Manual

Balance Series

FA Electronic Balance(Electronic Analytical Balance)

FB Electronic Balance(Auto Internal Calibration Electronic Analytical Balance)

JA Electronic Balance(Electronic Precision Balance)

FA/FB/JA Series

Quick Use Guide

Power On

Power Off

Calibration

Tare Piece

Zero

Percentage

Units Conversion

Function Mode Conve

rsion

Hold on to click the button , until appear required hints

开 关

Max:

d

g

g

Max: gdg

开 关

Max:

Max:

100%0

皮去

100%0

gdg

g

100%0

gdg

g

100%0

零置

Max:

Max:

Max:

d

g

Basic Weighing

g

g

Max:

g

Max:

g

100%0

d

g

g

100%0

d

g

g

100%0

皮

准校

Max: gdg

0

Max:

Max: gdg

Max:

Max: gdg

Max:

Max: gdg

Cal

Cal

g

100%0

d

g

g

Cal

100%0

Cal

g

100%0

d

g

g

Cal

100%0

Cal

100%0

d

g

g

g

100%0

去

能功

皮

去

能功

皮

去

Max: gdg

Max: gdg

Max: gdg

d

g

d

g

Max: gdgg

Max: gd

g

Max: gd

g

Max:

g

Max: gd

g

Max: gd

g

g

100%0

g

100%0

g

100%0

g

g

100%0

g

g

100%0

零置

能功

能功

皮

去

能功

100%0

Menu

pcs

100%0

pcs

100%0

d

g

pcs

100%0

pcs

100%0

pcs

100%0

能功

能功

Max:

g

Max:

g

Max: gd%g

Max: gd%g

Max: gd%g

Max: d

Max: gdgg

Max:

g

Max:

g

Max:

g

Max:

g

Max: gd

g

Max: gd%g

Max:

g

Density

Max: gdg

d

g

g

100%0

d

g

Menu

pcs

100%0

Menu

100%0

100%0

100%0

%

100%0

100%0

d

g

p

100%0

d

g

oz

100%0

d

g

oz

g

100%0

d

g

ct

100%0

Menu

pcs

100%0

Menu

100%0

d

g

3

/cm

g

100%0

Menu

100%0

2

CONTENTS

1 BALANCE SERIES INTRODUCTION ...........................................................................................................................4

1.1 INTRODUCTION ...................................................................................................................................................... 5

1.2 BALANCE STRUCTURE .......................................................................................................................................... 6

1.3 OPERAING KEY FUNCTION INDEX ............................................................................................................................... 7

2 USAGE ...................................................................................................................................................................8

2.1 PACKAGE LIST .......................................................................................................................................................... 8

2.2 INSTALL, LEVEL ADJUSTMENT ....................................................................................................................................... 9

2.3 SAFETY GUIDELINES/POWER ....................................................................................................................................... 9

2.4 CALIBRATION ..........................................................................................................................................................10

3 WEIGHING ................................................................................................................................................................ 11

3.1 POWER ON/OFF .....................................................................................................................................................11

3.2 BASIC WEIGHING ....................................................................................................................................................11

3.3 TARE ..................................................................................................................................................................11

3.4 ZERO .................................................................................................................................................................11

4 MENU ....................................................................................................................................................................... 12

4.1 OVERVIEW .............................................................................................................................................................13

4.2 FUNCTION MENU OPERATION ..................................................................................................................................13

4.3 BASIC WEIGHING OPERATION...................................................................................................................................14

1、 Basic Weighing ............................................................................................................................................. 14

2、Weighing with Container ................................................................................................................................ 14

3、Unit Conversion .............................................................................................................................................. 14

4.4 FUNCTION WEIGHING OPERATION.............................................................................................................................15

1

、

Piece Count .................................................................................................................................................... 15

2、Weighing in Percent ........................................................................................................................................ 16

4.5 DENSITY WEIGHING (ONLY FOR JS SERIES) ....................................................................................................................17

1、DENSITY DEVICE INSTALLATION ...............................................................................................................................17

2、DENSITY MODE SELECT .........................................................................................................................................17

3、STANDARD MATERIAL SELECT .................................................................................................................................18

4、OPERATION ........................................................................................................................................................19

4.6 SYSTEM .................................................................................................................................................................22

3

4.7 DATE COMMUNICATION ............................................................................................................................................23

5 CONFIGURING BALANCE ...................................................................................................................................... 23

5.1 OPERATING THE CONFIGURING KEYS ..........................................................................................................................23

5.2 BALANCE FUNCTION SETTING LIST(* MEASN FACTORY SET) ...........................................................................................24

5.3 BALANCE SETTING FUNCATION EXPLAIN ........................................................................................................................25

5.4 BALANCE SETTING FOR QUICK WEIGHING ......................................................................................................................25

5.5 BALANCE SETTING FOR STRONG AIR ENVIROMENT ...........................................................................................................25

5.6 BALANCE SETTING FOR LINEAR CORRECTION ..................................................................................................................25

5.7 RECOVER FACTORY SETTING .......................................................................................................................................26

6 TECHNICAL PARAMETERS, FUNCTION OPTIONSL, PARTS OPTIONAL, DIMENSION ................................................ 26

6.1 TECHNICAL PARAMETERS .........................................................................................................................................29

6.2 RS232 PORT .........................................................................................................................................................29

6.3 FIGURE DIMENSION .................................................................................................................................................30

