SoundTraxx ECO-21PNEM, TSU-21PNEM, TSU-PNP, ECO-PNP, TSU-4400 Installation Manual

...

Tsunami2 and Econami Digital Sound Decoder

Installation Guide

Rev.D 05/10/2017

Contents

All Aboard! ............................................................................................................................... 3

Overview ...................................................................................................................................... 3

Pre-Installation Considerations ................................................................................................... 4

Installation ................................................................................................................................ 6

Step 1. Test the Motor Stall Current ........................................................................................... 6

Step 2. Plan the Installation ........................................................................................................ 7

Step 3. Isolate Motor and Lights from the Frame ....................................................................... 9

Step 4. Modify the Tender or Body Shell .................................................................................. 10

Step 5. Mount the Speaker ....................................................................................................... 12

Step 6. Install and Wire the Decoder ........................................................................................ 13

Step 7. Test the Istallation ........................................................................................................ 16

Wiring Diagrams .....................................................................................................................17

TSU-1100/ECO-100 .................................................................................................................. 17

TSU-2200/ECO-200 .................................................................................................................. 18

TSU-21PNEM/ECO-21PNEM ................................................................................................... 19

TSU-PNP/ECO-PNP ................................................................................................................. 20

TSU-4400/ECO-400 .................................................................................................................. 21

Notice

The information in this document is subject to change without notice.

SoundTraxx (Throttle Up! Corp.) shall not be liable for technical or editorial errors or omissions contained

herein, nor for incidental or consequential damage resulting from the furnishing, performance or use of

this material.

This document contains information protected by copyright. No part of this document may be photocopied

or reproduced in any form without the prior written consent of Throttle Up! Corp.

Product names mentioned herein may be trademarks and/or registered trademarks of their respective

companies.

SoundTraxx, Tsunami2, Econami, Tsunami, SoundTraxx DCC, Dynamic Digital Exhaust, Auto-Exhaust,

Hyperlight, Hyperdrive2, SoundCar, and Intelligent Consisting are trademarks of Throttle Up! Corp.

All Aboard!

Tsunami2

Econami

TSU-1100

ECO-100

TSU-2200

ECO-200

TSU-21PNEM

ECO-21PNEM

TSU-PNP

ECO-PNP

TSU-4400

ECO-400

To download all user documentation, visit www.soundtraxx.com/manuals.php.

All Aboard!

Overview

Congratulations on the purchase of your Tsunami2 or Econami Digital Sound Decoder! Properly

installed, this decoder will provide high-quality sound, realistic lighting effects, and superior

motor control. This installation guide will give you step-by-step instructions to successfully install

the following Tsunami2 and Econami formats for steam, diesel, or electric locomotives:

Though each decoder is tested thoroughly before shipping, we cannot control the correctness or

quality of a given installation. It is imperative that you follow the directions, and never remove

the protective heat-shrink from the decoder; there are no adjustments that can be made to the

hardware and this will void your warranty.

The difficulty of an installation depends principally on the modeler, and may be more or less

challenging according to any given circumstance. However, an installer should generally have

basic modeling skills, be comfortable disassembling a model, and be able to identify wires, such

as power pickups and motor leads.

Note: In the event that you damage the decoder during installation, our warranty policy is

outlined in the User’s Guide and on our website. It includes information about returning the

decoder to SoundTraxx for repair or replacement.

Further documentation regarding steam, diesel, or electric versions of your decoder:

If you’re new to DCC and sound, refer to the Quick Start Guides for default operation and

programming highlights.

Refer to the User’s Guides for in-depth instructions regarding operating and programming

your digital sound decoder.

Refer to the Technical References for details regarding each CV included in your Digital

Sound Decoder.

Refer to the Sound Selection References for a quick guide of CV values to adjust sound

effects in each version.

Refer to the SoundTraxx Guide to Successful Soldering for soldering tips and

recommendations.

Tsunami2 and Econami Installation Guide 3

All Aboard!

Pre-Installation Considerations

Carefully read the instructions that are printed on the decoder’s packaging. Then, finish reading

this installation guide. While installing the decoder, keep these precautions in mind:

Handle the decoder carefully in a

static-free environment. To discharge

static electricity before handling the

decoder, touch a water pipe or another

grounded metal surface.

Never remove the decoder’s protective

shrink tubing; this voids your warranty.

Never make connections to the decoder

while it is receiving power.

Make sure all electrical connections are

insulated. Avoid using electrical tape; it

tends to unwrap over time. We

recommend using heat-shrink tubing

instead.

Never allow the decoder leads to come

in contact with any DCC track wiring not

specifically designed for that purpose.

