Soundstream Exact 5.3 Owner's Manual

Component

Speaker System

OWNER’S MANUAL

1

Component Speaker System

INTRODUCTION

AND

REGISTRATION

Congratulations on your purchase of the Soundstream EXACT5.3 Component Speaker

System. You now own one of the finest car audio speaker systems available.

As with all high quality car audio components, professional installation is recommended.

Your dealer’s knowledge and experience can ensure a problem-free, cosmetically

integrated installation. If you plan on installing the EXACT5.3 speaker system yourself,

please review this Owner’s Manual first before attempting installation. In addition, it’s a

good idea to keep the manual for future reference.

EXACT5 Serial Number _______________________________________

EXACT1 Serial Number _______________________________________

Date of Purchase _____________________________________________

Date of Installation _____________________________________________

Dealer’s Name _____________________________________________

HARDWARE

AND

CONNECTOR

PARTS LIST

Before beginning your installation, please check to see that the number of parts

contained in your box match the list below:

Hardware

2 each - flush-mount cups

16 each - 1 1/4” #8 sheet metal screws (for mounting EXACT5)

2 each - 1/4” 6-32 machine screws (for EXACT1 flush mount cup spring clips)

4 each - stainless steel tweeter spring clips (for EXACT1 flush mount cup)

4 each - 1/2” #8 sheet metal screws (for mounting EXACT5.3X)

4 each - 1/2” flat head screws (for EXACT1 surface mounting)

1 each - template set

Connectors

4 each -

16 each - gold spade connectors (for connecting to crossover)

4 each - 1/8” gold round female connectors (for connecting EXACT1 to speaker wire)

4 each - vinyl insulators (for insulating EXACT1 speaker connectors)

1

/4” tab female gold insulated slip-on connectors (for EXACT5 woofers)

2

EXACT5.3

DESIGN

FEATURES

The EXACT5.3 Component Speaker System is the result of highly focused engineering effort.

Each element of the EXACT5.3 represents several advances in automotive speaker technology.

When the EXACT5.3 project was initiated, the following goals were established:

• High performance sound reproduction in the automotive environment

• Ease of installation

• Superb ergonomics and visual appeal

• High output capability

• Ability to “tailor” sound to each vehicle

Through extensive testing and development, the EXACT5.3 has been designed to provide

extremely consistent on and off-axis response in the automobile. Installation flexibility and

ergonomics are enhanced by the mounting versatility of both the EXACT5 midrange/woofer and

the EXACT1 tweeter. Finally, the high output capability and low frequency extension of the

EXACT5.3 are atypical of 5” drivers due to the excursion capabilities of the EXACT5 and the

steep crossover slopes of the EXACT5.3X.

These efforts have resulted in an extremely flexible speaker system that performs flawlessly in a

EXACT5 Midrange / Woofer

The EXACT5 represents a departure from typical midrange/midbass drivers by combining

massive midbass and exceptionally smooth midrange.

•Die-cast Magnesium Frame designed specifically for extra long excursion. Results in higher

output and extended low frequency response.

•Copper Inductance Cap for lower distortion and extended high frequency response.

•Natural Fiber Cone designed for optimum rigidity and damping with minimal “coloration”.

EXACT1 Soft Dome Neodymium Tweeter

The EXACT1 tweeter is an ultra-high performance 1” Neodymium tweeter designed to deliver

outstanding high frequency reproduction.

• Fourth-generation Neodymium Magnetic Assembly providing performance comparable or

superior to tweeters three times the size.

• Specially-treated Textile Dome for a natural, smooth response to 20 kHz.

• Ferrofluid-immersed Voice Coil enhances heat dissipation.

EXACT5.3X Passive Crossover Network

The EXACT5.3X Passive Crossover represents a new concept in crossover philosophy. The

EXACT5.3X crossover consists of high quality, multi-element components with two switchable

functions. A three position switch controls the tweeter level and a two position switch controls the

midrange presence. The combination of each allows for a multitude of control options. Dual

inputs allow for multi-channel amp operation of woofer and tweeter circuits.

• 24 dB/octave Acoustic Summation Crossover Slopes for smooth response.

• Variable Tweeter and Midrange Controls for added flexibility.

• Dual Inputs for multi-amp operation and further flexibility.

• Dynamic Tweeter Level Control allows for improved power handling and continuous output.

• Ultra-low DCR Inductors for minimal signal loss (High power Air-core type in woofer path).

• Mylar Film Capacitors to ensure low saturation and accuracy in the high frequencies.

3

LOCATION

AND

MOUNTING

The first step in a successful installation is thorough planning. Choose the location for

your speaker components carefully. Follow these suggestions to ensure proper

imaging and the best performance:

• Select a location where each tweeter and midrange/woofer can be mounted close to

each other. A good rule of thumb is a maximum of one foot from midrange/woofer

to tweeter.

• Choose a location that offers the least amount of sound obstruction.

• Try to mount the components on the same plane.

• Always check behind the chosen mounting locations to make sure that there are no

obstructions (e.g., trunk springs, gas tank, window track) or wires in the way, as well

as to make sure that there is ample support on which to mount the components.

