Page 1

OPERATING

INSTRUCTIONS

SORVALU RC-28S

SUPRASPEED

CENTRIFUGE

Du Pont Company

Sorvall® Instruments

Wilmington, Delaware 19898

U.S.A.

Sorvall Centrifuges

PN 59154-1

Issued August 1989

Page 2

Sorvall® Centrifuges

This manual is a guide for use of the

SORVALL® RC-28S Supraspeed® Centrifuge

Data herein has been verified and validated and is believed adequate for the intended

use of the centrifuge. If the centrifuge or procedures are used for purposes over and

above the capabilities specified herein, confirmation of their validity and suitability

should be obtained, otherwise Du Pont does not guarantee results and assumes no

obligation or liability. This publication is not a license to operate under, nor a

recommendation to infringe upon, any process patents.

NOTES,

CAUTIONS, and WARNINGS within the text of this manual are used to

emphasize important and critical instructions:

WARNING: A Warning informs the operator of a hazard or an unsafe practice that

could result in personal injury, affect the operator's health, or contaminate

the environment.

CAUTION: A Caution informs the operator of an unsafe practice that could result in

damage of equipment.

NOTE:

1988 by E.I. du Pont de Nemours & Co.

A Note highlights essential information.

ii

Page 3

Sorvall® Centrifuges Safety

Important Safety Information

Certain potentially dangerous conditions are inherent to the use of all centrifuges. To

ensure safe operation of this centrifuge, anyone using it should be aware of all safe

practices and take all precautions described below and throughout this manual.

WARNING

Use Sorvall® rotors only. Use of another manufacturer's rotor can cause rotor failure

which could result in personal injury and/or centrifuge damage.

When using radioactive, toxic, or pathogenic materials, be aware of all characteristics of

the materials and the hazards associated with them in the event leakage or rotor failure

occurs during centrifugation, in which case neither the centrifuge nor the rotor can

protect you from particles dispersed in the air. To protect

additional precautions be taken to prevent exposure to these materials, e.g., use of

controlled ventilation or isolation areas.

Always be aware of the possibility of contamination when using radioactive, toxic, or

pathogenic materials. Take all necessary precautions and use appropriate

decontamination procedures if exposure occurs.

yourself,

we recommend

Never use any material capable of producing flammable or explosive vapors.

Never exceed the maximum rated speed of the installed rotor; to do so can cause rotor

failure.

Always reduce (derate) rotor speed whenever:

• the rotor speed/temperature combination exceeds the solubility of the gradient

material and would cause it to precipitate;

• rotor compartment load exceeds the maximum allowable compartment load

specified (check this whenever average fluid density is greater than 1.2 g/ml). See

Chapter 4, Operation.

Failure to reduce rotor speed under these conditions can cause rotor failure.

CAUTION

Do not run or precool a rotor at the critical speed, as this will have a detrimental effect

on centrifuge component life. See Table 4-1, Rotor Information.

Do not operate centrifuge with a rotor out of balance. To do so can cause damage to the

centrifuge drive assembly.

Do not operate centrifuge without rotor properly installed: rotor cover must be on and

locked in place, and the rotor locked to the centrifuge drive. See rotor instruction

manual.

Locate the centrifuge on a level floor to avoid rotor imbalance during operation.

The centrifuge can be damaged if connected to the wrong voltage. Check the voltage

before plugging the centrifuge into a power source. Du Pont is not responsible for

incorrect installation.

Always maintain the centrifuge in the recommended manner. See Chapter 7,

Maintenance.

iii/iv

Page 4

Sorvall® Centrifuges Table of Contents

Table of Contents

Page

Safety Information iii

Chapter 1. DESCRIPTION

General Description 1-1

Centrifuge Specifications 1-2

Centrifuge Features 1-3

System Descriptions 1-5

Chapter 2. INSTALLATION

Inspection 2-1

Location 2-1

Ambient Temperature 2-2

Leveling 2-2

Electrical 2-2

Chapter 3. CONTROLS

Control Panel 3-1

PROGRAM Key Functions & Display Screens 3-3

CALCULATE Key Functions & Display Screens 3-9

DIAGNOSTICS Key Functions & Display Screens 3-9

Chapter 4. OPERATION

Understanding the Centrifuge Controls 4-1

Turning the Centrifuge On 4-1

Normal Run 4-1

Slow Start/Slow Stop 4-3

RCF Run 4-5

Key#Code 4-6

Zonal Run 4-7

Hold Run 4-8

fctfdt Run 4-9

Programmed Run 4-10

Control Panel Lock 4-11

Precool/Preheat 4-12

Reducing Speed for Rotor Compartment Loads in

Excess of Design Mass 4-12

Page 5

Table of Contents Sorvall® Centrifuges

Table of Contents (continued)

Page

Chapter 5. CALCULATOR

Calculator Display Screens 5-1

Calculate Speed/RCF for Rotor Time/fo^dt 5-1

Calculate Speed/RCF at a Radius 5-2

Calculate K Factor 5-2

Calculate Rotor Conversion/Time 5-2

Chapter 6. TROUBLESHOOTING & DIAGNOSTICS

Display Messages 6-1

Diagnostics:

General 6-5

Screen 1, Faults 6-6

Screen 2 6-7

Screen 3 6-9

How to Assign or Change a Key# 6-9

How to Change Slow Start/Slow Stop Transition Speed 6-12

Chapter 7. MAINTENANCE

Maintenance Schedule 7-1

Cleaning:

Rotor Chamber 7-2

Tapered Drive Spindle 7-2

Cabinet 7-2

Control Panel 7-2

Door Seal 7-2

Refrigeration System Condenser 7-4

Air Louvers 7-4

Lubrication 7-4

Changing the Vacuum Pump Oil & Mist Eliminator Filter 7-4

Emergency Sample Recovery 7-8

Test of RUN Display Lights & Control Panel Indicators 7-10

Parts Ordering Information 7-11

Service Decontamination Policy 7-11

APPENDIX

Vacuum Pump Oil Specifications

Warranty

Glossary

Index

Program Log Cards

Decontamination Certificates

VI

Page 6

Sorvair Centrifuges

Table of Contents

List of Illustrations

Figure

1-1. SORVALL® RC-28S Supraspeed® Centrifuge viii

2-1.

Centrifuge Dimensions 2-1

2-2.

Leveling Adjustment 2-2

3-1.

Control Panel 3-2

7-1.

Door Seal Removal 7-3

7-2. Parts Identification, Vacuum Pump Oil Change 7-6

7-3.

Door Interlock Override 7-9

7-4. Vacuum Release Solenoid Valve Location 7-9

List of Tables

Table

4-1.

Rotor Information 4-4

6-1.

DIAGNOSTICS, Screen 2 Fields 6-7

6-2. DIAGNOSTICS, Screen 2 Operations 6-7

6-3.

DIAGNOSTICS, Screen 3 Fields 6-8

7-1.

Maintenance Schedule 7-1

Page

Page

vii

Page 7

Sorvall® Centrifuges

viii

Figure 1-1. SORVALL® RC-28S Supraspeed® Centrifuge

Page 8

Sorvall®Centrifuges Description

Chapter 1

DESCRIPTION

This manual provides you with the information you need to install, operate and

maintain your SORVALL® RC-28S Supraspeed® Centrifuge. If you encounter any

problem concerning either operation or maintenance that is not covered in the manual,

please telephone Du Pont for assistance. In the United States, call toll free

(800)551-2121.

SORVALL® Products.

General Description

The Sorvall® RC-28S Supraspeed® Centrifuge defines a new class of centrifuge that

brings an unparalleled level of performance to centrifugation. Created from the latest

design technology, it incorporates usability, dependability, and safety with an extremely

versatile speed range to set a new standard in value. When used with a Sorvall®

Supraspeed® rotor, the RC-28S can reach a top speed of 28 000 rpm with a maximum

g force of 100 095. At 100 095 x g you can perform applications in the RC-28S that

previously required an ultracentrifuge. In addition to the Supraspeed® rotors designed

for use with the RC-28S, the RC-28S accepts all Sorvall® superspeed rotors, increasing

its usefulness by making it capable of a wide range of applications.

Outside the United States, contact the distributor or agent for

The centrifuge is microcomputer controlled and designed to be user friendly. It can be

operated using basic parameters only or you can decide to use its special features.

Because of this versatility and its user-friendliness, it can easily be operated by

inexperienced persons learning centrifugation methods or by experienced persons

experimenting with new methods.

The brushless dc drive which offers the optimum in centrifuge drive performance is one

distinct feature of the RC-28S. Other features of the centrifuge are: automatic rotor

recognition; programmability; RCF and

for sample reorientation; overtemperature control; a control panel lock to prevent run

parameters from being changed; and a built-in calculator that can be used to perform

centrifugation calculations, including conversions between RCF and speed, time and

fco2dt or the calculation of K factors and run times when conversion of published run

parameters is desired.

The centrifuge also has extensive diagnostic routines that allow the user to identify

system malfunctions and perform maintenance and repair procedures.

For more on the features of the RC-28S, plus more on the centrifuge drive and other

systems, read the table on the next two pages and the descriptive paragraphs that follow

the table.

fco2dt

control; slow start and slow stop control

1-1

Page 9

Description

Centrifuge Specifications

Son/all® Centrifuges

Rotor Management

SPIN-RIGHT® Rotor Management System

automatically recognizes installed Sorvall®

rotor when chamber door is closed. Pre-

vents operation of rotors above their maxi-

mum speed. Primary function of the system

is to provide an added margin of safety

during operation; however it is effective only

when it is operated as intended. Any misuse of the system, as with any other centrifuge system or feature, could result in

unsafe operation.

Rotor Speed

Set Speed:

from 100 rpm to 28 000 rpm in

increments of 10

Speed Control:

±10 rpm from 0-2000 rpm;

±0.5 % above 2000 rpm.

Speed Displayed:

digital readout during a run of actual

speed

Rotor Temperature

Set Temperature:

from -20°C to +40°C

Overtemperature:

automatic or settable from 0°C to 45°C

Temperature Control:

±10Cfrom2°Cto40°C

Temperature Displayed:

digital readout during a run of actual

temperature in 1 ° increments

1

Time

Set Time:

one minute to 99 hours and 99

minutes; can select HOLD for

continuous operation

Time (continued)

Time Displayed:

digital readout indicates remaining

time for a timed run or elapsed time

for continuous run

Vacuum

Rotary vane pump system.

Chamber pressure:

< 15 millibars (1.5 kPa)

Ambient Temperature

Range

from 15°Cto38°C

2

Dimensions:

Width:

Height: 93 cm (36.5 in)

Depth:

Clearances:

15 cm (6 in) required on left side of

centrifuge

70 cm (27.5 in)

to top deck

123 cm (48.5 in)

to top of control panel

103 cm (40.5 in)

Net Mass

385 kg (850 lbs)

Electrical Requirements

Can be supplied for use on the following

single phase power sources

200 V, 60 Hz, 30 A 200 V, 50 Hz, 30 A

208 V, 60 Hz, 30 A3 220 V, 50 Hz, 30 A

230 V, 60 Hz, 30 A3 240 V, 50 Hz, 30 A

Receptacle:

power cord fits Hubbell receptacle

No.

