Page 1

Tsunami2 and Econami Digital Sound Decoder

Installation Guide

Rev.D 05/10/2017

Page 2

Contents

All Aboard! ............................................................................................................................... 3

Overview ...................................................................................................................................... 3

Pre-Installation Considerations ................................................................................................... 4

Installation ................................................................................................................................ 6

Step 1. Test the Motor Stall Current ........................................................................................... 6

Step 2. Plan the Installation ........................................................................................................ 7

Step 3. Isolate Motor and Lights from the Frame ....................................................................... 9

Step 4. Modify the Tender or Body Shell .................................................................................. 10

Step 5. Mount the Speaker ....................................................................................................... 12

Step 6. Install and Wire the Decoder ........................................................................................ 13

Step 7. Test the Istallation ........................................................................................................ 16

Wiring Diagrams .....................................................................................................................17

TSU-1100/ECO-100 .................................................................................................................. 17

TSU-2200/ECO-200 .................................................................................................................. 18

TSU-21PNEM/ECO-21PNEM ................................................................................................... 19

TSU-PNP/ECO-PNP ................................................................................................................. 20

TSU-4400/ECO-400 .................................................................................................................. 21

Notice

The information in this document is subject to change without notice.

SoundTraxx (Throttle Up! Corp.) shall not be liable for technical or editorial errors or omissions contained

herein, nor for incidental or consequential damage resulting from the furnishing, performance or use of

this material.

This document contains information protected by copyright. No part of this document may be photocopied

or reproduced in any form without the prior written consent of Throttle Up! Corp.

Product names mentioned herein may be trademarks and/or registered trademarks of their respective

companies.

SoundTraxx, Tsunami2, Econami, Tsunami, SoundTraxx DCC, Dynamic Digital Exhaust, Auto-Exhaust,

Hyperlight, Hyperdrive2, SoundCar, and Intelligent Consisting are trademarks of Throttle Up! Corp.

Page 3

All Aboard!

Tsunami2

Econami

TSU-1100

ECO-100

TSU-2200

ECO-200

TSU-21PNEM

ECO-21PNEM

TSU-PNP

ECO-PNP

TSU-4400

ECO-400

To download all user documentation, visit www.soundtraxx.com/manuals.php.

All Aboard!

Overview

Congratulations on the purchase of your Tsunami2 or Econami Digital Sound Decoder! Properly

installed, this decoder will provide high-quality sound, realistic lighting effects, and superior

motor control. This installation guide will give you step-by-step instructions to successfully install

the following Tsunami2 and Econami formats for steam, diesel, or electric locomotives:

Though each decoder is tested thoroughly before shipping, we cannot control the correctness or

quality of a given installation. It is imperative that you follow the directions, and never remove

the protective heat-shrink from the decoder; there are no adjustments that can be made to the

hardware and this will void your warranty.

The difficulty of an installation depends principally on the modeler, and may be more or less

challenging according to any given circumstance. However, an installer should generally have

basic modeling skills, be comfortable disassembling a model, and be able to identify wires, such

as power pickups and motor leads.

Note: In the event that you damage the decoder during installation, our warranty policy is

outlined in the User’s Guide and on our website. It includes information about returning the

decoder to SoundTraxx for repair or replacement.

Further documentation regarding steam, diesel, or electric versions of your decoder:

If you’re new to DCC and sound, refer to the Quick Start Guides for default operation and

programming highlights.

Refer to the User’s Guides for in-depth instructions regarding operating and programming

your digital sound decoder.

Refer to the Technical References for details regarding each CV included in your Digital

Sound Decoder.

Refer to the Sound Selection References for a quick guide of CV values to adjust sound

effects in each version.

Refer to the SoundTraxx Guide to Successful Soldering for soldering tips and

recommendations.

Tsunami2 and Econami Installation Guide 3

Page 4

All Aboard!

Pre-Installation Considerations

Carefully read the instructions that are printed on the decoder’s packaging. Then, finish reading

this installation guide. While installing the decoder, keep these precautions in mind:

Handle the decoder carefully in a

static-free environment. To discharge

static electricity before handling the

decoder, touch a water pipe or another

grounded metal surface.

Never remove the decoder’s protective

shrink tubing; this voids your warranty.

Never make connections to the decoder

while it is receiving power.

Make sure all electrical connections are

insulated. Avoid using electrical tape; it

tends to unwrap over time. We

recommend using heat-shrink tubing

instead.

Never allow the decoder leads to come

in contact with any DCC track wiring not

specifically designed for that purpose.

Never allow speaker or motor outputs to

be shorted together.

Do not exceed the output ratings for

which the decoder is designed.

Do not choose a locomotive with a stall

current exceeding the decoder’s rating;

always test the stall current of your

locomotive before installing the decoder.

If possible, mount the decoder in an

area with some airflow to provide

ventilation for the decoder.

Mount the decoder away from other

heat sources (such as the motor or

lamps) to avoid overheating.

Always use a proper speaker enclosure

(baffle) and select the largest speaker

possible.

