Sony ZSM-35 Service manual

ZS-M35

SERVICE MANUAL

Ver 1.2 2001.07

U.S. and foreign patents licensed from Dolby Laboratories

Licensing Corporation.

AUDIO POWER SPECIFICATIONS (US model)

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION

With 4-ohm loads, both channels driven from

150 - 10,000 Hz; rated 4 W per channelminimum RMS power, with no more than 10%

total harmonic distortion in AC operation.

CD

Section

MD

Section

US Model

Canadian Model

Taiwan Model

Model Name Using Similar Mechanism PMC-20

CD Mechanism Type KSM-213CDM

Optical Pick-up Name KSS-213C

Model Name Using Similar Mechanism PMC-MD55

MD Mechanism Type MDM-5GA

Base Unit Name MBU-5A

Optical Pick-up Name KMS-260B

CD player section

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wave length: 785 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance of

about 200 mm from the objective lens surface on

the optical pick-up block with 7 mm aperture.)

Spindle speed

200 r/min (rpm) to 500 r/min (rpm) (CLV)

Number of programme positions

2

Frequency response

20 - 20,000 Hz +1/–2 dB

Wow and flutter

Below measurable limit

Radio section

Frequency range

FM: 87.5 - 108 MHz

AM: 530 - 1,710 kHz

Antennas

FM: Telescopic antenna

AM: AM loop antenna

SPECIFICATIONS

MD player section

System

Minidisc digital audio system

Disc

MiniDisc

Laser diode properties

Material: GaAlAs

Wave length: 785 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance of

about 200 mm from the objective lens surface on

the optical pick-up block with 7 mm aperture.)

Recording/playback time

Stereo recording:

Maximum 80 minutes (with MDW-80)

Monaural recording:

Maximum 160 minutes (with MDW-80)

Revolutions

400 rpm to 900 rpm (CLV)

Error correction

Advanced Cross Interleave Reed Solomon Code

(ACIRC)

Sampling frequency

44.1 kHz

– Continued on next page –

PERSONAL MINIDISC SYSTEM

9-927-183-33

2001G0400-1

© 2001.7

Sony Corporation

Personal Audio Company

Shinagawa Tec Service Manual Production Group

– 1 –

Coding

Adaptive TRansform Acoustic Coding (ATRAC)

Modulation system

EFM (Eight-to-Fourteen Modulation)

Number of programme positions

2 stereo programme positions

Frequency response

20 - 20,000 Hz +1/–2 dB

Signal-to-noise ratio

Over 80 dB (during playback)

Wow and flutter

Below measurable limit

General

Speaker

Full-range: 8 cm (3 in.) dia., 4 ohms, cone type (2)

Inputs

LINE IN (stereo minijack): Sensitivity 436 mV/

870 mV

Outputs

Headphones jack (stereo minijack) (1):

For 32 ohms impedance headphones

Power output (excluding US model)

5 W + 5 W (at 4 ohms, 10 % harmonic distortion

in AC operation)

Power requirements

For personal minidisc system:

120 V AC, 60 Hz

For back-up memory:

4.5 V DC, 3 size AA (R6) batteries

For remote control:

3 V DC, 2 size AA (R6) batteries

Power consumption

24 W

Dimensions (incl. projecting parts)

Approx. 498.5 × 173.5 × 227 mm (w/h/d)

3

(17

/4 × 6 1/2 × 9 1/2 inches)

Mass

Approx. 5.2 kg (13 lb. 4 oz)

Supplied accessories

AC power cord (1)

Remote control (RMT-CM35A) (1)

AM loop antenna (1)

Design and specifications are subject to change

without notice.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage. Check

leakage as described below.

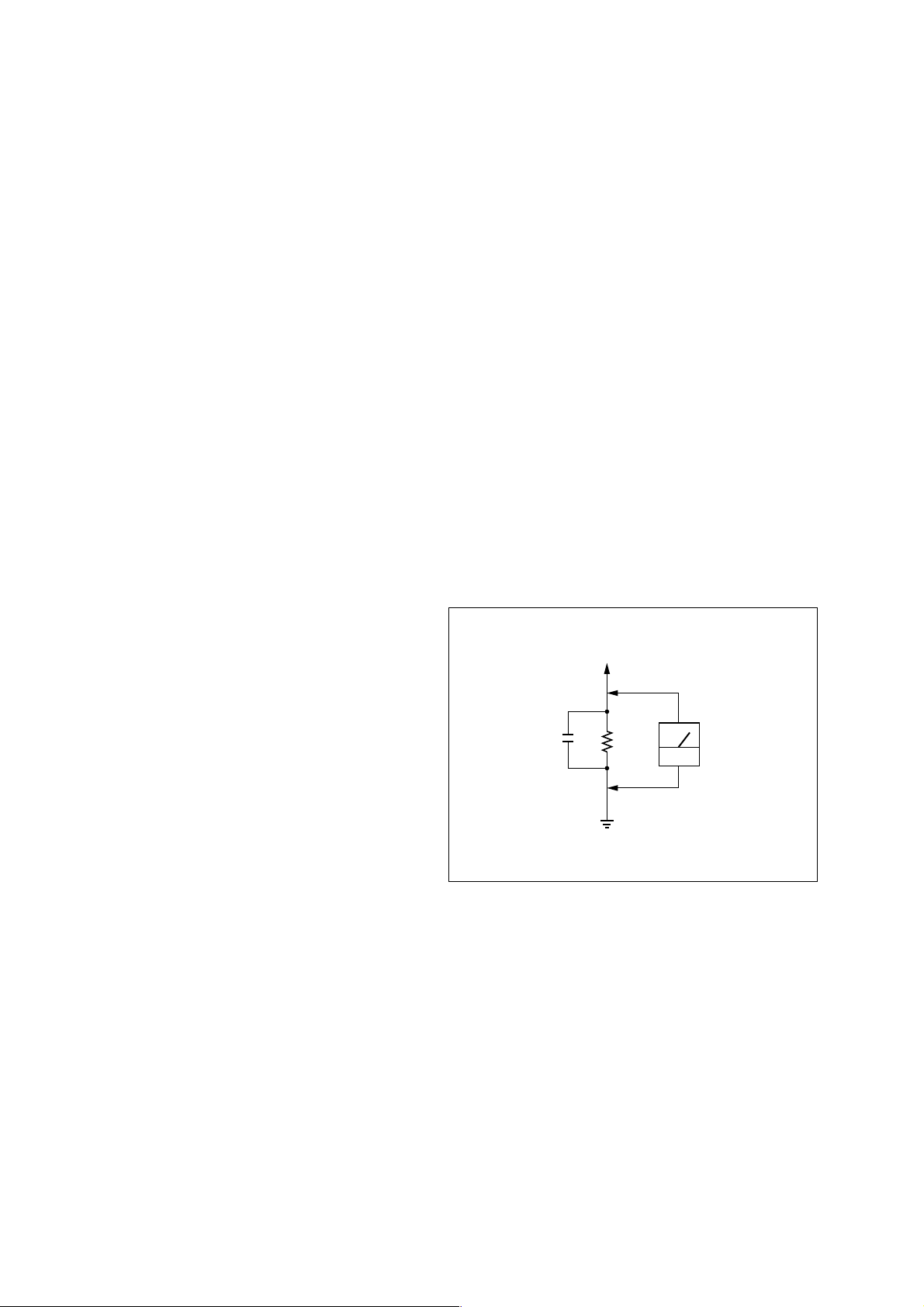

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive

VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

0.15µF

1.5k

Ω

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL

OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

À LA SÉCURITÉ!!

– 2 –

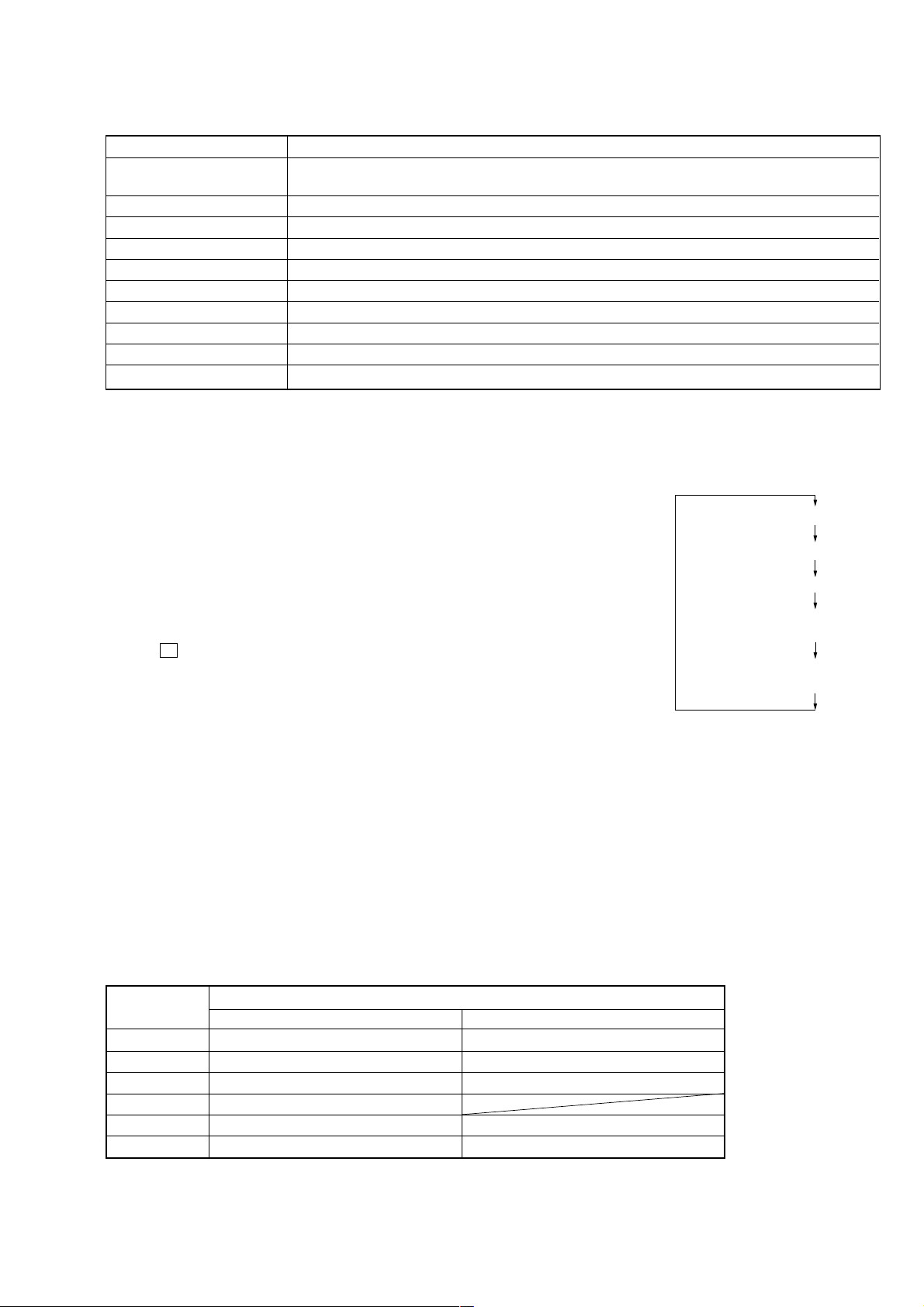

TABLE OF CONTENTS

1. SERVICING NOTES

1-1. Notes on Handling the Optical Pick-up Block or Base Unit .. 4

1-2. Notes on Laser Diode Emission Check............................... 4

1-3. Notes on Chip Component Replacement ............................ 4

1-4. Flexible Circuit Board Repairing ........................................ 4

1-5. Chuck Plate Jig on Repairing ..............................................4

1-6. Demonstration ..................................................................... 4

1-7. Checking the Laser Diode and Focus Search Operation.....4

1-8. Jig for Checking BD Board Waveform ............................... 5

1-9. Checks Prior to Parts Replacement and Adjustments ......... 6

1-10. Change of Pulley ................................................................. 6

2. GENERAL

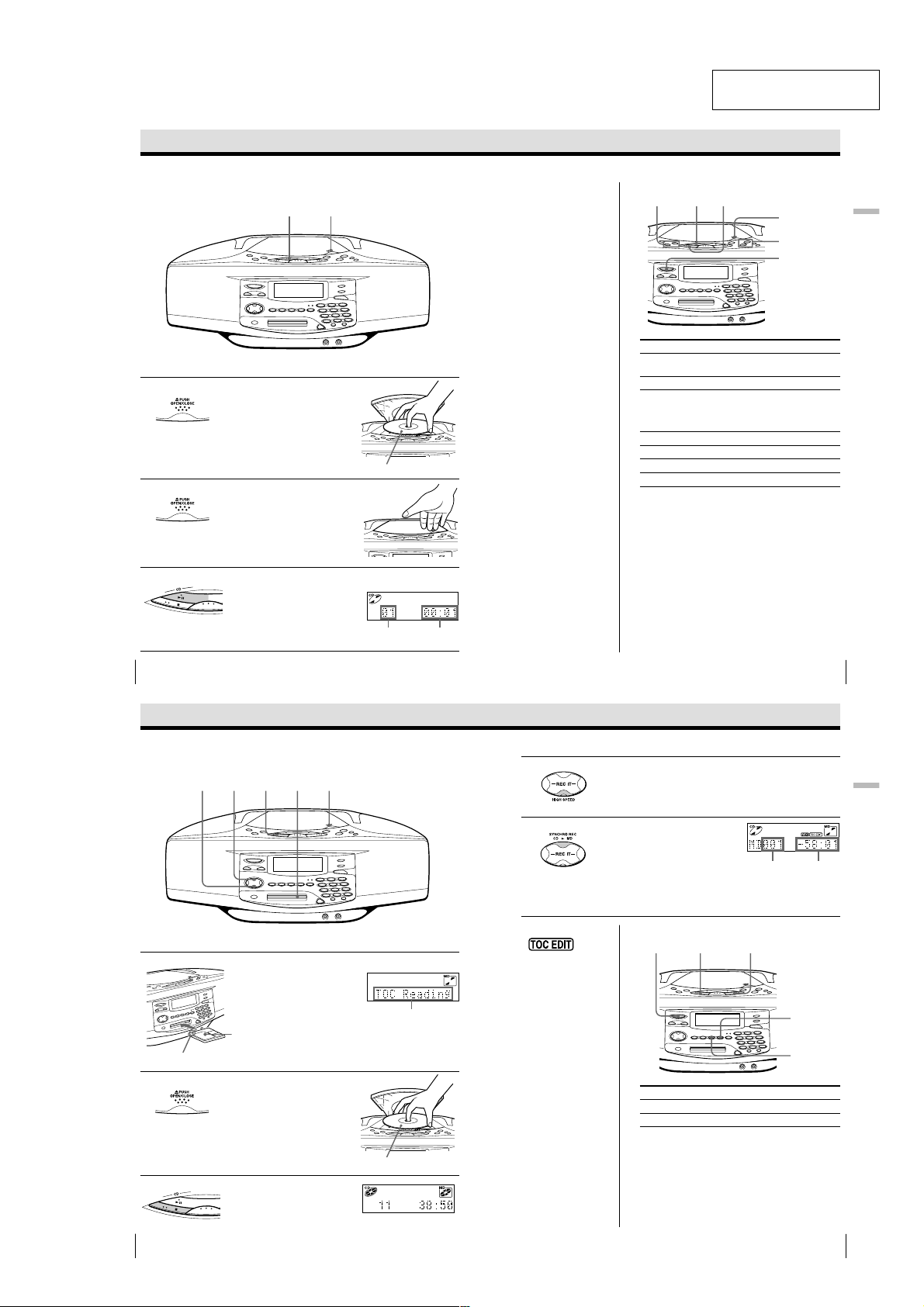

Playing a CD .......................................................................7

Recording a whole CD ........................................................ 7

Playing an MD..................................................................... 8

Listening to the radio...........................................................8

3. DISASSEMBLY

3-1. Cabinet (Rear) Assy ............................................................ 9

3-2. Power Board........................................................................9

3-3. Cabinet (Upper) Assy........................................................ 10

3-4. MD Block Assy.................................................................10

3-5. Tuner Board....................................................................... 11

3-6. Jack Board .........................................................................11

3-7. LED Board ........................................................................ 12

3-8. Key Board ......................................................................... 12