9330 or equivalent

1

Temperature range with power ON but no run in process (standby) is from -10°C to +30°C.

2

The centrifuge will operate at ambient temperatures up to 38°C, but refrigeration system performance will be less than optimal above 25°C.

3

CSA Certification applied for.

1-2

Page 10

Sorvall® Centrifuges

Description

Centrifuge Features

High Performance Drive

A brushless dc direct drive system de-

signed for longer motor life and greater

reliability; provides high torque; fast acceleration; and smooth, precise speed

control. No brushes means less maintenance. Controlled by dual microprocessors with accurate speed control during

acceleration and a Positive Action Brake

system that provides controlled braking

from set speed all the way to 0 rpm.

Includes Sorvall® Gyro-Action

Centering System that permits "eye balancing" of tubes. Imbalance detector

protects against damage from gross imbalance conditions. Accepts all Sorvall®

Superspeed and Supraspeed® rotors.

Self-

Automatic Rotor Recognition

SPIN-RIGHT® Rotor Management System

automatically recognizes installed

Sorvall® rotor when chamber door is

closed. Provides optimal instrument

control. Prohibits operation of a rotor

above its maximum speed. Primary

function of the system is to provide an

added margin of safety during operation;

however, it is effective only when it is

operated as intended. Any misuse of the

system, as with any other centrifuge

system or feature, can result in unsafe

operation.

Vacuum

Allows Sorvall® Supraspeed® rotors to be

operated at speeds up to 28 000 rpm.

Automatically activated when required.

RCF Run

RCF can be chosen in place of a speed to

control run. Allows RCF to be reproduced from run to run and rotor to rotor.

Accepts values up to 100 095 x g, de-

pending on the rotor used.

Slow Start / Slow Stop

Automatic control of acceleration and

deceleration to and from transition

speed; provides optimal reorientation

conditions which prevent disturbance of

gradient or pellet. Optimal times to and

from transition speed are automatically

determined for identified rotor or can be

manually selected; transition speed can

even be changed if desired. Flexibility of

control means you can duplicate a slow

start/slow stop run done in any other

centrifuge.

Zonal Run

Allows operation with the chamber door

open to dynamically load a Sorvall®

TZ-28 Zonal Rotor. Loading speed selection from 1300 rpm to 2500 rpm. A key

number is required for zonal operation.

Precise Temperature Control

A high-capacity, highly efficient refrigeration system that combines heating and

cooling. The combined heating and

cooling provides temperature control

from 2°C to 40°C and eliminates the

need to defrost the chamber. Temperature sensor is mounted away from the

chamber wall to further improve accuracy of rotor temperature measurement.

Automatic sample temperature protec-

tion; maximum temperature will be set

automatically or can be entered manually. Convenient precooling of rotors.

fco2dt Run

A built-in integrator that provides exact

run-to-run reproducibility by controlling

the accumulating

ing value is displayed during the run.

fo)2dt.

The accumulat-

Control Panel Lock

Locks the control panel to prevent run

conditions from being changed without

the operator knowing. A key number is

required to lock and unlock the control

panel.

1-3

Page 11

Description

Centrifuge Features

Sorvall® Centrifuges

Programmability

Records run settings in memory. Once

recorded, programs can be recalled to

allow duplication of run. Up to 20 programs can be recorded. A key number

is required to save a program to pre-

vent unauthorized changes; however,

programs can be recalled without a key

number.

Calculator

A built-in calculator that performs

basic centrifugation calculations: RCF,

Speed, Time,

leting time. Can be used to convert

run conditions from rotor to rotor.

S(o2dU

K Factor, and pel-

Security Key Number

A four digit security number that is

required to access protected data and

some diagnostics. Also required to

activate Zonal, Program Save, and the

Lock. Centrifuge is supplied with one

factory-set number, but you can program multiple numbers for greater security and multiple users.

Advanced Diagnostics

Built-in diagnostic routines include

several levels of electronic troubleshooting aids that allow you to diagnose problems if they occur. Also used

to perform limited maintenance procedures and centrifuge updates.

Rotor Chamber

The stainless steel rotor chamber is

epoxy coated and free of wall sensors

making it durable and easy to clean.

Chamber seal is located in the door

rather than in the top of the chamber;

minimizes accumulation of dirt on the

seal which improves the seal. The door

seal can easily be removed for cleaning.

The sliding chamber door retracts

which makes the chamber easy to

access and solves door clearance problems.

Size

The RC-28S is narrower than most

superspeed and ultraspeed centrifuges.

Requires less floor space.

Operator's Guide

Readily accessible operating instructions and aids that pull out from under

the control panel. Includes convenient

Program Log records and rotor specifications.

Serviceability & Technical

Support

Extensive diagnostics and easy to

access components make the RC-28S

easy to service. Complete product

literature available plus a toll free

number to call for technical assistance.

1-4

Page 12

Sorvall®Centrifuges Description

System Descriptions

Drive System

The RC-28S drive system uses state-of-the-art brushless dc motor technology that

offers the optimum in centrifuge drive performance.

A brushless dc motor uses an electronic commutator in place of a mechanical

commutator, which eliminates brushes and the maintenance problems associated with

them, plus it eliminates the speed and current limitations of a mechanical commutator.

The high torque of the dc motor results in faster acceleration and braking, while the

high efficiency means less power consumption and less heat. Less heat in the motor

means that the drive runs cooler which eliminates the need for any auxiliary means of

motor cooling, such as Freon® or water.

The motor used is inherently non-cogging which ensures the smoothest acceleration

and deceleration possible. Cogging is typical of induction and brush type motors and

can cause sample disturbance during acceleration and deceleration.

The RC-28S drive system is controlled by dual microprocessors allowing extremely

accurate speed control during acceleration and deceleration and eliminating overshoot

of set speed. The accuracy of the speed control results in smoother slow start and slow

stop,

plus positive action braking from set speed to 0 rpm. The microprocessors operate

independent of each other to constantly monitor various centrifuge functions and, as an

added safety factor, they maintain constant internal communication with each other to

test and evaluate the performance of the other. The many tests that are performed

routinely throughout operation determine if any preset limitations are exceeded; any

failure detected will cause immediate shutdown by the processor detecting the problem.

In addition, the centrifuge will shut down if communication fails between the processors

or in the unlikely event both processors fail.

SPIN-RIGHT® Rotor Management System

The Sorvall® RC-28S SPIN-RIGHT® Rotor Management System automatically insures

optimal control of the selected speed and temperature parameters and prevents the

inadvertent setting of a speed beyond the capability of a given Sorvall® rotor. The

Sorvall® rotor installed in the chamber is recognized through an ultrasonic scanning

device that is activated when the chamber door is closed. The rotor identity is then

displayed in the SET display of the control panel.

The primary function of the rotor management system is to provide an added margin of

safety during operation. This system is effective only when it is operated as intended.

Any misuse of the system, as with any other centrifuge system or feature,can result in

unsafe operation

Refrigeration System

The refrigeration system consists of: a stainless steel evaporator that acts as the rotor

chamber, a 2-hp hermetically sealed compressor, an air-cooled condenser, and the

suction-capillary tube assembly. A hot gas bypass circuit allows for quiet, non-cycling

1-5

Page 13

Description Sorvall®Centrifuges

compressor operation as well as improved temperature control and frost-free operation.

The refrigeration system is factory charged with Freon® 502.

The desired run temperature is entered on the control panel and is maintained by the

system electronics which cycles the hot gas circuit as required. If desired, a maximum

temperature can be entered on the control panel; if a value is not entered manually, the

maximum temperature will default to +5°C above set temperature. Any failure causing

the temperature to exceed the maximum setting will result in the termination of the run

and a corresponding message will be displayed on the control panel to alert the

operator.

Vacuum System

The vacuum system includes a direct drive vacuum pump, an air-inlet solenoid (bleed)

valve, mist eliminator, the evaporator chamber, and interconnecting tubes and fittings.

Reduced rotor chamber pressure is sensed by a Pirani convection gauge located at the

pump inlet manifold and monitored by the machine control microprocessor. When

activated, this system provides a vacuum level between 1 and 15 millibars.

The vacuum system is automatically activated only when the set speed is higher than

the top air speed of one of the Sorvall® Supraspeed® rotors designed specifically for use

with the RC-28S.

In the event of a vacuum loss or insufficient vacuum, a message will appear in the

control panel SET display to notify the operator. In an emergency, such as a power

failure, when sample recovery is desirable, the chamber door can be opened manually

(see Chapter 7 for procedure).

1-6

Page 14

Sorvall® Centrifuges

Installation

Chapter 2

INSTALLATION

This chapter contains instructions to prepare your Sorvall® RC-28S for operation.

Inspection

When you receive your centrifuge, carefully inspect it for any signs of shipping

damage. If you find damage, please report it immediately to the transportation

company and file a damage claim, then notify Du Pont.

Check the parts received with the centrifuge against the shipping list; if any parts

are missing, contact Du Pont (see back cover).

Location

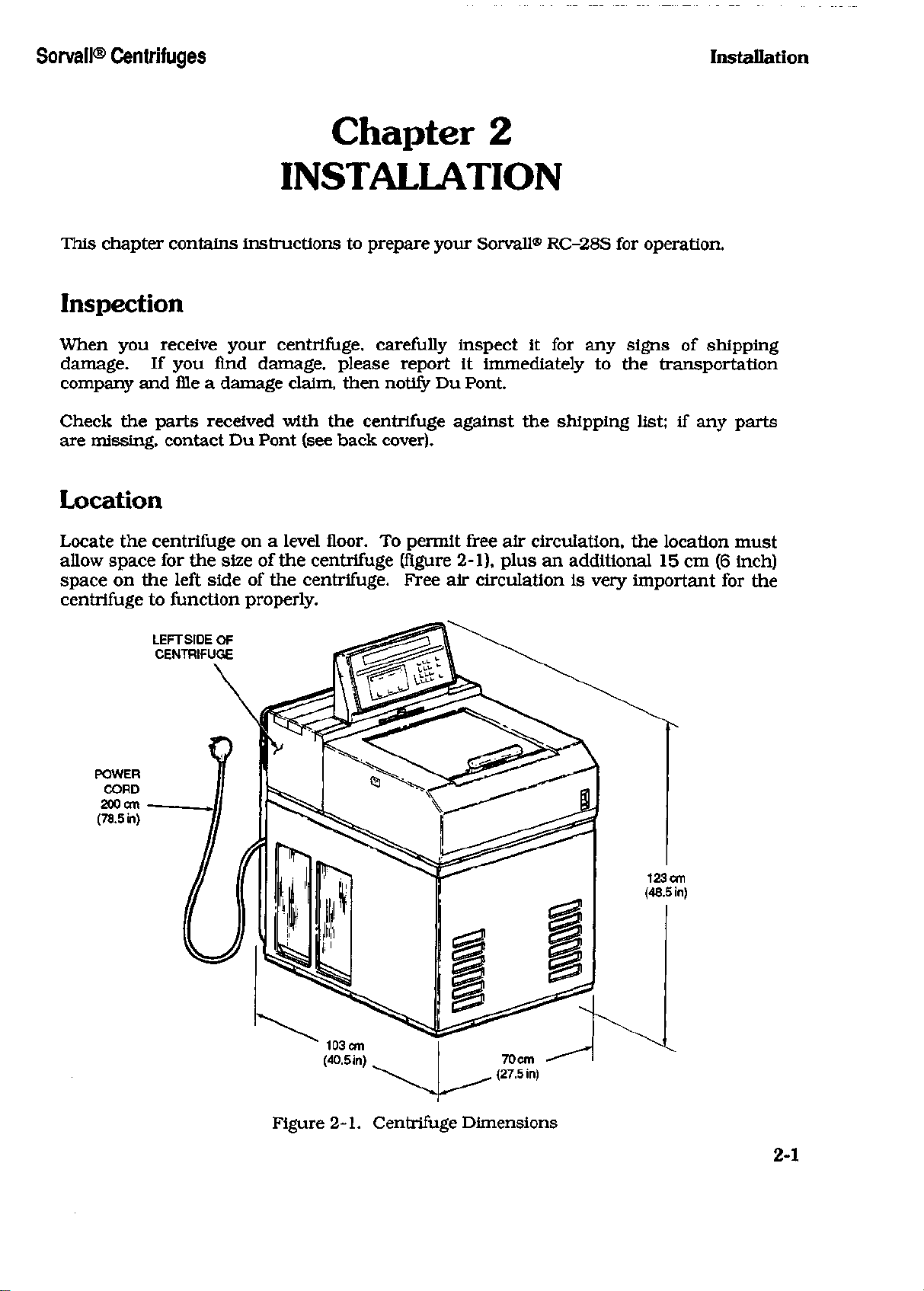

Locate the centrifuge on a level floor. To permit free air circulation, the location must

