltages.

Motor Trim Values

0 = Disabled

1 = Voltage × 0.008

↓

127 = Voltage × 0.99

128 = Disabled

129 = Voltage × 1.008

↓

255 = Voltage × 1.99

Tsunami2 Steam User’s Guide 26

Page 27

Basic Programming

Configuring Lighting Outputs

Tsunami2 provides up to six lighting outputs (depending on

the board format). Lighting output control CVs allow you to

enable Hyperlight effects, Grade-Crossing Logic, phase offset,

and LED Compensation Mode for each lighting output,

determine lighting output direction, adjust the flash rate of

flashing Hyperlight effects, and set lighting output brightness

levels.

Enabling Hyperlight Effects and Features

You can use CVs 49-54 to enable Hyperlight lighting effects

and features for the headlight, backup light, and FX3-FX6

lighting outputs. This section details each Hyperlight effect

and feature and shows you how to customize lighting outputs

to fit your operating preferences.

On/Off Output

The on/off lighting effect provides on/off control for the

corresponding function.

Dimmable On/Off Headlight

The output set to the dimmable headlight will be

reduced to the brightness setting in CV 63 when you

turn on the dimmer function (F7 by default).

Mars Light

This effect replicates the famous figure-eight sweep

pattern of the Mars Light warning beacon.

Pyle-National Gyralite

The Pyle-National Gyralite is similar to the Mars Light,

but oscillates in a circular or elliptical pattern.

Oscillating Headlight

The dual-oscillating headlight generates two beams

that follow each other in a tight, circular sweep pattern.

Single-Flash Strobes 1 and 2

The xenon single-flash strobe 1 effect flashes once

during each flash rate timing cycle. The xenon singleflash strobe 2 flashes once during each flash rate

timing cycle, but at a slightly faster rate.

Double-Flash Strobe

The xenon double-flash strobe effect emits two rapid

flashes of light during each flash rate timing cycle. CV

59 is used to modify the flash rate timing cycle.

Table E. Hyperlight Effect Select

Value Lighting Effect

0 On/Off Output

1 Dimmable On/Off Headlight

2 Mars Light

3 Pyle-National Gyralite

4 Oscillating Headlight

5 Single-Flash Strobe 1

6 Double-Flash Strobe

7 Western-Cullen Rotary Beacon

8 Prime Stratolite

9 Ditch Light I

10 Ditch Light II

11 FRED

12 Engine Exhaust Flicker (Steam)

13 Firebox Flicker (Steam)

14 Smart Firebox Flicker (Steam)

15 Dyno-Light (Steam)

16 Auto-Dim Forward

17 Auto-Dim Reverse

18 Brake Light

19 On/Off – Brightness 1

20 On/Off – Brightness 2

21 Emergency Gyralite

22 Electrical Arcing (Electric)

23 Ash Pan Flicker (Steam)

24 Reserved

25 Single-Flash Strobe 2

+32 Phase Offset (Phase B)

+64 Grade-Crossing Logic

+128 LED Compensation Mode

Lighting Output Control CVs

CV 49: Headlight Configuration

CV 50: Backup Light Configuration

CV 51: FX3 Configuration

CV 52: FX4 Configuration

CV 53: FX5 Configuration*

CV 54: FX6 Configuration*

CV 57: Forward Direction Enable

CV 58: Reverse Direction Enable

CV 59: Hyperlight Flash Rate

CV 60: Grade-Crossing Hold Time

CV 61: Brightness Register 1

CV 62: Brightness Register 2

CV 63: Dimmer Level

CV 64: Master Brightness Level

*Available on select formats

Tsunami2 Steam User’s Guide 27

Page 28

Basic Programming

Western-Cullen D312 Rotary Beacon

The Western-Cullen D312 Rotary Beacon effect follows a revolving reflector and bulb assembly

flash-pattern.

Prime Stratolite

The Stratolite is a new version of the rotary beacon. Four individual lamps are arranged in a

circular pattern and flash electronically in the clockwise direction. The Stratolite flashes in a

mechanical “stepped” fashion, unlike the smooth motion of the rotary beacon.