7 APPENDIX .............................................................................................................................................................. 31

7.1 RS232 PORT DATE COMMUNICATION ..........................................................................................................................31

7.2 FAILURE INFORMATION AND SOLUTIONS ......................................................................................................................32

7.3 MAINTENANCE AND CLEANING ..................................................................................................................................33

7.4 DENSITY PARAMETER TABLE ........................................................................................................................................34

4

1 BALANCE SERIES INTRODUCTION

1.1 Introduction

Same appearance, similar to the operation, not the

same sensor module. It contains four series products:

1. FA series electronic analytic balance

Readability: 0.1mg

2. FB series internal calibration balance

Readability: 0.1/1mg

3. JA series electronic precision balance

Readability: 1mg

4. JS series density balance

Readability: 0.1mg/1mg

The basic function of four series balance is almost same; expect special function (such as density measurement).

Detail as follow:

Series No FA FB JA JS

Weighing capacity (g)

Actual scale interval (g)

Accuracy class

Calibration method External Internal External External External

Density device None None None Have

contour dimension (mm) 365×223×338(length×width×height)

Package dimension(mm) 498×313×453(length×width×height)

Pan size(mm)

Effective height above pan

100- 220 120-220 220-420

0.0001 0.0001 0.001 0.001 0.0001 0.001

ø 90

150×165×2002(length×width×height)

100-500 110-210 300-500

Net weight(kg)

Gross weight(kg)

5.5 6 5.5 6

7.5 8 7.5 8

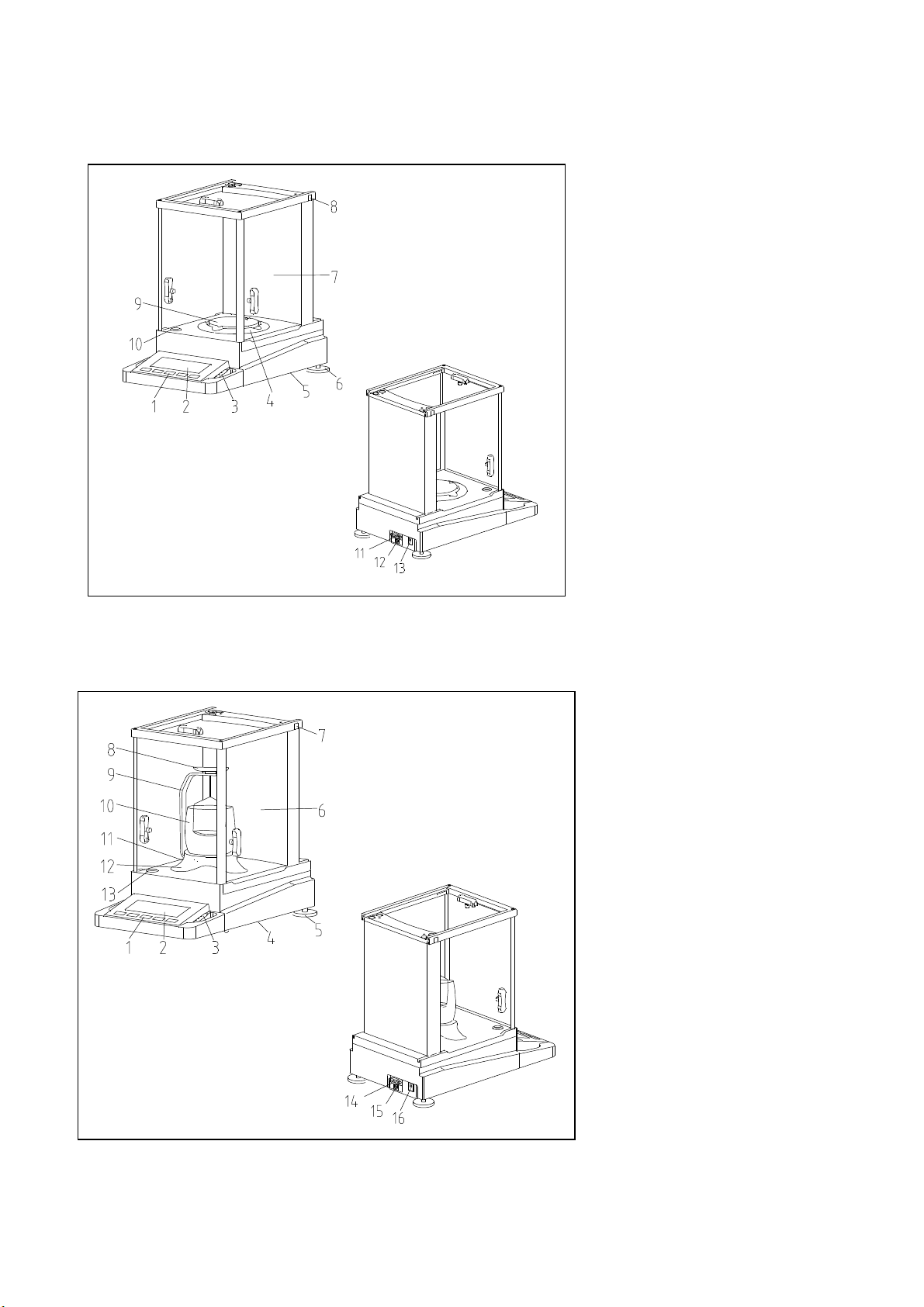

1.2 Balance Structure

1)Operating Key

2)Display Screen

3)Unlocked pen for glass doors

4)Windbreak

5)Handing ring for hook

(In the bottom of balance)

