Sony Ericsson K850 Schematics

ABOUT

SEMC Troubleshooting Manual

Troubleshooting Manual

K850

K850

ABOUT TROUBLESHOOTING MEASUREME NT POINTS

1203-2528 rev. 1

APPENDIXCOMPONENT OVERVIEW FUNCTIONAL OVE R VIEW

1 (101)

ABOUT

Con tents

SEMC Troubleshooting Manual

K850

ABOUT

General information

The purpose of this document is to provide enhanced technical information for Sony Ericsson

repair technicians in order to assist during service, repair and troubleshooting operations on Sony

Ericsson mobile phones. It should be used as a complement to other repair instructions and tools

as notifi ed by the local Sony Ericsson representative.

To search for components throughout the entire document use the “search” function in Adobe

Acrobat Reader 7.0 (or later version) and enter the component name or other word. Use zoom to

enlarge.

For easier navigation of the document you can use the bookmarks that appear in the Bookmarks

tab on the left side of the Adobe Acrobat Reader window. Each bookmark jumps to a page in the

document.

Disclaimer

This document is Sony Ericsson confi dential and should be treated as confi dential in accordance

with the agreement with Sony Ericsson. This document is intended for use by authorized service

technicians only. Sony Ericsson is not to be held responsible for any damages or losses caused

intentionally or unintentionally due to unauthorised use of the information in this document.

Revision History

Rev. Date Changes / Comments

1 2/14/2008 Initital revision.

ABOUT 2

Contents 2

TROUBLESHOOTING 3

Equipment List 3

On/Off Problems 8

Flash Problems 8

Dead Phone Problems 9

Display Problems 9

Display Illumination Problems 10

Key Problems 10

LED Problems 11

Main Camera Problems 11

VGA Camera Problems 12

Camera Door Problems 12

Vibrator Problems 13

Charging Problems 13

USB/VBUS Charging Problems 14

SIM Problems 14

Memory Stick Problems 15

Audio Internal Problems 15

Audio External Problems 16

FM Radio Problems 16

Bluetooth Problems 17

GSM Network Problems 18

WCDMA Network Problems 18

Xenon Flash Problems 19

System Connector Protection Test 20

Current Comsumption Test 20

Battery & Current Calibration Test 22

Backup Capacitor Test 22

Test Charging 23

ASIC Revision Test 23

Reference Measurement Points 24

TEST POINTS 25

Front Side 25

Back Side 26

SIM & Memory Card Holder 27

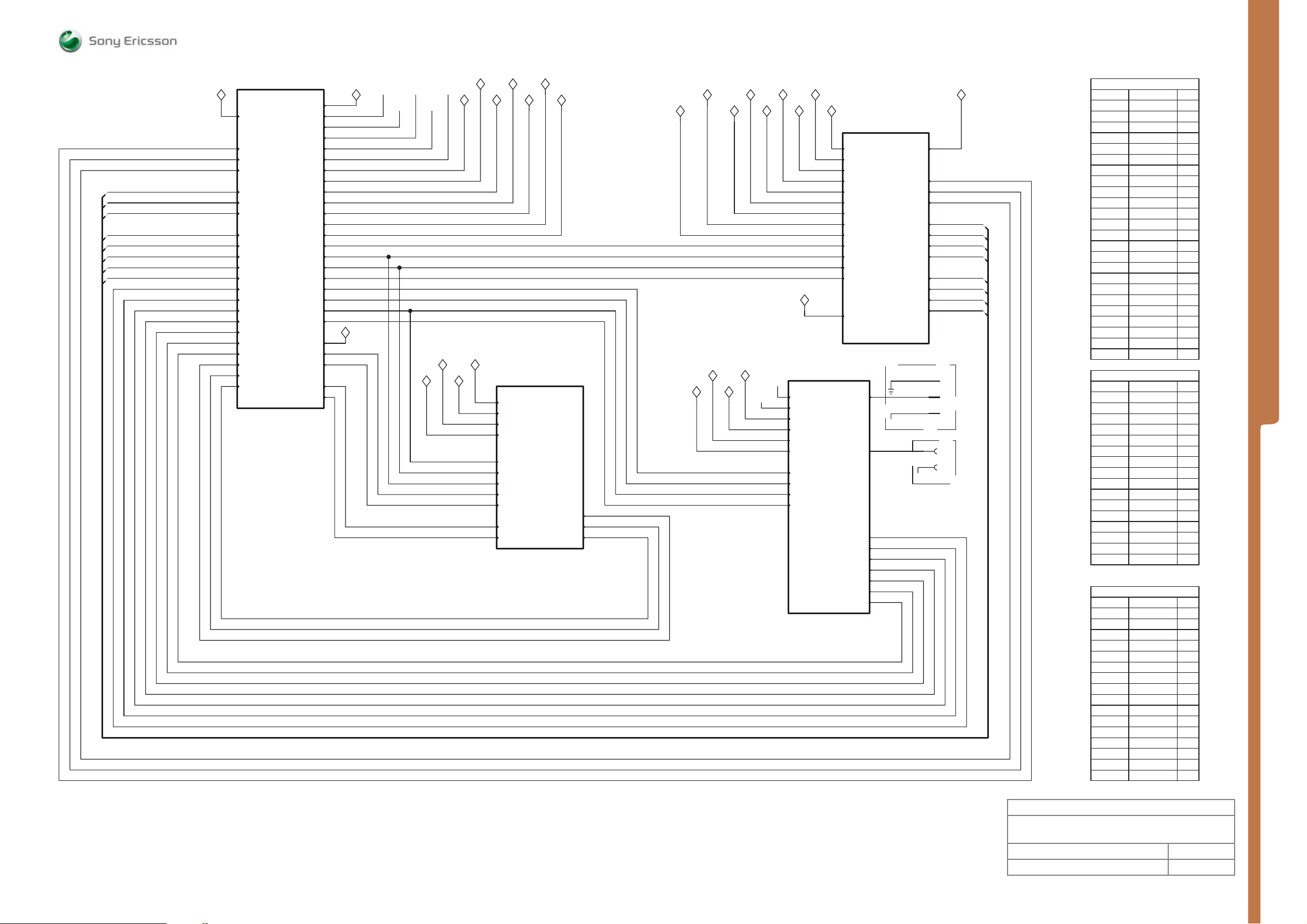

Sofi a Top Schematic 28

Application & System Performance Top 29

System Top 30

System Control - Clocks & Resets 31

System Memories 32

Power Top 33

Power Regulators & Charging 34

Power Camera 35

Power ASICs 36

Power Memories 37

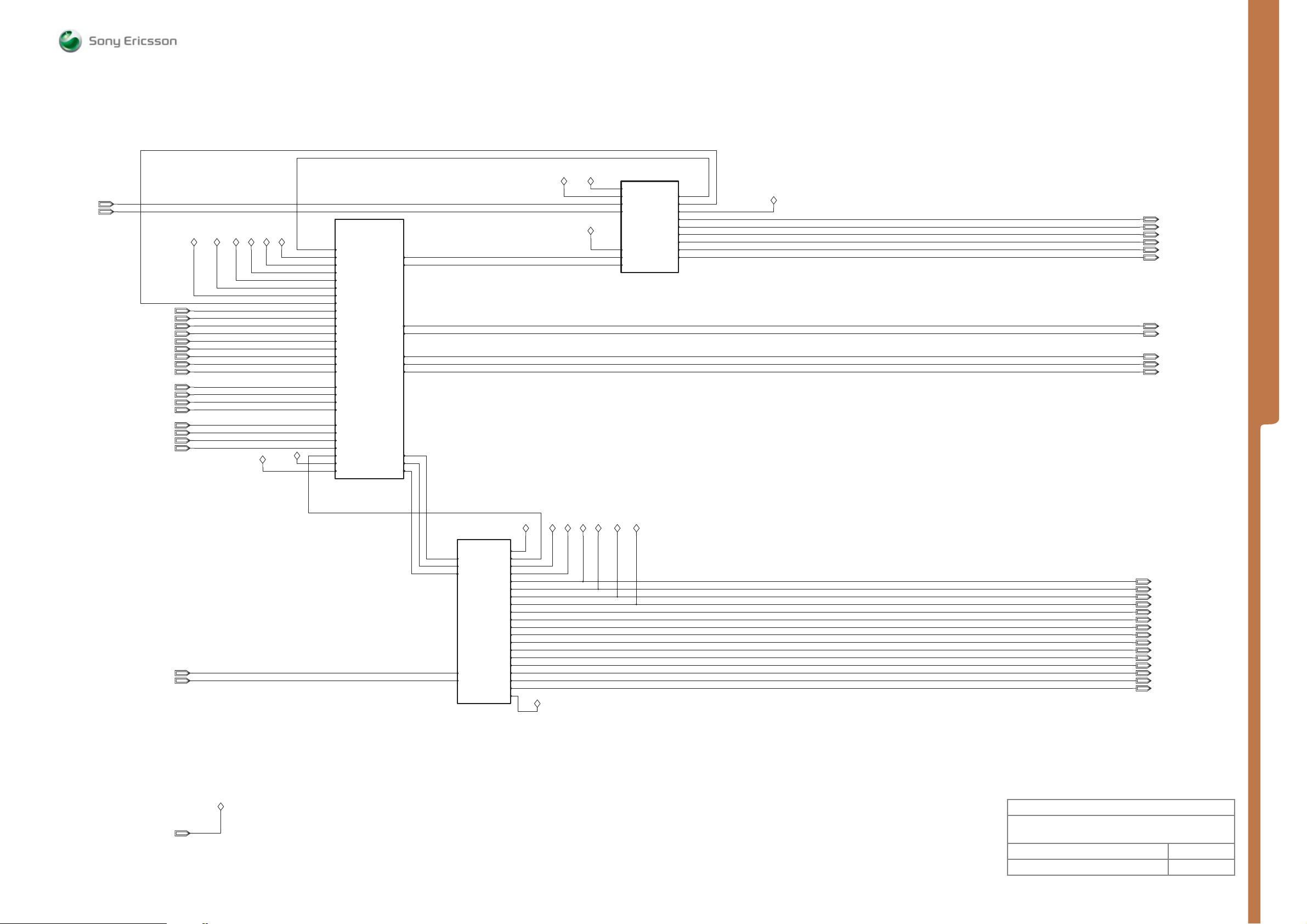

Connectivity Top 38

Connectivity ADC & I2C 39

Connectivity Cards 40

Connectivity Connectivity 41

Connectivity Keypad 42

Connectivity Camera Door & Flash 43

Access Top 44

Access - GSM & UMTS 45

Access - Bluetooth 46

Imaging Top 47

Imaging Display 48

Imaging Camera 49

Imaging LMU 50

Audio Top 51

Audio Analog 52

Audio Digital 53

FM Radio 54

Test 55

Thor RF Module Top 56

Thor RF Module GSM/EDGE Tx + FEM 57

Thor RF Module GSM/EDGE Rx + Synth 58

COMPONENT OVERVIEW 59

Front Side B - X 59

Back Side C - E 60

Back Side L - Z 61

FUNCTIONAL OVERVIEW 62

Technical Description 62

Block Diagram Access 71

Block Diagram Application 72

Power Distribution & Clocking Concept 73

APPENDIX 74

Replaceable Parts 74

Components B2101 - D2000 75

Components D2010 - D2105 - D2404 76

Components D2420 - D2460 77

Components L2200 - L2401-04 - N1200 78

Components N1210 - N1400 79

Components N2000 - N2201 80

Components N2202 - N2203 81

Components N2205 - N2208 82

Components N2400 - N2402 - N2500 83

Components N2525 - N3100 - N3101 84

Components N4101 - N4200 85

Components S2400 - S2402 - S2403 86

Components V2202 - V2402 - V2405 86

Components V2420-21 - V2425 - V2428 87

Components V2477-78 - V2500 87

Components X1200 - X1201-03 - X2200 88

Components X2409 - X4300 - X2410 89

Components X2511 - X3105 89

Components X4301 90

Camera Module 5 MPixel 90

VGA Camera 90

Xenon Flash Assembly 91

Display 91

Keyboard Schematics 92

Troubleshooting Software Documentation 93

Troubleshooting Fixture Setup Guide 100

ABOUT

1203-2528 rev. 1

2 (101)

TROUBLESHOOTING

Equip ment List

SEMC Troubleshooting Manual

K850

K850 Equipment List

Note: More additional information about the equipment used for TRS can be found in Repair

Tools Catalogue on CSPN or on the following location: CSPN – Repair Instructions – Electrical –

K850 – Equipment List.

TRS Fixture Kit

Location: CSPN-Repair Instructions-Electrical-K850-Equipment List

Dummy Battery

Location: CSPN-Repair Instructions-Electrical-K850-Equipment List

Part number: 1200-0725

Instruments

Power Supply Channel 1 VBATT

Agilent 6632B or similar

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

Instrument Settings:

Voltage: 3.8 Volt

Limiter: 2A

Note: During the calibration the accurate voltage from the VBATT must be within ±0.015 V. If this

is not fulfilled it will result in a faulty calibration. (For more information about recommended power

supply units, see the Repair Tool Catalogue on CSPN under the Mechanical level. The Power

Supply Channel 1 VBATT must allow reverse current.

Note: Maximal cable length between the Power Supply Channel 1 VBATT and the dummy

battery must not exceed 1m. The cable must have a capacity for at least 16A.

Digital Multimeter (DMM)

Fluke 83 or similar

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

Spectrum Analyzer

HP 8595E or similar

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

RF probe

HP 85024A or similar

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

Mobile Phone Tester

Yokogawa VC230 or similar

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

FM Signal Generator

Agilent E4433B or similar

Location: -

RF Connectors

Adaptor 33 N-BNC-50-1

Adaptor to Signal Generator RF Output

Se Picture 1

Location: -

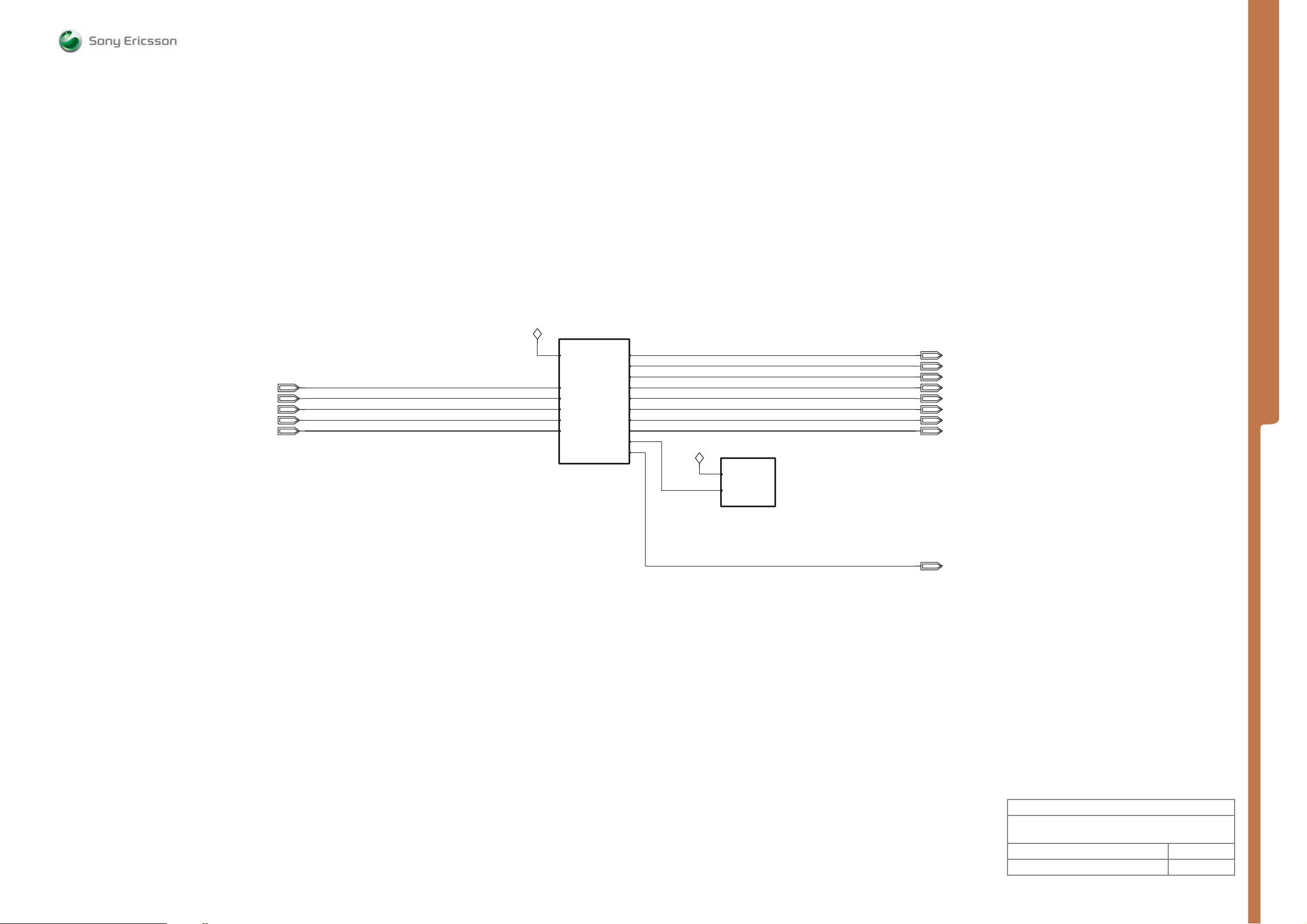

Picture 1

TROUBLESHOOTING

Note: It is very important to follow instrument settings instructions when performing the Battery

Calibration Test.

Power Supply Channel 2 DCIO/SEPI

Agilent 6632B or similar

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

Instrument Settings:

Voltage: 5.0 Volt

Limiter: 2A

Note: It is very important to follow instrument setting instructions when performing the Current

Calibration Test.

Oscilloscope

Tektronix TDS 2012 or similar

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

PC Package & PC Software

PC Package (Computer)

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

1203-2528 rev. 1

3 (101)

TROUBLESHOOTING

Equipment List

SEMC Troubleshooting Manual

K850

Urquell Fault Trace SW with project file

Location: CSPN-Repair Instructions-Electrical-Trouble Shooting Application

Project File: K850Project_R1A

Drivers

SEPI BOX Drivers

Location: EMMA III-Drivers-SEPI

SE Communication Interface SEPI BOX

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

Part number: LTN 214 1484

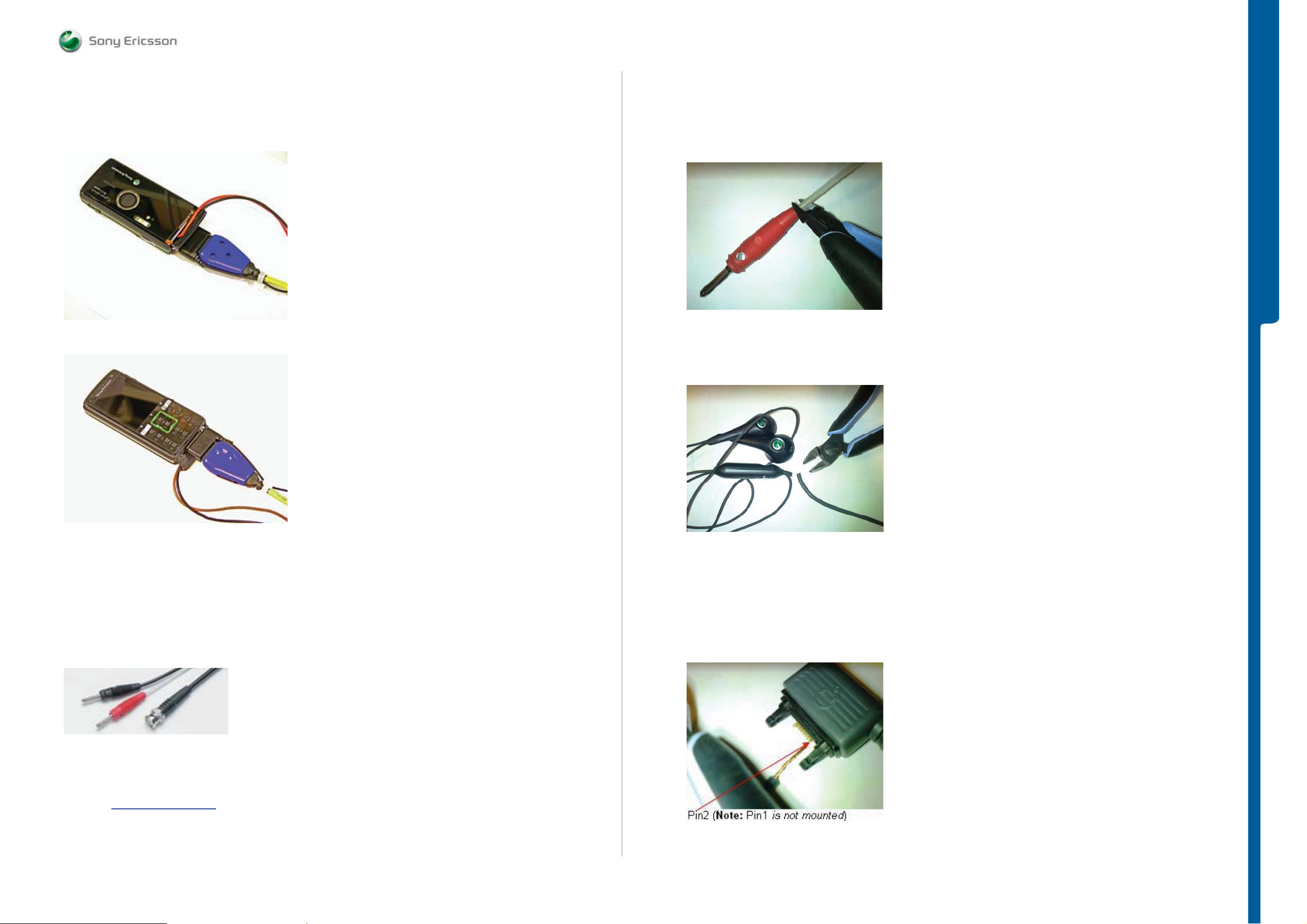

Se Picture 2.

