Page 1

Your future, our technology.

DINAMICA

Page 2

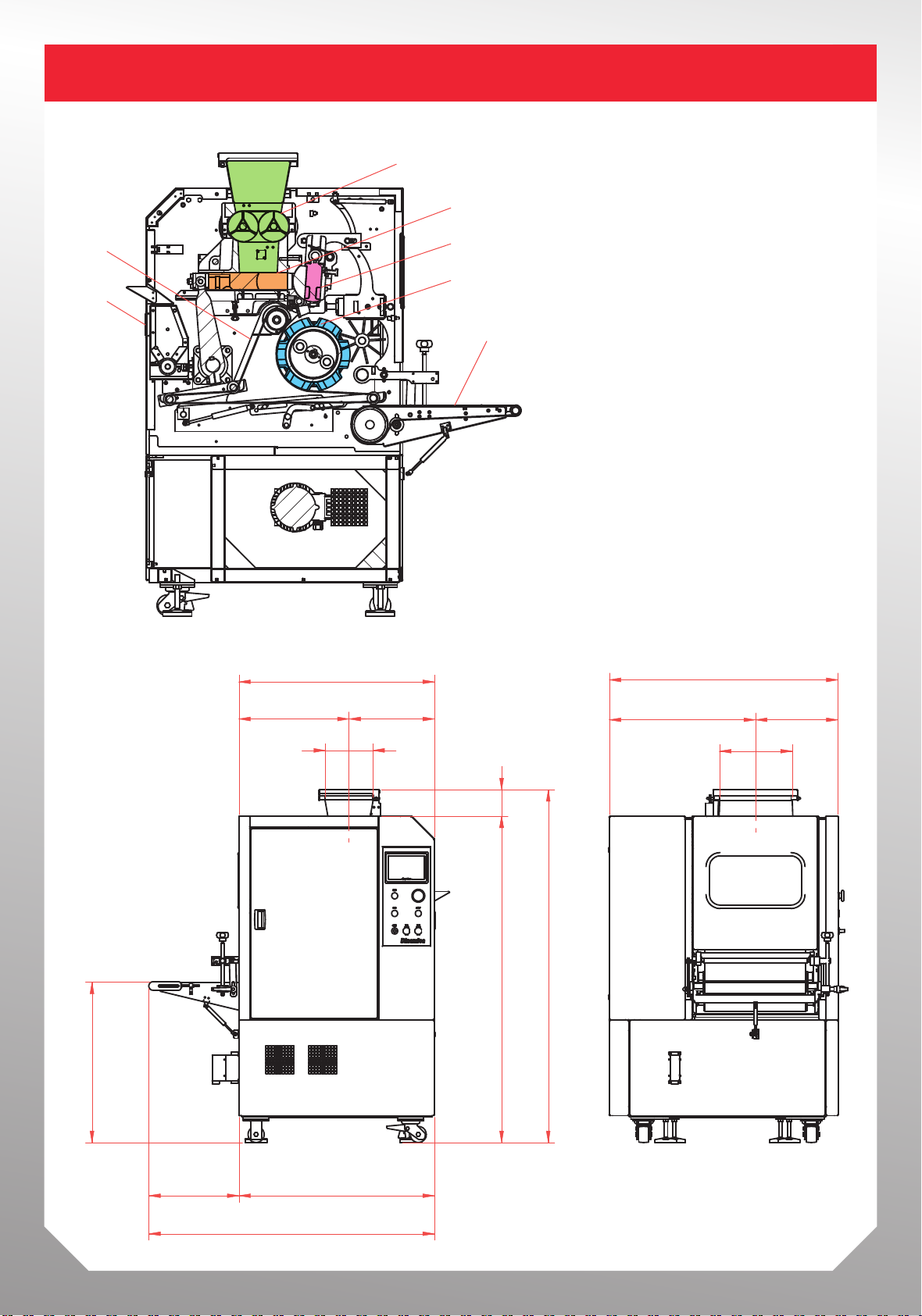

DINAMICA Overall Dimensions

1

2

5

6

3

4

7

LEGEND

1) Stress Free

Dividing Star System;

2) Dividing Chamber;

3) Dividing Pistons;

4) Rounding Drum;

5) Rounding Belt;

6) Flour Duster;

7) Exit Belt.

910

1065

710-780

513

222

397

1519 124

385680

338

1643

1330

910420

Page 3

DINAMICA

DINAMICA is our OIL FREE, heavy duty dough divider / rounder at 4-5 or 6 rows. Ideally

suited for dividing and rounding a variety of doughs which undergo further processing

to obtain a round, moulded, flattened, or long rolled shapes that we identify as

hamburger and hotdog buns, finger rolls, sub rolls or hoagies, bolillos, petit pains,

brioche, pita bread, pizza bread, egg buns and dinner rolls. The DINAMICA is suitable

for working soft and semi-hard dough, and, it is standard with a Teflon coated stainless

steel hopper with an approximate of 25kg (55 lbs.) of dough capacity.

All dough types are handled gently, thanks in part to the combination of our star wheel

dosing system, and, an adjustable spring system for the pressure in the portioning

chambers. These simple operator control features substantially reduce any stress to

dough that is coming from the mechanical action of the machine. The added benefit is

realized as the DINAMICA has a very accurate dough weight control, due to the reduced

stress in the dough cell structure

After the weight of the dough ball is determined, the pieces of dough are discharged

from the pistons and deposited into our innovative rounding drum design with the

double weight range.

Compared to regular rounding systems, this new and innovative design of our rounding

system accommodates a very large range of varied dough weight on one drum.

