Page 1

Page 2

Page 3

MR8, the latest advancement in Zero Stress Dough Technology to divide dough at

high hydration and all the type of dough for the best of the Artisan Bread Production.

Our MR8 Divider, which has the satellite dough reduction head, the gauging rollers,

strip and guillotine cutting system (for square, rectangular or diagonal cuts dough pieces

already) is designed to gently handle all types of ciabatta, artisan bread and rolls.

MR8 has a production capacity of 1000 Kg. of dough (2200 lbs.) per hour, and it is

able to divide at 1-2-3-4-5-6 pockets with a max infeed width of 240 mm (9.45”).

Single pocket, which can be divided according to the number of pockets of the knife.

At 6 pockets it has 40 mm (1.57”).

MR8 divider has a minimum length of any pieces of 10 mm (0.4”) and the max length

is approx 800 mm (31.5”). Adjustable thickness of dough lamination from 6 to 30

mm (0.2” to 1.19”) The larger size dough pieces is sized very well for typical focaccia

bread products.

MR8 has a weight range from 25gr up to 2000 gr (3/4 oz to 4.4 lb).

4

Page 4

The innovative satellite system with side and top

compacting systems. The entire system driven by a

sensor that feels the dough so the satellite will work

according to the dough situation.

All of this to treat the dough so gently that even the

hand cannot do the same.

Final sheeting roller for a smooth and well sheet pieces of

dough, in order to keep the weight of single pieces much more

consistent as possible.

Before the final sheeting roller there is a sensor roller which

allows to change the speed of the sheeting couple according

with the dough need. Easy change system for the strip knife

cutting which can be at 1-2-3-4-5-6 pockets.

MR8 has a stainless steel frame with special plastic material. The longitudinal cutting

discs system and the guillotine cutter have interchangeable blades in the number of

rows; the guillotine can have straight, inclined and/or triangle shaping blades, or different

shapes as per customer’s specifications.

Each movement of the MR8 is controlled by an inverter to give the maximum working

flexibility and it gives to the operator the possibility to adjust the machine parameter as

he desires in order to get the best of the final result.

Special heavy duty spreading belts. In the MR8, you

don’t need to change any frame or make any belt

adjustments in order to get the perfect dough strip

aligned.

Everything is done by a simple free tools operation.

The blade is easy

interchangeable

and they are in

stainless steel

with a special

Teflon coating.

5

Page 5

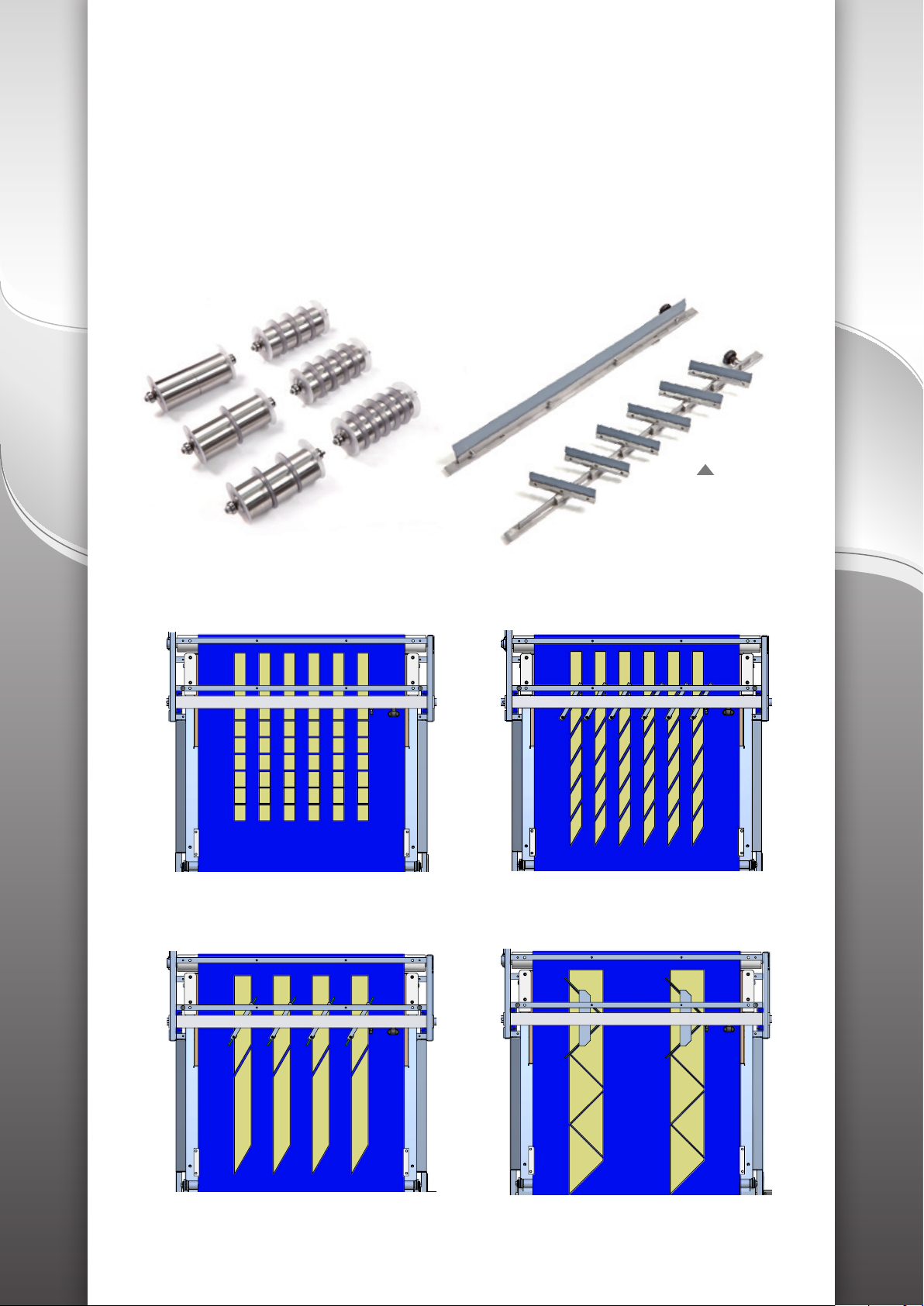

Wide range of knives is available for the longitudinal cutting disc system.