Picture 2

RF Test Cable Flexible

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

Part number: RPM 119 885

Se Picture 4.

Picture 4

SEPI Interface Cable

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

Part number: KRY 101 1119/1

Se Picture 5.

– A1

TROUBLESHOOTING

Cables

USB Computer Cable

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

Se Picture 3.

Picture 3

DSU-60/USB Cable

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

Part number: KRY 101 1413

Picture 5

Power Cable RED to Power Supply Channel 1 VBATT

Maximum Length: 1m

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

Power Cable BLACK to Power Supply Channel 1 VBATT

Maximum Length: 1m

Location: CSPN-Repair Instructions-Level: Mechanical-Tool Catalogue

Customized Power Supply Channel 2 DCIO/SEPI Cable

To perform Current Calibration the phone must be supplied directly through the system connector.

Customize the cable according to following instructions:

1203-2528 rev. 1

4 (101)

TROUBLESHOOTING

Equipment List

SEMC Troubleshooting Manual

K850

STEP 1:

Take the CST-75 battery charger and cut of the charger according to Picture 6.

Picture 6

Note: Cable length must be exact 1.3m.

STEP 2:

Connect the CST-75 charger Red or White wire to the Plus Output and the Black wire to the

Minus (GND) Output at Power Supply Channel 2 DCIO/SEPI according to Picture 7.

Picture 7

STEP 4:

Connect DCIO and SEPI Interface Cable – A1 cables according to Picture 9.

Picture 9

TROUBLESHOOTING

The setup in Picture 10 is WRONG!

Picture 10

STEP 3:

Trim the flex protection material from inside of the charger plug according to Picture 8.

Picture 8

Power Supply Channel 2 DCIO/SEPI Cable Connection Setups

Correct DCIO/SEPI Cable setup when TRS Fixture is used.

Picture 11

Note: Example of DCIO/SEPI and K750 TRS Fixture Setup.

1203-2528 rev. 1

5 (101)

TROUBLESHOOTING

Equipment List

SEMC Troubleshooting Manual

K850

Correct DCIO/SEPI Cable setup without the TRS Fixture.

Picture 12

Picture 13

STEP 2:

Cut the Red lab plug according to Picture 15

Picture 15

TROUBLESHOOTING

STEP 3:

Use any Hands free (PHF) Cable and cut according to Picture 16

Picture 16

Customized FM Radio Cable

STEP 1:

Use Cable according to Picture 14

Picture 14

Product Name: Test lead BNC-4mm 1,5m

Product Description: Test lead with 4 mm lab plugs at one end and a BNC plug at the other.

Manufacturer: PMK Germany

Location: http://www.elfa.se/en/

Part number: 46-310-40 (Note: This is ELFA part number)

or other supplier.

Note: Minimum Cable length 40 cm.

STEP 4:

Use only wire connected to Pin2 and cut all rest wires according to Picture 17.

Use digital multimeter instrument (DMM) and perform diode measurement to select wire

connected to Pin2 at hands free system connector plug.

Picture 17

1203-2528 rev. 1

6 (101)

TROUBLESHOOTING

Equipment List

SEMC Troubleshooting Manual

K850

STEP 5:

Connect by soldering cable from Picture 15 and cable from Picture 17 according to Picture 18.

Picture 18

Test Cards

Dummy SIM

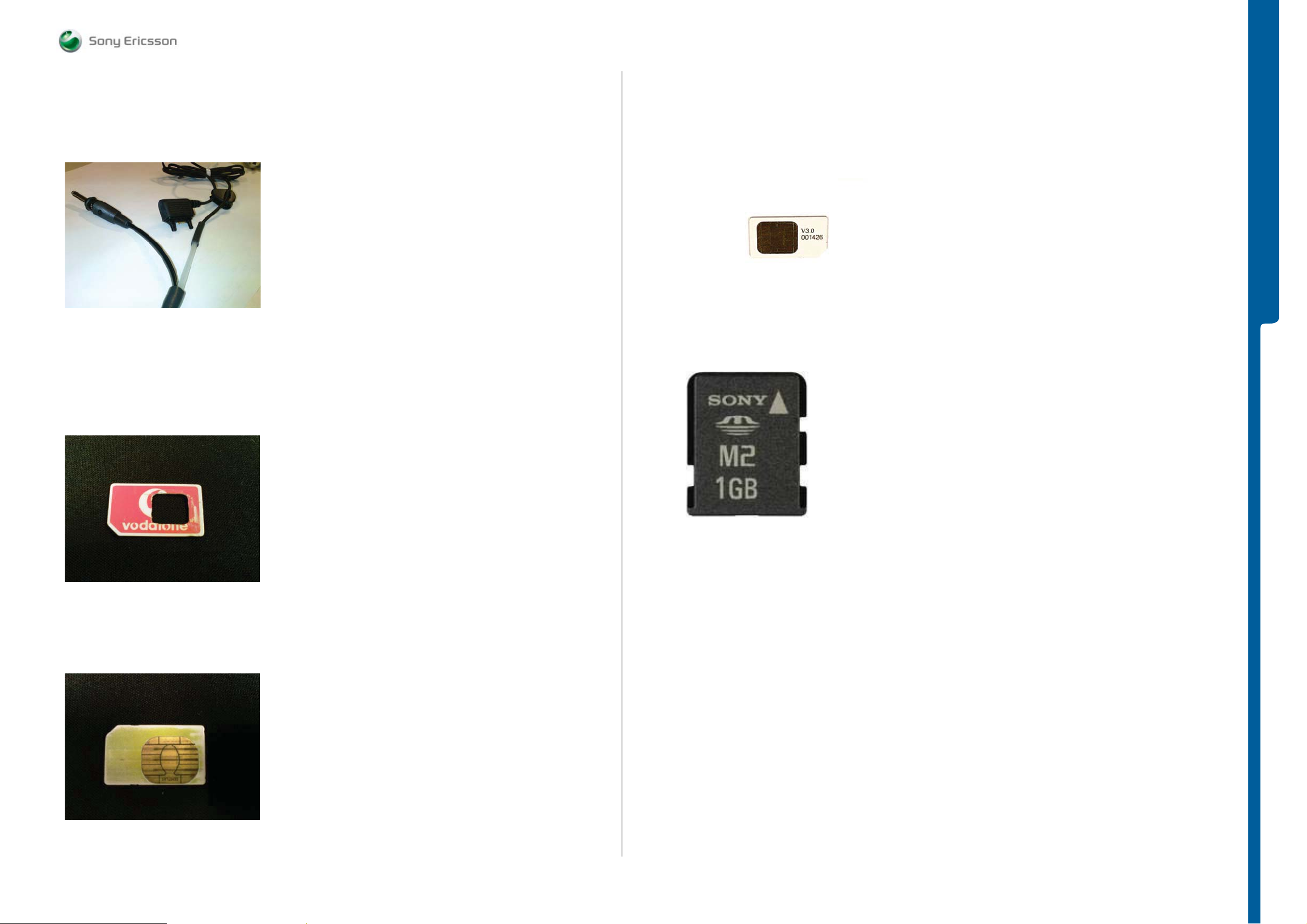

Customize SIM Card according to Picture 19.

Picture 19

Test SIM GSM/UMTS

One Test SIM GSM/UMTS is needed to perform Current Consumption Test, se Picture 21.

Location: To buy a Test SIM GSM/UMTS, please contact your supplier of test equipment.

Picture 21

TROUBLESHOOTING

Sony Memory Stick Micro Card M2

Any functional Memory Stick Micro M2 Card, se Picture 22

Picture 22

Local SIM

Any functional Local SIM Card, se Picture 20

Picture 20

1203-2528 rev. 1

7 (101)

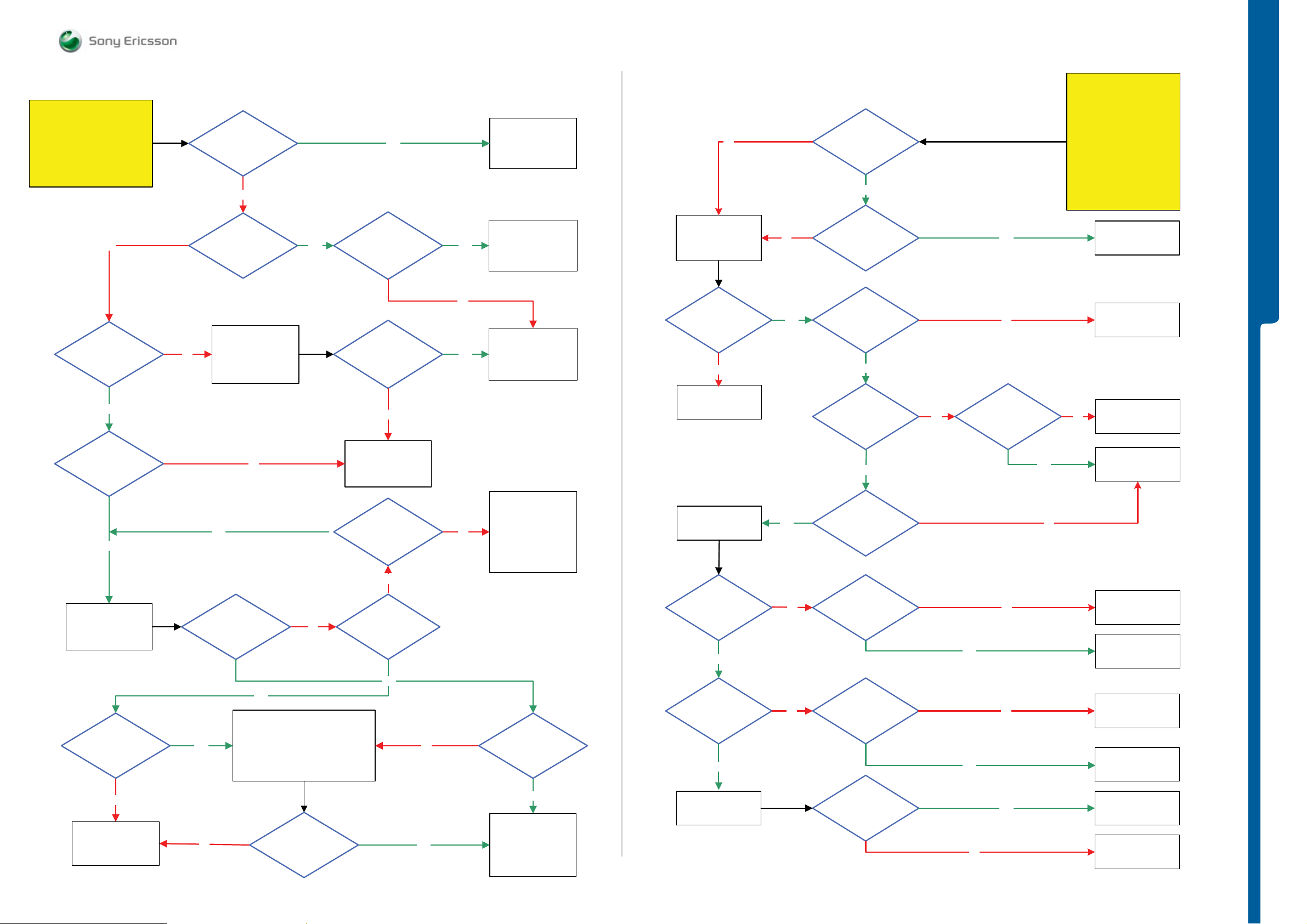

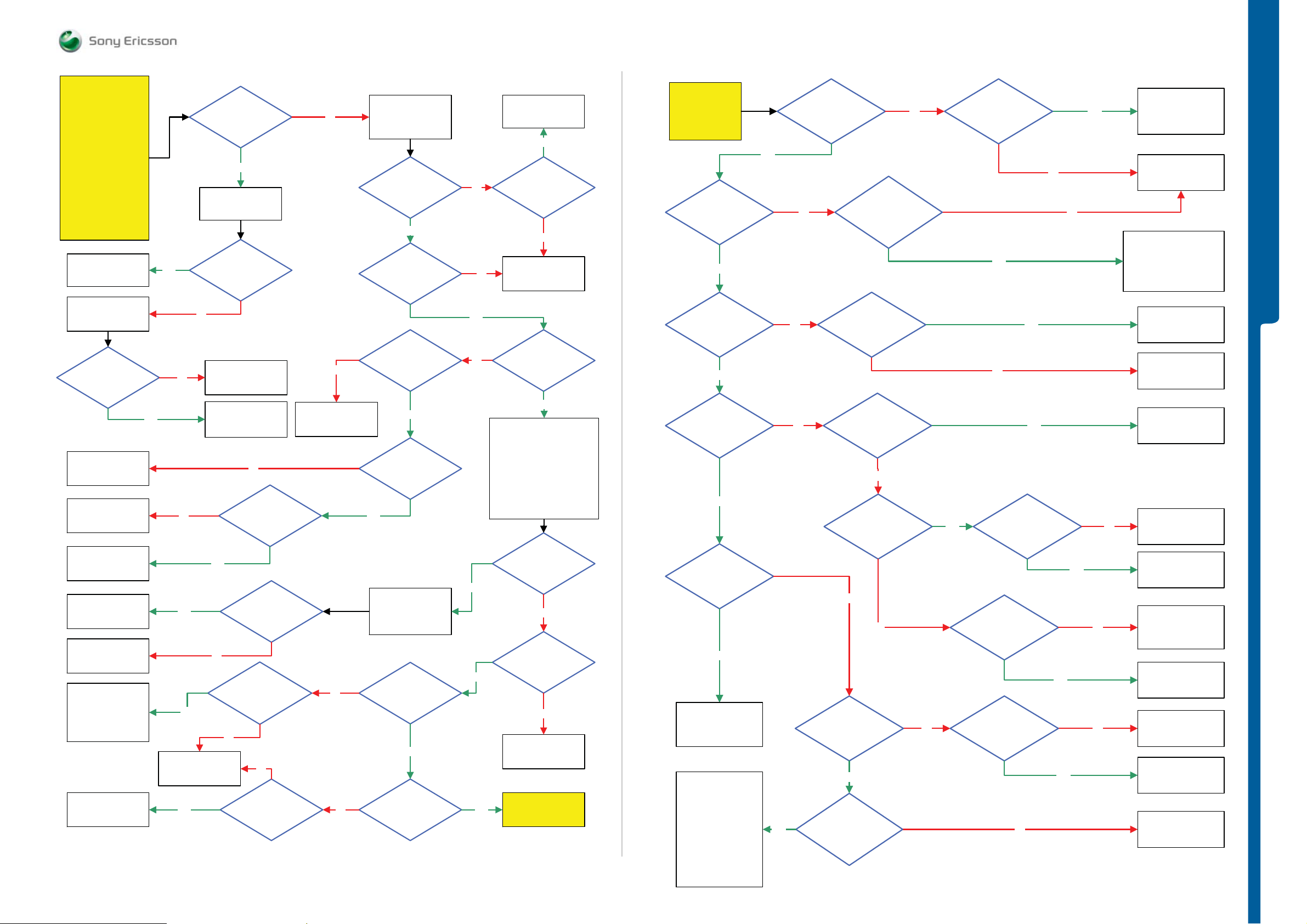

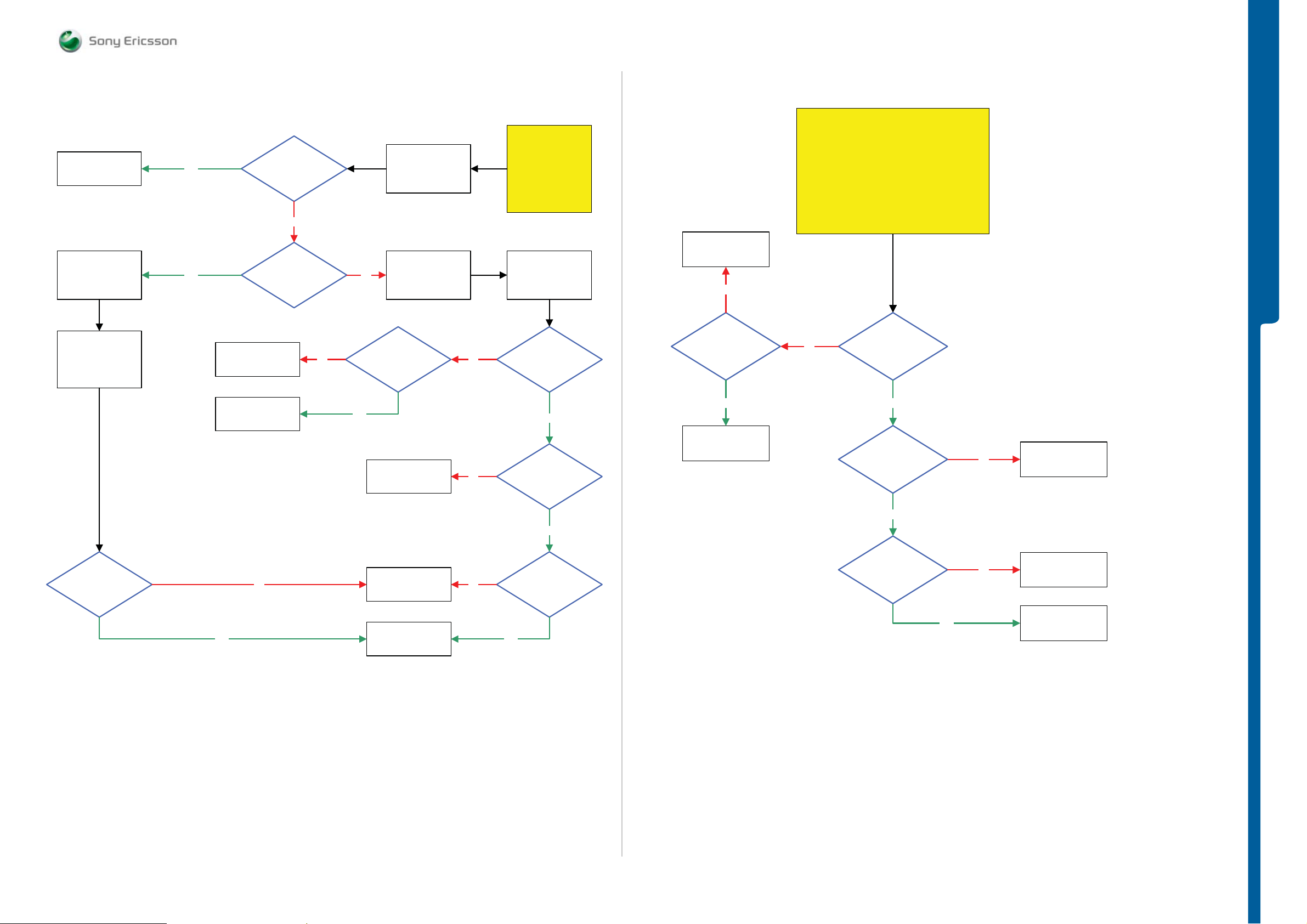

TROUBLESHOOTING On/Off Problems

/ Flash Problems

SEMC Troubleshooting Manual

K850

START

Connect:

Dummy Battery connected

to VBATT

No

Is the

phone consuming

any current when

powering on the

phone

Yes

On/Off problems

Is the phone

consuming more than

1mA when the phone

is powered off

No

Is it possible to

power on the phone

Connect a chargerNo

Yes

Yes

Is it possible to power

off the phone

Is the phones

behavior as normal

Optimized

charging

No

Yes

No

Yes

Go to

Dead phone

Problems part 1

Go to

Current

Consumption Test

After this go to

Charging Test.