allow space for the size of the centrifuge (figure 2-1), plus an additional 15 cm (6 inch)

space on the left side of the centrifuge. Free air circulation is very important for the

centrifuge to function properly.

LEFTSIDE OF

CENTRIFUGE

POWER

CORD

200cm -

(78.5 in)

123 cm

(48.5 in)

Figure 2-1. Centrifuge Dimensions

2-1

Page 15

Installation

Son/all® Centrifuges

Ambient Temperature

An ambient temperature range of 15°C to 38°C must be maintained. If the inlet air

temperature is above 25°C, the centrifuge will not maintain low temperatures at

high speeds.

Leveling

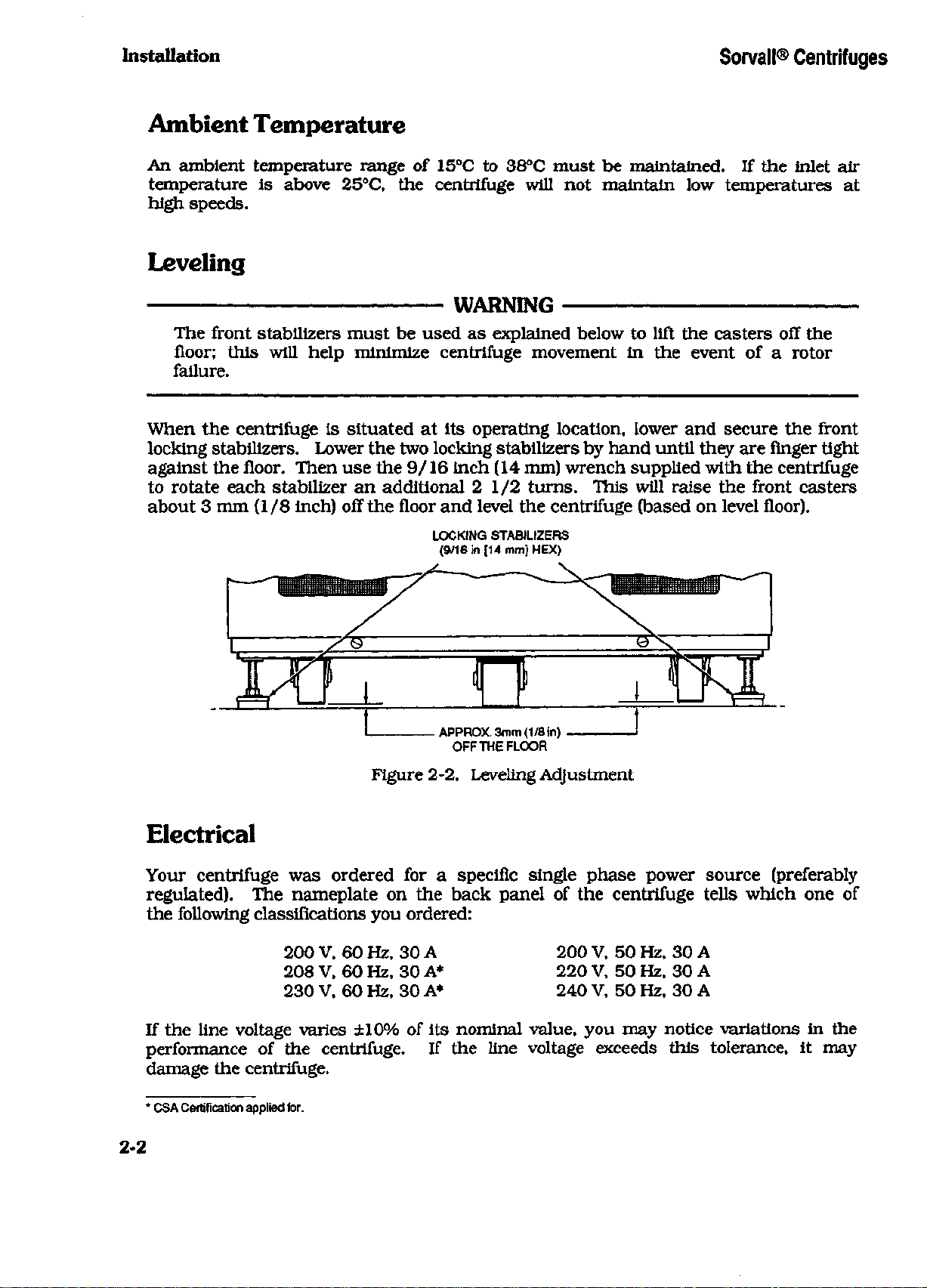

WARNING

The front stabilizers must be used as explained below to lift the casters off the

floor; this will help minimize centrifuge movement in the event of a rotor

failure.

When the centrifuge is situated at its operating location, lower and secure the front

locking stabilizers. Lower the two locking stabilizers by hand until they are finger tight

against the floor. Then use the 9/16 inch (14 mm) wrench supplied with the centrifuge

to rotate each stabilizer an additional 2 1/2 turns. This will raise the front casters

about 3 mm (1/8 inch) off the floor and level the centrifuge (based on level floor).

LOCKING STABILIZERS

(9/16 in [14 mm] HEX)

APPROX. 3mm (1/8 in)

OFF THE FLOOR

Figure 2-2. Leveling Adjustment

Electrical

Your centrifuge was ordered for a specific single phase power source (preferably

regulated). The nameplate on the back panel of the centrifuge tells which one of

the following classifications you ordered:

200 V, 60 Hz, 30 A

208 V, 60 Hz, 30 A*

230 V, 60 Hz, 30 A*

200 V, 50 Hz, 30 A

220 V, 50 Hz, 30 A

240 V, 50 Hz, 30 A

If the line voltage varies ±10% of its nominal value, you may notice variations in the

performance of the centrifuge. If the line voltage exceeds this tolerance, it may

damage the centrifuge.

* CSA Certification applied for.

2-2

Page 16

Sorvall® Centrifuges installation

CAUTION

The centrifuge can be damaged if connected to the wrong voltage. Check

the voltage before plugging the centrifuge into any power source. DuPont

is not responsible for improper installation.

The centrifuge is equipped with a 3-wire power cord with a 3-prong cap, including

ground connection, to fit Hubbell receptacle No. 9330 or equivalent.

To connect the centrifuge to a voltage other than what is specified on the nameplate, the

centrifuge will have to be rewired and the power cord may have to be replaced. In this

case,

contact DuPont to have a Service Representative do the rewiring.

The ON/OFF main power switch is a 30 A circuit breaker, therefore a separate line

disconnect switch is not needed unless required by local codes.

2-3/2-4

Page 17

Sorvall® Centrifuges Controls

Chapter 3

CONTROLS

This chapter provides:

• a detailed description of the RC-28S controls;

• a brief description of the built-in calculator; and

• a brief description of the diagnostic routines.

For step-by-step operating instructions see Chapter 4, and for further information

on the calculator and the diagnostics, see Chapters 5 and 6.

NOTE

A convenient Operator's Guide containing simplified instructions is located

under the centrifuge control console.

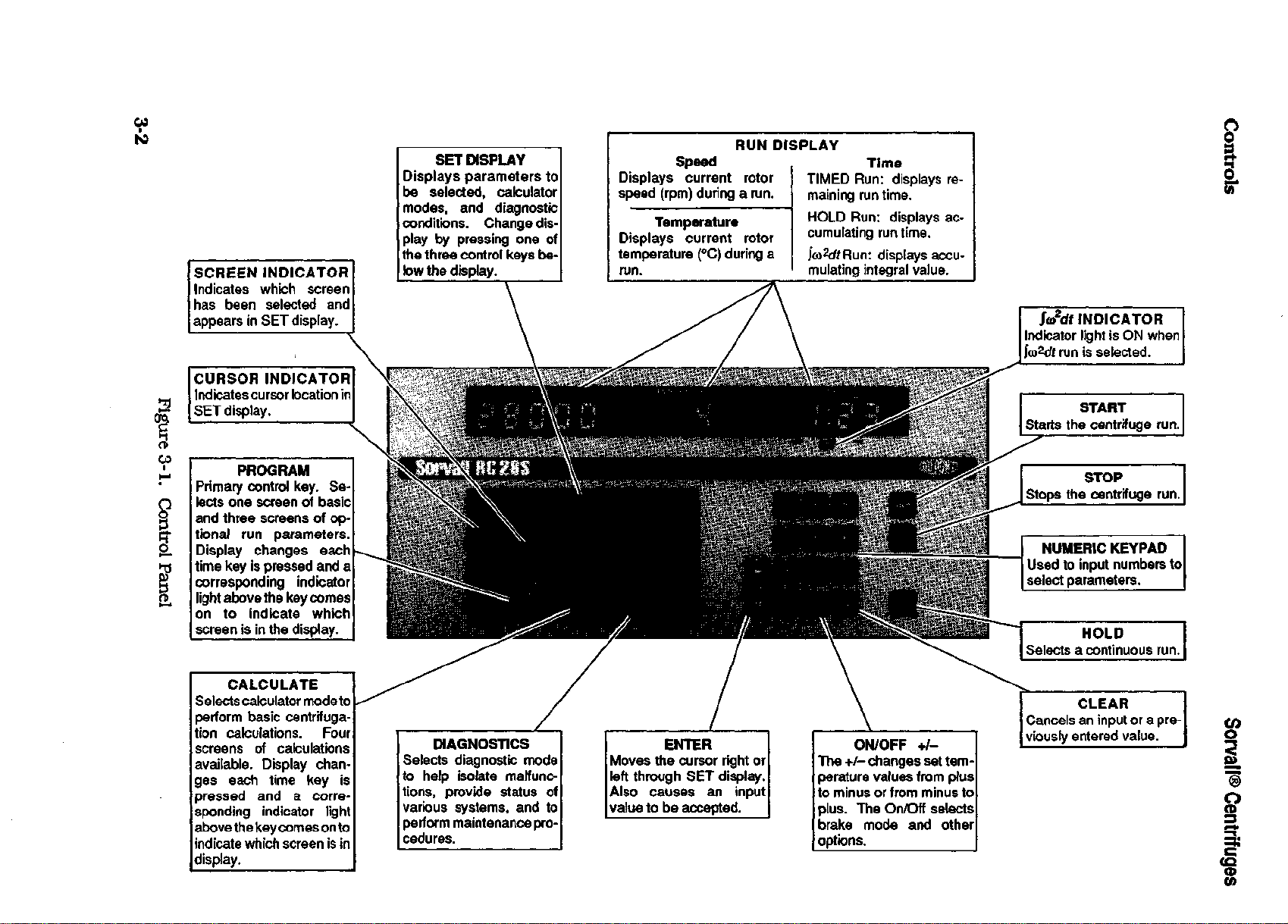

Control Panel

The RC-28S is easy to use. All commands are entered from the convenient keypad

on the control panel and the set and run parameters are visible in the displays. All

selected parameters can be locked to prevent changes to run settings. Figure 3-1

on the next page shows the RC-28S control panel and gives a brief description of

the keys and displays. A complete description follows the illustration.

