sotaturntables@kwom.com - www.sotaturntables.com

JEWEL, SAPPHIRE,

STAR and NOVA Turntables

PLEASE READ THE INSTRUCTIONS COMPLETELY BEFORE BEGINNING SET UP AND OPERATION!

UNPACKING

The SOTA turntable comes bolted to a plywood board, which “floats” in a cardboard sleeve. Begin by

placing the turntable carton on a large, sturdy work surface. Open the box top, fold the box flaps back,

invert the box and lift off. The turntable and the cardboard sleeve will remain on the work surface as you lift

off the outer carton.

Place the turntable and sleeve on edge with the front feet down. Set the following parts aside, which you

will find attached to the bottom of the packing board:

(1) Armboard (Wood, Co mposite or COSMOS with three (3) appropriate mounting screws and hex key

for installation).

(1) 3/32” Hex Key, used for transit set screws and for Wood Armboard screws

(1) Control Panel Cover

(1) Bubble level

(1) Ground Wire

(1) Bag of lead shot, weighing 2 lb. – 14.5 oz . (SAPPHIRE, STAR, and NOVA only. Note: STAR and

NOVA lead shot is packed with pump unit.)

(2) Lead slugs (SAPPHIRE, STAR and NOVA only)

(1) “Dummy” Plug (STAR and NOVA only)

(1) Reflex Clamp (NOVA only)

NOTE: Save ALL the turntable packing materials for re-use, should the turntable

ever need to be shipped.