Go to

Key problems

No

Power up the phone

Connect USB Cable

From PC

The phone

indicate charging

on display

No

Go to

USB/VBUS Charging

problems

No

Yes

Flash problems

Flash process

Start-up

When using

EMMA

Yes

Download

ITP SW

By using EMMA

Passed

5 Volt DC at

MP 123 (C2414)

Yes

3.3 Volt DC

Pulses at

MP 120 (C2476)

No

Yes

No

1.8 Volt DC

Pulses at

MP 23 (R2427)

START

Step 1:

Perform System

Connector Protection Test.

Try to Flash the phone by

No

Step 2:

Phone with Normal SW

Use TRS Fixture

Connect:

Display and Keypad

Connect: VBATT

using EMMA III SW

SL 5 Replace

D2010

SL 4 Scrap

SL 5 Replace

R2484

SL 4 Scrap

SL 5 Replace

D2000

SL 4 Scrap

TROUBLESHOOTING

Is the current

consumption between

10mA and 70mA

Yes

Flash

the phone with

correct CDA

software

Flash

the phone with

ITP software

successful

No

Yes

CDA Software

Flash

Successful

Yes

1. Customize the phone into DPY/Z

2. Startup the phone and wait for

the configuration to take place

(takes less than a minute)

3. Customize with correct CDA

4. Activate the phone

No

Go to

Dead Phone

Problems part 1

Press

2 and 5

Connect USB

Run Pre-config 1 and 2

Run DPY/Z

Successful

Flash

No

Flash process

started

Yes

Replace

D2404

No

Go to

System Connector

Protection Test.

Disconnect the

phone from

TRS Fixture

Yes

Yes

1.8 Volt DC

Pulses at

MP 125 (C2474)

Yes

No

After this go to

Flash problems

Max 2 Ohm between

MP 119 (X2400_Pin11)

and MP 117

(Z2450 pin 3)

Yes

Max 2 Ohm between

MP 118 (X2400_Pin10)

and MP 116

(Z2450 pin 4)

NoYes

Problem

solved

Yes

No

No

Max 0.5 Ohm between

MP 119 (X2400_Pin11)

and MP 121

(Z2450 pin 2)

Max 0.5 Ohm

between

MP 118 (X2400_Pin10)

and MP 122

(Z2450 pin 1)

No

Yes

No

Yes

Replace

System Connector

X2400

SL 5 Replace

Z2450

SL 4 Scrap

Replace

System Connector

X2400

SL 5 Replace

Z2450

SL 4 Scrap

No

Go to

Flash problems

No

Problem

solved

Yes

Yes

Claim for a

SW Upgrade

Replace

D2404

Problem

solved

No

Yes

Claim

D2404

SL 5 Replace

D2000

SL 4 Scrap

1203-2528 rev. 1

8 (101)

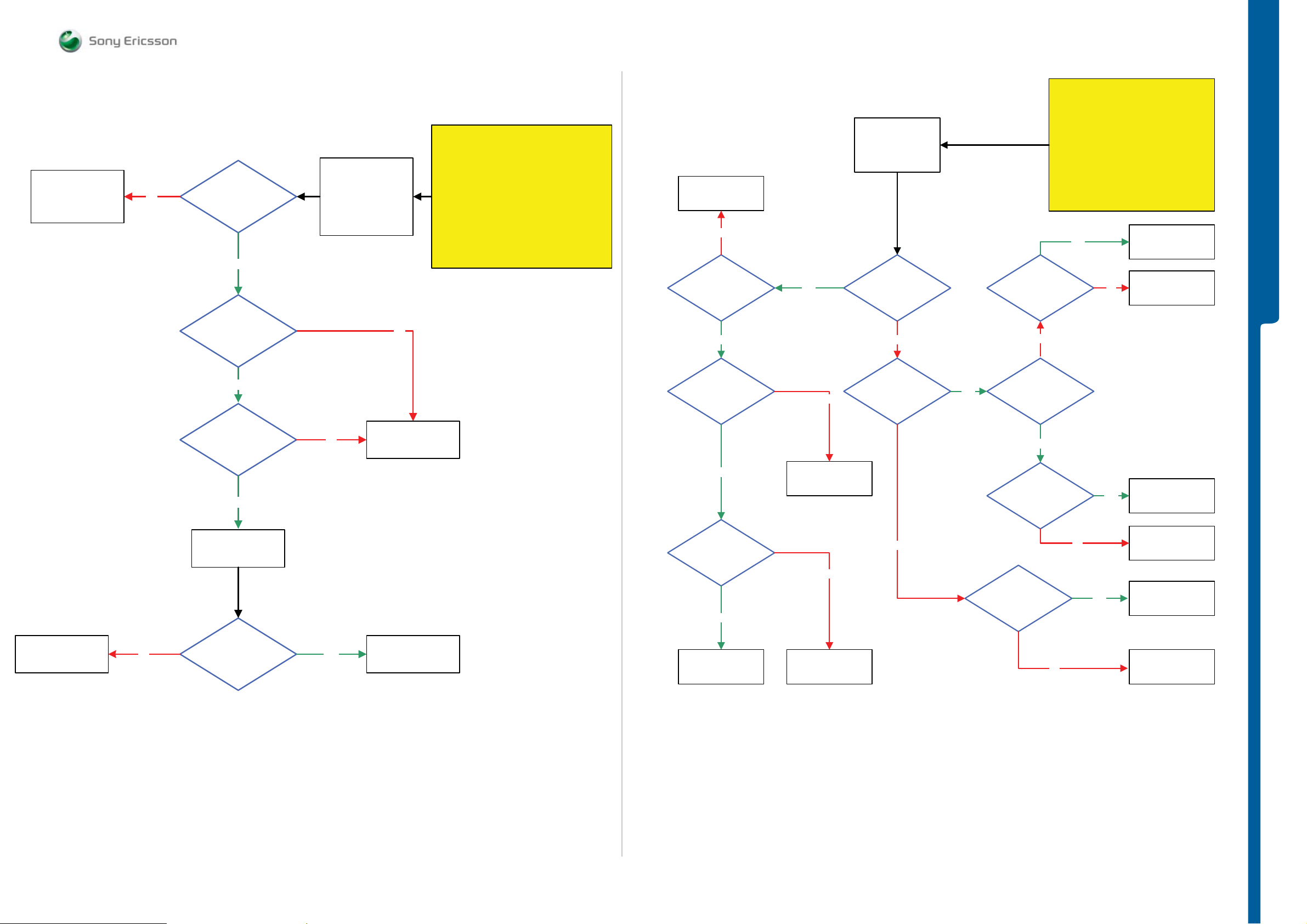

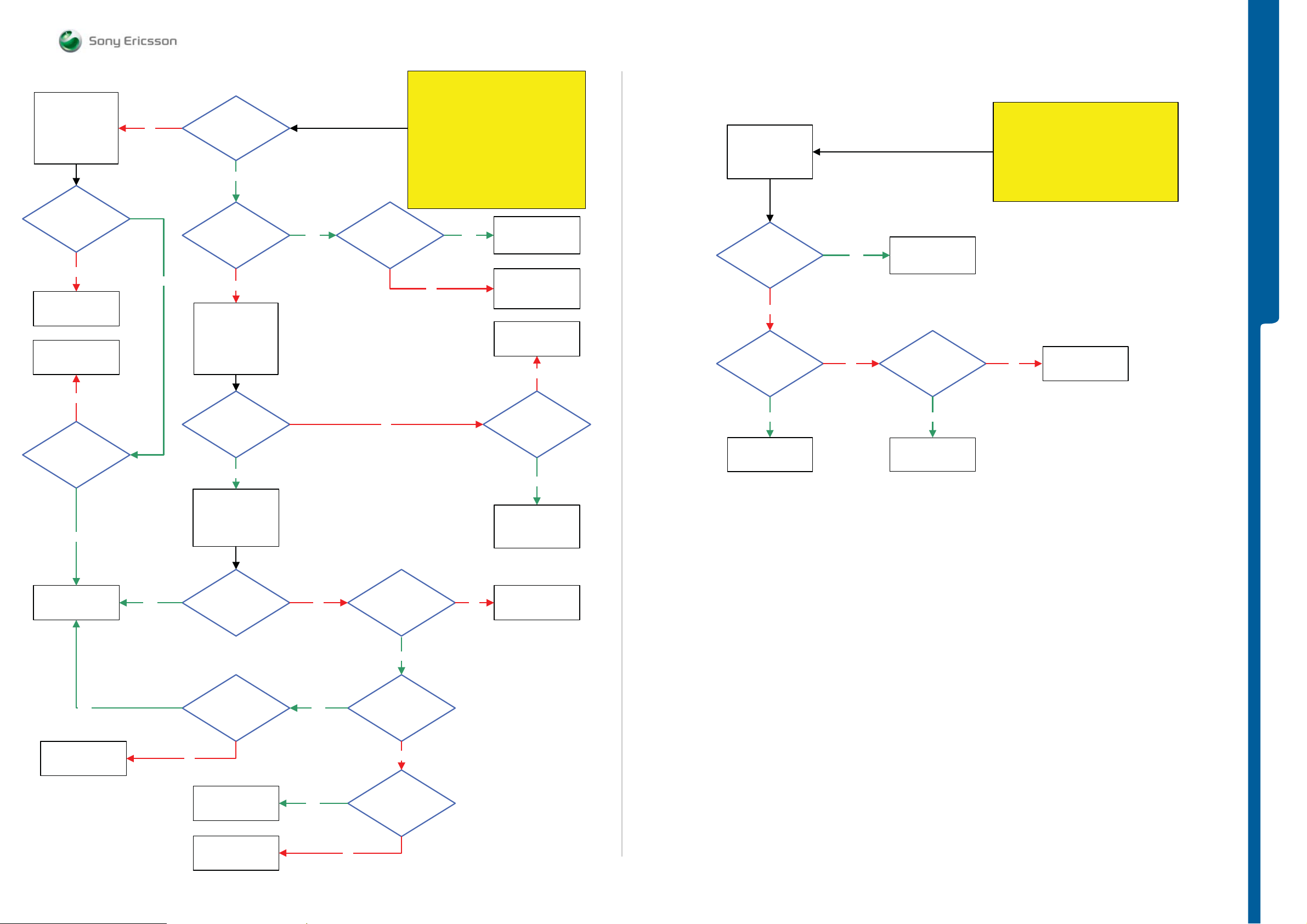

TROUBLESHOOTING Dead Phone Problems

SEMC Troubleshooting Manual

K850

START

Step 1:

Try to recover the phone

using EMMA III SW

Press key 2 and 5

Connect USB Cable

Run pre-config 1 or 2

Run DPY/Z

Step 2:

Use TRS Fixture

Connect VBATT

NOTE:

Do NOT use

DCIO/SEPI Cable!

Replace

N1002, N1200 or

N1210

SL 5 Remove

N2000

SL 4 Scrap

Using more than

1 mA

current

SL 5 Replace

N2000

SL 4 Scrap

Replace

N1200

SL 5 Replace

D2000

SL 4 Scrap

SL 5 Replace

D2010

SL4 Scrap

Go to

Flash Problems

SL 4 Replace

N2400 or V2405

SL 5 Replace

C2400, C2430,

C4213, C3135 or

C3136

SL 5 Replace

Faulty Component

SL 4 Scrap

Yes

Yes

No

No

Yes

Yes

SL 5 Replace

N2000

SL 4 Scrap

Yes

S2400

not pressed

Using more than

1 mA

current

Yes

Try to trace the

faulty component

with freezing spray

N1002

(inside N1200)

N1200, N1210

getting hot

No

SL 5 Replace

N2000

SL 4 Scrap

Try to trace the

faulty component

with freezing spray

MP 149 (R2100)

Yes

Flash process

No

V2405, N2400

C2400, C2430,C4213,

C3135,C3136

Short circuit

No

C2326, C2327,

C2328, C2329, C2330,

C2353, D2000,C2352

Dead Phone problems part 1

No

DCIO/SEPI Cable

MP 6 (B2101 Pin7)

Between Power

No

SL 5 Replace

R2200

SL 4 Scrap

No

26 MHz

MCLK at

successful

No

No

Short circuit

Supply GND and

MP 9 (ST2208 VDDE)

MP 12 (ST2215

Yes

by downloading

Keep S2400

pressed or

connect

32 kHz

RTCCLK at

Yes

32 kHz

RTCCLK at

MP 21 (R2125)

0 Volt

PBA GND

Yes

1.8V DC at

2.8V DC at

VccA)

Try to recover

the phone

ITP SW

AUDIO26

Voltage

Ok

Yes

VANA25

Voltage

Ok

Replace

B2101

No

No

Yes

No

2.6V MP 17 (ST2204 AUDIO26)

2.5V MP 11 (ST2203 VANA25)

2.7V MP 14 (ST2212 VBT27)

2.7V MP 34 (ST2213 VDIG)

2.6V MP 36 (ST2214 VBEAR26)

1.8V MP 158 (ST2217 VCORE18)

1.2V MP 56 (ST2206 VCORE12)

Yes

Yes

YesNo

2.2 Volt at

MP 7 (C2218 VDD_LP)

SL 5 Replace

N2000

SL 4 Scrap

26 MHz

MCLK at

MP 85 (C2116)

Check the following voltages:

All voltages

Current

consumption more

than 50mA

SL 5 Replace

N2000

SL 4 Scrap

Dead Phone

problems part 2

Yes

No

Yes

Ok

No

No

Go to

Dead Phone

problems

Part 2

VDIG

Voltage

Ok

Yes

VBEAR26

Voltage

Ok

Yes

VCORE18

Voltage

Ok

Yes

VCORE12

Voltage

Ok

Yes

Try to Recover the

Phone by

downloading

ITP SW

SL 5 Check

C2301 to C2305,

C2307,C2308,C2311,

C2313 to C2319

C2322,C2324,C2325

D2000

SL 5 replace

Faulty component

and L2200

Yes

Yes

No

No

No

VBT27

Voltage

Ok

D2405,C2402

D2460,C2525,C2524,

N2525,C1407,N1400

Short circuit

C3152

Short circuit

D2000,

D2010,V2231,

C2342 to C2351

Short circuit

1.8 Volt DC at

MP 157 (N2202 Pin1)

No

1.2 Volt DC at

MP 24 (V2207)

Yes

MP 56 (ST2206)

Short circuit

To PBA GND

Dead Phone problems part 2

No

C2470

No

No

No

N1400, C1409

Short circuit

Yes

No

Yes

3.8 Volt DC at

MP 161 (N2202 Pin6)

3.8 Volt DC at

MP 57 (L2201)

C2243

Short circuit

No

Yes

Yes

No

Yes

Yes

No

Yes

Yes

No

No

SL 4 Replace

SL 5 Replace

SL 5 Replace

SL 4 Scrap

SL 4 Replace

D2460, N2525 or

SL 5 Replace

C2470, D2405, C2402,

C2525, C2524 or C1407

SL 5 Replace

SL 4 Scrap

SL 5 Replace

SL 4 Scrap

SL 5 Replace

Faulty component

SL 4 Scrap

SL 5 Replace

No

SL 4 Scrap

SL 5 Replace

C2243 and L2203

SL 4 Scrap

SL 5 Replace

R2207, C2239

and N2202

SL 4 Scrap

SL 5 Replace

SL 4 Scrap

SL 5 Replace

SL 4 Scrap

N1400

C1409

N2000

TROUBLESHOOTING

N1400

C3152

N2000

L2203

Replace

N2202

L2201

N2000

Replace

L2200

SL 4 Scrap

1203-2528 rev. 1

9 (101)