Set Display

The SET display is the lower display that changes by pressing the PROGRAM,

CALCULATE or DIAGNOSTICS key to show various screens of parameters or

operations. A cursor in the SET display indicates the field where the next input

character will appear. Lights below the display indicate the position of the cursor.

Run Display

The RUN display includes the three upper displays that show actual speed,

temperature, and time or Jco2dt during a run.

3-1

Page 18

CO

SCREEN INDICATOR

Indicates which screen

has been selected and

appears in SET display.

CURSOR INDICATOR

Indicates cursor location in

SET display.

2

1

SET DISPLAY

Displays parameters to

be selected, calculator

modes, and diagnostic

conditions. Change display by pressing one of

the three control keys be-

low the display.

RUN DISPLAY

Speed

Displays current rotor

speed (rpm) during a run.

Temperature

Displays current rotor

temperature (°C) during a

run.

Time

TIMED Run: displays re-

maining run time.

HOLD Run: displays ac-

cumulating run time.

displays accu-

mulating integral value.

Ja/WflNDICATOR

Indicator light is ON when

lco2dt run is selected.

START

Starts the centrifuge run.

O

O

a

PROGRAM

Primary control key. Selects one screen of basic

and three screens of op-

B

tional run parameters.

Display changes each

I

time key is pressed and a

corresponding indicator

light above the key comes

on to indicate which

screen is in the display.

CALCULATE

Selects calculator mode to

perform basic centrifugation calculations. Four

screens of calculations

available. Display changes each time key is

pressed and a corresponding indicator light

above the key comes on to

indicate which screen is in

display.

DIAGNOSTICS

Selects diagnostic mode

to help isolate malfunctions,

provide status of

various systems, and to

perform maintenance procedures.

ENTER

Moves the cursor right or

left through SET display.

Also causes an input

value to be accepted.

ON/OFF +/-

The +/- changes set temperature values from plus

to minus or from minus to

plus.

The On/Off selects

brake mode and other

options.

STOP

Stops the centrifuge run.

NUMERIC KEYPAD

Used to input numbers to

select parameters.

HOLD

Selects a continuous run.

CLEAR

Cancels an input or a previously entered value.

CO

o

5

(D

CO

Page 19

Sorvall® Centrifuges

Controls

Description of Display & Key Functions

v

j v j V j

Cancels

the entry

again,

Starts

Stops

the

the

the

The numeric keypad

select parameter values.

The ENTER keys cause

accepted, plus they cause

the right

On/Off

word

On or Off

of

the SET

the temperature value from positive

negative

an

input

is set to

previously entered value

centrifuge

centrifuge

or a

previously entered value. When

zero

(0) and a new

run.

run.

is

or to the

is

used

to

is

used

to

left through

to

select options. When pressed,

will appear

display.

positive.

value

restored.

input numbers from

an

input value

the

cursor

the SET

in the

The +/- is

can be

input. When pressed

appropriate field

used only

to

the key is

0 to 9 to

to

move

display.

to

negative

pressed,

to be

to

the

change

or

Selects a continuous

the

SET

display

is pressed,

show accumulating

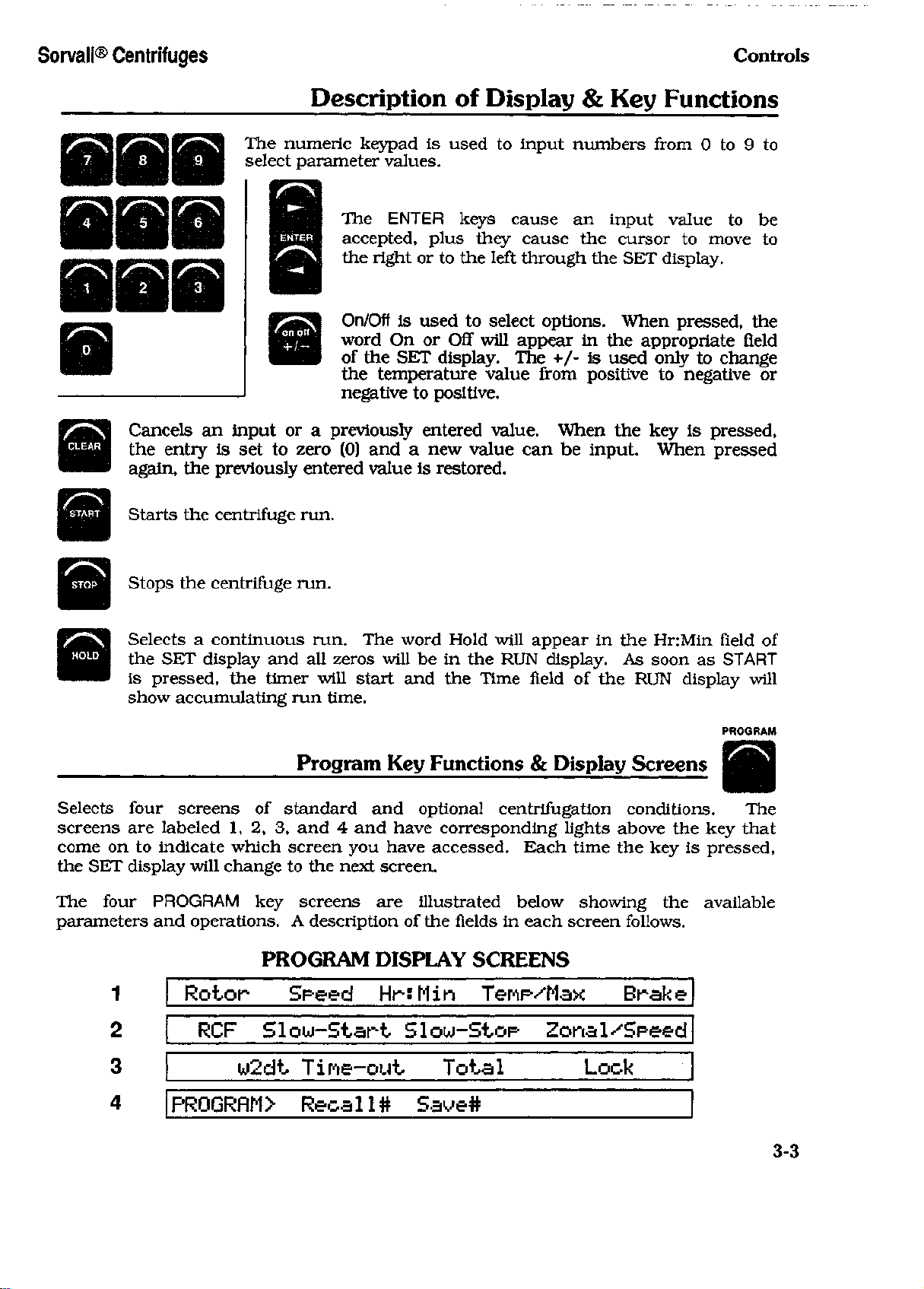

Selects four screens

screens

come

the

The four PROGRAM

parameters

are

labeled

on to

SET

indicate which screen

display will change

and

1

2

the

1, 2, 3, and 4 and

operations. A description

Rotor Speed Hr:Min Tenp/Max Brake

RCF Slow-Start Slow-Stop Zonal/Speed

3

run. The

and all

timer will start

run

zeros will

time.

Program

of

standard

you

key

to the

screens

next screen.

word Hold will appear

be in the RUN

and the

Key

and

optional centrifugation conditions.

have corresponding lights above

have accessed. Each time

are

illustrated below showing

of the

Time field

Functions & Display Screens

fields

in

each screen follows.

in the

display.