Choose an appropriately rated speaker.

Take your time and have fun!

Testing the Decoder Prior to Installation

In rare cases, damage received during shipping or improper handling can cause a decoder to

fail prematurely. We recommend that you test all Digital Sound Decoders and accessories

within the item’s warranty period prior to beginning the installation. Proper bench testing of

decoders can save countless hours of headache and frustration if problems are discovered after

the installation process has begun

Testing the decoder on your workbench can be accomplished by connecting the wires/pads

from the DSD to a surplus motor, 8 ohm speaker and 12 volt lamps. Refer to the appropriate

wiring diagram for your decoder when making these connections. Also ensure that the wire

connections are mechanically sound and well insulated to prevent damage to the decoder or

accessories during testing.

When the appropriate connections have been made, test the motor by running it in both forward

and reverse directions. Test each lighting output by turning on the corresponding function key.

Lastly, check the audio output of the DSD by blowing the horn or whistle, ringing the bell and

listening for changes in prime mover notch, exhaust chuff or traction motor whine.

If you should discover any issues during this test, please contact our Customer Support

department for assistance.

Note: Neither Tsunami2 nor Econami require a programming track booster.

Tsunami2 and Econami Installation Guide 4

Page 5

All Aboard!

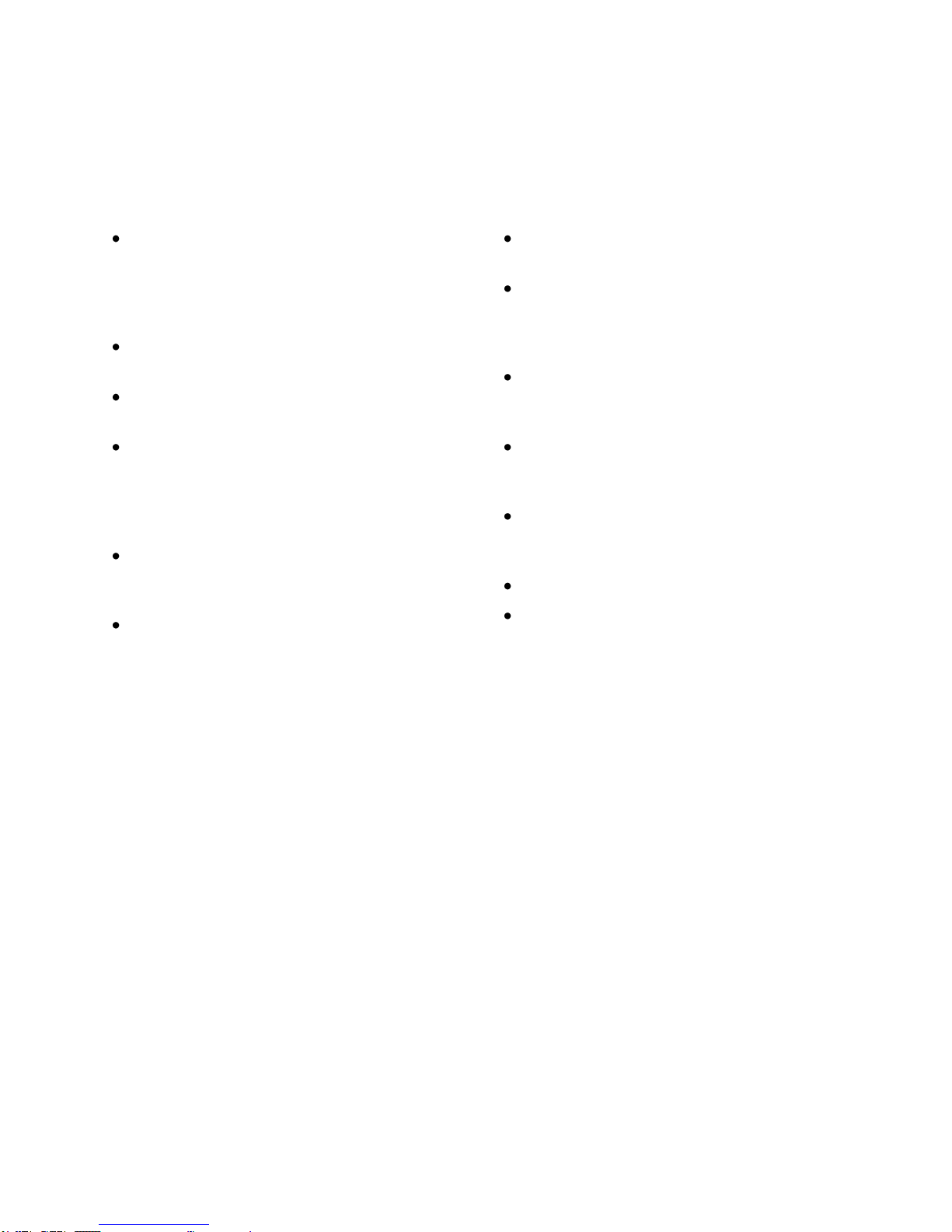

Miniature Speakers, Baffles, and Gaskets:

We have a variety of miniature speakers, baffles, and gasket kits for use with our digital sound

decoders; choose the largest speaker the installation will allow.