3-9. Top Board .......................................................................... 13

3-10. FL Board ........................................................................... 13

3-11. Main board ........................................................................ 14

3-12. CD Board .......................................................................... 14

3-13. CD Mechanism Block ....................................................... 15

3-14. DG Board .......................................................................... 15

3-15. Plate (Front), Shield .......................................................... 16

3-16. MD Mechanism Block-1 (MDM-5GA) ............................ 16

3-17. MD Mechanism Block-2 (Slider (Cam) Assy) ................. 17

3-18. MD Mechanism Block-3 (BD Board)...............................18

3-19. MD Mechanism Black-4 (SW Board)............................... 18

6. DIAGRAMS

6-1. IC Pin Function Descriptions ............................................ 33

6-2. Circuit Boards Location .................................................... 42

6-3. Block Diagram –Tuner Section–....................................... 43

6-4. Block Diagram –MD Section–..........................................46

6-5. Block Diagram –CD Section–........................................... 49

6-6. Block Diagram –Audio Section– ...................................... 51

6-7. Schematic Diagram –CD Section (1/2)–...........................53

6-8. Schematic Diagram –CD Section (2/2)–...........................55

6-9. Printed Wiring Boards –CD Section– ............................... 57

6-10. Printed Wiring Boards –Tuner Section– ........................... 59

6-11. Schematic Diagrams –Tuner Section– .............................. 61

6-12. Printed Wiring Boards –BD Section– ............................... 63

6-13. Schematic Diagram –BD Section (1/2)–...........................65

6-14. Schematic Diagrams –BD Section (2/2)– ......................... 67

6-15. Schematic Diagram –DG Section– ................................... 69

6-16. Schematic Diagram –DG Section– ................................... 71

6-17. Printed Wiring Board –DG Section– .................................73

6-18. Printed Wiring Board –Main Section– .............................. 75

6-19. Schematic Diagram –Main Section (1/3)– ........................77

6-20. Schematic Diagram –Main Section (2/3)– ........................79

6-21. Schematic Diagram –Main Section (3/3)– ........................81

6-22. Printed Wiring Boards –Panel Section– ............................83

6-23. Schematic Diagrams –Panel Section–............................... 85

6-24. Printed Wiring Boards –Switch Section– .......................... 87

6-25. Schematic Diagrams –Switch Section– ............................ 89

6-26. Printed Wiring Boards –Power Supply Section– .............. 91

6-27. Schematic Diagrams –Power Supply Section– ................. 93

6-28. IC Block Diagrams............................................................ 95

7. EXPLODED VIEWS

7-1. Cabinet (Rear) Section .................................................... 101

7-2. Cabinet (Front) Section ................................................... 102

7-3. Cabinet (Upper) Section.................................................. 103

7-4. MD Block Section...........................................................104

7-5. MD Mechanism Section (MDM-5GA) ..........................105

7-6. MD Base unit Section (MBU-5A) ................................. 106

7-7. Optical Pick-up Section (KSM-213CDM)......................107

4. TEST MODE

4-1. MD section ........................................................................ 19

5. ELECTRICAL ADJUSTMENTS

5-1. Tuner section .....................................................................22

5-2. MD section ........................................................................ 24

5-3. CD section .........................................................................31

8. ELECTRICAL PARTS LIST....................................108

– 3 –

SECTION 1

SERVICING NOTES

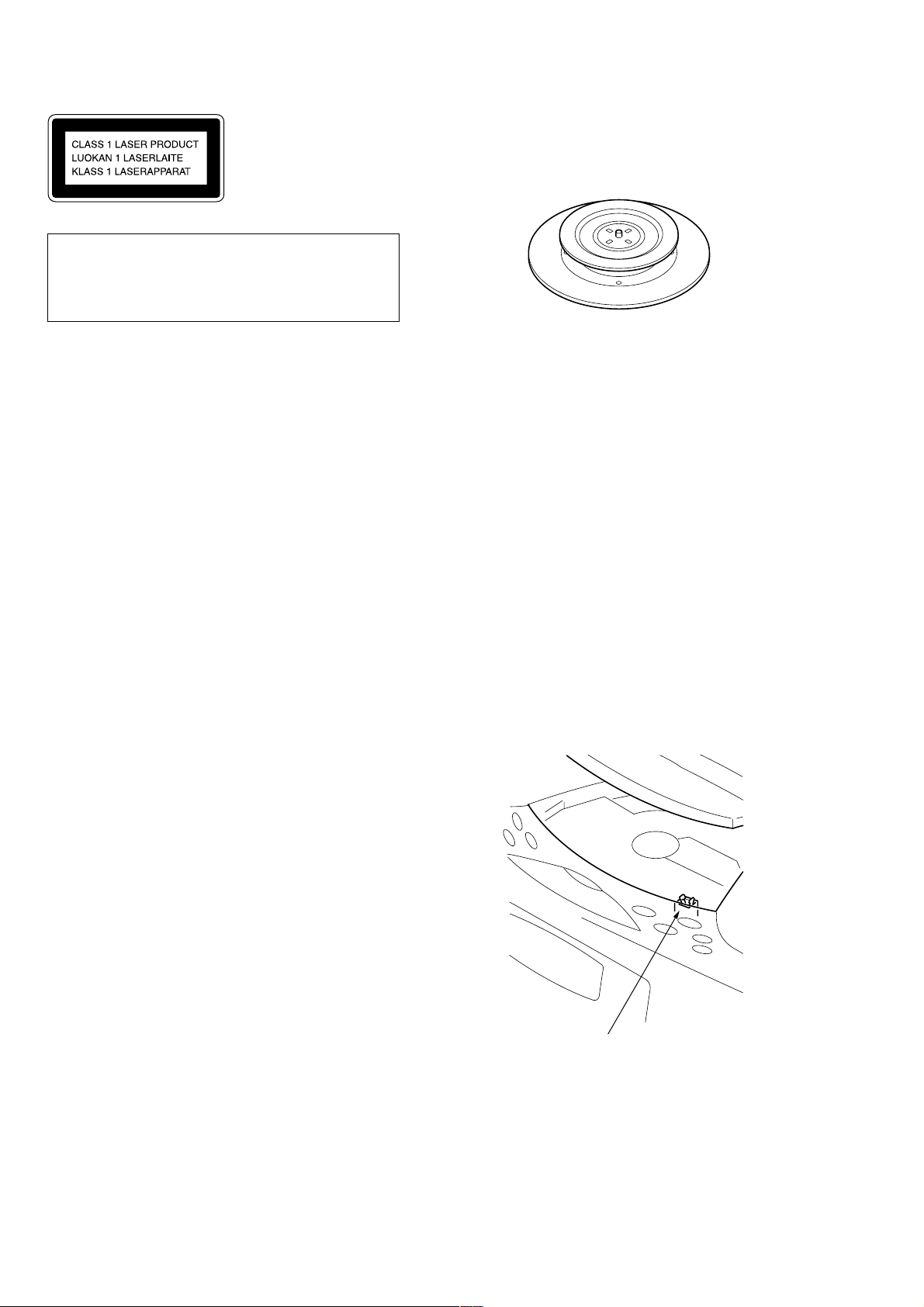

This Compact Disc player

is classified as a CLASS 1

LASER product.

The CLASS 1 LASER

PRODUCT label is located

on the bottom exterior.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

1-1. NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

1-2. NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

1-3. NO TES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

1-5. CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use

Chuck Plate Jig.

• Code number of Chuck Plate Jig: X-4918-255-1

1-6. DEMONSTRATION

This set enters the demonstration mode about 10 seconds after the

power cord is connected. The demonstration displays such as

“DEMONSTRA TION MODE” and “CREA TE YOUR ORIGINAL

MD” then appears.

When no operation is entered for one minute after the [POWER]

button is turned on, the demonstration mode is also entered.

T o release the demonstration mode, set the timer in this set or press

and hold down the [NO/CANCEL] button for about 2 seconds.

1-7. CHECKING THE LASER DIODE AND FOCUS

SEARCH OPERATION

1. Turn on the POWER and open the CD cover.

2. As shown below, push S402 (CD DOOR) with a screwdriver or

other tool.

3. Press the CD button.

4. Check the objective lens to make sure that the laser diode is

emitting light. If not so, the auto power control circuit or optical

pickup would be damaged.

Verify that the objective lens moves vertically three times for

focus search.

1-4. FLEXIBLE CIRCUIT BOARD REPAIRING

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

S402

– 4 –

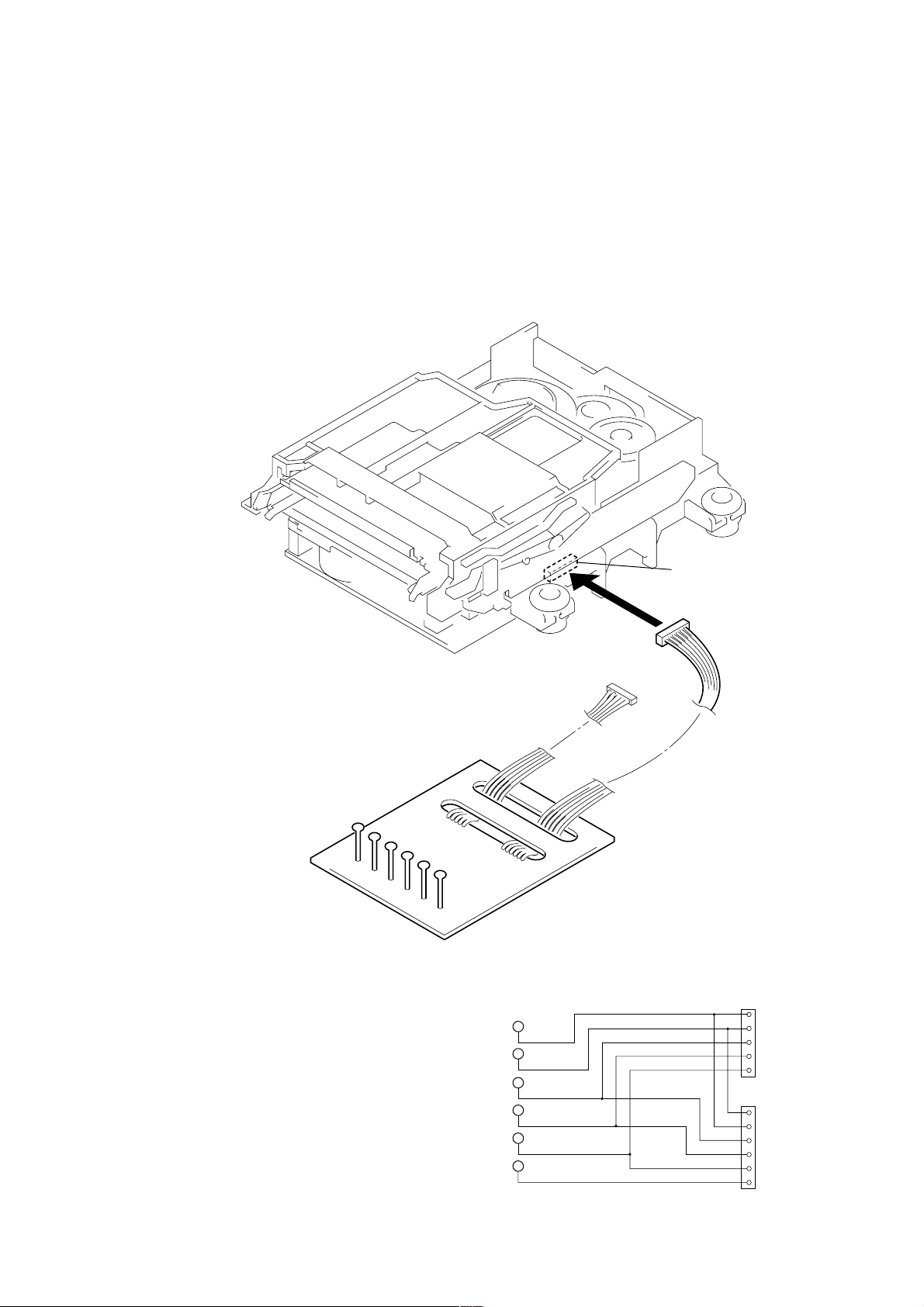

1-8. JIG FOR CHECKING BD BOARD WAVEFORM

r

3

5

The special jig (J-2501-149-A) is useful for checking the waveform of the BD board. The names of terminals and the checking items to

be performed are shown as follows.

GND: Ground

I+3V : For measuring IOP (Check the deterioration of the optical pick-up laser)

IOP : For measuring IOP (Check the deterioration of the optical pick-up laser)

TEO : TRK error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

Mechanism deck

RF

VC

TEO

IOP

I+3V

GND

RF

VC

TEO

CN110

6P connecto

5P connector

1

RF

VC

TEO for MDMIOP

I+3V

5

1

IOP

I+3V

GND

– 5 –

VC

RF

TEO

for MDM-

IOP

I+3V

6

GND

1-9. CHECKS PRIOR TO PARTS REPLACEMENT AND ADJUSTMENTS (FOR MD SECTION)

m

Before performing repairs, perform the following checks to determine the faulty locations up to a certain extent.

Details of the procedures are described in “5 Electrical Adjustments”.

Laser power check

(6-1 : See page 26)

Focus bias check

(6-2 : See page 26)

C PLAY check

(6-3 : See page 26)

Self-recording/playback

check

(6-4 : See page 26)

Criteria for Determination

(Unsatisfactory if specified value is not satisfied)

• 0.9 mW power

Specified value : 0.84 to 0.92 mW

• 7.0 mW power

Specified value : 6.8 to 7.2 mW

lop (at 7mW)

• Labeled on the optical pickup

Iop value ± 10mA

• Error rate check

Specified value : For points a, b, and c

C1 error : About 200

ADER : Below 2

• Error rate check

Specified value:

a. When using test disc (MDW-74/AU-1)

C1 error : Below 80

ADER : Below 2

b. When using check disc (TDYS-1)

C1 error : Below 50

• CPLAY error rate check

Specified value:

C1 error : Below 80

ADER : Below 2

• Clean the optical pick-up

• Adjust again

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

If always unsatisfactory:

• Replace the overwrite head

• Check for disconnection of the circuits around the

overwrite head

If occasionally unsatisfactory:

• Check if the overwrite head is distorted

• Check the mechanism around the sled

Measure if unsatisfactory:

Note:

The criteria for determination above is intended merely to determine if satisfactory or not, and does not serve as the specified value for

adjustments.

When performing adjustments, use the specified values for adjustments.

1-10. CHANGE OF PULLEY

pulley

M102, 103

Install the pulley to the motor.

2.5 m

– 6 –

Basic Operations

SECTION 2

GENERAL

This section is extracted

from instruction manual.

Playing a CD

For hookup instructions, see pages 57 - 59.

1 Press Z PUSH OPEN/CLOSE

2 Close the lid of the CD

3 Press CD u (CD N on the

Basic Operations

4

down to open the CD

compartment and place the CD

on the CD compartment.

compartment.

remote).

The player turns on (direct

power-on) and the player plays

all the tracks once.

1, 23

With the label side up

Display

Track

number

Playing

time

Tip

Next time you want to

listen to a CD, just press

CD u. The player

turns on automatically

and starts playing the

CD.

Use these buttons for additional operations

To Press

adjust the volume VOLUME +, –

stop playback CD x

pause playback CD u (CD X on the

go to the next track >

go back to the previous track .

remove the CD Z PUSH OPEN/CLOSE

turn on/off the player POWER

CD u. , >

CD x

Z PUSH

OPEN/CLOSE

VOLUME –, +

POWER

(VOL +, – on the remote)

remote)

Press the button again to

resume play after pause.