6)Leveling foot

7)Windproof cover

8)Lock for glass

9)Weighting pan

10)Level indicator

11)RS232 port

12)USB port(optional)

13)Power adapter socket

1) Operating Key

2) Display Screen

3) Unlocked pen for glass doors

4) Handing ring for hook

(In the bottom of balance)

5) Leveling foot

6) Windproof cover

7) Lock for glass

8) Testing Shelf

9) C-Style Bracket

10) Arched glass

11) Shelve table

12) Fixed Ring

13) Level indicator

14) RS232 port

15) USB port(optional)

16) Power adapter socket

6

ON/OFF ON/OFF

/

CAL /

TARE

TARE

ZERO

ZERO

ON/OFF ON/OFF

CAL

/

TARE

TARE

ZERO

ZERO

Return to function

Return to basic

1.3 Operating Key Function Index

The balance have two operating methods:weighing mode and function mode. According to the choice of

operating mode and the length of pressing key. It has different meaning.

Weighing Mode

Max: gdg

能开 关 功 准校皮去

Function Mode

Operating key in weighing mode

Press key for short time Press key for long time

ON(Shutdown State)

MODE

g

100%0

零置

CAL/

/

/

Unit convert Into function mode

Print Calibration

Weighting tare

Zero, cancel

MODE/

/

/

OFF(Start State)

Operating key in function mode

Press key for short time Press key for long time

Max:

g

能开 关 功 准校皮去

7

d

g

Menu

pcs

100%0

零置

MODE/ MODE/

/

/

Switch

Print

Enter, choice

Return to previous

menu

CAL/

/

/

OFF(Start State)

menu

weighing mode

2 USAGE

2.1 Package List

FA、FB、JA Balance Standard

Configuration:

FA、FB、JA Electronic Balance

♦ Balance 1 pc

♦ AC Power 1 pc

♦ Pan 1 pc

♦ Windbreak 1 pc

♦ Calibration weight 1 pc(Except

internal calibration balance)

♦ Manual 1 pc

♦ Certificate of quality 1 pc

♦ Guarantee card 1 pc

♦ Unlocked pen for glass doors 1pc

♦ Panel shelter 1 pc

JS Density balance

Configuration:

♦ Balance 1 pc

♦ AC Power 1 pc

♦ Pan 1 pc

♦ Windbreak 1 pc

♦ Calibration weight 1 pc(Except

internal calibration balance)

Manual 1 pc

♦ Certificate of quality 1 pc

JS Electronic Density Balance

♦ C-Style bracket 1pc ♦ Shelve table 1pc ♦ Arched glass 1pc ♦ Testing shelf 2pc ♦ Standard weight 1pc

Explanation:

Open the package, take out the balance and accessories. Then check the balance if there is damage, accessories

are complete. Check all the windproof door is in perfect condition and operation normally. If there is any fault,

please connect to the agency of Shanghai Sunny Hengping.

♦ Guarantee card 1 pc

♦ Unlocked pen for glass doors 1pc

♦ Panel shelter 1 pc

8

Different model balance has different calibration weight, please see parameter list at part six.

Please keep packing materials properly for transport

2.2 Install, level Adjustment

Best placed place

For high resolution analytical and precise balance, the right

placed place is the key for accurately weighing. So please

ensure that:

·Stable and no vibration position, as far as possible be level

·Avoid direct sunlight

·Avoid strenuous temperature variations

·Avoid air convection

Best placed place: the corner of shelter, stable table, as far as

possible from the door, window, radiator and the outlet of air

condition

Through regulating the leveling foot, make the level bubble moving to the

center of circle. Please adjust balance in the stable table, avoid the

position of the large air flow, virbration and high rate temperature change.

(as shown)

Notice: Please adjust level, when the balance move to a new place.

2.3 Safety Guidelines/Power

• Do not use the balance equipped with standard AC power in the

damage area.

• Please confirm the power adapter whether is match to your local

volatge before getting through the power.

• The balance can only be used in dry enviroment.

Power connection:

→Plug jack-plug of AC adapter in the socket of balance, another side

connect the power.

→Turn on the power, a buzzer emits beep. The balance could be used.

Notice:The balance should be warmed-up for 60 minutes in first time, to

9

achieve the working temperature, in order to obtain the accurate resultes.

Zero/

CAL/

2.4 Calibration

In order to obtain the accurate resultes, it is need to calibration according to the local acceleration of gravity.

Necessary situations to calibrate the balance:

·Before the first measurement

·After weighing for a period

·Weighing location changed

Should start the balance for 60 minutes before calibration to achieve the working temperature, in order to obtain

the accurate.

External Calibrtaion

Clear weighting pan, perpare calibration weights.

准校

Max:

0

Max: gdg

Max:

Max: gdg

Max:

Max:

Max:

d

g

g

Cal

Press , untill display " ".

The needed calibraion weight value will flicker on the display

Cal

g

100%0

d

g

g

Cal

100%0

screen.

Put the right calibration weight on the scale pan. When it

shows” “, remove weight.

g

When it displays " " and emits prompting

Cal

g

100%0

d

g

g

Cal

voice, the calibration is over. The balance return to the

working situtaion. When shows “ ”, the balance is

g

ready.

