Page 1

®

SORVALL

Cellwasher 2

OPERATING

INSTRUCTIONS

PN 04505-32

Page 2

Page 3

OPERATING

INSTRUCTIONS

®

SORVALL Cellwasher 2

Cell Washing

System

Kendro Laboratory Products

Asheville, North Carolina

U.S.A.

PN 04505-32

Issued January 2005

Page 4

Table of Contents SORVALL® Centrifuges

!

This manual is a guide to the use of the

SORVALL® Cellwasher 2 Cell Washing System

Data herein has been verified and is believed adequate for the intended use of the Cellwasher 2.

Because failure to follow the recommendations set forth in this manual could produce personal

injury or property damage, always follow the recommendations set forth herein. Kendro does not

guarantee results and assumes no obligation for the performance of centrifuges or other products

that are not used in accordance with the instructions provided. This publication is not a license to

operate under, nor a recommendation to infringe upon, any process patents.

The SORVALL Cellwasher 2 is intended to be used in strict accordance with The American

Association of Blood Banks' guidelines defined in the most recent edition of the AABB Technical

Manual (published by AABB Press. Bethesda, MD).

Publications prior to the Issue Date of this manual may contain data in apparent conflict with that

provided herein. Please consider all data in this manual to be the most current.

WARNING, CAUTION

important and critical instructions.

WARNING

personal injury, affect the operator’s health, or contaminate the environment.

CAUTION

equipment.

NOTE

CAUTION

sidebar near the information they correspond to.

©1988,1995,1996,1998,1999,2002,2003,2004,2005 by Kendro Laboratory Products

highlights essential information.

and

informs the operator of a hazard or an unsafe practice that could result in

informs the operator of an unsafe practice that could result in damage of

WARNING

, and

NOTE

are accompanied by a hazard symbol

within the text of this manual are used to emphasize

and appear in the left

ii

Page 5

Cellwasher 2 Table of Contents

!

!

Important Safety Information

Important Safety Information

Certain potentially dangerous conditions are inherent to the use of all centrifuges. To ensure

safe operation of this centrifuge, anyone using it should be aware of all safe practices and take

all precautions described below and throughout this manual.

WARNING

When using radioactive, toxic, or pathogenic materials, be aware of all characteristics of the

materials and the hazards associated with them in the event leakage occurs during cell washing. If

leakage does occur, neither the Cellwasher 2 nor the rotor can protect you from particles dispersed

in the air. To protect yourself, we recommend additional precautions be taken to prevent exposure

to these materials, e.g., use of controlled ventilation or isolation areas.

Always be aware of the possibility of contamination when using radioactive, toxic, or pathogenic

materials. Take all necessary precautions and use appropriate decontamination procedures if

exposure occurs.

Never use any material capable of producing flammable or explosive vapors, or creating extreme

exothermic reactions.

Use only tubes that meet the criteria provided in this manual (see Tube Selection and Use, Chapter

3). Results may be affected if tubes are not within specifications. If tubes are of inadequate strength

so that tube breakage occurs, sample and test results will be lost, the rotor and distributor could be

damaged, and during required cleanup, contact with sharp glass fragments could result in personal

injury.

CAUTION

Do not operate Cellwasher 2 without a rotor properly installed on the drive shaft. See Rotor and

Distributor Installation, Chapter 2.

Do not operate the Cellwasher 2 with a rotor out of balance. To do so can cause damage to the

Cellwasher 2 drive assembly. See Rotor Loading and Balancing, Chapter 2.

We recommend using Coomb's control cells to confirm all negative results.

The Cellwasher 2 can be damaged if connected to the wrong voltage. Check the voltage before

plugging the instrument into a power source. Kendro is not responsible for incorrect installation.

Always maintain the Cellwasher 2 in the recommended manner. See Chapter 4, Maintenance.

iii

Page 6

Table of Contents SORVALL® Centrifuges

Table of Contents

Page

Safety Information Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Chapter 1. DESCRIPTION

Cellwasher 2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Applications Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Cellwasher 2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2. INSTALLATION

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Tubing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Rotor and Distributor Installation . . . . . . . . . . . . . . . . . . . . . . 2-5

Rotor Loading and Balancing . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Chapter 3. OPERATION

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Tube Selection and Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Priming the System & Adjusting Saline Fill Volume . . . . . . . 3-6

Auto Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

High and Low Speed Operation . . . . . . . . . . . . . . . . . . . . . . . 3-10

Tube Breakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Momentary Power Interruption . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Emergency Sample Recovery . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

iv

Chapter 4. MAINTENANCE

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Sevice Decontamination Policy . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Parts Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Tubing Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Page 7

Cellwasher 2 Table of Contents

APPENDIX

Warranty

Index

Decontamination Certificates

List of Illustrations

Figure Page

2-1. Cellwasher 2 Tubing Diagram . . . . . . . . . . . . . . . . . . 2-3

2-2. Stainless Steel Rotating Bowl Installation . . . . . . . . . 2-6

2-3. Distributor Installation . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-4. Tube Placement for Balancing Less Than 12 Tubes . 2-7

3-1. Cellwasher 2 Controls and Indicators . . . . . . . . . . . . 3-3

3-2. Location of Mechanical Override . . . . . . . . . . . . . . . 3-12

4-1. Collecting Ring Assembly, Exploded View . . . . . . . . 4-3

4-2. Location of Decant Coil and Drive Ring . . . . . . . . . . 4-10

4-3. Location of Lift Plate Ring . . . . . . . . . . . . . . . . . . . . 4-10

List of Tables

Table Page

1-1. Accessories Supplied . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2-1. Parts Location: Tubing Diagram . . . . . . . . . . . . . . . . 2-3

3-1. Cellwasher 2 Controls and Indicators . . . . . . . . . . . . 3-1

4-1. Troubleshooting Chart: Problem A . . . . . . . . . . . . . . 4-8

4-2. Troubleshooting Chart: Problem B . . . . . . . . . . . . . . 4-8

4-3. Troubleshooting Chart: Problem C . . . . . . . . . . . . . . 4-9

4-4. Troubleshooting Chart: Problem D . . . . . . . . . . . . . . 4-9

4-5. Applications Troubleshooting Chart:

False Negative Results . . . . . . . . . . . . . . . . . . . . . . . 4-11

4-6. Applications Troubleshooting Chart:

False Positive Results. . . . . . . . . . . . . . . . . . . . . . . . 4-12

4-7. Applications Troubleshooting Chart:

Inconsistent Reaction Strength. . . . . . . . . . . . . . . . . 4-13

v/vi

Page 8

Page 9

Cellwasher 2 Description

Chapter 1: DESCRIPTION

This manual contains information required to operate and maintain the SORVALL® Cellwasher 2 Cell

Washing System. If you require additional information regarding operation or maintenance, please contact

Kendro for assistance. In the United States, call Kendro toll-free 1-800-522-7746; outside the United

States, contact the nearest Kendro office (see back cover) or your local representative for SORVALL

products. SORVALL

or http://www.kendro.de.

®

product information is available on our internet web site at http://www.kendro.com

Cellwasher 2 Description

The Cellwasher 2 is designed to perform the washing phase of the

Coomb's Procedure automatically. In normal AUTO mode operation, after placing two or three drops of a pre-prepared 2 to 5% red

blood cell/saline suspension* into each tube, the Cellwasher 2 will

automatically add saline, spin at high speed to concentrate the cells,

decant the saline, and agitate to resuspend the washed cells for the

addition of Coomb's reagent. The Cellwasher 2 is also capable of

being used manually as a low speed centrifuge, spinning at either of

two preset speed ranges (LOW speed or HIGH speed mode, see

Cellwasher 2 Specifications on next page).

®

The Cellwasher 2 combines a peristaltic saline pump and a wet

chamber centrifuge in one cabinet. The centrifuge portion uses a

dedicated DA-12 Rotor, which is a unique dual-angle swingingbucket rotor that is designed to accommodate up to 12 each of

either 3 ml or 5 ml tubes. The Cellwasher 2 is microprocessorcontrolled, featuring a front control panel with sensor-touch keys

and a digital timer for the wash cycle. Other features include a

saline-detect system with an audible low-saline warning, and an

agitate cycle that ensures complete resuspension of cells and

eliminates manual agitation.

Applications Infor mation

The Cellwasher 2 is intended to be used in routine blood work to

speed up and simplify the procedures for determining human blood

groups and types. Often, the results of blood tests made using the

Cellwasher 2 determine donor/patient compatibility for blood transfusions, and the results of these tests must be accurate to prevent

serious transfusion reactions. If testing procedures provided by the

reagent manufacturers are not followed exactly, or if test materials

are outdated, accurate test results cannot be guaranteed.