Basic Operations

Basic Operations

5

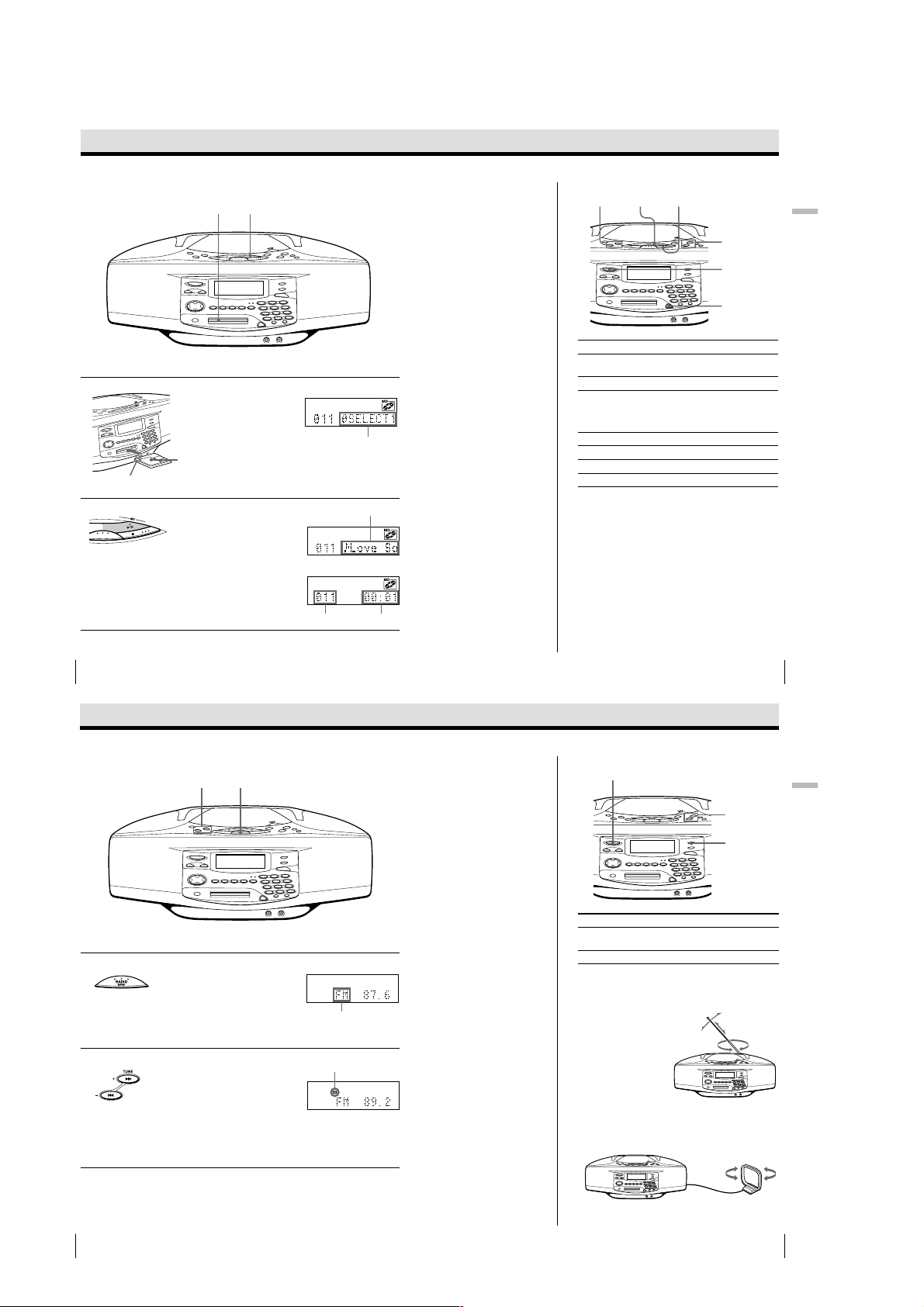

Recording a whole CD

(Synchronized recording)

34

5

For hookup instructions, see pages 57 - 59.

1 Insert a recordable MD (direct

Insert in the direction of

the arrow

2 Press Z PUSH OPEN/CLOSE

power-on).

With the label

side up

and place the CD on the CD

compartment.

Press Z PUSH OPEN/CLOSE

again to close the CD

compartment.

3 Press CD x.

Basic Operations

6

21

Display

After “TOC Reading” is

displayed, the disc name

will be displayed if it is

labeled.

With the label side up

4 To record at high speed, press

5 Press SYNCHRO REC CD N

Notes

• After you

stop recording, do not

disconnect the AC

power cord or move

the player while “TOC

EDIT” is flashing in the

display. If you do so,

recording may not be

done properly.

• When you record a

whole CD, you cannot

pause recording.

Tips

• Adjusting the volume or

the audio emphasis

(page 49) will not affect

the recording level.

Keep the volume at a

moderate level so as to

prevent the sound from

skipping.

• To record over the

previous recording, see

page 33.

• Once the clock is set, the

recording date and time

are stamped

automatically (page 50).

• You can label an MD or a

track during recording

(page 44).

HIGH SPEED.

The indicator lights up.

To record at normal speed, skip this step.

MD.

The player starts recording

automatically.

If the MD has any previous

recording, recording will be

made from the last recorded

position.

Use these buttons for additional operations

POWER

To Press

stop recording MD x or CD x

turn on/off the player POWER

If “CD>MD OK?” alternates with time display

There is not enough space on the MD to record the whole

CD.

If it is all right to record as much as possible and cancel

recording of some tracks, press YES•ENTER. To stop

recording, press NO•CANCEL.

If any other messages are displayed, see page 72.

CD x

Track number

of MD

MD x

Remaining

recording

time of MD

YES

ENTER

NO

CANCEL

Basic Operations

Basic Operations

7

– 7 –

Playing an MD

Use these buttons for additional operations

2

1

., >

MD u

MD x

Basic Operations

VOLUME –, +

POWER

Z

For hookup instructions, see pages 57 - 59.

1 Insert the MD (direct power-on).

With the label

Insert in the direction of

the arrow

2 Press MD u (MD N on the

Basic Operations

8

side up

remote).

The player plays all the tracks

once.

Listening to the radio

2

1

Display

After “TOC Reading” is

displayed, the disc name

will be displayed if it is

labeled.

Track name is displayed

if it is labeled.

m

Track number

Playing time

Tip

Next time you want to

listen to a MD, just press

MD u. The player

turns on automatically

and starts playing the

MD.

To Press

adjust the volume VOLUME +, –

stop playback MD x

pause playback MD u (MD X on the

go to the next track >

go back to the previous track .

remove the MD Z

turn on/off the player POWER

Use these buttons for additional operations

POWER

(VOL +, – on the remote)

remote)

Press the button again to

resume play after pause.

Basic Operations

VOLUME –, +

9

Basic Operations

For hookup instructions, see pages 57- 59.

1 Press RADIO BAND until the

2 Hold down TUNE + or TUNE –

Basic Operations

10

band you want appears in the

display (direct power-on).

until the frequency digits begin to

change in the display.

The player automatically scans

the radio frequencies and stops

when it finds a clear station.

If you can’t tune in a station,

press TUNE + or TUNE –

repeatedly to change the

frequency step by step.

Display

“FM” or “AM” appears

Indicates an FM stereo

broadcast

– 8 –

Tips

• If the FM broadcast is

noisy, press MONO/

ST•REPEAT (MODE on

the remote) until

“Mono” appears in the

display and radio will

play in monaural.

• Next time you want to

listen to the radio, just

press RADIO BAND.

The player turns on

automatically and starts

playing the previous

station.

MONO/ST

REPEAT

To Press

adjust the volume VOLUME +, –

turn on/off the radio POWER

To improve broadcast reception

FM:

Reorient the antenna for FM.

AM:

Keep the AM loop antenna as far as possible from the

player and reorient it.

(VOL +, – on the remote)

Basic Operations

11

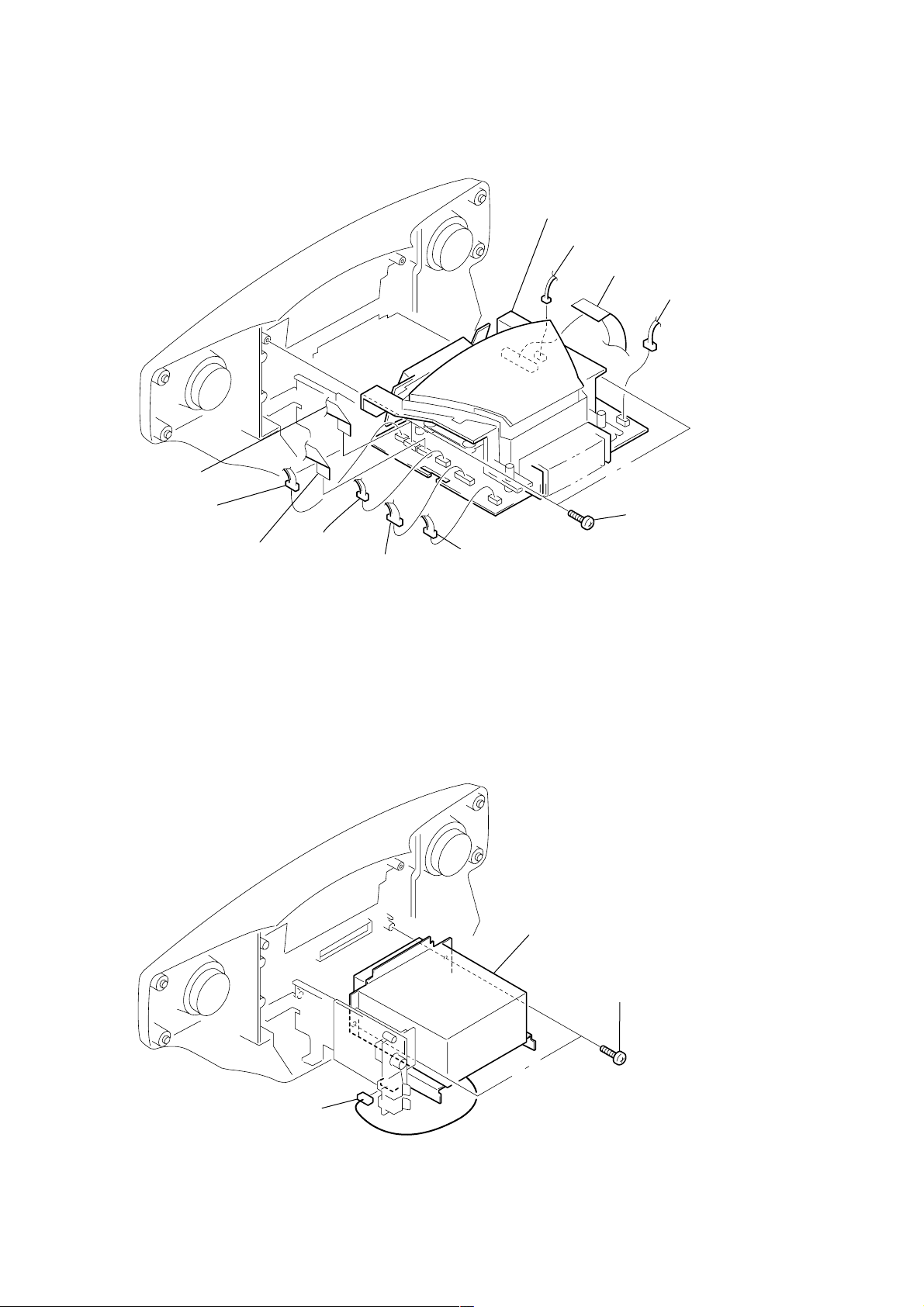

SECTION 3

4

DISASSEMBLY

Note : This set can be disassemble according to the following sequence.

Set Cabinet (Rear)

Assy

DG Board

LED Board

Plate (Front), Shield

Note : Follow the disassembly procedure in the numerical order given.