of the RUN

As

the key is

PROGRAM DISPLAY SCREENS

w2dt Tine-out Total Lock

HnMin field

soon

as

START

display will

PROGRAM

The

the key

the

available

that

pressed,

of

4

PROGRflM> Recal1# Save#

3-3

Page 20

Controls Sorvall® Centrifuges

PROGRAM

Program Key Functions & Display Screens

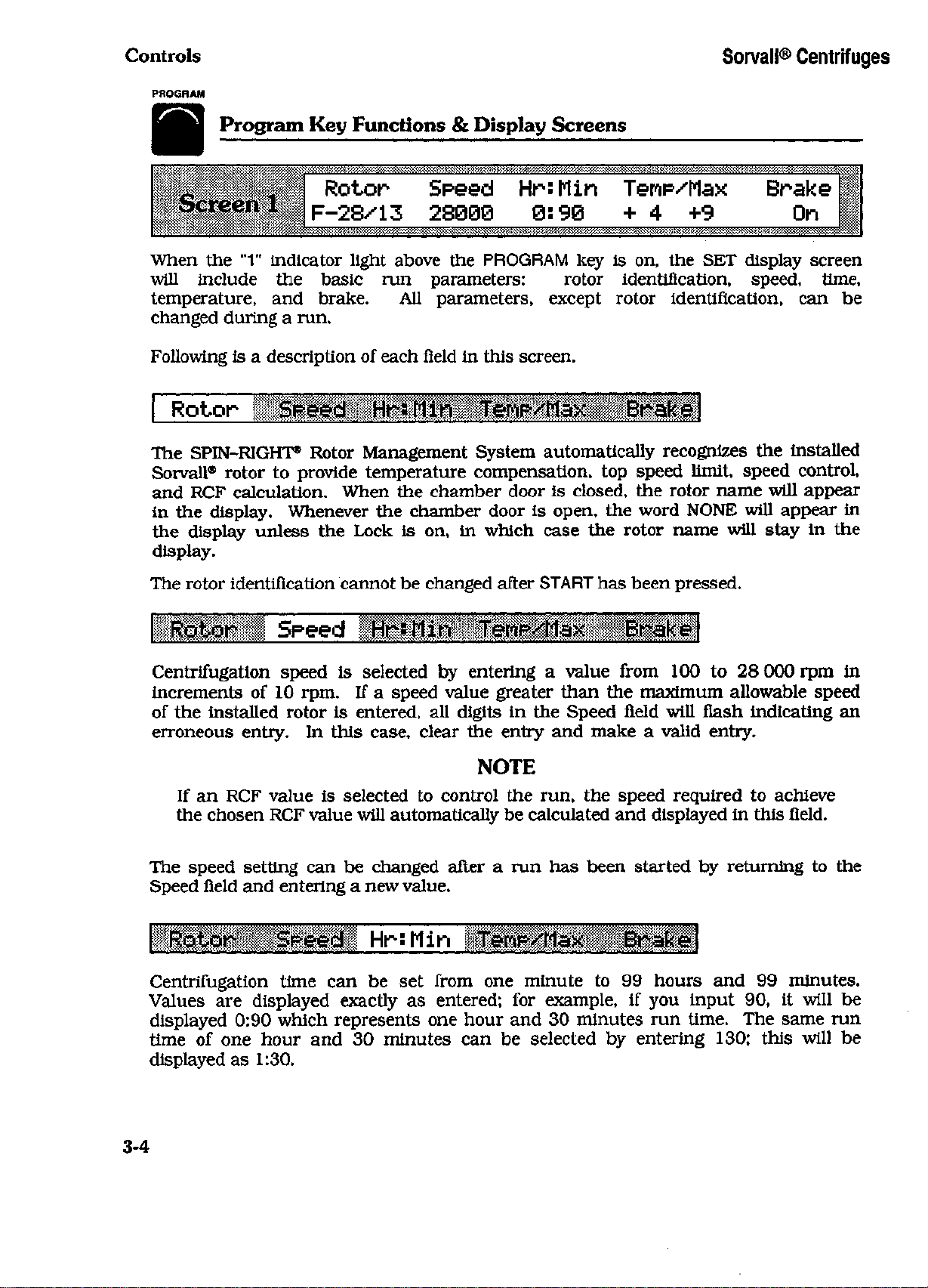

Rotor Speed HrsMin Temp^Max Brake

Screen

1

F-28^13 23000

0:90

+4+9

On

When the "1" indicator light above the PROGRAM key

will include

temperature,

changed during a run.

Following is a description of each field in this screen.

the

and

basic

brake.

run

All

parameters: rotor identification, speed, time,

parameters, except rotor identification,

is

on, the SET display screen

can be

Rotor Speed HrsMin TeMp/Max Brake

The SPIN-RIGHT® Rotor Management System automatically recognizes the installed

Sorvall® rotor

and RCF calculation. When the chamber door

in the display. Whenever the chamber door

the display unless the Lock

display.

The rotor identification cannot be changed after START has been pressed.

Iliiiiiil Speed

Centrifugation speed

increments

of the installed rotor

erroneous entry.

to

of

provide temperature compensation, top speed limit, speed control,

is

closed, the rotor name will appear

is

open, the word NONE will appear

is

on,

in

is

10 rpm.

is

In

which case the rotor name will stay

selected

If a

entered, all digits

this case, clear the entry and make a valid entry.

by

entering a value from 100

speed value greater than the maximum allowable speed

in

the Speed field will flash indicating an

to

28 000 rpm

in

in

the

in

NOTE

If an RCF value

the chosen RCF value will automatically be calculated and displayed in this field.

The speed setting can

Speed field and entering a new value.

is

be

selected

to

control the run, the speed required

changed after a run has been started by returning

to

achieve

Rotor Speed HrsMin TerwMax Brake

Centrifugation time can

Values are displayed exactly

displayed 0:90 which represents one hour and 30 minutes run time. The same run

time

of

one hour and

displayed as 1:30.

3-4

be set

as

30

minutes can

from one minute

entered;

for

be

example,

selected

to 99

if

by

hours and

you input 90,

entering 130; this will

99

minutes.

it

to

will

the

be

be

Page 21

Sorvall® Centrifuges Controls

PROGRAM

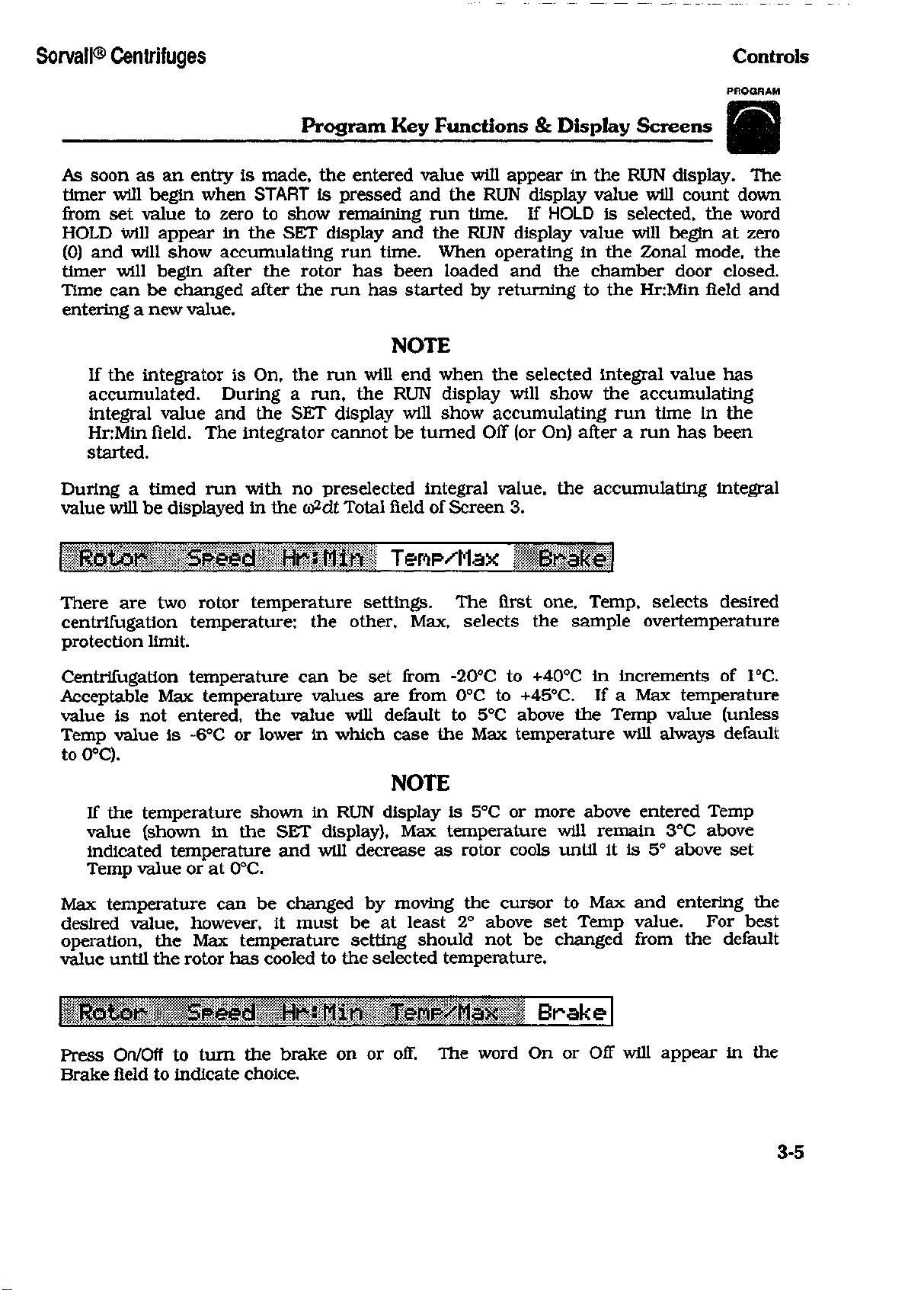

As soon

timer will begin when START

from

HOLD will appear

(0)

timer will begin after

Time

entering a new value.

as an

set

value

and

will show accumulating

can be

entry

to

changed after

is

zero

in the SET

made,

to

show remaining

the

rotor

the run has

Program

the

is

pressed

display

run

Key

entered value will appear

and the RUN

time. When operating

has

been loaded

Functions & Display Screens

and the RUN

run

time.

started

by

display value will count down

If

display value will begin

and the

returning

HOLD

NOTE

If

the

integrator

accumulated. During

integral value

HnMin field.

started.

During a timed

value will

be

displayed

is On, the run

a run, the RUN

and the SET

The

run

integrator cannot

with

no

in the

will

end

when

display will show accumulating

be

turned

preselected integral value,

G&dt

Total field

of

the

selected integral value

display will show

Off (or On)

Screen

3.

the

Rotor 5r*eed HrsMin Tenp/Max Ilillfil

. i

in the

in the

to the

after

RUN display.

is

selected,

Zonal mode,

chamber door closed.

Hr:Min field

the

accumulating

run

time

a run has

accumulating integral

the

at

has

in the

been

The

word

zero

the

and

There

centrifugation temperature;

protection limit.

Centrifugation temperature

Acceptable

value

Temp value

to 0°C).

Max temperature

desired value, however,

operation,

value until

are two

is not

If

the

temperature shown

value (shown

indicated temperature

Temp value

the Max

rotor temperature settings.

Max

the

temperature values

entered,

is -6°C or

or at

rotor

the

lower

in the SET

0°C.

can be

temperature setting should

has

and

changed

it

cooled

the

other.

can be set

value will default

in

which case

Max,

from -20°C

are

from

NOTE

in RUN

display),

will decrease

must

to the

display

Max

as

by

moving

be at

least

selected temperature.