Wiring Aids

Micro-connectors can be used to facilitate easy separation of components. NMRA-Compatible

Connectors are used for converting universal-style decoders to a “plug-and-play” format.

DBX-9000 Wiring Kit facilitates easy separation of the locomotive and tender. Super-flexible

wire is ideal for working in tight spaces.

DCC Accessories

The CurrentKeeper helps maintain decoder performance during momentary power losses.

Microbulbs and LEDs let you take advantage of our Hyperlight lighting effects.

Tools and Materials You Will Need

In addition to the common hand tools found on most modeler’s workbenches, you should have

the following at your disposal:

Low-wattage soldering iron

Rosin-core solder and electronics

safe flux

Hobby knife

Miniature screwdriver set

Diagonal wire cutters

We have a variety of accessories to aid your installation. For more information about our full line

of installation accessories, visit www.soundtraxx.com/access/index.php.

Handheld rotary tool

Multimeter

Double-sided foam tape

Heat-shrink tubing

Silicone RTV

Drill bit assortment

Tsunami2 and Econami Installation Guide 5

Page 6

Installation

Installation

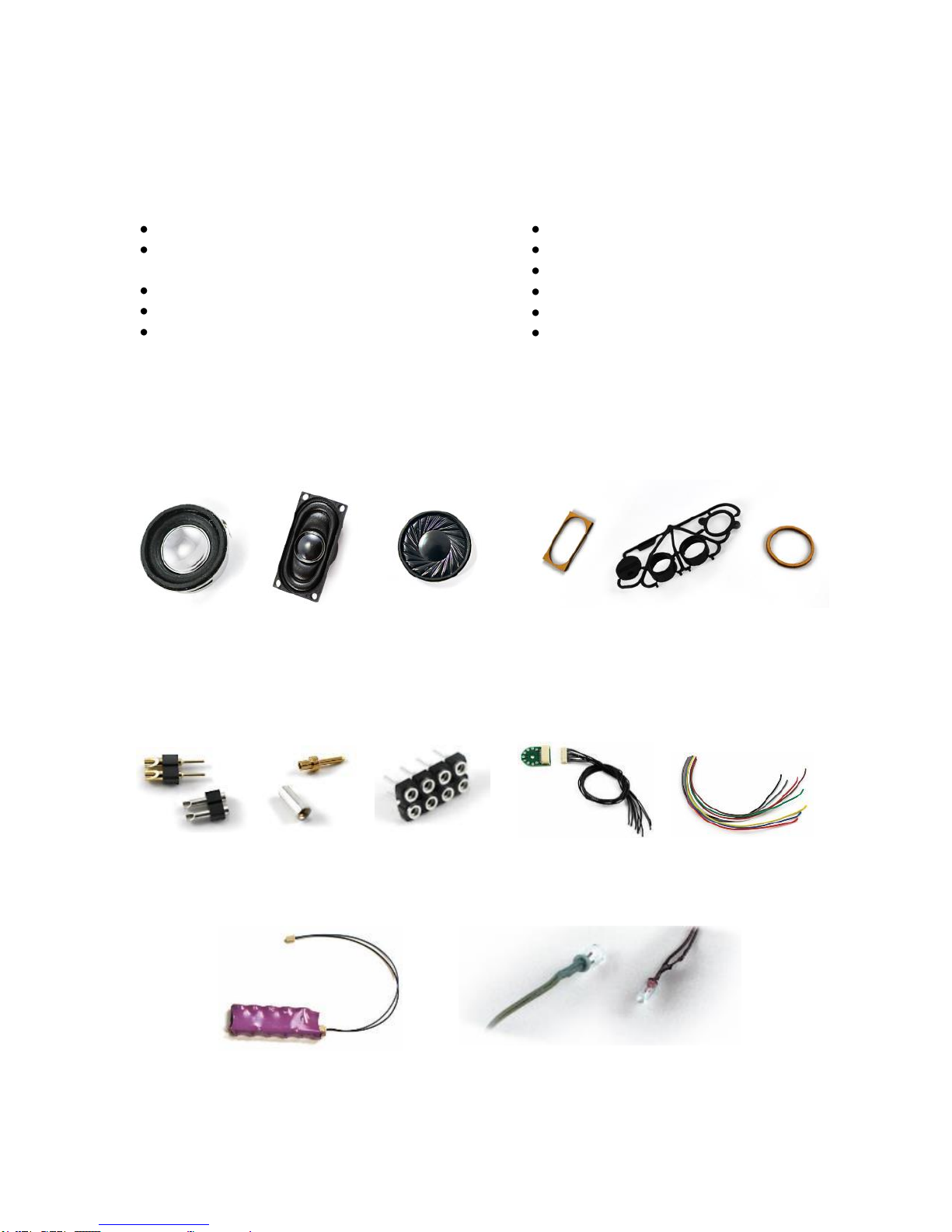

Step 1. Test the Motor Stall Current

Test the locomotive’s stall current to ensure that it is compatible with the decoder that you have

chosen:

1. Place the locomotive on a section of track powered by a conventional DC powerpack set to

the same track voltage as your command station (typically 12-14 volts).