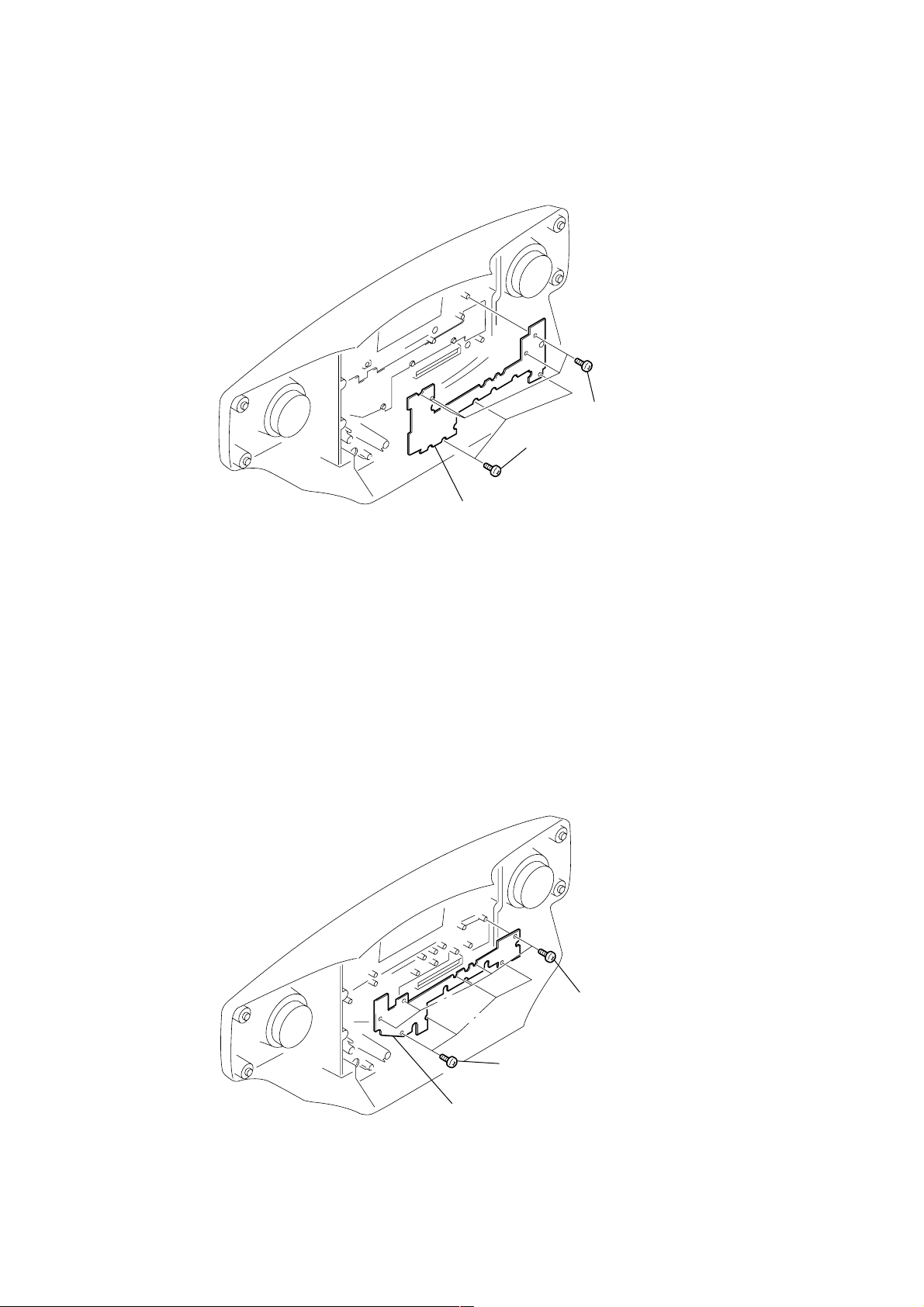

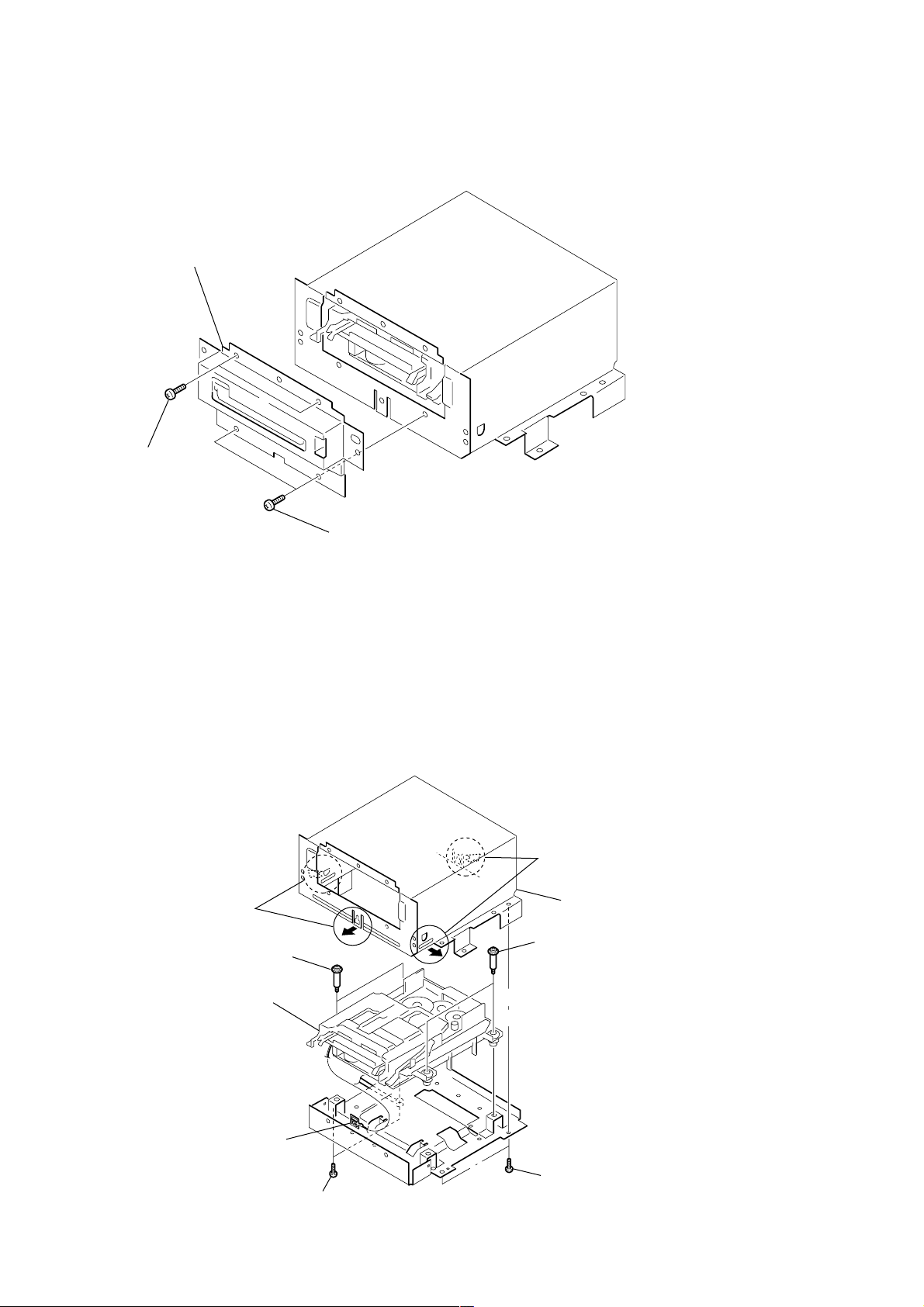

3-1. CABINET (REAR) ASSY

Cabinet (Upper) Assy

Power Board

Tuner Board

Key Board

MD Mechanism

Block - 1

(MDM-5GA)

Jack Board

MD Mechanism

Block - 2

(Slider (Cam) Assy)

7 CN401

FL Board Main

Top Board

Board

MD Block Assy

6 CN402

CD

Board

MD Mechanism

Block - 3

(BD Board)

1 BVTP 3x12

handle

CD Mechanism

Block

MD Mechanism

Block - 4

(SW board)

3-2. POWER BOARD

3 BVTP 4x12

8 cabinet (rear) assy

cabinet (rear) assy

chassis, transformer

5 BVTP 3x14

5

2 BVTP 3x1

3 BVTP 3x14

4 BVTP 3x12

1 BVTP 3x12

4 BVTP 3x12

2 CN903

6 POWER board

– 9 –

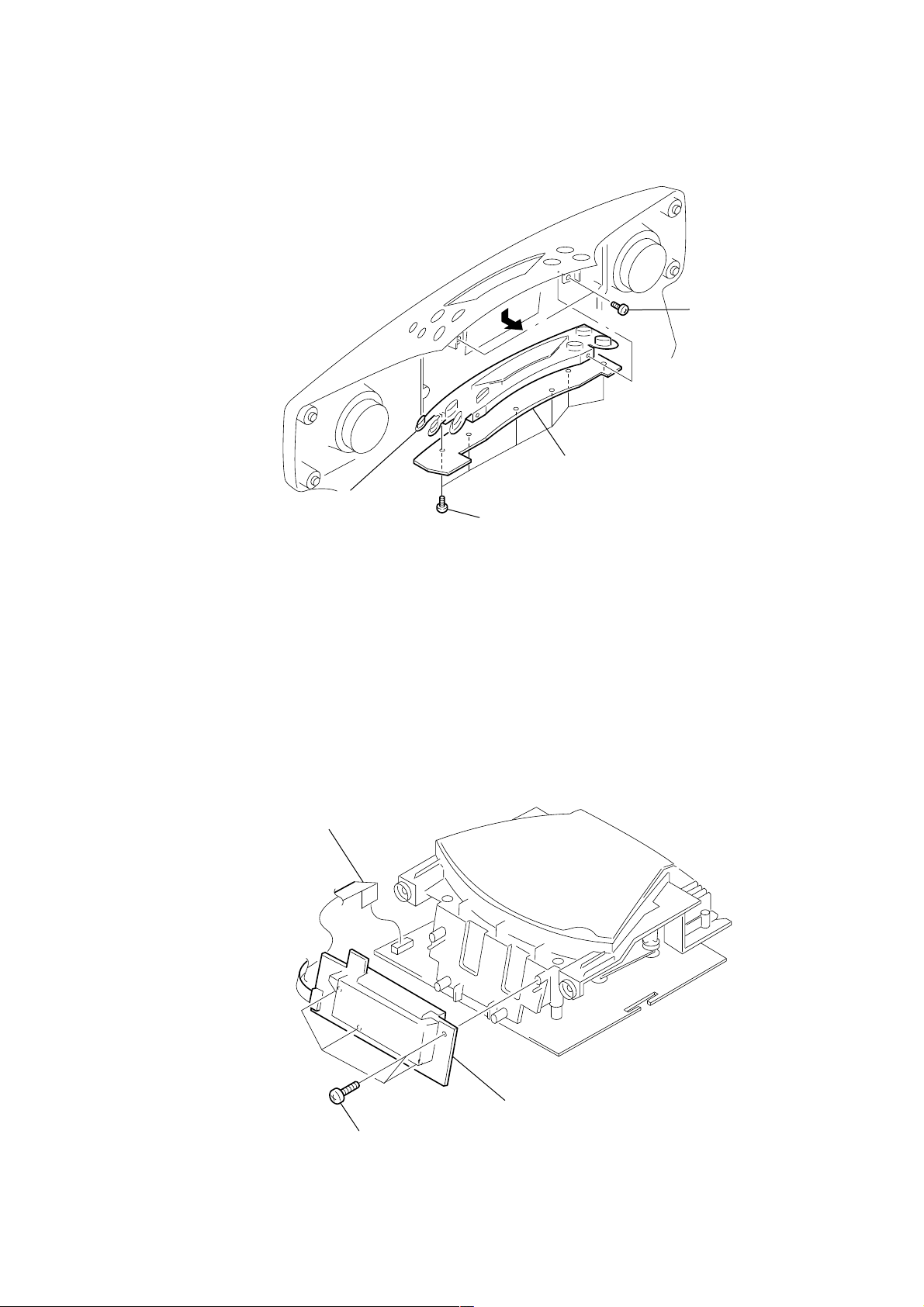

3-3. CABINET (UPPER) ASSY

4

9 CN406

qacabinet (upper) assy

2 CN705

3 CN404

4 connector

q; CN409

3-4. MD BLOCK ASSY

8 CN407

7 CN303

6 CN408

1 BVTP 3x10

5 CN301

3 MD block assy

1 CN2

2 BVTP 3x1

– 10 –

3-5. TUNER BOARD

)

8

1 BVTP 3x10

chassis (TU

4 BVTP 3x10

3-6. JACK BOARD

5 TUNER board

2 BVTP 3x10

3 BVTP 3x10

3 JACK board

– 11 –

1 BVTP 2.6x

2 CN306

3-7. LED BOARD

8

1 BVTP 2.6x8

2 BVTP 2.6x8

3 LED board

3-8. KEY BOARD

1 BVTP 2.6x

2 BVTP 2.6x8

3 KEY board

– 12 –

3-9. T OP BOARD

1 BVTP 2.6x8

3 BVTP 2.6x8

5 TOP board

4 button (top)

2

2 BVTP 3x10

3 FL board

1 CN405

3-10. FL BOARD

– 13 –

3-11. MAIN BOARD

5 BVTP 3x10

6 BVTP 3x10

8 MAIN board

7 CN403

2 CN707

1 CN410

3 CN704

4 BVTP 3x10

CD board

3-12. CD BOARD

CD board

5

BVTP 3x10

3

CN801

1

BVTP 3x10

2

4

CN701

– 14 –

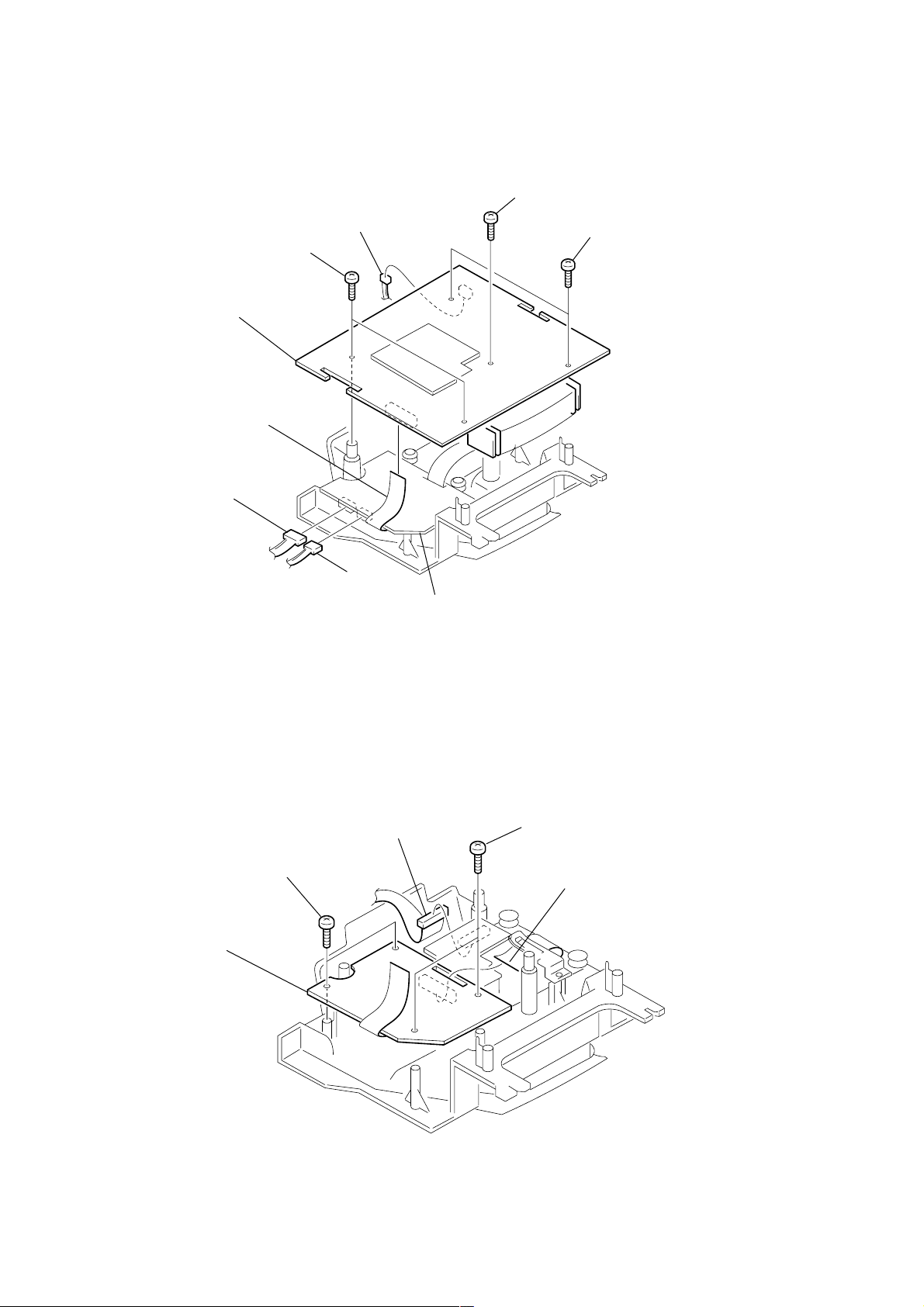

3-13. CD MECHANISM BLOCK

4 CD mechanism block

1 PWH 2.6x10

2 PWH 2.6x10

3

3-14. DG BOARD

4 P 2.6x5

q; DG board

7

1 P 2.6x5

2 plate (lower) , shield

5 CN605

6 CN603

3 P 2.6x5

8 CN602

9 CN601

claws

– 15 –

3-15. PLATE (FRONT), SHIELD

3 plate (front), shield

2 P 2.6x5

1 P 2.6x5

3-16. MD MECHANISM BLOCK-1 (MDM-5GA)

4 claws

7 BVTTWH M3

9 MD mechanism block

(MDM-5GA)