100%0

d

g

g

g

Cal

100%0

d

g

Hint:

Press short time, could interrupt calibration

10

g

100%0

any time.

ON/OFF

Tare/

ON/OFF

3 WEIGHING

3.1 Power On/Off

开 关

Max:

Max:

d

g

g

g

d

g

Power On

→Press

A self-test will be performed, and then return to zero, now it can be used.

100%0

Max:

关

开

Max:

d

g

g

g

g

d

g

g

3.2 Basic Weighing

Max: gdg

Max: gdg

Max:

d

g

g

100%0

Power Off

100%0

→Press for a while,then display screen power off.

100%0

→Put the sample on the weighing pan.

g

100%0

→Wait until it is stable.

g

100%0

→Read the data

g

100%0

3.3 Tare

皮

去

11

Max:

Max:

Max: gdg

→Put vacant container on the weighing pan.

→It shows weight of container.

d

g

g

g

g

d

g

g

g

100%0

→Press

100%0

→Put the sample on the container, it reads data of weight of sample.

100%0

If remove the container from balance, the data will be negative. The data will keep until power off or

ZERO

/

Tare/

MODE

/

press .

Notice: This function can not be used under zero or above the maximum weighing.

3.4 Zero

Max: gd

Max:

g

g

100%0

d

g

g

g

100%0

零置

In the menu, you can change the weighing unit or choose other functions for different settings. It can be found in

the 4.2.

Function menu

Press , balance return to zero.

4 MENU

4.1 Overview

12

Into the function menu: Press

TARE

/

MODE

/

ZERO

/

ZERO

/

MODE

/

pcs

MODE

/

Menu Navigation: Press to switch menu items.

Exit menu: Press for long time to return weighing mode, or press for short time to

return to last menu.

4.2 Function Menu Operation

能功

Max:

Max: gd

能

功

Max: g

Max: gd

Max:

Max: gd

Max: g

去

皮

Max:

Max:

d

g

g

g

g

100%0

Menu

pcs

100%0

Enter the function mode.

In the mode of basic weighing, press for long

time untill screen displys “ ”. It now in the piece mode.

d

g

Function menu switch

g

100%0

g

p

Press for short time to switch different items

100%0

d

g

g

g

g

oz

100%0

oz

g

100%0

d

100%0

ct

d

g

g

g

Menu

pcs

100%0

d

g

pcs

Function menu enter

Press for short time to into the next menu

13

100%0

ZERO

/

ZERO

/

TARE

/

MODE

/

M

ax:gd

g

Return

零

置

Max:

d

g

g

g

100%0

Press for short time to return last menu.

4.3 Basic Weighing Operation

1、 Basic Weighing

Max:

d

g

g

g

shows” ”, put the sample on the weighing pan. When it is stable,

100%0

Max:

d

g

g

Max: gdg

read the data.

g

100%0

g

100%0

2、Weighing with Container

Max:

Max: gdg

皮

去

Max:

Max: gdg

Max:

d

g

g

g

g

g

100%0

g

100%0

d

g

g

100%0

g

100%0

d

g

g

100%0

If it is necessary to weight the object (such as liguid) with a container

(the weight of container will not be including), please follow the streps:

·Put the vacant container on the scale pan firstly.

·Press , then it shows” ”.

·Then put the object for weighing into the container. Please read the data

after the balance is stable.

Press ,to make the balance return to zero, the balance

g

g

14

3、Unit Conversion

能功

Max: g

Max:

Max: gdg

d

g

g

100%0

d

g

g

p

100%0

oz

100%0

There are seveal units in the balance, including gram, pound, gold ounces,

ounces and carat. Press to shift the units.

TARE

/

MODE

/

MODE

/TARE

/

pcs

TARE

/

MODE/

TARE

/

Their relationship as follows

Pound 1P=453.59237g Gold Ounces 1oz.g=31.1034768g

Ounces 1oz=28.349523125 g Carat 1ct=0.2g

4.4 Function Weighing Operation

Press to switch piece count, percentage and system.

1、 Piece Count

The reference coefficient could be chose from 5pcs, 10pcs, 20pcs, 50pcs and 100pcs. The bigger the coefficient is,

the higher precision the result is.

Steps(Such as 10pcs):

·Put container on the balance. (Quit this step if no container is

needed.)

皮

去

Max :

d

g

g

g

100%0

·Press , then balance shows” ”;

g

·Place 10 sample on the weighing pan.

Max : gd

g

能功

皮

去

能功

皮

去

Ma x:

Ma x:

Ma x: gd

Ma x:

Menu

pcs

100%0

d

g

g

g

g

g

pcs

100%0

d

g

pcs

100%0

pcs

100%0

d

g

pcs

100%0

·Press for long time,then balance shows

“ “

·Press enter into piece count mode.

·Press to choose reference coefficient.

·Press to switch to “ “

pcs

·Put the same quantity of sample

·Press for longtime to exit.

Notice:The minimum weight =10d(d:minimum scale), Minimum weight of one piece not less than 1d. The

sample could not be more than maximum weight.

15

Switching between piece and weight reading

ZERO

/

TARE

/

ZERO

/

TARE

/

TARE

/

TARE

/

pcs

%

pcs

TARE

/

MODE

/MODE

/

· Add sample on the container, shows piece count

· Press , shows weight.