* The Cellwasher 2 is not designed to automatically separate donor whole blood to create

the necessary 2 to 5% red blood cell/saline suspension. The Cellwasher 2 may, however,

be used as a centrifuge to manually separate red blood cells from whole blood.

1-1

Page 10

Description SORVALL® Centrifuges

!

!

False Coomb's readings can be caused by any of the following:

• Improper ratio of patient serum and cells.

• Incomplete washing of cells.

• Contaminated saline or supply tubing.

• Improper decanting of saline solutions.

• Inactive Coomb's serum.

• Failure to add Coomb's serum to a tube.

• Improper final centrifugation.

• Inaccurate reading or recording of results.

W A R N I N G

We recommend using

Coomb's control cells to confirm all

negative results.

W A R N I N G

The SORVALL Cellwasher 2

is intended to be used in strict accordance with The American Association

of Blood Banks' guidelines defined in

the most recent edition of the AABB

Technical Manual (published by AABB

Press. Bethesda, MD).

While the Cellwasher 2 provides accurate washing, decanting, and a

proper speed for the final spin, it does not eliminate all potential

errors. Proper laboratory procedures require adequate controls of all

tests performed with this instrument (read the WARNINGS). Refer to

Tables 4-5, 4-6, and 4-7 for applications troubleshooting information. When using the Cellwasher 2, always follow standard laboratory procedures in handling and disposing of blood serum, and

observe safety precautions and good laboratory practices.

Cellwasher 2 Specifications

Dimensions:

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.6 cm (14.0 inches)

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . .31.8 cm (12.5 inches)

Height: Lid closed . . . . . . . . . . . . . . . . . .36.8 cm (14.5 inches)

Lid open . . . . . . . . . . . . . . . . . . .57.2 cm (22.5 inches)

Mass (Weight):

Motor Type:

Speeds:*

60 Hz Models: Low 1100 to 1200 rpm

. . . . . . . . . . . . . . . . . . . .16.4 kg (36.0 lbs)

. . . . . . . . . . . . . . . . . . . . . . .3-speed induction

High 3500 to 3600 rpm

Decant 550 to 600 rpm

50 Hz Models: Low 1400 to 1500 rpm

High 2900 to 3000 rpm

Decant 550 to 600 rpm

Length of Modes:

Automatic . . . . . . . . . . . . . . . . . . . . . . . . . Each multi-step wash cycle

is 80 seconds, except on

100V 50 Hz models, which

have 90-second cycles.

Manual . . . . . . . . . . . . . . . . . . . . . . . . . . .High or low, optional, up to

999 seconds if timed; high

speed indefinite if in HOLD

* Speed in revolutions per minute (rpm) is related to angular velocity, ω, according to the

following:

Where w = rad/s. All further references in this manual to speed will be designated as rpm.

1-2

ω

= (rpm) = (rpm) (0.10472)

2π

()

60

Page 11

Cellwasher 2 Description

!

Time Display Accuracy:

Noise Level:

. . . . . . . . . . . . . . . . . . . . . .<60 dB**

........................ ±3% (Ma nual Mo de*)

Rotor Radii:

r

maximum

r

average

r

minimum

Relative Centrifugal Force:

60 Hz Models: Low at r

High at r

50 Hz Models: Low at r

High at r

at r

at r

at r

at r

at r

at r

at r

at r

max

avg

min

max

avg

min

max

avg

min

max

avg

min

9.43 cm

6.015 cm

2.60 cm

127 to 152 g

81 to 97 g

35 to 42 g

1290 to 1365 g

823 to 871 g

356 to 376 g

206 to 237 g

132 to 151 g

57 to 65 g

886 to 948 g

565 to 605 g

244 to 261 g

W A R N I N G

Tubes must be able to withstand up to 1365 g (948 g in 50 Hz

operation) when run at a 45° angle

with tube walls point-loaded and otherwise unsupported. Using tubes of inadequate strength could result in tube

breakage: sample and test results will

be lost, the rotor and distributor could

be damaged, and cleanup will be required. During cleanup, be aware that

glass fragments are sharp, and contact could result in personal injury.

Electrical Requirements:***

Electrical Supply . . . . . . . . . . . . . . . . . . . . 120V ±10%. 60 Hz, 5A

100V ±10%. 60 Hz, 5A

100V ±10%. 50 Hz, 5A

230V ±10%. 50 Hz, 2.5A

Tube Requirements:

Tube Strength . . . . . . . . . . . . . . . . . . . . . .Centrifuge-rated to handle

at least 1365 g unsupported

(for 50 Hz operation, at

least 948 g unsupported)

Tube Material: . . . . . . . . . . . . . . . . . . . . . . Type 1, class A borosilicate

or equivalent high-strength

rolled glass (such as Pyrex®)

Tube Style: . . . . . . . . . . . . . . . . . . . . . . . .Round bottom, thick walled,

rimless (no flange or bead)

Tube Size: Volume (all places) . . . . . . . .5 ml or 3 ml****

Diameter . . . . . . . . . . . . . . . 5 ml: 12 mm +0.0/–0.5

3 ml: 10 mm +0.0/–0.5

Length . . . . . . . . . . . . . . . . . 75 mm ±1.5

Wall Thickness . . . . . . . . . . . 0.9 mm ±0.1

* At the start of a Manual run, the timer function is delayed for several seconds before

beginning, so that timing occurs only when the rotor is spinning; the timer is inactive

during the initial aggitation step that occurs before the spin starts.

** The maximum noise output with the instrument running at HIGH speed, measured 3 feet

from the front panel at an approximated operator's height.

*** Electrical requirements are indicated on the rating plate on the back of the instrument.

**** A set of Adapter Clips (Catalog No. 04330, 12/pkg., supplied) is required when using

3 ml, 10 mm diameter tubes in the DA-12 Rotor.

1-3

Page 12

Installation SORVALL® Centrifuges

Accessories

The accessories listed in Table 1-1 are supplied with all Cellwasher 2

models.

Table 1-1. Accessories Supplied

Catalog

Number Description

43260 Distributor Assembly – for 12 mm x 75 mm and

10 mm x 75 mm tubes

12977 Tubing Kit containing:

1-255 mm (10 inch) long frosted Pump Tubing

1-1650 mm (65 inch) long, large diameter (5/16 inch i.d.,

7/16 inch o.d.) clear Tygon

1-Overflow Tubing 150 mm (6 inch) long

1-Discharge Tubing 200 mm (8 inch) long

1-Drain Tubing (cut desired length from remainder;

1220 mm [48 inch] supplied on new product)

1-2900 mm (114 inch) long, small diameter (1/4 inch i.d.,

3/8 inch o.d.) clear Tygon

1-Flow Tubing 305 mm (12 inch) long

1-Vent Tubing 150 mm (6 inch) long

1-Supply Tubing (cut desired length from remainder;

610 mm [24 inch] supplied on new product)

1-Pump Connector

2-Y-Connectors

2-Adjustable Tubing Clamps

2-Nylon Cable Ties

Installation Instructions

®

Tubing from which to cut:

®

Tubing from which to cut:

1-4

12925 Flow Control Valve

04285 DA-12 Rotor (includes a set of 12 Adapter Clips for use

with 3 ml 10 mm x 75 mm tubes, Catalog No. 04330)

12796 Rotating Bowl Assembly

SORVALL

®

5 ml, 12 mm x 75 mm Pyrex® tubes (Catalog Number

03102, 50/box), and SORVALL® 3 ml, 10 mm x 75 mm Pyrex® tubes

(Catalog Number 03100, 50/box) are not supplied, but are recommended for use in the Cellwasher 2.

Page 13

Cellwasher 2 Installation

!

!

Chapter 2: INSTALLATION

This chapter contains the information needed to unpack and install the SORVALL® Cellwasher 2.

Unpacking

As soon as you receive your Cellwasher 2, carefully inspect it for

any shipping damage that may have occurred. If you find any

damage, please report it immediately to the transportation company

and file a damage claim, then notify Kendro. Check all packages

received against the shipping list and, after unpacking, check the

accessories received against Table 1-1 on page 1-4; if any items are

missing, contact Kendro (see back cover).

C A U T I O N

Cooling air is drawn into the

Cellwasher 2 from all four sides of

the base. Be sure that the entrances

are not obstructed.

W A R N I N G

During operation, never

lean on or move the instrument, keep

the defined clearance area clear of

all objects (including all hazardous

and flammable materials), and do not

work within the clearance area.

Location

Place the Cellwasher 2 on a sturdy, level bench or table near a sink,

drain, or waste container that can receive the decanted saline. The

following factors should be considered when selecting a location:

• Allow a 150 mm (6 inch) clearance area behind the instrument

for tubing and a waste container. For safe operation, maintain a

50 mm (2 inch) "clearance envelope" on all sides.