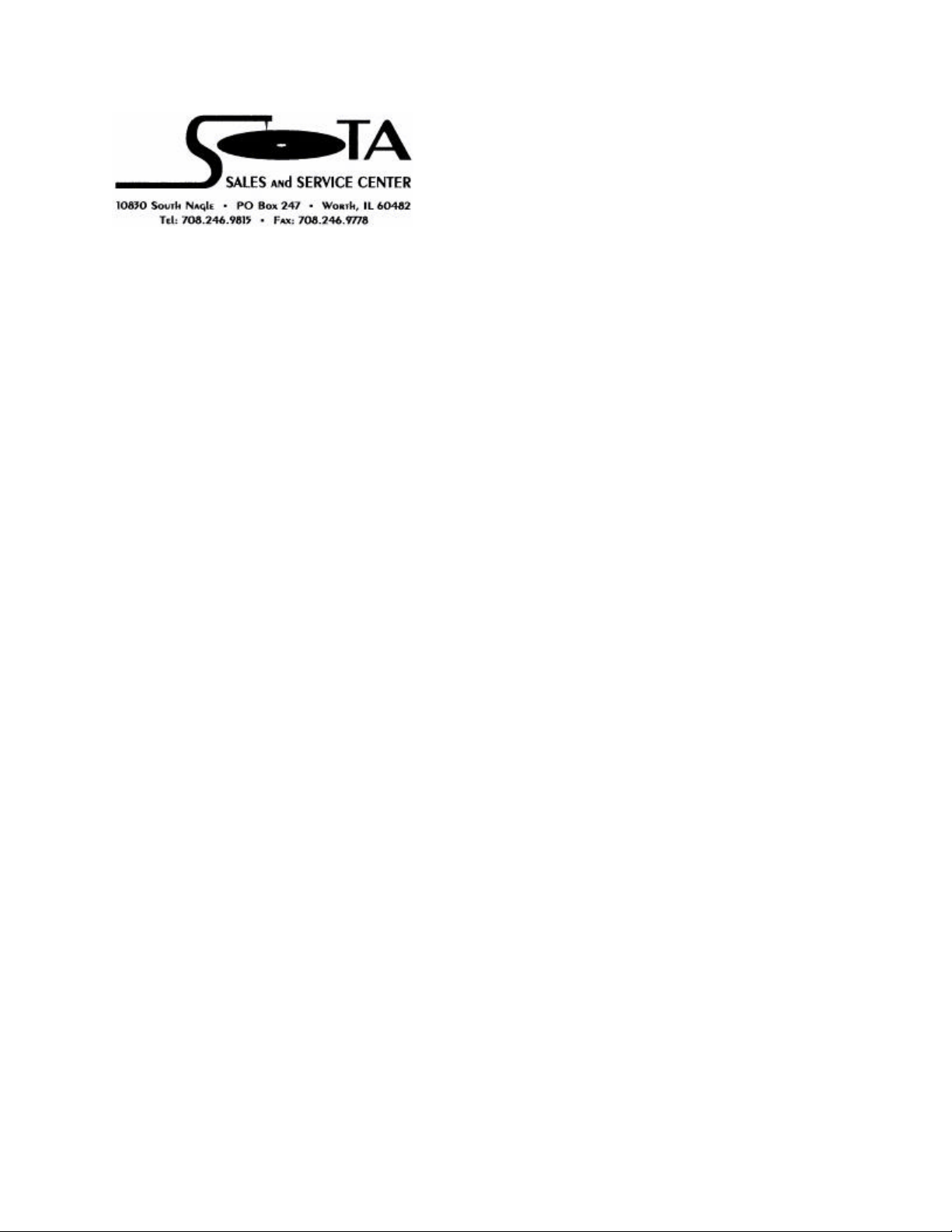

Using a wrench or nut-driver, remove the lower two shipping bolts, which are adjacent to the feet (See

Figure 2). Cut the tape securing the inner sleeve and remove the inner sleeve. Loosen the third shipping

bolt one turn, and gently lower the table with attached packing board back onto its feet. Now, position the

last shipping bolt over the edge of the work surface and remove it. Lift the table from the shipping board

(save the shipping board) and set the turntable on the work surface. Carefully unpeel the plastic wrapping

and save. If included, lift the Dust Cover straight up and off.

For the JEWEL and SAPPHIRE only, remove the power supply from the armboard well and set aside.