8 harnes

3 claws

5 plate (upper), shield

6 BVTTWH M3

2 P 2.6x5

1 P 2.6x5

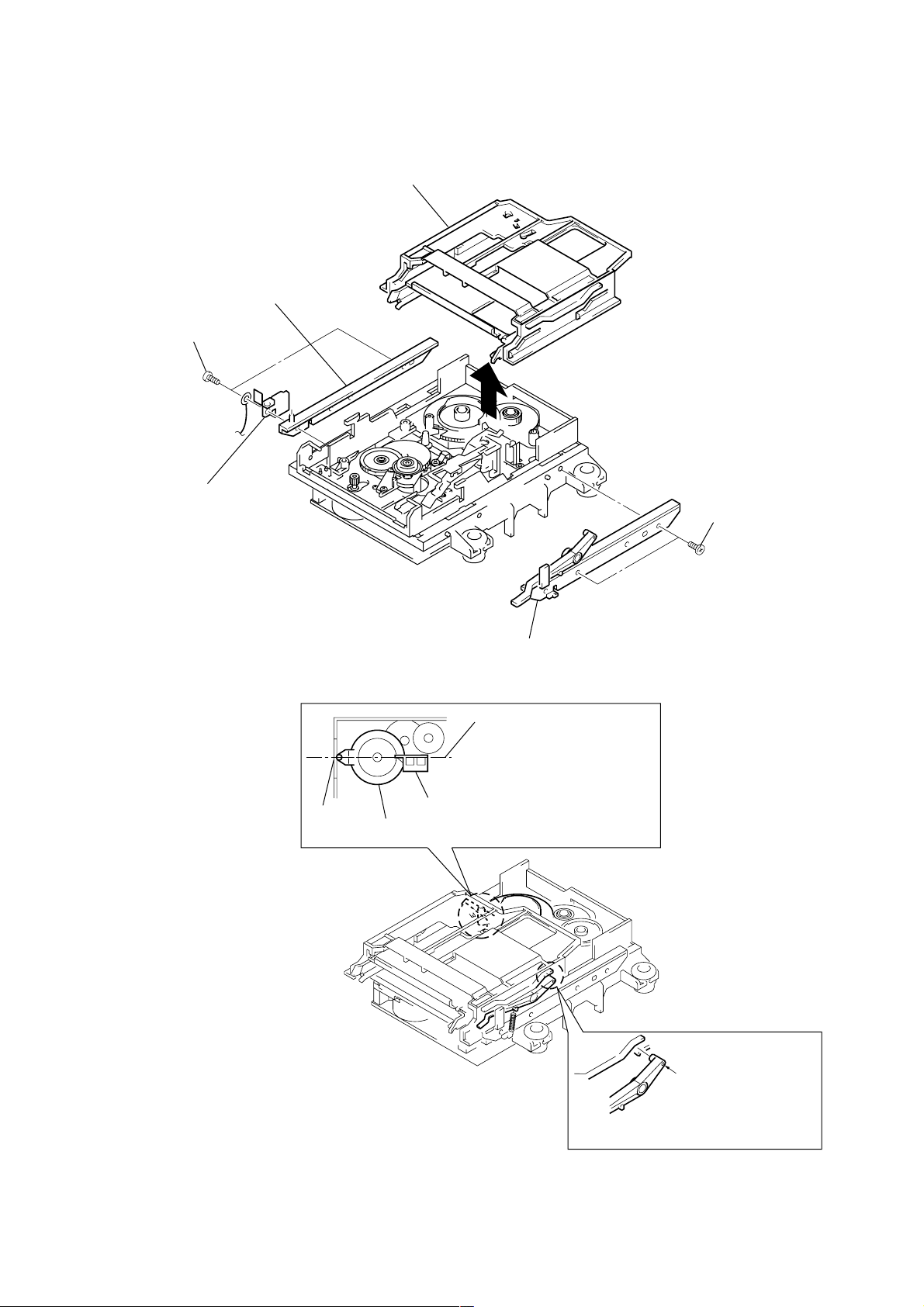

– 16 –

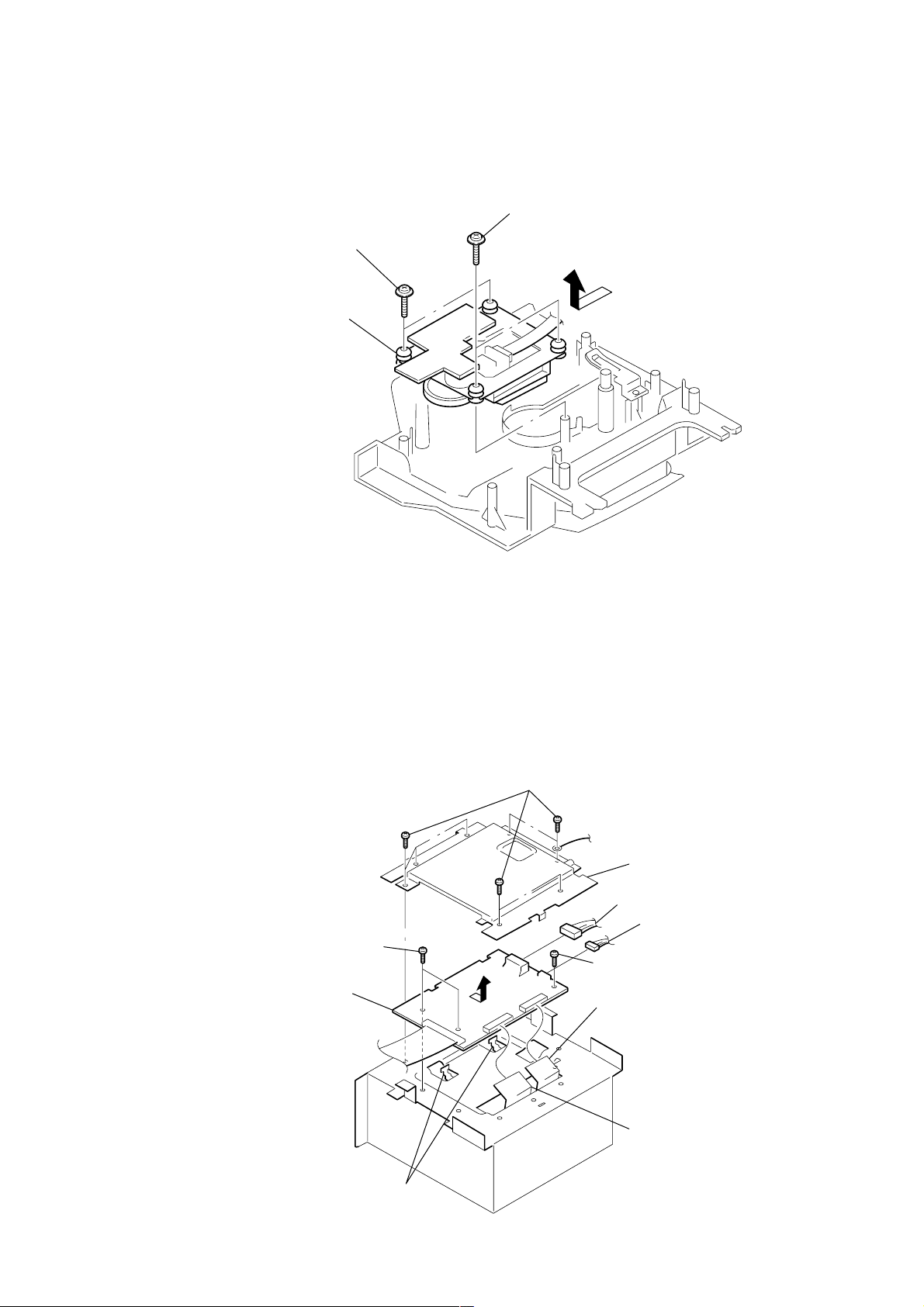

3-17. MD MECHANISM BLOCK-2 (SLIDER (CAM) ASSY)

6 slider (cam) assy

3 bracket (guide L)

1 BV 2.6 (1T3B)

2 spring, leaf

4 BV 2.6 (1T3B)

press

fitting

shaft

5 bracket (guide R)

horizontal

When assembling, set the press

fitting shaft of the cam gear

horizontal to the lever (head).

lever (head)

cam gear

A

When assembling, insert the

shaft of the lever (O/C)

with A part fit in the slot.

– 17 –

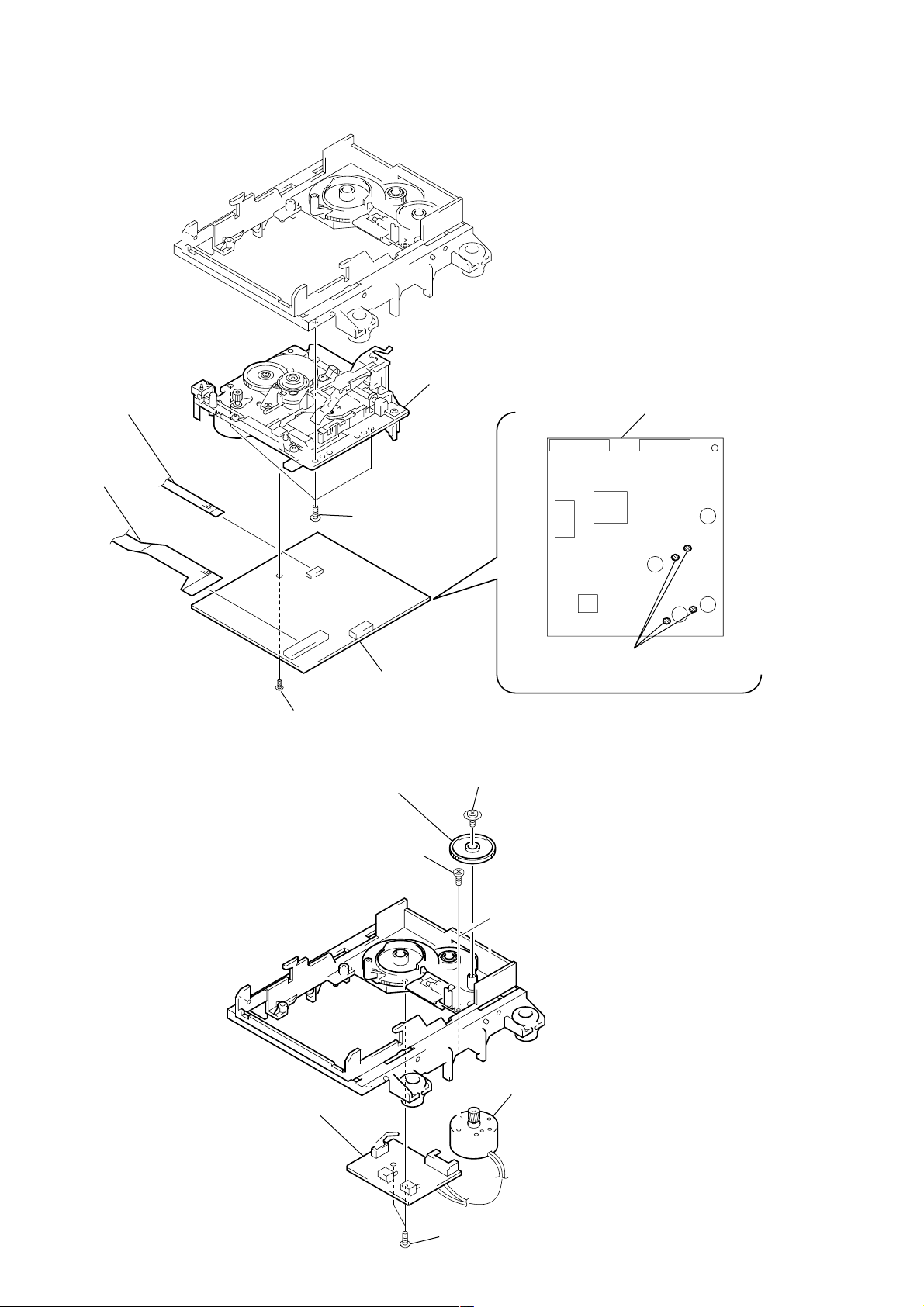

3-18. MD MECHANISM BLOCK-3 (BD BOARD)

5 CN104

6 CN101

1 BV 2.6 (1T3B)

2 MD base unit

BD board (side A)

4 M 1.7

3-19. MD MECHANISM BLOCK-4 (SW BOARD)

3 PWH 1.7x4

6 SW board

7 BD board

2 gear (B)

3 Removal the solders

1 PTPWH M 2.6x6

4 motor assy, loading

5 BTP 2.6x6

– 18 –

SECTION 4

TEST MODE

Refer to “5. ELECTRICAL ADJUSTMENT” for the test mode of CD section.

4-1. MD SECTION

1. PRECAUTIONS FOR USE OF TEST MODE

• As loading related operations will be performed regardless of the test mode operations being performed, be sure to check that the disc is

stopped before setting and removing it.

Even if the Z (MD) button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will not

stop rotating.

Therefore, it will be ejected while rotating.

Be sure to press the Z (MD) button after pressing the [REC/REC MODE] button and the rotation of disc is stopped.

1-1. Recording laser emission mode and operating buttons

• Continuous recording mode (CREC MODE)

• Laser power check mode (LDPWR CHECK)

• Laser power adjustment mode (LDPWR ADJUST)

• When pressing the [REC] button.

2. SETTING THE TEST MODE

1. Set to standby state.

2. Press the buttons [SOUND] and [EDIT] and . (TUNE –) at the same time and then release them soon (within 100m sec). The TEST

MODE is entered.

3. RELEASING THE TEST MODE

Hold down the [POWER] button and remove the power cord to reset the set.

4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed with the following buttons: u (MD), x (MD), [RADIO/BAND], and [REC/REC MODE].

The functions of these buttons are as follows.

Function name Function

u (MD) Proceeds the parameter/mode change.

x (MD) Returns to the parameter/mode change.

RADIO/BAND Goes ahead. Determines the setting/selection.

REC/REC MODE Suspends.

5. SELECTING THE TEST MODE

There are 9 types of test modes as shown below. The groups can be switched by press the u (MD) or x (MD) button. After selecting the

group to be used, press the [RADIO/BAND] button. After setting a certain group, press the u (MD) or x (MD) button between these modes.

Display

TEMP ADJUST

LDPWR ADJUST

LDPWR CHECK

EFBAL ADJUST

FBIAS ADJUST

FBIAS CHECK

CPLAY MODE

CREC MODE

EEP MODE

Temperature compensation offset adjustment

Laser power adjustment

Laser power check

EF balance adjustment

Focus bias adjustment

Focus bias check

Continuous playback mode

Continuous recording mode

Non-volatile memory control

Contents

• For details of each adjustment mode, refer to “5. Electrical Adjustments”.

• If a different mode has been selected by mistake, press the [REC/REC MODE] button to release that mode.

• EEP MODE is not used for servicing and therefore are not described in detail. If these modes are set accidentally, press the [REC/REC MODE]

button to release the mode immediately. Be especially careful this mode will overwrite the non-volatile memory and reset it, and as a

result, the unit will not operate normally.

– 19 –

5-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

(1) Set the disc in the unit. (Whichever recordable discs or discs for playback only are available)

(2) Press the u (MD) or x (MD) button to display “CPLAY MODE”.

(3) Press the [RADIO/BAND] button to change the display to “CPLAY MID”.

(4) When access completes, the display changes to “C1 = AD = ”.

Note: The numbers “

2. Changing the parts to be played back

(1) Press the [RADIO/BAND] button during continuous playback to change the display as below.

“CPLAY MID” t “CPLAY OUT” t “CPLAY IN”

When pressed another time, the parts to be played back can be moved.

(2) When access completes, the display changes to “C1 = AD = ”.

Note: The numbers “

3. Ending the continuous playback mode

(1) Press the [REC/REC MODE] button. The display will change to “CPLAY MODE”.

(2) Press the Z (MD) button and take out the disc.

Note: The playback start addresses for IN, MID, and OUT are as follows.

IN : 40h cluster

MID : 300h cluster

OUT: 700h cluster

5-2. Operating the Continuous Recording Mode (Use only when performing self-recording/palyback check)

1. Entering the continuous recording mode

(1) Set a recordable disc in the unit.

(2) Press the u (MD) or x (MD) button to display “CREC MODE”.

(3) Press the [RADIO/BAND] button to change the display to “CREC MID”.

(4) When access completes, the display changes to “CREC ( )” and “[REC]” lights up.

Note: The numbers “

2. Changing the parts to be recorded

(1) When the [RADIO/BAND] button is pressed during continuous recording, the display changes as below.

“CREC MID” t “CREC OUT” t “CREC IN”

” displayed show you error rates and ADER.

” displayed show you error rates and ADER.

” displayed shows you the recording position addresses.

When pressed another time, the parts to be recorded can be changed. “[REC]” goes off.

(2) When access completes, the display changes to “CREC ( )” and “[REC]” lights up.

Note: The numbers “

3. Ending the continuous recording mode

(1) Press the [REC/REC MODE] button. The display changes to “CREC MODE” and “[REC]” goes off.

(2) Press the Z (MD) button and take out the disc.

Note 1: The recording start addresses for IN, MID, and OUT are as follows.

IN : 40h cluster

MID : 300h cluster

OUT: 700h cluster

Note 2: The [REC/REC MODE] button can be used to stop recording anytime.

Note 3: Do not perform continuous recording for long periods of time above 5 minutes.

Note 4: During continuous recording, be careful not to apply vibration.

5-3. Non-Volatile Memory Mode (EEP MODE)

This mode reads and writes the contents of the non-volatile memory.

It is not used in servicing. If the unit entered this mode accidentally, press the [REC/REC MODE] button immediately to release it.

” displayed shows you the recording position addresses.

– 20 –

6. FUNCTIONS OF OTHER BUTTONS

Function

u (MD) and EDIT

x (MD) and EDIT

>

.

REC/REC MODE and EDIT

x (CD) and EDIT

RADIO/BAND and EDIT

LINE/LINE LEVEL

Z (MD)

POWER

Sets continuous playback when pressed in the STOP state. When pressed during continuous playback,

the tracking servo turns ON/OFF.

Stops continuous playback and continuous recording.

The sled moves to the outer circumference only when this is pressed.

The sled moves to the inner circumference only when this is pressed.

When pressed during continuous playback, REC ON/OFF.

Switches between the pit and groove modes when pressed.

When pressed during continuous playback, switches the spindle servo mode (CLV-S y CLV-A).

Switches the displayed contents each time the button is pressed

Ejects the disc

Releases the test mode

Contents

7. TEST MODE DISPLAYS

Each time the [LINE/LINE LEVEL] button is pressed, the display changes in the following order.

1. Mode display

Displays “TEMP ADJUST”, “CPLAYMODE”, etc.

2. Error rate display

Displays the error rate in the following way.

C1 = ssss AD = ss

C1 = Indicates the C1 error.

AD = Indicates ADER.

Mode display

Error rate display

Address display

3. Address display

The address is displayed as follows. (MO: recordable disc, CD: playback only disc)

Press the x (CD) and [EDIT] buttons at the same time to switches between the groove display

and pit display.

h = ssss s = ssss (MO pit and CD)

h = ssss a = ssss (MO groove)

h = Indicates the header address.

s = Indicates the SUBQ address.

a = Indicates the ADIP address.

Note: “–” is displayed when servo is not imposed.

4. Auto gain display (Not used in servicing)

The auto gain is displayed as follows.

AG F = ss T = ss

5. IVR display (Not used in servicing)

The IVR is displayed as follows.

