Page 1

Tsunami™ Digital Sound Decoder

Steam Sound

User’s Guide

Software Release 1.00

Rev. B 1/13//06

Page 2

Notice

The information in this document is subject to change without notice.

SoundTraxx (Throttle Up!) shall not be liable for technical or editorial errors or omissions contained herein; nor for incidental or consequential dam

ages resulting from the furnishing, performance or use of this material.

This document contains information protected by copyright. No part of this document may be photocopied or reproduced in any form without the

prior written consent of Throttle Up! Corp.

-

Product names mentioned herein may be trademarks and/or registered trademarks of their respective companies.

SoundTraxx, Tsunami, SoundTraxx DCC, Digital Sound Decoder, Dynamic Digital Exhaust, Auto-Exhaust and Hyperlight are

trademarks of Throttle Up! Corp.

Page 3

Table of Contents

All Aboard! ...........................................................................1

Overview ................................................................................................1

Operation .............................................................................2

Using Your Tsunami Digital Sound Decoder ..........................................2

Basics of Programming ......................................................6

Programming the CVs ...........................................................................6

Step 1: Configuring the Address ..........................................................13

Step 2: Configuring the Decoder .........................................................15

Step 3: Configuring the Throttle ...........................................................17

Step 4: Configuring for Consist Operation ........................................... 21

Step 5: Function Mapping ...................................................................24

Step 6: Configuring the Lighting Outputs ............................................30

Sound Programming .........................................................35

Step 7: Modifying the Sound Effects ................................................... 35

Advanced Programming ...................................................50

Step 8: Configuring the Dynamic Digital Exhaust ................................ 50

Step 9: Setting up the Hyperdrive .......................................................57

Step 10: Configuring Tsunami’s Miscellaneous Features ....................61

Troubleshooting ................................................................68

Appendix A - Decimal-Hex-Binary Conversion ...............

Appendix B - List of Configuration Variables .................

71

72

Appendix C - License Agreement ....................................72

Page 4

Overview

All Aboard!

Congratulations on the purchase of your SoundTraxx™ Tsunami™ Digital

Sound Decoder™. This User’s Guide will walk you through the various

aspects of programming your Tsunami decoder, as well as some tips on

troubleshooting. For the power user, the Tsunami Technical Reference will

provide a list of all the CVs available for use with Tsunami decoders and their

exact function and make-up for those who wish to have a complete reference

for advanced programming techniques.

Technical Bulletins and Application Notes covering various topics are also

published from time to time, and these may be downloaded free of charge

from our website at www.soundtraxx.com.

Tsunami Steam Sound User’s Guide Page 1

Page 5

Operation

Using Your Tsunami Digital Sound Decoder

Your SoundTraxx Tsunami has been shipped with all CVs pre-programmed

so you can begin using your locomotive immediately without having to worry

about what adjustments to make. Function Assignments are as follows:

Steam Decoders

Function Key Effect

F0 Headlight/Backup Light/Dynamo

F1 Bell

F2 Whistle

F3 Short Whistle

F4 Steam Release

F5 FX5 Output

F6 FX6 Output

F7 Dimmer

F8 Mute the Sound

F9 Water Stop

F10 Injectors

F11 Brake Squeal/Release

F12 Coupler Clank

Direction Button Johnson Bar

Throttle Exhaust Chuff, Snifter Valve

While these are the default settings, you may wish to make changes to the

function mapping later. For now, simply set your controller to Locomotive 3,

place the locomotive on the mainline and away you go! Now that you have

control of your decoder, let’s see what happens!

Turn on the Lights

Press F0 on your cab to turn on the Headlight. As you turn on the headlight,

the dynamo will ‘spool up’ in an accelerating whine until it reaches full power,

when it will sound more like a soft buzz – can’t have lights without turning on

the generator now can you? Reverse locomotive direction and the headlight

turns off as the backup light turns on.

If you have wired your Tsunami decoder for Functions 5 and/or 6, pressing

these keys will activate these effects. While waiting on a siding, you can

press F7 to dim the headlight for an oncoming train.

Ring the Bell

Engineers are required to ring the bell during yard movement. To ring the

bell, press F1 on your cab. This is an on/off function, i.e. once on, the bell will

continue to ring until you turn it off. Press F1 again to turn it off.

Tsunami Steam Sound User’s Guide Page 2

Page 6

Tsunami Steam Sound User’s Guide Page 3

Operation

Whistle Signals

Note: � = Short Blast — = Long Blast

— — � — Approaching Grade Crossing. (Hold final blast until crossing

is reached.)

�

— Approaching a bridge or tunnel

� Stop, set brakes

— — Release brakes and proceed forward

� � � Backup

� � � � Request signal from Trainman

— � Warning whistle, used when approaching points where

view is obstructed.

Blow the Whistle

Engineers are required to blow various whistle signals to warn of the

approaching train as well as notify both passengers and train crew to the

planned movement of the locomotive. Some of these are signals for grade

crossings, stopping, moving forward, backing up and more.

Learning and using the various whistle signals can add a lot of fun to your

operating sessions! Some of the more common signals are indicated here.

To activate the Whistle, press F2 on your cab: the longer you press the key,

the longer the whistle will blow. While this allows you to make short or long

signals, F3 is designated as a ‘short’ whistle so your shorts will have that

nice, crisp, ‘toot’ regardless of how responsive your cab controls are…try a

grade crossing whistle!

Blow Down the Boiler

If your steam engine’s been sitting in the station awhile, there’s bound to be

some particle buildup in the boiler. Press the F4 key to open the blowdown

valve and blow out the sediment. Press the F4 key again to close the

blowdown valve.

Automatic Steam Sound Functions

Some sound effects happen in response to an action other than pressing a

function key. The blowers will automatically simmer in the background to help

vent the steam and keep up a good draft.

Airpumps

Brakes on trains operate using air pressure. When the engineer activates

the brakes, he is releasing air pressure, forcing the brake shoes against the

wheels and causing the train to slow down. When the engine stops the air

pressure is build up using a compressor, also called an airpump. The air

pumps will pound out a steadily slowing cadence that simulates the build up

of air pressure in the main reservoir. Deceleration of the locomotive while

applying the brakes will cause the air pump to resume pumping.

Tsunami Steam Sound User’s Guide Page 3

More Automatic Sound Functions on Next Page

Page 7

Operation

Snifter Valve

Just as you start to move the engine, you’ll hear the Pffffffft! of the snifter

valve.

Johnson Bar

Changing the locomotive direction will automatically activate the sound of the

Johnson Bar being thrown one way or the other.

Fireman Fred

Each time the engine is brought to a stop, Fireman Fred may attend to a

randomly selected task (or tasks), including shoveling coal, oiling the side

rods, and more.

Exhaust Chuff and Rod Clank

The exhaust chuff and rod clank sounds are automatically generated

whenever the locomotive is set into motion. Both effects may be optionally

synchronized to a cam (see page 44) and may also be configured to vary

in volume in response to load changes using Tsunami’s Dynamic Digital

Exhaust setting (see page 54).

Activating other Functions and Effects

Depending on the number of function keys provided on your cab, you might

have additional functions immediately available for you to activate.

Mute the Sound

Pressing F8 on all Tsunami decoders will gradually mute all sound effects

- great for a quick answer of the telephone! Pressing it a second time will

allow you to hear the sounds again.

Water Stop

All steam engines require water! The Water Stop initiates a sequence of

events beginning with the fireman opening a rather squeaky water hatch,

followed by the sound of water filling the tender. This effect is activated when

the engine is stopped by pressing F9 and can be stopped by pressing F9

again. If the locomotive is started while the effect is running, the effect will

automatically turn off.

Injector

The injector delivers feed water to the boiler. Pressing F10 on all Tsunami

decoders will turn on the sound of the injector. Pressing it a second time will

turn the injector off.

Brake Squeal/Release

The sound of the brakes squealing is typically heard just before the wheels

of the locomotive stop turning. Pressing F11 when the engine is moving will

initiate a brake squeal effect. Press F11 again to turn this feature off.

Tsunami Steam Sound User’s Guide Page 4

Page 8

Tsunami Steam Sound User’s Guide Page 5

Operation

Coupler Clank

Pressing F12 will activate the coupler clank sound effect, see how well you

can time the effect to the actual coupling of the locomotive to the train!

As you see, no programming is necessary to begin enjoying your DSD!

However… after you have had a chance to play with your decoder for a little

while, you may wish to make some changes such as selecting a new address

or altering a sound effect. The following section will introduce you to CVs and

how and why you might wish to change them.

Tsunami Steam Sound User’s Guide Page 5

Page 9

Basics of Programming

Programming the CVs

What is a CV?

CV stands for Configuration Variable, which is the industry-adopted term

for a decoder’s user-programmable memory locations. CVs allow you to

customize individual decoder properties such as the address, momentum,

throttle response, sound volume and much more. Once a CV has been

programmed, the setting will be permanently remembered even after the

power has been turned off. A CV can be modified as often as necessary by

simply reprogramming it with a new value.

With the large number of CVs available, first inspection of the available

options may cause confusion and little panic! Relax. As you have already

seen the DSD has been shipped with all CVs pre-programmed so you can

begin using your locomotive immediately without having to worry about what

adjustments to make.

The following paragraphs break the sound decoder’s CVs into various

subsystems so it is only necessary to change a few CV’s at a time. As you

become comfortable with it’s operation, move onto a new section and begin

exploring the options and capabilities found there. For more technically

inclined users, detailed information on any CV can be found in the Tsunami

Technical Reference.

Bits and Bytes

One of the most confusing aspects of programming a CV is figuring out what

all the different bits, bytes and x’s found in the various decoder manuals

mean. The problem is compounded further by differences in each command

station manufacturer’s user interface. For users unfamiliar with such terms, a

short math lesson (ugh!) is in order before proceeding:

Each decoder CV stores a numeric value that can be represented in one of

three forms:

Decimal - This is the form everyone is familiar with and we use in our day-today lives. Numbers are represented as a sequence of digits composed of the

numerals 0,1,2,3,4,5,6,7,8, and 9.