Figure 2

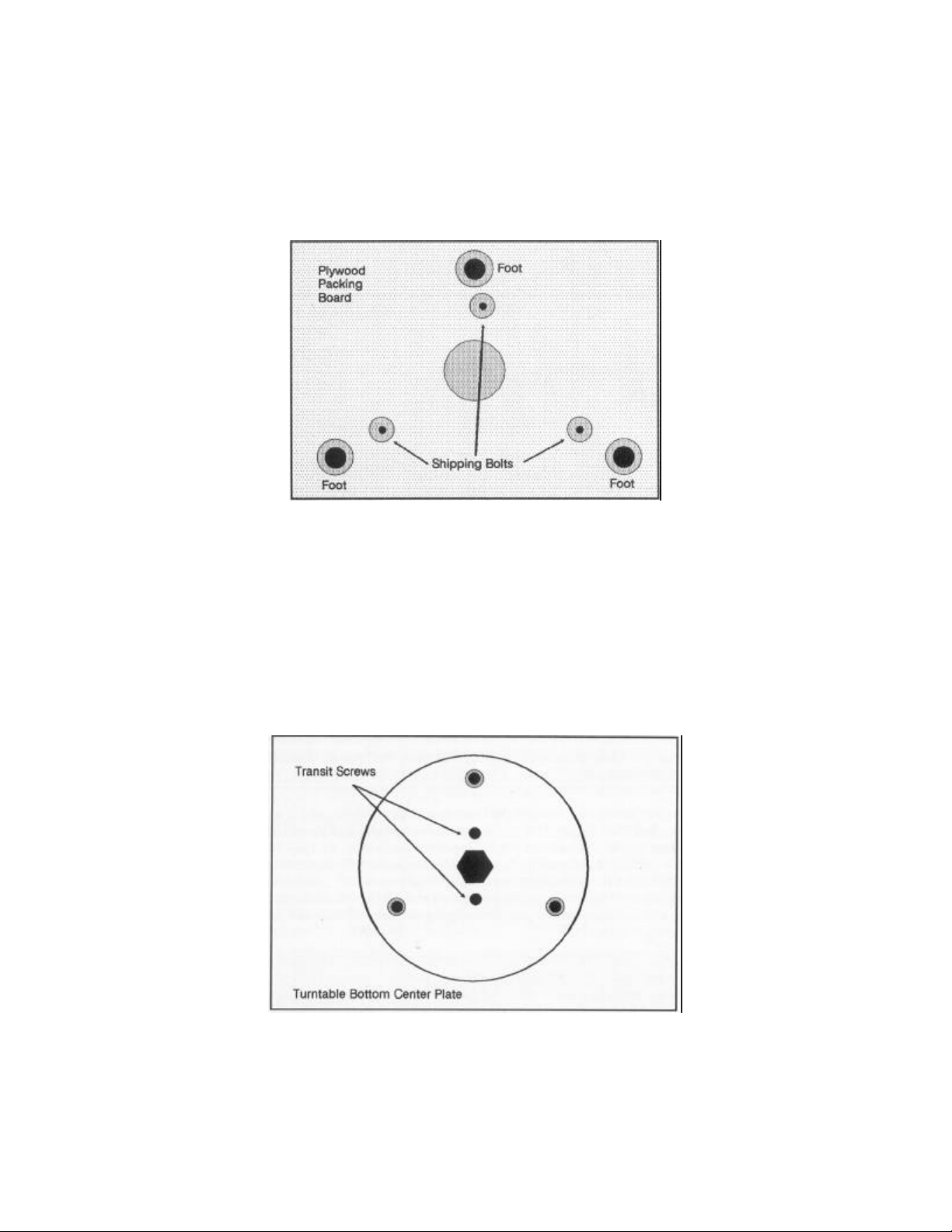

Place the turntable on its side with the controls down. Remove the feet and the foam pads. (Save the

foam pads.) Replace the feet, screwing them each in approximately two full turns. Loosen the transit

screw lock nuts, and then using the supplied 3/32” hex key, release (unscrew) one transit set screw – leave

the other in place until the unit is ready to play. Loosen the transit set screw about ¼”, and then use the

transit nut to lock the transit screw in place. (See Figure 3).

Figure 3

2

Put the table on its feet and remove the cardboard shims from under the pulley and the three pads from

around the platter, sliding them out towards the motor. (Save all pads and shims.) Care should be taken

not to disturb the belt. Position the control panel and press in place.

SET UP

STEP 1

(JEWEL only) Place the bubble level on the platter at the mid -point of the cartridge sweep. Adjust the feet

so that the platter is level. At this point the platter should appear parallel to the cabinet. Similarly the

underside of the sub-assembly and the bottom of the cabinet should appear to be parallel. Variations of

3/32” are acceptable. Now proceed to Step 3.

STEP 2

(ALL except JEWEL) Place the bubble level on the platter at the mid -point of the cartridge sweep (see

Figure 4). Place the bag of lead shot upright (vertically) in the armboard well, positioning it to “perch” on

the bar between the arm tube hole and the balancing reservoir. The bag should not make any contact with

the cabinet. Adjust the feet so that the platter is level. At this point the platter should appear parallel to the

cabinet. Similarly the underside of the sub-assembly and the bottom of the cabinet should appear to be

parallel. Variations of up to 3/32” are acceptable. Now remove the bag of lead shot but not the bubble

level.

STEP 3

Attach the tonearm (complete with counterweight, head shell and cartridge) to the armboard and insert the

board into the turntable’s armboard mounting block. On JEWEL only, insert the three armboard mounting

screws, tighten securely using the supplied hex key, and proceed directly to Step 7.

STEP 4

Balance the arm and cartridge approximately. Rotate the tonearm towards the spindle to clear the shot

reservoir. (See Figure 4.) The bubble should be off-center toward s the arm. If it is also biased towards the

REAR, carefully remove the armboard and add one or both of the lead slugs by inserting them into the

holes at the rear of the arm mounting block. (If you need to remove the lead slugs, use the allen wrench

provided to push the slug out from the hole beneath the slug). When the lead slugs have been installed as

needed, replace the armboard assembly with mounting screws, but do not tighten yet.

