Page 1

Service Manual

SORVALL

TC6

Parts Section

Updated March '02

IMPORTANT INFORMATION REGARDING USE OF THIS MANUAL

READ BEFORE USING

This manual provides technical information for the proper servicing of the product(s) specified. This manual is

intended only for use by Sorvall Service personnel, or by qualified technicians who have been trained by Sorvall

in the safe, proper servicing of that product.

This manual has been designed as a supplement to training, not a substitute for training; servicing should not

be attempted by untrained personnel. Technicians who have not been trained by Sorvall are not familiar with the

product design or the hazards that may be encountered during servicing. In addition, lack of training can result

in faulty repair – possibly making subsequent product use dangerous, or product yields unreliable.

Although content of this manual is believed to be adequate for its intended use, Sorvall makes no representation or warranty regarding completeness, adequacy or otherwise (not even as a supplement to a given training

course) and assumes no obligation or liability. In the event a qualified, trained technician is unable to repair the

product using this manual, Sorvall Technical Service should be contacted for additional guidance.

Page 2

OPERATING

INSTRUCTIONS

SORVALL TC6

Tabletop

Centrifuge

Sorvall Products, L.P.

Newtown, Connecticut

U.S.A.

PN 78006-1

Issued August 1996

Page 3

Table of Contents

This manual is a guide for service of the

SORVALL Centrifuges

SORVALL TC6 Tabletop Centrifuge

Data herein has been verified and validated and is believed adequate for the intended use of the

centrifuge. Because failure to follow the recommendations set forth in this manual could produce

personal injury or property damage, always follow the recommendations set forth herein. Sorvall does

not guarantee results and assumes no obligation for the performance of rotors or other products that are

not used in accordance with the instructions provided. This publication is not a license to operate under,

nor a recommendation to infringe upon, any process patents.

This service manual is intended as a service aid. While the manual is kept current and includes

information regarding significant design changes, specific designs may still vary from centrifuge to

centrifuge.

This service manual is intended for use only by service personnel who have been trained by Du␣Pont.

Due to the high electrical potential in this centrifuge, untrained individuals must not attempt any of the

procedures in this service manual.

WARNINGS, CAUTIONS, and NOTES within the text of this manual are used to emphasize important

and critical instructions:

WARNING

: A Warning informs the operator of a hazard or an unsafe practice that could result in

personal injury, affect the operator's health, or contaminate the environment.

CAUTION:

NOTE:

A Caution informs the operator of an unsafe practice that could result in damage of

equipment.

A Note highlights essential information.

W A R N I N G

!

When using radioactive, toxic, or pathogenic material, be aware of all characteristics of the material and

the hazards associated with it. In the event that leakage or rotor failure occurs, neither the centrifuge nor the rotor

can protect you from the particles dispersed into the air. To protect yourself, we recommend additional precautions

be taken to prevent exposure to these materials, for example, controlled ventilation or isolation. DO NOT USE

MATERIALS CAPABLE OF PRODUCING FLAMMABLE OR EXPLOSIVE VAPORS.

© 1996 by Sorvall Products, L.P.

ii

Page 4

®

TC6

Table␣ of␣ Contents

Paragraph Page

Section 1.␣ ␣ ␣ INTRODUCTION and DESCRIPTION

1-1. Intended Use of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2. Service Decontamination Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3. Warranty Responsibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-4. Centrifuge Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-5. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-6. Controls, Displays, Switches and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Section 2.␣ ␣ INSTALLATION and OPERATION

Table of Contents

2-1. Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2. Preinstallation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3. Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-4. Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-6. Rotor Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-7. Running Hazardous Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-8. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-9. Emergency Sample Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Installation Checklist

Section 3. SYSTEM DESCRIPTIONS

3-1. General System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2. Power System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-3. Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-4. Brushless Motor Drive Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-5. Speed Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-6. Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-7. Door Latching Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Section 4. PRINTED CIRCUIT BOARDS and

SCHEMATIC DIAGRAMS

iii

Page 5

Table of Contents

Table␣ of␣ Contents (continued)

Paragraph Page

Section 5. REPAIR and REPLACEMENT

5-1. Latch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2. Latch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-3. Door Latched Microswitch Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-4. Hinge Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-5. Door Closed Sensor Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-6. Door Closed Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-7. Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-8. Precautions for Handling of Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-9. Printed Circuit Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-10. Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5-11. Fan and Grille Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5-12. Power Connector Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5-13. Speed Potentiometer Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

SORVALL Centrifuges

Section 6. TROUBLESHOOTING

Section 7. MAINTENANCE

7-1. Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2. Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Preventive Maintenance Checklist

Section 8. ILLUSTRATED PARTS

iv

Page 6

TC6

®

Table of Contents

List of Tables

Table Page

1-1. Description of Controls, Displays, Switches and Indicators . . . . . . . . . . . . . . . . 1-6

4-1. Component Description, Control Printed

Circuit Board, PN 78189 Rev. 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4-2. Component Description, Display Printed

Circuit Board, PN 78178 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4-3. Component Description, Display Printed

Circuit Board, PN 78178 Rev. 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4-4. Component Description, Power Supply Printed

Circuit Board, PN 78049 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

4-5. Component Description, Power Supply Printed

Circuit Board, PN 78049 Rev. 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4-6. Component Description, Power Supply Printed

Circuit Board, PN 78049 Rev. 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4-7. Component Description, Motor Control Printed

Circuit Board, PN 78230 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

4-8. Component Description, Motor Control Printed

Circuit Board, PN 78230 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

4-9. Component Description, Motor Control Printed

Circuit Board, PN 78230 Rev. 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

6-1. TC6® Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

8-1. Parts: TC6® Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8-2. Parts: TC6® Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

List of Illustrations

Figure Page

1-1. TC6® Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2-1. Voltage Selection (SN 9501733 and below) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2. Location of Mechanical Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

4-1. System Wiring Diagram, Rev. 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-2. System Wiring Diagram, Rev. 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-3. Schematic for Control Printed Circuit Board, PN 78189 Rev. 3 . . . . . . . . . . . . . . 4-7

4-4. Control Printed Circuit Board Assembly, PN 78189 Rev. 3 . . . . . . . . . . . . . . . . . 4-9

4-5. Schematic for Display Printed Circuit Board, PN 78178 Rev. 4 . . . . . . . . . . . . . . 4-13

4-6. Display Circuit Board Assembly, PN 78178 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4-7. Schematic for Display Printed Circuit Board, PN 78178 Rev. 2 . . . . . . . . . . . . . . 4-19

4-8. Display Printed Circuit Board Assembly, PN 78178 Rev. 2 . . . . . . . . . . . . . . . . . 4-21

4-9. Schematic for Power Supply Printed Circuit Board, PN 78049 Rev. 4 . . . . . . . . 4-24

4-10. Power Supply Printed Circuit Board Assembly, PN 78049 Rev. 4. . . . . . . . . . . . 4-25

4-11. Schematic for Power Supply Printed Circuit Board, PN 78049 Rev. 2 . . . . . . . . 4-27

4-12. Power Supply Printed Circuit Board Assembly, PN 78049 Rev. 2. . . . . . . . . . . . 4-28

4-13. Schematic for Power Supply Printed Circuit Board, PN 78049 Rev. 1 . . . . . . . . 4-30

v

Page 7

Table of Contents

SORVALL Centrifuges

List of Illustrations (continued)

Figure Page

4-14. Power Supply Printed Circuit Board Assembly, PN 78049 Rev. 1. . . . . . . . . . . . 4-31

4-15. Schematic for Motor Control Printed Circuit Board, PN 78230 Rev. 4 . . . . . . . . 4-33

4-16. Motor Control Printed Circuit Board Assembly, PN 78230 Rev. 4 . . . . . . . . . . . 4-35

4-17. Schematic for Motor Control Printed Circuit Board, PN 78230 Rev. 4 . . . . . . . . 4-39

4-18. Motor Control Printed Circuit Board Assembly, PN 78230 Rev. 4 . . . . . . . . . . . 4-41

4-19. Schematic for Motor Control Printed Circuit Board, PN 78230 Rev. 0 . . . . . . . . 4-45

4-20. Motor Control Printed Circuit Board Assembly, PN 78230 Rev. 0 . . . . . . . . . . . 4-47

5-1. Latch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2. Door Closed Sensor Parts Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-3. Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-4. Fuse Replacement/Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-5. Reinstalling the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

8-1. TC6® Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8-2. TC6® Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

vi

Page 8

®

TC6

Contents

Section 1. Introduction and Description

1.1. Intended Use of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2. Service Decontamination Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3. Warranty Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-4. Centrifuge Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-5. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-6. Controls, Displays, Switches and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table of Contents

Page

vii

Page 9

®

TC6

Introduction and Description

Section 1: INTRODUCTION and␣ DESCRIPTION

This manual is a service guide for the SORVALL® TC6® Tabletop Centrifuge. It contains descriptive

information, repair and replacement procedures, schematics, troubleshooting, calibrations, and an

illustrated parts list for ordering replacement parts.