Hexadecimal - Also referred to as simply “hex”, this is a more specialized

number representation that, in addition to 0 through 9, also uses the

characters A-F. It has the advantage that a given decimal number can be

more compactly represented. For example, the decimal number 127 converts

to a simple 7F in hex (one less digit). This allows user interfaces with a

limited number of digits (i.e., the LCD on your cab) to display a wider range of

numbers.

Binary - Binary numbers get their name from the fact they use only two

digits 0 and 1 called ‘bits’ and is the fundamental number system used by all

computers including the ones found inside a digital decoder. Because there

Tsunami Steam Sound User’s Guide Page 6

Page 10

Tsunami Steam Sound User’s Guide Page 7

Basics of Programming

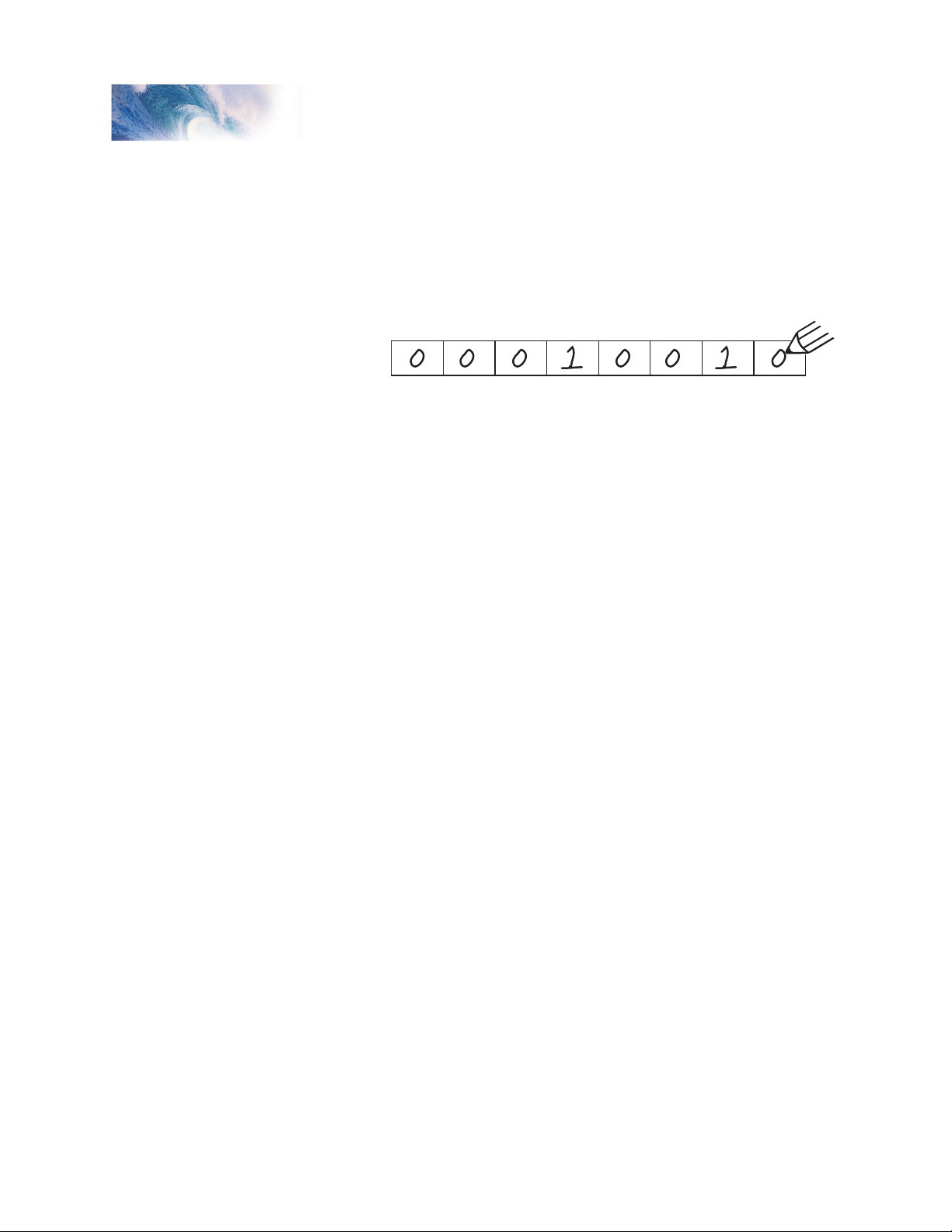

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

are only two bit values, it takes more digits to represent a number using

binary. The decimal number 127, for example, is written as 01111111 in binary

notation. A ‘byte’ is a binary number made up of eight bits. And a ‘nibble’ is

half a byte or four bits. Really! We didn’t make that up.

Coincidentally, each CV is made up from one byte or eight bits and can store

any number between 0 and 255. Most of the CVs contain a single piece of

data that can be easily represented in any of the three forms, i.e., CV 3, the

acceleration rate, can be loaded with any value from 0 to 255 and it always

affects the same thing - the acceleration rate.

On the other hand, some CVs use individual bits to control different features.

This allows up to eight individual features to be controlled by a single CV and

is done to conserve the number of CVs. As the bit variables can take on only

one of two values (0 and 1) they are usually used for simple variables that

are either On or Off, enabled or disabled or something similar. Unfortunately,

bit variables are difficult to represent in any form other than binary and still

preserve any meaning. Because most DCC system user interfaces don’t use

binary representation, these numbers are the most difficult to work with and

require a tedious series of additions to convert to the decimal or hex form

used by most systems.

We have tried to use the decimal number system in this manual when

describing the proper values to program into a given CV; however, you will

occasionally find values listed in the Technical Reference in binary, hex and

decimal values. Hex numbers can be distinguished from a decimal number

by noting a 0x prefix. Thus 0x10 is the hex version of sixteen and not ten as

one might guess. Binary numbers are represented using a ‘b’ suffix. 100b

is really the number four and not one hundred. To further assist the mathimpaired, we have provided a handy-dandy conversion table in Appendix A

that allows one to quickly convert between decimal, hex and binary.

When working with individual bits such as in CV 29, we suggest the following

procedure for determining the correct value to program. Referring to the CV

description, write down the value desired for each individual bit. Consider

for example, the case of CV 29. We would like to set this CV so that speed

tables are enabled and the 28 speed-step mode is in effect. Referring to the

Technical Reference, we see that bit 4 and bit 1 should be set to 1 and all

other bits are cleared to zero. Remembering that we are dealing with binary,

write down the individual bit values and we get:

We then look up the binary value 00010010b in Appendix A and see that it

corresponds to the decimal value 18 (0x12 in hex). This is the value to use

when programming the CV.

Tsunami Steam Sound User’s Guide Page 7

Page 11

Basics of Programming

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

When bit is

set to 1, value = 128 64 32 16 8 4 2 1

Therefore: 0 + 0 + 0 + 16 + 0 + 0 + 2 + 0 = 18

If you don’t have the conversion chart available, you can also calculate

the value in the following manner. Reading from right to left, each bit has a

decimal value associated with it, beginning with a 1 and doubling this value

as you go from bit 0 to bit 7. This value is only counted when the bit is a ‘1’.

Looking at the figure below, you can see that using this method, bit 1 has a

value of 2 and bit 4 has a value of 16. Adding these two numbers together

gives the correct decimal value of 18.

Programming Methods

There are two methods for changing the sound decoder’s CVs:

Service Mode Programming - This programming mode usually requires the

locomotive to be placed on a special programming track or connected to a

dedicated programmer. Tsunami is an advanced line of decoders and support

four types of service mode instructions:

Address Mode - Can change CV 1 (Primary Address) only.

Register Mode - Can change CVs 1,2,3,4,7,8 and 29 only.

Paged Mode - Uses a page register to indirectly modify any CV.

Direct Mode - Can directly change any CV.

Operations Mode Programming - Sometimes called ‘Ops Mode’ or

‘Programming on the Main’, this programming mode allows the CVs to be

changed while the locomotive is operating on the layout even when other

locomotives are present. The neat thing about this mode is that the CVs can

be changed in the middle of operation allowing the engineer for example, to

increase the momentum rate of a locomotive after it couples to a train. The

main disadvantage of operations mode programming is that the CV data

cannot be read back to verify its value.