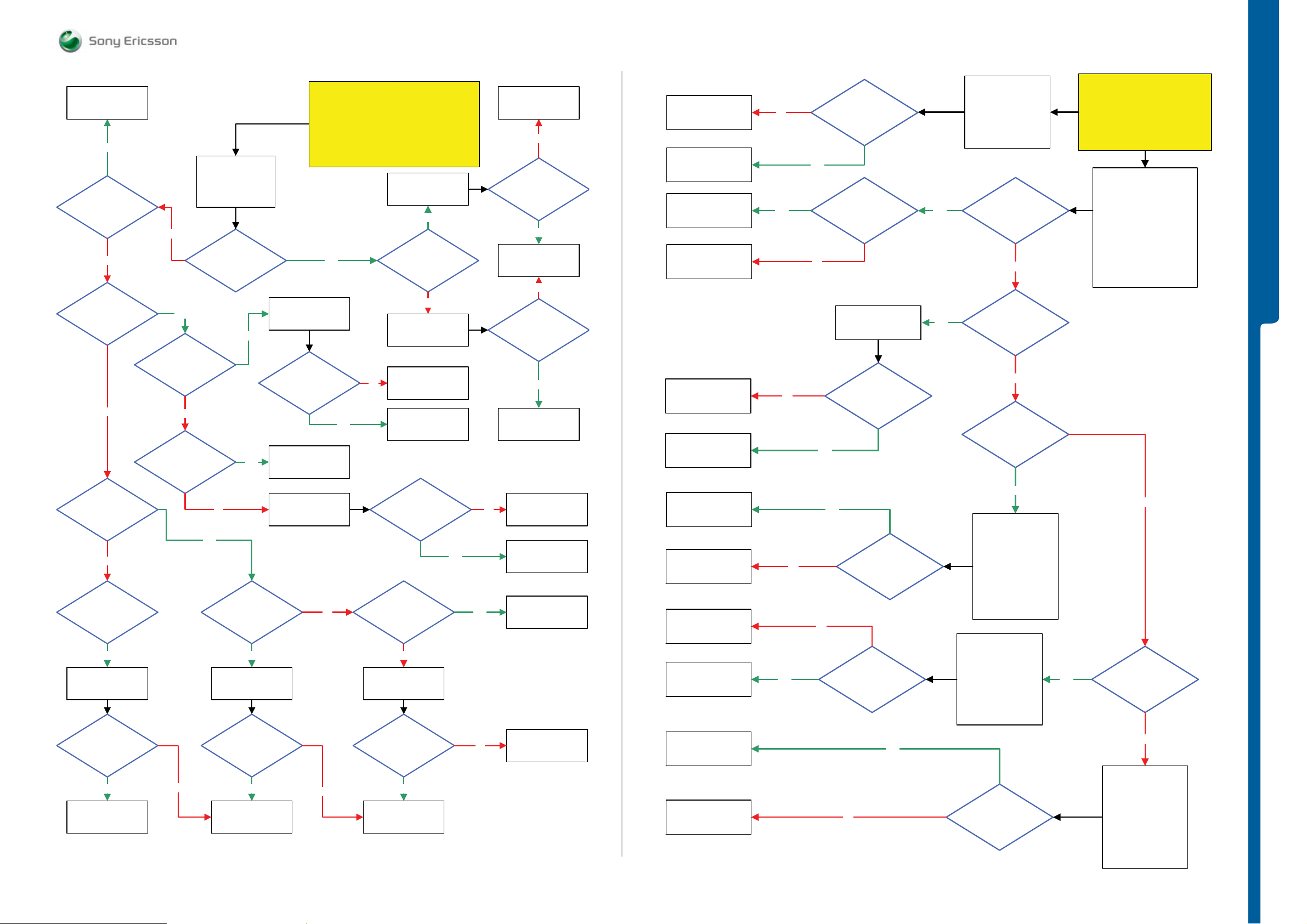

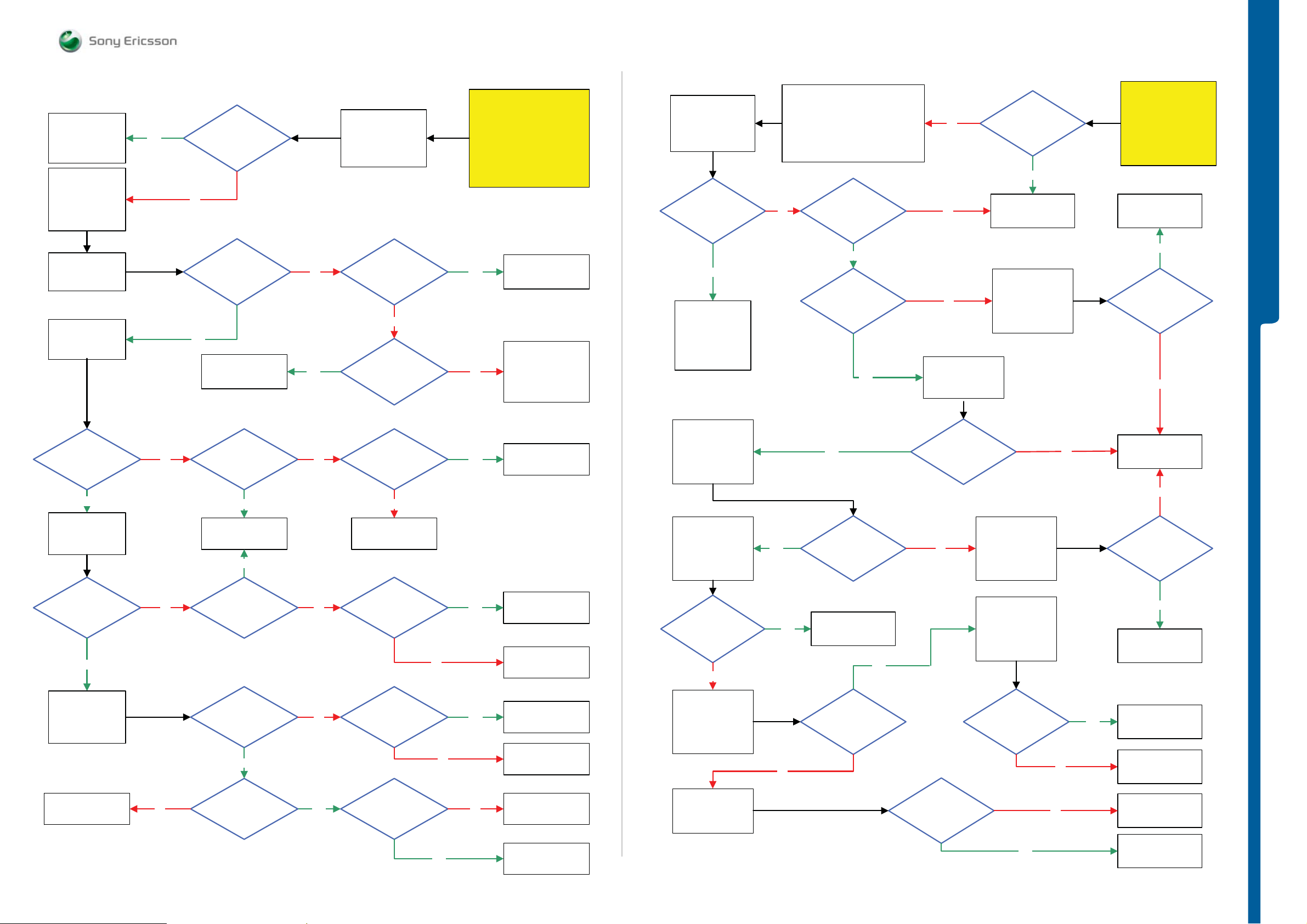

TROUBLESHOOTING Display Problems

/ Display Illumination Problems

SEMC Troubleshooting Manual

K850

Go to Display

illumination

problems

No

Display problems

Display Backlight

Ok

Yes

1.8 Volt DC

at

MP 5 (ST4200

VDDE18)

Yes

2.6 Volt DC

at

MP 4 (ST4201

VAUDIO26)

Yes

Use Fault Trace SW

MMI

Display pattern

Activate

Tri color pattern

No

SL 5 Replace

No

SL 4 Scrap

N2000

START

Step 1:

Use TRS Fixture and connect the display

and keypad. Connect VBATT.

If the display is working properly at the

TRS Fixture then replace the display

If not then continue with Step 2.

Step 2:

Load ITP SW into the phone

Use TRS Fixture and connect the display

Connect: VBATT and DCIO/SEPI

Continue with the

Display problems TRS guide

SL 5 Replace

N2000

SL 4 Scrap

No

1.8 Volt

Pulses at

MP 8 (R2206 OPTO_EN)

shortly after phone

Power On

Yes

3.0 Volt

Pulses at

MP 3 (TP2203 VOPTO30)

shortly after phone

Power On

Yes

Yes

No

Replace

N2201

Display illumination problems

Use Fault Trace SW

MMI

Misc

Activate

Display Backlight

Display Backlights

Ok

No

3.8 Volt DC at

MP 26 (TP4200)

Yes

at MP 49 (R4215) shortly

after Display Backlights

after Display Backlights

When Display Backlight

Use TRS Fixture and connect the display

and the keypad. Connect VBATT.

If the display is working properly at the

Use TRS Fixture and connect the display

Display illumination problems TRS guide

3.8V

Pk-Pk Pulses

is set

No

15V Pk-Pk

Pulses at

MP 26 (TP4200) shortly

Is set

Yes

0 Volt DC

At MP 25 (TP4201)

is activated

START

Step 1:

fixture then replace the display

If not then continue with Step 2.

Load ITP SW into the phone

Connect: VBATT and DCIO/SEPI

Yes

Step 2:

Continue with the

Replace

No

Yes

SL 5 Replace

SL 4 Scrap

Replace

X4200 or Display

V4200

N2000

TROUBLESHOOTING

SL 5 Replace

D2000

SL 4 Scrap

Replace

X4200

No Yes

Display

Ok

Claim Component

X4200

0.8 to 2.5

Volt Pulses at

MP 52 (N4200 Pin6)

shortly after phone

Power On

Yes

Flash the Phone with

EMMA

SUCR SW

No

Replace

N4200

No

3.8 Volt DC at

MP 51 (V4201

Anode)

No

No

Yes

SL 5 Replace

V4205 or N2000

SL 4 Scrap

Replace

V4201

SL 5 Replace

L4201

SL 4 Scrap

1203-2528 rev. 1

10 (101)

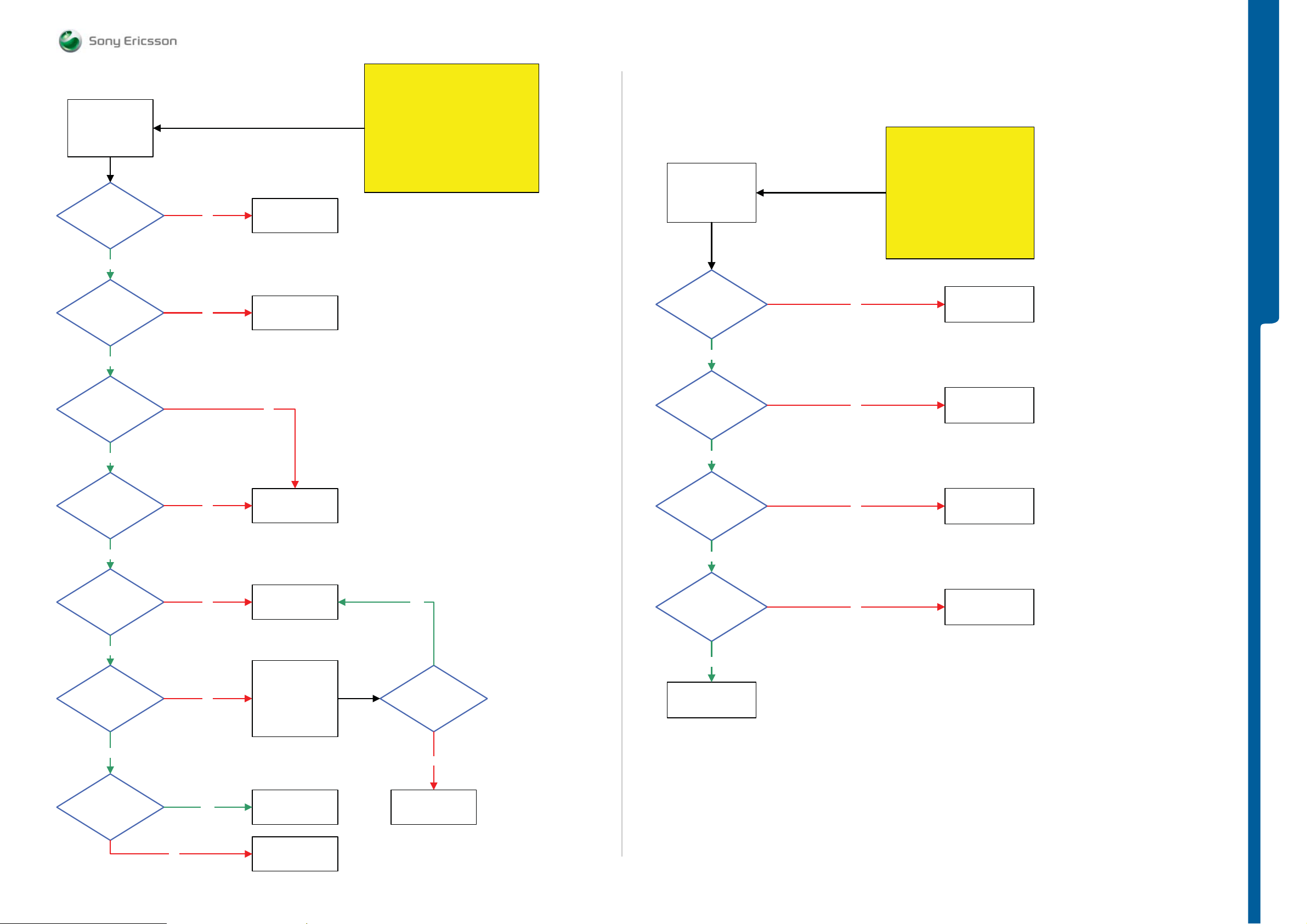

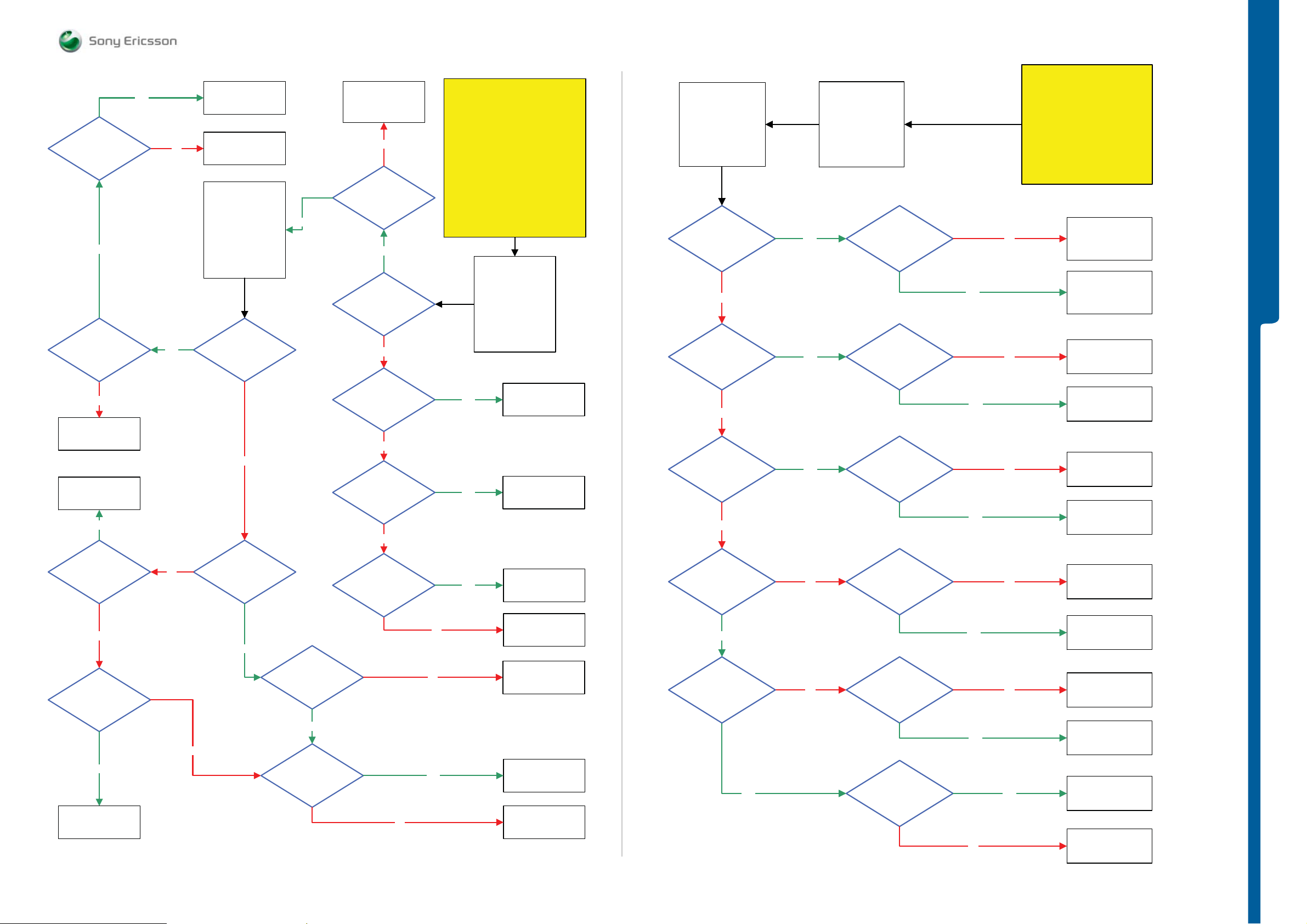

TROUBLESHOOTING Key Problems

/ LED Problems

SEMC Troubleshooting Manual

K850

Replace

V2402

Yes

Problem with

Phone Off

No

Problem with

Volume Down

key

No

Problem with

Volume Up

key

Perform Diode

Measurement

No

Problem with

Yes

More than

2.0 Volt DC between

MP 134 (S2402 A) and

MP 135 (S2402) C

No

Short circuit

between

MP 135 (S2402 C) and

MP PBA GND

No

Phone On

Yes

Volume Down key

MP 134 (S2402 A) and

Yes

Key problems

START

Use TRS Fixture and connect Display and

Perform Keyboard Test in Service Tests

If All Keys working properly at the

TRS Fixture then replace Keypad. If not then

disconnect VBATT and continue with the

Yes

Press the

S2402

0 Volt DC

between

MP 135 (S2402 C)

Yes

SL 5 Replace

V2478

SL 4 Scrap

Remove

S2402

Step 1:

Keypad. Connect: VBATT

Key problems TRS guide

Press the On/Off

MP PBA GND. More than

MP 127 (S2400 A)

No

2.0 Volt DC between

MP 134 (S2402 A) and

MP 135 (S2402 C)

key S2400

Yes

Connect the

black probe to

2.0 Volt DC at

No

Remove

S2400

Replace

S2402

SL 5 Replace

D2000

SL 4 Scrap

More than

MP 127 (S2400 A)

SL 5 Replace

2.0 Volt DC at

MP 127 (S2400 A)

No

Replace

S2400

No

0 Volt DC at

Yes

N2000

SL 4 Scrap

No

More than

Yes

Replace

S2400

SL 5 Replace

D2000

SL 4 Scrap

SL 5 Replace

N2000

SL 4 Scrap

Replace

V2428 Red LED

Replace

X2410

Replace

N4101

SL 5 Replace

N2000

SL 4 Scrap

Claim Component

X2410

Replace

N4101

No

Yes

No

MP 128 (C2427)

Yes

MP 18 (TP4112)

No

Yes

Yes

More than

1.8 Volt DC at

4.5 Volt DC

at

Replace

X2410

Keypad LEDs

Ok

LED problems

Yes

Yes

On Red LED

problems:

Use Fault Trace SW

MMI

LED and Backlight

Activate:

Red LED

Problem with all

Keypad LED

rows

No

Problem with any

of the Keypad LED

rows

No

Problem with

Camera Keypad

LED

Yes

Load ITP SW into the phone.

START

Use TRS Fixture

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW

On Keypad LED

problems:

Connect Keypad

Use Fault trace SW

MMI

LED and Backlight

Activate:

Keypad Backlight

If Keypad LED works

properly at the

TRS Fixture then replace

Keypad

No

TROUBLESHOOTING

No

Problem

With all other

keys

Yes

Replace

X2410

Problem

solved

Yes

Claim

X2410

No

Yes

More than

2.0 Volt DC between

MP 132 (S2403 A) and

MP 131 (S2403 C)

Yes

Press the

Volume Up key

S2403

0 Volt DC

between

MP 132 (S2403 A) and

MP 131 (S2403 C)

Yes

SL 5 Replace

D2000

SL 4 Scrap

No

No

Short circuit

between

MP 131 (S2403 C) and

MP PBA GND

No

Remove

S2403

More than

2.0 Volt DC between

MP 132 (S2403 A) and

MP 131 (S2403 C)

Yes

Replace

S2403

Yes

Yes

No

Replace

S2402

SL 5 Replace

V2477

SL 4 Scrap

SL 5 Replace

D2000

SL 4 Scrap

Replace

X2410

Replace

X2511

Replace

N4101

SL 5 Replace

N2000

SL 4 Scrap

Replace

X2511

Yes

No

No

More than

0.8 Volt DC at

MP 162 (R4114)

MP 164 (R4115)

MP 163 (R4116)

1.8 Volt DC

at

MP 20 (TP4106

AF_LED)

Yes

No

Connect Keyflex to

the PBA

Use Fault trace SW

MMI

LED and Backlight

Activate:

Camera Keypad LED

Connect Single

Flash Assembly to

PBA

Use Fault trace SW

MMI

LED and Backlight

Activate:

Autofocus LED

More than

1.2 Volt DC

at MP 30 (R2544

LED_BACK)

Yes

Problem with

Autofocus LED

No

Camera Light Ring

problems:

Connect Single

Flash Assembly to

PBA

Use Fault trace SW

MMI

LED and Backlight

Activate:

Camera Light Ring

1203-2528 rev. 1

11 (101)

TROUBLESHOOTING Main Camera Problems

/ VGA Camera Problems

SEMC Troubleshooting Manual

K850

Fault Trace SW

MMI

Misc

Activate:

Main Camera Test

1.8 Volt DC at

MP 76 (R2280

CAM_LDO_EN)

Yes

2.8 Volt DC at

MP 32 (TP2204

VCAMAF)

Yes

Main Camera problems

No

No

Replace

D2420

Replace

N2206

START

Load ITP SW

into the phone.

Use TRS Fixture and

Connect: Display and Main Camera Module

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW

If the Main camera module is not connected

or not working properly the Fault Trace SW

will show an error message in the Trace

window.

VGA Camera problems

Fault trace SW

MMI

Misc

Activate:

VGA Camera Test

1.8 Volt DC at

MP 76 (R2280

CAM_LDO_EN)

Yes

No

START

Load ITP SW

into the phone.

Use TRS Fixture and

connect Display and VGA Camera

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW

If the VGA camera is not connected

or not working properly the Fault

Trace SW will show an error

message in the Trace window.