The guillotine cutters have interchangeable blades in the number of rows; the guillotine

can have a straight, inclined and/or triangle shaping blades, or, different shapes as per

the customer’s specifications. The blades are easily interchanged and they are fabricated

in S/S with a special Teflon coating.

The big number of guillotine blade and strip disc cutting roller allows the MR8 to have

maximum flexibility and a huge product range.

A special disc is available to close the edge of the dough strip.

Range

of guilliotine

blades.

Ciabatta Diamond Cut

Baguette Cut Triangle Cut

6

Page 6

MR8 system layout.

SEZIONE B-B

The MR8 Zero stress System layout with the dough sensors.

This is the system that handle your dough like an human hand.

MODEL NET WEIGHT

Kgs

MR8 985 1090 340 x 165 x 210 730x645x1225

GROSS WEIGHT

Kgs

PACKAGING DIMENSIONS

(Lenght x Width x Height) cm

VOLUME

3

m

100

3100

1235

1000

820

1595

740

7

1280

Page 7

MR8 Line 2

MR8 is not only a single machine, but it is the beginning of a wide range of automatic

lines able to produce all types of high quality artisan bread.

lines

The MR8 line has many modules to satisfy all customers demands in terms of bread shape

production. As you can see from a 5,2 m (17’-0”) long line, we can extend to 17.6 m (57’-7”).

MR8 Line 6

8

Page 8

MR8 Line Range

MR8 Line 1

5200

MR8 Line 2

6600

MR8 Line 3

9500

MR8 Line 5

MR8 Line 6

MR8 Line 4

11200

15800

17000

MR8 Line 7

17600

9

Page 9

Dough Chunker.

The Dough Chunker for 170 kg (370 lbs) of raw dough.

Fabricated in stainless steel.

The chunking stars have a special design for an

even dough loading into the MR8, and they are

removable for an easy cleaning.

Rounding Cup Station.

The Rounding Cup station has many different rounding cups available for 6-5-4-3-2 pockets.

Capable of rounding dough pieces from 30 grams up to 400 grams (1 oz to 14 oz).

10

Page 10

Intermediative Proover and Stamping Unit.

Different types of intermediate proofers are available according to the required resting time and

hourly production capacity.

The intermediate proofers are fabricated with heavy gauge steel and covered by stainless

steel side panels. The trays are open trough type so that every number of rows of dough balls

are possible and that long rolled or round products with a weight up to 350 gr. are possible

in accordance with the model of proofer chosen.

They are built for different weight ranges. Type “A” up to 130 grams, Type “B” up to 350 gr.

The “by pass” that goes through the entire proofer is an option.

Stamping Unit and Aligner.

Stamping Unit.

The unique Sottoriva stamping unit can stamp

round or long products with a weight range

from 30 gr up to 150 gr on Kaiser rolls (for

example) in accordance with the proper size

of stamping bar and dough holder.

Many different stamping bars are available.

Aligner.

11

The hamburger bun aligner, out of the

intermediate proofer, onto the spreading

belts, for perfect dough piece loading

onto baking sheets or proofing trays.

Page 11

Moulding Stations.

First Moulding Station. Second Moulding Station with Aligner Device.

MR8 can be equipped with a single or a double moulding stations. This depends on the size of the

products that the customer wants to produce. For long baguettes, the aligner device is available.

The first moulding station has a sheeting head with a pre-sheeting roller, and final sheeting

rollers, in order to avoid dough stress during the moulding.

The first and the second moulding station can also be equipped with a pressing board or with

a reverse moulding belt.

Wetting and Seeding Station.

The wetting and seeding station, with a

removable chain belt/flat belt for a better

cleaning, or for using a solid belt for

different production.

Additional seed hoppers are available for

each different type of seed.

12

Page 12

Cutting Station.

Panning System.

Our Cutting station for finger rolls

can be added to the line.

The system uses a longitudinal

cutting disc, which can be set straight,

45 or 90 degrees.

The reciprocating belt panning device for trays, boards, or any other belt type you want to

load. Maximum bread board dimensions of 800 x 1000mm.

Also available as a retracting belt for trays.

The belt tray loading on reciprocator with a corn or flour duster is the top end of the automation.

Page 13

Our MR8 HEAD MACHINE or FULL LINE is the latest advancement

in zero stress technology, and provides all bakers with the ability to produce

an artisan bread better than anybody could ever believe that was made

by a machine, equal to bread made by hand.

SOTTORIVA MR8, the new answer for your artisan bread production requirements.

Some example of the various MR8 type of bread range.

Hourly Capacity: 1000 Kg of dough (2200 lbs).

Cross Buns

Portuguese Rolls

Rosetta bread

Kaiser Rolls

Pugliese bread

Knot Rolls

Subway

Long loaf

Caterpillar Rolls

Turtle Rolls

Lines Rolls

Long Cut Roll

Banana bread

14

Hamburger bun

Triangle Bread Unmoulded Baguette Diamond Bread

Hamburger bun

Baguette

Hot dog

Square roll

Ciabatta bread

Petit pain

Page 14

Loading...

Loading...