Reading CVs

Certain command stations also allow you to read a CV during Service

Mode Programming, which is useful to verify its current setting. If you have

trouble reading or verifying CVs, the problem may be due to the design

of your command station and not the DSD itself. Tsunami and all other

decoders communicate back to the command station using what’s called an

acknowledgment pulse, which is defined in NMRA RP-9.2.3 as “an increased

load on the programming track of at least 60mA for at least 5ms.” Like most

decoders, the DSD generates the acknowledgment pulse by momentarily

applying power to the motor. You can often visually verify that the Tsunami is

properly responding to your programmer by observing a slight twitch in the

Tsunami Steam Sound User’s Guide Page 8

Page 12

Tsunami Steam Sound User’s Guide Page 9

Basics of Programming

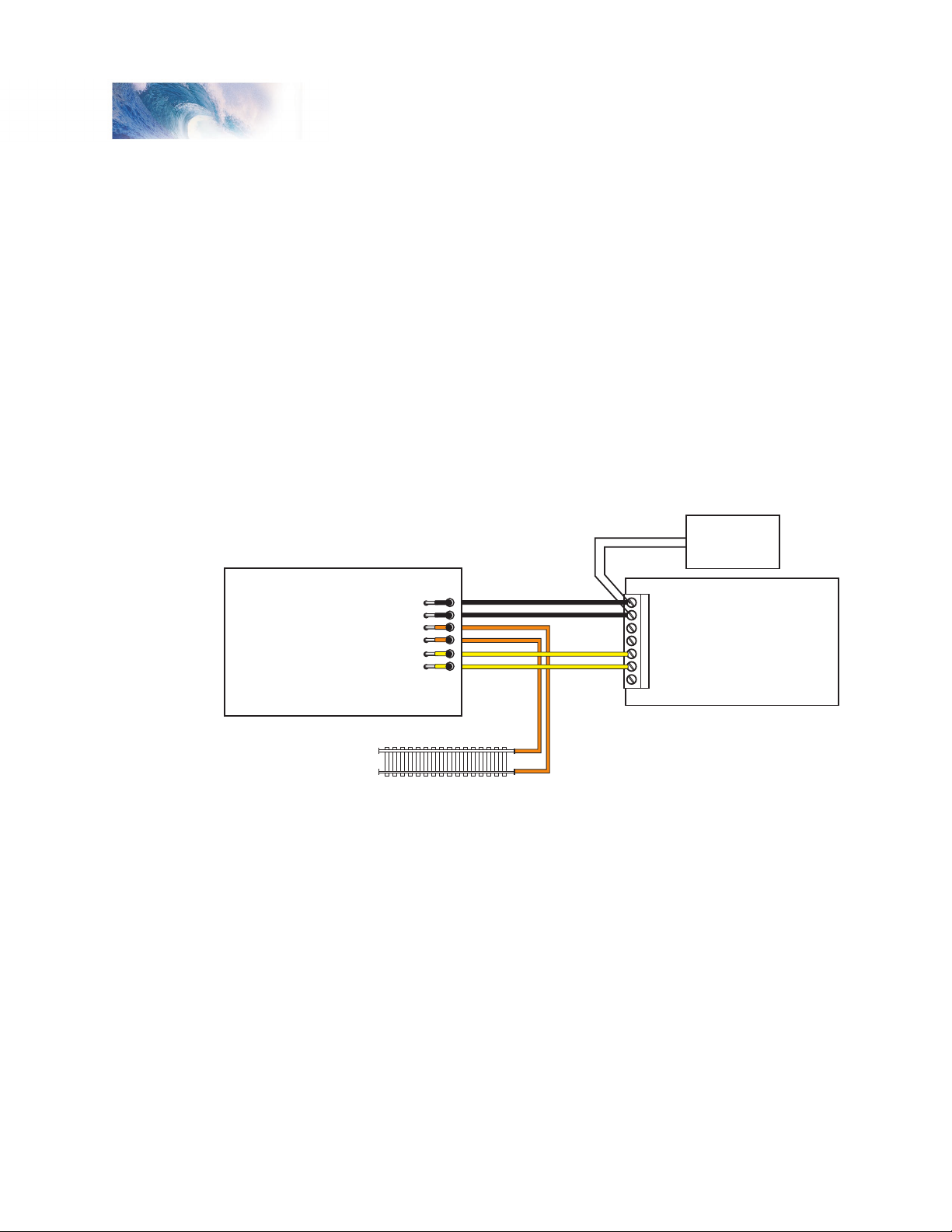

Power In

Po

wer In

Programming Track Output

Programming Tr

ack Output

Programming Track

To Programming Track

COMMAND

STATION

POWER

SUPPLY

COMMAND

STATION

PTB-100

BLACK

BLA

CK

ORANGE

ORANGE

YELLOW

YELLOW

motor shaft when a read or write command is given.

If your DSD is otherwise working properly (i.e., responds properly on the

mainline to speed and direction commands) but your command station

is having troubles reading CV data from the DSD, it may be due to

incompatibilities between the electrical requirements of the DSD (which are

different from conventional decoders due to the added audio circuitry) and

the electrical characteristics of your programming track. In such an event,

we suggest you simply go ahead and program the data into the CVs anyway.

Usually the DSD will accept the data and function properly when placed back

on the main track.

Another option is to use a Programming Track Booster, such as SoundTraxx

PTB-100 (P.N. 829002). The PTB-100 amplifies the programming track

signals to levels that work best with Tsunami. It is easy to install (see below)

and inexpensive. An advantage to using the PTB-100 is that it also provides

short circuit detection and some helpful diagnostics. It works well with all

other SoundTraxx decoders, too.

Figure 1 - General Wiring Diagram for the SoundTraxx PTB-100

Finally, if you continue to experience difficulties, try a different programming

mode. If your system supports it, the best way to program the CVs is

Operations Mode, as it allows you to immediately see or hear the results of

your changes. It is important, however, to realize that not all programming

modes will program all CVs. Additionally, the specific programming mode

you use will depend upon the type of DCC system you are using. Some of

the newer DCC systems can automatically select the proper programming

mode so all you need to do is specify the CV number and its new value. On

the other hand, some systems support only a few of the programming modes

and may restrict which CVs you can program. If in doubt, refer to your DCC

Tsunami Steam Sound User’s Guide Page 9

system’s manual or contact the manufacturer to determine which methods

they support.

Page 13

Basics of Programming

Programming Procedure

As each DCC system is different, the procedure for programming a CV will

vary depending upon the system. Unfortunately, we cannot provide detailed

instructions to cover every command station and have to assume that you

have some level of understanding regarding it’s capabilities and operating

procedures. For specific programming procedures, please consult your DCC

system manual.

Locking and Unlocking CVs

The CV Lock/Unlock is a relatively new feature available in some DCC

decoders which allows you to program a decoder without the danger of

overwriting the programming in another. This especially useful in installations

where multiple decoders are used. For example, if you have installed a

function decoder in addition to the sound decoder, you may wish to lock the

CVs after programming to prevent accidentally programming one or the other.

To use the CV Lock feature implemented in CV 15 and 16, Bit 0 of CV 30

must first be set to 1 (the default value is 0). This is to avoid inadvertently

locking the decoder when the CV Lock feature is not needed.

CV 15 and 16 are used for locking and unlocking the decoder. CV 15 is

the Unlock Code and may be programmed to any value between 0 and

255 regardless of whether the decoder is locked or unlocked. CV 16 is the

Lock Code and may be set to any value between 0 and 7 but only when the

decoder is unlocked. Attempts to program CV 16 with a value greater than 7

will be ignored.

The decoder is unlocked when the value in CV 15 matches the value in CV

16. Otherwise the decoder is locked and can not be programmed in either

operations mode or service mode. Further, a locked decoder can not be reset

to its factory defaults until it is first unlocked. Tsunami decoders are shipped

from the factory with all CVs unlocked, that is, CV 15 and 16 are both set

to 0.

Note that if the decoder is unlocked, changing the value in CV 16 will

instantly lock the decoder. You must then set CV 15 to the same value as

was just programmed into CV 16 to unlock the decoder again.

If you decide to use the CV Locking feature for a multi-decoder installation,

each decoder installed inside that locomotive must first have its Lock Code

in CV 16 set prior to installation of any other decoders. Otherwise, all the

decoders will have the same Lock Code and the feature will not work. The

easiest way to go about this is to first install one decoder and program its

Lock Code. Then install the next decoder and program its Lock Code. Since

the first decoder is now locked it will be unaffected by the programming of

the second decoder (unless you accidentally set the Lock Code of the two

decoders to the same value. If this happens you will need to disconnect one

decoder and start over). Continue in this manner until all decoders have been

installed and their Lock Codes have been set.

Tsunami Steam Sound User’s Guide Page 10

Page 14

Tsunami Steam Sound User’s Guide Page 11

Basics of Programming

It is a good idea to set up a standardized system so you don’t forget the Lock

Code settings. You might, for example, set all motor decoders to a CV Lock

Value of 1, sound decoders to a value of 2 and function decoders to a value

of 3. Keeping CV 15 set to 0 will guarantee the decoder stays locked until

you are ready to begin programming.

Example: Let’s say you will be installing motor decoder, a sound decoder

and a function decoder in one locomotive. Using the previously described

system, you would first install the motor decoder and set its Lock Code by

programming CV 16 to 1. Since CV 15 is currently set to 0 (the default

value), the decoder is immediately locked. Now install the sound decoder

and set its Lock Code by programming CV 16 to 2. Since CV 15 is still set to

0, this decoder is also immediately locked. Now install the function decoder

and set its Lock Code by programming CV 16 to 3. At this point, all three

decoders are installed and locked. Starting with the motor decoder, set CV 15

(the Unlock Code) to 1 to unlock and program the motor decoder. When you

are finished set CV 15 to 2 and program the sound decoder. Finally, set CV

15 to 3 and program the function decoder. When you are done, set CV 15

back to 0 to lock all the decoders.

If You Forget the Lock Code

As there are only eight possible combinations, you can easily determine a

forgotten Lock Code setting using trial and error with the following procedure:

Place the locomotive on the Programming Track and set CV 15 to 0. Then

try to read the value in CV 16. If CV 16 does not read back, the decoder is

locked. Set CV 15 to 1 and try reading CV 16 once more. Again, if CV 16

does not read back, the decoder is still locked. Program CV 15 to 2 and try

reading CV 16 again. Continuing in the manner, you should eventually find

the value stored in CV 16 as it can only be programmed between 0 and 7.

If you have tried setting CV 15 to all eight values between 0 and 7 and the

decoder still does not respond, there may be a problem with the installation,

the program track or the decoder itself and further investigation will be

required.

If you do not have access to a programming track with read-back capabilities

(or are uncertain as to whether it is working properly) you can also use

operations mode to discover the Lock Code by alternately programming CV

15 and setting another CV to a value where there is a known response. For

example, changing CV 128, the master volume control, will provide auditory

feedback as to whether the decoder is unlocked by virtue of a change in

sound level. Thus, you would begin by setting CV 15 to 0 and then setting

CV 128 to 0. If the volume does not fall to zero, the decoder is locked. Then

set CV 15 to 1 and try programming CV 128 again. Repeat this process until

you find a value for CV 15 that results in a change in sound volume as you

change CV 128.

Troubleshooting Tip

Be aware that even if you are not planning to use the CV Lock feature, it

can still be accidentally activated by inadvertently programming CV 15 or 16

with a non-default value. If you have a decoder that is otherwise working

Tsunami Steam Sound User’s Guide Page 11

Page 15

Basic Programming

(i.e., making sound and responding to throttle function commands) but

has suddenly stopped accepting CV changes, then first run through the

procedure under “If you Forget the Lock Code” to determine if the decoder

has been locked.