2. Referring to Figure 1, connect a DC ammeter in series with one of the track feeders. If your

powerpack has built-in meters, you may use them for this purpose.

Figure 1: Testing the Locomotive’s Motor Stall Current

3. Immobilize the locomotive by holding it to the track, and turn on the powerpack.

4. Firmly press down on the locomotive or hold the motor’s flywheel to stop it from spinning.

5. Ensure the powerpack voltage remains the same to receive an accurate measurement.

6. Measure the current the locomotive is drawing while the motor is stalled; this is the stall

current.

7. Ensure the motor stall current is less than the decoder’s rated capacity.

Tsunami2 and Econami Installation Guide 6

Page 7

Installation

Mini Cube Speakers

28 mm (1”) Round Speaker

16 x 35mm Oval Speaker

Step 2. Plan the Installation

The sound quality you will receive from your

Digital Sound Decoder depends upon your

speaker selection, the way you install the

speaker, and the location of the decoder

within the model. Consider the following as

you plan your sound installation:

Provide ventilation for the decoder if

possible.

Mount the decoder away from other

heat sources (such as the motor or

lamps) to reduce the chance of

overheating.

Always provide a proper enclosure

(baffle) for the speaker. Lack of a

speaker baffle will cause poor sound

quality.

Speaker Considerations

Select the largest speaker that your model

permits to achieve higher volume and better

quality low-frequency response for a more

realistic sounds. We offer a range of

speakers that you can use with your model.

Note: Be sure that your speaker is rated to

match the audio amplifier of your decoder;

failure to do so could cause damage to your

speaker. Check the packaging and our

website for ratings for each decoder format.

Note: If a single large speaker isn’t an

option, you may be able to use two or three

smaller speakers to improve the frequency

response. For details, refer to “Wiring

Multiple Speakers” within Step 6. Install

and Wire the Decoder (Pg. 13).

Speaker Enclosures

A speaker enclosure (baffle) should be used

to allow air pressure to build up and amplify

sound.

The enclosure should fit the speaker. The

pressure building within an enclosure that is

too small for the speaker will compromise

certain frequencies and muffle the sound

response. As a guideline, enclosures for

speakers measuring less than 3” in

diameter should be built using the cubic

relationship between height, length and

width. For example, a 1” speaker should be

paired with a 1” x 1” x 1” enclosure.

Note: Employing a proper speaker

enclosure cannot be emphasized enough;

the absence of an effective enclosure is

almost always the cause of poor sound

quality.

Speaker enclosures should also be:

Fixed with stiff walls to prevent

vibrations and buzzing

Installed flush with the speaker

dimensions to create an airtight space

for the speaker cone to build pressure

and produce a strong sound response

We offer various snap-together baffle kits

like the one shown below.

SoundTraxx Speaker Baffle Kit

Tsunami2 and Econami Installation Guide 7

Page 8

Installation

Steam Locomotive Considerations

Sound quality is greatly affected by speaker placement, which depends on the size and type of

locomotive. The speaker will produce higher quality sound when fixed within an airtight

enclosure with the front of the speaker facing open air. Most steam engines have a tender that

can be used as an enclosure. You can orient the speaker face up toward the coalbunker or face

down toward the floor – both offer quality sound.

In small tenders, the speaker can be mounted in the coalbunker area with higher walls covering

the speaker magnet. If this isn’t possible, you may need to get creative and install the speaker in

the boiler or smokestack. We also offer an assortment of baffle kits, or you can create

enclosures from sheet styrene, basswood, or cardboard. If you’re in a pinch, try using a plastic

bottle lid, a 35mm film canister, or the paperboard core from a roll of paper towels.

Figure 2 shows a typical sound installation for a steam locomotive with the speaker pointing up

through the coal load. The tender shell acts as a baffle for the speaker. To allow the sound to

escape, the plastic coal load can be perforated with small holes.

Figure 2: Steam Sound Installation

Diesel Locomotive Considerations

When planning a diesel installation, we recommend providing additional airflow if possible.

When possible avoid mounting the decoder above the motor; the motor will raise the decoder’s

temperature during operation.

Figure 3 shows a typical diesel installation where the speaker has been mounted in the fuel tank

with the decoder under the fan grilles. Opening the fan grilles and drilling a number of small

holes through the underside of the frame will create some airflow, and the fuel tank will act as a

baffle for quality sound.

Figure 3: Diesel Sound Installation

Tsunami2 and Econami Installation Guide 8

Page 9

Installation

Step 3. Isolate Motor and Lights from the Frame

Note: If you have a DCC-ready model with an NMRA 8-pin connector, NMRA 9-Pin “JST”

connector, or 21-Pin “NEM” connector, proceed to page 15.