[ss][ss][ss]

MEANINGS OF OTHER DISPLAYS

Display

SHUF

PGM

[REC]

TOC EDIT

TRACK

TIMER

When Lit

During continuous playback (CLV: ON)

Tracking servo OFF

Recording mode ON

ABCD adjustment completed

Pit

CLV-S

Contents

When Off

STOP (CLV: OFF)

Tracking servo ON

Recording mode OFF

Groove

CLV-A

Auto gain display

(Not used in servicing)

IVR display

(Not used in servicing)

– 21 –

)

SECTION 5

ELECTRICAL ADJUSTMENTS

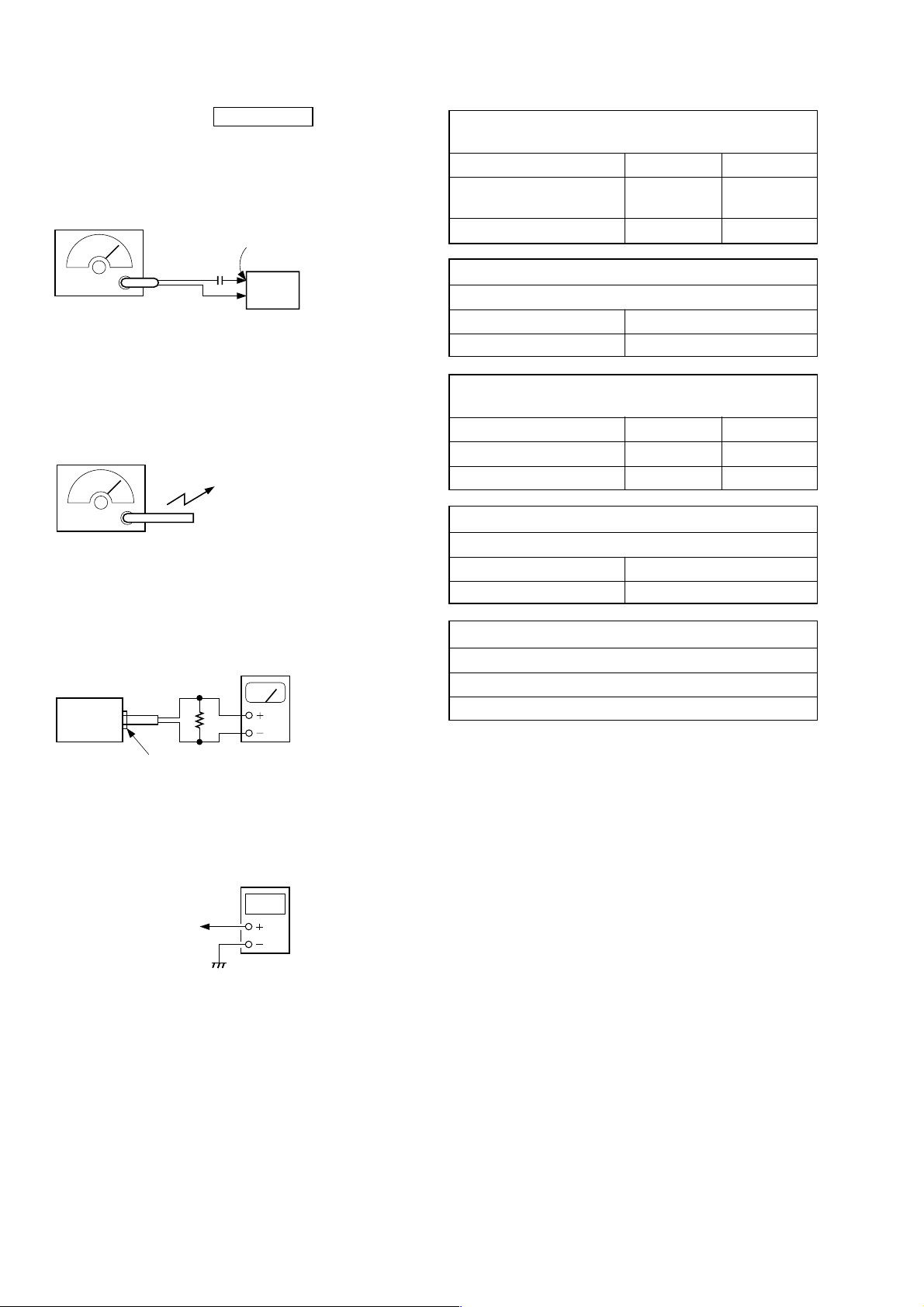

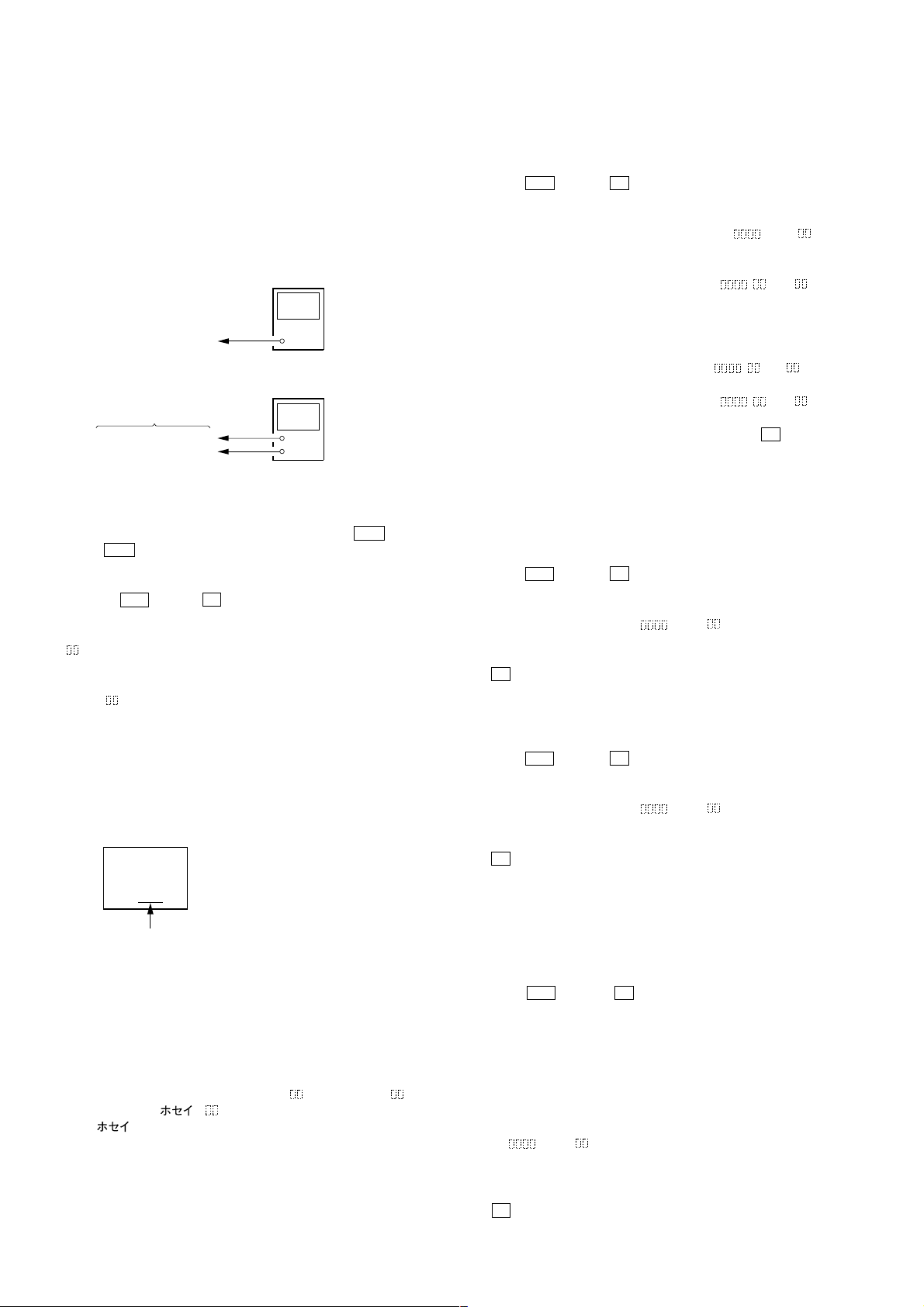

5-1. TUNER SECTION 0 dB = 1 µV

• FM Section

Setting:

BAND button: FM

FM RF signal

generator

FM antenna

(JW1,2)

0.01 µF

set

75 kHz frequency

deviation by 1 kHz signal

output level : as low as possible

• AM Section

Setting:

BAND button: AM

AM RF signal

generator

Put the lead-wire

antenna close to

the supplied

AM loop antenna.

30% amplitude

modulation by 400 Hz signal

output level : as low as possible

• Connecting Level Meter (FM and AM)

level meter

(range: 0.5-5 V ac

32 Ω

set

FM FREQUENCY COVERAGE

ADJUSTMENT

Frequency Display 87.5 MHz 108 MHz

Reading on Digital voltmeter 1.3

+ 0.4 V

– 0.2 V – 0.5 V

3.0

+ 0.3 V

Adjustment Part <confirmation> L2

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 CT1

87.5 MHz 108 MHz

AM FREQUENCY COVERAGE

ADJUSTMENT

Frequency Display 530 kHz 1,710 kHz

Reading on Digital voltmeter 0.8 ± 0.2 V 5.5 ± 0.3 V

Adjustment Part <confirmation> L4

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 CT2

620 kHz 1,400 kHz

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1

450 kHz

i jack (J301)

• Connecting Digital Voltmeter (FM and AM)

digital

voltmeter

tuner board

TP (VT)

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

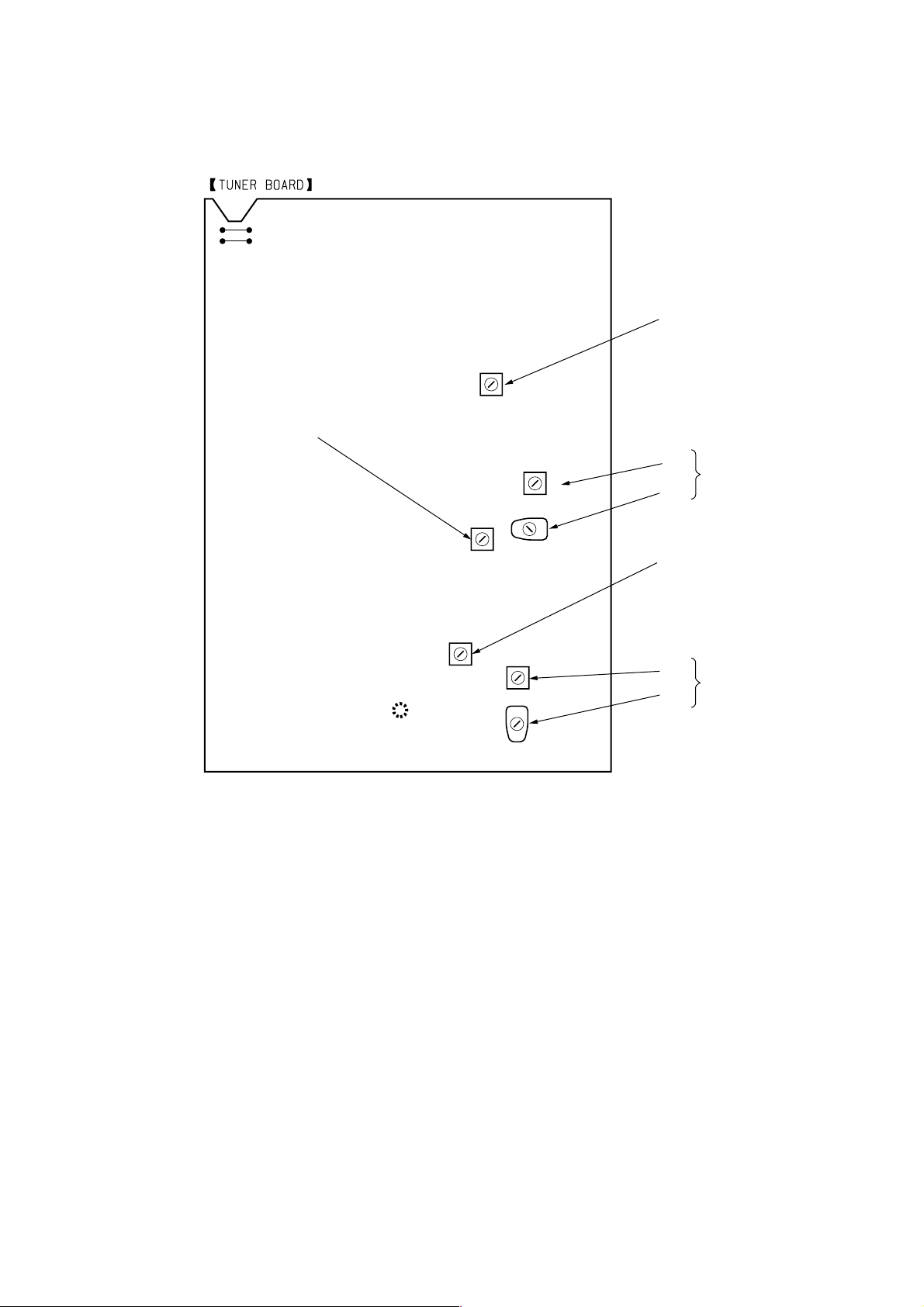

Adjustment Location: TUNER board (See page 23.)

– 22 –

Adjustment Location:

T

FM FREQUENCY

(COMPONENT SIDE)

JW1

JW2

T1

AM IF

ADJUSTMENT

L2

COVERAGE

ADJUSTMENT

TP(VT)

L1

CT1

AM FREQUENCY

COVERAGE

ADJUSTMENT

L3

CT2

FM

TRACKING

ADJUSTMEN

L4

AM

TRACKING

ADJUSTMENT

– 23 –

5-2. MD SECTION

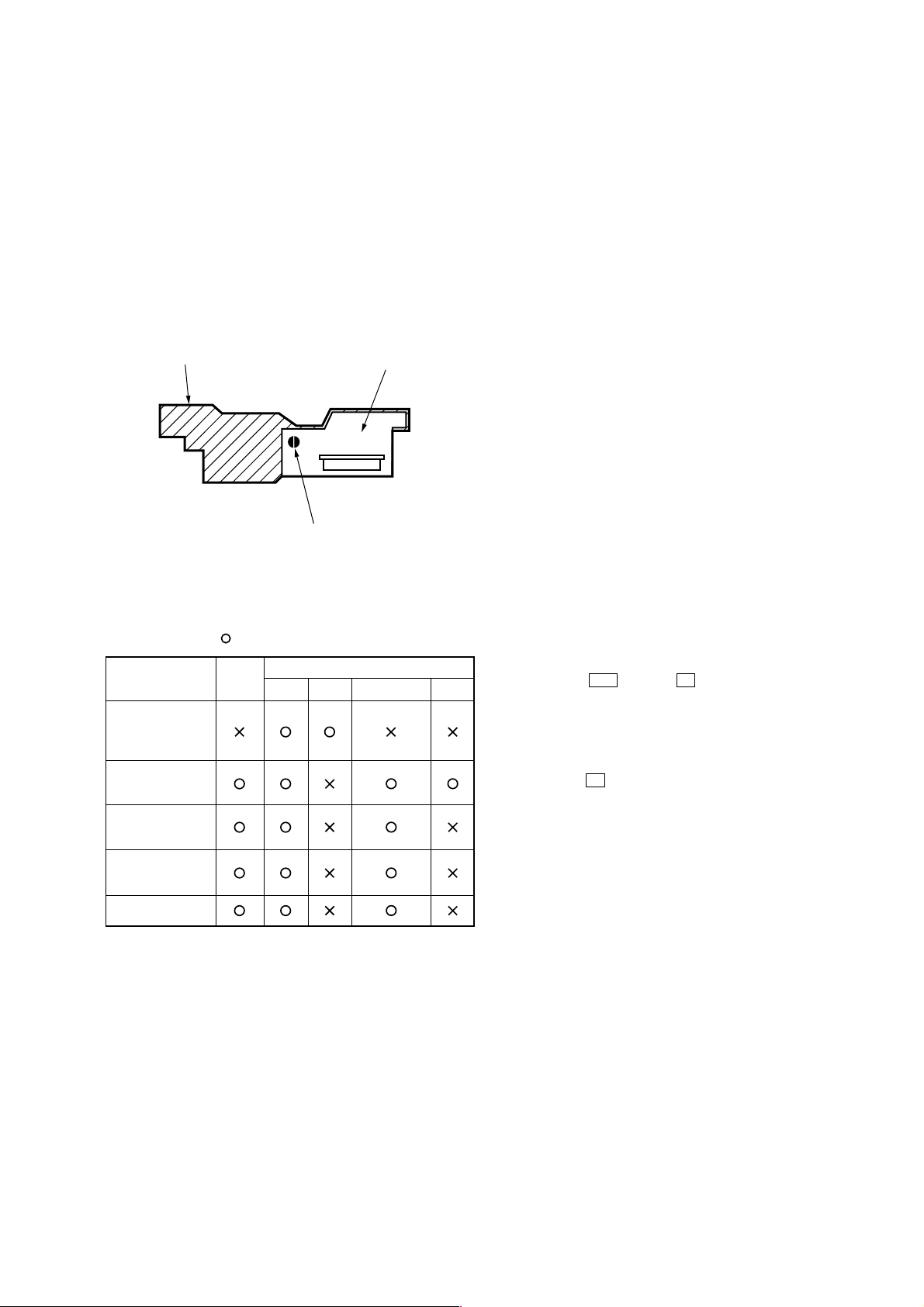

1. PARTS REPLACEMENT AND ADJUSTMENT

• Check and adjust the mechanism deck as follows.