Never allow speaker or motor outputs to

be shorted together.

Do not exceed the output ratings for

which the decoder is designed.

Do not choose a locomotive with a stall

current exceeding the decoder’s rating;

always test the stall current of your

locomotive before installing the decoder.

If possible, mount the decoder in an

area with some airflow to provide

ventilation for the decoder.

Mount the decoder away from other

heat sources (such as the motor or

lamps) to avoid overheating.

Always use a proper speaker enclosure

(baffle) and select the largest speaker

possible.

Choose an appropriately rated speaker.

Take your time and have fun!

Testing the Decoder Prior to Installation

In rare cases, damage received during shipping or improper handling can cause a decoder to

fail prematurely. We recommend that you test all Digital Sound Decoders and accessories

within the item’s warranty period prior to beginning the installation. Proper bench testing of

decoders can save countless hours of headache and frustration if problems are discovered after

the installation process has begun

Testing the decoder on your workbench can be accomplished by connecting the wires/pads

from the DSD to a surplus motor, 8 ohm speaker and 12 volt lamps. Refer to the appropriate

wiring diagram for your decoder when making these connections. Also ensure that the wire

connections are mechanically sound and well insulated to prevent damage to the decoder or

accessories during testing.

When the appropriate connections have been made, test the motor by running it in both forward

and reverse directions. Test each lighting output by turning on the corresponding function key.

Lastly, check the audio output of the DSD by blowing the horn or whistle, ringing the bell and

listening for changes in prime mover notch, exhaust chuff or traction motor whine.

If you should discover any issues during this test, please contact our Customer Support

department for assistance.

Note: Neither Tsunami2 nor Econami require a programming track booster.

Tsunami2 and Econami Installation Guide 4

All Aboard!