1-1. Intended Use of Manual

W A R N I N G

!

To avoid personal injury, all

replacement and calibration procedures should be performed by qualified service personnel.

W A R N I N G

!

Because of the characteristics of the samples likely to be processed in this centrifuge, biological

or radioactive contamination may occur. Always be aware of this possibility, and take normal precautions. Use

appropriate decontamination procedures should exposure occur.

This manual is for qualified service personnel who are familiar with

factory methods for performing repairs, adjustments and calibrations.

Warnings, Cautions, and Notes are used throughout this manual to

emphasize important and critical instructions. Service personnel

are expected to be familiar with their meaning (see page ii) and to

read them before servicing the centrifuge.

1-2. Service Decontamination

Policy

If a centrifuge or rotor that has been used with radioactive or

pathogenic material requires servicing by Sorvall personnel, either

at the customer’s laboratory or at a Sorvall facility, comply with the

following procedure to ensure the safety of all personnel:

1. Clean the centrifuge or rotor to be serviced of all encrusted

material and decontaminate it prior to servicing by the Sorvall

representative or returning it to the Sorvall facility. There must

be no radioactivity detectable by survey equipment.

The SORVALL® Rotors, Tubes, Bottles, Adapters and Accessories Catalog contains descriptions of commonly used decontamination methods and a chart showing method compatibility

with various materials. This service manual contains specific

guidance about cleaning and decontamination methods appropriate for the centrifuge or rotor it describes (see paragraph 7-1).

Clean and decontaminate your centrifuge or rotor as follows:

For TC6

a. Remove rotor from the rotor chamber.

b. Remove motor cover and wash with appropriate

c. Decontaminate door, rotor chamber, chamber door seal,

®

tabletop centrifuges:

decontaminant.

and drive, using an appropriate method.

1-1

Page 10

Introduction and Description

SORVALL Centrifuges

For rotors:

Remove tubes, bottles, and adapters from the rotor and

decontaminate rotor using an appropriate method. If tubes

or rotor caps are stuck in the rotor, or the rotor door is stuck,

notify Sorvall representative; be prepared with the name

and nature of the sample so the Sorvall Chemical Hazards

Officer can decide whether to authorize the rotor's return to

a Sorvall facility.

2. Complete Decontamination Information Certificate (SORVALL

products Form No. IPDP-59 or E53603) and attach it to the

centrifuge or rotor before servicing or returning to Sorvall facility. Certificates are included in the back of this manual. Additional certificates are available from the local Account Representative or Field Service Engineer. In the event that these

certificates are not available, it will be acceptable to include a

written statement certifying that the unit has been properly

decontaminated and outlining the procedures used.

If the centrifuge or rotor must be returned to a Sorvall facility:

1. Contact your Sorvall representative to obtain a Return Service

Order Number (RSO No.). Be prepared with the name and

serial number of the centrifuge or rotor and the repairs required.

2. Send item(s) with the RSO No. clearly marked on the outside

packaging to the address obtained from your Sorvall representative.

NOTE

United States federal regulations require that parts and

centrifuges

ported. Outside the United States, check local regulations.

must

be decontaminated before being trans-

®

1-2

If a centrifuge or rotor to be serviced does not have a

Decontamination Information Certificate attached and, in Sorvall's

opinion presents a potential radioactive or biological hazard, the

Sorvall representative will not service the equipment until proper

decontamination and certification is complete. If Sorvall receives a

centrifuge or rotor at its Service facilities which, in its opinion, is a

radioactive or biological hazard, the sender will be contacted for

instructions as to disposition of the equipment. Disposition costs

will be borne by the sender.

NOTE

The Field Service Engineer will note on the Customer

Service Repair Report if decontamination was required

and, if so, what the contaminant was and what procedure was used. If no decontamination was required, it

will be so stated.

Page 11

TC6

®

Introduction and Description

1-3. Warranty Responsibility

Whenever service of the centrifuge is attempted by anyone other

than an employee of Sorvall or an authorized representative, the

individual is assuming the risk of voiding the centrifuge warranty,

which is as follows:

Sorvall Products, L.P. makes no warranty of any kind, expressed or

implied, except as stated in this warranty policy.

The SORVALL® TC6® Tabletop Centrifuge is warranted to be free

from defects in materials and workmanship for a period of one year

from the date of delivery. Sorvallwill repair or replace and return

free of charge any part which is returned to its factory within said

period, transportation prepaid by user, and which is found upon

inspection to have been defective in materials or workmanship.

This warranty does not apply to any damage to any instrument

resulting from: normal wear and tear; misuse; abuse; use of electrical currents or circuits other than those specified on the plate affixed

to the instrument; or use of any rotor other than those intended for

use in this instrument.

Sorvall reserves the right to change, alter, modify or improve any of

its instruments without any obligation whatsoever to make corresponding changes to any instrument previously sold or shipped.

The foregoing obligations are in lieu of all other obligations and liabilities

including negligence and all warranties, of merchantability or otherwise,

expressed or implied in fact or by law, and state our entire and exclusive

liability and buyer's exclusive remedy for any claim or damages in connection with the sale or furnishing of goods or parts, their design, suitability

for use, installation or operation. Sorvall will in no event be liable for any

special or consequential damages, and our liability under no circumstances will exceed the contract price for the goods for which liability is

claimed.

1-3

Page 12

Introduction and Description

SORVALL Centrifuges

1-4. Centrifuge Description

The TC6® is a lowspeed, non-refrigerated tabletop centrifuge that

features digital readout displays, a dc brushless (maintenance free)

motor, a closed-loop speed control, a removable stainless steel rotor

chamber, ergonomically designed front panel control knobs and

switches, and has a see-through chamber door that allows rotor

calibration and visual inspection of a run in progress. The chamber

door is counterbalanced for easy opening and safe closing. The

door latch automatically locks when the chamber door is closed

and an interlock prevents the chamber door from being opened

during operation.

1-5. Specifications

Maximum Operating Speed: . . . . . . . . 6000 rpm*

Maximum heat output

during operation: . . . . . . . . . . . . . . . . . 650 Btu/hour (190 Watts)

Electrical Requirements: . . . . . . . . . . . . 100 - 120 Vac, 60Hz,

3.15A, single phase

220 - 240 Vac, 50 Hz,

2A, single phase

Dimensions:

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . 39.4 cm (15.5 inches)

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.9 cm (22.0 inches)

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . 26.7 cm (10.5 inches)

Height (with door open) . . . . . . . . . . . 78.7 cm (31.0 inches)

Mass (Weight): . . . . . . . . . . . . . . . . . . . . . 31 kg (70 lbs)

Decibel Level: . . . . . . . . . . . . . . . . . . . . . <60 dB at 3500 rpm

Operating Temperature Range: . . . . . . 10°C to 35°C

(50°F to 95°F)

Relative Humidity

(Normal Operating Range): . . . . . . . . 20% to 70%

1-4

*Speed in revolutions per minute (rpm) is related to angular velocity, ω, according to the

following:

ω

= (rpm) = (rpm) (0.10472)

Where ω = rad/s. All further references in this manual to speed will be designated as rpm.

(

2π

60

)

Page 13

TC6

®

Introduction and Description

1-6. Controls, Displays,

Switches and Indicators

Figure 1-1 shows the TC6® control panel and provides a brief description for each control, display, switch and indicator. Table 1-1

(on the next page) gives a complete description.

SPEED DISPLAY

Displays actual rotor speed

from 0 to 6000 rpm (± 1%

or 10 rpm, whichever is

greater).

SPEED DIAL

Sets desired rotor

speed.

5

1

SPEED

RPM

R

TIME DIAL

Sets length of run

time up to 99 minutes.

TIME DISPLAY

Displays set run time and,

during a run, remaining run

time.

67

2

TIME

MIN

HOLD SWITCH

Selects a continuous run.

When lit, indicates that the

chamber door is closed and

latched and that the centrifuge is ready for operation.