Resetting the CVs or Starting Over

Occasionally, something goes wrong and Tsunami will not respond as

expected. Usually, this is caused by one or more CVs being programmed to

the wrong value. The CVs can be quickly reset to their factory default values

using the following procedure.

1. Program CV 30 to 2 (or CV 8 to 8) using either Service Mode or

Operations Mode

2. Place locomotive on a powered section of track. If locomotive is already

on the mainline, cycle power to the decoder by turning power to the track

off and then back on.

3. After power is restored to the track there should be no indication of

activity other than the power LED turning on for a period of six seconds.

If sound comes on imediately upon restoring power, the decoder did not

reset. Repeat steps 1 and 2.

4. Once the six-second period has elapsed, the sound should come on

and the headlight, backup light and onboard diagnostic light will blink 16

times indicating that the CVs were successfully reset.

5. Tsunami should now respond to short address 3 just as it did when it was

first unpacked.

6. If you cannot get the decoder to reset, check to see that it has not been

inadvertently locked (see “If You Forget the Lock Code” in the previous

section).

Tsunami Steam Sound User’s Guide Page 12

Page 16

Tsunami Steam Sound User’s Guide Page 13

Basic Programming

Step 1: Configuring the Address

The first group of CVs you will want to change are those that set Tsunami’s

address:

CV 1, Primary Address

CV 17:18, Extended Address

Tsunami may be set up to recognize either the primary address (also called

the short address), which provides a range of 1 to 127 or the extended (long)

address, which has a range of 1 to 9999! Whether you use the primary or

extended address will first depend on whether or not your DCC system uses

extended addressing (not all of them do - if in doubt, see your command

station owner’s manual.) Second, it will depend on your preferences and

the numbering scheme you use for setting your decoder addresses. The

extended address has the advantage that you can use all four digits of

a locomotive’s road number for the decoder address making it easy to

remember. Be aware that some DCC systems do not support the full range of

available addresses.

Primary Address

To use the primary address, simply set CV 1 to the desired address between

1 and 127.

Programming Notes: Both the primary and extended address may be

changed at any time using service mode.

Some DCC systems will also allow the decoder address to be modified using

operations mode programming (consult your system manual for details).

Please note that when programming in operations mode, the following

restrictions apply:

If the decoder’s primary address is enabled (i.e., CV 29, bit 5 is 0),

only the extended address may be changed using operations mode

programming.

If the decoder’s extended address is enabled (i.e., CV 29, bit 5 is 1),

only the primary address may be changed using operations mode

programming.

Extended Address

The extended address is actually made up of two CVs, 17 and 18. Unless

you are an experienced user, you should not try to program these CVs

individually as a specific protocol is required in order for the DSD to accept

the new data (See the Technical Reference for details). Since most command

stations that support extended addressing will automatically generate the

correct protocol, simply follow their instructions for setting the extended

address.

Tsunami Steam Sound User’s Guide Page 13

Page 17

Basic Programming

Once the extended address is stored in CV 17 and 18, bit 5 of CV 29 must

be set to 1 so the decoder will recognize the extended address format.

Otherwise, the decoder will continue to respond only to its primary address.

See the next section, Configuring the Decoder.

Tsunami Steam Sound User’s Guide Page 14

Page 18

Tsunami Steam Sound User’s Guide Page 15

Basic Programming

Bit 7 Bit 0

0 0 EAM STE ACK APS F0 DIR

Step 2: Configuring the Decoder

The next CV you will want to change is CV 29, Decoder Configuration

Byte. CV 29 is one of those complicated bit variables mentioned earlier

and is used in conjunction with other CVs to set a multitude of decoder

characteristics including Locomotive Direction, Speed Step Mode Selection,

Speed Table Enable and Alternate Power Mode Enable.

Locomotive Direction - Causes the decoder to invert direction commands

so that the locomotive runs in reverse when it receives a command to move

forward and vice-versa. This operating mode is most useful for setting up

diesel engines that ran with the long hood section forward. However, it is also

useful for electronically correcting installations where the motor wires were

accidentally reversed and avoids tearing apart the locomotive a second time.

Speed Step Mode Selection - As it is a digital system, Tsunami splits the

throttle voltage over its minimum and maximum range into discrete speed

steps. Tsunami can be configured so there are 14, 28 or 128 individual speed

steps. The largest number of steps will give the smoothest throttle response.

Since not all DCC systems have the ability to control 28 or 128 speed steps,

your choice will depend upon the technical capabilities of your command

station.

Speed Table - Sets the decoder to use the speed table specified by CV 25

(see “Configuring the Throttle”, page 17).

Primary or Extended Address

address in CV 1 or extended address in CV 17:18 (see “Configuring the

Address”, page 13).

Alternate (Analog) Power Mode - Enables the decoder to work with an

alternate power mode (such as DC operation) as set by CV 12 when a DCC

signal is not present.

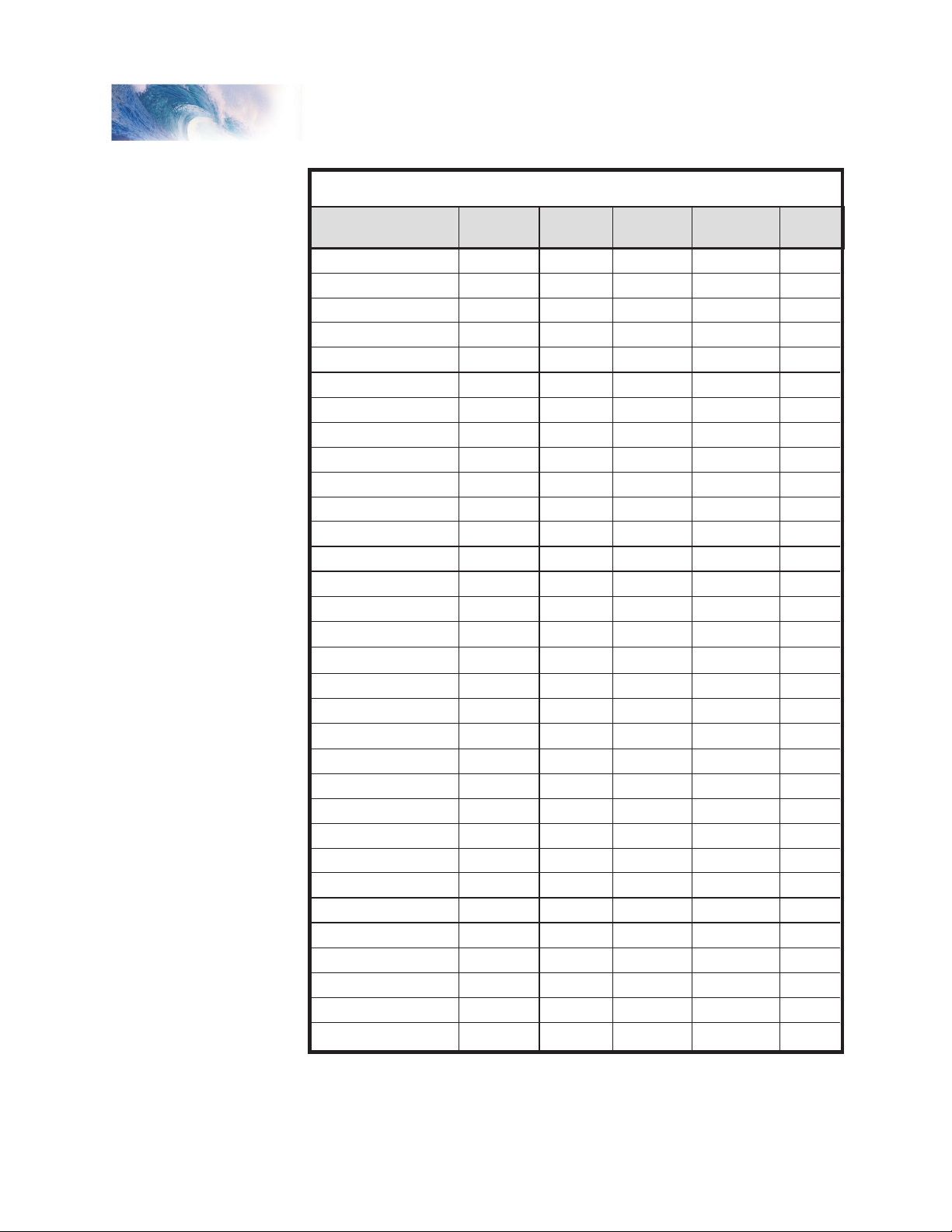

To assist the novice user, we have created Table A on the next page that lists

the correct value for CV 29 to get the desired operating modes.

To use the table, simply find the row that has the modes you want and

program CV 29 with the listed value.

The advanced user should refer to the Technical Reference for more details.

Remember, table values are in decimal. If your command station uses Hex

(Hexadecimal), you will need to convert the value shown using Appendix A.

- Sets the decoder to recognize its primary

Tsunami Steam Sound User’s Guide Page 15

Page 19

Basic Programming

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Primary (CV1)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Extended (CV17:18)

Address Type

14

14

28/128

28/128

14

14

28/128

28/128

14

14

28/128

28/128

14

14

28/128

28/128

14

14

28/128

28/128

14

14

28/128

28/128

14

14

28/128

28/128

14

14

28/128

28/128

Speed

Steps

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Normal

Reversed

Locomotive

Direction

0

1

2

3

4

5

6

7

16

17

18

19

20

21

22

23

32

33

34

35

36

37

38

39

48

49

50

51

52

53

54

55

CV 29

Valu

e

Analog

Mode?

No

No

No

No

Ye

s

Ye

s

Ye

s

Ye

s

No

No

No

No

Ye

s

Ye

s

Ye

s

Ye

s

No

No

No

No

Ye

s

Ye

s

Ye

s

Ye

s

No

No

No

No

Ye

s

Yes

Ye

s

Ye

s

Use Speed

Ta

bles?