Personnel should know that the Cellwasher 2 routinely deals

with significant energy levels and could move suddenly in the

unlikely event of a rotor failure. Laboratory management procedures should require that no person or any hazardous materials

are within the clearance envelope while the Cellwasher 2 is

operating. During operation, personnel should be instructed not

to lean on or move the Cellwasher 2, not to stay within the

clearance envelope longer than necessary for operational reasons, and not to deposit potentially hazardous materials within

the clearance envelope.

• Allow a 610 mm (24 inch) clearance above the tabletop or

bench surface for lid to open.

• Drainage in the Cellwasher 2 is accomplished by gravity, so

the discharge tubing must extend downward from the instrument to drain, sink, or waste receptacle.

• The preferred location for the saline supply is either at or

above instrument level.

• To obtain best results, minimize tubing length from the

saline supply to the Cellwasher 2 and from the Cellwasher 2

to the drain, sink, or waste receptacle.

2-1

Page 14

Installation SORVALL® Centrifuges

!

Environmental Conditions

An ambient temperature range of 10°C to 38°C (50°F to 100°F)

should be maintained for Cellwasher 2 operation. The relative humidity can be up to 90%, non-condensing.

The Cellwasher 2 is intended for use in 1) a Pollution Degree 2

Environment, 2) an installation category II supply circuit, and 3) at a

maximum altitude of 2000 meters. The Cellwasher 2 is a Class A

product and is not intended for home use. If used in a domestic

environment, it may cause radio interference, in which case the user

may be required to take adequate measures.

Electrical Requirements

W A R N I N G

The receptacle used should

be a grounded 3-wire system. If it is

not, the equipment must be grounded

to reduce the possibility of electrical

shock.

The Cellwasher 2 has a 3-wire (2-pole and earth) power cord with a

universal keyed plug that inserts into a receptacle at the back of the

instrument. The other end must be connected to the appropriate

power supply as specified below and on the rating plate on the back

of the instrument.

120V ±10%, 60 Hz, 5A; 100V ±10%, 60 Hz, 5A;

100V ±10%, 50 Hz, 5A; or 230V ±10%, 50 Hz, 2.5A

Cellwasher 2 120V and 100V power cords use a NEMA 5-15P

three-prong molded plug with a ground pin and parallel blades that

will fit Hubbell receptacle No. 5261 for 120 volts. 230V power cords

are CE-rated, and are supplied with a 3-pin plug that fits a 16A CEE17 single-phase receptacle (2-pole and earth).

The ON/OFF main power switch has a 3-Amp fuse; however, for

emergency disconnect purposes, we recommend a separate means of

power interruption in a remote location.

Tubing Installation

NOTE

The Cellwasher 2 comes with the tubing already connected to the

instrument, but not installed in the peristaltic pump (do not open

the tubing replacement kit, save it for future use). To complete

the tubing installation, unwrap the bundle of tubing at the back of

the instrument and, referring to figure 2-1 and table 2-1, install

the tubing according to the procedure that follows.

2-2

The overflow tubing serves as an emergency liquid exit

to protect instrument components in the event of tube

breakage or drain blockage. To ensure that potentially

biohazardous liquid does not exit into the work surface,

route overflow tubing to a 250 ml (or larger) open waste

container.

Page 15

Cellwasher 2 Installation

4

5

FLOW

CONTROL

10

VALVE

SALINE

2

6

1

3

9

PUMP HOUSING

THUMBSCREW

9

10 8

7

WASTE

Figure 2-1. Cellwasher 2 Tubing Diagram

Table 2-1. Parts Location: Tubing Diagram

(keyed to figure 2-1)

Item Description

1* Overflow Tubing (from overflow tray), 150 mm (6 inch)

2 Vent Tubing, 150 mm (6 inch)

3 Pump Tubing, 255 mm (10 inch), frosted

4 Flow Tubing (to nozzle), 305 mm (12 inch)

5 Discharge Tubing (from collector ring), 200 mm (8 inch)

6 Supply Tubing, 610 mm (24 inch),

7 Drain Tubing 1220 mm (48 inch),

8 Pump Connector

9 Y-Connector

10 Adjustable Tubing Clamp

* In the event of saline residual in the rotor chamber (for example, from overfill of tubes or

tube breakage) saline will exit through this tube. Under normal operating conditions, saline

will exit through the drain tubing not through the overflow tube.

2-3

Page 16

Installation SORVALL® Centrifuges

!

1. Unscrew the four knurled thumbscrews from the peristaltic pump,

and remove the front half of the pump housing (do not remove

the pump roller assembly).

2. Turn the roller assembly so that one of the rollers is in the 11

o'clock position.

3. Position the 255 mm (10 inch) frosted pump tubing (with pump

connector) in front of the pump so that the connector is positioned just above the left side of the pump, then without turning

the roller assembly, route the pump tubing around the rollers.

4. Pull up on the two ends of the pump tubing to fit the tubing

between the pump housing and the lower roller.

W A R N I N G

Saline solution from some

manufacturers contain sodium azide

as a preservative. If this solution is

discharged directly down the drain,

explosive azide salts may form as

the sodium azide reacts with the

plumbing. Check with your saline supplier before discharging saline from

the Cellwasher 2 into a drain.

NOTE

Do not try to fit the pump tubing with a sharp object, this

could puncture the tubing.

5. With the pump tubing properly positioned in the back half of the

pump housing, reinstall the front half of the housing. Gently

stretch the ends of the pump tubing to eliminate slack while

fitting the front half of the housing in place.

6. Visually check to make sure that the front half of the housing is

properly aligned and fully seated against the back half (a gap

indicates that the pump tubing is pinched; if so, remove the front

half of the housing and repeat steps 3 through 6).

7. Install the four thumbscrews and hand-tighten.

8. Check the pump tubing installation by turning the roller assembly shaft counterclockwise using pliers (the rollers should rotate

smoothly without pinching tubing).

9. If the 610 mm (24 inch) supply tubing is too long, cut it to an

appropriate length, then slide the flow control valve (catalog

number 12925, supplied) onto the supply tubing, and connect the

end of the supply tubing to a saline supply reservoir.

NOTE

The preferred location for the saline supply is either at or

above instrument level. If, at some later time, the saline

reservoir is moved from its original location, recheck the

saline volume by priming the system as directed in

Chapter 3, Operation, Priming the System.

10. Make sure the drain tubing flows downward to an open sink,

drain, or waste receptacle because drainage is accomplished by

gravity. Use the shortest length of drain tubing possible (if the

1220 mm (48 inch) tubing is too long, cut it to an appropriate

length) and make sure the drain tubing is positioned so there is

no upward travel to result in a "trap" for collected waste fluid.

2-4

Page 17

Cellwasher 2 Installation

!

11. Ideally, the drain tubing should be positioned so that it can not

become immersed in collected waste fluid. However, if there is a

possibility that the drain tubing will become immersed in waste

fluid, cut the drain tubing at a convenient point near the waste

receptacle and insert the Y-Connector. Always insert a Y-Connector in the drain line when using a waste receptacle.

NOTE

The Y-Connector prevents pressure from building up in

the drain tubing due to submerged tubing or air blockage. Failure to vent the drain tubing by installing the YConnector can result in improperly decanted samples.

12. If necessary, use additional tubing and connectors from the

Tubing Kit shipped with the Cellwasher 2 to supply saline and

discharge waste properly.

Rotor and Distributor Installation

a. DA-12 Dual Angle Rotor and Rotating

Bowl Installation

1. Open the lid of the Cellwasher 2.

NOTE

There may be one or more holes in the stainless steel

rotating bowl. The holes are for balancing purposes only

and will not affect the performance of the rotating bowl.

2. Position the rotating bowl assembly (catalog number 12796,

supplied) over the motor drive shaft. Align the two drive pins

in the bowl with the slot in the drive shaft (see figure 2-2).

Slide the bowl down the drive shaft until the two pins in the

bowl engage the rubber drive ring. Press the bowl down

firmly.

3. Slide the DA-12 Rotor (catalog number 04285, supplied)

over the drive shaft and lower it gently into the bowl.

C A U T I O N

If the rotating bowl assembly, rotor, and distributor are not

installed properly, damage to the instrument could result. Before

operating the Cellwasher 2:

• Make sure the drive pins in rotat-

ing bowl are engaged in the rubber

drive ring and in the rotor.

• Make sure the distributor is firmly

seated on the rotor with the distributor pins completely engaged

in the rotor (see figure 2-3).

4. Hold the edge of the bowl and turn the rotor slowly until the

drive pins in the bowl engage the rotor and the rotor drops

down onto the bottom of the bowl.

b. Distributor Installation

Place the Distributor (catalog number 43260, supplied) over the

rotor knob (see figure 2-3). Turn the distributor until its three

pins engage the three holes in the rotor. Press the distributor

down until it is completely seated on the rotor.