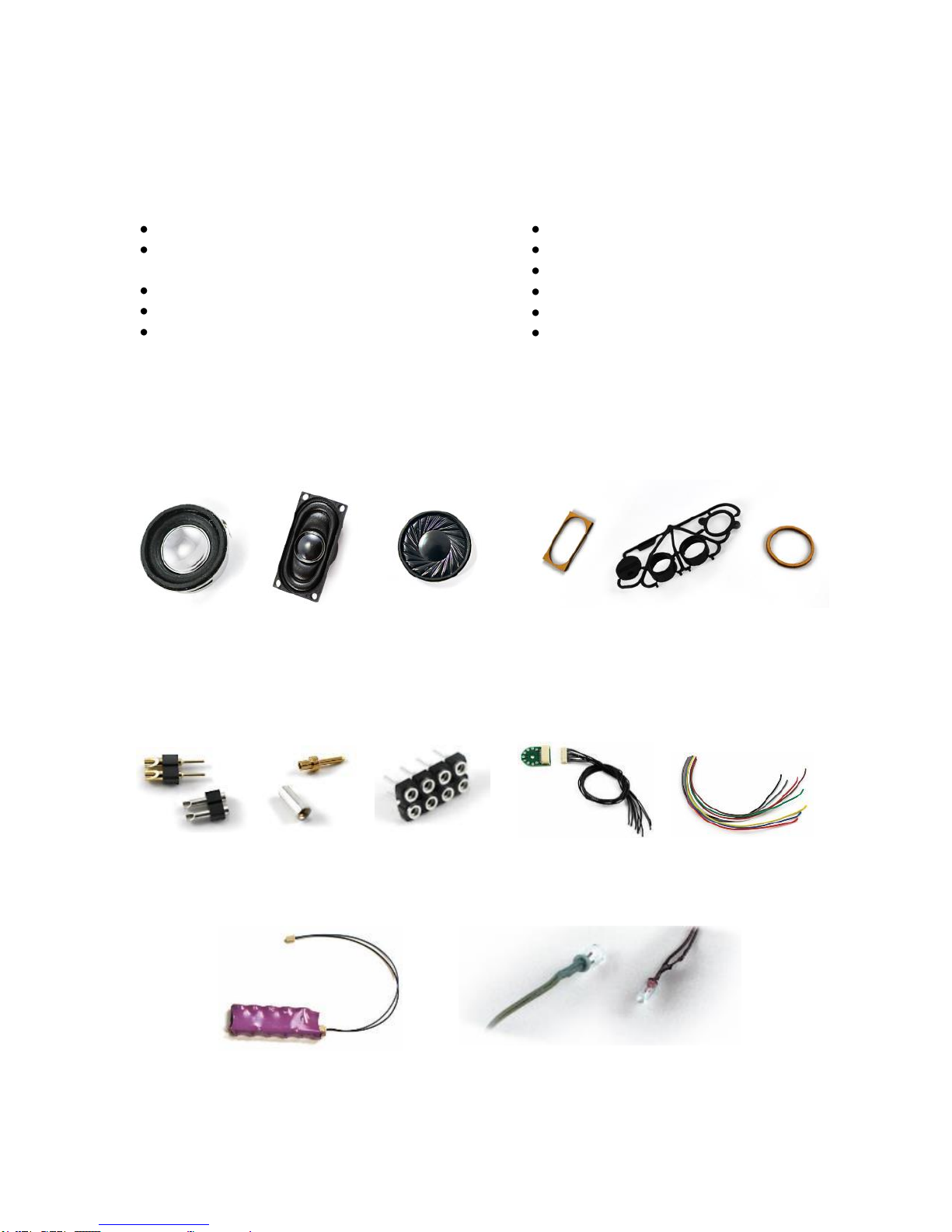

Miniature Speakers, Baffles, and Gaskets:

We have a variety of miniature speakers, baffles, and gasket kits for use with our digital sound

decoders; choose the largest speaker the installation will allow.

Wiring Aids

Micro-connectors can be used to facilitate easy separation of components. NMRA-Compatible

Connectors are used for converting universal-style decoders to a “plug-and-play” format.

DBX-9000 Wiring Kit facilitates easy separation of the locomotive and tender. Super-flexible

wire is ideal for working in tight spaces.

DCC Accessories

The CurrentKeeper helps maintain decoder performance during momentary power losses.

Microbulbs and LEDs let you take advantage of our Hyperlight lighting effects.

Tools and Materials You Will Need

In addition to the common hand tools found on most modeler’s workbenches, you should have

the following at your disposal:

Low-wattage soldering iron

Rosin-core solder and electronics

safe flux

Hobby knife

Miniature screwdriver set

Diagonal wire cutters

We have a variety of accessories to aid your installation. For more information about our full line

of installation accessories, visit www.soundtraxx.com/access/index.php.