Ditch Lights I and II

Ditch lights I and II flash together by default. When Grade-Crossing Logic is enabled, ditch light I

assumes a steady “on” state before and after the crossing hold timer countdown. Conversely,

ditch light II will remain off before and after the crossing hold timer countdown. To configure

alternating ditch lights, set one lighting output to ditch light I or II and enable Grade-Crossing

Logic, and then set a second lighting output to the same ditch light and enable Grade-Crossing

Logic and phase offset.

FRED (Flashing Rear End Device)

The FRED effect is a flashing red taillight that indicates the rear of the train.

Exhaust Flicker

This effect produces a random flicker whose intensity increases with locomotive speed. This

effect is best used by placing a red/orange LED in the exhaust stack. As the locomotive

increases speed, it will glow brighter, imitating an increase in sparks and exhaust gases.

Firebox Flicker

This effect produces a random flicker whose intensity resembles a burning fire and can be used

with a lamp placed in the firebox area. The effect is improved when two lights are used, one

yellow and one red or orange and each connected to a separate function output.

Smart Firebox Flicker

This effect produces a random flicker whose intensity is synchronized with the sound of Fireman

Fred shoveling coal. Whenever Fred ‘opens’ the firebox door and begins shoveling, the lighting

effect increases in brightness and then returns to a subdued level when the firebox doors are

‘closed’.

Dyno-Light

The Dyno-light effect synchronizes the lamp brightness with the output of the dynamo to

simulate the spool-up and shut off of the dynamo, and the heating and cooling of the bulb

filament. The brightness increases as the dynamo heats up and decreases as it cools down.

Auto-Dim Forward and Reverse

The auto-dim forward effect will automatically dim lighting outputs to the dimmer level in CV 63

when in the forward direction, and the auto-dim reverse effect will automatically dim lighting

outputs to the dimmer level in CV 63 when in the reverse direction.

Brake Light

The brake light effect is dimmed to the brightness setting in CV 63 when active. The brake light

brightness level will be automatically set to 100% when you turn on the independent or train

brake function (F11 by default).

Tsunami2 Steam User’s Guide 28

Page 29

Basic Programming

On/Off Brightness 1 and 2

The on/off brightness 1 and 2 effects will set lighting outputs to the brightness levels of CVs 61

and 62, respectively.

Emergency Gyralite

The emergency Gyralite follows the same oscillating sweep pattern as the Gyralite, and will

automatically disable all active lighting effects.

Ash Pan Flicker

The ash pan flicker effect slowly flickers from 25% to 100% brightness to simulate the glowing

embers that filter into the ash pan from the firebox.

Phase Offset

Add a value of 32 to the value of flashing Hyperlight effects to set the corresponding lighting

output to Phase B from Phase A. Flashing effects set to Phase B will flash opposite of flashing

effects set to Phase A, i.e., Phase A turns off when Phase B turns on, and Phase A turns on

when Phase B turns off.

Grade-Crossing Logic

Grade-Crossing Logic allows you to set up lighting

functions, the bell, and whistle to automatically

simulate encountering grade crossings. Add a

value of 64 to enable Grade-Crossing Logic.

Turning on the long whistle function (F2 by

default) or the grade-crossing signal function (F9

by default) will start the crossing hold timer

countdown and allow lighting effects to assume a

flashing state. Shown in Table F, flashing

Hyperlight effects will return to an on or off state

after the countdown ends. Practice activating

Grade-Crossing Logic as your locomotive

approaches a grade crossing. You can adjust the

crossing hold timer countdown from 0 to 15

seconds by entering a value from 0 to 15 into CV

60 (Grade-Crossing Hold Time).

To allow the bell to ring during the crossing hold timer countdown, enable the grade-crossing

bell in CV 122 (Bell Select). Refer to “Configuring Sound Effects” for more information about the

grade-crossing bell.

LED Compensation Mode

The brightness of an incandescent bulb is determined by voltage, whereas an LED’s brightness

is determined by current. LED Compensation Mode alters the method of sending current to the

LED to balance the LED and incandescent brightness levels. Add a value of 128 to enable LED

Compensation Mode for the corresponding lighting output.

Note: Enabling LED Compensation Mode will not change the output voltage. Resistors may still

be necessary depending on the board format.