Upon completion of the rounding cycle, the dough balls are transferred onto the

discharge conveyor belt for pick-up (by hand), or to be further conveyed to attached

moulding equipment (for product shaping and forming).

Production is electronically variable from 800 to 1600 pcs/hour per row.

The DINAMICA is available with touch-screen control panel, with 50 storable programs,

that controls and stores all the machine functions, from adjustment of sizes to rounding

and production speed.

The panel also has a diagnostics screen to identify possible

operational problems. Further, the panel can identify conflicts

where the dough weight, the production speed, and, the overall

machine speed are non-synchronous, mechanically or through

the potentiometer.

The “NEW” DINAMICA “E” electronic version control panel

is also supplied with a USB key port and an Ethernet RS232

cable connection in order to upload or download program

modifications into the PLC (if required), store the machine

programs(externally), or, to update the software to or from a

PC connection for a change to the machine control.

Page 4

Due to the innovative design of the rounding drum,

the DINAMICA, with only one drum, can cover the

entire weight range in one single machine

execution, and, of course, with the highest standard

for rounding that only a drum system can deliver at

the maximum speed of hourly production.

Our INNOVATIVE special double size rounding

drum which allows a very wide range of dough

weights. This is a real innovative design for the most

UNIQUE dough divider and rounder machine

named DINAMICA for the bakery that needs a wide

range of flexibility for their customer’s product

requirements.

DINAMICA is produced in 3 different models, the DINAMICA 4, 5, or 6 pockets.

Each model has different versions and the customer can choose one, two, or all the

variables inside the same model.

Different versions (factory set) can be modified later to meet the changing needs of the

client, with the purchase and installation of a special kit of “changeover” pistons and

the rounding drum.

Version 1

Version 2

Version 3

Version 4

Version 5

DINAMICA 4

Version 6

DINAMICA 5 - 5M

Version 1

Version 2

Version 3

Version 4

DINAMICA 5

Version 5

DINAMICA 6 - 6M

Version 1

Version 2

DINAMICA 6

Version 3

Version 4

Choice of dividing set up

WEIGHT RANGE TYPE OF PISTONHOURLY PRODUCTIONDINAMICA 4 - 4M

20-35 gr

30-55 gr

1

55-80 gr

80-110 gr

2

110-140 gr

140-180 gr

3

WEIGHT RANGE TYPE OF PISTONHOURLY PRODUCTION

4

20-35 gr

30-55 gr

1

55-80 gr

80-105 gr

2

105-130 gr

3

WEIGHT RANGE TYPE OF PISTONHOURLY PRODUCTION

20-35 gr

1

30-55 gr

55-80 gr

2

80-110 gr

0.70-1.24 oz

1.05-1.94 oz

X

1.94-2.82 oz

2.82-3.88 oz

X

3.88-4.93 oz

4.93-6.35 oz

X

X

0.70-1.24 oz

1.05-1.94 oz

X

1.94-2.82 oz

2.82-3.70 oz

X

3.70-4.58 oz

X

0.70-1.24 oz

X

1.05-1.94 oz

1.94-2.82 oz

X

2.82-3.88 oz

Weight Range Hourly Capacity

6400

20-50 gr (0.70-1.76 oz)

30-90 gr (1.05-3.17 oz)

80-130 gr (2.82-4.58 oz)

120-180 gr (4.23-6.35 oz)

20-50 gr (0.70-1.76 oz)

40-110 gr (1.41-3.85 oz)

6400

6400

6400

6400

6400

8000

8000

8000

8000

8000

80-130 gr (2.82-4.58 oz)

20-50 gr (0.70-1.76 oz)

40-110 gr (1.41-3.85 oz)

9600

9600

9600

9600

Extra Piston set 1

Extra Piston set 2

6400 PCS

Extra Piston set 2

Standard Piston

6400 PCS

Standard Piston

Standard Piston

6400 PCS

6400 PCS

Extra Piston set 1

Standard Piston

8000 PCS

Standard Piston

Standard Piston

8000 PCS

Standard Piston

8000 PCS

Extra Piston set 1

9600 PCS

Standard Piston

Standard Piston

9600 PCS

Standard Piston

Page 5

The special plastic material allow the machine to be OIL FREE. This feature provides a

huge advantage to the baker, by reducing the time required for maintaining a clean

machine, being a great money saver to rid the need for divider oil for machine operation.

NO OIL, NO MESS, SAVES MONEY!

Cleaning the machine after every production run is very easy and just takes a few

minutes. Faster clean-up yields more operation time and profits, so it pays for the

customer to take care of his DINAMICA machine so it will last for ever.

Solid and heavy duty out feed belt

for hand panning (Standard).

Finger belt to connect the Dinamica with

a moulding station or a line (Optional).

DINAMICA can work with different types of dough: HARD, MEDIUM, and “SOFT and

STICKY”, thanks to different set-ups available.

These great features make the DINAMICA very flexible and user-friendly, while

delivering the Baker the possibility to use ONE machine for his/her production.

Page 6

www.hhdesign.it

SOTTORIVA S.p.A.

Via Vittorio Veneto, 63

36035 Marano Vicentino (VI) ITALIA

Tel. +39.0445.595111

Fax +39.0445.595155

sottoriva@sottoriva.com

www.sottoriva.com

SOTTORIVA AMERICA INC

620- C Griffith Road

Charlotte, NC 28217 - USA

Tel: +1(704).714.5880

Fax +1(704).714.5881

sottorivaamerica@sottoriva.com

www.sottoriva.com

Cod. 3527541701

Rev. A

Loading...

Loading...