Handheld rotary tool

Multimeter

Double-sided foam tape

Heat-shrink tubing

Silicone RTV

Drill bit assortment

Tsunami2 and Econami Installation Guide 5

Installation

Installation

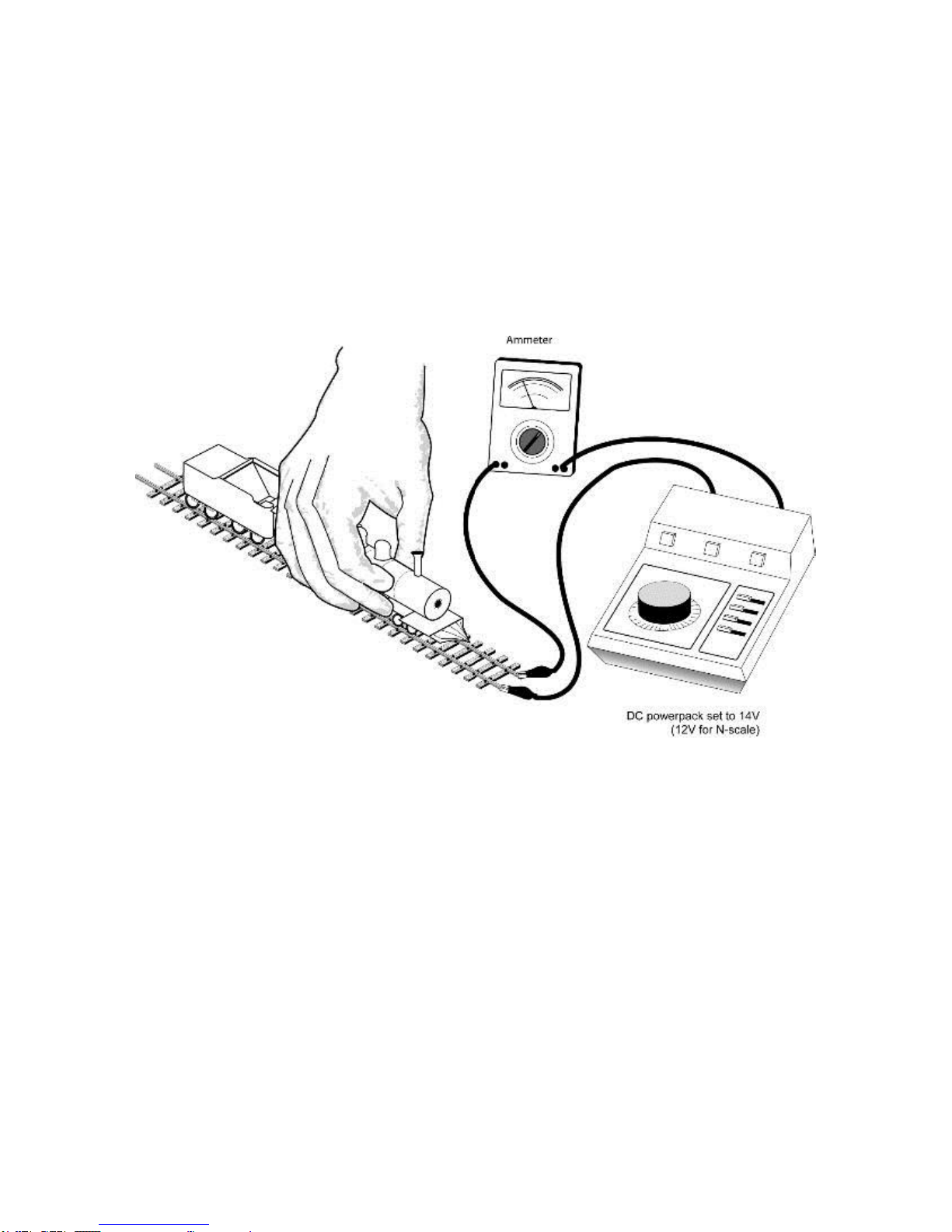

Step 1. Test the Motor Stall Current

Test the locomotive’s stall current to ensure that it is compatible with the decoder that you have

chosen:

1. Place the locomotive on a section of track powered by a conventional DC powerpack set to

the same track voltage as your command station (typically 12-14 volts).

2. Referring to Figure 1, connect a DC ammeter in series with one of the track feeders. If your

powerpack has built-in meters, you may use them for this purpose.

Figure 1: Testing the Locomotive’s Motor Stall Current

3. Immobilize the locomotive by holding it to the track, and turn on the powerpack.

4. Firmly press down on the locomotive or hold the motor’s flywheel to stop it from spinning.

5. Ensure the powerpack voltage remains the same to receive an accurate measurement.

6. Measure the current the locomotive is drawing while the motor is stalled; this is the stall

current.

7. Ensure the motor stall current is less than the decoder’s rated capacity.

Tsunami2 and Econami Installation Guide 6

Installation

Mini Cube Speakers

28 mm (1”) Round Speaker

16 x 35mm Oval Speaker

Step 2. Plan the Installation

The sound quality you will receive from your

Digital Sound Decoder depends upon your

speaker selection, the way you install the

speaker, and the location of the decoder

within the model. Consider the following as

you plan your sound installation:

Provide ventilation for the decoder if

possible.

Mount the decoder away from other

heat sources (such as the motor or

lamps) to reduce the chance of

overheating.

Always provide a proper enclosure

(baffle) for the speaker. Lack of a

speaker baffle will cause poor sound

quality.

Speaker Considerations

Select the largest speaker that your model

permits to achieve higher volume and better

quality low-frequency response for a more

realistic sounds. We offer a range of

speakers that you can use with your model.

Note: Be sure that your speaker is rated to

match the audio amplifier of your decoder;

failure to do so could cause damage to your

speaker. Check the packaging and our

website for ratings for each decoder format.

Note: If a single large speaker isn’t an

option, you may be able to use two or three

smaller speakers to improve the frequency

response. For details, refer to “Wiring

Multiple Speakers” within Step 6. Install

and Wire the Decoder (Pg. 13).

Speaker Enclosures

A speaker enclosure (baffle) should be used

to allow air pressure to build up and amplify

sound.

The enclosure should fit the speaker. The

pressure building within an enclosure that is

too small for the speaker will compromise

certain frequencies and muffle the sound

response. As a guideline, enclosures for

speakers measuring less than 3” in

diameter should be built using the cubic

relationship between height, length and

width. For example, a 1” speaker should be

paired with a 1” x 1” x 1” enclosure.

Note: Employing a proper speaker

enclosure cannot be emphasized enough;

the absence of an effective enclosure is

almost always the cause of poor sound

quality.

Speaker enclosures should also be:

Fixed with stiff walls to prevent

vibrations and buzzing

Installed flush with the speaker

dimensions to create an airtight space

for the speaker cone to build pressure

and produce a strong sound response

We offer various snap-together baffle kits

like the one shown below.

SoundTraxx Speaker Baffle Kit

Tsunami2 and Econami Installation Guide 7

Loading...

Loading...