The procedure changes according to the part replaced.

• Laser power check

• Focus bias check

• C PLAY check

• Self-recording/playback check

NG

Parts Replacement and Repair

• Abbreviation

OP : Optical pick-up

OWH : Overwrite head

OK

Check the sled and spindle

mechanisms.

Other causes can be suspected.

Has the OWH been replaced?

NO

Has OP, IC171, IC101, or

IC121 been replaced?

YES

Initial setting of the adjustment value

Has OP or IC171 been replaced?

YES

IOP information recording

(IOP value labeled on OP)

YES

NO

NO

Has IC171 or D101

been replaced?

YES

Temperature compensation offset adjustment

• Laser power adjustment

• Traverse adjustment

• Focus bias adjustment

• Error rate adjustment

• Focus bias check

• Auto gain adjustment

– 24 –

NO

2. PRECAUTIONS FOR CHECKING LASER DIODE

EMISSION

T o check the emission of the laser diode during adjustments, ne v er

view directly from the top as this may lose your eye-sight.

3. PRECAUTIONS FOR USE OF OPTICAL PICK-UP

(KMS-260B)

As the laser diode in the optical pick-up is easily damaged by static

electricity, solder the laser tap of the flexible board when using it.

Before disconnecting the connector, desolder first. Before connecting the connector, be careful not to remove the solder. Also take

adequate measures to prevent damage by static electricity. Handle

the flexible board with care as it breaks easily.

pick-up

laser tap

Optical pick-up flexible board

flexible board

4. Use the following tools and measuring device.

• Check Disc (MD) TDYS-1

(Part No. 4-963-646-01)

• Test Disc (MDW-74/AU-1) (Part No. 8-892-341-41)

• Laser power meter LPM-8001 (Part No. J-2501-046-A)

or MD Laser power meter 8010S (Part No. J-2501-145-A)

• Oscilloscope (Measure after performing CAL of prove)

• Digital voltmeter

• Thermometer

• Jig for checking BD board waveform

(Part No. : J-2501-149-A)

5. When observing several signals on the oscilloscope, etc., make

sure that VC and ground do not connect inside the oscilloscope.

(VC and ground will become short-circuited)

6. Using the above jig enables the waveform to be check ed without the need to solder.

(Refer to Servicing Notes on page 5)

7. As the disc used will affect the adjustment results, make sure

that not dusts nor fingerprints are attached to it.

Laser Power Meter

When performing laser power checks and adjustment (electrical

adjustment), use of the new MD laser power meter 8010S (Part No.

J-2501-145-A) instead of the conventional laser po wer meter is convenient.

It sharply reduces the time and trouble to set the laser power meter

sensor onto the objective lens of optical pick-up.

4. PRECAUTIONS FOR ADJUSTMENTS

1. When replacing the following parts, perform the adjustments

and checks with in the order shown in the following table.

Optical

Pick-up

1.Temperature

compensation

offset adjustment

2.Laser power

adjustment

3.EF balance

adjustment

4.Focus bias

adjustment

5.Error rate check

IC171 D101 IC101, IC121 IC192

2. Set the test mode when performing adjustments.

After completing the adjustments, release the test mode.

Perform the adjustments and checks in “group S” of the test

mode.

3. Perform the adjustments to be needed in the order shown.

BD Board

5. CREATING CONTINUOUSLY-RECORDED DISC

* This disc is used in focus bias adjustment and error rate check.

The following describes how to create a continuous recording

disc.

1. Insert a disc (blank disc) commercially available.

2. Press the u (MD) or x (MD) button to display “CREC

MODE”.

3. Press the [RADIO/BAND] button again to display “CREC MID”.

Display “CREC (0300)” and start to recording.

4. Complete recording within 5 minutes.

5. Press the [REC/REC MODE] button and stop recording.

6. Press the Z (MD) button and remove the disc.

The above has been how to create a continuous recorded data for

the focus bias adjustment/check and MO error rate check.

Note:

• Be careful not to apply vibration during continuous recording.

– 25 –

6. CHECK PRIOR TO REPAIRS

r

r

These checks are performed before replacing parts according to

“approximate specifications” to determine the faulty locations. For

details, refer to “Checks Prior to Parts Replacement and Adjustments” (See page 6).

6-1. Laser Power Check

Connection:

CN110 pin 5 (I +3V)

CN110 pin 4 (IOP)

Optical pick-up

objective lens

BD board

laser

power mete

digital voltmete

+

–

6-2. Focus Bias Check

Change the focus bias and check the focus tolerance amount.

Checking Procedure:

1. Load the test disc (MDW-74/AU-1).

2. Press the u (MD) or x (MD) button to display “CPLAY

MODE”.

3. Press the [RADIO/BAND] button twice to display “CPLA Y MID”.

4. Press the [REC/REC MODE] button w hen “C1 =

AD = ”

is displayed.

5. Turn the JOG dial to display “FBIAS CHECK”.

6. Press the [RADIO/BAND] button to display “ / c = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [c =] indicate the

focus bias value.

Check that the C1 error is below 50 and ADER is below 2.

7. Press the [RADIO/BAND] button to display “ / b = ”.

Check that the C1 error is about 200 and ADER is below 2.

8. Press the [RADIO/BAND] button to display “ / a = ”.

Check that the C1 error is about 200 and ADER is below 2.

9. Press the [REC/REC MODE] button, then press the Z (MD)

button and take out the test disc.

Checking Procedure:

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly, press the . but-

ton or > button to move the optical pick-up)

Connect the digital voltmeter to CN110 pin 5 (I+3 V) and

CN110 pin 4 (IOP) on the BD board.

2. Press the u (MD) or x (MD) button to display “LDPWR

CHECK”.

3. Press the [RADIO/BAND] button once to display “LD 0.9 mW $

”. Check that the reading of the laser power meter become

0.84 to 0.92 mW.

4. Press the [RADIO/BAND] button once more to display “LD 7.0

mW $ ”. Check that the reading the laser power meter and

digital voltmeter satisfy the specified value.

Specified Value:

Laser power meter reading : 7.0 ± 0.2 mW

Digital voltmeter reading :Value on the optical pick-up label

± 10 %

(Optical pick-up label)

KMS260B

27X40

B0825

lOP=82.5 mA in this case

lOP (mA) = Digital voltmeter reading (mV)/1 (Ω)

5. Press the [REC/REC MODE] button to display “LDPWR CHECK”

and stop the laser emission.

(The [REC/REC MODE] button is effective at all times to stop

the laser emission)

Note 1: After step 4, each time the [RADIO/BAND] button is pressed, the

display will be switched “LD 0.7 mW $ ”, “LD 6.2 mW $ ”,

and “LD WP $ ”. Nothing needs to be performed here.

( = correction)

6-3. C PLAY Check

MO Error Rate Check

Checking Procedure:

1. Load the test disc (MDW-74/AU-1).

2. Press the u (MD) or x (MD) button to display “CPLAY

MODE”.

3. Press the [RADIO/BAND] button to display “CPLAY MID”.

4. The display changes to “C1 = AD = ”.

5. If the C1 error rate is below 80, check that ADER is below 2.

6. Press the [REC/REC MODE] button to stop playback, then press

the Z (MD) button and take out the test disc.

CD Error Rate Check

Checking Procedure:

1. Load the check disc (MD) TDYS-1.

2. Press the u (MD) or x (MD) button to display “CPLAY

MODE”.

3. Press the [RADIO/BAND] button twice to display “CPLA Y MID”.

4. The display changes to “C1 = AD = ”.

5. Check that the C1 error rate is below 50.

6. Press the [REC/REC MODE] button to stop playback, then press

the Z (MD) button and take out the check disc.

6-4. Self-Recording/playback Check

Prepare a continuous recording disc using the unit to be repaired

and check the error rate.

Checking Procedure:

1. Load a recordable disc (blank disc).

2. Press the u (MD) or x (MD) button to display “CREC

MODE”.

3. Press the [RADIO/BAND] button to display “CREC MID”.

4. When recording starts, lights up “[REC]” and display “CREC

@@@@” (@@@@ is the address).

5. About 1 minute later, press the [REC/REC MODE] button to stop

continuous recording.

6. Turn the JOG dial to display “CPLAY MODE”.

7. Press the [RADIO/BAND] button to display “CPLAY MID”.

8. “C1 = AD = ” will be displayed.

9. Check that the C1 error becomes below 80 and the ADER below 2.

10. Press the [REC/REC MODE] button to stop play back, then press

the Z (MD) button and take out the disc.

Note: After the TEST MODE is entered, insert the disc.

– 26 –

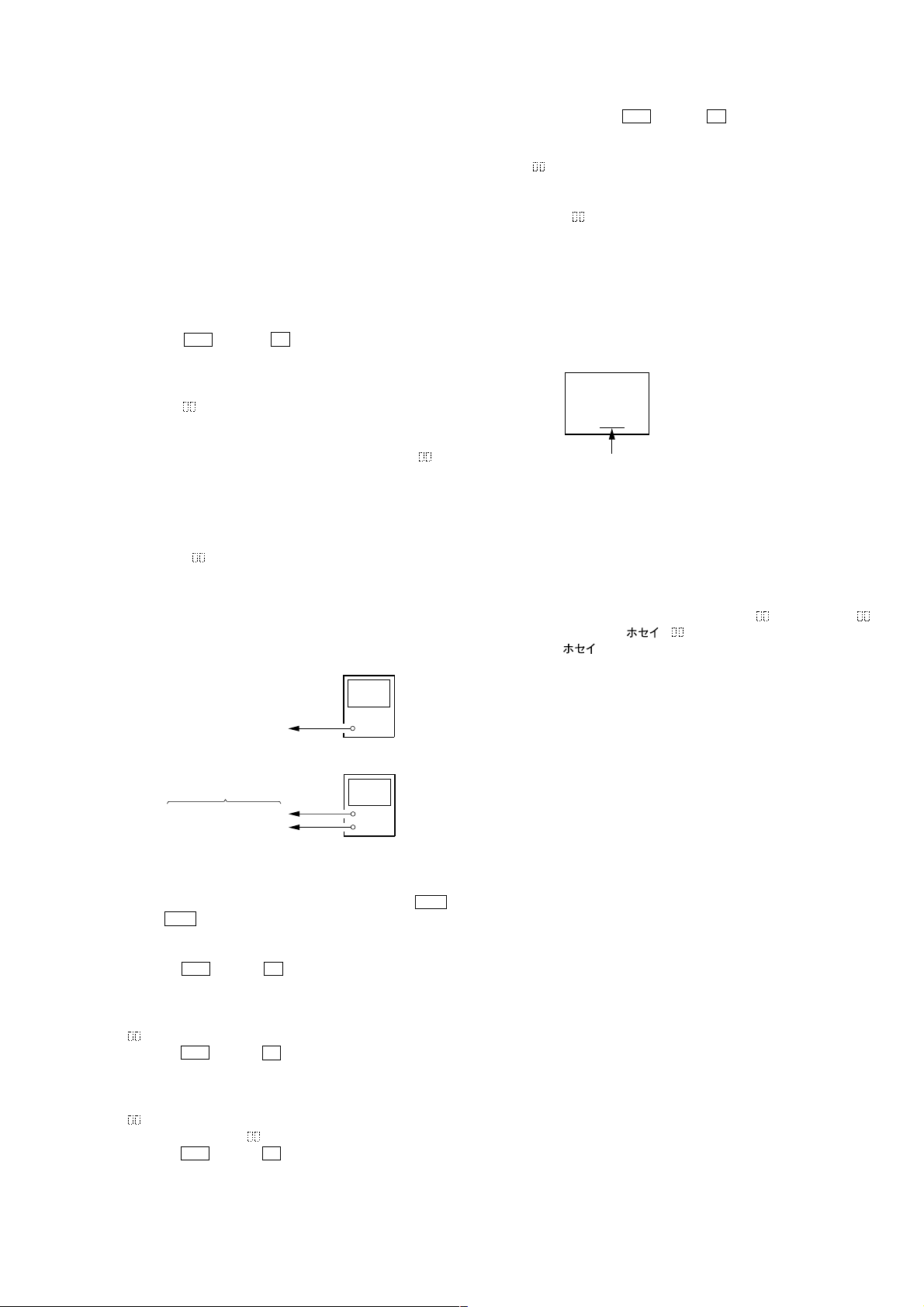

7. TEMPERATURE COMPENSATION OFFSET

r

r

ADJUSTMENT

Save the temperature data at that time in the non-volatile memory

as 25 °C reference data.

Note:

1. Usually, do not perform this adjustment.

2. Perform this adjustment in an ambient temperature of 22 °C to 28 °C.

Perform it immediately after the power is turned on when the internal

temperature of the unit is the same as the ambient temperature of 22 °C

to 28 °C.

3. When D101 has been replaced, perform this adjustment after the temperature of this part has become the ambient temperature.

Adjusting Procedure:

1. Press the u (MD) or x (MD) button to display “TEMP

ADJUST”.

2. Press the [RADIO/BAND] button to select the “TEMP ADJUST”

mode.

3. “TEMP = ” and the current temperature data will be displayed.

4. To save the data, press the [RADIO/BAND] button.

When not saving the data, press the [REC/REC MODE] button.

5. When the [RADIO/BAND] button is pressed, “TEMP = SA VE”

will be displayed and turned back to “TEMP ADJUST” display

then. When the [REC/REC MODE] button is pressed, “TEMP

ADJUST” will be displayed immediately.

Specified V alue:

The “TEMP = ” should be within “E0 - EF”, “F0 - FF”, “00 0F”, “10 - 1F” and “20 - 2F”.

7. Then, press the u (MD) or x (MD) to display “LDPWR

CHECK”.

8. Press the [RADIO/BAND] button once to display “LD 0.9mW $

”. Check that the reading of the laser power meter become

0.85 to 0.91 mW.

9. Press the [RADIO/BAND] button once more to display “LD 7.0

mW $

”. Check that the reading the laser power meter and

digital voltmeter satisfy the specified value.

Note down the digital voltmeter reading value.

Specified Value:

Laser power meter reading : 7.0 ± 0.2 mW

Digital voltmeter reading :Value on the optical pick-up label

± 10%

(Optical pick-up label)

KMS260B

27X40

B0825

lOP=82.5 mA in this case

lOP (mA) = Digital voltmeter reading (mV)/1 (Ω)

10. Press the [REC/REC MODE] button to display “LDPWR CHECK”

and stop the laser emission.

(The [REC/REC MODE] button is effective at all times to stop

the laser emission)

8. LASER POWER ADJUSTMENT

Connection:

Optical pick-up

objective lens

BD board

CN110 pin 5 (I +3V)

CN110 pin 4 (IOP)

Adjusting Procedure:

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly, pr ess the . but-

ton or > button to move the optical pick-up)

Connect the digital voltmeter to CN110 pin 5 (I+3 V) and

CN110 pin 4 (IOP) on the BD board.

2. Press the u (MD) or x (MD) button to display “LDPWR

ADJUST”.

(Laser power: For adjustment)

3. Press the [RADIO/BAND] button once to display “LD 0.9 mW $

”.