The

to 5°C

the Max

is 5°C or

temperature will remain

2°

first

one,

selects

0°C to

rotor cools until

the

not be

the

sample overtemperature

to

+40°C

+45°C.

above

temperature will always default

cursor

above

the

more above entered Temp

to Max and

set

Temp value.

changed from

Brak

Temp, selects desired

in

increments

If a Max

Temp value (unless

it is 5°

e

of 1°C.

temperature

3°C

above

above

entering

the

set

For

default

the

best

Press On/Off

Brake field

to

turn

the

to

indicate choice.

brake

on or off. The

word

On or Off

will appear

in the

3-5

Page 22

Controls Sorvall® Centrifuges

PROGRAM

Program Key Functions & Display Screens

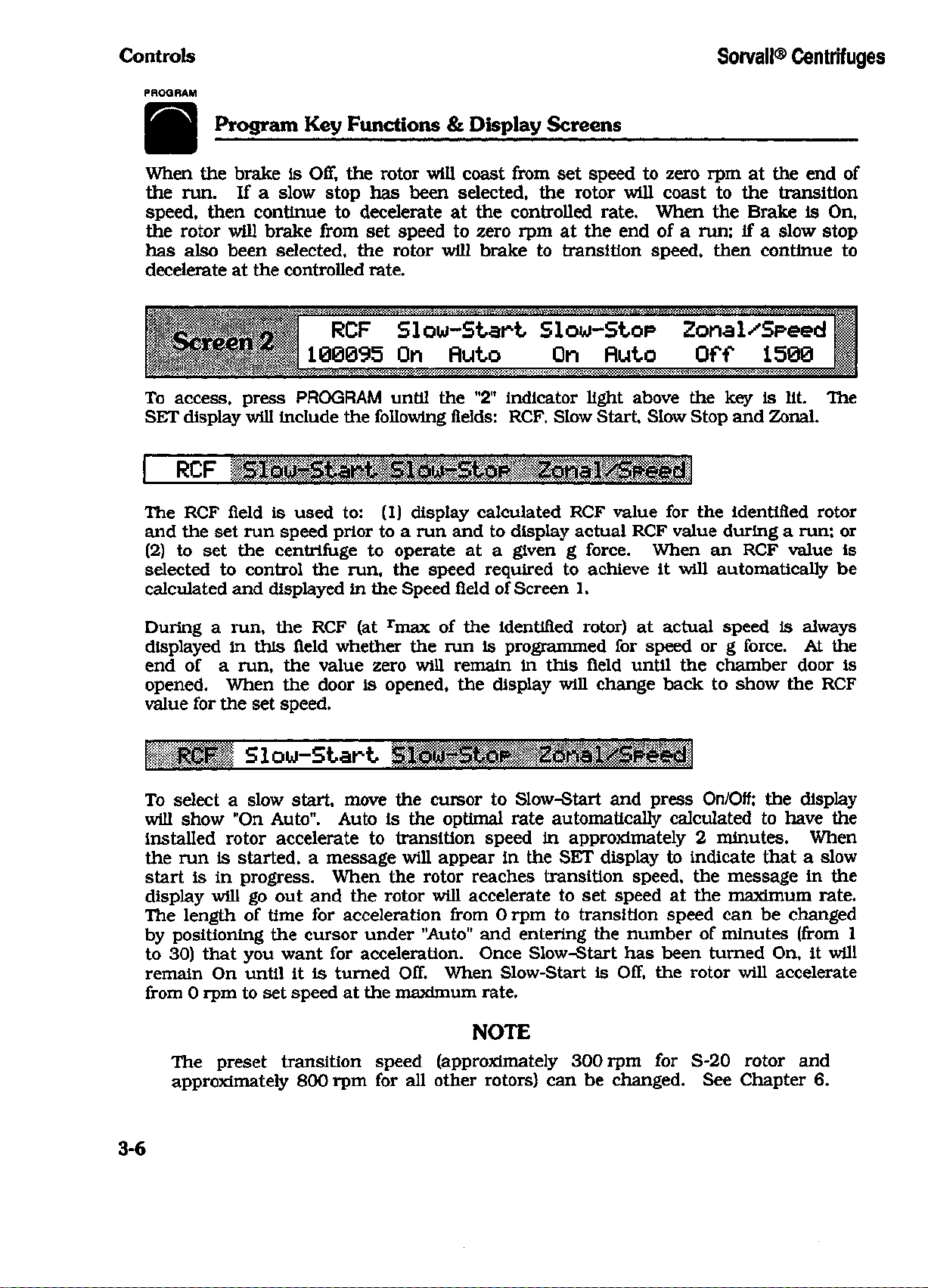

When the brake is Off, the rotor will coast from set speed to zero rpm at the end of

the run. If a slow stop has been selected, the rotor will coast to the transition

speed, then continue to decelerate at the controlled rate. When the Brake is On,

the rotor will brake from set speed to zero rpm at the end of a run; if a slow stop

has also been selected, the rotor will brake to transition speed, then continue to

decelerate at the controlled rate.

C

o *> "CF

screen

To access, press PROGRAM until the "2" indicator light above the key is lit. The

SET display will include the following fields: RCF, Slow Start, Slow Stop and Zonal.

RCF

z

100095 On fluto On fluio Off 1500

Slow-Start Slow-Stop Zonal/Speed

The RCF field is used to: (1) display calculated RCF value for the identified rotor

and the set run speed prior to a run and to display actual RCF value during a run; or

(2) to set the centrifuge to operate at a given g force. When an RCF value is

selected to control the run, the speed required to achieve it will automatically be

calculated and displayed in the Speed field of Screen 1.

During a run, the RCF (at rmax of the identified rotor) at actual speed is always

displayed in this field whether the run is programmed for speed or g force. At the

end of a run, the value zero will remain in this field until the chamber door is

opened. When the door is opened, the display will change back to show the RCF

value for the set speed.

RCF Slow-Start

To select a slow start, move the cursor to Slow-Start and press

will show "On Auto". Auto is the optimal rate automatically calculated to have the

installed rotor accelerate to transition speed in approximately 2 minutes. When

the run is started, a message will appear in the SET display to indicate that a slow

start is in progress. When the rotor reaches transition speed, the message in the

display will go out and the rotor will accelerate to set speed at the maximum rate.

The length of time for acceleration from 0 rpm to transition speed can be changed

by positioning the cursor under "Auto" and entering the number of minutes (from 1

to 30) that you want for acceleration. Once Slow-Start has been turned On, it will

remain On until it is turned Off. When Slow-Start is Off, the rotor will accelerate

from 0 rpm to set speed at the maximum rate.

On/Off;

the display

3-6

NOTE

The preset transition speed (approximately 300 rpm for S-20 rotor and

approximately 800 rpm for all other rotors) can be changed. See Chapter 6.

Page 23

Sorvall® Centrifuges Controls

PROGRAM

Program Key Functions & Display Screens

RCF Slow-Start Slow-Stop Zonal/Speed

To select a slow stop, move the cursor to Slow-Stop and press the On/Off key; the

display will show "On Auto". When On, the rotor will decelerate from set speed to

transition speed at the rate controlled by the brake setting. When the rotor

reaches transition speed, a message will appear in the SET display to indicate that

a slow stop has been initiated and the rotor will decelerate at a rate that will take it

approximately 3 minutes to reach 0 rpm. This rate of deceleration from transition

speed to 0 rpm is automatically calculated for the rotor in use. The rate of

deceleration can be changed by positioning the cursor under "Auto" and entering

the number of minutes (from 1 to 30) desired for deceleration. Once Slow-Stop

has been turned On, it will remain On until turned Off. When Slow-Stop is Off, the

rotor will decelerate at the rate controlled by the brake setting from set speed to

0 rpm.

NOTE

The preset transition speed (approximately 300 rpm for S-20 rotor and

approximately 800 rpm for all other rotors) can be changed. See Chapter 6.

RCF Slow-Start Slow-Stop Zonal/Speed

Used to select the Zonal mode of operation when dynamically loading a sample

and/or gradient into the Sorvall® TZ-28 Rotor. A Key# is required to activate the

Zonal mode.

When the Key# is entered and accepted, the word On appears in the display and

the cursor moves to Speed. Enter the Zonal loading speed from 1300 to 2500 rpm

(in increments of 10 rpm). When the chamber door is closed and START is

pressed, the rotor will accelerate to the Zonal speed, at which time the chamber

door can be opened and the sample/gradient loaded. After the sample and

gradient are loaded, close the chamber door and the rotor will accelerate to the

run speed selected in Screen 1 (the maximum Zonal run speed is 20 000 rpm).

At the end of the run, Zonal will turn Off automatically; therefore, each Zonal run

requires this option be turned On and the Key# entered.

Zonal cannot be stored in program memory; the zonal speed can be saved, but the

option must be turned On before the run.

w2dt Tine-out Total Lock

On

1.97e07

This screen includes w2dt and Lock. To access, press PROGRAM until the "3"

indicator light above the key is lit.

5.2QeQ7

On

3-7

Page 24

Controls Sorvall® Centrifuges

PROGRAM

Program Key Functions & Display Screens

w2dt Tine-out Total Lock

The Ja)2dt option

than a time value. Press On/Off

previous

deceleration,

(ENTER

Time-out value, first enter a three digit (X.XX) coefficient value

will automatically

the

During

and

accumulating value. During a timed

value

The integrator cannot

run

O) or

run.

an

integrator

the SET

and the

is

used

will automatically

and

Total

(START)

be

display will show selected Time-out integral value

Time-out value

to

program

to

be

is the

to

accept

placed), then

run, the RUN

be

turned

value

the

at the

On or Off

a run to end at a

turn

the |

displayed: Time-out

at 0 rpm,

Time-out value

a two

beginning

digit exponent value. Press (START)

display will show accumulating integral value

run, the SET

after

u2dt 1 on. The

which includes deceleration. Press

and

of

deceleration.

a run has

desired integral value rather

J(o2dt values from

is the

begin

display shows

the run. To

been started.

value

w2dt Tine-out Total Lock

This feature locks

changed until unlocked.

proper Key#. Once

in

the

Lock field

enter

the

Key#.

all set run

The

run

conditions have been locked

and in all

conditions (including options)

Lock

calculator screens.

is

activated

by

pressing On/Off

in, the

To

unlock, press On/Off again

cursor will only appear

at the

(the

decimal point

and the

the

accumulating

so

they cannot

and

start

change

to

begin

Total

entering

the

of

the

be

the

and

The lock cannot

~

A

screen

Run conditions

control centrifuge operation.

however, a program

be stored

Chapter

To access, press PROGRAM until

and a

6).

be

stored

in

program memory.

PROQRflM> Recall* Sauett

4

1

are

stored

can be

different Key#

in

program memory

A

Key# must

recalled without

can be

the "4"

PROGRFlM> Recall** Save*

Used

to

recall

the assigned program number (from

will automatically appear

run.

an

established program. Position

in

Screen

1 of the SET

^

and

be

entered

the

Key#. A total

assigned

indicator light above

1 to 20). The

to

the

display. Press START

recalled from memory

to

save

each program,

the key is lit.

cursor

recorded program parameters

in

a new

of 20

this field

programs

if

desired

to

program;

and

begin

to

can

(see

enter

the

3-8

Page 25

Sorvall® Centrifuges

Controls

PROGRAM

Program

Key

PROGRRM> Recall* Sauett

Used

to

save

all set

this field

Key#. When

and

enter a number from

the

assigned program number appears

that

was

the program.

which case,

input becomes

If

the

program numbers have been used, a new

program.

old program

In

this case,

is

automatically deleted from memory.

The CALCULATE

RCF,

speed,

below.

See

run

Chapter 5 for

run

conditions except Zonal

1 to

Key#

is

entered

and

in the

the

assigned program number that will

the

incorrect Key#

is

program number must

the

number assigned

Calculate

key

is

used

to

perform basic centrifugation calculations, including

time, Ju)2dt

and K Factor.

instructions

on

accepted,

entered,

be

Key

how

Functions & Display Screens

and

20. The

the

Save#

and

Lock. Position

display will prompt

display shows "Saved"

Recall# fields.

the

you

The

be

the

display will show

reentered, then

program

is

can

stored

for

the

be

stored over

the

new

"Not

correct Key#.

program

Functions & Display Screens

The

four calculator screens

to

use the

calculator.

used

Saved";

an

are

cursor

to

enter

and

in

the

number

to

recall

in

If

all

existing

and the

CALCULATE

pictured

1

2

3

4

CflLO

CRLO

CflLO

CRLO

Rotor

r(om)

Speed

Speed

Speed

K-Faciorl

Rrcax

Tinel

Diagnostics Key Functions & Display Screens

DIAGNOSTICS

is

used

to

monitor system operation, view system accumulators,

perform user diagnostic routines, install

calibrate replacement subassemblies.

screens

and

instructions

1

2

3

Fault

User-1

Maint-2

on

the use

Door- Sysien

User-2

Calib

of

See

this

new

key.