· Press again,return to showing piece.

100%

2、Weighing in Percent

Steps:

100%

%

100%

%

100%

%

100%

%

100%

·Put container on the balance. (Quit this step if no container is

needed.)

· Press , then balance shows” ”.

g

· Place sample on the weighing pan.

· Press untill balance show “ “.

· Press to switch “ ”.

· Press twice, then shows “ “.

%

%

· Remove reference sample, then balance shows “ “.

%

· Put the tested sample on the weighing pan.

· Press for long time to exit.

Notice:Notice:The minimum weight =10d(d:minimum scale),. The sample could not be more than maximum

weight.

Switching between percentage and weight reading

· Add sample on the container, shows percentage.

Ma x:

皮

去

Ma x: gd

d

g

g

g

%

100%0

· Press , shows weight.

· Press again,return to showing percentage.

g

100%0

16

4.5 Density Weighing*(The function is just for JS series)

1、Density device installation

Adjust two level adjusting foots.

The fixed ring is mounted to the table top.

秤盘

吊篮

Install the C-Style on the core of

weighting pan, and it could

turn agilely.

Put the shelve table on the working platform, the limited post fix

17

on the edge of fixed circle. Level rotate and the shelve table do not

meet the C-style bracket.

Put arched glass on the shelve table.

Then put the testing shelf on the C-style bracket.

2. Density Mode Select

Long press into the mode menu

Short press into the desity mode.

In the Density Mode, short press to shift:

Solid Density Measure → Liquid Density Measure

(g/cm3). Short press to shift unit of density

→ Standard Solid Set→ Standard Liquid Set

Short press to confirm.

18

3. Standard Material Select

When the material is soluble in water or the density of material is close to the density of water, user could choose

appropriate standard media to measure. The system has set eight kinds of solid density and eight kinds of liquid

density for chosen, also the system store the last choose, avoid repetitive operation. Factory preset material

density in system as follows:

Table One: Standard Liquid Density (Windows Default: 4)

Table Two: Standard Liquid Density (Windows Default: 4)

Table one: Table two:

S-LD Name Standard Density Value

(g/cm3)

1 Gasoline 0.70

2 Alcohol 0.79

3 Kerosene 0.80

4 Water(20℃) 0.998229

5 Water(4℃) 1.0000

6 Honey 1.40

7 Bromine(0℃)

3.12

8 Mercury 13.60

9 User-defined

4.

Opera

tion

1)

Solid

Densit

y

Measu

re

S-SD Name Standard Density Value

1 Wax 0.9

2 Aluminum 2.7

3 Copper 8.9

4 Steel 7.8597

5 Silver 10.5

6 Aluminum 11.3

7 Gold 19.3

8 Osmium 22.5

9 User-defined

1.

Balance display , and then remove the object on the weighting pan and press

(g/cm3)

2. Balance display , until showing put the measure solid on the weighting pan. When the

g

balance is table, press .

3. Balance display , until showing , immerse the measure solid to the liquid. When the

g

balance is stable, press .

4. Balance display , Showing the density of measure solid.

19

5. Short press , return to the step one.

6. In the process of measurement, press , to return to the step one directly.

2)Liquid Density Measure

1. Balance display , and remove the object on the weighing pan and basket, then short

press .

2. Balance display , until showing put the solid which have known the density on the

g

weighting pan. When the balance is stable, press.

3. Balance display , until showing . Immerse the solid into the measure liquid. When balance

g

is stable, press.

4. Balance display ,showing the density of measure liquid.

5. Short press , return to the step one.

6. In the process of measurement, short press to return to the step one directly.

3)Standard Solid Set

1. Balance display , XX means the solid system selecting currently.

2. Short press , to shift the kind of solid. Balance display , the range of XX is from 01 to 09.

XX

-XX

Each number stands each kind of standard solid.

3. Short press , select current solid. Balance display to return to the step one.

XX

4) Standard Liquid Set

1. Balance display ,XX means the liquid system selecting currently.

2. Short press ,to shift the kind of liquid. Balance display t, the range of XX is from 01 to 09.

XX

-XX

Each number stands each kind of standard liquid.

3. Short press , select current solid. Balance display to return to the step one.

XX

Notice: In the process of measurement, press at any time to return to the mode of basic weighing.

5)User-defined Standard Material

According to the method of test of solid density or liquid density to measure the density of a

standard material. When balance display the density of material, long press

Then store the density of standard material to the corresponding table number 09

20

6)Example----Solid Density Measure (Example for JA3003J)

1. Start the Balance and warm-up. Then install the density device.

2. Long press , enter the mode of switching –mode, short

press to . Short press enter the mode of

density of solid.

3. Short press to start measure.

Max:

4. Put the determined object into the weighting pan

d

g

g

g

100%00

5. After weighting stably, press

Max: gd

g

6. Put the determined object on the nacelle under the testing shelf.

g

100%0

Notice: Immerse the object into the liquid.

7. When balance is stable, shore press , balance display the

density of measured solid.

Notice: In order to ensure the accuracy of measurement, in the process of measurement, the test shelf do not

touch the glass, the C-style bracket do not touch the shelve table.

7). Example-----Liquid Density Measure (Example for JA3003J)

21

1. Start the Balance and warm-up. Then install the density device.

TARE

/

MODE

/

2. Long press , enter the mode of switching –mode, short press

enter . Short press enter the mode of density

Short press to into the . Press enter the

density of liquid.