Replace

D2420

TROUBLESHOOTING

1.8 Volt DC at

MP 27 (TP2206

VCAMIO)

Yes

1.2 Volt DC at

MP 28 (TP2207

VCAML)

Yes

2.8 Volt DC at

MP 82 (ST2275

VCAMSA)

Yes

1.8 Volt DC at

MP 54 (TP2208

VCAMSD)

No

No

No

No

Replace

N2203

Replace

N2208

Fault Trace SW

Logic

GPIO Manager

Application

GPIO_11 Read

Yes

Is

Result GPIO_11

= High

1.8 Volt DC at

MP 27 (TP2206

VCAMIO)

Yes

2.8 Volt DC at

MP 82 (ST2275

VCAMSA)

Yes

13MHz at

MP 77 (R4301)

Yes

Replace

X4300

No

No

No

Replace

N2203

Replace

N2208

SL 5 Replace

D2000

SL 4 Scrap

Yes

26MHz at

MP 77 (R4301)

No

Yes

Replace

X4301

SL 5 Replace

D2000

SL 4 Scrap

No

Replace

D2420

1203-2528 rev. 1

12 (101)

TROUBLESHOOTING Camera Door Problems

/ Vibrator Problems

SEMC Troubleshooting Manual

K850

Flash the Phone with

EMMA

SUCR SW

Disassemble the

phone

Use TRS Fixture

Fault trace SW

MMI

Misc

Activate:

Camera Door Test

Yes

Yes

Camera Door problems

Camera Door Test

Open/Close

Ok

No

Camera Door

Open position

Ok

Replace

D2420

No

Fault trace SW

MMI

Misc

Activate:

Camera Door Test

No

shortly after camera door

Disassemble the

Use TRS Fixture

1.8V,

225ms Pulses

test activation at

MP 91 (R2500)

phone

No

START

Load ITP SW

into the phone.

Insert the

Dummy Battery

Connect: VBATT and

DCIO/SEPI

Use Fault Trace SW

Fault trace SW

MMI

Misc

Activate:

Camera Door Test

3V, 225ms

Pulses shortly

after camera door test

activation at

MP 59 (TP2500)

SL 5 Replace

N2000

SL 4 Scrap

No

Is any of

C4206 or C4207

Short circuit

Vibrator problems

START

Load ITP SW into the phone

Use TRS Fixture.

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

If Vibrator is working properly at the

TRS Fixture then replace Vibrator if not

Continue with the Vibrator problems TRS guide

No

MMI-Misc

Activate:

Vibrator Test

2.8 Volt Pk-Pk

Pulses at

MP 141 (C4206

VIBR_OUT)

TROUBLESHOOTING

3V, 250ms

Pulses shortly

after camera door test

activation at MP 58

(TP2501)

Yes

Replace

N2500

No

Yes

Replace

V2500

Replace

D2420

Replace

X2511

No

No

Yes

3V,

225ms

Pulses shortly

after camera door test

activation at MP 93

(V2505 Pin 4)

Yes

3V, 225ms

Pulses shortly

after camera door test

activation at MP 55

(TP2502)

Yes

Yes

SL 5 Replace

C4206 or C4207

SL 4 Scrap

Yes

2.8 Volt Pk-Pk

Pulses at

MP 136 (X2506)

Yes

Connection

between

MP PBA GND and

MP 137 (X2507)

Ok

Yes

No

No

SL 5 Replace

L4202

SL 4 Scrap

SL 5 Replace

L4203

SL 4 Scrap

Clean Pad X2506

Clean Pad X2507

1203-2528 rev. 1

13 (101)

TROUBLESHOOTING Charging Problems

/ USB/ V BUS Cha rg in g Proble ms

SEMC Troubleshooting Manual

K850

Use TRS Fixture and

Fault Trace SW

Connect:

VBATT and

DCIO/SEPI

Start Battery

Calibration Test

3.2V

and 4.1V DC

at MP 31 (TP2200)

during Battery

Calibration

No

Replace

X2200

SL 5 Replace

R2200

SL 4 Scrap

No

Yes

Charging problems

Battery Calibration.

Passed

Yes

Current Calibration

Passed

No

Use TRS Fixture and

Fault Trace SW

Connect:

VBATT and

DCIO/SEPI

Yes

Is

MP 29 (TP2202)

Short circuit

To GND

Perform System Connector Protection Test

START

Load ITP SW into the phone

Connect: Dummy Battery

Connect:VBATT and DCIO/SEPI

Use Fault Trace SW:

Logic, Phone Power

Battery and Current Calibration

It is very important to follow

instrument settings instructions

when performing the Battery and Current

No

Perform

Calibration Test.

SL 5 Replace

Yes

Flash with EMMA

Charging Test

System Connector

N2000

SL 4 Scrap

SUCR SW

Go to

Replace

X2400

No

Connect

DSU-60/ USB cable

from PC to

the phone

5 Volt DC at

MP 44 (ST2201)

No

5 Volt DC at

MP 108 (R2470/1)

USB/VBUS Charging problems

SL 5 Replace

Yes

No

N2000

SL 4 Scrap

5 Volt DC at

MP 107 (R2470/2)

START

Perform System Connector Protection Test

If step 1 is Ok then continue with step 2.

Use Phone with Normal SW

No

Step 1:

Step 2:

Use TRS Fixture

Connect: VBATT

Replace

System Connector

X2400

TROUBLESHOOTING

No

Connection

between

PBA GND to Power

supply GND

Ok

Yes

SL 5 Replace

N2000

SL 4 Scrap

Yes

5 Volt DC at

MP 40 (C2201

DCIO)

Yes

Start

Current Calibration

(C.C.)

Phone

Consuming

more than 10mA

DCIO Current

(During C.C.)

R2201

0.1 Ohm

Phone

consuming more

No

MP 47

No

YesYes

(C2241 DCIO_INT)

Higher than

3,8 Volt DC

Yes

MP 41 (R2201)

CHSENSEP Higher

than 3,8 Volt DC

(During C.C.)

No

than 10mA

Charger (DCIO)

Current

Yes

SL 5 Replace

C2423 and C2424

SL 4 Replace

V2421

SL 5 Replace

N2000

SL 4 Scrap

Yes

Replace

N2402

Yes

SL 5 Replace

R2470

SL 4 Scrap

SL 5 Replace

R2201

SL 4 Scrap

No

Replace

V2202

SL 5 Replace

N2000

SL 4 Scrap

Yes

(V2202 Pin2)

CHREG Lower than

MP 47 (C2241)

(During C.C.)

No

No

MP 39

1203-2528 rev. 1

14 (101)

TROUBLESHOOTING SIM Problems

/ Memory Stick Problems

SEMC Troubleshooting Manual

K850

Replace combo

reader and

Flash the Phone

with EMMA

SUCR SW

Remove Test SIM

and Insert

Dummy SIM

Restart the Phone

Use:

Fault Trace SW

Activate:

SIMVCC

SIMVCC on

Activate:

SIMRST

Yes

Sim Com Test

Passed

No

1.8 Volt DC

At MP SIM1

(Fixture Sim reader

Pin 1)

Yes

SL 5 Replace

C2406 or C2411

SL 4 Scrap

SIM problems

No

Yes

Fault trace SW

Logic

SIM Card control

Activate:

SIM Com Test

1.8 Volt DC at

MP 50 (TP2400)

No

C2406

or C2411

Short circuit

Load ITP SW into the phone.

START

Use TRS Fixture.

Connect: Fixture Combo

reader to the PBA and

Insert Test SIM

Connect:

VBATT and DCIO/SEPI

Use Fault Trace SW

Yes

No

Replace

X2409

SL 4 Replace

X2409

If still faulty

SL 5 Replace

N2000

SL 4 Scrap

Fault trace SW

Logic

SIM Card control

Activate:

Memory Stick Test

Memory Stick Test

Passed

Yes

Replace Combo

Reader and

Flash the Phone

with

EMMA

SUCR SW

Memory Stick problems

Load ITP SW

into the phone.

Use TRS Fixture

Fixture Combo reader to PBA

Connect : VBATT and DCIO/SEPI

No

Connect:

Insert Memory Card

Use Fault Trace SW

0 Volt DC at

MP 105 (R2406

MSDETECT)

Yes

1.8 Volt DC at

MP 94 (R24102

CMDDIR

D2410 Pin 4)

Yes

No

No

No

Restart the phone

and measure the

pulses after 5 sec

Is

X2409

damaged

Yes

Replace

X2409

Disconnect Combo

reader and restart

the phone, measure

the pulses after

5 sec

START

SL 5 Replace

D2410

SL 4 Scrap

Yes

1.8 Volt at

MP 95 (R24102

MCCMDDIR

D2410 Pin 3)

No

TROUBLESHOOTING

1.8 Volt DC at

MP SIM2 (Fixture SIM

reader Pin 2)

Yes

SIMVCC on

SIMRST on

Activate:

SIMCLK

1.0 Volt DC at

MP SIM3 (Fixture Sim

reader Pin 3)

Yes

SIMVCC on

SIMRST on

SIMCLK on

Activate:

SIM DATA

No

No

1.8 Volt DC at

MP 69 (TP2401)

Yes

Replace

X2409

Yes

1.0 Volt DC at

MP 65 (TP2402)

1.8 Volt DC at

MP SIM7 (Fixture SIM

reader Pin 7)

Yes

No

No

No

C2410

Short circuit

No

SL 5 Replace

N2000

SL 4 Scrap

C2408

Short circuit

1.8 Volt DC at

MP 70 (TP2403)

No

No

Yes

Yes

Yes

SL 5 Replace

C2410

SL 4 Scrap

Sl 5 Replace

C2408

SL 4 Scrap

SL 5 Replace

N2000

SL 4 Scrap

Replace

X2409

SL 5 Replace

N2000

SL 4 Scrap

Disconnect Combo

reader and restart

the phone, measure

the pulses after

5 sec

Restart the phone

after each

measurement.

Measure pulses

after 5 sec.

1.8 V to 2.8V

at MP 63 (R24106)

to MP 64 (R24110)

No

Restart the phone

Measure pulses

after 5 sec.

Yes

No

Yes

Yes

2.8 Volt at

MP 66 (R24105

MC_CLK)

Replace

X2409

Yes

1.8 V to 2.8V

at MP 103 (R2490)

1.8 Volt at

MP 96 (SP2408

MCDATDIR)

repair instructions

No

At MP 98 (R2444) to

Cut the fence

according to the

for D2460. Restart

the phone and

measure pulses

after 5 sec.

Restart the phone

after each

measurement.

Measure pulses

after 5 sec.

From High to

Low pulses Signal

MP 99 (R2448)

No

No

Yes

SL 5 Replace

D2000

SL 4 Scrap

No

1.8 Volt at

MP 100 (R2496

MCCLK)

Yes

Replace

D2460

Replace

D2460

SL 5 Replace

D2000

SL 4 Scrap

Replace

X2409

No

Connection

Between MP PBA GND

and MP SIM5 (Fixture

Sim reader Pin 5)

Ok

Yes

10 Kohm

Between MP 50

(TP2400) and MP 70

(TP2403)

Yes

No

SL 5 Replace

R2419

SL 4 Scrap

SL 5 Replace

N2000

SL 4 Scrap

Restart the phone .

Measure pulses

after 5 sec.

1.8 V to 2.8V

at MP 104 (R24101)

Yes

No

SL 5 Replace

N2000

SL 4 Scrap

Replace

D2460

1203-2528 rev. 1

15 (101)

TROUBLESHOOTING Audio Internal Problems

/ Audio Exter n al Problem s

SEMC Troubleshooting Manual

K850

0 Volt DC

at MP 160

(V2405_ Pin 6)

Yes

2.6 Volt DC

at MP 124 (ST2441)

No

Replace

N2400

SL 5 Replace

L3108 and L3109

SL 4 Scrap

Yes

Yes

Yes

No

Audio Internal problems

Go to

Audio External

Problems

Replace

V2405

Fault Trace SW

Audio and FM Radio

Audio Loop test

Audio Input: Mic1

Loop Mode: Analog

Audio Output:

Loudspeaker

Apply Audio Loop

Whistle into the

PBA Mic

More than

100mV AC Pk-Pk

at MP 74 (X3102) and

MP 75 (X3103)

No

Yes

SL 5 Replace

L3103,L3104,

L3110,L3111

SL 4 Scrap

No

More than

100mV AC Pk-Pk

at MP 1 (X3100) and

MP 2 (X3101)

Yes

More than

100mV AC Pk-Pk

at MP 43 (L3103 BEARP)

and MP 45 (L3104

BEARN)

No

More than

100mV AC Pk-Pk at

MP 37 (ST3100)

No

2.2 Volt DC

at MP 106 (R3109

CCO_INTMIC)

No

START

System Connector Protection Test

Use TRS Fixture. Connect Display

perform Audio Service Tests. If all

Audio Service Tests work properly at

the fixture then replace Loudspeaker

and continue with the Audio internal

Step 1: Perform

Step 2:

and Keypad. Connect VBATT and

or Earphone

Load ITP SW into the phone.

Connect VBATT and DCIO/SEPI

Yes

Yes

If not then

Use TRS Fixture.

Use Fault Trace SW

problems TRS guide

Fault Trace SW

Audio and FM Radio

Audio Loop test

Audio Input: Mic1

Loop Mode: Analog

Audio Output:

Earphone

Apply Audio Loop

Whistle into the

PBA Mic

SL 5 Replace

N2000

SL 4 Scrap

Replace

Electret Mic or

X3105

Disconnect

DCIO/ SEPI cabel

and Insert PHF set

Whistle into the AUX

mic

Can you

hear at AUX

earphone when you

whistle in to the

AUX mic

No

More than

80mV AC Pk-Pk

at MP 112 (L2403 SPL) and

MP 113 (L2404 SPR) When

whistle in to the

AUX mic

No

More than

20mV AC Pk-Pk at

MP 109 (R3130 MICP_int)

and MP 89 (R3131

MICN_int)

No

Audio External problems

Fault trace SW

Audio and FM Radio

Audio Loop test

Audio Input: AUX1

Loop Mode: Analog

Audio Output:

AUX Earphone

Apply Audio Loop

Yes

Yes

Yes

Audio Internal

Tested

L2403 and L2404

Ok

More than

20mV AC Pk-Pk at

MP 88 (C3155) and

MP 87 (C3156)

Yes

Yes

Yes

START

Step 1: Perform

System Connector Protection

Connect: VBATT and DCIO/SEPI

No

No

No

Test

Step 2:

Load ITP SW into

the phone.

Use TRS Fixture

Use Fault Trace SW

Audio Internal

problems

Flash the Phone

with EMMA

SUCR SW

SL 5 Replace

L2403 or L2404

SL 4 Scrap

Replace

System Connector

X2400

SL 5 Replace

N2000

SL 4 Scrap

Replace

N3101

TROUBLESHOOTING

Go to

1.9 Volt DC

at MP 139 (V3101_Pin 1)

and MP 138 (V3101_Pin

2)

No

Is any of

C3137 and C3160

Short circuit

Yes

Replace

Faulty Component

No

1.9 Volt DC

at MP 74 (X3102) and

MP 75 (X3103)

No

Yes

More than

100mV AC Pk-Pk

at MP 38 (C3137) and

MP 42 (C3160)

Yes

1.8 Volt DC

at MP 19 (TP3100

AMPCTRL)

2.2 Volt DC

at MP 35 (L3105

CCO1)

No

No

Yes

No

Yes

SL 5 Replace

N2000

SL 4 Scrap

SL 5 Replace

L3105

SL 4 Scrap

SL 5 Replace

N2000

SL 4 Scrap

Replace

N3100

Replace

D2420

Connection

between

MP 114 (X2400_Pin 3)

and MP 110 (L2401)

Ok

Yes

Connection

between

MP 115 (X2400_Pin 4)

and MP 111 (L2402)

Ok

Yes

No

L2401

Ok

No

Yes

No No

L2402

Ok

Yes

2.2 Volt DC at

MP 86 (R3156)

Yes

No

SL 5 Replace

L2401

SL 4 Scrap

Replace

System Connector

X2400

SL 5 Replace

L2402

SL 4 Scrap

Replace

System Connector

X2400

Replace

N3101

SL 5 Replace

L3106 or N2000

SL 4 Scrap

1203-2528 rev. 1

16 (101)

TROUBLESHOOTING FM Radio Problems

/ Bluetooth Problems

SEMC Troubleshooting Manual

K850

Replace

N3101

SL 5 Replace

N2000

SL 4 Scrap

Disconnect:

DCIO/SEPI Cable

Connect:

Customized FM Radio Cable

Black Lab Plug to

TRS Fixture GND Input and

PHF Connector to the Phone

System Connector

Signal Generator

Instrument Settings:

Frequency:

Use free Freq. Channel

Example:

103 MHz in Sweden

Amplitude: 25.0 uVrms

FM Dev: +/-22.5 kHz

FM Rate: 1kHz

FM Radio problems

PHF

No Yes

Yes

working properly

during

Voice call

Yes

3.8 Volt DC

at MP 151 (ST2282)

and 1.8V at

MP 154 C3305

No

SL 5 Replace

N2000

SL 4 Scrap

Speaker and

FM Radio Tests

working properly

No

Load ITP SW

into the phone.

Use TRS Fixture

Connect VBATT and

DCIO/SEPI

Use Fault Trace SW

Fault trace SW

Audio and FM Radio

FM Radio

Audio Output

Loudspeaker

Frequency

According to

Instrument Settings

Set FM Radio

START

Go to

Service Tests and

Perform:

Speaker and

FM Radio Test

Load ITP SW

Into the phone

Use TRS Fixture

Connect:

VBATT and DCIO/SEPI

Use Fault Trace SW

Fault trace SW

TX and RX

Bluetooth

Channel 0

Set MaxPwr MOD 0

Use

Spectrum Analyzer

Instrument settings:

Frequency: 2402 MHz

Span: 1MHz

Amplitude: -5dBm

Use Peak Search

Signal

At MP 142 (X1400

BT_ANT)

Bluetooth problems

START

Flash the phone with the

EMMA SUCR SW and retest the phone.

If successful claim SW Flashing

If not then continue with

Bluetooth problems TRS guide.

Replace

N1400

No

Is

MOD 1 Freq.

Minimum 230 KHz

higher then

MOD 0 Freq.

Fault Trace SW

TX and RX

Bluetooth

Yes

Channel 0

Set MaxPwr MOD 1

Use Spectrum Analyzer

with the previous

instrument settings

Yes

Change the

Bluetooth channels

In Fault Trace SW

and test the output.

Use

Spectrum Analyzer

Span 10MHz

Use Peak Search when

changing the channel.

Note:

1MHz channel spacing

Yes

-20dBm at

MP 142 (X1400

BT_ANT)

(±5dBm)

No

-15dBm at

MP 78 (Z1400 Pin 1)

(±5dBm)

No

Yes

Replace

N1400

No

All channel

passed

TROUBLESHOOTING

Yes

Replace

BT Antenna

and clean

X1400 and X1401

SL 5 Replace

C1402 and L1402

SL 4 Scrap

Any signal at

MP 156 (C3145)

MP 155 (C3146)

Yes

Can you

hear 1KHz ton at

TRS Fixture

Loudspeaker

No

SL 5 Replace

N2000

SL 4 Scrap

No

Yes

SL 4 Replace

N1400

SL 5 Replace

L3300 and C3306

Replace

System Connector

X2400

Signal

Ok

No

SL 4 Replace

V2425

SL 5 Replace

L2405 and C2434

Signal

Ok

Yes

Yes

Claim

System Connector

X2400

Claim

Component

No

26 MHz Signal

At MP 148 (R2118

BT_CLK)

Yes

2.7 Volt DC at

MP 14 (ST2212

VBT27)

No

C2205

Short circuit

No

Yes

No

More than

60KOhm

between MP 148

(R2118) and

PBA GND

1.8 Volt DC at

MP 9 (ST2208 VDDE18)

and 2.7 Volt DC at MP 34

(ST2213 VDIG)

SL 5 Replace

N2000

SL 4 Scrap

Yes

Yes

MP 144 (Z1400_Pin 5)

MP 145 (Z1400_Pin 7)

No

No

-15dBm at

and

(±5dBm)

Yes

Replace

N1400

SL 5 Replace

D2105

SL 4 Scrap

SL 5 Check C2214

and C2215 then

Replace N2000

SL 4 Scrap

Replace

N1400

No

Replace

N1400

SL 5 Replace

Z1400

SL 4 Scrap

No

Replace

N1400

Yes

SL 5 Replace

C2205

SL 4 Scrap

1203-2528 rev. 1

17 (101)

TROUBLESHOOTING GSM Network Problems

/ WCDMA Networ k Problem s

SEMC Troubleshooting Manual

K850

START

Replace

X1200

No

Is

Max Pwr 23dBm

Ok

(±3dBm)

Yes

Perform RSSI Test at

GSM 900, 1800 and 1900 Band

Instrumet Settings

System Mode:

TX/RX Tester Mode (GSM)

GSM BAND:

E-GSM 900, Channel 124

E-GSM 900, Channel 975

DCS 1800, Channel 512

PCS 1900, Channel 512

Measurement Mode:

RF Power -60dBm, Repeat, CW

Use

Spectrum Analyzer

Instrument settings:

TX Freq: 824.2MHz

Span: 300KHz,

Amplitude: -5dBm

Measure with

RF Probe

Signal at

MP 130 (Z1001)

-12dBm (±

(Inside GSM module)

MP 129 (L1006)

5dBm)

No

Replace

N1002

No

Signal at

-20dBm

(±15dBm)

MP 73 (R1201) and

Spectrum Analyzer

Instrument settings:

TX Freq: 1710.2MHz

Span: 300KHZ,

Amplitude: -5dBm

Measure with

RF Probe

0 Ohm

Between

MP 72 (L1200)

Instrument

Settings:

System Mode:

TX/RX Tester Mode

(WCDMA)

Downlink Channel:

10562

Measurement

Mode:

Repeat, Burst

Yes

Yes

Use

GSM Network problems

Load the ITP SW

into the phone.