START SWITCH

Starts the centrifuge run.

READY INDICATOR

3

READY DOOR

8

STOP SWITCH

Stops the centrifuge run.

DOOR INDICATOR

Blinks at end of run indicating the chamber door

may be opened.

9

4

DOORSTOPSTARTHOLD

DOOR SWITCH

10

Opens the chamber door.

Figure 1-1. TC6

®

Controls and Indicators

1-5

Page 14

Introduction and Description

SORVALL Centrifuges

Table 1-1. Description of Controls,

Displays, Switches and Indicators

SPEED display Indicates actual rotor speed from 0

to 6000 rpm (± 1% or 10␣rpm, whichever is greater).

TIME display Indicates set run time at the begin-

MIN

READY indicator light When lit, indicates that the chamber

DOOR indicator light At the end of the run this light blinks

ning of the run and the remaining

run time after the START switch is

pressed. In HOLD mode, two dashes

are displayed.

door is closed and latched and that

the centrifuge is ready for operation.

indicating that the rotor has stopped

spinning and that the chamber door

may be opened.

SPEED dial Sets the desired rotor speed in rpm.

As indicated by the symbol, turn the

dial to the right to increase speed.

TIME dial Sets length of run time up to 99 min-

utes.

HOLD switch Selects a continuous run (two dashes

will appear in the TIME display to

indicate a run in HOLD mode).

START switch Starts the centrifuge run.

STOP switch Stops the centrifuge run.

DOOR switch At the end of a run, after the rotor

has stopped spinning and the DOOR

light blinks, this switch releases the

chamber door.

POWER switch The power switch is a rocker switch

(NOT SHOWN)

that toggles on and off. When set to

"I", applies power to the centrifuge.

1-6

Page 15

Table of Contents

Contents

Section 2. Installation and Operation

2-1. Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2. Preinstallation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3. Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-4. Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-6. Rotor Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-7. Running Hazardous Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-8. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-9. Emergency Sample Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Installation Checklist

SORVALL Centrifuges

Page

viii

Page 16

®

TC6

Installation and Operation

Section 2: INSTALLATION and OPERATION

This section contains information to install and operate your SORVALL TC6® Tabletop Centrifuge.

2-1. Inspection

W A R N I N G

!

The TC6® weighs 70 lbs.

Refer to the unpacking instructions

for proper care when lifting and installing the centrifuge. Failure to use

proper lifting techniques can result in

personal injury and/or possible damage to the centrifuge.

C A U T I O N

!

Do not lift the centrifuge by

the front panel or the door. To do so

can result in damage to these parts.

C A U T I O N

!

The centrifuge can be damaged if connected to the wrong voltage. Check the voltage before plugging the centrifuge into any power

source. Sorvall is not responsible for

incorrect installation.

When you receive your centrifuge, carefully inspect it for any signs

of shipping damage. If you find damage, report it immediately to

the transportation company and file a damage claim, then notify

Sorvall.

Check the parts received with the centrifuge against the shipping

list; if any parts are missing, contact Sorvall (see office list in back of

manual).

2-2.␣ Preinstallation Require-

ments

The TC6® centrifuge is ordered for a specific voltage. The nameplate

on the back of the centrifuge tells the voltage ordered. Before using

the TC6®, be sure the proper operating voltage and corresponding

fuse is selected. If required (for instruments serial number 9501733

and below), the voltage setting and fuses can be changed (refer to

page 2-2, paragraph 2-4, Voltage Selection for procedure to change

the voltage).

Other preinstallation requirements include:

• providing a flat, level surface to support the weight of the

centrifuge (31 kg; 70 lbs),

• allowing adequate space for proper air circulation (5 cm;

2␣inches),

• allowing for the proper height clearance to open the chamber

door (78.7 cm; 31.0 inches); and

• providing the proper electrical requirements.

2-1

Page 17

Installation and Operation

SORVALL Centrifuges

C A U T I O N

!

If the power cord is

connected to the wrong voltage, it

can cause damage to the centrifuge.

Check the voltage listed on the

nameplate before plugging the power

cord into the power source. Sorvall is

not responsible for incorrect

installation.

2-3. Electrical Requirements

The centrifuge has specific power requirements and must be

connected to the correct power supply for proper performance. The

nameplate on the back of the centrifuge specifies one of the following:

100 - 120 Vac, 60 Hz, single phase, 3/15 amps*

220 - 240 Vac, 50 Hz, single phase, 2 amp*

Check line voltage with a voltmeter. Then, verify that the voltage

indicated on the nameplate on the back of the centrifuge agrees

with the measured line voltage.

If the line voltage is beyond the ±10% tolerance (of nominal) given,

the result can be variations in the performance specifications and

damage to the centrifuge.

The power cord has a keyed plug that inserts into a receptacle at the

back of the centrifuge. The other end of the power cord has a threeprong molded cap with a ground pin and parallel blades. (60 Hz

instruments require receptacle NEMA 5-15R and 50 Hz instruments

require NEMA 6-15 R.).

For connection to other receptacles, the power cord may have to be

replaced. Follow local electrical regulations.

Check that the gound lug of the electrical plug is properly grounded

and is shorted to the frame of the centrifuge.

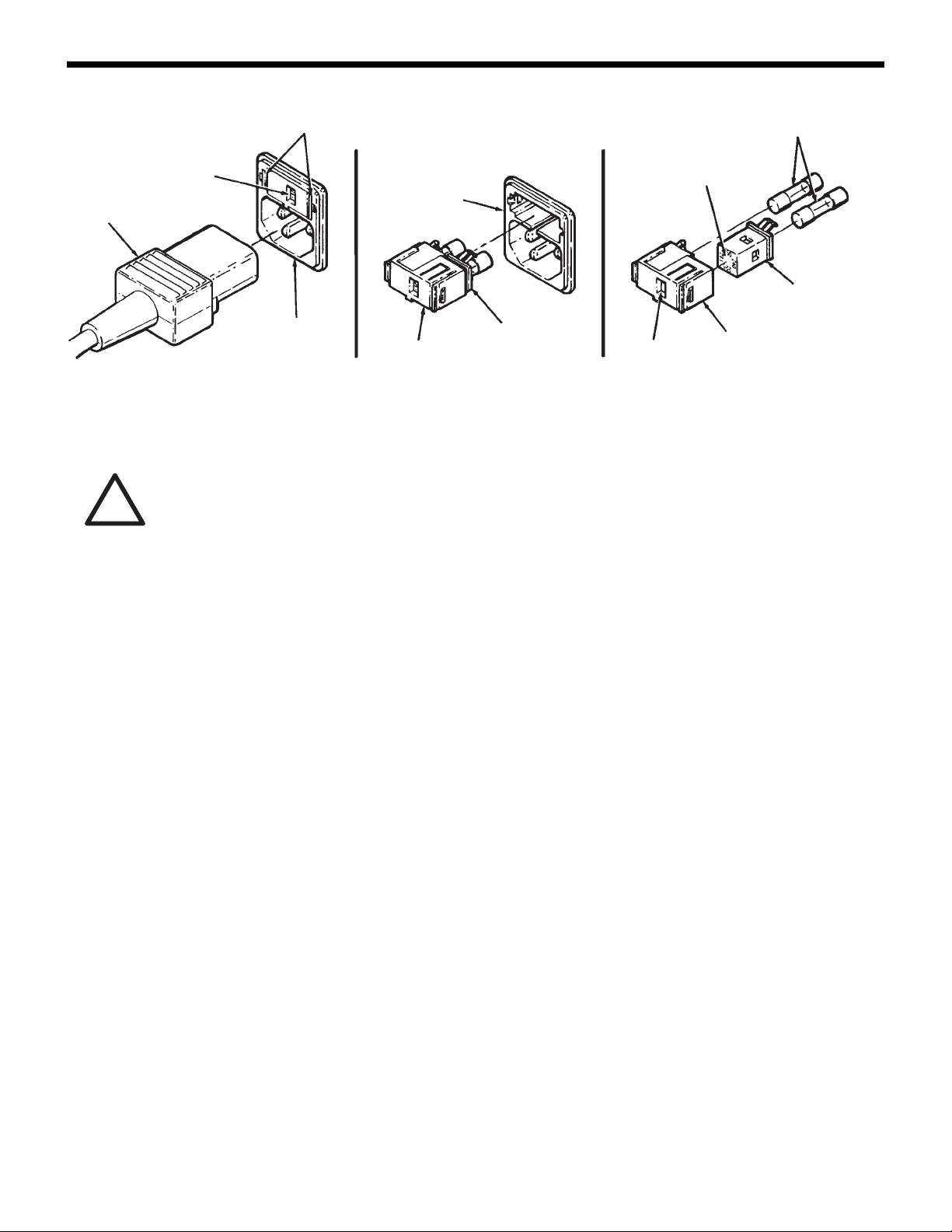

2-4. Voltage Selection

(SN 9501733 and Below)

The voltage is set by the voltage selector (in the fuse block) located

in the power connector on the back of the TC6® (refer to figure 2-1

for SN 9501733 and below). The current voltage setting (100, 110**,

220, or 240) is displayed in the window of the fuse block.