Table F. Flashing Effect On/Off State

Hyperlight Effect On/Off State

Mars Light On

Gyralite On

Oscillating Headlight On

Single-Flash Strobe 1 Off

Single-Flash Strobe 2 Off

Double-Flash Strobe Off

D312 Rotary Beacon Off

Prime Stratolite Off

Ditch Light I On

Ditch Light II Off

FRED Off

Tsunami2 Steam User’s Guide 29

Page 30

Basic Programming

Adjusting Lighting Output Settings

After configuring Hyperlight effects and features with CVs 49-54, adjust CV 57 (Forward

Direction Enable), CV 58 (Reverse Direction Enable), CV 59 (Hyperlight Flash Rate), CV 61

(Brightness Register 1), CV 62 (Brightness Register 2), CV 63 (Dimmer Level), and CV 64

(Master Brightness Register) to customize lighting output direction, the Hyperlight flash rate, and

brightness levels.

Enable Lighting Output Direction

CV 57 determines the lighting outputs active in the forward

direction, and CV 58 determines lighting outputs active in the

reverse direction. Table G shows values used to enable

lighting outputs for the forward and reverse directions. To

enable lighting outputs for the forward direction, add the

values of your preferred lighting outputs and enter the sum

into CV 57. To enable lighting outputs for the reverse

direction, add the values of your preferred lighting outputs

and enter the sum into CV 58.

The headlight is disabled in the reverse direction and the backup light is disabled for the forward

direction by default, i.e., CV 57 is set to 61 by default and CV 58 is set to 62 by default.

Set the Hyperlight Flash Rate

Adjust the flash rate of flashing Hyperlight effects from the fastest setting to the slowest setting

by entering a value from 0 to 15 into CV 59.

Adjust Brightness Registers 1 and 2

Adjust the brightness level of lighting outputs set to the on/off brightness 1 effect from 0% to

100% by entering a value from 0 to 255 into CV 61. Adjust the brightness level of lighting

outputs set to the on/off brightness 2 effect from 0% to 100% by entering a value from 0 to 255

into CV 62.

Adjust the Dimmer Level

Adjust the brightness level of the dimmer function (F7 by default) from 0% to 100% by entering

a value from 0 to 255 into CV 63. The dimmer level is set to 60% brightness by default.

Adjust the Master Brightness Level

Adjust the brightness level of all lighting outputs from 0% to 100% by entering a value from 0 to

255 into CV 64. CV 64 adjusts the brightness levels of lighting outputs set to on/off brightness 1

or on/off brightness 2 from the brightness levels of CV 61 and CV 62, respectively. This does

not eliminate the need for resistors. Due to the nature of certain lighting effects, values below

100 may diminish its overall effectiveness.

Example: Gyralite with Grade Crossing Logic and Firebox Flicker

This example details using CV 51 (FX3 Configuration) and CV 52 (FX4 Configuration) to enable

a Gyralite effect with Grade-Crossing Logic and a Firebox Flicker effect. Follow the steps below

to set the FX3 lighting output to an on/off output with a Gyralite effect in Grade-Crossing logic

and the Firebox Flicker effect to FX4.

Table G. CVs 57-58 Values

Lighting Output CV Value

Headlight +1 to enable

Backup Light +2 to enable

FX3 Output +4 to enable

FX4 Output +8 to enable

FX5 Output +16 to enable

FX6 Output +32 to enable

1. Add the CV values for Grade-Crossing Logic (64) and Gyralite effects (3):

64 + 3 = 67

2. Enter a value of 67 into CV 51 to set the FX3 lighting output to a Gyralite and enable the

Grade-Crossing Logic. Add a value of 128 for LED Compensation Mode, if using LEDs.

Tsunami2 Steam User’s Guide 30

Page 31

Basic Programming

3. Enter a value of 13 into CV 52 to set the FX4 lighting output to Firebox Flicker effect.

Add a value of 128 for LED Compensation Mode, if using LEDs.

Now “light off” the fire in the firebox by turning on F24 (by default) and watch the intensity of the

fire change as fuel is burned.

Next, turn on F25 (by default) to enable the FX3 output. It will remain in a steady “on” state until

your locomotive approaches a grade crossing and the long whistle function (F2 by default) is