Use TRS Fixture

Connect VBATT

Yes

and DCIO/SEPI

Fault Trace SW

Fault Trace SW

TX and RX WCDMA

Radio Settings:

Modes: Max Pwr

All Bands

Passed

RSSI Test

No

Replace

N1200 Thor

Go to

SERP Calibration

Fault Trace SW

Switch GSM Mode

Settings to:

TX Static

N1200 Thor

SERP Calibration

N1200 Thor

Fault Trace SW

Switch GSM Mode

Settings to:

TX Static

Use

SL 5 Replace

N2000

SL 4 Scrap

Select Band:

BAND I

Fast Select

Channels:

Ch LOW

23dBm

Replace

Go to

Replace

Yes

Yes

Yes

No

2.8 Volt DC at

MP 12 (ST2215

VccA)

NoNo

No

RSSI Test

Passed

Instrument Settings:

System Mode:

TX/RX Tester Mode (GSM)

GSM BAND: GSM850

Measurment Mode:

Repeat, Burst

Correction: 1.6dB

Is

measured value

±

5dBm

No

1.4V-1.6V Pk-Pk

Pulses at

MP 133 (R1000

VAPC)

No

Yes

Is

measured value

±

5dBm

Yes

Connect Mobile Phone

Instrument Settings:

System Mode:

TX/RX Tester Mode (GSM)

Yes

No

No

GSM BAND: GSM850

RF Power ON: -60dBm

Measurement Mode:

Repeat, CW

Correction: 1.6dB

Fault Trace SW

TX and RX GSM

GSM Mode Settings:

RX Switched

GSM Radio Settings:

Select Band: GSM 850

Channel: 128

GSM RSSI Measurements:

Start RSSI Test

Fault Trace SW

TX and RX GSM

GSM Mode Settings:

TX Switched

GSM Radio Settings:

Select Band : GSM 850

Channel : 128

Power Level: 5

measured value

33dBm

(±3dBm)

Instrument Settings:

System Mode:

TX/RX Tester Mode

GSM BAND: DCS1800

Measurement Mode:

Repeat, Burst

Fault Trace SW

TX and RX GSM

GSM Mode Settings:

TX Switched

GSM Radio Settings:

Select Band : GSM 1800

Channel : 512

Power Level: 0

measured value

30dBm

(±3dBm)

WCDMA Network

problems

Tester

Is

Yes

(GSM)

Is

Yes

Go to

START

Before TRS WCDMA

the GSM TRS guide

must be done!

Replace

X1200

SL 5 Replace

D2000

SL 4 Scrap

Replace

N2205

SL 5 Replace

N2000

SL 4 Scrap

Replace

N1200

Go to

SERP

Calibration

Replace

Faulty Component

Go to

GO-NOGO

Test

No

Yes

Yes

Yes

0 Ohm

between

MP 73 (R1201) and

MP 72 (L1200)

No

1.8Volt DC at

MP 81 (R2220

DCDC_EN)

1.3V-1.8V DC at

MP 83 (R2221

WPAVCC)

No

Current

consumption

between

500 – 800 mA

Replace

N1210

Are any of

X1201,

X1202 or X1203

damaged

No

WCDMA Network problems

Yes

DCIO/SEPI: 5V, Limiter 2A

Yes

Yes

No

No

No

Yes

Load ITP SW

into the phone.

Use TRS Fixture

Connect:

VBATT: 3.8V, Limiter 3A

Use Fault Trace SW

3.4V-3.8V DC at

MP 80 (L2210

VBATI)

No

SL 5 Replace

L2210

SL 4 Scrap

Instrument Settings:

System Mode:

TX/RX Tester Mode

WCDMA

Downlink Channel:

BAND I: 10562

BAND II: 9662

BAND V: 4375

Measurement Mode:

Repeat

Correction: 1.6dB

Max Pwr.

23dBm (±3dBm)

all bands

Ok

Phone reports

correct values

At all bands

(±3dBm)

Fault Trace SW

TX and RX WCDMA

Radio Settings:

Fast Select Channels:

Modes: Max Pwr 23dBm

3.4V-3.8V DC at

No

Fault Trace SW

TX and RX WCDMA

Radio Settings:

BAND I, II and V

Fast Select Channels:

Modes: Max Pwr 23dBm

Test Max Pwr 23dBm

for each WCDMA Band

Only one WCDMA Band

Instrument Settings:

System Mode:

TX/RX Tester Mode

Downlink Channel:

Yes

BAND I: 10562

BAND V: 4375

Measurement Mode:

RF Power: ON (-60dBm)

Correction: 1.6dB

Fault Trace SW

TX and RX WCDMA

Radio Settings:

Fast select channels:

Modes: Read RSSI

Read Measurement

Test Read RSSI

for each WCDMA Band

Only one WCDMA Band

Select Band:

BAND I

Ch LOW

TROUBLESHOOTING

MP 84 (L2207

VCC_WPA)

Yes

Select Band:

Ch LOW

at the time

WCDMA

BAND II: 9662

Repeat

Select Band :

BAND I, II, V

Ch LOW

RX On:

at the time

1203-2528 rev. 1

18 (101)

Xenon Flash problems

TROUBLESHOOTING Xenon Flash Problems

SEMC Troubleshooting Manual

K850

Disassemble the

phone

Use TRS Fixture

Connect Display and

Main Camera

Fault trace SW

MMI

Led and Backlight

Activate:

Xenon Flash Test

Disconnect

Main Camera

1.8 Volt DC

At

MP 92 (R4305)

No

Xenon Flash Test

Flash the Phone with

No

Ok

Yes

EMMA

SUCR SW

1.8 Volt DC

MP 90 (R4304)

Fault trace SW

MMI

Led and Backlight

Activate:

Xenon Flash Test

Connect: VBATT and DCIO/SEPI

START

Load ITP SW

into the phone.

Insert Dummy Battery

Use Fault Trace SW

TROUBLESHOOTING

At

No

Replace

D2420

Yes

Replace

X2511

Problem

solved

Yes

No

SL 5 Replace

D2000

SL 4 Scrap

Claim Component

X2511

Yes

SL 5 Replace

D4300

SL 4 Scrap

1203-2528 rev. 1

19 (101)

TROUBLESHOOTING System Connector Protection Test

/ Current Comsu m pt ion Test

SEMC Troubleshooting Manual

K850

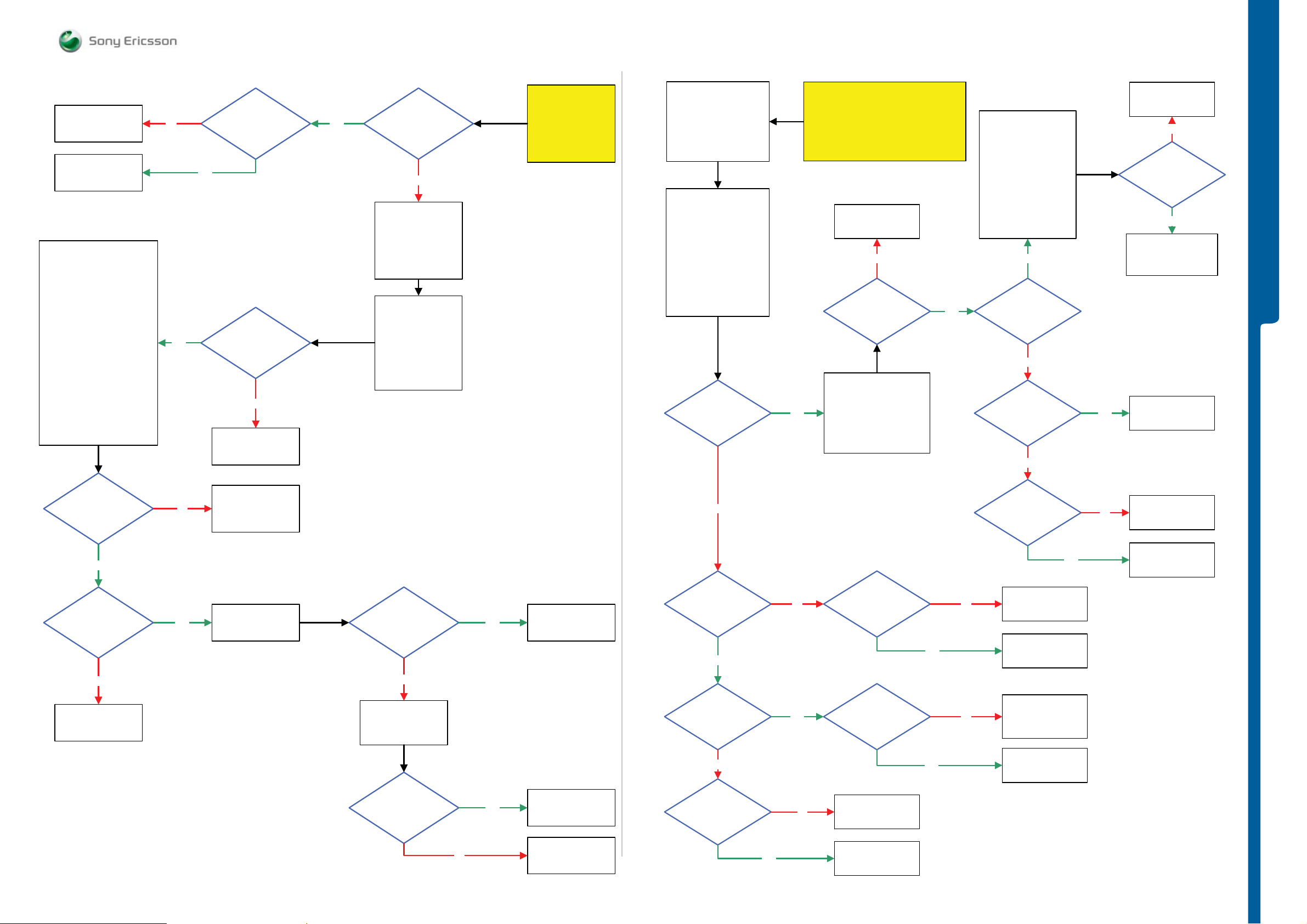

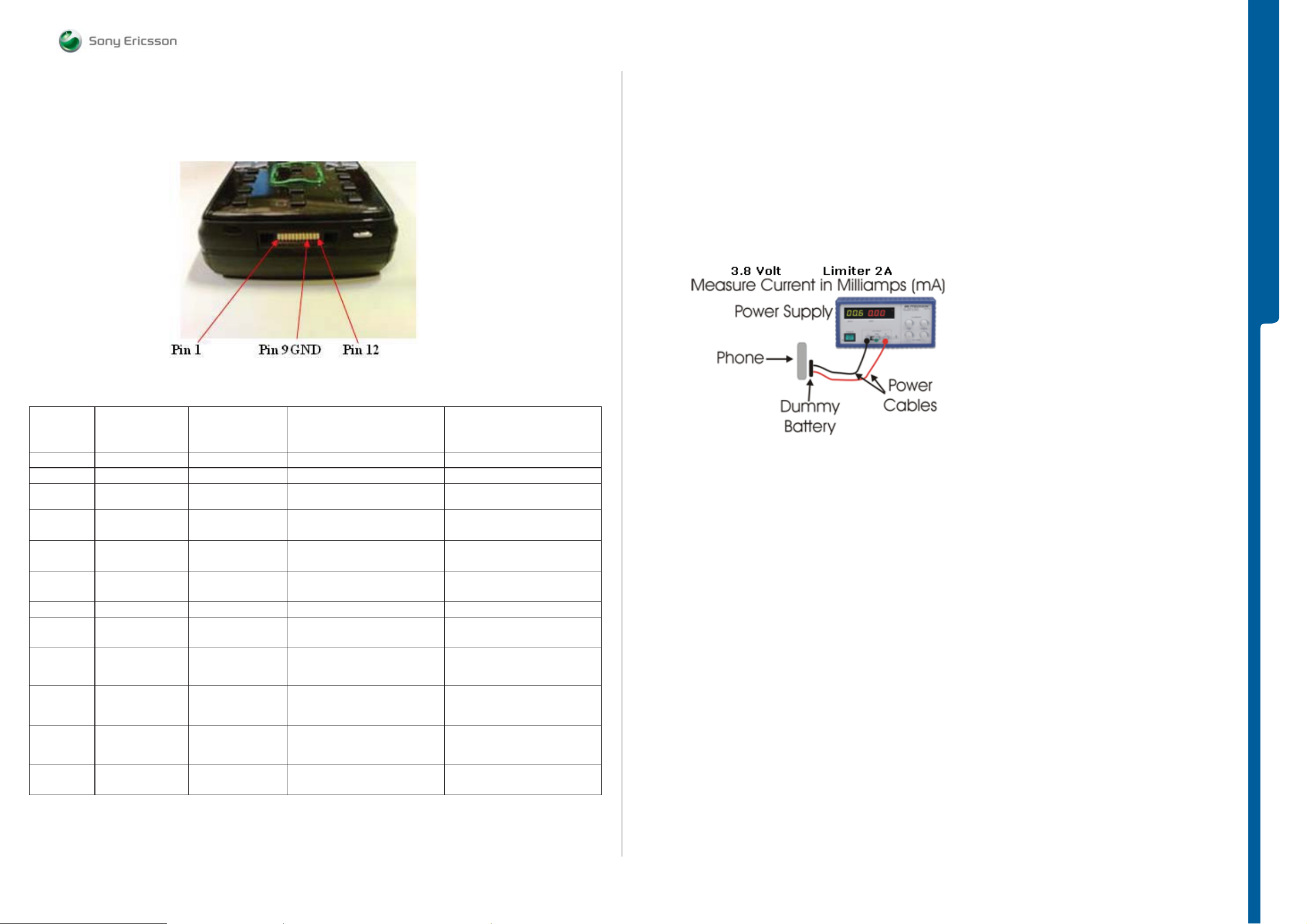

System Connector Protection Test

Perform Diode and Ohm measurements with DMM

Connect the black probe at ground (Pin 9 system connector)

Current Consumption Test

Step 1:

Insert Local SIM Card and use the phone with the Normal SW (SSW) and dummy

battery connected to Power Supply Channel 1 VBATT according to Picture 1.

Instrument settings: Voltage: 3.8 Volt, Limiter 3A.

TROUBLESHOOTING

Measure the current when Phone is off. Check the current consumption at Power

Supply Channel 1 VBATT.

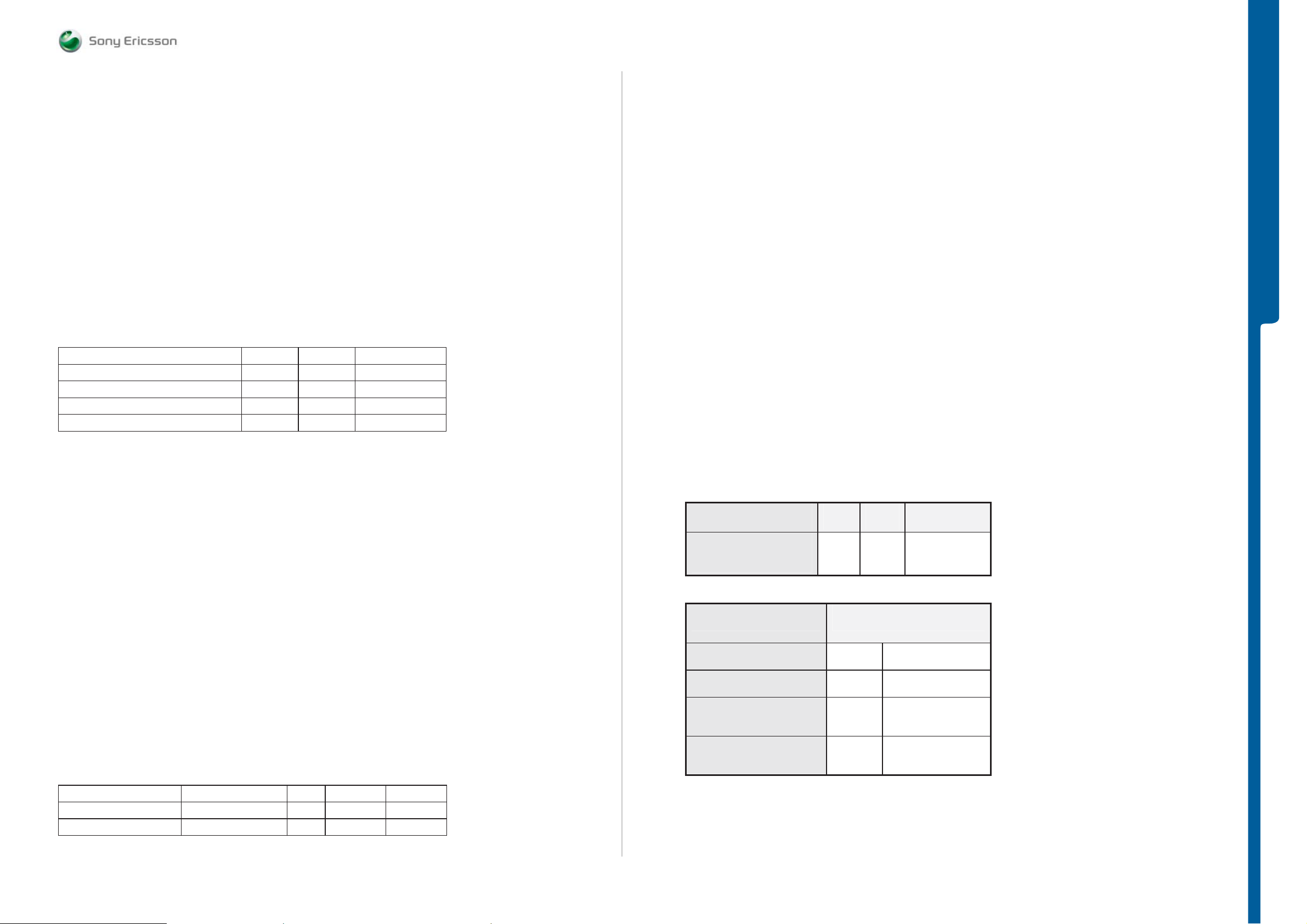

Picture 1

Diode

Pin at

X2400

1 0L 0L N2402 if Not 0L C2422 if Not 0L

2 0.0 1.4 No Action L2405 If higher than 1.4Ω

3 2.0 12K

4 1.0 1K

5 2.0 9K

6 2.0 9K

7 0L 0L Not connected Not connected

8 1.4 1.5K V2420 if lower than 1.5KΩ

9 0 0 No Action

10 0.7 200K-470K N2401if lower than 200KΩ

11 1.0 200K-470K N2401if lower than 200KΩ

12 0L 80K V2421 if lower than 80KΩ

Measurement

/ Volt

Ohm

Measurement

/ Ohm

SL 4 Action SL 5 Action

N3101 if lower than 12KΩ

L2401 if higher than 12KΩ C2421 If lower than 12KΩ

N3101 if lower than 1KΩ

L2402 if higher than 1KΩ C2420 if lower than 1KΩ

N3101 if lower than 9KΩ

L2403 if higher than 9KΩ C2416 if lower than 9KΩ

N3101 if lower than 9KΩ

L2404 if higher than 9KΩ C2415 if lower than 9KΩ

R2451, R2440, R2436

if higher than 1.5KΩ

R2455 if Not 0Ω between

X2400_Pin9 and PBA GND

D2450 if lower than

200KΩ R2465 if higher

than 470KΩ

D2450 if lower than

200KΩ R2466 if higher

than 470KΩ

C2423, C2424

if lower than 80KΩ

Current consumption in off mode should be less than 1mA.