To change the voltage:

1. Unplug the power cord from the wall receptacle and from the

power connector.

2. Squeeze the two tabs located on either side of the fuse block and

carefully remove the fuse block from the power connector.

2-2

NOTE

*CSA and UL Certified.

**For 120 V operation, the voltage selector is set to 110.

Voltage can only be changed on instruments with serial

numbers 9501733 and below. Instruments with serial

numbers 9501734 and above must be ordered prewired

for specific voltages.

Page 18

TC6

®

Installation and Operation

SELECTED

VOLTAGE

POWER

CORD

WINDOW

POWER

CONNECTOR

Figure 2-1. Voltage Selection (SN 9501733 and below)

C A U T I O N

!

When changing the voltage

setting, be sure that the voltage

selector is installed so that the voltage

displayed in the voltage window

matches the intended input voltage.

Also, be sure that the proper fuses

have been installed, and that you are

using the proper power cord.

Incorrect installation can result in

damage to the centrifuge. Sorvall is

not responsible for incorrect

installation.

TABS

FUSES

SELECTABLE

POWER

CONNECTOR

FUSE

BLOCK

VOLTAGE

SELECTOR

VOLTAGE

WINDOW

VOLTAGES

VOLTAGE

SELECTOR

FUSE

BLOCK

3. Gently pull the voltage selector from the fuse block.

4. Rotate the voltage selector until the desired voltage is aligned

with the window in the fuse block. Then, reinstall the voltage

selector into the fuse block.

5. Check that proper fuses are installed. Fuses are Type T, 250 V,

but change amperage rating depending on the voltage selected:

• 100 or 110 setting requires two 3.15-amp fuses, (PN 91428),

• 220 or 240 setting requires two 2-amp fuses, (PN 91203).

Change fuses if necessary.

6. Reinstall the fuse block into the power connector and plug in

the centrifuge power cord.

NOTE

If the voltage was changed from 100-110 setting to 220240 setting, a different power cord is required.

2-3

Page 19

Installation and Operation

SORVALL Centrifuges

2-5. Installation

C A U T I O N

!

Do not lift the centrifuge by

the front panel or the chamber door.

To do so can result in damage to

these parts.

If the power cord is connected to the

wrong voltage, it can cause damage

to the centrifuge. Check the voltage

listed on the nameplate before

plugging the power cord into the

power source. Sorvall is not

responsible for incorrect installation.

Do not operate the centrifuge without

making sure the rotor is properly

balanced. Also, when installing a

rotor, carefully place it on the

centrifuge drive spindle. The

centrifuge spindle bearings can be

damaged if rotor is dropped on the

drive spindle.

To install the centrifuge:

1. Place the centrifuge on a sturdy bench or work table that will

support its weight, leaving space for sample preparation. Be

sure to leave a minimum clearance of 10 cm (4 inches) on all

sides for proper air circulation.

2. Make sure the centrifuge is level.

3. Make sure the centifuge is set for the proper voltage (see page

2-3, Voltage Selection).

4. Make sure the power switch is set to "O" (OFF position).

5. Insert the universal keyed end of the power cord into the power

connector at the back of the centrifuge and the other end into a

wall receptacle. The centrifuge is now ready for use.

2-6. Rotor Considerations

a. Rotor Temperature

W A R N I N G

!

Blocking the air flow entering and/or exiting the TC6® centrifuge will cause an increase in temperature within the rotor chamber. The

temperature increase can temporarily

distort non-metal surfaces allowing

particles to exit the rotor chamber

resulting in personal injury and/or centrifuge damage should tube breakage or rotor failure occur.

When loading the rotor, be sure not

to exceed the maximum compartment

mass of the rotor (see the individual

rotor instruction manual). If maximum

compartment mass is exceeded,

maximum rotor speed must be

lowered as described in the rotor

instruction manual, Compartment

Loads in Excess of Design Mass.

Failure to do so can cause rotor failure

which could result in personal injury

and/or centrifuge damage.

Centrifugation creates an increase in rotor temperature. The increase

in temperature is caused by variables including rotor speed, length

of the run, and the type of rotor.

Air flow through the TC6® Centrifuge is designed to minimize the

increase in rotor temperature. Air enters through the air vent in the

front panel and exits through the fan vent located at the back of the

centrifuge.

When running temperature-sensitive material, a trial run is

recommended.

b. Rotor Installation, Loading and Balancing

Before placing the rotor on the drive spindle, make sure that there

are no loose objects inside the rotor chamber; for example, clips,

tubing, tape, or labels, and that the rotor centerhole and drive

spindle are clean and free of nicks and scratches. Wipe these surfaces

before each use.

Gently place the rotor body on the tapered spindle of the centrifuge,

aligning the shaft pin with the slots in the rotor. Secure the rotor to

the drive spindle by turning the rotor locking knob clockwise.

2-4

Page 20

TC6

®

Installation and Operation

C A U T I O N

!

Do not operate the centrifuge without making sure the rotor is

properly balanced. Also, when installing a rotor,

centrifuge drive spindle. The centrifuge drive spindle bearings can be

damaged if the rotor is dropped on

the drive spindle.

carefully

place it on the

W A R N I N G

!

When using radioactive,

toxic, or pathogenic materials, be

aware of all characteristics of the

materials and the hazards associated

with them in the event leakage occurs during centrifugation. If leakage

does occur, neither the centrifuge nor

the rotor can protect you from particles dispersed in the air. To protect

yourself, we recommend additional

precautions be taken to prevent exposure to these materials, for example, use of controlled ventilation

or isolation areas.

Always be aware of the possibility of

contamination when using radioactive, toxic, or pathogenic materials.

Take all necessary precautions and

use appropriate decontamination procedures if exposure occurs.

NOTE

The rotor locking knob cannot be tightened if the rotor is

not properly installed on the drive spindle.

Refer to the rotor instruction manual for bucket loading and balancing procedures as well as information regarding the selection and

use of tubes, bottles, and adapters.

2-7. Running Hazardous

Material

Because the centrifuge chamber of the TC6® is not designed for

biocontainment, some vapors or aerosols released from uncapped,

leaking or broken tubes may leak from the chamber during operation.

Once a run is completed and the chamber door is opened, the

vapors or aerosols which have concentrated in the chamber will be

released into the laboratory area. For this reason, when materials

which are radioactive, pathogenic, toxic, or otherwise hazardous in

nature are to be run, the centrifuge should be located in a biohazard

safety enclosure and operated using all appropriate safety

precautions. If desired, we recommend the use of sealed bucket

assembly (Catalog No. 78016) to offer increased protection from

contamination from uncapped, leaking or broken tubes.

NOTE

The sealed bucket assemblies (Catalog No. 78016) are

designed to seal tightly during operation and meet the

British Standards BS 4402:1982 Appendix D. They have

been tested at the Public Health Laboratory Service

Centre for Applied Microbiology and Research, Porton

Down, United Kingdom, and found suitable for use with

materials up to ACDP Category 3.

The use of sealed rotors, buckets and/

or sample containers will provide increased protection from contamination during routine operation. However, these items will not guarantee

contamination protection from accidents resulting in damage to the rotor

or buckets. Do not run hazardous material in the centrifuge unless it is

placed in a biohazard enclosure and

operated using appropriate safety precautions.

Use appropriate decontamination procedures should exposure to

any hazardous material occur. Read paragraph 1-2, page 1-1 for the

procedure to follow if a centrifuge or rotor that has been used with

a hazardous material must be returned to our service facilities for

repair.

2-5

Page 21

Installation and Operation

SORVALL Centrifuges

2-8. Operation

W A R N I N G

!

Be sure the rotor chamber

and chamber door gasket are installed

before the centrifuge run. Operating

the centrifuge without these parts in

place could allow small particles to

exit the rotor chamber in the event of

a rotor failure.