INSTALLING THE

EXACT1

TWEETER

The EXACT1 tweeter can be installed in a variety of ways: a simple yet elegant

installation cup is provided for flush mounting; or the tweeter may be easily

disassembled for custom applications, such as installation in vents, custom painting, or

mounting behind a factory grille. Hardware is provided for each mounting

configuration.

For surface mounting, locate a flat mounting surface for the EXACT1. A direct “onaxis” location is not necessary, as the EXACT1 provides extraordinary “off-axis”

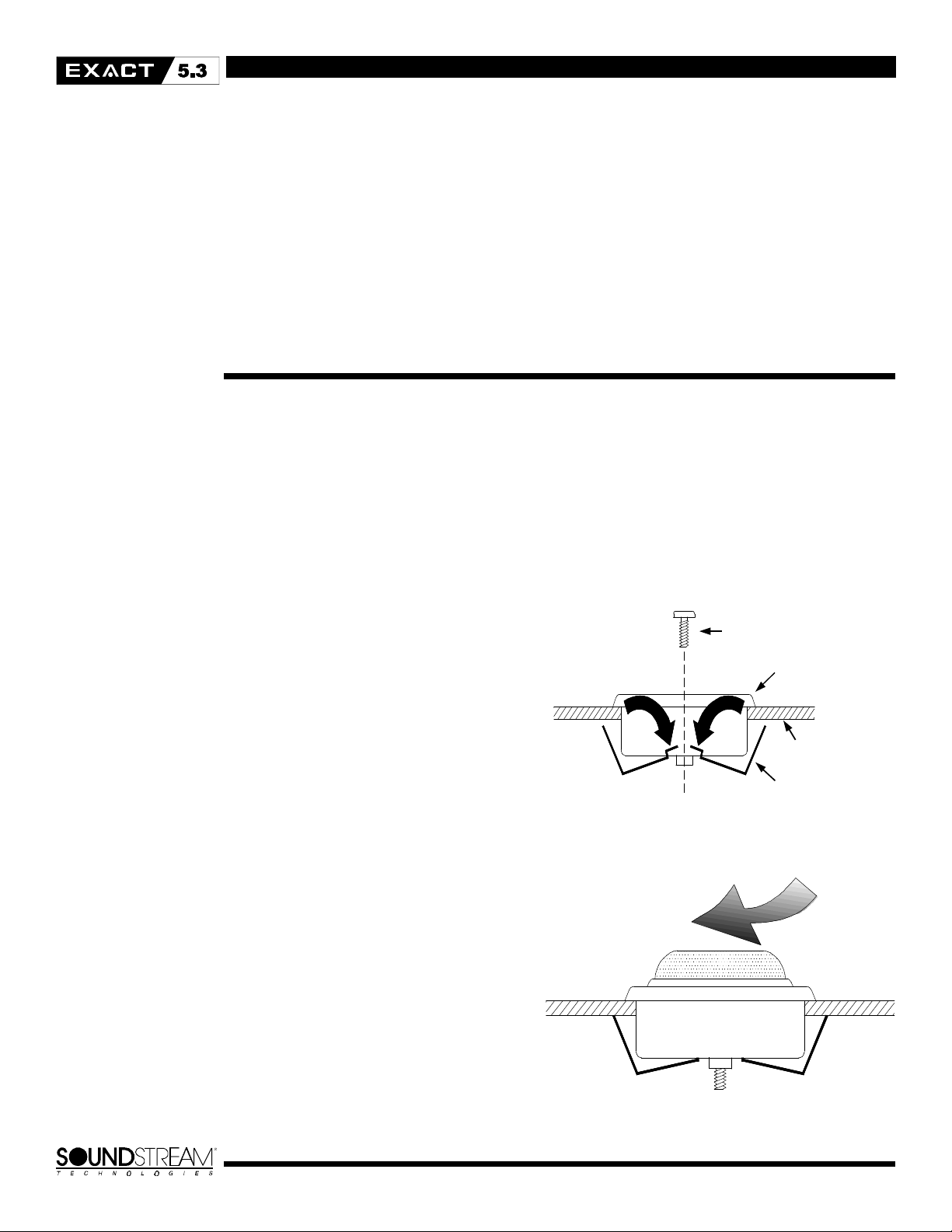

Flush Mounting

1) Cut a 1 7/8” diameter hole

through the mounting surface. If

the surface is covered with cloth

or carpet, be careful not to tear

or pull the material. Sometimes

it is a good idea to peel the

material away and then trim it by

hand.

2) Secure the cup in the mounting

cutout by using the spring clips

and screw provided. Slip the

spring clips through the bottom

of the cup and tighten the screw

until the cup is firmly seated.

See Figure 1.

3) Once the cup is secure, mount

the tweeter into the cup making

sure to pass the tweeter wires

through the openings in the cup.

The tweeter will lock into the cup

when turned clockwise. See

Figure 2.

FIGURE 1

1

/4” 6-32 machine screw

Flush mount cup

Mounting surface

Spring clip

Turn

Clockwise to

Lock

4

FIGURE 2

Loading...

Loading...