No

No

No

No

No

No

No

No

Ye

s

Ye

s

Ye

s

Yes

Ye

s

Ye

s

Ye

s

Ye

s

No

No

No

No

No

No

No

No

Ye

s

Ye

s

Ye

s

Yes

Ye

s

Ye

s

Ye

s

Ye

s

Table A. Quick-Reference Table for CV 29 Values

Tsunami Steam Sound User’s Guide Page 16

Page 20

Tsunami Steam Sound User’s Guide Page 17

Basic Programming

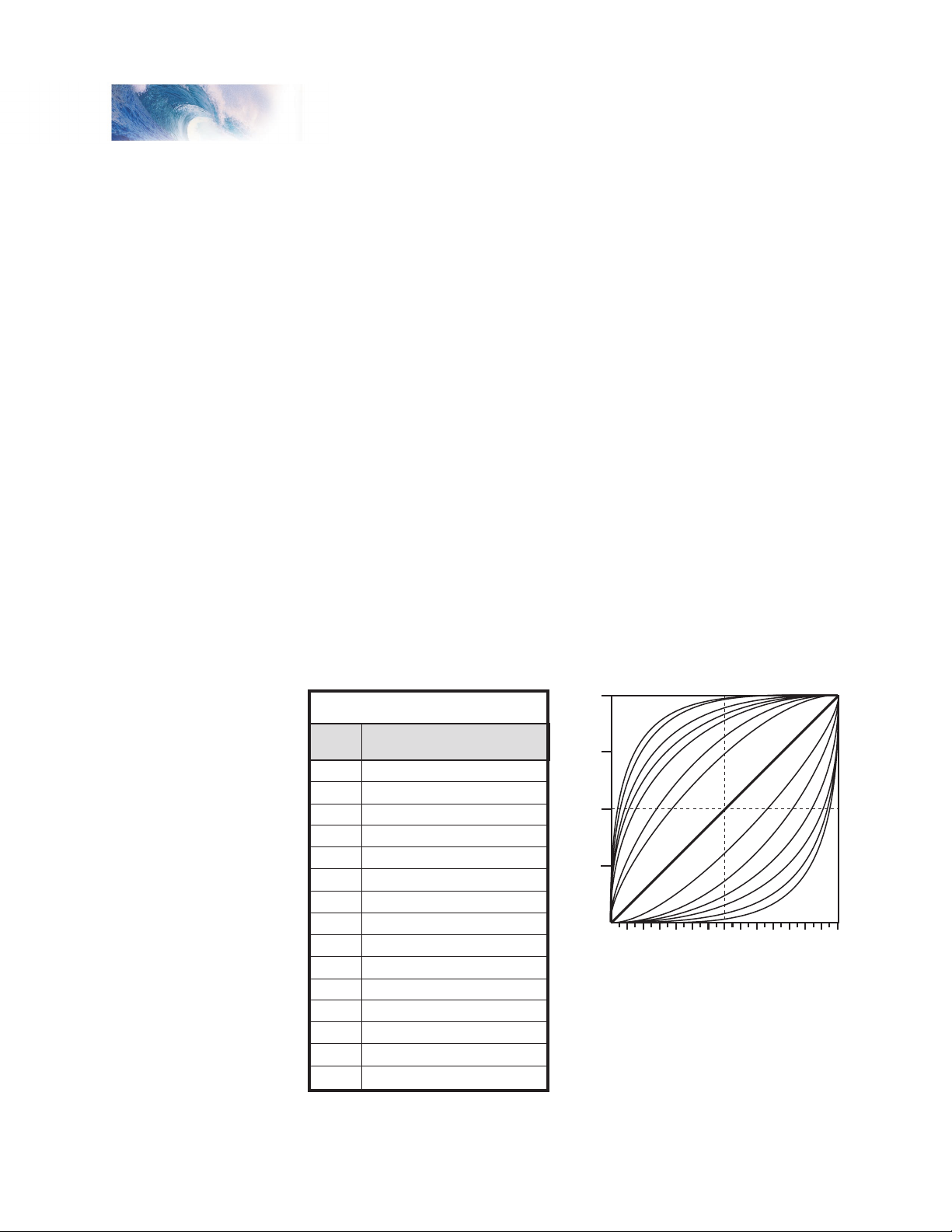

Step 3: Configuring the Throttle

There are seven CVs that characterize the Tsunami’s throttle response and

28 more used to create a custom speed table:

CV 2, VStart

CV 3, Acceleration Rate

CV 4, Braking Rate

CV 25, Speed Table Select

CV 29, Configuration Data

CV 66, Forward Trim

CV 95, Reverse Trim

CV 67-94, Loadable Speed Table

This may sound like a lot of CVs but don’t worry; it’s not necessary to change

all of them if you don’t want to. We’ve already talked about speed step

selection in CV 29 (Step 2).

Set the Start Voltage

Tsunami provides CV 2, Vstart, to set the starting voltage that is applied to

the motor at Speed Step 1 and is used to compensate for inefficiencies in

the locomotive’s motor and driveline. CV 2 may be programmed with any

value between 0 and 255 with each step in value being about 0.5% of the

maximum available motor voltage. To calculate the value of CV 2, you can

use the formula:

Desired Starting Voltage

CV 2 = 255 X ——————————————

Maximum Motor Voltage

If your DCC system supports Operations Mode Programming, an alternative

method for setting Vstart is to turn your throttle to the first speed step and

then use the operations mode programming feature to increase the value in

CV 2 until the locomotive just begins to move.

Set the Acceleration and Braking Rates

Tsunami provides two CVs to simulate the momentum due to train weight.

CV 3, Acceleration Rate, controls how fast the locomotive responds to

increases in throttle settings and CV 4, Braking Rate, controls how fast the

locomotive will respond to decreases in the throttle setting.

Both CVs can be programmed with any value between 0 and 255 with 255

corresponding to the slowest acceleration or braking rate. Lower settings

yield a more responsive locomotive, which is useful for switching. When both

CVs are set to 0, the locomotive will respond nearly instantly to any throttle

changes. A setting of 255, on the other hand, will require several minutes for

a locomotive to reach full speed from a standing stop!

Tsunami’s Dynamic Digital Exhaust feature will be more dramatic if you use

Tsunami Steam Sound User’s Guide Page 17

Page 21

Basic Programming

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CV 25

Speed Curve Type

Straight LIne

Logarithmic Curve 1

Logarithmic Curve 2

Logarithmic Curve 3

Logarithmic Curve 4

Logarithmic Curve 5

Logarithmic Curve 6

Logarithmic Curve 7

Exponential Curve 1

Exponential Curve 2

Exponential Curve 3

Exponential Curve 4

Exponential Curve 5

Exponential Curve 6

User Loadable Speed Table

Table B. Speed Table Selection

100%

75%

50%

25%

0%

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28

LOG

7

LOG

5

LOG

6

LOG

3

LOG

2

LOG

1

LOG

4

LINEAR

EXP

1

EXP

2

EXP 3

EXP

4

EXP

5

EXP

6

Speed Step

Motor Speed

larger values for these CVs; we therefore suggest setting CV 3 and CV 4 to a

minimum value of 16 or higher.

If you are using 14 or 28 Speed Step modes, setting CV 3 and CV 4 to any

value greater than 0 will also improve the Tsunami’s throttle response. While

it is accelerating or braking, Tsunami interpolates between speed steps so

in effect, your locomotive will respond as if it were being controlled with 128

speed steps. No more sudden lurching from one speed step to another!

Select the Speed Table

Tsunami provides 14 preset and one loadable speed table that can be used

for several purposes:

1. Matching the Auto Exhaust chuffing rate to locomotive speed.

2. Speed matching one locomotive to another.

3. Changing the feel of the throttle. For example, you could configure

a switching locomotive so there are more speed steps available at

lower speeds for switching and fewer steps at high speeds where the

locomotive is seldom operated.

4. Compensating for an improperly designed driveline so the locomotive will

operate within its prototypical speed range.

Tsunami Steam Sound User’s Guide Page 18

Preset Speed Tables

CV 25, Speed Table Select, is used to select which speed curve will be used

by the DSD. CV 25 may be programmed with any value between 2 and 15 to

select one of the preset speed curves shown in Table B, below.

Page 22

Tsunami Steam Sound User’s Guide Page 19

Basic Programming

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

CV#

4

7

11

14

18

22

25

39

32

36

39

43

46

50

54

57

61

64

67

71

75

78

82

86

89

93

96

100

% Full

Speed

9

18

27

36

45

55

64

73

82

91

100

109

118

127

137

146

155

164

173

182

191

200

209

219

228

237

246

255

CV

Value

Speed

Step

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Table C. Calculating the

User Loadable Speed Table

The exact throttle response for each curve is shown graphically. The

logarithmic curve provides a rapid throttle response at low speeds, while the

exponential curve provides a rapid throttle response at higher speeds.

In order for the speed table selection in CV 25 to take effect, bit 4 of CV 29

must be set to 1. Refer to the previous section “Configuring the Decoder” or

the Technical Reference to determine the correct value for CV 29.