C A U T I O N

!

Be sure the rotor is properly balanced and seated on the drive

spindle. All four buckets must be

used on every run (even if empty).

See rotor instruction manual.

To perform the run:

1. Set the POWER switch to "I".

2. Press the DOOR switch to release the chamber door.

3. Install the rotor on the drive spindle and close the chamber

door. When properly closed, the lid latch automatically locks

the door and the READY indicator light comes on.

4. Set the SPEED dial to the desired run speed.

NOTE

5. Turn the TIME dial to the desired run time (the run time, in

Selected run speed is to be verified and adjusted during

the run after the value shown in the SPEED display has

stabilized. Adjust the SPEED dial until the SPEED

display indicates desired run speed (in rpm). If it is not

disturbed, the SPEED dial will retain its position, allowing

for run-to-run repeatability.

minutes, will appear in the TIME display); or press the HOLD

switch to ON for a continuous run and two dashes (--) will

appear in the TIME display.

6. Press START switch to begin run.

NOTE

7. At the end of the run, the DOOR indicator light blinks indicating

NOTE

If the door is not properly closed, the READY indicator

light will not come on and the rotor will not spin when the

START switch is pressed.

To end a run before the selected run time has elapsed or

to end a run set to HOLD, press the STOP switch.

that the chamber door can be opened. Press the DOOR switch to

open the chamber door.

Remove the sample from the rotor, close the chamber door, and

set the POWER switch to "O".

The speed and time values selected at the beginning of

the run are automatically retained unless the power cord

is disconnected from the power source. To do another

run with the same run speed and time parameters:

prepare the rotor, install it in the centrifuge, close the

chamber door, and press the START switch.

2-6

Page 22

TC6

®

Installation and Operation

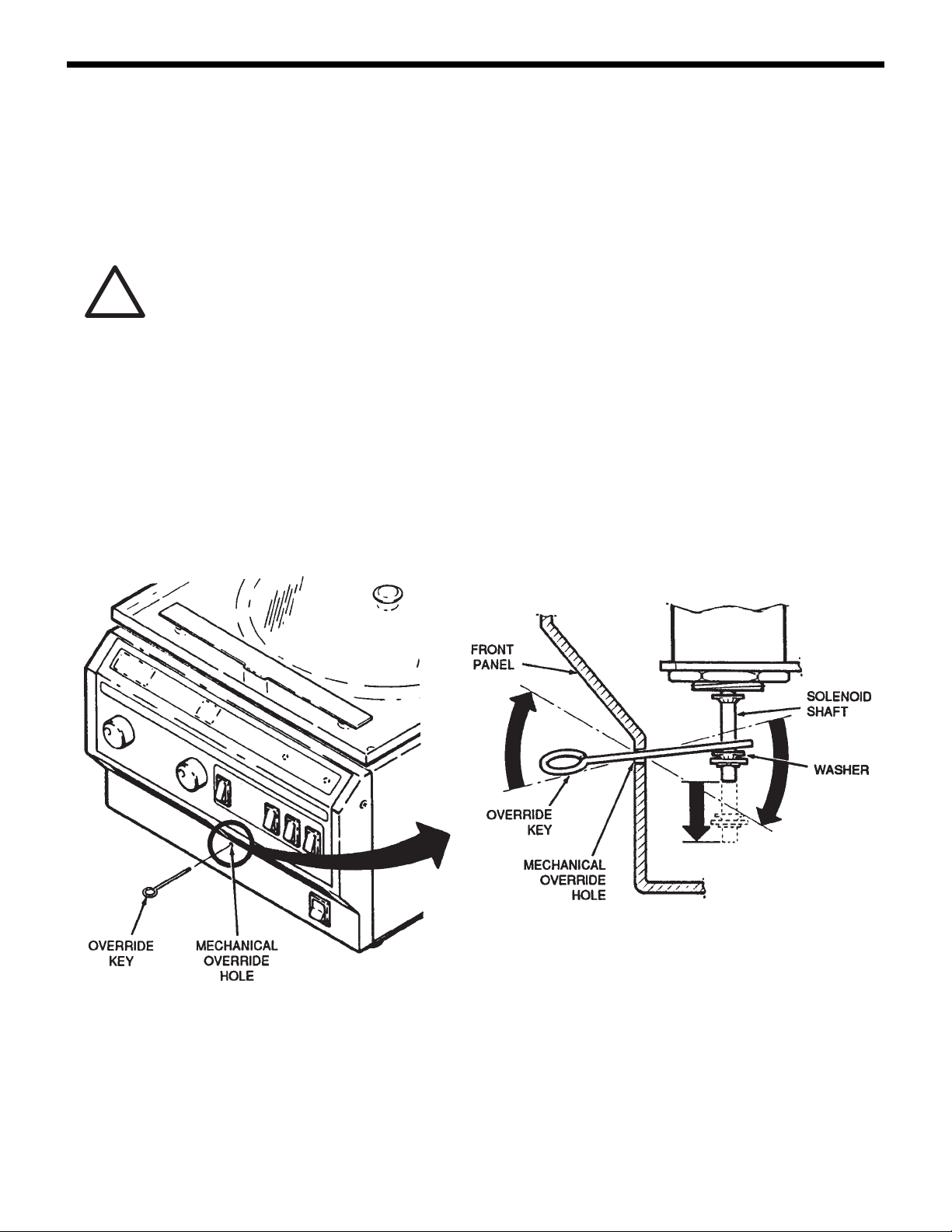

2-9. Emergency Sample

Recovery

If the main power shuts off because of a power failure or system

malfunction, the chamber door will not open. A mechanical override is provided to allow sample recovery in the case of an emergency.

W A R N I N G

!

This procedure is included

for

emergency sample recovery only

and should never be used for any

purpose other than those explained

in this section.

When the main power shuts off, the

brake will not operate. Unplug the

centrifuge plower cord and wait until

the motor stops spinning

ing the mechanical override.

before

us-

The mechanical override is located below the air inlet vent in the

front panel, as shown in figure 2-3. To operate the override, insert

the end of the override key (PN 78170 supplied), at a slight upward

angle 2/3 of the way into the hole. Carefully move the key left-toright until you locate the solenoid shaft. Slowly move the end of the

key downward to contact the washer located at the bottom of the

shaft. With the key pressed tight against the solenoid shaft, use the

key as a lever to apply downward pressure on the washer to release

the chamber door.

Figure 2-2. Location of the Mechanical Override

2-7/2-8

2-7

Page 23

®

SORVALL Centrifuges

INSTALLATION CHECKLIST

TC6® TABLETOP

CENTRIFUGE

Institution _________________________________

Street Address _____________________________

___________________________________________

City _______________________________________

State/Province _____________________________

Postal Code ________________________________

Country ___________________________________

Phone No. _________________________________

Inspection (paragraph 2-1)

Shipping damage

Accessories included

Preinstallation (paragraph 2-2)

Confirm voltage on instrument

Electrical Requirements

(paragraph 2-3)

Line voltage

Ground Continuity

Date _________________________________

Serial Number _______________________

Packing List No.______________________

User _________________________________

Installed by __________________________

Voltage Selection (paragraph 2-4)

Check fuse block/correct fuses

Installation (paragraph 2-5)

Sturdy bench

Level surface

Operation (paragraph 2-8)

Perform run

Acceleration time

Deceleration time

Door Latch

Comments: ______________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Signature of Installer ____________________________________________________________________

Date

Page 24

®

TC6

Contents

Section 3. System Descriptions

3-1. General System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2. Power System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-3. Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-4. Brushless Motor Drive Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-5. Speed Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-6. Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-7. Door Latching Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Table of Contents

Page

ix

Page 25

®

TC6

Section 3: SYSTEM DESCRIPTIONS

3-1. General System Description

The TC6® is an assembly that consists of the following:

• Power System

• Drive Motor System

• Control System

• Input/Output System

• Cabinet System

• Ventilation System

• Containment System

The Power System consists of the cord, voltage selector (SN 9501733

and below), power supply, and electrical connectors. It takes electricity from the electric outlet, converts it to low voltage and then

distributes it to the other instrument systems.

System Descriptions

The Drive Motor System consists of the motor, drive electronics and

drive mount hardware. It receives controlled voltage from the control

system to spin the rotor while providing support for itself and the

rotor system.

The Control System consists of electrical circuits that are located on

printed circuit boards to control operation of the motor speed, the

timer and the latch mechanism.