3. Short press to start measure.

4. Use the determined liquid into cup (about 2/3 of cup)

Press to start measure.

5. Put the standard plumb on the weighting pan

Max:

d

g

g

g

100%0

6. Press after stable.

Max:

d

g

7. Put the standard plumb on the nacelle

Notice: Immerse plumb into the liquid.

8. Press after stable. The balance display the density

of the determined liquid.

Max: gd

g

Menu

3

/cm

g

100%0

4.6 System

This series balance can check temperature, data and time. Press untill shows “ ”, then

g

g

100%0

22

press key shortly to choose. Press to switch after enter system.

ON/OFF MODE

/

TARE

/

TARE

/

TARE

/

CAL/

4.7 Date Communication

Press , could output the current reading of weight from RS232C port. There is another way to output

reading date, shown at part seven.

5 CONFIGURING BALANCE

5.1 Operating the Configuring Keys

·Connet to the power. Keep pressing both the and on the shutdown of balance.

·Balance full – screen displays and displays self-inspection sign, then display

·Page area, line area and word area all display number from “ zero ” to a certain number automatic circulated

·The zero show in page, line or word area means that if now press shortly, the balance will

return to last menu.

·Nonzero digital in page or ine zrea, if press shortly, enter to the next menu.

· Nonzero digital in word area, if press shortly, select setting and showing “V” at same time.

C ×

Page area line area word area

· When balance displays , the “V” means the new setting is valid.

· All functions are set on when produced. No need to set all the functions. You can set some of the functions to

meet your special requirements.

23

Page area line area word area

C××× V

C 2 1 4 Auto print not stoppable at stability

5.2 Balance Function Setting List(* measn factory set)

Page Line Word Function Optional

C 1 1 1

C 1 1 2 stable *

C 1 1 3 Unstable

C 1 1 4 Very unstable

C 1 2 1

C 1 2 2 0.5 digit

C 1 2 3 1 digit *

C 1 2 4 2 digit

C 1 2 5 4 digit

C 1 2 6 8 digit

C 1 2 7 16 digit

C 1 2 8 32 digit

C 1 2 9 64 digit

C 1 3 1

C 1 3 2 Not displaying the last decimal place

C 1 3 3 Display the last decimal place stability

C 1 3 4 Display all decimal places at stability

C 1 4 1

C 1 4 2 Remove at stability *

C 1 5 1

C 1 5 2 Auto-zero off

C 2 1 1

C 2 1 2 Print on request after stability *

C 2 1 3 Auto print no stoppable regardless of stability

Adapting the balance to ambient

conditions

Ambient conditions

Stability range

Display

Remove the container

Auto-zero function

RS232C output

Remove regardless of stability

Print on request regardless of stability

Very stable

0.25 digit

Display all decimal places *

Auto-zero on *

C 2 2 1

C 2 2 2 2400

C 2 2 3 4800

C 2 2 4 9600 *

C 2 2 5 19200

24

1200

Baud

C 2 2 6 38400

C 2 2 7 57600

C 2 2 8 115200

C 2 3 1

C 2 3 2 6

C 2 3 3 7

C 2 3 4 8 *

C 2 4 1

C 2 4 2 2

C 2 5 1

C 2 5 2 Odd

C 2 5 3 Even

C 2 5 4 Retention for 1

C 2 3 5 Retention for 0

C 3 1 1 Version

C 3 1 2 Linear correction

C 3 1 3 Recovery factory set

Data Bit

Stop Bit

Parity

5

1 *

无 *

End

5.3 Balance Setting Funcation Explain

【Adapting the balance to ambient conditions】:Room to place the balance uses ordinary air-condition, generally

select C113. If the air is large, should select C114.

【Ambient conditions Stability range】:If need to weighing quickly, can extend the display range. If the air is

lager,should extend the range.

【Display】:Select your desired mode.

【Remove the container】:Please operate carefully if you select 141.

【Auto zero】:To do measurement ranging from a few to tens of digit around zero, please choose C152, and please

pay attention to drifting of the zero digit, that might affect the precision of the measurement.

5.4 Balance Setting for Quick Weighing

【Adapting the balance to ambient conditions】:Select C111or C112, the speed is more fast.

5.5 Balance Setting for Strong Air Enviroment

Avoid strong air , select C114, C126, C127, C128, C129, C141 or C211.

5.6 Balance Setting for Linear Correction

Balance completely preheating, first to calibraion, then shutdown the balance. Restart the balance, thenenter the

setting mode. Choose linear correction function (C312)

25

“ ”flickering means that there is nothing on the weighing pan. Press shortly. When send

TARE

/

TARE

/

out voice of “du” and stop flickering, it is means finishing corretion. Then the balance auto turn to the next

correcting point “ ” , it need to add 50g weight. Then press shortly to ensure. After

finishing all the correction point, the balance will display “ ”. Now the balance is still processing the

data, please wait. Finishing data processing, the balance will shut down automatically.

5.7 Recover Factory Setting

If customer need to recovery the factory setting, please enter the balance setting mode when starting. Choose

C313 to recover, then the balance will shut down automatically. Also it need to do linear correction.