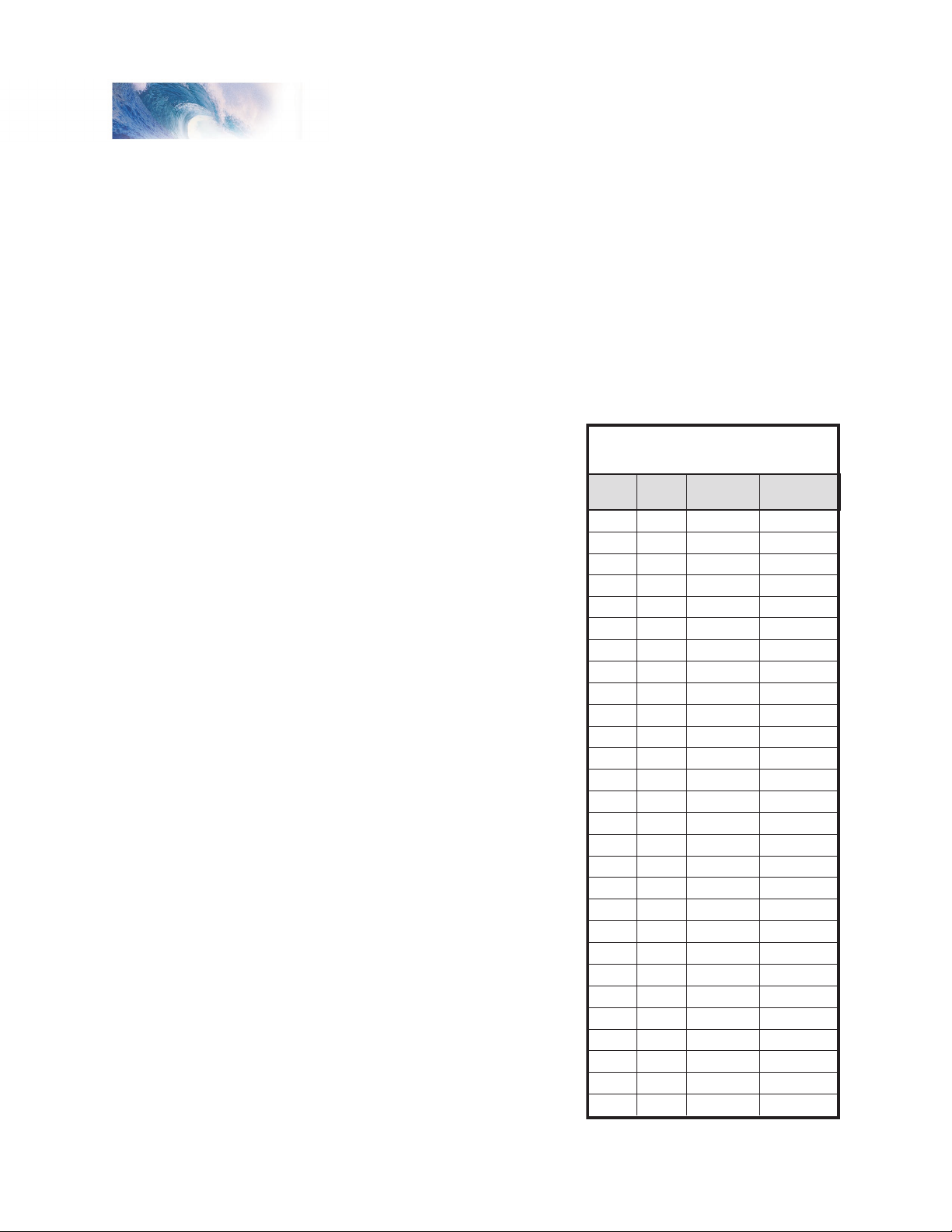

Set the User Loadable Speed Curve

The User Loadable Speed Table allows you to create virtually any throttle

response curve you can imagine. You will first need to design and program

the Loadable Speed Table. The Loadable Speed Table consists of 28 data

points contained in CVs 67 through

94, each defining the percentage

of motor voltage applied at a

given speed step. Each data point

can contain a value of 0 to 255

corresponding to 0 to 100% of

available motor voltage.

Tsunami Steam Sound User’s Guide Page 19

In 28 speed-step mode, each data

point directly corresponds to a speed

step. In 128 speed-step mode,

each data point corresponds to

every four and a half speed steps.

The motor voltage for intermediate

steps is interpolated by Tsunami

to produce a smooth curve. In 14

speed-step mode, alternate (odd

numbered) data points correspond

to speed steps 1-14. Important: all

28 data points must be programmed

even for 14 speed-step mode or an

unpredictable throttle response may

occur while accelerating or braking.

To create a speed curve, begin

by assuming that Tsunami will be

operated in 28-speed step mode.

Don’t worry if you are using another

mode - Tsunami will automatically

take care of the translation between

modes.

1. Start by making a table

containing 28 entries - one entry

for each speed step.

2. For each entry, record the

desired throttle response as a

percentage of full speed, i.e., 0

to 100%.

Page 23

Basic Programming

3. Compute and record the CV value for each step using the following

formula:

Percentage of Full Speed (from Step 2)

CV Value = 255 X ———————————————————

100

4. Program CV 67 with the value computed in step 3 for the first data entry

(Speed Step 1).

5. Program CV 68 with the value computed in step 3 for the second data

entry (Speed Step 2).

6. Repeat step 5 for each of the remaining 26 CVs from CV 69 to CV 94

until they have been programmed with their respective values.

7. Set CV 25 to 16 to select the user loadable speed table.

8. Set bit 4 of CV 29 to 1 to enable speed table use. Refer back to the

previous section “Configuring the Decoder” to determine the correct

value for CV 29.

Table C may be followed as an example and lists the CV values for a straightline response.

Adjust the Forward and Reverse Trim

Tsunami provides two CVs for adjusting or ‘trimming’ the forward and reverse

speeds.

CV 66, Forward Trim

CV 95, Reverse Trim

These CVs multiply all data points in the speed tables by a factor of n/128 (n

is the CV value) allowing the overall speed curve to be adjusted up or down

without reloading all 28 data points again. These CVs will not have any effect

when the speed tables are disabled (i.e., CV 29, bit 4 = 0)

These CVs may contain any value between 0 and 255. Trim values between

129 and 255 will increase speed curve values between 100% and 200% in

approximately 1% steps. Trim values between 1 and 127 will decrease speed

curve values between 1% and 99%. A value of 128 yields a scaling factor of

1.0 and has no effect on the speed curve.

Using different values for the forward and reverse trim will yield different

forward and reverse speeds.

Tsunami Steam Sound User’s Guide Page 20

Page 24

Tsunami Steam Sound User’s Guide Page 21

Basic Programming

Step 4: Configuring for Consist Operation

The DSD supports advanced consist operations, which use five related CVs:

CV 19, Consist Address

CV 21, Consist Function Control 1

CV 22, Consist Function Control 2

CV 23, Consist Acceleration Rate

CV 24, Consist Braking Rate

Consists Explained

A consist is a group of locomotives that are set up to respond to throttle

commands as a single unit. Consists make it easy for one operator to run a

double headed steam train or a multi-unit diesel lash-up for example. The

consist CVs allow the DSD to recognize a new address assigned to the

consist without changing its primary or extended addresses. Additionally,

they allow each locomotive in the consist to be run as a single unit but with

different function properties allowing for example, only the horn to blow on

the lead engine.

Consist Address

Each locomotive in the consist is assigned the same consist address by

programming CV 19 with the consist address between 1 and 127. If a

locomotive is facing backwards in the consist (common in diesel operations),

it should be programmed with the same consist address plus 128. If the

forward facing locomotives are set to consist address 60 for example, the

backwards engine must be set to 60+128 = 188. Failure to do this will turn

the consist into an angry pushme-pullyou as all locomotives will try to move

forward from the perspective of their own cab and a few pulled couplers

might result!

To deactivate the consist address and restore normal operation, CV 19 must

be reprogrammed to 0.

Note that when the consist address is set, the DSD will continue to respond

to instructions sent to its primary or extended address except for speed and

direction data.

The DSD will not respond to operations mode programming commands

sent to its consist address. These commands must always be used with the

primary or extended address.

Consist Function Enable

CV 21 and 22 allow you to define how each engine individually responds

to function commands sent to the consist address. When the consist is

enabled, CV 21 controls which of functions 1-8 are active and CV 22 controls

the F0 function for forward (F0(f)) and reverse (F0(r)), as well as functions

9-12.

Tsunami Steam Sound User’s Guide Page 21

Page 25

Basic Programming

1 2

F0(f) F0(r)

22

CV#

F12

4

F11

8

F10

16

F9

32

Table E. Consist Function Control 2

F8

21

CV#

F11F22F3

4

F48F5

16

F6

32

Table D. Consist Function Control 1

F7

64 128

Direction

CV 19 (Consist Address)

CV 21

CV 22

Engine Address

Nor

mal

40

128

18

5239

4088

Normal

40

135

17

Lead Unit Trailing Unit

CV 21 and 22 take effect only when the consist address is set. When

function commands are used with the DSD’s primary or extended address, all

functions will continue to work regardless of the settings of CV 21 and 22.

Use Table D to calculate the correct value for CV 21, and Table E to calculate

the correct value for CV 22. Begin by looking at Table D and determining

which functions you want active in the consist and circle the number below it.

When you are done, add up all the circled numbers in the row and program

the total into CV 21.

Now look at Table E and do the same: add up all the circled numbers in the

row and program CV 22 with the sum.

Tsunami Steam Sound User’s Guide Page 22

Note that each DSD in the consist will require a different set of values for CV

21 and 22 depending upon your requirements.

Consist Example:

Consider a double-header consisting of two engines, #4088 and #5239. Let’s

suppose we wish to operate these two engines as a single unit with consist

address 40.

You might want the brake squeal (F11) and audio mute (F8) functions to work

on both engines. However, you will likely want the headlight (F0(f)), whistle

(F2) short whistle (F3) and bell (F1) to only work on the lead engine, #4088,

and the backup light (F0 (r)) to work only on #5239.

Page 26

Tsunami Steam Sound User’s Guide Page 23

Basic Programming

Engine 4088.

This is the lead engine. Program CV 19 to 40, the new consist address.

Using Table D, program CV 21 with the sum of the value corresponding to

F1, F2, F3 and F8:

CV 21 = 1 + 2 + 4 + 128 = 135

Then using Table E, determine the value for CV 22 by summing the values

for F0(f) and F11:

CV 22 = 1 + 16 = 17

Engine 5239.