STEP 5

Place a small paper or styrofoam cup (i.e. very light) on the armboard, being careful to keep it clear of the

cabinet. Rotate the tonearm towards the spindle to allow room for the cup. (See Figure 4.) Pour lead shot

into the cup until the bubble in the level is centered. If the platter is not exactly level, minor adjustments of

3

the feet can be made without affecting the table’s performance. If the platter is still not level, we

recommend repeating the set up procedure.

Figure 4

STEP 6

Now remove the armboard assembly and pour the lead shot from the cup into the shot reservoir. (Note: A

plastic sandwich bag may be used to contain the lead shot in the well, for convenience of later

removal.) Re-insert the armboard assembly into the turntable’s armboard mounting block. Insert the three

armboard mounting screws into the armboard. Support the sub -assembly from beneath the armboard

mounting block and securely tighten the screws using the provided hex key. We suggest you keep all of

the lead shot so that you may combine it and begin again if you ever change tonearms.

STEP 7

Slightly raise the cabinet and release the final transit set screw approximately ¼” using the 3/32” hex key.

Secure the transit set screw in the down position by tightening the transit nut.

Caution: The Sapphire bearing assembly is now unprotected. Handle with extreme

care when moving. The table may be carried from room to room but should be place

down gently. Do not ship by car or truck with the transit setscrews in the down

position. This constitutes mishandling and is not covered by the warranty.

STEP 8

Position the turntable in its place of operation. Using the bubble level on the platter, adjust the feet so that

the platter is level. (Take care not to over tighten the feet to the extent that the threaded leg pushes

through or deforms the bottom of the rubber foot.) Always use the platter for the reference, the cabinet

level is secondary. The turntable can be grounded via the grounding post on turntable bottom using the

supplied ground wire. Final tonearm balancing can now be performed.

4

This completes the set up procedures. If included, the optional Dust Cover can now be mounted.

CAUTION: Lead leaves an unhealthy film when handled directly. Wash hands with

soap and water after every contact. Keep lead shot out of children’s reach.

HOOK UP and OPERATION

JEWEL and SAPPHIRE only

Plug the gray DC power cord from the turntable into the jack on the small black power supply box. Plug the

power supply box into an AC outlet, switch the power supply on and locate in a position well away from

tonearm cables and pre-amp.

On SAPPHIRE only, remove the wood control cover, turn on the turntable and verify that the belt runs

parallel to the cabinet surface and is centered on the pulley. If it does not, repeat set up procedure.

Check the speed with the enclosed strobe disk. Any bright AC light source may be used for this procedure.

Fluorescent is most effective. To adjust speed accuracy, use the speed knob for the selected speed

setting. The speed has been set at the factory but minor shifts may occur during shipping. The range of

adjustments is about 3%. If you are not able to get the speed properly set, check to see that the platter

spins freely. If the platter does not move freely it may be that the transit set screws are not fully released.

Loosen each transit set screw an additional ¼” and lock in position with the transit screw nuts.

STAR and NOVA only

The STAR and NOVA are powered from the vacuum pump/power supply unit. This unit is controlled from

the turntable via the multi -conductor cable from the table, using the turntable’s on/off switch. There are no

controls on the pump/power supply unit itself, so it can be located in a remote spot. A twelve-foot cable has

been provided to allow flexibility in choosing a location. The pump should be placed in a non-resonant

location, ideally a carpeted floor or on a foam pad on the floor. If placed too near a pre-amp, induced hum

may occur; if placed on a hard shelf, vibration may be audible.

When in place, plug the cord from the turntable into the pump/power supply unit and tighten securely.

Locate the length of vacuum hose enclosed with the pump/power supply unit. Connect the end with the

screw-on hose coupler to the vacuum fitting on the pump/power supply unit and tighten securely. The other

end of the hose attaches to the vacuum nipple on the underside of the turntable at the platter’s center bolt.

Make sure that both ends of the vacuum hose are securely attached, and the hose is not crimped or

pinched. Now plug the power supply’s power cord into an AC outlet. Remove the wood control cover, turn

on the turntable and verify that the belt runs parallel to the cabinet surface and dead center on the pulley. If

it does not, repeat the set up procedure.