RCF

Tine w2dt

RCF

Rnin

K-Factor2

rotors

and

Chapter

Maint-1

Serv-1

K-Factor

Tine2

software, troubleshoot,

6 for

examples

Instal

of

1

Serv-2

DIAGNOSTICS

and

display

3-9/3-10

Page 26

Son/all® Centrifuges Operation

Chapter 4

OPERATION

This chapter provides:

• step-by-step operating instructions for the normal and zonal modes of

operation; RCF and

stop;

and HOLD runs;

• a description of the control panel lock and the Key# code;

• a precool/preheat procedure to equilibrate rotor and chamber temperature;

and

• a Rotor Information Chart.

Jco2dt

operation; programmed runs; slow start and slow-

Understanding the Centrifuge Controls

It is recommended that you read the description of the controls in Chapter 3

before using the centrifuge for the first time. You probably won't use all of the

controls right away, but reading Chapter 3 will give you information that will be

helpful in understanding the displays and how the control keys function, and it will

help you become familiar with all features of the centrifuge. As you use the

centrifuge, continue to refer to Chapter 3 whenever additional information is

needed.

Turning the Centrifuge On

The power ON/OFF switch is placed in the upper right hand corner of the front

cabinet panel. The microprocessor automatically runs a diagnostic test everytime

the centrifuge is turned on. If an error is found, a display message will appear in

the SET display on the control panel. If no error is found, the run parameters will

appear in the display indicating that the centrifuge is ready for operation.

Normal Run

A normal run is one that is controlled by time with selected run temperature and

run speed parameters and the brake set on or off. These parameters are selected

in the first screen of the (PROGRAM) key.

Prior to performing the run, prepare and install the rotor according to the

instructions in the rotor manual. To ensure that the sample, rotor, and chamber

temperatures are at equilibrium at the start of the run, follow the precool/preheat

procedure on page 4-12.

4-1

Page 27

Operation Sorvall® Centrifuges

WARNING

When loading the rotor, be sure not to exceed the maximum compartment

mass of the rotor (see Table 4-1, Rotor Information). If maximum compartment mass is exceeded, the maximum operating speed must be lowered

(see Reducing Speed for Rotor Compartment Loads In Excess of Design Mass,

page 4-12). Failure to do so can cause rotor failure which could result in

personal injury and/or centrifuge damage.

To perform the run:

1.

Turn the centrifuge power ON.

NOTE

For best run conditions and prolonged centrifuge life, the rotor chamber

should be dry at the start of a run. Before installing the rotor, wipe chamber

dry with a clean cloth or papertowel.

2.

Open chamber door all the way and install rotor. Close chamber door.

WARNING

Use Sorvall® rotors only. Use of another manufacturer's rotor can cause rotor

failure which could result in personal injury and/or centrifuge damage.

3.

The

"1"

light above the (PROGRAM) key should be on. If not, press (PROGRAM) until it is.

The name of the installed rotor will appear in the display and the cursor will be

positioned in the | Speed I field.

NOTE

If using an

to the 1 Rotor 1 field and input 18 for

rotor will be recognized as an S-20/36. Press (ENTER O).

4.

Input desired run parameters: | speed|, lHr:tiinl, and jTer>p/riax|. Press (ENTER E>) after

each input.

Max temperature will automatically default to 5°C above set run temperature; if

desired, enter a different value. For a continuous run, press (HOLD).

5.

Press (onoft) to make 1 Brake 1 selection. The word |0n| or [off | will appear in the

display to indicate selection made.

S-20/17

or

S-20/20

rotor ONLY: Press (ENTER <J) to move the cursor

S-20/17

or 17 for S-20/20; otherwise the

After you have selected the above parameters, the SET display should look similar

to the example below:

Rotor Speed HrsMin Tenp/Max Brake

F-28/13 28090

4-2

0:90

+4+9

On

Page 28

Sorvall® Centrifuges Operation

6. Select [siou-start] and/or [siou-SioH if desired (see below).

7.

Press (START).

Any of the run parameters, except rotor identification, can be changed while a run

is in process.

The rotor will accelerate to the set run speed and remain there for the selected

length of time then decelerate to a stop. To end a run in HOLD or before the

selected run time has elapsed, press (STOP).

NOTE

Integral value can be checked anytime during a timed run by pressing (PROGRAM)

until | u2dt | is in the display ("3" indicator light on). The accumulating fa)2dt

value will be in the | Total 1 field.

To do another run with the same parameters: prepare rotor and install it in the

centrifuge, then close chamber door and press (START) . All entered parameters

remain until a change is made.

Slow Start/Slow Stop

Slow Start and Slow Stop are used to prevent gradient disturbance during

acceleration and deceleration. When they are on, the rotor will accelerate or

decelerate to or from transition speed at a controlled rate that is slower than

normal (transition speed is preset at approximately 800 rpm for all rotors except

the S-20, which is preset at approximately 300 rpm; preset transition speed can be

changed, if desired - see Chapter 6). The length of time for the acceleration/

deceleration phase will automatically default to the optimal time for identified

rotor; or, if desired, time (from 1 to 30 minutes) can be entered manually.

NOTE

If Slow Start or Slow Stop are on, they will remain on for future runs until

turned off.

1.

Follow Steps 1 through 5 for a Normal run (page 4-2).

2.

Press (PROGRAM). The "2" indicator light above the key will light.

To select Slow Start:

1.

Press (ENTER O) to move cursor to |siou>-stari|.

2.

Press (on off).

3.

To accept the "Auto" time for acceleration and begin the run, press (START).

RCF blow-Start blow-Stop Zonal/Speed

100995

To change the length of time for acceleration from 0 to transition speed, press

(ENTER c>) to move cursor to | Ruto

30).

If a slow stop is desired (see page 4-5); if not, press (START) to begin the run.

On

fluto

Off Off 1509

I

and input desired number of minutes (from 1 to

4-3

Page 29

Operation

Use Sorvall® rotors only. Use of another manufacturer's rotor can cause rotor

failure which could result in personal injury and/or centrifuge damage.

Sorvall® Centrifuges

Table 4-1. Rotor Information

WARNING

ROTOR

SV-288

SV-80

GS-3

SA-600

SS-34

SE-12

HB-4

HS-4

SM-24

GSA

TZ-28

SH-MT

SH-80

CODE

#

1

2

3

4

5

6

7

8

9

10

11

12

13

MAX

SPEED

(rpm)

20 000

19.000

9000

16 500

20 000

21000

13 000

7000

20 000

13 000

20 000

13 730

20 000

CRITICAL

SPEED

(rpm)

1000

$

1600

1650

1200

1050

750

1200

1350

1700

1200

1000

1300

900

MAX

RCF

40 301

40 96$

13 689

39 411

47 807

45 959

27 579

9425

49 460

27 504

42 535

19140

45 394

FACTOR

4201

1678

4487

2

2019

s

K

210

97

792

750

513

457

605

656

399

COMPART-

MENT MASS

250.0 g

1035,0 0

2

680.0 g

1620.0 g

3

MAX

50.0 g

6.4 g

780.0 g

115,0$

115.0 g

30,0 $

27.0 g

36.4 g

78.0 g

r

MAX

(cm)

9.02

10.16

15.13

12.96

10.70

9.33

14.61

17.22

11.07

14J7

9.52

9.Q9

10.16

r

MIN

(cm)

6.47

8.84

3.93

5,52

3.26

3.81

4.75

7.21

2

5.37

2

3.77

3.65

3

5.57

5.40

3

F-28/13

F-28/36

3-20/36

S-20/20

S-20/17

SS-34/KSB-R

TZ-28/GK

1

With maximum allowable volume at maximum speed.

2

Outer row

3

Maximum speed of rotor is 20 000 rpm; actual maximum speed depends on tubes. Values given are typical for 1.5 ml microtubes.

14

15

16

17

18

19

20

28 000

28 000

20 000

20 000

20 000

20 000

19 000

1300

1300

400

400

400

1350

1000

100 09$

100 095

71934

58 083

7416S

47 807

38 38$

143

198

466

299

573

750

671

23,0 8

66.0 g

. 156.6 g

115.1 g

130.1 $

115.0g

1620.0g

11x43

11.43

16.10

13.00

16*60

10.70

9.52

4-4

7,34

6.18

7.70

8.10

6.70

3.26

3,65

Page 30

Sorvall® Centrifuges Operation

As soon as (START) is pressed, the |*** sioui start in Progress ***[ message will appear in

the SET display and will remain there until the rotor has accelerated to

approximately 20 rpm.

To select Slow Stop:

1.

Press (ENTER E>) to move cursor to [Sloui-stop].

2.

Press (on off).

3.

To accept the "Auto" rate of deceleration and begin the run, press (START).

RCF Slow-Start Slow-Stop Zonal/Speed

190095 On Ruto On Ruto Off 1500

To change the length of time for deceleration from transition speed to 0 rpm,

press (ENTER O) to move cursor to I nuto | and input desired number of minutes (from

1 to 30). To begin run, press (START).

During deceleration, the | *** siou stop in Progress *** [ message will appear in the

SET display as soon as the rotor reaches transition speed; the message will remain

in the display until the rotor stops spinning.

RCF Run

The centrifuge can be set to operate at a given g force rather than speed. When

you know the RCF (g force) you want applied to the particles during centrifugation,

you can use this feature to select the value. The run speed required for the set RCF

value will automatically be calculated.

To perform an RCF Run:

1.

Load and balance the rotor according to the instructions in the rotor manual. To

ensure that the rotor and chamber temperatures are at equilibrium, follow the

precool/preheat procedure on page 4-12.

WARNING

Use Sorvall® rotors only. Use of another manufacturer's rotor can cause rotor

failure which could result in personal injury and/or centrifuge damage.

Do not exceed maximum compartment mass of the rotor (see Table 4-1, Rotor

Information). If maximum compartment mass is exceeded, the maximum

operating speed must be lowered (see Reducing Speed for Rotor

Compartment Loads In Excess of Design Mass, page 4-12). Failure to do so

can cause rotor failure which could result in personal injury and/or centrifuge

damage.

2.

Turn the centrifuge power ON.

4-5

Page 31

Operation Sorvall® Centrifuges

NOTE

For best run conditions, the rotor chamber should be dry at the start of a run.

Before installing a rotor, wipe the chamber dry with a clean cloth or

papertowel.

3.

Open chamber door all the way and install rotor. Close chamber door.

4.

The

"1"

light above the (PROGRAM) key should be on. If not, press (PROGRAM) until it is.

NOTE

If using an S-20/17 or S-20/20 rotor ONLY: Press (ENTER O) to move the cursor

to the 1 Rotor 1 field and input 18 for an S-20/17 or 17 for an S-20/20; otherwise

the rotor will be recognized as an S-20/36. Press (ENTER O).

5. Input desired lHr:Minl and | Tenp/Max | values. Press (ENTER O) after each input. (Speed

is not entered because run speed will automatically be calculated and set when

the RCF value is entered.)