To ensure only the decoder’s motor outputs are driving the two motor connections, isolate the

motor connections from the locomotive frame, left rail, and right rail pickups. Many locomotives

are “DCC-ready,” and this step may not be necessary, though it varies depending upon the

manufacturer. Under Step 6. Install and Wire the Decoder, refer to “Installing into DCC-Ready

Locomotives” for more information regarding DCC-ready installations.

Note: Failure to properly isolate the motor may damage the decoder and we recommend

always practicing this step during the installation process.

To verify that the motor terminals are isolated from the chassis and rail pickups, refer to the

following procedure:

1. Make sure to have an ohmmeter or

continuity tester that you can use to

confirm that each motor terminal is

isolated.

2. Remove the body shell from the

locomotive (and the tender shell for

steam installations).

3. Examine the locomotive wiring and

locate each wire and where each wire is

connected; identify the power pickups

for the left and right rails and the

positive (+) and negative (−) motor

connections.

Note: The positive motor connection is

connected to the right rail (engineer

side) power pickup.

Figure 4: Conventional DC Power Pickups

4. Disconnect all wires that lead to motor

terminals.

Note: Some motor connections are

made by a spring contacting the “live”

chassis. In this instance, remove or

modify the spring contact. Be aware that

the motor and frame are permitted to

make contact when the body is

reinstalled in some locomotives.

5. Set the multimeter to continuity or

ohmmeter, and touch both meter probes

together. Ensure it reads 0 (short circuit)

to verify the meter is functioning

correctly.

6. Touch one probe to a motor terminal.

7. Touch the other probe to the

locomotive’s frame, then to the power

pickup wire for the left rail, then to the

power pickup wire for the right rail and

ensure the meter indicates an open

circuit.

8. To complete the test, remove the probe

from the terminal that has already been

tested and touch it to the other motor

terminal. Then, ensure the meter

indicates an open circuit by performing

the same test with the other probe:

touch it to the frame, the left rail pickup,

and then the right rail pickup.

9. Disconnect all lighting wires.

10. Using the ohmmeter (or continuity

tester), verify each lamp lead is isolated

from the locomotive’s frame, the left rail

pickup, and the right rail pickup.

Tsunami2 and Econami Installation Guide 9

Page 10

Installation

Figure 5: For some models, you may

have to heighten sidewalls to provide

clearance for the sound system.

Figure 6: For models with a molded

coal load, create a subdeck to

provide a flat mounting surface.

Figure 7: If necessary, replace the

slope sheet and inside walls with

sheet brass or styrene to

accommodate the sound system.

Step 4. Modify the Tender or Body Shell

A certain amount of “bodywork” may be necessary to accommodate the speaker and sound

system. This typically includes removing weights, mounting brackets, and internal bracing, as

well as modifying other structural features.

Steam Modification

Installing a decoder in a steam locomotive often involves modifying the tender and tender floor.

Heighten Low Tender Sidewalls

On tenders with low sidewalls, the speaker will often be

mounted face up in the coalbunker to provide adequate

clearance for the sound system fixed to the tender floor.

To heighten the sidewalls, add wooden retaining boards:

1. On the tender deck, trace around the speaker.

2. With a jeweler’s saw, cut an opening around the outline.

3. File and remove all sharp edges and burrs.

4. Contour a piece of fine mesh or foam and cover the coal

load to disguise the speaker.

Note: Tenders with flat decks across the coalbunker are

less difficult to modify.

Styrene Subdeck Speaker Mount

Plastic tenders often have a molded coal load already in

place. The inside surface is contoured to match the coal load

and does not provide a flat mounting surface. A subdeck can

be fabricated from 0.060” styrene to fit tightly against the

tender sides below the coal load:

1. Cut a large circular opening appropriate for the speaker’s

diameter into the styrene sheet.

2. Glue the subdeck to the inside of the tender shell.

3. Using a No. 60 drill bit, drill through the coal load several

times at random angles between the coal “nuggets” to

allow sound to escape.

Tenders with Exposed Coal Slope Sheets

More prototypical tenders have fuel bunkers that extend to

the tender floor. Consider tender size before mounting the

speaker:

For larger tenders, the speaker should be mounted on

the tender floor.

For smaller tenders, the slope sheet and interior walls

will interfere with the speaker and the sound system. It

will usually be necessary to remove and replace them

with sheet brass or styrene to create a flat-decked tender.

Tsunami2 and Econami Installation Guide 10

Page 11

Installation

Figure 8: For speakers mounted on the

tender floor, drill holes below the speaker

to allow the sound to escape.

Modify the Tender Floor

Speakers can be located on the tender floor in many instances. Consider the following when

mounting the speaker to the tender floor:

1. Determine the exact speaker location within the tender and verify that there is clearance

between the tender body and speaker magnet.

2. In the pattern shown in Figure 8, drill 10-15 holes to provide an opening for the sound to

escape; each hole should measure roughly 1/4” in

diameter.

3. Take care not to alter the tender underbody detail

and drill towards the center of the circle, only within

the specified area.