2-5

Page 18

Installation SORVALL® Centrifuges

MOTOR DRIVE

SHAFT

SLOT

ALIGNMENT

STAINLESS STEEL

ROTATING BOWL

ASSEMBLY

Figure 2-2. Stainless Steel Rotating Bowl Installation

DISTRIBUTOR

CANNULA

DISTRIBUTOR

PIN

ROTOR

KNOB

DA-12

ROTOR

DRIVE PINS

2-6

Figure 2-3. Distributor Installation

Page 19

Cellwasher 2 Installation

!

W A R N I N G

Results may be affected if

tubes are not within the specifications provided in Chapter 1 on page

1-3. Using tubes of inadequate

strength could result in tube breakage: sample and test results will be

lost, the rotor and distributor could be

damaged, and cleanup will be required. During cleanup, contact with

glass fragments could result in personal injury.

Rotor Loading and Balancing

The Cellwasher 2 can process any balanced load up to twelve tubes.

When using less than a full complement of tubes, place the tubes in

opposing compartments to ensure that the rotor is symmetrically

balanced (see figure 2-4). The volume of saline delivered through

the distributor will be the same; at the locations without tubes, the

saline will be dispensed into the basin and drained off. Read the

WARNING.

TWO

THREE

= TUBE

= EMPTY

FOUR

NINE

SIX

TEN

EIGHT

Figure 2-4. Tube Placement for Balancing Less Than Twelve Tubes

2-7/2-8

Page 20

Installation SORVALL® Centrifuges

2-8

Page 21

Cellwasher 2 Operation

!

Chapter 3: OPERATION

This chapter describes the controls, indicators and operating procedures for the SORVALL® Cellwasher 2.

Controls and Indicators

All controls and indicators for the Cellwasher 2 are located on the

W A R N I N G

The SORVALL Cellwasher 2

is intended to be used in strict accordance with The American Association

of Blood Banks' guidelines defined in

the most recent edition of the

Technical Manual (published by AABB

Press. Bethesda, MD).

AABB

front panel keyboard, except for the main power switch and the

remote saline flow control valve. The sensor-touch controls register

commands visually and/or audibly.

Power to the instrument is controlled by a switch located in the

lower right hand corner of the Cellwasher 2, beneath the keyboard.

The symbol "l" indicates ON, while the symbol "O" indicates the

OFF position. Switching the power off erases any manually programmed spin times from the memory.

Table 3-1 lists and describes the controls and indicators that can be

found on the front panel. Figure 3-1 identifies each item and shows

the location on the keyboard.

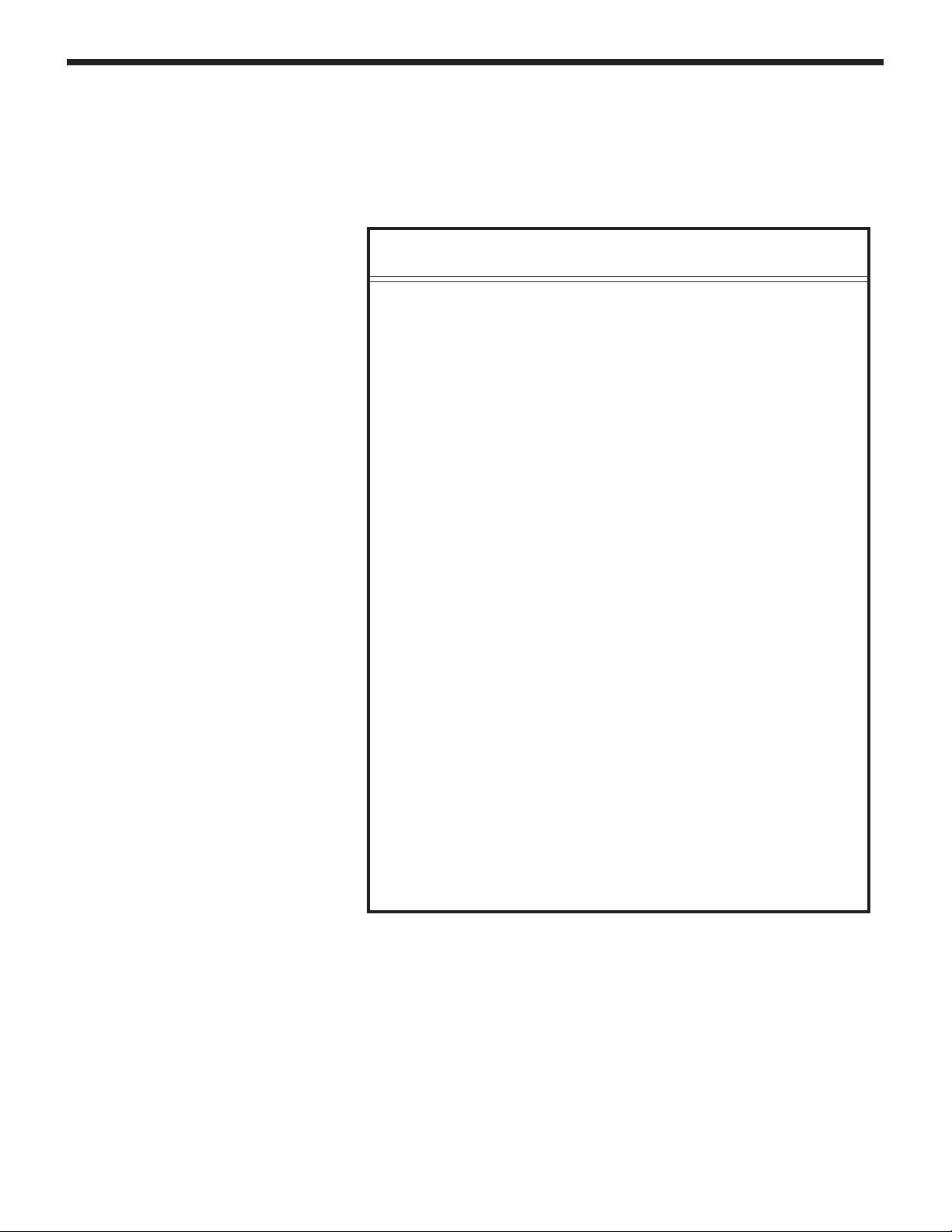

Table 3-1. Cellwasher 2 Controls and Indicators

(keyed to Figure 3-1)

Item Name Acceptance Signal Function

1 AUTO LED* Lights up, Selects AUTO run mode for automatic wash

accompanied by one beep. cycle.

2 HIGH LED* lights up, Selects HIGH speed run for duration of time

accompanied by one beep. selected, or indefinitely if HOLD is selected.

3 LOW LED* lights up, Selects LOW speed run for duration of time

accompanied by one beep. selected; HOLD is not to be selected.

4 CHECK LED* lights up, When in AUTO mode only, stops at the end

accompanied by one beep. of any step in the wash cycle to allow verifi-

cation of procedure.

5 CYCLE Panel key illuminates, Selects 1, 2, 3 or 4 wash cycles during the

digital cycle display AUTO mode.

accompanied by one beep.

*LED, or light emitting diode, refers to the small amber light adjacent to the panel button.

(continued)

3-1

Page 22

Operation SORVALL® Centrifuges

Table 3-1. Cellwasher 2 Controls and Indicators

Item Name Acceptance Signal Function

(continued)

6 CYCLE Displays the number of wash cycles

DISPLAY selected in the AUTO mode.

7 TIME Displays the time selected for AUTO,

DISPLAY HIGH, or LOW mode in seconds.

8 TIME Digital time display, In HIGH or LOW mode only, selects

accompanied by one beep. duration of centrifugation time in seconds.

9 START LED* lights up, Starts the mode selected.

accompanied by one beep.

10 STOP LED* lights up, Stops the spin in progress. In AUTO,

accompanied by one beep. HIGH, or LOW mode, the program will

return to conditions at the start of the run.

11 PRIME Single beep. Primes the pump for 6 seconds.

12 AG Single beep. Agitates the rotor for 5 seconds to

resuspend cell button.

13 CLEAR Single beep. In HIGH or LOW mode only, clears

digital display so that time can be reset.

14 ALARM In AUTO mode only, turns off the alarm.

OFF

15 STEP In AUTO mode only, bypasses one step

at a time in the wash cycle for each push

of the button.

16 HOLD Single beep. In HIGH mode only, sets the centrifuge

to spin indefinitely; not to be selected in

LOW mode.

17 ALARM Single beep, ALARM In AUTO mode only, activates an alarm

lights up. that sounds at the end of the cycle.