If more than 1mA go to Dead Phone problems part 1 TRS guide.

Step 2:

Start the phone:

Measure the deep sleep current max 6mA typical between 0-3mA.

Make sure that the operator is running with deep sleep. (This operation can be

switched off by operator if the network is busy).

If phone using more than 6mA, then go to EMMA III and perform Software Update

Contents Refresh (SUCR).

Step 3 with Mobile Phone Tester Instrument

Insert Test SIM Card and use the phone with the Normal SW (SSW) and dummy

battery connected to Power Supply Channel 1 VBATT according to Picture 1.

Instrument settings: Voltage: 3.8 Volt, Limiter 3A.

Use Mobile Phone Tester Instrument in signalling mode direct connected to the

phone with RF Connector or use Shield Box if not possible. Phone Display must be

on during these tests to get correct current measurements.

Perform Radio TX measurements at GSM and WCDMA Band and compare with limits

according to text below.

1203-2528 rev. 1

20 (101)

TROUBLESHOOTING Current Comsumption Test

SEMC Troubleshooting Manual

K850

- Transmitter current 850 MHz at Ch: 128 power level 5. Typical 400mA

- Transmitter current 900 MHz at Ch: 1 power level 5. Typical 400mA

- Transmitter current 1800 MHz at Ch: 512 power level 0. Typical 400mA

- Transmitter current 1900 MHz at Ch: 512 power level 0. Typical 400mA

- Transmitter current WCDMA BAND I Low RX Ch: 10562 at 23dBm output

power. Max 750mA

If current consumption is not correct, the fault could be fixed by running SERP

calibration if not then go to GSM and WCDMA Network problems TRS guides.

If the current consumptions are equal to test limits then go to Charging Test.

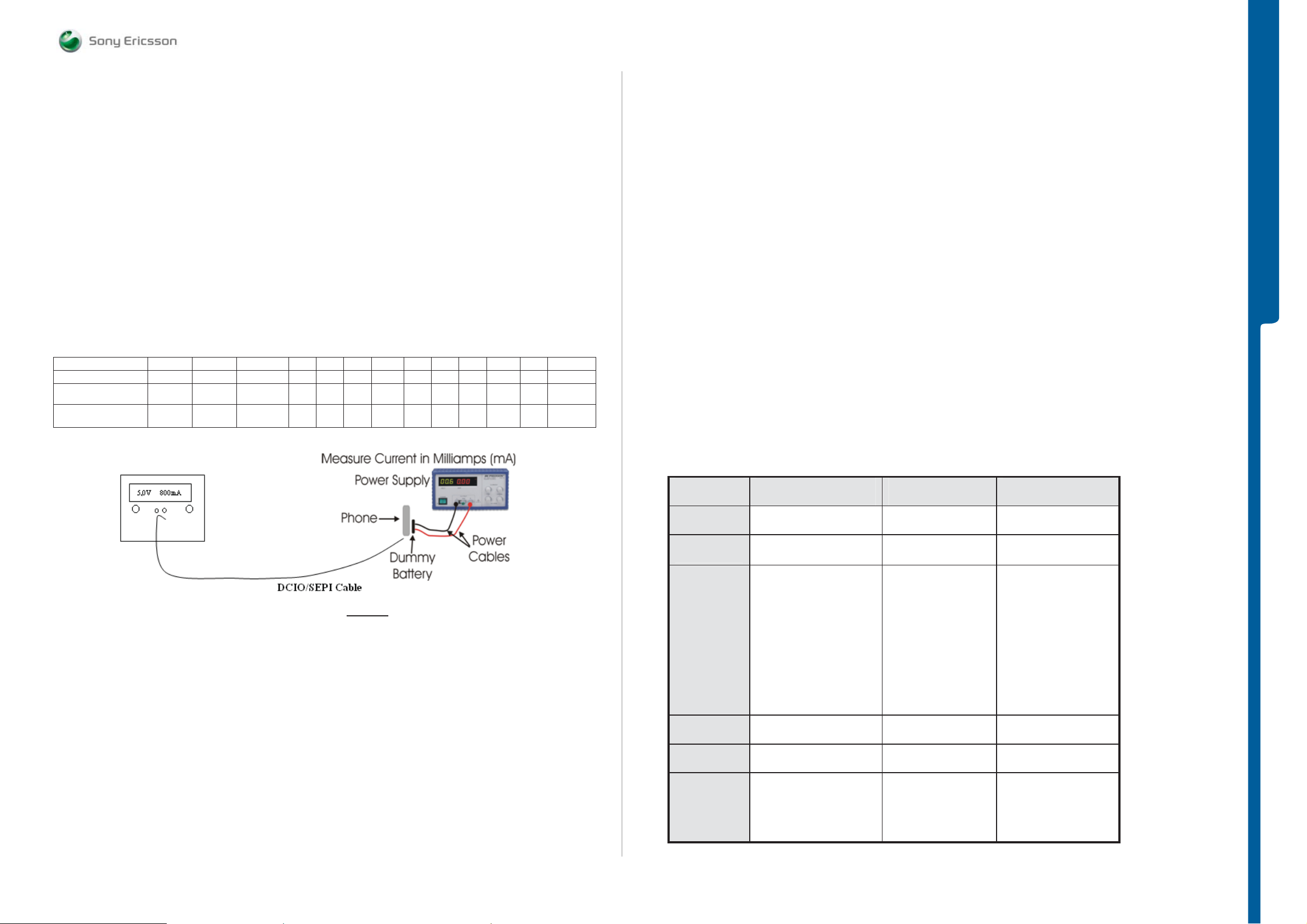

Step 4 with Fault Trace SW application:

- Flash the phone with ITP SW

-Use TRS Fixture

- Connect the:

Power Supply Channel 1 VBATT:

Instrument settings: Voltage: 3.8 Volt, Limiter 3A

Power Supply Channel 2 DCIO/SEPI

Instrument settings: Voltage: 5 Volt, Limiter 2A

- Connect DCIO/SEPI Cable to the phone

Perform the following tests:

- Max TX Power GSM 1800 MHz

Fault Trace SW settings:

TX and RX GSM

GSM Mode Settings:

TX Switched

GSM Radio Settings:

Select Band: GSM 900

Channel: 512

Power Level: 0

- Max TX Power GSM 1900 MHz

Fault Trace SW settings:

TX and RX GSM

GSM Mode Settings:

TX Switched

GSM Radio Settings:

Select Band: GSM 900

Channel: 512

Power Level: 0

TROUBLESHOOTING

- Max TX Power GSM 850 MHz

Fault Trace SW settings:

TX and RX GSM

GSM Mode Settings:

TX Switched

GSM Radio Settings:

Select Band: GSM 850

Channel: 128

Power Level: 5

- Max TX Power GSM 900 MHz

Fault Trace SW settings:

TX and RX GSM

GSM Mode Settings:

TX Switched

GSM Radio Settings:

Select Band: GSM 900

Channel: 1

Power Level: 5

- Max TX Power WCDMA BAND I

Fault Trace SW settings:

TX and RX WCDMA

Radio Settings:

Select Band: BAND I

Fast Select Channels: Ch LOW

Modes: Max Pwr 23dBm

Compare current consumption during Max TX Power Tests with the current

consumption limits below.

- Transmitter current 850 MHz at Ch: 128 power level 5. Typical 255mA

- Transmitter current 900 MHz at Ch: 1 power level 5. Typical 240mA

- Transmitter current 1800 MHz at Ch: 512 power level 0. Typical 200mA

- Transmitter current 1900 MHz at Ch: 512 power level 0. Typical 220mA

- Transmitter current in WCDMA BAND I

Low RX Ch: 10562 mode at max

power level 23 dBm and Rx on.Typical 600mA

Tolerance: ±10%

If current consumption is not correct, the fault could be fixed by running SERP

calibration if not then go to GSM and WCDMA Network problems TRS guides.

If the current consumptions are equal to the sheet then go to Charging Test.

1203-2528 rev. 1

21 (101)

TROUBLESHOOTING Battery & Curre nt Calib rat io n Test

/ Backup Capacitor Test

SEMC Troubleshooting Manual

K850

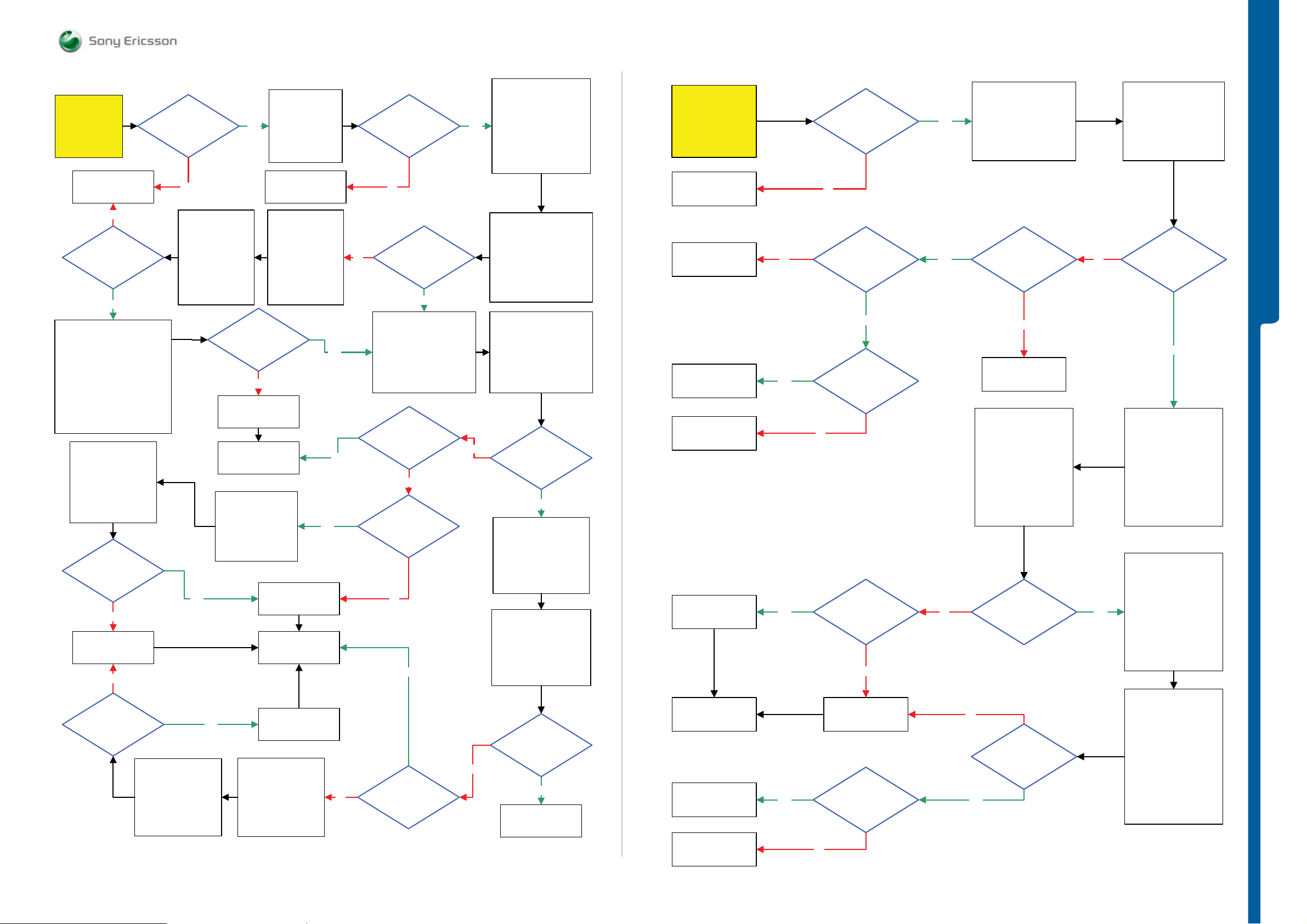

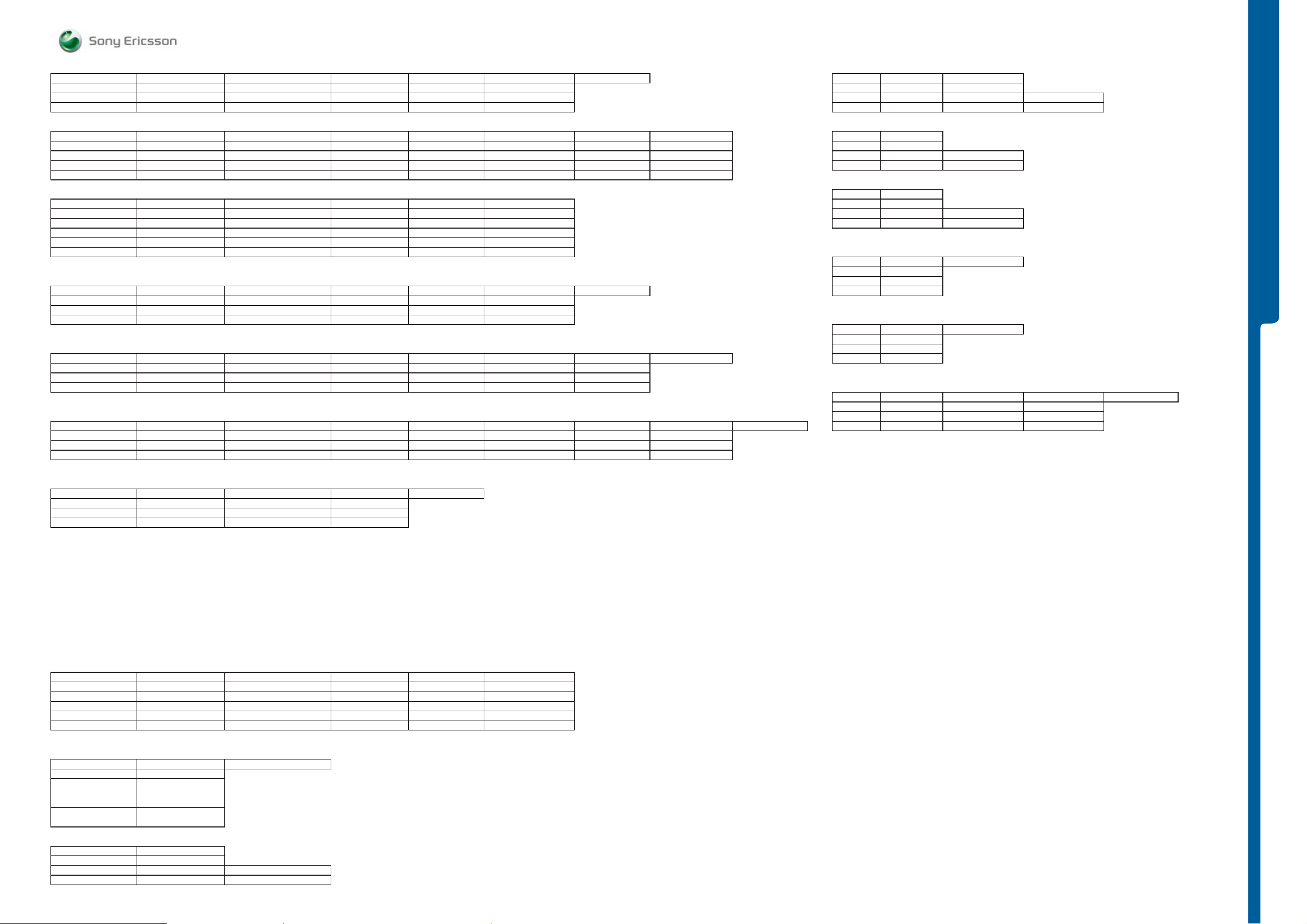

Battery and Current Calibration Test

Instrument settings for the Battery Calibration Test

Power Supply Channel 1 VBATT:

X Volt according to the Fault Trace SW Test Instructions:

Fault Trace SW-Logic-Phone Power-Battery Calibration and follow test instructions.

Limiter: 2A.

If test is performed at the Core Level then use dummy battery according to the K850

Equipment List for this test. If using TRS Fixture no dummy battery is needed.

Note: Maximal cable length between Power Supply Channel 1 VBATT and the dummy

battery or TRS Fixture must be 1m. The cable must have a capacity for at least 16A.

Limits Table for the Battery Calibration Test

Voltage Level on VBATT Min Max UNIT

3.2 Volt

3.2 Volt

4.1 Volt

4.1 Volt

Instrument settings for the Current Calibration Test

202 338 mV

CA 152 HEX

743 886 mV

2E7 376 HEX

Backup Capacitor Test

To perform this test use:

- Phone with the ITP SW

- Power Supply Channel 1 VBATT: Instrument settings: Voltage: 3.8V, Limiter: 2A

- Power Supply Channel 2 DCIO/SEPI: Instrument settings Voltage: 5V, Limiter: 2A

This test should be preformed in 3 steps:

Step1:

Measure the voltage at the Back up capacitor by using Fault Trace SW- Logic ADC Values – Read ADC Value (Reading 1).

Step2:

This step should be done 30 seconds after Step 1. Measure the voltage at the

Backup capacitor by using Fault Trace SW - Logic – ADC Values - ADC Channels

– Read ADC Value (Reading 2).

Step3:

Compare the difference between Reading 1 and Reading 2 with the reference table

below. If the Reading 1 value is between 50 and 680 go to Interval 1, if between 681

and 800 go to Interval 2, if between 801 and 880 go to Interval 3 and compare with

the Reading 2 – Reading 1 Min and Max Limits.

TROUBLESHOOTING

If test is performed at the Core Level then use dummy battery according to the K850

Equipment List for this test. If using TRS Fixture no dummy battery is needed.

Note: The Power Supply Channel 1 VBATT must allow reverse current.

Note: Maximal cable length between Power Supply Channel 1 VBATT and the dummy

battery or TRS Fixture must be 1m. The cable must have a capacity for at least 16A.

Note: Length of the Power Supply Channel 2 DCIO/SEPI customized cable must be

exact 1,3m.

Power Supply Channel 1 VBATT:

3.8 Volt

Limiter 2A

Power Supply Channel 2 DCIO/SEPI:

5.0 Volt

Limiter: 2A

Limits Table for the Current Calibration Test

Measured Current Name Min Max Unit

100mA

800mA

DCIO Current 50 150 mA

DCIO Current 725 875 mA

Reference Table:

Min Max Unit

Absolute readout

Reading 1

Reading 1 (Dec) Reading 2–Reading 1 (Dec)

Interval 1 (50 – 680)

Interval 2 (681 – 800)

Interval 3 (801 – 880)

Note: The upper table contains the absolute limits for the readouts. The lower table

contains the allowed delta between the first and the second readout, separated in

time with 30 seconds.

50 880 Dec

Min Max

20 210

530

010

If the readings is out of limits replace C2217 Backup capacitor.

If problem is not solved then SL 5 Replace N2000 SL 4 Scrap.