Program CV 19 with the new consist address, 40. As this engine will only

have the reverse light, mute, and brake squeal functions active, different

values are required for CV 21 and 22. Using Table D, program CV 21 with the

value corresponding to F8:

CV 21 = 128

Then using Table E, determine the value for CV 22 by summing the values

for F0(r) and F11:

CV 22 = 2 + 16 = 18

Consist Inertia Control

CVs 23 and 24 can be used to increase or decrease the locomotive’s

acceleration and braking response whenever it is part of a consist (i.e., CV 19

is programmed with a valid address).

CV 23 controls the consist acceleration rate and CV 24 controls the consist

braking rate. When the consist address is active a new acceleration rate

is calculated by adding the value in CV 23 to the baseline acceleration rate

in CV 3. Similarly, a new braking rate is calculated by adding CV 24 to the

baseline braking rate in CV 4. When the consist address is set to 0, CV 23

and 24 have no effect.

Both CV 23 and 24 may be set to any value between -127 and +127. A

positive value will produce a slower throttle response while a negative value

will result in a quicker throttle response.

If the sum of consist and baseline rate exceeds 255, then the final rate is

set to the maximum value of 255. If the sum of consist and baseline rate is

negative, then the final rate is set to the minimum value of 0.

To set a positive value, simply program the CV with the desired number

between 0 and 127. To set a negative value, first change the sign of the value

back to positive and then add 128. Thus, to set -5, program the CV with 5 +

128 = 133. Note that a setting of 128 is the same as 0 and has no effect.

Tsunami Steam Sound User’s Guide Page 23

Page 27

Basic Programming

33

34

35

36

37

38

39

40

41

42

43

44

45

46

128

128

128

128

16

16

16

16

2

2

2

1

1

1

64

64

64

64

8

8

8

8

1

1

1

32

32

32

32

4

4

4

4

X

16

16

16

16

2

2

2

2

X

8

8

8

8

1

1

1

1

X

4

4

4

4

2

2

2

2

1

1

1

1

32

32

32

32

4

4

4

2

2

2

64

64

64

64

8

8

8

4

4

4

128

128

128

128

16

16

16

8

8

8

X

X

X

32

32

32

16

16

16

64

64

64

32

32

32

128

128

128

64

64

64

128

128

128

Control CV

F0 (f)

F0 (r)

F1

F2

F3

F4

F5

F6

F7

F8

F9

F10

F11

F12

Function Key

HL

BL

WH

BEL

SHW

STM

WS

FX5

DY

N

FX6

Table F. Function Mapping Table

DIM

MUT

INJ

BRK

CPL

Bold Numbers indicate default settings.

Step 5: Function Mapping

Function Mapping Explained

Function mapping allows the DSD to be reconfigured so that sound effects

and function outputs can respond to a different function key input. This is

especially useful for users who have throttles with less than thirteen function

keys as now they can pick and choose what effects they can control instead

of being restricted to an arbitrary assignment.

There are 14 function mapping CVs - twelve CVs, 35-46 are used to assign

output control to function keys 1 through 12 respectively.

The other two CVs, 33 and 34 are both for the F0 function. CV 33 controls

which outputs are on when F0 is on and the locomotive is moving forward.

CV 34 controls which outputs are on when F0 is on and the locomotive is

moving in reverse. If the same output is selected in both CV 33 and CV 34,

that function will turn on when the F0 function is on regardless of locomotive

direction.

Not all keys can control all outputs or effects. The table below shows which

functions can be mapped to which outputs. Note that a function key can be

set up to control more than one output.

Tsunami Steam Sound User’s Guide Page 24

Page 28

Tsunami Steam Sound User’s Guide Page 25

Basic Programming

An output can be also be controlled by more than one function key. In the

second case, if an output is mapped to two function keys, either key will turn

that output on, however, the output will not turn off until both function keys

have been turned off.

To determine the correct CV value,

1. Find the column in the Function-Mapping Table corresponding to the

function or sound effect output you wish to control.

2. Next locate the row corresponding to the function key you wish to use for

controlling the selected output.

3. Note the number located in the box at the intersection of the row and

column you have selected.

4. Program the CV listed in the row chosen in step 2 with the value found in

step 3.

Example 1, Swapping the Bell and Short Whistle functions:

Some DCC systems label Function 3 on their cab as the Bell control.

However, Tsunami’s default Bell control is Function 1. Fortunately, we can

use function mapping to re-assign the controls so that the label on the cab

matches the utility in the decoder. Since F3 controls the Short Whistle, we will

simply swap it with F1 as follows:

Using Table F, we first re-assign Function 3 to the Bell. First, find the column

corresponding to the Bell. Then find the row for Function 3. Note the value,

1, found in the box intersected by the row and column. Finally, program this

value into the CV controlling Function 3, in this case CV 37.

Next, re-assign Function 1 to the Short Whistle following the same procedure.

Locate the column corresponding to the Short Whistle. Then find the row for

Function 1. Note the value, 128, found in the box intersected by the row and

column and program this value into CV 35, the CV controlling Function 1.

Example 2, Independent Dynamo Control:

As shipped from the factory, Function 0 controls both the Headlight (or

Backup Light when in reverse) and the Dynamo sound together. Let’s

suppose you desire to use another function to control the Dynamo sound so

it can be turned on or off without affecting the headlight. This would be simple

enough were it not for the fact that all the other function keys are already in

use. The solution then, is to decommission another function so it may be reassigned to the dynamo.

Looking over Table F, we see that any of Function F0 thru F9 may be

remapped to include the Dynamo function. Functions 10-12 are not

candidates since the boxes for these functions are blacked out under the

Dynamo column. However, we could logically assign Function 5 to control

both the FX5 and FX6 lights, which frees up Function 6 to control the

Dynamo.

But first, we need to reprogram the mapping for F0 so that the Dynamo is

no longer controlled with this function. Remembering that F0 uses two CVs,

(CV 33 for forward and CV 34 for reverse), we program CV 33 to 1 so that F0

Tsunami Steam Sound User’s Guide Page 25

Page 29

Basic Programming

turns on the headlight in the forward direction. Then we program CV 34 to 2

so F0 turns on the Backup light in the reverse direction.

Next, setup Function 5 to control both FX5 and FX6. Using Table F, find the

columns corresponding to FX5 and FX6. Then find the row for Function 5.

Note the first value, 2, found in the box intersected by the F5 row and FX5

column. Then find the second value, 4, found in the box intersected by the F5

row and FX6 column. Add these two values together (2 + 4 = 6) and program

the sum into CV 39, the CV controlling Function 5.

Finally, we set CV 40 to 8 so F6 turns the Dynamo on and off.

To summarize, program:

CV 33 = 1 (sets F0(f) to headlight)

CV 34 = 2 (sets F0(r) to backup light)

CV 39 = 6 (sets F5 to FX5 and FX6)

CV 40 = 8 (sets F6 to Dynamo)

Remember, if the lighting functions are still set to the Dyno-Light effect, both

the F0 and F6 functions must now be turned on for the lights to illuminate!

Working with 8-Function Cabs

While Tsunami can support 12 function keys, many cabs are limited to only

8 or 9 functions and you may feel as though you will lose some ability to

enjoy your new Tsunami Digital Sound Decoder. Most of the time, some

clever function mapping will allow you to access and use all of the available

features.

Instant Function Swapping

By setting CV 30 to 4, the function assignments for F5-F8 are instantly

swapped with the function assignments for F9-F12. Think of CV 30 as sort of

a ‘shift’ key so that when it is set to 4,

F5 = Water Stop F9 = FX5

F6 = Injector F10 = FX6

F7 = Brake Release/Squeal F11 = Dimmer

F8 = Coupler F12 = Mute

And when it is set back to 0,

F5 = FX5 F9 = Water Stop

F6 = FX6 F10 = Injector

F7 = Dimmer F11 = Brake Release/Squeal

F8 = Mute F12 = Coupler

If you do not need the mute, dimmer or extra lighting functions, you can set

CV 30 to 4 and simply be done with it. Otherwise, programming CV 30 back

and forth between 0 and 4 is a little inconvenient and a more sophisticated

solution is needed.

Tsunami Steam Sound User’s Guide Page 26

Page 30

Tsunami Steam Sound User’s Guide Page 27

Basic Programming

A Better Method

In order to more fully utilize the Tsunami with an 8 Function cab, it is

necessary to free up some function keys by doubling up on some functions

and/or turning other functions over to automatic control.

We begin by noting which sound functions may be relegated to automatic

control (see page 62 for details):

Short Whistle (F3)

Steam Release (F4)

Brake Squeal (F11)

The Injector sound (F10) may also be automatically triggered by Fireman

Fred (see page 48).

The Mute function (F8) may be automatically set by way of the Quiet Mode

(page 48).

Next, we look to see which outputs could be combined so that they are

controlled with a single function. There aren’t too many of these but it might

be reasonable to decide to use F0 to turn on all lighting outputs including

FX5 and FX6 as well as the Dynamo sound. Or you could use one function to

control both FX5 and FX6 as was done in Example 2.

Finally, we could decide that some functions aren’t needed and simply

discard them.

We now have seven or so functions that can be juggled about. Since we

need to make room for only four, this provides us some flexibility to pick and

choose to best meet our requirements.

Example 3:

In this example, we will let Fireman Fred run the injectors so we no longer

need F10. We’ll also set up the Short Whistle for automatic signaling so F3 is

now available. Let’s presume that FX5 will be used for number board lights

and FX6 for a cab light. We can gang up FX5 and FX6 with Function 0 so

that these lights are on whenever the headlight or backup light is on freeing

up functions F5 and F6.

Using Table F, we can proceed to re-map functions as follows. Starting with

F0, configure the forward direction to control the Headlight, FX5, FX6 and

Dynamo:

Set CV 33 = 1 + 16 + 32 + 64 = 113

For the reverse direction, set F0 to control the Backup light, FX5, FX6 and

Dynamo:

Set CV 34 = 2 + 16 + 32 + 64 = 114

Tsunami Steam Sound User’s Guide Page 27

Page 31

Basic Programming

Then configure F3 to control the Water Stop Sound:

Set CV 37 = 64

Next, we configure F5 and F6 to control the Brake Squeal and Coupler

respectively. But wait! Looking at Table F, it appears that this can’t be done.