18 SALINE SALINE lights up. Lights up when saline supply is

interrupted during AUTO fill.

19 LID LED* lights up.** Opens the lid latch at the end of a run.

20 ALARM ALARM lights up. In AUTO mode only, lights up to indicate

the alarm will sound at the end of the run.

*LED, or light emitting diode, refers to the small amber light adjacent to the panel button.

**The Cellwasher 2 can only be opened when the LID light is illuminated.

3-2

Page 23

Cellwasher 2 Operation

Figure 3-1. Cellwasher 2 Controls and Indicators

Principles of Operation

The SORVALL® Cellwasher 2 has three modes of operation: AUTO,

HIGH, and LOW. In the AUTO mode, the washing steps of the

Coomb's Procedure are performed automatically. In the HIGH and

LOW modes, the Cellwasher 2 spins at a fixed speed (see Chapter 1,

Cellwasher 2 Specifications, page 1-2).

NOTE

a. The AUTO Mode

The Cellwasher 2 is not designed to be able to automatically separate donor whole blood to create the 2 to 5%

red blood cell/saline suspension that is required for

washing cells. The Cellwasher 2 may, however, be operated as a centrifuge to manually separate red blood

cells from whole blood (refer to b. HIGH and LOW

Modes on page 3-4). To prevent loss of blood sample

and avoid the subsequent blood cleanup required, do

not attempt to use the AUTO mode to separate whole

blood.

In the AUTO mode, the Cellwasher 2 performs a 80-second wash

cycles* that include the following steps: fill, high speed spin,

decant, and agitate. The AUTO mode proceeds automatically

through the number of wash cycles selected, unless interrupted

by the operator or by the SALINE alarm.

* 100V 50Hz models perform 90-second wash cycles.

3-3

Page 24

Operation SORVALL® Centrifuges

The operator can interrupt the AUTO mode at any point to check the

progress of the wash cycle by pressing the CHECK button. When the

CHECK button is activated, the Cellwasher 2 will stop at the end of

the washing step in progress (fill, spin, or decant).

The instrument may also stop if the saline supply is interrupted. The

SALINE alarm will sound, and the cycle in progress will stop after

the filling step. To restart the instrument, the pump must be primed

until the saline flow is continuous (see Auto Operation, step b.

SALINE alarm, page 3-8). When the Cellwasher 2 is restarted, it

begins at the next step of the wash cycle – the high speed spin.

The information programmed into the Cellwasher 2 at the start of the

AUTO cycle remains in memory until the POWER switch is turned

off.

b. HIGH and LOW Modes

NOTE

The HIGH speed mode allows the Cellwasher 2 to be

used as a centrifuge to separate red blood cells from

donor whole blood, for use in the creation of the 2 to 5%

red blood cell/saline suspension that is required for

washing cells. To do so, fill tubes with the desired proportions of whole blood and saline, then perform a 30 to

60 second run in the HIGH speed mode according to

standard protocols.

The HIGH and LOW modes are used for agglutination spins. These

spins are preceded by a 5 second agitation to allow reagent and

sample to mix. After agitation, the samples are spun at a constant

rate of speed for the amount of time selected. The spin time programmed by the operator remains in the memory for that mode,

appearing automatically in the digital TIME display whenever that

mode is selected. Once the run begins, the TIME displays counts

down the spin time in seconds to zero. At the end of the spin, the

rotor will come to a stop. The Cellwasher 2 lid cannot be opened

until the light next to the LID button is illuminated.

NOTE

Depending on run conditions and component variability

from instrument to instrument, the rotor may still be

rotating slowly after the LID light is illuminated.

3-4

Page 25

Cellwasher 2 Operation

!

Tube Selection and Use

The Cellwasher 2 is designed to use either 5 ml 12 x 75 mm, or 3 ml 10 x

75 mm*, glass centrifuge tubes (saline flow must be adjusted to one size

tube or the other). In normal operation, tubes are subjected to significant

stress, making the use of high-strength centrifuge tubes necessary to avoid

tube breakage. The Cellwasher 2 spins tubes at a 45° angle with tube

walls point-loaded and otherwise unsupported. Maximum RCF generated may be as high as 1365 g (948 g in 50 Hz operation), and adequate

tubes would typically be strength-rated for an even higher g-force, as tube

manufacturers' strength ratings are based on the tubes being fully supported.

W A R N I N G

Tubes must be able to withstand up to 1365 g (948 g in 50 Hz

operation) when run at a 45° angle

with tube walls point-loaded and otherwise unsupported. Using tubes of inadequate strength could result in tube

breakage: sample and test results will

be lost, the rotor and distributor could

be damaged, and cleanup will be required. During cleanup, be aware that

glass fragments are sharp, and contact could result in personal injury.

Use only centrifuge tubes that meet the following criteria.

Tube Material . . . . . . . . . . . . . . . . . . . . . . . . Type 1, class A borosilicate

or equivalent high-strength

rolled glass (such as Pyrex®)

Tube Style . . . . . . . . . . . . . . . . . . . . . . . . .Round bottom, thick walled,

rimless (no flange or bead)

Tube Size: Volume (all places) . . . . . . . . . 5 ml or 3 ml*

Diameter . . . . . . . . . . . . . . . . . 12 mm +0.0/–0.5 (5 ml)

10 mm +0.0/–0.5 (3 ml)*

Length . . . . . . . . . . . . . . . . . . .75 mm ±1.5

Wall Thickness . . . . . . . . . . . . 0.9 mm ±0.1

NOTE

As additional criteria, do not use tubes that have been

dropped, scratched, or that have a visible defect, as

they may not be able to withstand centrifugation.

Be advised that, even if you do not intend to reuse tubes, you may

find that centrifuge-rated tubes of adequate strength are often labeled reusable, not disposable. SORVALL® 5 ml 12 x 75 mm Pyrex

tubes (Catalog Number 03102, 50/box) and SORVALL® 3 ml 10 x

75 mm Pyrex® tubes (Catalog Number 03100, 50/box) are not

supplied, but are recommended for use in the Cellwasher 2.

®

* Before using 3 ml, 10 mm diameter tubes, a set of Adapter Clips (Catalog No. 04330, 12/

pkg., supplied) must be installed on the DA-12 Rotor.

3-5

Page 26

Operation SORVALL® Centrifuges

Priming the System & Adjusting

Saline Fill Volume

NOTE

If sterilization is required, follow the Decontamination

procedure in Chapter 4 on page 4-2, then prime the

system as described below.

The Cellwasher 2 must be primed and adjusted using the following

procedure at installation, and whenever the saline supply reservoir

or the tubing is changed.

NOTE

When the saline flow is interrupted, prime the Cellwasher

2 as described in Auto Operation, step b. SALINE alarm,

page 3-8.

To Prime the System:

1. Open the lid (press LID button).

2. Select:

MODE CYCLE

AUTO 2

■■

■

■■

■■

■

■■

3. Holding a graduated cylinder under the saline dispenser in the

lid, press:

CMD

FLOW CONTROL

VALVE (located on

saline supply tubing)

PRIME

■■

■

■■

NOTE

If air bubbles remain in the tubing, repeat the PRIME

command. Air bubbles may cause uneven distribution of

saline in the test tubes.

4. Once air bubbles have been removed, empty the graduated cylinder and repeat step 3 to check total saline volume. If an adjusted

total fill volume (based on tube fills) has previously been determined, compare the collected volume to that volume; if not,

initial recommended coarse-adjust total volumes are 54 ml for

12 mm (5 ml) tubes, or 36 ml for 10 mm (3 ml) tubes.

5. If total volume is not correct, adjust the flow control valve (turn

counterclockwise to allow more saline or clockwise to allow

less), then repeat steps 3 and 4 until the desired total volume is

obtained. This completes coarse-adjustment based on nominal

total volume; a fine-adjustment based on tube fills is still required.

6. Place 12 tubes in the DA-12 rotor, close the lid, press START,

and then press CHECK. After filling is complete, the lid light

will come on. Press the LID button, open the lid and check the

saline level in each tube.

3-6

Page 27

Cellwasher 2 Operation

7. Fine-adjust saline volume based on tube fills as follows:

Fine-Adjusting Saline Fill Volume

Based On Tube Fills

This adjustment procedure is required when the system is initially set

up, when priming the system, or whenever saline fill volume adjustments are required.

5 mm

TOP OF TUBE

FILL RANGE

HIGHEST FILL IS

TO BE WITHIN

1. Fine-adjust the

saline fill volume

until the level

of saline in the

highest tube fill

is between 5 &

8 mm from the

top of the tube.

8 mm

NOTE

Correct tube fills are necessary for proper cell washing;

we recommend that you check fill volume periodically.