4. Once you have drilled the holes, file all burrs and

uneven edges and ensure no solder joints, screw

bosses, or mounting studs obstruct the speaker

mount; the tender floor should be smooth and flush

against the surface of the speaker.

Diesel Modification

Consider the following for diesel models:

You may need to remove weight from the fuel tank or replace the model’s fan grilles with

some open-grille detail parts.

You will need to fashion a mounting plate for the speaker and seal it well.

If you place the speaker under open fan grilles, consider using a separate speaker baffle

rather than the body, as it may be difficult to seal the chassis well enough to achieve the

desired results.

Figure 9 shows some common diesel modifications:

Figure 9: Common Diesel Body Modifications

Tsunami2 and Econami Installation Guide 11

Page 12

Installation

Step 5. Mount the Speaker

After you’ve modified the model appropriately, arrange the speaker components and secure

them in place.

Mount the Speaker

Once bodywork is complete and the speaker has been fitted in place, it must be secured tightly

to the enclosure. For the best sound, the seal around the speaker’s edge should be airtight. We

offer several speaker gasket kits for easy and neat speaker mounting. You may also hold the

speaker in place using a silicone RTV to provide a seal and allow the speaker to be removed in

the future. Using epoxy or other hard glues does not allow this. Be careful that you don’t get any

RTV onto the speaker cone, as this will cause sound distortion.

Speaker Gaskets

We recommend using a speaker gasket to secure the speaker into place. Please visit our

website for a full list of speakers, speaker enclosures, and speaker gaskets.

Installing Speakers with Gaskets

Consider the following as a guide for mounting the speaker with a gasket:

For each side of the gasket, peel back the paper backing with a pair of tweezers or a hobby

knife and expose the adhesive.

Fix the gasket to the speaker, and fix the speaker to the desired surface.

Take care not to fix the gasket to the speaker cone.

Figure 10: SoundTraxx Speaker Gasket Installation

Tsunami2 and Econami Installation Guide 12

Page 13

Installation

Figure 13: Multi-Speaker Wiring

Note: Values assume 8-ohm speaker impedance.

Step 6. Install and Wire the Decoder

Track Connections

1. Connect the decoder’s red wire to the

right rail power pickup.

Speaker Connections

1. Connect the decoder’s purple speaker

(+) wire to one of the speaker terminals.

2. Connect the decoder’s black wire to the

left rail power pickup.

2. Connect the decoder’s purple speaker

(−) wire to the other speaker terminal.

Motor Connections

1. Connect the decoder’s orange wire to

the motor’s positive (+) terminal.

2. Connect the decoder’s gray wire to the

motor’s negative (−) terminal.

Figure 11: Track and Motor Connections

Figure 12: Soldering to Speaker Terminal

Connections

Wiring Multiple Speakers

Refer to Figure 13 when wiring multiple

speakers. Be aware of the speaker

polarity. If a speaker is wired backwards

relative to another speaker, the two

speakers will release opposing sound

waves and will be unable to reproduce

sound effectively. This will result in

diminished volume levels. If the speaker

does not indicate polarity on its terminal,

wire terminals to corresponding terminals,

i.e., wire left terminals to left terminals,

and right terminals to right terminals,

respectively.

Note: The polarity of the speaker terminals is only important when using multiple speakers (see

above). If you have installed multiple speakers, make sure they are phased properly, i.e.,

positive lead to positive lead and negative lead to negative lead of each speaker. On smaller

speakers, solder the wires to the outside edges of the solder pads.

Note: Do not use SoundTraxx Digital Sound Decoders with speakers with a total impedance

less than 8 ohms. Doing so may result in erratic operation, or even cause component failure.

Tsunami2 and Econami Installation Guide 13

Page 14

Installation

Lighting Connections

Up to 6 lighting outputs are connected by way of the Function Common (Blue wire or “+” pad) and

the Headlight, Backup Light, FX3, FX4, FX5, and FX6 function wires (or corresponding pads)

found on the decoder.

Because of the wide variety of lighting used by model manufacturers, it’s important to know the

voltage rating of your locomotive’s lamps or LEDs. Connecting lighting rated for less than 12 volts

(such as 1.5V microbulbs, 3.3V LEDs, 3V lamps or 6V lamps) directly to the decoder can cause

damage to the on-board circuitry as well as damage to the lamps or LEDs themselves.

Refer to the information below for proper wiring of the most common types of lighting installed in

locomotives.

Wire the decoder to 12V Lamps

Refer to Figure 14 to use 12V Lamps. Wire the 12V lamps

directly to the headlight and backup light. The 12V lamps

may also be wired directly to FX3-FX6 lighting outputs.

Wire the decoder to 1.5V Microbulbs

To use 1.5V microbulbs, refer to Figure 15. Wire a small

current-limiting resistor with each lamp to prevent lights from

burning out. A separate resistor must be used for each

bulb even if you connect it to the same output. We

recommend using a 560-ohm, 1/4-watt resistor with each

bulb. However, you may need to adjust the resistance to

achieve the appropriate brightness. This is determined by the

output voltage for your command station. Lower resistance

will increase the lamp brightness.