6 TECHNICAL PARAMETERS, FUNCTION OPTIONSL,

PARTS OPTIONAL, DIMENSION

6.1 Technical Parameters

Standard Configuration Protection Class

·Power:100-240VAC、50/60Hz。 ·dustproof, waterproof

Output:DC12V、600mA ·Pollution prevention level: 2

·Installation category: 11

Raw Material Environment Requirement:

·Bass:pack alloy, painting ·Environment Conditions:

·Cover:plastic (ABS/PC)

·Weighing pan:stainless steel 20℃±7.5℃,fluctuations in temperature is not more

26

·Environment Temperature: 20℃±2.5℃ fluctuations in

temperature is not more than 1℃/h

than 5℃/h

·Relatice Humidity: 50%~75%; 40%~80%

·Working Voltage: 124DC; 12VDC

Parameter List

·There is no vibration, air and magnetic to effect

measurement.

·The preheating is at least 45 minutes, 1 hours is more better.

FA series

FA1204 FA2204

Actual division value(d)

Verification scale interval(g)

Weighing Capacity(Max)

Repeatability(s)

Linearity(-/+)

Maximum Permissible Error(Mpe)

Calibraion Weight 50g 50g

Type Standard

Dimension(W/D/H)(mm) 238×335×364

Packing Measurement(W/D/H)(mm)

Pan Size(mm) φ90

Effective height above pan(mm)

Net Weight(Gross Weight)kg 5.8(8.2)

0.0001g 0.0001g

0.001g 0.001g

120g 220g

0.0001g 0.0001g

0.0002g 0.0003g

GB/T26497-2011

520×385×555

220

FB series

27

FB124 FB224 FB223 FB323 FB423

Actual division value(g)

Weighing Capacity(g)

Repeatability(g)

Maximum Permissible Error(MPE)

Calibraion Weight(g)

0.0001 0.0001 0.001 0.001 0.001

120 220 220 320 420

0.0001 0.0001 0.001 0.001 0.001

GB/T26497-2011

100 200 200 200 200

Type Standard

Dimension(W/D/H)(mm)

Packing Measurement(W/D/H)(mm)

365×223×338

500×310×450

Pan Size(mm) φ90

Effective height above pan(mm)

Net Weight(kg)

Gross Weight(kg)

150×165×200

6

8

JS series

FA1104J FA2104J JA3003J JA5003J

Actual division value(g)

Weighing Capacity(g)

Measured the air quality ≥0.25

Measured by the buoyancy of water

Output RS232C

Maximum Permissible Error(MPE)

Calibraion Weight(g)

Type

Dimension(W/D/H)(mm)

Packing Measurement(W/D/H)(mm)

Pan Size(mm) φ90

Effective height above pan(mm)

Net Weight(kg)

Gross Weight(kg)

28

0.0001 0.0001 0.001 0.001

110 210 300 500

<- 0.125

GB/T26497-2011

100 200 200 500

安装

365×223×338

500×310×450

150×165×200

6

8

TARE

/

6.2 RS232 Port

29

Each balance can be connected to equipment through RS232. ( For example:

RS232 series printer or Computer with 9 needles).

Connect to printer, parameter setting:

C2 2×、C2 3×、C2 4×、C2 5× then press shortly.

6.3 Figure Dimension

Balance

30

acant

acant

7 APPENDIX

7.1 RS232 Port Date Communication

Connect to microcomputer setting as follow:

Microcomputer: (9 needle hole)——Balance(9 needle hole)

2(SI)——3(SO)

5(GND)——5(GND)

Port baud: 9600bps。

Data format: 10 bit Start bit:(0) Data bit: 8(ASCII code,low in the former) Stop bit(1)

No Parity

The data is for continuous output, does not need special reading command.

One string output format:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

± V

code

Weighting area V

code

Unit

area

Return Line

feed

31

3~11 weighing area,same to the balance. The byte no showing is vacant code.

13~14 unit area,may be not same to the balance.

Balance display

13 14

g g(lowcase) vacant code

oz o(lowcase) z(lowcase)

oz.g o(lowcase) g(lowcase)

ct c(lowcase) t(lowcase)

p p(lowcase) vacant code

pcs p(lowcase) s(lowcase)

% % vacant code

Output

7.2 Failure Information and Solutions

Recovery Processing:Please contact your sales department or us if your balance works wrongly.

Some problems can be solved immediately.

1)If the self-test is not correctly performed, will display as follow:

E C ×

E C 2

E C 3

E C 4

2)Errors occurred during weighing

CPU broken, need to repair.

Keyboard error

Storage lost

A/D model is not started

a. Weight is too heavy, exceed the max weight:

·The sample is too heavy, please decrease the weight.

·The balance may be calibrated incorrectly (using calibration weight lighter than the standard),

32

H

please re-calibrate your balance.

ON/OFF TARE

/

ZERO/

b. Weight is too light:

L

·The weighing pan is not in place.

·Check below the weighing pan, see if it is touching any objects.

c. Display over 9999999. Display capacity exceeded.

E1

• If occurred at piece count, unload the balance ( disappear ), re-select the samples.

E1

20,50,100 or more pieces of samples can be taken as 10 pieces of samples. Each time multiply the weight by the

number ( divide the number of the pieces you take by 10 )

If occurred at weighing in percent, unload the balance ( disappear ), and reselect sample.

E4

d. When gross value <- 0, no tare

·Press “tare” key, tare.

·Unplug the power adapter. Then plug in after 10 seconds.

e. Error occurs when receiving data through RS232C

E8

·Press , , if disappears, please check data communication.