Fill volume should also be checked whenever the saline

supply reservoir is moved or replaced.

To check, install tubes with samples in all 12 places,

start an AUTO run, and press CHECK. The Cellwasher 2

will stop after the fill step – open the lid and examine the

level of saline in each tube. Fill volume is considered

acceptable if:

• When using the recommended tubes (page 3-5), the

level of saline in the highest tube fill is between 5 and 8

mm (0.2 and 0.3 inch) from the top of the tube.

• the difference between the highest fill tube and lowest

fill tube is not more than 10 mm (0.4 inch).

Using a graduated cylinder (following the procedure on the previous

page), first adjust the flow control valve to the previously-determined adjusted total fill volume (if an adjusted total fill volume has

not yet been established, set the volume to 54 ml for 12 mm diameter

[5 ml] tubes, or to 36 ml for 10 mm diameter [3 ml] tubes). After

adjusting to achieve the desired total fill volume, fine-adjust the

volume based on tube fills.

HIGHEST FILL

10 mm RANGE

ALL FILLS ARE

TO BE WITHIN

MINIMUM LINE

– LOWEST FILL

TO BE ABOVE

2. Make sure that

the difference

between the

highest tube fill

and the lowest

tube fill does not

exceed 10 mm.

Install tubes in all 12 places, and after filling, check each tube to

determine the highest tube fill –the highest fill should be between 5

and 8 mm (0.2 and 0.3 inch) from the top of the tube when recommended tubes are used – adjust the flow control valve and recheck

fills as required. After the highest tube fill is correct, make sure that the

difference between the highest tube fill and the lowest tube fill is not

more than 10 mm (0.4 inch), equating to a maximum variance of

approximately 0.7 ml in 12 mm diameter tubes, or 0.45 ml in 10 mm

diameter tubes – troubleshoot if the fill variance is too great.

If, after initially coarse-adjusting the total fill volume (to 54 or 36

ml), the flow control valve had to be readjusted based on tube fills,

again use a graduated cylinder to measure the new adjusted total fill

volume and record the new value to use as an initial coarse-adjustment point for subsequent checks (volume adjustments will continue to change due to tube lot tolerances and normal changes to

system flow over time).

3-7

Page 28

Operation SORVALL® Centrifuges

!

W A R N I N G

During operation, never

lean on or move the instrument, keep

the defined clearance area clear of

all objects (including all hazardous

and flammable materials), and do not

work within the clearance area (see

Location in Chapter 2).

Auto Operation

a. The basic operating sequence in the AUTO mode is as follows:

1. Press the LID button to open the lid.

2. Install the rotor, tubes, and distributor as described in Chapter 2, Installation.

3. Close the lid.

4. Select:

5. For an audible signal at the end of the run, press ALARM

ON.

6. Press START to begin the run.

NOTE

If you wish to check for proper fill, press CHECK after

beginning the run. At the end of the fill step, the

Cellwasher 2 will stop. Examine the level of saline in

each tube. Fill is considered acceptable if:

• When using the recommeded tubes (page 3-5), the

• the difference between the highest fill tube and lowest

Press START to continue run.

MODE CYCLE

AUTO 1-4

■■

■

■■

level of saline in the highest tube fill is between 5 and 8

mm (0.2 and 0.3 inch) from the top of the tube.

fill tube is not more than 10 mm (0.4 inch).

7. At the end of the run, if the alarm sounds, press ALARM

OFF to turn off the alarm.

8. Once the lid LED is illuminated, press LID to open the lid.

b. SALINE alarm – this alarm will sound during the filling step if

the saline supply is interrupted. To deactivate the alarm and

correct the problem, prime the Cellwasher 2 as follows:

1. Open the lid (press LID button).

2. Holding a graduated cylinder under the saline dispenser in

the lid, press:

CMD

NOTE

PRIME

The SALINE alarm will not shut off until the PRIME

button is pressed.

■■

■

■■

3-8

Page 29

Cellwasher 2 Operation

3. Close the lid and press START to continue the wash cycle in

progress.

NOTE

The SALINE alarm may also indicate broken or obstructed tubing. If the saline reservoir is adequate, check

the tubing. Clean or replace tubing if necessary (see

Chapter 4, Maintenance).

To ensure adequate washing, perform one additional

wash cycle at the completion of the cycles in progress.

c. During AUTO operation, the following features may also be

used:

• CHECK button – the automatic wash cycle can be checked

after any step (fill, spin, or decant) by pressing the CHECK

button during that step. The Cellwasher 2 will automatically

stop at the end of the step in progress, and the lid may then be

opened. After checking the tubes, close the lid and press

START to continue run.

• STOP button – when STOP is pressed, the run in progress

will stop immediately. When the LID light goes on, the lid

may be opened. When the Cellwasher 2 is restarted, it will

begin the programmed cycle over again unless steps are

bypassed (see STEP button, Table 3-1).

• STEP button – if the AUTO mode is interrupted by a STOP

command, it will restart at the beginning of the programmed

run. To move the sequence ahead (to avoid refilling tubes for

instance), press the STEP button once for each step in the

cycle to be bypassed.

3-9

Page 30

Operation SORVALL® Centrifuges

!

W A R N I N G

During operation, never

lean on or move the instrument, keep

the defined clearance area clear of

all objects (including all hazardous

and flammable materials), and do not

work within the clearance area (see

Location in Chapter 2).

High and Low Speed Operation

a. To operate the Cellwasher 2 in the HIGH or LOW speed mode,

proceed as follows:

1. Press the LID button to open the lid.

2. Install the rotor, tubes, and distributor as described in Chapter 2, Installation.

3. Select:

NOTE

When HIGH or LOW is pressed, the time selected for the

previous run will appear automatically in the digital time

display. In the HIGH and LOW modes, the spin time that is

input remains in the memory of that mode until a new time

is input, or until the power is switched off.

MODE TIME CMD

HIGH 1-999

SECONDS

LOW

START

After the START button is pressed, agitation will occur automatically for 5 seconds before the run begins. The time will count down

in seconds. At the end of the run, the lid light will come on. Press

LID to open the lid.

NOTE

NOTE

Depending on run conditions and component variability

from instrument to instrument, the rotor may still be

rotating slowly after the lid is opened.

The Cellwasher 2 is not intended to perform repetitive

Low Speed TIMED runs without allowing a rest period of

at least 10 minutes between runs with the door open to

allow the motor to cool. Failure to allow the motor to cool

between repetitive Low Speed runs can cause the motor to overheat and shut down.

b. During HIGH or LOW speed operation, the following features

may also be used:

• AGITATE – pressing the AG button, when the rotor is not

spinning, will provide an additional 5 seconds of agitation.

• HOLD – after selecting HIGH mode only, press HOLD to

provide an indefinite spin period; HOLD is not to be selected

in LOW speed mode. To end the run, press STOP.

NOTE

The Low Speed Mode is not intended for continuous

use; performing lengthy Low Speed HOLD runs could

cause the motor to overheat and shut down. Because of

this, Low Speed HOLD runs are not recommended.

3-10

Page 31

Cellwasher 2 Operation

!

!

T ube Breakage

Necessary Action to Prevent Instrument

Malfunction

W A R N I N G

In the event of tube breakage, be careful to avoid personal injury due to sharp fragments. Always

make sure all glass is removed, including any pieces that may have

become lodged in the overflow and

drain tray exits and tubing. Also, make

sure that the overflow container is

empty before resuming use.

C A U T I O N

The distributor is balanced

as an assembly. In extreme cases, if

it must be disassembled for cleaning,

all parts must be marked for position/

orientation so that it will be in balance

after reassembly.

Tube breakage followed by an inadequate cleanup can be a major

cause of instrument malfunction. Residual glass fragments can block

drains and cannulas, leading to flooding of internal components and

an accelerated buildup of encrusted salt/media. Every time tube

breakage occurs, or if fluid exits through the overflow tubing or

appears from under the cabinet, a thorough cleaning and inspection

should be completed before continued operation. Disconnect power

and decontaminate the Cellwasher 2 as required, then perform the

cleaning and inspection as follows:

1. In the lid, separate the collector ring from the retaining ring by

removing the four mounting screws and stepwashers (for parts

identification, refer to Figure 4-1 on page 4-3). Clean all glass

and residue from both sides of the collector ring, and from inside

its drain nozzle and the connected discharge tubing. Using water, be sure the collector ring drains freely through the tubing – if

not, clear blockage and recheck as required. Clean the surface of

the retaining ring and its O-ring, then reassemble, making sure

the collector ring is fully seated on the retainer ring before

securing it with screws and stepwashers.