Note: Econami PNP and Tsunami2 PNP format decoders are equipped with a 1.5 Volt

regulated output. Refer to the wiring diagrams on page 21 for more information.

Wire the decoder to LEDs

SoundTraxx decoders support the use of LEDs wired in-series using 1K (1000) OHM, 1/4 watt

resistors.

Unlike incandescent bulbs, LEDs are sensitive to polarity:

Figure 17: Wiring 12V Lamps

Figure 14: Wiring to 12V Lamp

Figure 15: Wiring to 1.5V Microbulbs

The negative (−) LED cathode (shorter lead) connects to

the decoder’s corresponding lighting output.

The positive (+) LED anode (longer lead) connects to the

decoder’s blue Function Common wire.

Tsunami2 and Econami Installation Guide 14

Figure 16: Wiring 3.3V LEDs

Page 15

Installation

DCC-Ready Locomotive Installations

NMRA 8-Pin Sockets

If your locomotive is wired with an NMRAcompatible 8-pin socket, you may solder a

mating connector to the decoder’s wire

harness to allow simplified plug-in

installation for all wiring excluding speaker

connections. We offer a package of four

connectors (P.N. 810123) that meet NMRA

specifications. Wire the connector according

to Figure 17.

Note: Some models equipped with 8-pin sockets may not be compatible with the NMRA

standard. If you are unsure of the wiring standard used in your 8-pin socket equipped model,

please refer to the Technical Note entitled “Testing NMRA 8-Pin Sockets” found on our website.

NMRA 9-Pin “JST” Plug

Many models are being equipped with this DCC “Quick-Plug” connector for easy installation of

TSU-2200 or ECO-200 decoders. The following procedure can be used when installing these

decoders:

1. Remove the factory supplied 9-pin

dummy plug from the model and ensure

that the NMRA 8-Pin dummy plug (if

equipped) has been removed as well.

2. Using a hobby knife, remove a small

amount of shrink wrap from the decoder

around the 9-pin plug.

3. Pull gently with even force applied to all

9 wires to remove the SoundTraxx wire

harness from the decoder.

4. Plug the decoder into the NMRA 9-pin

“JST” wire harness located in the model.

21-Pin NEM Connector Interface Figure 19: 21-Pin NEM Wiring Diagram

Please refer to page 19 for more information

about this interface and SoundTraxx 21-Pin

NEM decoders.

Note: SoundTraxx 21-Pin NEM decoders

are designed for use with factory supplied

motherboards which support the NEM

specifications. Our decoders are not

intended for use with 21-Pin NMRA

standard sockets.

Figure 17: NMRA 8-Pin Wiring Diagram

5. Refer to the wiring diagram for TSU2200 and ECO-200 decoders for

connection of the speaker and any

additional lighting functions.

Figure 18: NMRA 9-Pin “JST” Wiring Diagram

Tsunami2 and Econami Installation Guide 15

Page 16

Installation

Step 7. Test the Installation

At this point, you should be ready for the test track. We recommend your test track be equipped

with a fast-blow fuse appropriately rated for your decoder (1-amp decoder = 1-amp fuse).

Test the installation according to the following:

1. Place the locomotive on the track and turn the power on.

2. Set your controller to locomotive address 3.

3. Verify that your locomotive will move in both directions and turn the headlight and backup

light on and off with the corresponding function keys (F0 forward and reverse).

4. For steam decoders, verify the airpump is running automatically in the background.

5. For diesel decoders, verify the engine RPM is at a steady idle.

If your locomotive responds to direction changes incorrectly, the motor connections have been

reversed. Refer to the following to correct them:

1. Turn the power off.

2. Reconnect the decoder’s orange wire to the motor terminal previously connected to the

decoder’s gray wire, and reconnect the decoder’s gray wire to the motor terminal previously

connected to the decoder’s orange wire.

3. Place your locomotive back on the test track and verify correct movement in the forward and

reverse directions.

After successfully testing your installation, secure the decoder and all loose wires with Kapton

tape or double sided foam tape to prevent interference with the locomotive’s shell, motor or

other drive-line components. Trim, insulate the ends and secure all unused FX lighting outputs

to prevent accidental contact with other components during reassembly.

Tsunami2 and Econami Installation Guide 16

Page 17

Wiring Diagrams

TSU-1100/ECO-100

The TSU-1100 and ECO-100 are “universal” style decoders for hard-wired installations in many

W scale and small HO scale models.

Wires are color-coded according to the NMRA Standard (where applicable):

Power, Motor, Headlight, and Backup Light Wires:

Black: Left Rail Pickup (-)

Gray: Motor (-)

Yellow: Backup Light

White: Headlight

Speaker and FX Wires:

Purple: Speaker (+)

Purple: Speaker (-)

Green/Yellow Stripe: Ground

Blue: Function Common (12V)

Orange: Motor (+)

Red: Right Rail Pickup (+)

Green: FX3

Brown: FX4

CurrentKeeper Installation

The TSU-1100 and ECO-100 both include an optional 220µF, 25V capacitor or may be used

with a SoundTraxx CurrentKeeper to maintain performance during momentary power losses.