Check the sp eed with the speed with the enclosed strobe disk. Any bright AC light source may be used for

this procedure. Fluorescent is most effective. To adjust speed accuracy, use the speed knob for the

selected speed setting. The speed has been set at the factory but minor shifts may occur during shipping.

5

The range of adjustment is about 3%. If you are not able to get the speed properly set, check to see that

the platter spins freely. If the platter does not move freely it may be that the transit set screws are not fully

released. Loosen each transit set screw an additional ¼” and lock in position with the transit set screw

nuts.

Place a record on the platter and secure the clamp over the spindle. Switch the table on. You will notice

that initially the pump runs quite hard (and may be audible) before switching automatically to the

“maintenance” mode after a seal has been achieved. This is normal. In this maintenance mode the pump

noise should be minimal, if audible at all. A seal is normally achieved within 10-30 seconds. The best

visual way to tell if a seal has been achieved is to observe the vacuum lip on the outside edge of the

platter. Before the record is vacuum clamped, the lip will angle up, rising above the top surface of the

record. Once the record is fully sealed, the vacuum lip will appear flat and parallel to the record’s surface.

If in doubt, gently tap the upper surface of the record with your fingertip (avoiding the finger nail). You

should hear a solid thud. If you hear a rattle from the record hitting the mat, you have not achieved vacuum

seal. (For tips on vacuum system use and maintenance, see the sections titled General Hints For Best

Results and Vacuum System Trouble Shooting, below.)

To set the initial arm height accurately, the vacuum must be on and the record vacuum-clamped. To

facilitate this procedure, we have provided a “dummy” plug to allow running the vacuum pump without

turning on the turntable’s motor. Simply remove the multi -conductor cable attached to the pump/power

supply and in its place insert the included dummy plug. The pump will begin operating as soon as the

dummy plug is inserted and screwed in tight. When the tonearm height is set, remove the dummy plug and

re-install the turntable’s connecting cable.

SOTA Sales & Service Center

10830 S. Nagle, P.O. Box 247

Worth, Illinois 60482 USA

www.sotaturntables.com

sotaturntables@kwom.com

800- 772-SOTA

6

Removal of Platter

Initial Procedure

It is advisable to remove tonearm/armboard assembly and lead shot/slugs (if any) before

removing the platter to prevent damage, but this is not required for assembly. If not removed,

make sure to secure the arm to its arm-post, and place the stylus guard over the cartridge. We

suggest you move the turntable to a large work area where you can place the turntable on a

sturdy, flat working surface. For easiest platter removal and re-installation, we suggest the use of

two chairs used to support each side, providing easy access to platter mounting hardware on

bottom of the turntable.

Removal of Platter

Preparation

Remove mat if it is removable (older models only). Remove the motor control panel (lift off

wood cover, or use 5/64” Allen Key on older models to remove metal control cover and black

bezel underneath) and the drive belt. The platter may now be removed, as follows:

Step 1:

Gently turn the cabinet on it side so that left side is down flush with working surface (that is, the

motor side becomes the base). The assistance of a second person, to steady the turntable, is

recommended. Tighten (screw UP, towards turntable top) the two transit screws with the 3/32”

Allen key until they stop (do not over-tighten). Now remove the locking nut from each transit

screw and set aside. The turntable should now be placed on the two chairs, to allow easy access

to the bottom and top for platter removal.

Step 2:

Using 1/2” socket or wrench, remove the center-retaining bolt. On newer tables, using the 5/32”

Allen Key also remove the three hex socket cap screws holding the platter retaining plate in

place, and remove the plate. Save all the hardware for re-installing the platter after the new

motor is installed. You should now return the turntable to your work surface.

Step 3:

Important: At all times insure that the heavy platter cannot fall and damage the turntable,

your working surface, or your fingers.

Working from the top now, extract platter by easing it away from the sub -assembly. The easiest

way to do this is by using your SOTA clamp. Simply clamp onto the spindle and lift up. You

may need to rock the platter back and forth slightly to free it from the sub -chassis. Take great

care not to damage the edge of the platter cut out with the underside of the platter, causing

chipping or scratching.

Loading...

Loading...