2. Remove and clean the distributor assembly, the rotor, and the

rotating bowl assembly. On the distributor assembly, make sure

that no fragments have fallen down inside the center area, to

ensure that cannulas will not become obstructed, and make sure

cannulas have not been damaged. On the rotating bowl assembly, make sure that no fragments have become situated between

parts by checking that the lift plate mechanism slides up and

down freely.

3. Clean the wet guard (black plastic liner) that covers the chamber

and top deck, then remove it. Locate the small white overflow

tray, which is positioned directly under, and obstructed by, the

decant coil (a black ring around the top of the motor assembly).

Clean all glass and residue from the overflow tray, and from

inside its drain nozzle and the connected overflow tubing. Using

water, be sure the overflow tray drains freely through the tubing

(being careful not to overflow the tray, if drainage is still impaired) – if not, clear blockage and recheck as required.

4. Reinstall the wet guard, then, being sure to engage the drive pins

on each, reinstall the rotating bowl assembly, the rotor, and the

distributor assembly. If the problem recurs, contact Kendro Service.

3-1 1

Page 32

Operation SORVALL® Centrifuges

!

!

W A R N I N G

To avoid exposure to a

spinning rotor and potential for personal injury, if a momentary power

failure terminates a run, wait at least

ten seconds (from when power was

lost) before trying to open the lid.

W A R N I N G

This procedure is included

for emergency sample recovery only

and should never be used for any

purpose other than those explained

in this section.

When the main power shuts off the

brake will not operate. Wait until the

rotor stops spinning before using the

mechanical override.

Momentary Power Interruption

If a momentary power interruption occurs when a run is in progress

with the rotor spinning, it can take up to ten seconds before the rotor

comes to a stop. Do not open the lid with the rotor spinning.

Emer gency Sample Recovery

If, while the rotor is spinning, the Cellwasher 2 main power shuts off

due to a power failure or system malfunction, the lid is designed not

to open, to keep the operator safe. For emergency situations such as

these, where the rotor has stopped spinning but the LID button will

not allow access to the chamber, a mechanical override is provided

to allow sample recovery.

The mechanical override is located on the left side of the Cellwasher

2 as shown in figure 3-2, below. To operate the override, insert a

small screwdriver or similar object into the hole and push to cause

the latch pin to disengage the striker plate and release the lid.

HOLE FOR

MECHANICAL

OVERRIDE

Figure 3-2. Location of Mechanical Override

3-12

Page 33

Cellwasher 2 Maintenance

!

!

Chapter 4: MAINTENANCE

This chapter describes routine maintenance procedures that should be performed on a regular basis, with

the specific time interval or duty cycle determined by the user, and based on product use. It is also the

responsibility of the user to make certain that these procedures are followed whenever necessary. If further

service is needed, contact Kendro or your local representative for SORVALL® products.

W A R N I N G

There are no user-serviceable items inside the Cellwasher 2.

Due to the hazards involved, repair

should only be attempted by a qualified technician who is familiar with

electronics and trained in the servicing of this product.

Preventive Maintenance

The following preventive maintenance checks and cleaning procedures should be performed regularly. If etiologic or biologically

hazardous materials are processed in the Cellwasher 2, be sure

appropriate decontamination procedures have been followed before

inspecting or cleaning the instrument.

a. Inspection

• Inspect the vents on the bottom of the Cellwasher 2 to be sure

they are not blocked, and remove any obstructions.

• Check all sealing surfaces, tubing, liners, and the collecting ring

assembly for cleanliness and good condition.

• Inspect the distributor, rotor, and stainless steel rotating bowl:

1. Remove the distributor from the top of the rotor; check for

cracks and make sure cannulas are not bent, damaged, or

clogged. From underneath, make sure the metal clip that

holds the distributor to the rotor is not cracked or broken.

2. Remove the DA-12 rotor from the rotating bowl assembly.

Make sure that the rotor does not wobble on its base. Make

sure that the pivot pin at the top of each tube holder is not

W A R N I N G

Continued use of a rotor

with tube holder band gaps greater

than 2 mm, or that has had bands

compressed to close the gaps, can

cause tube breakage, possibly resulting in instrument damage or personal

injury.

NOTE

loose. Also, check the gaps in the tube holder bands – gaps

may widen over time due to centrifugal force, and the rotor

should not be used if the gaps become greater than 2 mm. Do

not compress the tube holder bands to close the gaps; bands

are precisely shaped to support tubes during centrifugation,

and tube support will be compromised if the bands are

deformed in this manner (read the WARNING).

3. Remove the stainless steel rotating bowl assembly (located in

the rotor chamber, directly beneath the rotor), and inspect the

rotating bowl assembly for signs of cracks or corrosion.

If inspection reveals that any part of the Cellwasher 2 is

not functioning properly, do not use the instrument until

it is repaired.

4-1

Page 34

Maintenance SORVALL® Centrifuges

!

b. Cleaning

C A U T I O N

All saline solutions have

long term corrosive effects. Routine

cleaning and maintenance are essential to ensure safe and efficient

operation.

• Clean the Cellwasher 2 cabinet with a damp cloth and mild

detergent.

• Wipe up spills from the interior and exterior whenever they

occur.

• Remove the rotor, distributor, and rotating bowl and wash them

with warm water and mild detergent.

• Remove the collecting ring assembly and tubing for routine

cleaning as follows (see figure 4-1):

1. From the back of the instrument, open the adjustable tubing

clamp that secures the Y-Connector in place and remove the

discharge tubing from the Y-Connector (see figure 2-1).

2. Remove the four mounting screws and step washers securing

the collecting ring assembly to the lid.

3. Pull the collecting ring assembly away from the lid, and pull

the discharge tubing up through the wet guard (molded black

liner).

4. Disconnect the flow tubing from the spray nozzle in the lid

and pull it through the hole in the retainer ring.

5. Separate the collector ring assembly by pulling the collector

ring off.

6. Remove discharge tubing and flow tubing, wash with warm

water and mild detergent, and reinstall (see figure 2-1).

7. Wash the retainer ring, O-ring seal, and collector ring with

warm water and mild detergent.

8. To reassemble, place the retainer ring on work surface (small

opening down), and work the O-ring seal around the large

opening of the retainer ring until it is fully seated in the

groove. Then, place the collector ring so that it rests concentrically over the O-ring seal and press firmly into place.

NOTE

Make sure the nozzle for the discharge tubing on the

collector ring aligns with the groove in the wet guard when

the collecting ring assembly is reinstalled in the lid.

9. Reinstall the collecting ring assembly by reversing steps 1

through 4 of this procedure.

NOTE

4-2

When replacing the four mounting screws, make sure

the flat side of each step washer faces the screw head.

Page 35

Cellwasher 2 Maintenance

!

SPRAY

NOZZLE

LID

COLLECTOR RING

ASSEMBLY

O-RING

GROOVE

RETAINER

RING

O-RING

SEAL

COLLECTOR

RING

STEP

WASHER

MOUNTING

SCREW

Figure 4-1. Collecting Ring Assembly, Exploded View

W A R N I N G

If tubes have been broken

in the Cellwasher 2, be aware of the

potential for residual glass fragments

and take extra precautions.

The Cellwasher 2 is intended for use

with human blood. Always observe

Universal Precautions.

FLOW

TUBING

DISCHARGE

TUBING

TO FLOW

DETECTOR

TO WASTE

CONTAINER OR

T-CONNECTOR

c. Decontamination

The Cellwasher 2 is intended for use in Coomb's testing and incorporates the use of human blood. If the Cellwasher 2 has been used

with other hazardous materials, be aware of all hazards involved and

decontaminate using additional appropriate methods. As a guide, the

SORVALL® Product Guide contains descriptions of commonly used

decontamination methods and a chart showing method compatibility

with various materials. Otherwise, observe Universal Precautions

and proceed as directed on the next page.

4-3

Page 36

Maintenance SORVALL® Centrifuges

If the Cellwasher 2 is oper ational

1. Prepare a 3-10% solution of household liquid chlorine bleach.

2. Soak a wash rag or sponge with the bleach solution and gently

wipe the bowl assembly, the wet guard, and the inner portion of

the Cellwasher 2, making sure all encrusted material is gone. Do

this step twice.

3. Disconnect the supply tubing from the saline supply and set the

tubing to draw from the bleach solution.

4. Pump the bleach solution through the Cellwasher 2 for four cycles.

5. Set the tubing to draw from clean water and follow the bleach

solution with 4 to 12 water washes, so that no bleach remains.

6. Reconnect the tubing to the saline supply and follow the water

washes with four cycles of saline.

7. Check the pH level to make sure it is normal. If not, continue

with saline cycles until pH checks normal.

8. Open the lid, turn the main power switch OFF, and unplug the

power cord. Wipe all parts (including parts inside the lid and

chamber, the cabinet, the control panel, and the front surface of the

main power switch) with a 70% ethanol solution and allow to dry

(do not flood the switch or power cord connector areas).