1203-2528 rev. 1

22 (101)

TROUBLESHOOTING Test Charging

/ ASIC Revision Test

SEMC Troubleshooting Manual

K850

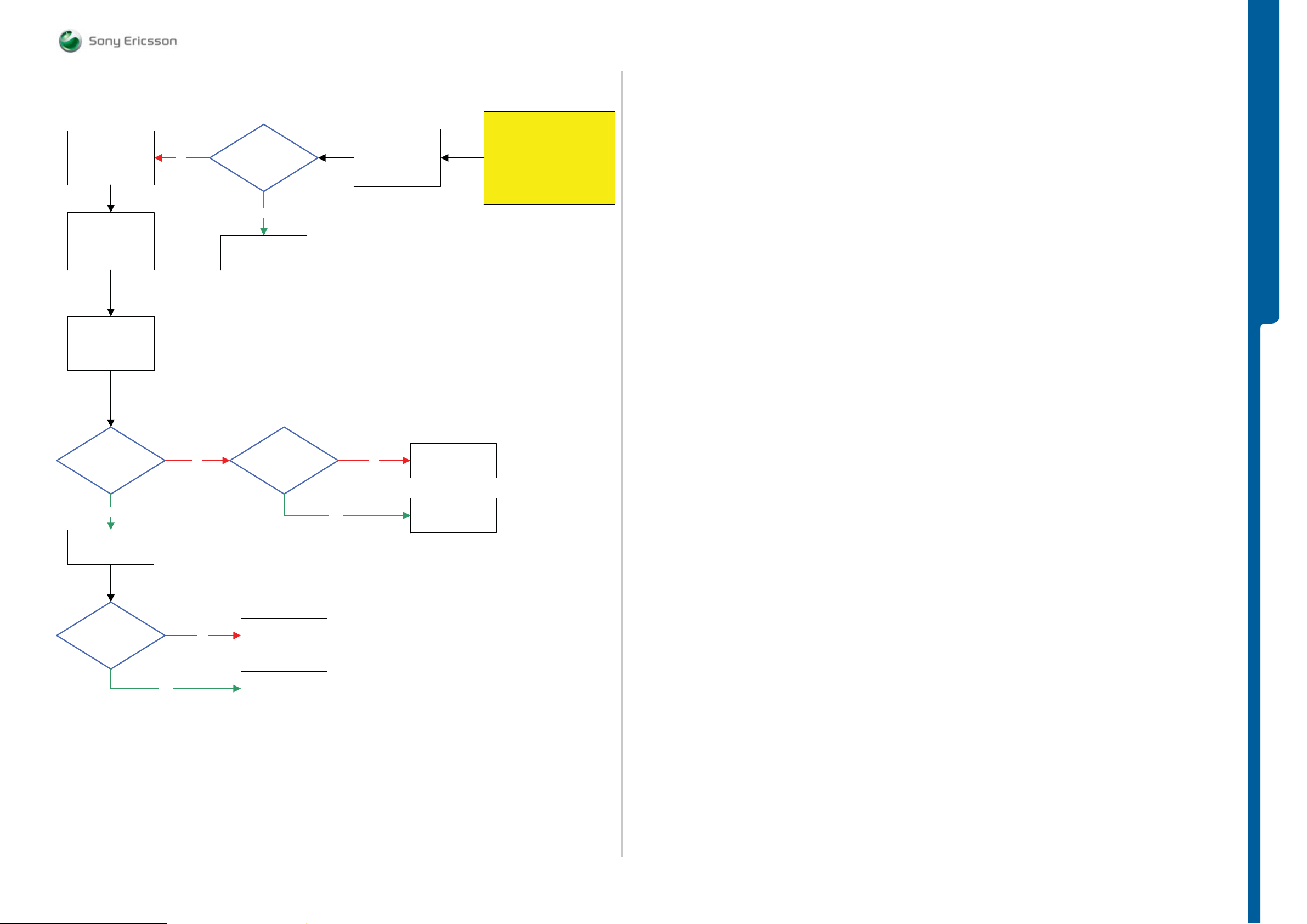

To perform this test use:

- Phone with the Normal SW (SSW)

- Dummy Battery connected to Power Supply Channel 1 VBATT

- Power Supply Channel 1 VBATT instrument settings:

Voltage: 3.0 to 4.2 Volts, according to VBATT row in the Reference Table.

Limiter: 2A

- Power Supply Channel 2 DCIO/SEPI instrument settings:

Voltage: 5V

Limiter: 2A

Test instructions:

- Disconnect the DCIO/SEPI Cable between each measurement and wait phone

- Take a note of Current measurements at Power Supply Channel 2 DCIO/SEPI

- Compare test results with reference table below, tolerance +/-20%.

Reference Table

VBATT x Volt

Test Time x sec.

DCIO/SEPI Current

mA

Display indicate

charging

Test Charging

to shutdown when changing VBATT voltage.

and Display charging indicator status, X seconds after DCIO/SEPI cable has

been inserted according to Test Time row in the reference table below.

3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 4.0 4.1 4.2

15s 15s 25s 25s 25s 25s 25s 25s 25s 25s 25s 25s 35s

200 200 200-400 200 200 200 200 750 750 750 650 380 0

Nothing Nothing Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Fully

Charged

ASIC Revision Test

Purpose with this test is to check following items:

- that ASIC-s Revision State is correct

- Check if communication to and from the ASIC-s is Ok

TROUBLESHOOTING

The following ASIC-s is tested:

- D2000 (Anja)

- N2000 (Vera)

- N1400 (Bluetooth and FM Radio ASIC)

- N2525 (Accelerometer)

- Touchpad ASIC

To perform this test use:

- Phone with the ITP SW

- TRS Fixture

- Power Supply Channel 1 VBATT (Voltage: 3.8V, Limiter: 2A)

- Power supply Channel 2 DCIO/SEPI (Voltage: 5V, Limiter: 2A)

- Fault Trace SW choose General – Asic Revisions – Read All

Power Supply Channel 1 VBATT must allow reverse current.

If the charging current is Not equal to the reference table go to Charging probl ems

TRS Guide.

If the charging current is equal to reference table then insert the normal battery and

test the charging current to define if the phone battery is working properly.

Measure the voltage at the battery to define the current level.

If the battery is receiving the right current, then the phone and the battery are

working properly.

Reference returned value can be found in the table below.

ASIC Description Product number Return value (hex)

D2000

N2000

N1400

N1400

N2525

Anja 1200-0795 0x2C8

Vera 1000-8142 0xC5

Bluetooth:

Firmware Revision

Chip ID

1200-6182

Ox5,0x1

0x0,0x0,0x0,0x0

Will always return 0

on STLC because

Chip ID is not

supported.

FM Radio 1200-6182 Ox800

Accelerometer 1200-1223 0x3B

Touchpad

ASIC

Touchpad

1200-1603 0x1975

Will always return

0xFFFF on PBA level

1203-2528 rev. 1

23 (101)

TROUBLESHOOTING Reference Measurement Points

-

Voltages to N2000 Clocks to N2000

MP MP PBA GND MP 79 (X2200 Pin 3) MP 31 (TP2200) MP 29 (TP2202) MP 48 (C2242) Power sup 3.80 V MP MP 85 (C2116) MP 6 (B2101_Pin7)

GND VBAT VBATI BDATA VDD_REF SYSCLK1/MCLK RTCCLK

Phone Off 0.00V 3.8V 3.8V 0.00V 3.8V Phone Off 0Hz 32.768kHz Power sup 0.00 Volt

Phone On 0.00V 3.8V 3.8V 0.00V 3.8V Phone On 26MHz 32.768kHz Power sup 3.80 Volt

Voltages from N2000 Clocks from N2000

MP MP 17 (ST2204) MP 11 (ST2203) MP 9 (ST2208) MP 14 (ST2212) MP 34 (ST2213) MP 36 (ST2214) MP MP 21 (R2125)

VAUDIO26 VANA25 VDDE18 VBT27 VDIG VBEAR26 RTCCLK

0.00V 0.00V 0.00V 0.00V 0.00V 0.00V Power sup 0.00 Volt Phone Off 0Hz Power sup 3.80 Volt

Phone Off 0.00V 0.00V 0.00V 0.00V 0.00V 0.00V Power sup 3.80 Volt Phone On 32.768kHz Power sup 3.80 Volt

Phone On 2.6V 2.5V 1.8V 2.7V 2.7V 2.6V Power sup 3.80 Volt

VCORE18 from N2202

Voltages from N2000 MP MP 158 (ST2217)

MP MP 56 (ST2206) MP 12 (ST2215) MP 7 (C2218) MP 22 (ST2210) VCORE18

VCORE12 VccA VDD_LP VBACKUP Phone Off 0.00V Power sup 0.00 Volt

0.00V 0.00V 2.2V 2.2V Power sup 0.00 Volt Phone On 1.8V Power sup 3.80 Volt

Phone Off 0.00V 0.00V 2.2V 2.2V Power sup 3.80 Volt

Phone On 1.2V 2.8V 2.2V 2.2V Power sup 3.80 Volt Memory Card

C2217 Completely charged Memory Card inserted and Combo Reader connected to the PBA

MP MP 16 (ST2202) Power sup 3.80 Volt

WCDMA N1210 VMC28

Use Fault Trace SW to activate and deactivate WCDMA Radio Phone Off 0.00V

MP MP 84 (L2207) MP 83 (R2221) MP 81 (R2220) MP 12 (ST2215) MP 9 (ST2208) Power sup 3.80 Volt Phone On 2.8V

VCC_WPA WPAVCC DCDC_EN VccA VDDE18

WCDMA Radio Off 0.00V 0.00V 0.00V 2.8V 1.8V Red LED V2428

WCDMA Radio On 3.4V 1.4V 1.8V 2.8V 1.8V Use Fault Trace SW to activate and deactivate Red LED

MP MP 128 (C2427) Power sup 3.80 Volt

Bluetooth N1400 REDLED

Use Fault Trace SW to activate and deactivate Bluetooth REDLED Off 0.00V

MP MP 147 (ST1404) MP 143 (C1408) MP 146 (C1409) MP150 (C1412) MP 148 (R2118) MP 21 (R2125) Power sup 3.80 Volt REDLED On 1.8V

VDIG VDDE18 VBT27 VDDE18 BT_CLK RTCCLK

Bluetooth Off 2.7V 1.8V 2.7V 1.8V 26MHz 32.768kHz FM Radio N1400

Bluetooth On 2.7V 1.8V 2.7V 1.8V 26MHz 32.768kHz Use Fault Trace SW to activate and deactivate FM Radio

MP MP 151 (ST2282) MP 154 (C3305) MP 152 (R3301) Power sup 3.80 Volt

Main Camera VBATI VDDE18 RTCCLK

Use Fault Trace SW to activate and deactivate Main Camera. Display and Main Camera module must be connected to the PBA FM Radio Off 3.8V 1.8V 32.768kHz

MP MP 76 (R2280) MP 27 (TP2206) MP 28 (TP2207) MP 32 (TP2204) MP 82 (ST2275) MP 54 (TP2208) MP 77 (R4301) Power sup 3.80 Volt FM Radio On 3.8V 1.8V 32.768kHz

CAM_LDO_EN VCAMIO VCAML VCAMAF VCAMSA VCAMSD CAMSYSCLK/MCLK

Main Camera Off 0.00V 0.00V 0.00V 0.00V 0.00V 0.00V 0Hz

Main Camera On 1.8V 1.8V 1.2V 2.8V 2.8V 1.8V 26MHz

SEMC Troubleshooting Manual

K850

TROUBLESHOOTING

VGA Camera

Use Fault Trace SW to activate and deactivate VGA Camera. Display and VGA Camera must be connected to the PBA

MP MP 27 (TP2206) MP 82 (ST2275) MP 77 (R4301) Power sup 3.80 Volt

VGA Camera Off 0.00V 0.00V 0Hz

VGA Camera On 1.8V 2.8V 13MHz

Charging

Charging off 1:

DCIO/SEPI not

connected.

Charging off 2:

DCIO/SEPI connected.

MP MP 40 (C2201) MP 47 (C2241) MP 39 (V2202 Pin2) MP 41 (R2201) Power sup 3.8 Volt

Charging off 1 0.00V 3.6V 3.2V 3.8V Charger voltage 0.0 Volt

Charging off 2 5.0V 4.7V 4.7V 3.8V Charger voltage 5.0 Volt

Charging 100mA 5.0V 4.7V 4.7V 3.8V Charger voltage 5.0 Volt

Charging 800mA 4.5V 4.4V 2.8V 4.2V Charger voltage 5.0 Volt

VBUS

USB cable connected to PC

MP MP 44 (ST2201) Power sup 3.80 Volt

USB Cable disonnected

from the phone

USB Cable connected to

the phone

VCAMIO VCAMSA CAMSYSCLK/MCLK

Charging 100mA:

Use Fault Trace SW:

Start Current Calibration

> Set VBATT to 3.8

Note: The Current

Calibration Test must be

repeated if current

consumption goes below

50mA at Power Supply

Channel 2 when you are

performing this

measurements.

DCIO DCIO_INT CHREG CHSENSEP

VBUS

0.00V

5.0V

Charging 800mA:

Use Fault Trace SW:

Start Current Calibration ->

Set VBATT to 3.8V ->

Perform Step1 Note: The

Current Calibration Test must

be repeted if current

consumtion goes below

725mA at Power Supply

Channel 2 when you are

performing this

measurements.

MCLK 26MHz from N1200

MP MP 149 (R2100)

MCLK

Phone Off 0Hz Power sup 3.80 Volt

Phone On 26MHz Power sup 3.80 Volt

1203-2528 rev. 1

24 (101)

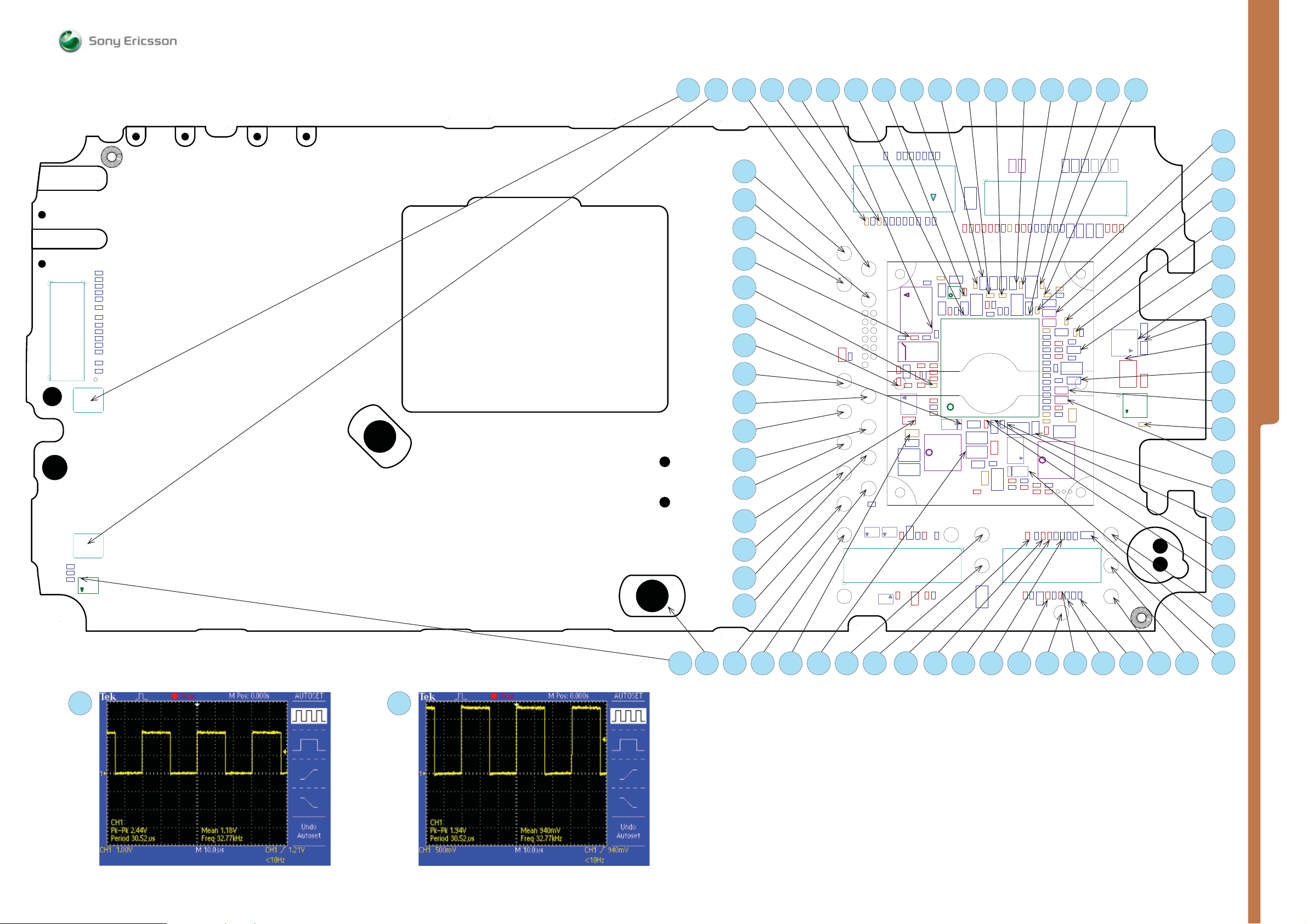

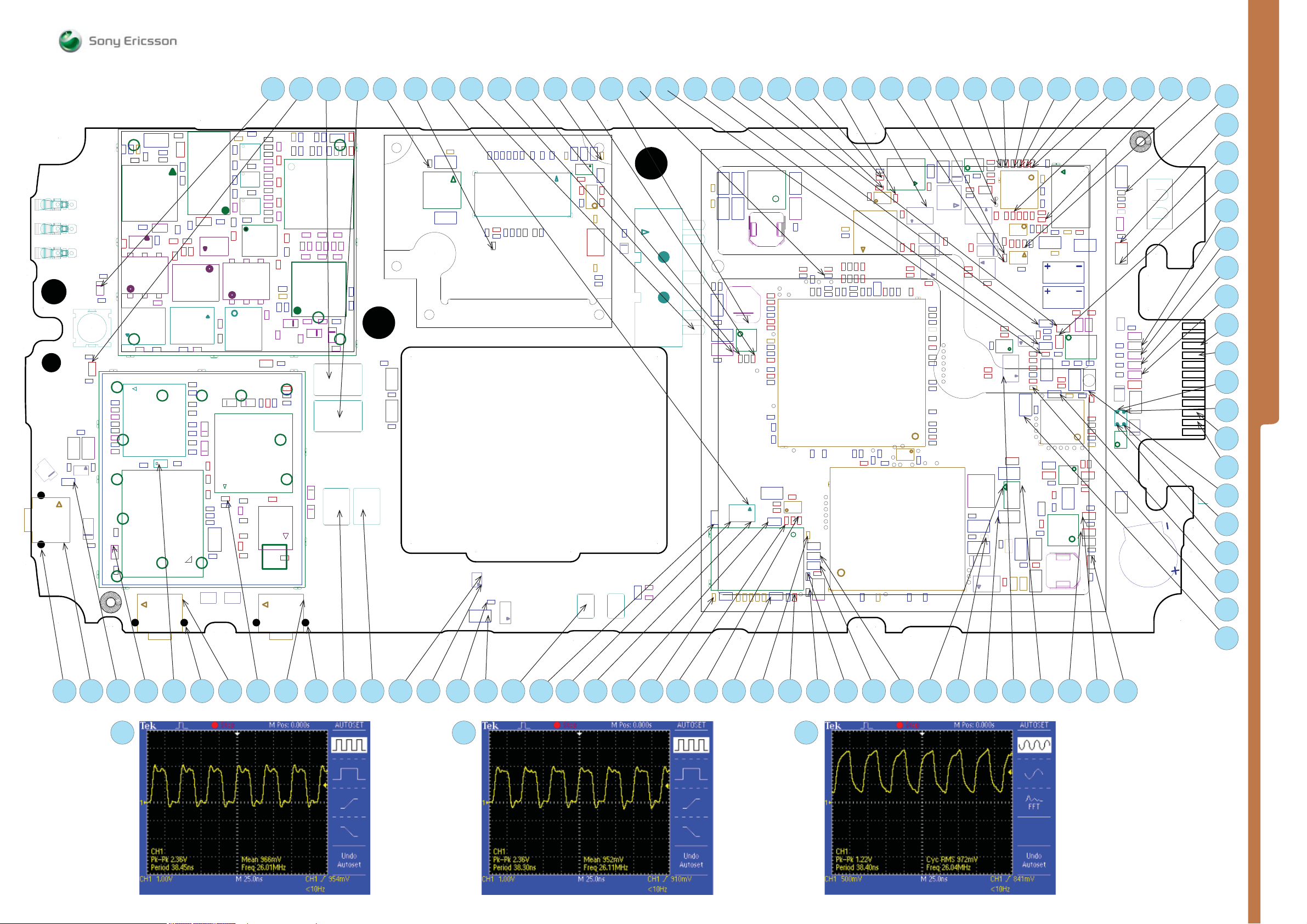

A1

B1

X4300

X3100

X3101

C4210

C4209

C4208

N4200

C4343

C4342

C4341

C4340

C4339

C4325

C4330

C4338

C4337

C4336

C4332

C4328

C4331

C4329

SP4300

MEASUREMENT POINTS Front Side

MP 18

MP 19

MP 20

MP 21

MP 22

MP 23

MP 24

MP 25

MP 26

MP 27

MP 28

MP 29

MP 30

MP 31

MP 32

MP 33

TP4112

TP4106

TP4201