4. Press the u (MD) or x (MD) button so that the reading of

the laser power meter becomes 0.85 to 0.91 mW. Press the

[RADIO/BAND] button after setting the range knob of the laser

power meter, and save the adjustment results. (“LD SAVE $

” will be displayed for a moment)

5. Then “LD 7.0 mW $ ” will be displayed.

6. Press the u (MD) or x (MD) button and adjust so that the

reading on the laser power meter is 6.9 to 7.1 mV. Press the

[RADIO/BAND] button to save the setting.

laser

power mete

digital voltmete

+

–

Note 1: After step 9, each time the [RADIO/BAND] button is pressed, the

display will be switched “LD 0.7 mW $ ”, “LD 6.2 mW $ ”,

and “LD WP $ ”. Nothing needs to be performed here.

( = correction)

Note: Do not perform the emission with 7.0 mW more than 15 seconds

continuously.

– 27 –

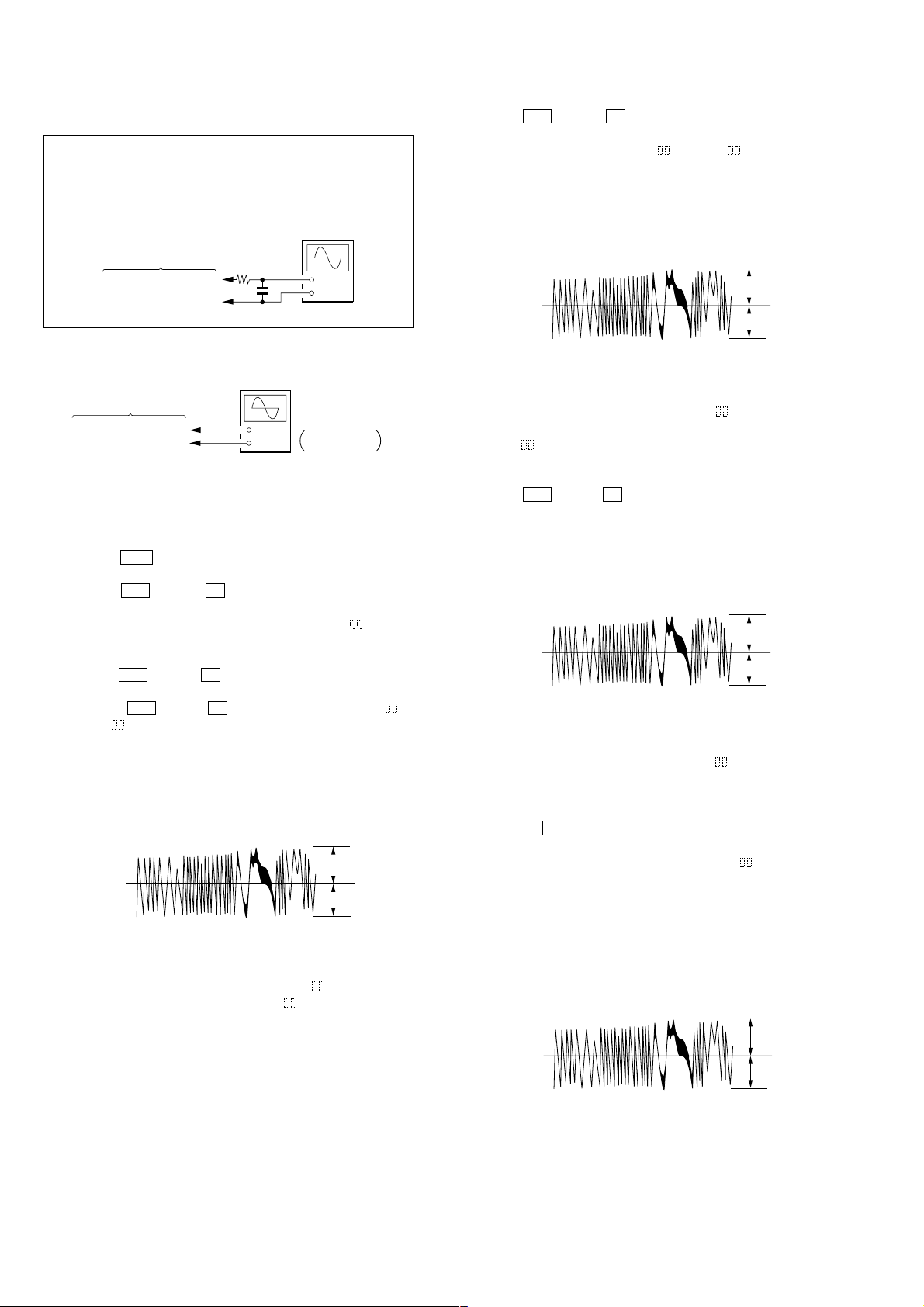

9. EF BALANCE ADJUSTMENT

Note 1: Data will be erased during MO reading if a recorded disc is

Note 2: If the traverse waveform is not clear, connect the oscilloscope

used in this adjustment.

as shown in the following figure so that it can be seen more

clearly.

BD board

CN110 pin 3 (TEO)

CN110 pin 1 (VC)

330 k Ω

10 pF

oscilloscope

(DC range)

+

–

8. Press the u (MD) or x (MD) button so that the waveform

of the oscilloscope becomes the specified value.

(When the JOG dial is turned, the of “EFB- ” changes and

the waveform changes) In this adjustment, waveform varies at

intervals of approx. 2%. Adjust the wa veform so that the specified value is satisfied as much as possible.

(Write power traverse adjustment)

Traverse Wa vef orm

A

VC

B

Connection:

oscilloscope

(DC range)

BD board

CN110 pin 3 (TEO)

CN110 pin 1 (VC)

+

–

V: 0.1 V/div

H: 10 ms/div

Adjusting Procedure:

1. Connect an oscilloscope to CN110 pin 3 (TEO) and CN110

pin 1 (VC) on the BD board.

2. Load a disc (any available on the market). (Refer to Note 1)

3. Press the > button to move the optical pick-up outside the

pit.

4. Press the u (MD) or x (MD) button to display “EFBAL

ADJUST”.

5. Press the [RADIO/BAND] button to display “EFB =

MO-R”.

(Laser power READ power/Focus serv o ON/tracking servo OFF/

spindle (S) servo ON)

6. Press the u (MD) or x (MD) button so that the wav eform

of the oscilloscope becomes the specified value.

(When the u (MD) or x (MD) button is pressed, the of

“EFB = ” changes and the waveform changes ) In this adjustment, waveform varies at intervals of approx. 2 %. Adjust the

waveform so that the specified value is satisfied as much as

possible.

(Read power traverse adjustment)

Traverse Wav ef orm

A

VC

B

Specification A = B

7. Press the [RADIO/BAND] button and save the result of adjustment to the non-volatile memory. (“EFB = SAVE” will be

displayed for a moment. Then “EFB = MO-W” will be displayed)

Specification A = B

9. Press the [RADIO/BAND] button, and save the adjustment results in the non-volatile memory. (“EFB = SAVE” will be

displayed for a moment)

10. “EFB = MO-P” will be displayed.

The optical pick-up moves to the pit area automatically and

servo is imposed.

11. Press the u (MD) or x (MD) button until the waveform of

the oscilloscope moves closer to the specified value.

In this adjustment, waveform varies at interv als of approx. 2%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

Traverse Wa vef orm

A

VC

B

Specification A = B

12. Press the [RADIO/BAND] button, and save the adjustment results in the non-volatile memory. (“EFB = SABE” will be

displayed for a moment)

Next “EFBAL ADJUST” is displayed. The disc stops rotating

automatically.

13. Press the Z (MD) button and take out the disc.

14. Load the check disc (MD) TDYS-1.

15. Press the [RADIO/BAND] button to display “EFB = CD”. Servo

is imposed automatically.

16. Turn the JOG dial so that the waveform of the oscilloscope

moves closer to the specified value.

In this adjustment, waveform varies at interv als of approx. 2%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

Traverse Wa vef orm

A

VC

B

– 28 –

Specification A = B

17. Press the [RADIO/BAND] button, display “EFB = SAVE” for

a moment and save the adjustment results in the non-volatile

memory.

Next “EFBAL ADJUST” will be displayed.

18. Press the Z (MD) button and take out the disc.

10. FOCUS BIAS ADJUSTMENT

Adjusting Procedure:

1. Load the continuously-recorded disc. (Refer to “5. CREA TING

CONTINUOUSLY-RECORDED DISC”)

2. Press the u (MD) or x (MD) button to display “CPLAY

MODE”.

3. Press the [RADIO/BAND] button to display “CPLAY MID”.

4. Press the [REC/REC MODE] button when “C1 = AD = ”

is displayed.

5. Press the u (MD) or x (MD) button to display “FBIAS

ADJUST”.

6. Press the [RADIO/BAND] button to display “ / a = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [a =] indicate the

focus bias value.

7. Turn the JOG dial clockwise and find the focus bias value at

which the C1 error rate becomes about 200 (Refer to Note 2).

8. Press the [RADIO/BAND] button to display “ / b = ”.

9. Press the u (MD) or x (MD) button counterclockwise and

find the focus bias value at which the C1 error rate becomes

about 200.

10. Press the [RADIO/BAND] button to display “ / c = ”.

11. Check that the C1 error rate is below 50 and ADER is 00. Then

press the [RADIO/BAND] button.

12. If the “( )” in “ - - ( )” is above 20, press the

[RADIO/BAND] button.

If below 20, press the [REC/REC MODE] button and repeat the

adjustment from step 2.

13. Press the Z (MD) button and take out the disc.

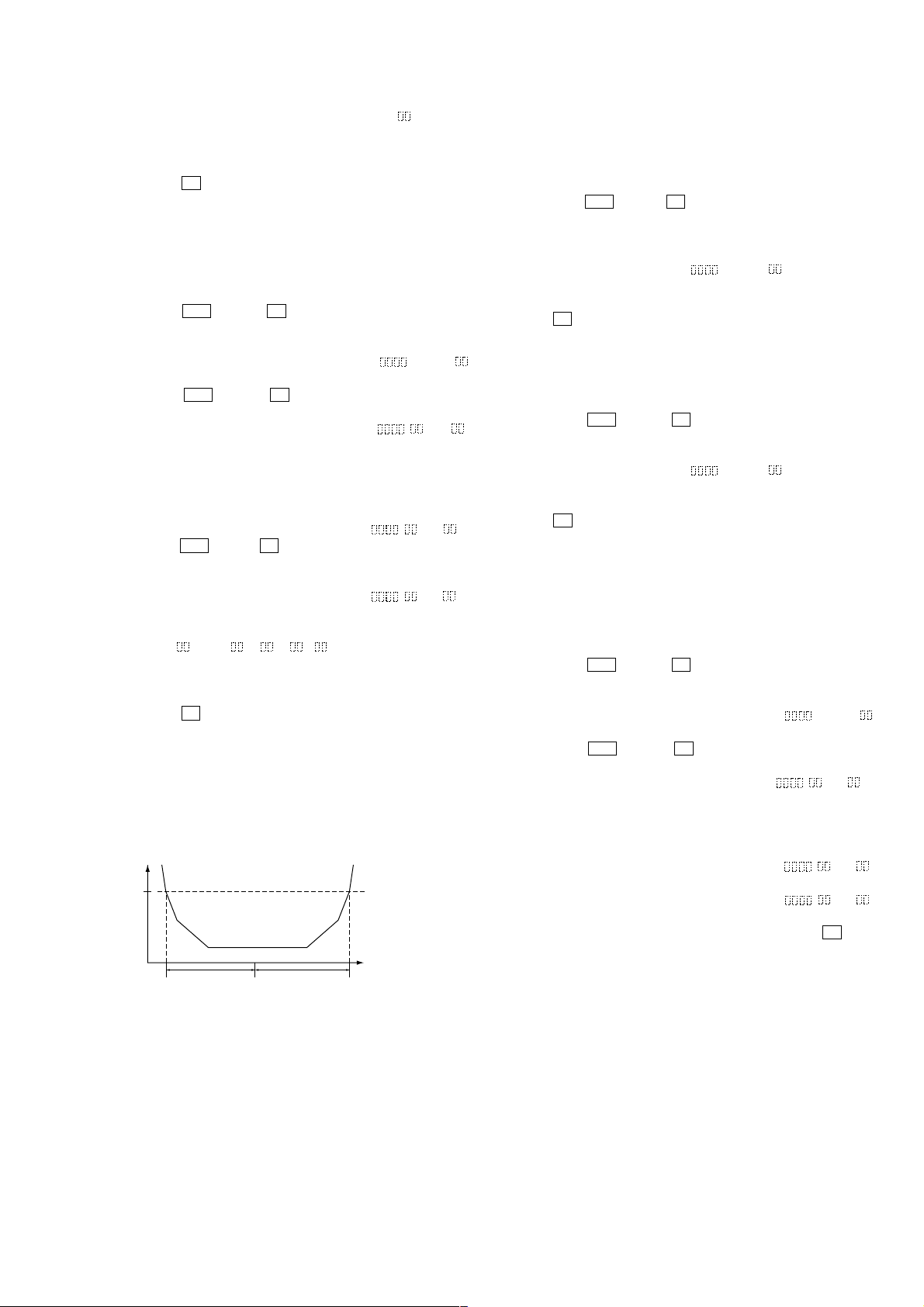

Note 1: The relation between the C1 error and focus bias is as shown in

the following figure. Find points A and B in the following figure

using the above adjustment. The focal point position C is automatically calculated form points A and B.

Note 2: As the C1 error rate changes, perform the adjustment using the

average value.

C1 error

about

200

11. ERROR RATE CHECK

11-1. CD Error Rate Check

Checking Procedure:

1. Load the check disc (MD) TDYS-1.

2. Press the u (MD) or x (MD) button and display “CPLAY

MODE”.

3. Press the [RADIO/BAND] button twice and display “CPLAY

MID”.

4. The display changes to “C1 = AD = ”.

5. Check that the C1 error rate is below 20.

6. Press the [REC/REC MODE] button to stop playback, then press

the Z (MD) button and take out the check disc.

11-2. MO Error Rate Check

Checking Procedure:

1. Load the continuously-recorded disc. (Refer to “5. CREA TING

CONTINUOUSLY-RECORDED DISC”)

2. Press the u (MD) or x (MD) button to display “CPLAY

MODE”.

3. Press the [RADIO/BAND] button to display “CPLAY MID”.

4. The display changes to “C1 = AD = ”.

5. If the C1 error rate is below 50, check that ADER is 00.

6. Press the [REC/REC MODE] button to stop playback, then press

the Z (MD) button and take out the test disc.

12. FOCUS BIAS CHECK

Change the focus bias and check the focus tolerance amount.

Checking Procedure:

1. Load the continuously-recorded disc. (Refer to “5. CREATING CONTINUOUSLY-RECORDED DISC”)

2. Press the u (MD) or x (MD) button to display “CPLAY

MODE”.

3. Press the [RADIO/BAND] button twice to display “CPLA Y MID”.

4. Press the [REC/REC MODE] button when “C1 = AD = ”

is displayed.

5. Press the u (MD) or x (MD) button to display “FBIAS

CHECK”.

6. Press the [RADIO/BAND] button to display “ / c = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [c =] indicate the

focus bias value.

Check that the C1 error is below 50 and ADER is below 2.

7. Press the [RADIO/BAND] button and display “ / b = ”.

Check that the C1 error is about 200 and ADER is below 2.

8. Press the [RADIO/BAND] button and display “ / a = ”.

Check that the C1 error is about 200 and ADER is below 2.

9. Press the [REC/REC MODE] button, then press the Z (MD)

button and take out the disc.

B

C A Focus bias value

(F. BIAS)

Note 1: If the C1 error and ADER are above other than the specified value

at points A (step 8. in the above) or B (step 7. in the above), the

focus bias adjustment may not have been carried out properly.

Adjust perform the beginning again.

– 29 –

Adjustment Location:

– BD BOARD (COMPONENT SIDE) –

CN101

D101

CN110

GND

I+3V

IOP

TEO

RF

VC

NOTE

IC171

– BD BOARD (CONDUCTOR SIDE) –

IC101

IC121

IC192

Note: It is useful to use the jig for checking the waveform. (Refer to Ser-

vicing Notes on page 5)

– 30 –

Loading...

Loading...