The Input/Output System is a user interface system that consists of

knobs, switches, and displays. It allows the user to input run

parameters and also monitors a run in progress.

The Cabinet System consists of the upper and lower frame sections.

This system forms the main body of the centrifuge and supports the

other instrument systems.

The Ventilation System consists of a fan, gaskets and baffles. It

directs air movement in the centrifuge to cool the circuits and motor

and also seals the rotor chamber to minimize windage.

The Containment System consists of radial and vertical containment

sub-systems. The radial sub-system is the guard and containment

rings and their supports. The vertical containment sub-system is

the door, latch and striker, and the mounting hardware. The

containment system is designed to contain any parts or fragments

that may result from a rotor failure.

3-1

Page 26

System Descriptions

SORVALL Centrifuges

3-2. Power System

Theory of Operation

The electrical power portion of this centrifuge starts in the line cord

entry module. This module accepts a standard three wire power

cord. Both sides of the line are fused. The 100 - 120 volt centrifuges

are fused at 3.15 amps and the 220 - 240 volt centrifuges at 2 amp.

(SN 9501733 and below), 120 V (±10%) and 230 V (±10%) (SN

9501734 and above). This centrifuge is designed to work on either

50 or 60 hertz at any of the input voltages. No changes are necessary

to accommodate different line frequencies.

The other portion of the power system is the dc power supply. This

is a dual supply generating nominally 30␣volts at 10␣amps and

5␣volts at 500␣milliamps. Ther e is a fast acting fuse of 6.3␣amps on

the 30␣volt secondary of the transformer and a fast-acting fuse of 1.6

amps on the 5␣volt secondary of the transformer . The bridge rectifiers and 5 volt regulator are heatsinked to the chassis. The 30␣volt

supply is used by the motor control circuitry, the motor, and the

latch release solenoid. The 5␣volt supply is for powering the displays, speed and timer logic; and the operator I/O logic.

3-3. Drive Motor

Theory of Operation

The motor is a brushless dc type. Four Ferrite magnets are adhesive

bonded to the steel shaft to make up the rotor. Arranged around the

rotor in the case are three excitation coils. To sense motor position,

three␣Hall-ef fect devices are mounted at the bottom of the case.

3-4. Brushless Motor Drive

Electronics

The TC6® drive is a type of power inverter motor drive. The functional purpose is to convert raw single phase ac power into synchronous three-phase power to the motor. This is accomplished in

several stages. The following is a brief description of how the

internal power conversion process occurs.

Power Conversion from ac to dc – The ac power source may be

selected for a nominal voltage of 100 - 120 or 220 - 240 volts ac-RMS

at a frequency of between 48 to 62 Hz. Only single phase ac is used.

Raw ac, used for the motor power, passes into a full wave bridge

3-2

Page 27

TC6

®

System Descriptions

rectifier and then into filter capacitors. The combination of these

components provides a nominal 30 volt unregulated dc power

source.

Power Inversion from dc to ac – The unregulated dc power available

in the TC6® must be converted back to phased ac power for the

motor to operate. This process is called inversion. For proper control

of motor rotation, the drive must synchronize the application of

power precisely with the rotational position of the rotor. This process

is commonly referred to as commutation. The motor used in the

centrifuge requires three-phase ac power for commutation.

The three-phase ac power used to "commutate" the motor is phase

displaced in time by 120 electrical degrees. The ac power delivered

is pulsed square waves and provides variable frequency ac to the

motor. This feature enables the motor to operate at variable speeds.

The three-phase ac power delivered to the motor is developed by an

active circuit network consisting of six power transistors. This network is called the output bridge. In order to sustain the rotation of

the centrifuge the drive continuously processes and decodes rotor

position information. This information is used to sequentially apply

power from the output bridge to the motor.

It is not sufficient to precisely control the motor through commutation

alone. The power applied to the motor must be carefully metered in

order to throttle both torque and speed. This is accomplished through

a technique called pulse width modulation, or PWM.

The PWM technique provides a method of efficient power control

through the use of high frequency output bridge modulation. In

effect, as each motor winding is turned on in sequence during

motor rotation, PWM is superimposed upon the normal

commutation signals. PWM results in the application of power to

the motor by chopping it on and off at a high rate (24 kHz). This

chopping scheme controls average motor current by varying the

ratio of "on time" versus "off time" for each PWM cycle. This chopping

scheme provides proportional output torque from the motor through

the direct adjustment of the average motor current.

The drive limits torque by continuously monitoring the electrical

current to the motor and comparing it to the commanded level

requested by the control setting. The difference between these two

levels results in an error signal which is then converted to a PWM

ratio. This PWM is used to modulate the output bridge as described

above.

3-3

Page 28

System Descriptions

SORVALL Centrifuges

a. Theory of Operation

The drive is built with Motorola's MC33035 and a support chip

MC33039.

The MC33035 is a 24-pin linear integrated circuit (I.C.) that operates

as the control center for the brushless dc motor control system. The

main functions of MC33035 are to decode the signals from the

Hall-effect sensors and generate logic for electronically commutating

the motor. The commutation logic is internally delivered to the six

output drivers consisting of three open collector NPN transistors

that drive the upper legs of the bridge and three totem pole drivers

that control the devices. The open collector outputs can sink 50 mA.

With some additional circuitry this allows control of either N-channel

MOSFETs for higher power applications or P-channel MOSFETs if a

simple interface is desired. Since the three lower totem pole outputs

can source and sink 10 mA, they can drive power MOSFETs directly.

b. Fault Management

The MC33035 can detect and manage several types of faults. A

common method of overcurrent detection is to tie the sources of the

lower three transistors together and return them to the negative

supply rail through a current sense resistor. The sense voltage,

which is proportional to load current, is delivered into a comparator

on board the MC33035. The comparator then delivers an RS flip-flop,

which ensures that the output drivers will turn off the power

transistors for the remainder of the oscillator cycle if an overcurrent

condition is detected. Without the internal flip-flop, the overcurrent

protection loop would rapidly cycle on and off about the

comparator's threshold, causing excessive power transistor heating.

In addition to overcurrent management, the MC33035 provides

undervoltage lockouts that terminate the drive to the output transistors if any of three conditions occur:

• insufficient voltage to operate the I.C.;

• insufficient voltage to drive the power MOSFET gates; or

• output drivers turn the power transistors off when the MC33035

does not sustain its on-board 6.25 V reference.

An invalid set of Hall-effect signals or excessive temperature will

also cause shutdown.

3-4

Whenever any fault condition exists, an NPN transistor capable of

sinking 16 mA pulls the Fault Output pin low.

Page 29

TC6

®

System Descriptions

c. Control Features

The MC33035's circuitry contains all except one major element for

closed-loop speed control. The missing element is that which

monitors motor rpm (speed) and generates a signal proportional to

motor speed, a function that has been the domain of a tachometer

Once provided with a motor speed signal, the MC33035's high

performance error amplifier and its internal oscillator form the last

major links in the speed control loop.

The MC33035's on-board oscillator operates at a frequency set by an

external resistance/capacitance (R-C). Each cycle capacitor is charged

from the reference output through a resistor and then rapidly

discharged through an internal transistor.

At each positive or negative transition of the Hall-effect sensors,

the MC33039 generates a pulse with a fixed on time. The output

signal can then be filtered to obtain a voltage proportional to motor

speed. Design of an MC33035/39 based system should begin with

setting the system timing, which originates in the MC33039. Selection

of timing components for MC33039 is based on the desired maximum

motor rpm. For the motor used in this application, there are two

electrical degrees for every mechanical degree since the permanent

magnet on the rotor has two pairs of poles. Therefore, for every

mechanical revolution each Hall-effect sensor delivers two pulses

and the three sensors generate six pulses. The MC33039 generates

12 pulses for each revolution, one for each rising and falling edge.

For a given maximum rotor speed, the output pulse width has a

maximum limit. For example, the maximum speed is 6000␣rpm,

which is 100␣r evolutions per second, the MC33039 will generate

100␣x␣12, or 1200␣pulses per second. The >1kHz␣fr equency determines that the maximum pulse width must be less than 1␣ms. One

can determine that R1 and C1 values of 30␣k and 22␣nF r esults in a

pulse width of 600␣ µs. To set the system PWM frequency, refer to the

MC33035's data sheet. There it shows that setting R2 and Cw to

5.1␣k and 0.01␣ µ F gives a nominal PWM frequency of 24␣kHz, just

above the audible range.