To install a CurrentKeeper, remove the connector and trim the blue and black wires to about 3”.

Strip and tin the ends of the CurrentKeeper’s wires, as well as the decoder’s blue (Function

Common) and green/yellow stripe (Ground) wires. Slide a piece of heat-shrink tubing over each

of the CurrentKeeper’s wires. Solder the blue CurrentKeeper wire to the blue decoder wire, and

the black CurrentKeeper wire to the decoder’s green/yellow stripe wire. Slide the pieces of

heat-shrink tubing over the connections and heat to insulate.

Figure 20: TSU-1100/ECO-100 Wiring Diagram

Tsunami2 and Econami Installation Guide 17

Page 18

Wiring Diagrams

TSU-2200/ECO-200

The TSU-2200 and ECO-200 are considered to be “universal” style decoders for installation in a

variety of models. These decoders are equipped with a NMRA 9-Pin “JST” plug for easy

installation in many DCC ready models.

Wires are color-coded according to the NMRA Standard (where applicable):

Power, Motor, Headlight, and Backup Light Wires:

Black: Left Rail Pickup

Gray: Motor (-)

Yellow: Backup Light

White: Headlight

Green/Yellow Stripe: Ground

Speaker and FX Wires:

Purple: Speaker (+)

Purple: Speaker (-)

Green: FX3

CurrentKeeper Installation

These decoders are equipped with a 2-pin socket specifically for the CurrentKeeper. You may

need to trim back a small amount of the heat shrink surrounding this connector before plugging

the CurrentKeeper wire harness into this socket.

Blue: Function Common (12V)

Orange: Motor (+)

Gray: Motor (-)

Red: Right Rail Pickup

Brown: FX4

Green/White Stripe: FX5

Brown/White Stripe: FX6

Figure 21: TSU-2200/ECO-200 Wiring Diagram

Note: If you’re replacing an older TSU-1000 decoder with a TSU-2200 or ECO-200 format

decoder, you will also need to upgrade the speaker prior to completing the installation. Newer

DSDs are equipped with a higher powered amplifier that will damage older, low power handling

speakers. Please refer to our website for a full list of speakers rated for use with the TSU-2200

and ECO-200 decoders.

Tsunami2 and Econami Installation Guide 18

Page 19

Wiring Diagrams

TSU-21PNEM/ECO-21PNEM

The TSU-21PNEM and the ECO-21PNEM have a 21-pin, dual-row, bottom-entry connector

arranged according to the NEM Standard. Orient the decoder so that Pin 1 on the factoryinstalled board lines up with the appropriate connector on the decoder, which is indicated by the

white dot on top of the decoder. Plug the decoder into the factory-installed board. Solder or plug

in the purple speaker wires to the appropriate location on the factory-installed board.

CurrentKeeper Installation

In most cases, a CurrentKeeper may be soldered to the locomotive's factory-installed board to

help maintain performance during momentary power interruptions. Please contact our Customer

Support at (970) 259-0690 or support@soundtraxx.com for assistance with determining the

correct soldering locations.

Figure 22: TSU-21PNEM/ECO-21PNEM Wiring Diagram

Tsunami2 and Econami Installation Guide 19

Page 20

Wiring Diagrams

TSU-PNP/ECO-PNP

Designed as a factory board replacement format decoder, the TSU-PNP and ECO-PNP both

provide mounting points for many Athearn, Atlas, Bowser, Kato, and Intermountain Railway Co.

HO scale models.

Current Keeper Installation

Plug the CurrentKeeper wire harness directly into the 2-pin socket located next to the motor

connections on the decoder.

1.5V Wiring Diagram

Figure 23: TSU-PNP/ECO-PNP 1.5V Wiring Diagram

LED Wiring Diagram

Figure 24: TSU-PNP/ECO-PNP LED Wiring Diagram

Tsunami2 and Econami Installation Guide 20

Page 21

Wiring Diagrams

TSU-4400/ECO-400

Wiring the TSU-4400 and the ECO-400 is done by way of two terminal blocks on the circuit

board. Use a small flathead screwdriver to loosen the screws on the top of the block. If

necessary, trim any excess length from the wires to prevent them from interfering with

installation. Strip about 1/4" of insulation off each wire, tin the end, and insert it into the

appropriate terminal. Tighten the screw to make the connection.

CurrentKeeper Installation

The TSU-4400 and ECO-400 include a socket designed for the CurrentKeeper’s quick-plug for

easy installation.

Figure 25: TSU-4400/ECO-400 Wiring Diagram

Function Common is rated at track voltage minus 1.5V.

Note:

This rating will vary between command stations and layout

Tsunami2 and Econami Installation Guide 21

Page 22

Tsunami2 and Econami Installation Guide 22

Loading...

Loading...