If the Cellwasher 2 is not oper ational

1. Turn the power switch OFF, unplug the power cord, and open the lid

using the mechanical override (see page 3-12, Emergency Sample

Recovery). Remove tubes (if any) from the DA-12 rotor.

2. Prepare a 3-10% solution of household liquid chlorine bleach.

Disassemble the collector ring assembly (see Cleaning, page 4-2);

immerse components for 10 minutes in the bleach solution.

3. Remove the discharge tubing, vent tubing, and drain tubing

along with any Y-connectors, draining any excess saline from the

pieces. Immerse and completely fill the tubing and connectors in

the bleach solution (try not to leave any air in the tubing); keep

them immersed for 10 minutes.

4-4

NOTE

Depending on the age or condition of the tubing, as well

as the type or amount of contamination, you may choose

to replace tubing instead of decontaminating it. If so,

discard contaminated tubing in an appropriate manner,

then, after the instrument has been decontaminated,

install a Tubing Replacement Kit (Catalog No. 12977,

supplied), following instructions supplied in the kit.

Page 37

Cellwasher 2 Maintenance

4. Individually remove the distributor, the DA-12 rotor, and the

stainless steel bowl. Immerse the distributor for 10 minutes in

the bleach solution. Wipe the DA-12 rotor and stainless steel

bowl using a 70% solution of ethanol, making sure that all

encrusted material is gone, then rinse with water. Repeat the

ethanol wash a second time.

5. Remove the wet guard (black plastic liner) from the chamber.

Soak a wash rag or a sponge in the bleach solution and gently

wipe the wet guard and the inner portion of the unit (including

the nozzle and inside of the lid, the motor shaft and the decant

coil). Make sure that all encrusted material is gone.

6. Make sure a container is positioned to collect fluid from the

overflow tubing. Pouring slowly so that the tray doesn't overflow, pour some bleach solution into the white plastic overflow

tray (below the decant coil) this should drain out freely through

the overflow tubing. Follow with clean water to rinse.

7. Wipe the entire cabinet, including the control panel and the front

surface of the main power switch, with 70 % ethanol (do not

flood the power switch or power cord connector areas).

8. After 10 minutes in the bleach solution, remove all components

that had been soaking and rinse with water several times.

9. Allow all components to dry, then reassemble the unit as before.

NOTE

When reinstalling the four mounting screws of the collector ring assembly, make sure that the flat side of each

step washer is against the screw head.

Ser vice Decontamination Policy

If a Cellwasher 2 requires servicing by Kendro personnel, either at

the customer’s laboratory or at a Kendro facility, comply with the

following to ensure the safety of all personnel.

If the Cellwasher 2 has been used with other hazardous materials, be

aware of all hazards involved and decontaminate using additional

appropriate methods. As a guide, the SORVALL® Product Guide

contains descriptions of commonly used decontamination methods

and a chart showing method compatibility with various materials.

Otherwise, if a Cellwasher 2 requires servicing by Kendro, proceed

as follows:

1. Decontaminate the Cellwasher 2 to be serviced, and clean it of

all encrusted material prior to servicing by a Kendro representative or returning it to the Kendro facility. There must be no

radioactivity detectable by survey equipment. Decontaminate

according to the instructions that begin on page 4-3.

4-5

Page 38

Maintenance SORVALL® Centrifuges

2. Complete and attach a Decontamination Information Certificate

(in the back of this manual) to the Cellwasher 2 before servicing.

In addition to those included with in this book, Decontamination

Information Certificates are available from the local Kendro

Representative or Field Service Engineer. In the event that certificates are not available, a signed, written statement certifying

that the unit has been properly decontaminated, identifying what

the contaminants were and outlining the decontamination procedures used will be acceptable.

NOTE

The Field Service Engineer will note on the Customer

Service Repair Report if decontamination was required

and, if so, what the contaminant was and what procedure was used. If no decontamination was required, it

will be so stated.

If a Cellwasher 2 to be serviced does not have a Decontamination

Information Certificate attached and, in Kendro's opinion presents a

potential radioactive or biological hazard, the Kendro representative

will not service the equipment until proper decontamination and

certification is complete.

If the Cellwasher 2 must be returned to a Kendro facility:

1. Contact your Kendro representative to obtain an Equipment

Return Decontamination Form; be prepared with the product

name (Cellwasher 2), serial number and the repairs required.

2. Complete the Equipment Return Decontamination Form and

return it to Kendro. Upon receipt of a completed form, a Returned Material Authorization Number (RMA Number) will be

issued to you.

4-6

3. With the RMA Number clearly marked on the outside of packaging, send the items to the address obtained from your Kendro

representative.

NOTE

United States federal regulations require that parts and

instruments must be decontaminated before being transported. Outside the United States, check local regulations.

If equipment is received at Kendro facilities without a valid RMA

Number on the outside of the shipping container and a completed

Equipment Return Decontamination Form on file, the equipment

will be treated as a potential contamination hazard, and will not be

serviced until decontamination certification has been completed.

The sender will be contacted for instructions regarding disposition

of the equipment in question; all disposition costs will be borne by

the sender. If contaminated equipment is received at Kendro facilities, both the carrier and appropriate authorities shall be notified.

Page 39

Cellwasher 2 Maintenance

!

Par ts Replacement

To order replacement parts, telephone toll-free 800-522-7746 in the

United States. Outside the United States, contact Kendro or your

local representative for SORVALL

partial list). Be prepared to supply the product name (Cellwasher 2),

serial number, and a description of the parts required.

®

products (see back cover for a

Tubing Replacement

If tubing is damaged and must be replaced, install tubing supplied in

the Tubing Replacement Kit (Catalog No. 12977) following installation instructions supplied with the kit.

Fuse Replacement

W A R N I N G

There are no user-serviceable items inside the Cellwasher 2.

Due to the hazards involved, repair

should only be attempted by a qualified technician who is familiar with

electronics and trained in the servicing of this product.

To replace the fuse in the power supply adapter:

1. Unplug the power cord.

2. Remove the power cord from the power supply adapter.

3. Slide the clear plastic guard to the left of the power cord connection.

4. Pull out the FUSE PULL lever. The end of the fuse will pop out.

5. Remove the fuse, and replace it with the appropriate slow-blow

fuse. (Fuse rating is indicated on rear nameplate).

6. Move the guard to the right, and replace the power cord.

Troubleshooting

Tables 4-1 through 4-4 contain troubleshooting information for

some common problems that occur during operation of the Cellwasher

2. The customer should not attempt any further troubleshooting.

Tables 4-5 through 4-7 contain applications troubleshooting information which identify possible causes of false negative results, false

positive results, or inconsistent reaction strength.

4-7

Page 40

Maintenance SORVALL® Centrifuges

Table 4-1. Tr oubleshooting Chart: Problem A

Instrument completely

inoperative and displays not

illuminated.

Is instrument plugged in?

Yes

Is power switch on?

Yes

Is AC line fuse blown?

No

Contact Kendro

Representative

No

No

Yes

Connect power cord as

required.

Place power switch in the

ON position.

Replace fuse. See fuse replacement

procedure on page 4-7.

Table 4-2. Troubleshooting Chart: Prob lem B

Is saline volume correct?

Yes

Is distributor dirty? Are cannulas

clogged?

No

Are tubes the correct length and

diameter?

No

Replace with tubes of correct length

and diameter.

Improper saline fill of tubes.

No

Yes

Yes

Adjust volume (see page 3-7, Fine-Adjusting

Saline Fill Volume Based on Tube Fills).

Clean distributor and each cannula.

Contact Kendro Representative.

4-8

Page 41

Cellwasher 2 Maintenance

Table 4-3. Troubleshooting Chart: Pr oblem C

Instrument will not operate and displays

Is lid properly latched?

Yes

Contact Kendro Representative

are illuminated.

No

Table 4-4. Troubleshooting Chart: Pr oblem D

(see figures 4-2 and 4-3)

Decant Malfunction.

Close lid properly.

Is decant coil aligned properly?

(Alignment is improper if lift plate ring

shows abnormal rubbing on one side.)

Yes

Does lift plate ring move

freely?

Yes

Is the drive ring loose of

deformed?

No

Does motor turn

counterclockwise?

No

Contact Kendro

Representative

Yes

No

Yes

No

Align decant coil to be concentric

with motor shaft.

Clean ring – look for glass

fragments, rust, salt residue, or

other foreign substances.

Secure or replace

drive ring.

Faulty clutch – replace.

4-9

Page 42

Maintenance SORVALL® Centrifuges

DRIVE

RING

MOTOR

SHAFT