Max temperature will automatically default to 5°C above set run temperature; if

desired, enter a different value. For a continuous run, press (HOLD).

6. Press (on off) to make 1 Brake I selection. The word |0n | or joff | will appear in the

display to indicate selection made.

7. Press (PROGRAM) again.

I

RCF I will appear in the display with the cursor positioned in the I RCF 1 field and the

"2"

light above the (PROGRAM) key will be on.

8. Input desired |RCF| value (for rmax of the installed rotor). Press (ENTER O).

The display should look similar to the example below.

RCF Slow-Start Slow-Stop Zonal/Speed

93180 Off Off Off 1500

9. Press (START).

The rotor will accelerate to the speed required to achieve the set RCF value and

remain there for the selected length of time or until (STOP) is pressed, then

decelerate to a stop.

Key# Code

The Key# is a security number that must be entered in order to access Zonal,

Program Save, the control panel Lock, and some Diagnostic routines. Whenever

you attempt to use these features, the display will prompt you to enter the Key#.

4-6

Page 32

Sorvall® Centrifuges Operation

A different number can be assigned to each of the features that require a Key#,

including a different number for each of the 20 programs saved. There is also a

System Access Key# that allows access to any of the fields that require a Key#,

except for some Diagnostic routines. The centrifuge is shipped with the System

Access Key# 1234. This is the only number assigned when you receive the

centrifuge. For the procedures to change the System Access number or to assign

Key#s to the various features, see Chapter 6.

Zonal Run

Zonal operation allows you to operate the centrifuge with the door open at speeds

from 1300 rpm to 2500 rpm. This is used with a Sorvall® TZ-28 Zonal Rotor to

dynamically load gradient and sample. A Key# is required to access Zonal mode.

Assemble the rotor according to the procedure in the rotor instruction manual. To

ensure that rotor and chamber temperatures are at equilibrium at the start of the

run, follow the precool/preheat procedure on page 4-12.

To perform the run:

1.

Turn the centrifuge power ON.

2.

Open chamber door all the way and install rotor. Close chamber door.

3.

The

"1"

light above the (PROGRAM) key should be on. If not, press (PROGRAM) until it is.

4.

Input desired run parameters: I Speed I, |Hr:Minl and | Tenp/Max]. Press (ENTER O) after

each input.

NOTE

Maximum speed in the Zonal Mode is 20 000 rpm.

Max temperature will automatically default to 5°C above set run temperature; if

desired, enter a different value. For a continuous run, press (HOLD).

5.

Press (on off) to make | Brake I selection. The word

display to indicate selection made.

6. Press (PROGRAM) until the "2" light above the key is on and [ Zonal /Speed | appears in the

display.

[ On

| or |off [ will appear in the

NOTE

It is best to use a slow start and slow stop when doing gradient separations in

the TZ-28 Rotor (see Slow Start/Slow Stop, page 4-3).

7.

Select Isiou-start] and/or lsiou-stop] if desired.

8. Press (ENTER t>) to move the cursor to [ Zonal /Speed [. Press (on off). The display will

prompt you to enter | Ke^tt | (page 4-6).

9. Input | Ke^tt I and press (ENTER O). When the Key# has been accepted, the word

will appear in the display indicating that the centrifuge will operate in the Zonal

mode.

I On I

4-7

Page 33

Operation Sorvall® Centrifuges

10.

Input the desired loading speed (from 1300 rpm to 2500 rpm in increments

of 10). Press (ENTER D>).

At this point, the display should look similar to the following:

RCF Slow-Start Sloui-Stop Zonal/Speed

42535

When rotor reaches selected loading speed, the I*** Rotor at Zonal Speed> Load ***|

message will appear in the display indicating that the door can be opened.

When operating the centrifuge with the chamber door open and the rotor

spinning, remove any articles that could fall into the chamber (e.g., jewelry,

necktie, objects in shirt pockets). Tie back long hair and roll up shirt sleeves.

12.

Open chamber door and load the sample/gradient according to the instructions

in the rotor manual. When loading is complete, disconnect and remove any

equipment that was used to load it.

Off Off On 1500

WARNING

WARNING

When loading the sample and gradient, be sure not to exceed maximum

compartment mass specified for the rotor (see Table 4-1, Rotor Information).

If maximum compartment mass is exceeded, operating speed must be

lowered (see Reducing Speed for Rotor Compartment Loads In Excess of

Design Mass, page 4-12). Failure to do so can cause rotor failure which could

result in personal injury and/or centrifuge damage.

13.

Close the chamber door. The timer will begin and the rotor will accelerate to

the set run speed and remain there for the selected run time. At the end of the

run, the rotor will decelerate to 0 rpm and the Zonal function will turn off

automatically.

Hold Run

A Hold run is a run that will continue until (STOP) is pressed. All parameters except

time are entered as described for the type of run you will perform.

To select Hold:

Press (HOLD). Hold will appear in the iHrtliinl field of the SET display. While the

run is in process, the RUN display will show the accumulating time.

To end a HOLD run:

Press (STOP). The rotor will begin to decelerate and the run will end.

4-8

Page 34

Sorvall® Centrifuges Operation

To change a HOLD run to a timed run:

Press (HOLD). The key is a toggle switch so pressing it while in HOLD will return

the centrifuge to a timed condition. The last entered time value will appear in

the iHr:Hinl field of the SET display and the RUN display will show the

remaining time.

NOTE

When the centrifuge returns to a timed condition, the computer will account

for the length of time the centrifuge was in HOLD. Therefore, if the last

entered time value had already elapsed when the HOLD key was pressed again,

the RUN display will show zeros (0.00) and the rotor will begin to decelerate.

To enter a new time value and cancel the accumulated HOLD time:

Enter the new time value. The |Hr:Min| field of the SET display will show the

new set time, and the RUN display will change to countdown from the newly

entered value. The length of time the centrifuge was in HOLD has no affect on

the new set time.

fw2dt Run

An fa)2dt run allows you to set the centrifuge to end a run when a desired integral

value is reached.

To perform an fo>2dt run:

1.

Load and balance rotor according to instructions in the rotor manual. To

ensure that the rotor and chamber temperatures are at equilibrium, follow the

precool/preheat procedure on page 4-12.

WARNING

Use Sorvall® rotors only. Use of another manufacturer's rotor can cause

rotor failure which could result in personal injury and/or centrifuge damage.

Do not exceed maximum compartment mass of the rotor (see Table 4-1,

Rotor Information). If maximum compartment mass is exceeded, the

maximum operating speed must be lowered (see Reducing Speed for Rotor

Compartment Loads In Excess of Design Mass, page 4-12. Failure to do so can

cause rotor failure which could result in personal injury and/or centrifuge

damage.

2.

Turn the centrifuge power ON.

NOTE

For best run conditions, the rotor chamber should be dry at the start of a run.

Before installing a rotor, wipe the chamber dry with a clean cloth or

papertowel.

4-9

Page 35

Operation

3.

Open chamber door all the way and install rotor. Close chamber door.

4.

The

"1"

light above the (PROGRAM) key should be on. If it is not, press (PROGRAM) until

it is.

NOTE

Sorvall® Centrifuges

If usingan_S-20/17 or S-20/20 rotor ONLY: Press

to the [Rotor| field and input 18 for an S-20/17 or 17 for an S-20/20; otherwise

the rotor will be recognized as an S-20/36. Press (ENTERED).

5. Input desired I Speed! and press (ENTER >) twice to move the cursor to | Tenp/Max I.

(Time is not entered since the run will end when the integral value has

accumulated.)

6. Input desired 1 Tenp/Max 1 values. Press (ENTER PQ after each input.

7. Press (on off) to make [Brake! selection. The word [On] or | Off | will appear in the

display to indicate the selection made.

8. Press (PROGRAM) until the "3" light above the key is lit and |

display. The word [on] or [off] will appear in the | u2dt | field with the integral values

from the previous run displayed next to it. See example below.

CENTER<Q

to move the cursor

u>2dt I

appears in the

NOTE

Tine-out | is the

Total | is the fafdt value from the previous run at 0 rpm, which includes the

deceleration time.

J(o2dt

value from the previous run at the start of deceleration.

u2dt Tine-out Total Lock

On

1.94e07

5.29e07

Off

9. If Off, press (on off) to turn On.

10.

To use the |Tine-out) value, press (START). TO change the [ Tine-out 1 value, press

(ENTER

a two digit exponent value. Press (START).

The rotor will accelerate to the set speed and remain there until the integral value

has accumulated.

To end a run before the selected integral value has accumulated, press (STOP).

t>) and enter a new value: first a three digit (X.XX) coefficient value, then

Programmed Run

The RC-28S memory will store up to 20 programs. Each program saves a set of run

parameters that can be recalled by entering the assigned program number (from 1

to 20) and pressing (START).

4-10

Page 36

Sorvall® Centrifuges Operation

A Key# must be entered in order to store a new program or to make a change to an

existing program; however, a stored program can be recalled without the Key#. A

different Key# can be assigned to each program, if desired; see Chapter 6 for

procedure.

Program Save

1.

Enter all desired run parameters.

NOTE

Program Save will not store if the control panel Lock is on; also, Program

Save will not turn Zonal On.

2.

Press (PROGRAM) until the "4" indicator light above the key is lit.

3.

Press (ENTERO) to move the cursor to fsavettl and input a number from 1 to 20.

Press CENTER

4.

Input 1 Ke'd# | (page 4-6). Press (ENTER O) to store program. Press (START) to begin the

run.

PROGRflN > Reca11# Save#

1

1

5.

Record program number and run parameters in the Program Log Record

(located in back of the Operator's Guide under the centrifuge control panel).

NOTE

Program Recall will not turn Zonal On, but it will set loading speed and all

other parameters.

Program Recall

To recall a program:

1.

Press (PROGRAM) until the "4" indicator light above the key is lit.

2.

Input assigned program number (from 1 to 20). Press (START).

All prerecorded run parameters will automatically be established to control centri-

fuge operation. The displays will change to show the set run parameters for the

selected program.

Saved

Control Panel Lock

The control panel Lock will lock all set run conditions (including options) so they

cannot be changed until unlocked.

To lock or unlock set run conditions:

1.

Press (PROGRAM) until the

"3"

indicator light above the key is lit.

4-11

Page 37

Operation Sorvall® Centrifuges

2.

Press (ENTER oj to move the cursor to I Lock].

3.

Press (onoff) and input 1 Ke*#l (page 4-6). Press (ENTER O).

After run conditions have been locked in, the cursor will only appear in the [Lock

field and in all calculator screens.

Precool/Preheat

The following precool/preheat procedure is recommended to ensure that the rotor

and the chamber temperatures are at equilibrium at the start of a run.

1.

Open chamber door and install rotor. Close chamber door.

2.

Press (PROGRAM) until the

3.

Input I speed I of 2000 rpm. Press (ENTER O).

4.

Press (HOLD), then press (ENTER O).

5.

Input desired iTenpl. Press (ENTER O).

"1"

light above the key is lit.

6. Press (START) . The rotor/chamber should achieve temperature in approximately

30 minutes.

Reducing Speed for Rotor Compartment Loads

in Excess of Design Mass

There is a maximum allowable compartment mass established for each centrifuge