The trick is to use the Instant Function Swapping feature so Function 5 now

controls the output assigned to Function 9, Function 6 now controls the

output of Function 10, and so forth.

To activate Function Swapping, set CV 30 to 4. Once this is done, the control

CVs for a particular function also get swapped so that the function mapping

CVs are assigned as follows:

Function 5 is now mapped with CV 43

Function 6 is now mapped with CV 44

Function 7 is now mapped with CV 45

Function 8 is now mapped with CV 46

Function 9 is now mapped with CV 39

Function 10 is now mapped with CV 40

Function 11 is now mapped with CV 41

Function 12 is now mapped with CV 42

Now use Table F to remap F5 to control the Brake Squeal:

Set CV 43 = 128

Then map F6 to control the coupler:

Set CV 44 = 128

We would like to keep the original function assignments for F7 (dimmer)

and F8 (mute). By turning on the Function Swapping feature, however, the

outputs for these functions are now mapped through CV 45 and 46 which,

by default, are set to control some other output. It is necessary to reprogram

these CVs as well to get the desired functionality:

Re-map F7 to control the dimmer:

Set CV 45 = 8

Re-map F8 to control the mute:

Set CV 45 = 16

Finally, we must activate the automatic whistle signals by setting CV 198 to 2.

The injectors are already part of Fireman Fred’s repertoire so there is nothing

else needing change.

Tsunami Steam Sound User’s Guide Page 28

Page 32

Tsunami Steam Sound User’s Guide Page 29

Basic Programming

Working with 4 Function Cabs

With a 4-function cab (actually in most cases, five functions - F0 plus F1-F4),

you will have to give something up! By using Tsunami’s automatic sound

controls, hopefully it doesn’t need to be much.

Example 4:

In this example, we will use automatic control for the Short Whistle, Mute,

Injector, Brake Squeal, and Steam Release. FX5 and FX6 will be ganged up

with F0 as was done for the 8-Function Cab example. F1 and F2 will continue

to be used for the Bell and Whistle.

This frees up F3, which we can assign to the water stop, and F4, which we

can use to control the dimmer. The only effect we must completely give up

under this scenario is the coupler sound since it only maps to F10 -F12 (or

F6-F8 with Function Swapping turned on). Sorry.

Using Table F, we can proceed to re-map functions as follows. Starting with

F0, configure the forward direction to control the Headlight, FX5, FX6 and

Dynamo:

Set CV 33 = 1 + 16 + 32 + 64 = 113

For the reverse direction, set F0 to control the Backup light, FX5, FX6 and

Dynamo:

Set CV 34 = 2 + 16 + 32 + 64 = 114

Then configure F3 to control the Water Stop Sound:

Set CV 37 = 64

Set F4 to control the dimmer function:

Set CV 38 = 128.

To activate the automatic whistle signal, brake squeal and steam release,

program CV 198 to 26. To activate auto-mute, program CV 113 to 120 which

will shut the sounds off after 30 seconds once the train is brought to a stop

and all the functions are turned off (See page 48).

You can see that function mapping allows you a great degree of flexibility

to solve a variety of problems even if your cab is limited to less than 14

functions.

Tsunami Steam Sound User’s Guide Page 29

Page 33

Basic Programming

Bit 7 Bit 0

LED R17 XING PHSE HYPERLIGHT SELECTION

Step 6: Configuring the Lighting Outputs

Tsunami has four function outputs used for controlling the locomotive lights.

Each can be set for a variety of effects or as simple on/off lights. In addition,

you can use the Grade Crossing Logic to automatically activate the selected

lighting effect when you blow the whistle.

Tsunami provides six CVs for customizing the lighting effects:

CV 49, Headlight Configuration

CV 50, Backup Light Configuration

CV 51, FX5 Light Configuration

CV 52, FX6 Light Configuration

CV 59, Lighting Effect Flash Rate

CV 60, Grade Crossing Effect Hold Time.

Setting the Hyperlight Effects

Each lighting output has a corresponding CV that determines its operating

characteristics:

Hyperlight Select - Each output can be programmed to one of several

Hyperlight™ Lighting Effects as listed in Table G. Most effects are selfdescriptive and primarily warning beacons used for diesel locomotives. Some

effects, such as the Mars Light, were used in some steam engines as well.

Dimmable Headlight - The function output is normally an on/off output.

If the output is on, the output level will be reduced about 60% whenever

the dimmer function is on.

Mars Light - This effect simulates the sweeping figure-8 pattern of this

popular warning beacon.

Pyle National Gyralite - The Gyralite is similar to the Mars Light, but

generates a slow, wide, oval headlight sweep pattern.

Dual Oscillating Headlights - Similar in appearance to the common twinsealed-beam headlight, the oscillating headlight uses a moving reflector

to sweep the headlight beam in a tight circular motion.

Single and Dual Strobes - The Strobe effects simulate the white-hot burst

of light associated with the Xenon Strobe.

Tsunami Steam Sound User’s Guide Page 30

Page 34

Tsunami Steam Sound User’s Guide Page 31

Basic Programming

Western-Cullen D312 Rotary Beacon - This effect provides a spectacular

rendition of the revolving reflector and bulb assembly of the prototype

warning beacon found atop many diesels of the 60’s and 70’s.

Prime Stratolite - The Stratolite was a newer version of the rotary

beacon, with the prototype consisting of a revolving reflector with four

individual lamps arranged in a circular pattern which are electronically

flashed in a clockwise sequence. The Stratolite flashes in a rather

mechanical ‘stepped’ fashion, as opposed to the smooth motion of the

Rotary Beacon.

Type I and Type II Ditch Lights - These are identical when operating.

However, if the grade crossing logic is enabled, the Type I ditch light will

revert to a steady on state when it is not flashing whereas the Type II

lights will turn off.

Exhaust Flicker - This effect produces a random flicker whose intensity

increases with locomotive speed. This effect is best used by placing a

red/orange LED in the firebox or in the smokestack. As the locomotive

increases speed, it will glow brighter, imitating an increase in sparks and

exhaust gases.

Firebox Flicker - This effect produces a random flicker whose intensity

resembles a burning fire and can be used with a lamp placed in the

firebox area. The effect is improved when two lights are used, one yellow

and one red or orange and each connected to a separate function output.

Smart Firebox Flicker - This effect produces a random flicker whose

intensity is synchronized with the sound of Fireman Fred shoveling

coal. Whenever Fred ‘opens’ the firebox door and begins shoveling, the

lighting effect increases in brightness and then returns to a subdued level

when the firebox doors are ‘closed’.

Dyno-Light - This effect for steam locomotives synchronizes the lamp

brightness to the “output” of the dynamo such that the lamp brightness

gradually increases as the dynamo builds up speed.

Phase Select - Alters the timing of the effect so that it is 180 degrees out of

phase with the other effects. This allows you to have two light effects that

blink back and forth if desired. Set one effect to phase A and the other to

phase B.

Grade Crossing Logic - Causes the lighting effect to become active only

when the whistle has been sounded (and the corresponding lighting function

key is also on). A typical use would be to cause the ditch lights to flash at

a grade crossing. The grade crossing logic can be used with almost all

the Hyperlight effects. The on/off, dimmable headlight, Dyno-Light, FRED,

exhaust flicker, and firebox flicker effects will not be affected. The other

effects will either turn off (strobes and beacons) or revert to a steady on state

(mars light, ditch lights, etc.) as appropriate to prototype practice.

Tsunami Steam Sound User’s Guide Page 31

Page 35

Basic Programming

Rule 17 Headlight Operation - Converts the headlight and backup light

to independent, non-directional functions. When enabled, the headlight is

controlled as if it were FX5, Function 5 and the backup light as FX6,

Function 6.

LED Compensation Mode - Tsunami’s lighting effects can be used with

either incandescent bulbs or LEDs. However, because of their differences in

brightness characteristics, some lighting effects will appear less life-like when

initially set up with an LED. To correct this, Tsunami’s LED compensation

mode should be enabled which will improve the contrast of the lighting effect

by automatically adjusting the function output level to correct for the different

brightness characteristics of an LED.

To set the Hyperlight configuration CVs, proceed as follows:

1. First find the CV value in Table G on the next page for the desired

lighting effect and operating mode.

2. If you wish to enable Rule 17 Mode, add 64 to the table value shown,

otherwise, proceed to Step 3.

3. If you’re using incandescent bulbs, skip to Step 4. If you are using

LEDs, enable the LED Compensation Mode by adding 128 to the sum

computed in Step 2.

4. Program the sum computed in Step 3 into the CV corresponding to the

appropriate function output. Use CV 49 to set the headlight, CV 50 for

the backup light, CV 51 for Function 5 and CV 52 for Function 6.

Setting the Flash Rate and Hold Time

CV 59 is used to adjust the flash rate of the Hyperlight effect and has a range

of 0-15 with 15 being the slowest flash rate. When the Grade Crossing Logic

feature is enabled, CV 60 is used to adjust the length of time (in seconds)

an effect will remain active after the whistle key is released. CV 60 can be

programmed with any value between 0 and 15.

Example 1, Mars Light with Grade Crossing Logic

In this example, we will configure the headlight output for use with an

incandescent bulb as a Mars Light with Grade Crossing Logic enabled.

Following the steps outlined above, we proceed as follows:

1. We first look up the initial CV value in Table G for a Mars Light under the

column labeled ‘Crossing Logic On’ and find it is 34 for Phase A and 50

for Phase B. Since we are only setting up one light, we do not care about

the Phase and choose to the value for Phase A, 34.

2. Since we are not using Rule 17, we skip to Step 3.

3. Since we are not using LEDs, we skip to Step 4.

4. CV 49 (Headlight Configuration) is programmed with the value found in

Step 1 or 34.

Lastly, we need to set the grade crossing hold time to about six seconds by

programming CV 60 to 6.