Both inputs and the outputs of the MC33035's error amplifier are

accessible to accommodate various control methods. For open-loop

control a reference signal proportional to the desired speed can be

fed into the error amplifier's non-inverting input. The error amplifier output is then configured as a unity gain voltage follower by

connecting its inverting input to its output. The error amplifier's

output is then compared to the output of the oscillator to obtain a

PWM signal proportional to the desired motor speed--unless the

control loop is overridden by an overcurrent or fault condition.

3-5

Page 30

System Descriptions

SORVALL Centrifuges

For closed-loop control, one approach is to filter the MC33039's

output with a low pass filter to generate a voltage proportional to

motor speed and feed the resulting signal into the inverting input of

the MC33035's comparator. A signal proportional to desired motor

speed drives the non-inverting input, and the ratio of the input and

feedback resistors R3 and R4 control gain. In this design, low pass

filtering and generating the error signal are combined by using

feedback capacitor, C3.

Ideally, the integrator/error amplifier should produce a ripple free

output even at low motor speeds. To do so at very low speeds

reduces system response time, however. Component values must

be adjusted according to the rotors' load, inertia and friction. In this

particular application the values 2 M ohm and 0.01 µF give good

dynamic response and stability.

When motor speed is less than the desired speed, the MC33035

extends the output pulse width to the drive transistors. When

motor speed is greater than the desired speed, the duty cycle decreases. However, if the input signal abruptly demands a much

lower speed, the duty cycle could fall to zero and the motor would

coast to desired low speed. Therefore, since the MC33035 has no

provision to dynamically brake the motor and thus control rapid

deceleration, it is best suited for applications which have a large

frictional load or those that do not require a controlled, abrupt

deceleration.

d. Braking

Dynamic braking is used. The three high-side motor drive transistors are turned off and the three low-side drive transistors are

turned on, in sequence. This circulates the back Electro Magnetic

Force (EMF) generated currents through the motor winding for

dissipation of stored energy.

A logic high at pin 2 of the motor drive control connector calls for

dynamic braking.

3-5. Speed Control

Theory of Operation

Speed control is accomplished by a 10k ohm potentiometer used in

conjunction with the Motorola brushless motor control chip

integrated circuit set (MC33035 and MC33039). The wiper of the

potentiometer is the control input to MC33035. Lower speed is

selected when the voltage on the wiper is decreased (by turning

counterclockwise) and higher speed is selected when voltage on the

wiper is increased (by turning clockwise).

3-6

Page 31

TC6

®

The motor has three Hall-effect sensors internally mounted to

generate pulses as the motor turns. These pulses are monitored by

the MC33035 allowing the controller to change the width of the

pulse sent to the motor drive to control the speed. The wider the

pulse, the faster the motor runs.

The sensors are also used to generate a pulse string for the speed

indicator. MC33039 generates 12 pulses for each revolution of the

motor.

System Descriptions

3-6. Timer

Theory of Operation

The timer consists of a crystal controlled oscillator and a variety of

"HC" (High speed Complementary metal oxide semiconductor)

logic circuitry operating on 5 Vdc. When the timer elapses to zero,

the rotor motor begins to brake.

If HOLD mode is selected, the timer is disabled and the centrifuge

continues to run until the operator presses the ST OP switch to end

the run.

3-7. Door Latching Mechanism

Theory of Operation

The door closing/locking mechanism is a latch, secured to the

underside of the frame; a striker, secured to and extending through

the chamber door; a latch release activated by a solenoid; a door

closure sensor; and a door release button. Door open/close position

is monitored by a magnetic switch.

The circuitry that controls the door latch solenoid is on the Control

Printed Circuit Board. When the door open switch is closed, the

solenoid is energized for less than one second no matter how long

the switch is held. It consists of logic gate controls and solenoid

driver circuits. The logic controlling the door release solenoid must

meet all of the following conditions before the door open switch

will operate:

• door closed

• timer not active

• low speed (less than 90 rpm).

The Latch solenoid cannot be energized when rotor speed is more

than 62 rpm.

3-7/3-8

3-7

Page 32

Table of Contents

SORVALL Centrifuges

Contents

Section 4. Printed Circuit Boards and Schematics

Figures

Page

4-1. System Wiring Diagram, Rev. 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-2. System Wiring Diagram, Rev. 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-3. Schematic for Control Printed Circuit Board, PN 78189 Rev. 3 . . . . . . . . . 4-7

4-4. Control Printed Circuit Board Assembly, PN 78189 Rev. 3 . . . . . . . . . . . . . 4-9

4-5. Schematic for Display Printed Circuit Board, PN 78178 Rev. 4 . . . . . . . . . 4-13

4-6. Display Circuit Board Assembly, PN 78178 Rev. 4 . . . . . . . . . . . . . . . . . . . . 4-15

4-7. Schematic for Display Printed Circuit Board, PN 78178 Rev. 2 . . . . . . . . . 4-19

4-8. Display Printed Circuit Board Assembly, PN 78178 Rev. 2 . . . . . . . . . . . . . 4-21

4-9. Schematic for Power Supply Printed Circuit Board, PN 78049 Rev. 4 . . . . 4-24

4-10. Power Supply Printed Circuit Board Assembly, PN 78049 Rev. 4 . . . . . . . 4-25

4-11. Schematic for Power Supply Printed Circuit Board, PN 78049 Rev. 2 . . . . 4-27

4-12. Power Supply Printed Circuit Board Assembly, PN 78049 Rev. 2 . . . . . . . 4-28

4-13. Schematic for Power Supply Printed Circuit Board, PN 78049 Rev. 1 . . . . 4-30

4-14. Power Supply Printed Circuit Board Assembly, PN 78049 Rev. 1 . . . . . . . 4-31

4-15. Schematic for Motor Control Printed Circuit Board, PN 78230 Rev. 4 . . . 4-33

4-16. Motor Control Printed Circuit Board Assembly, PN 78230 Rev. 4 . . . . . . . 4-35

4-17. Schematic for Motor Control Printed Circuit Board, PN 78230 Rev. 4 . . . 4-39

4-18. Motor Control Printed Circuit Board Assembly, PN 78230 Rev. 4 . . . . . . . 4-41

4-19. Schematic for Motor Control Printed Circuit Board, PN 78230 Rev. 0 . . . 4-45

4-20. Motor Control Printed Circuit Board Assembly, PN 78230 Rev. 0 . . . . . . . 4-47

Tables

x

4-1. Component Description, Control Printed

Circuit Board, PN 78189 Rev. 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4-2. Component Description, Display Printed

Circuit Board, PN 78178 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4-3. Component Description, Display Printed

Circuit Board, PN 78178 Rev. 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4-4. Component Description, Power Supply Printed

Circuit Board, PN 78049 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

4-5. Component Description, Power Supply Printed

Circuit Board, PN 78049 Rev. 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4-6. Component Description, Power Supply Printed

Circuit Board, PN 78049 Rev. 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4-7. Component Description, Motor Control Printed

Circuit Board, PN 78230 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

4-8. Component Description, Motor Control Printed

Circuit Board, PN 78230 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

4-9. Component Description, Motor Control Printed

Circuit Board, PN 78230 Rev. 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Page

Page 33

®

TC6

Printed Circuit Boards & Schematic Diagrams

Section 4: PRINTED CIRCUIT BOARDS and

SCHEMATIC DIAGRAMS

This section contains a system wiring diagram as well as schematic diagrams and component description

tables for printed circuit boards found in the TC6® Tabletop Centrifuge.

4-1/4-2

4-1

Page 34

TC6

®

Printed Circuit Boards & Schematic Diagrams

Figure 4-1. System Wiring Diagram,

(SN 9501734 and above)

(SN 9600946 and above, 60 Hz only, Do Not Use Line Filter)

4-3/4-4

Page 35

TC6

®

Printed Circuit Boards & Schematic Diagrams

Figure 4-2. System Wiring Diagram,

(SN 9501733 and below)

4-5/4-6

Page 36

TC6

®

Printed Circuit Boards & Schematic Diagrams

Figure 4-3. Schematic for Control Printed

Circuit Board, PN 78189 Revision 3

4-7/4-8

Page 37

TC6

®

Printed Circuit Boards & Schematic Diagrams

Figure 4-4. Control Printed Circuit Board

Assembly, PN 78189 Revision 3

4-9/4-10

Page 38

TC6

®

Printed Circuit Boards & Schematic Diagrams

Table 4-1. Component Description,

Control Printed Circuit Board, PN 78189 Revison 3

(refer to figure 4-4)

Component Description

R5 Resistor, 1.0 KΩ, 1/4W, 5%, Carbon Comp.