E8

·Unplug the power adapter. Then plug in after 10 seconds.,recheck the set of data communication.

f.The weighting data do nor changeable with weighting changing.

·Recheck the data communication.

·The balance may be calibrated incorrectly (using calibration weight heavier than the standard), please

re-calibrate your balance.

3)When balance display , it means storage lost. Please press “MODE” & “TARE” to try to

E C 3

restore data.

4)After power connection, press , the balance display for long time in

-——————————

self-checking. It indicates an unstable weighing location.

·The glass door is improperly shut down.

·Check below the weighing pan, see if it is touching any objects.

·Strong airflow, please reset the balance.

·There is more than 20% object on the weighing pan.

7.3 Maintenance and Cleaning

Maintenance

The regular maintenance will extend the life of balance.

33

Cleaning

Please use a soft and non-fluffy cloth to clean the figure and pa. If necessary, can use neuter cleaner.

Explain

It is recommended that clean the pan and workbench after weighing chemicals.

7.4 Density Parameter Table

Table 1(Sample size table)

Density effective number of three digital

(Repeatability≤±0.0001g/cm3)

JA3003J JA5003J FA1104J FA2104J

Densityρ

Sample Quality

(g/cm3)

(≥g)

0.10 0.020 0.020 0.0020 0.0020

Sample Quality

(≥g)

Density effective number of three digital

(Repeatability≤±0.0001g/cm3)

Sample Quality

(≥g)

Sample Quality

(≥g)

0.20 0.080 0.080 0.0080 0.0080

0.30 0.180 0.180 0.0180 0.0180

0.40 0.320 0.320 0.0320 0.0320

0.50 0.500 0.500 0.0500 0.0500

0.60 0.720 0.720 0.0720 0.0720

34

0.70 0.980 0.980 0.0980 0.0980

0.80 1.280 1.280 0.1280 0.1280

0.90 1.620 1.620 0.1620 0.1620

1.00 2.000 2.000 0.2000 0.2000

2.00 8.000 8.000 0.8000 0.8000

3.00 18.000 18.000 1.8000 1.8000

4.00 32.000 32.000 3.2000 3.2000

5.00 50.000 50.000 5.0000 5.0000

6.00 72.000 72.000 7.2000 7.2000

7.00 98.000 98.000 9.8000 9.8000

8.00 128.000 128.000 12.8000 12.8000

9.00 162.000 162.000 16.2000 16.2000

10.00 200.000 200.000 20.0000 20.0000

11.00 242.000 242.000 24.2000 24.2000

12.00 288.000 288.000 28.8000 28.8000

13.00 -- 338.000 33.8000 33.8000

14.00 -- 392.000 39.2000 39.2000

15.00 -- 450.000 45.0000 45.0000

Explanation: the solid density measurement, the sample of different quality, dimensional accuracy and

repeatability is different. In order to improve the measurement accuracy, reduce the measuring error; please refer

to the sample chart to choose the appropriate sample size

35

Table 2 (Commonly used material density table)

No Material Density No Material Density

1 Construction Steel 7.85 27 Interleaving Paper 0.9

2 Cast Steel 7.8 28 Fiber Paperboard 1.1~1.4

3 Grey Cast Steel 6.8~7.2 29 Waterproof Paper 1.0~1.1

4 High-Quality Cast Iron 7.0~7.6 30 Felt 0.24~0.38

5 Malleable Cast Iron 7.2~7.4 31 Rubber 1.3~1.8

6 Hard Alloy (Tungsten Alloy) 13.9~14.9 32 Cork 0.25~0.45

36

7 Tungsten Carbide

9.5~12.2 33 Mica 2.8~3.2

(Titanium Alloy)

8 Aluminum 2.77 34 Amino Plastic 1.45~1.55

9 Pressure Processing

2.67~2.8 35 Asbestos Cloth Plastic 2

Aluminum Alloy

10 Foundry Aluminum Alloy 2.6~2.85 36 Asbestos Screen Plastic 2

11 Babbitt Metal 7.5~10.5 37 Fibre Resin 1.35~1.45

12 Red Copper 8.89 38 Paper Fillin Plastic 1.4~1.7

13 Pressure Processing with

8.4~8.85 39 Fabric Bakelite 1.3~1.4

Brass

14 Casting Brass 8.622 40 Polyvinyl Chloride Plastics 1.28~1.37

15 Cast Bronze without Tin 7.5~8.6 41 Celluloid 1.35~1.40

16 Pressure Processing Tin

8.65~8.9 42 Organic Glass 1.18

Bronze

17 Nickel 8.9 43 Glass 2.5~2.7

18 Manganese 7.44 44 Leather 0.86~1.02

19 Magnesium 1.74 45 Graphite 1.9~2.3

20 Tin 7.3 46 Gasoline 0.66~0.75

21 Lead 11.34 47 Kerosene 0.78~0.82

22 Silver 10.5 48 Alcohol 0.807~0.810

23 Gold 19.361 49 Charcoal 0.27~0.58

24 Platinum 21.561 50 Smokey Coal 1.2~1.5

25 Zinc (Casting) 6.872 51 Anthracite 1.4~1.8

26

Wood(Humidity 15%)

0.4~1.05 52 Coke 0.27

Note: the value in the table is mostly approximation, for reference only.

37

Loading...

Loading...