R15, R16, R18, Resistor, 10 KΩ, 1/4W, 5%, Carbon Comp.

R20, R23, R24, R25

R6 Resistor, 1.0 MΩ, 1/4W, 5%, Carbon Comp.

R8, R9 Resistor, 1.5 KΩ, 1/4W, 5%, Carbon Comp.

R10 Resistor, 2 KΩ, 5W, 5%, Wirewound

R11, R12, R13, Resistor, 22 KΩ, 1/4W, 5%, Carbon Comp.

R14, R17

R22 Resistor, 3.3 KΩ, 1W, 5%, Carbon Comp.

R19, R21 Resistor, 4.7 KΩ, 1/4W, 5%, Carbon Comp.

R4, R7 Resistor, 47 KΩ, 1/4W, 5%, Carbon Comp.

R1 Resistor, 75Ω, 15W, 5%, Carbon Comp.

C5, C7, C9, C13, Capacitor, 0.01 µF, 50V

C14, C15, C16, C18,

C19, C20, C21, C22,

C23, C24, C25, C26,

C27, C28, C29, C30,

C32, C33, C34, C35

C6, C8 Capacitor, 0.1 µF, 50V, 20%

C4, C11, C36 Capacitor, 2.2 µF, 50V, 20%

C2, C10, C12 Capacitor, 47 µF, 16V, 20%

U13, U14, U15 I.C., CMOS, Dual BCD, MC14518BP

U18, U21 I.C., CMOS, Phase Comp/Prog Cntrs, MC14568BP

U10, U11 I.C., CMOS, Dual J-K Flip Flop, MC74HC76N

U3, U8, U19 I.C., CMOS, Schmitt Trigger, MC14106BP

U20 I.C., CMOS, Time Base Gen., MC14566BP

U2 I.C., CMOS, Bounce Elim., MC14490P

4-11

Page 39

Printed Circuit Boards & Schematic Diagrams

Table 4-1. Component Description,

Control Printed Circuit Board, PN 78189 Revision 3 (continued)

(refer to figure 4-4)

Component Description

U9 I.C., CMOS, Quad AND, MC74HC08N

U5 I.C., CMOS, 3 Input NAND, MC74HC10N

U4, U6, U22 I.C., CMOS, Quad NAND, MC74HC00N

U1 I.C., Hi-Volt Source Driver, UND-2983A

U7 I.C., CMOS, Dual Multivibrator, MC74HC4538N

U16 I.C., CMOS, Opto-Isolator, H11A1

SORVALL Centrifuges

U17 I.C., CMOS, Hex Inverter, CD4069UBE

Q1 Transistor, Power N-Channel E-FET

Q2 I.C. Undervolt Sensing, MC34064P-5

Q3 Transistor, NPN Type, 2N2222

Y1 Resonator, Ceramic, 2MHz

K1 Relay, PCB Type, SPDT

CR1, CR2, CR3, CR4 Diode, Zener, IN6270A, 9.1V

CR5. CR6 Diode, Silicon, 100V/1A, IN4002/IN4002GP

CR7 Diode, Surge Type, 600W

J30 Connector, Header, 26 Position

J31 Connector, Header, 20 Position

J33 Connector, Header, 16 Position

4-12

J32 Connector, Header, 10 Position

TP2 Connector, Header, 3 Pin

J1 Plug, Interconnection, 2 Position

TP1 Test Points

Page 40

TC6

®

Printed Circuit Boards & Schematic Diagrams

Figure 4-5. Schematic for Display Printed

Circuit Board, PN 78178 Revision 4

4-13/4-14

Page 41

TC6

®

Printed Circuit Boards & Schematic Diagrams

Figure 4-6. Display Printed Circuit Board

Assembly, PN 78178 Revision 4

4-15/4-16

Page 42

TC6

®

Printed Circuit Boards & Schematic Diagrams

Table 4-2. Component Description,

Display Printed Control Board, PN 78178 Revision 4

(refer to figure 4-6)

Component Description

R1, R2 Resistor, 4.7 KΩ, 1/4W, 5%, Carbon Comp.

R3, R4, R5 Resistor, 82Ω, 1/4W, 5%, Carbon Comp.

C1, C2, C3,C4, Capacitor 0.01 µF, 50V

C5, C6, C7, C8,

C9, C10, C11,

C13, C14, C15

C12 Capacitor 47 µF, 6 V

DS1, DS2 LED, Green, Diffused

CR1, CR2, Diode, SI., IN914 or IN4148

CR3, CR4

U5 I.C., CMOS, Octal Bus Transceiver, 74HC245AN

U10, U13 I.C., CMOS, BCD Decoder/Driver, Harris CA3161E

U7 I.C., CMOS, Dual Multivibrator, 74HC4538N

U6 I.C., CMOS, Quad NAND, 74HC132AN

U9 I.C., CMOS, Quad or, 2-Input, 74HC32AN

U1, U2, I.C., CMOS, BCD Counter, MC14510BP

U3, U4

U8 I.C., CMOS, Schmitt Trigger, MC14106BCP

U11, U12, U15, I.C., Display, 7 Segment, HP5082-7651

U16, U17, U18

U14 I.C., Display, 4 1/2 Digit, Harris ICM7225IPL

C16 Capacitor, 22 µF, 50V

4-17/4-18

4-17

Page 43

TC6

®

Printed Circuit Boards & Schematic Diagrams

Figure 4-7. Schematic for Display Printed

Circuit Board, PN 78178 Revision 2

4-19/4-20

Page 44

TC6

®

Printed Circuit Boards & Schematic Diagrams

Figure 4-8. Display Printed Circuit Board

Assembly, PN 78178 Revision 2

4-21/4-22

Page 45

TC6

®

Printed Circuit Boards & Schematic Diagrams

Table 4-3. Component Description,

Display Printed Circuit Board, PN 78178 Revision 2

(refer to figure 4-8)

Component Description

C1, C2, C3, C4, Capacitor, 0.01 µF, 50V

C5, C6, C7, C8,

C9, C10, C11,

C13, C14, C15

C12 Capacitor, 47 µF, 6V

CR1, CR2, Diode, IN914 or IN4148

CR3, CR4

DS1, DS2 LED, Green, Diffused

R1, R2 Resistor, 4.7 KΩ, 1/4W, 5%, Carbon Comp.

R3, R4, R5 Resistor, 82 Ω, 1/4W, 5%, Carbon Comp.

U1, U2, I.C. CMOS, BCD Counter, MC14510BP

U3, U4

U5 I.C., CMOS, Octal Bustransceiver, 74HC245AN

U6 I.C., CMOS, Quad NAND, 74HC132AN

U7 I.C., CMOS, Dual Multivibrator, 74HC4538N

U8 I.C., CMOS, Schmitt Trigger, MC14106BCP

U9 I.C., CMOS, Quad or, 2-Input, 74HC32AN

U10, U13 I.C., CMOS, BCD Decoder/Driver, Harris CA3161E

U11, U12, U15, I.C., Display, 7 Segment, HP5082-7651

U16, U17, U18

U14 I.C., Display, 4 1/2 Digit, Harris ICM7225IPL

4-23

Page 46

4-24

Figure 4-9. Schematic for Power Supply Printed Circuit Board, PN 78049 Revision 4

Printed Circuit Boards & Schematic Diagrams

SORVALL

Centrifuges

Page 47

Figure 4-10. Power Supply Printed Circuit Board Assembly, PN 78049 Revision 4

TC6

®

4-25

Printed Circuit Boards & Schematic Diagrams

Page 48

Printed Circuit Boards & Schematic Diagrams

Table 4-4. Component Description,

Power Supply Printed Circuit Board, PN 78049 Revision 4

(refer to figure 4-10)

Component Description

R1 Resistor, 1000 Ohm, 5W, 5%, Wirewound

C3 Capacitor, 100 µF, 10V

C4 Capacitor, 6800 µF, 16V

C1, C2 Capacitor, 8200 µF, 50V

CR3 Diode, SI, 100V, 1A, IN4002/IN4002GP

CR2 Rectifier, Bridge, 100V, 4A, KBU4B

SORVALL Centrifuges

CR1 Rectifier, Bridge, 100V, 1W, KBPC2501/W