Page 1

XVM-F65WL

SERVICE MANUAL

Ver. 1.1 2005.08

• This set consists of the following units.

AEP, UK model US, Canadian model E, Chinese model

MONITOR XVM-F65WL XVM-F65WL XVM-F65WL

CONNECTION BOX XA-126 XA-125 XA-125

REMOTE COMMANDER RM-X709 RM-X709 RM-X709

CORDLESS HEADPHONES —— MV-02HP ——

US Model

Canadian Model

AEP Model

UK Model

E Model

Chinese Model

Monitor XVM-F65WL

System Liquid crystal colour display

Drive system TFT-LCD active matrix system

Picture size 6.5 inches wide screen (16:9)

143.4 × 79.3 mm, 165.1 mm (w/h, d)

Picture segment

280,800 (w 1,200 × h 234) dots

Power requirements

12 V DC car battery (negative ground)

Current drain Approx. 1 A

Dimensions 194 × 101 × 27.1 mm (w/h/d)

(7 3/4 × 4 × 1 1/8 in.)

Operating temperature

0 °C – 45 °C

Mass Approx. 424 g (15 oz)

Connection box XA-126 (AEP, UK model),

XA-125 (US, Canadian, E, Chinese model)

A/V Output

Output Impedance:less than 470 Ω

less than 1,000 pF

Output Level: 0 dBs ±0.3 dB (0.775 V rms)

Video: 75 Ω 1 Vp-p

A/V Input × 2

Input Impedance: more than 10 kΩ

less than 1,000 pF

Input Level (max.):1.3 dBs +0/–0.3 dB (1 V rms)

Video: 75 Ω 1 Vp-p

Dimensions 147.5 × 40 × 80 mm (w/h/d)

(5 7/8 × 1 5/8 × 3 1/4 in.)

Mass Approx. 282 g (10 oz)

SPECIFICATIONS

Card remote commander RM-X709

Power requirements

CR2025 lithium battery

Operable range

Approx. 2.5 m

Dimensions 55 × 125 × 15 mm (w/h/d)

Mass Approx. 40 g

(including batteries)

Headphones (US, Canadian model)

Modulation system

Frequency modulation

Carrier frequency

Right: 2.8 MHz (CH1)/3.8 MHz (CH2)

Left: 2.3 MHz (CH1)/3.2 MHz (CH2)

Frequency response

18 – 22,000 Hz

Power source DC 3.0 V; using R6 dry batteries (2)

Mass Approx. 230 g

(including batteries)

– Continued on next page –

MOBILE MONITOR

9-879-756-02

2005H04-1

© 2005.08

Sony Corporation

e Vehicle Group

Published by Sony Engineering Corporation

Page 2

XVM-F65WL

Ver. 1.1

Supplied accessories

Design and specifications are subject to change

without notice.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged

by heat.

UNLEADED SOLDER

•

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

Installation kit (1)

Monitor stand (1) (AEP, UK, E, Chinese model)

(with supplied screws (5))

Connection box XA-126 (1) (AEP, UK model)

Connection box XA-125 (1)

(US, Canadian, E, Chinese model)

Cordless headphones MV-02HP (1)

(US, Canadian model)

Rechargeable battery MV-100BAT (1)

(AEP, UK, E, Chinese model)

Battery rechargeable cable (1)

(AEP, UK, E, Chinese model)

Card remote commander RM-X709

(with supplied battery) (1)

Power supply cord (1)

Detach cradle (3 m) (1)

Cigar plug (0.3 m) (1)

Operating Instructions (1 set)

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PA RT NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 3

2. GENERAL

Location of Controls ........................................................ 4

Connections ..................................................................... 6

3. DISASSEMBLY

3-1. Cabinet (Rear) Assy ......................................................... 9

3-2. Monitor Board ................................................................. 9

3-3. LCD1 ............................................................................... 10

4. TEST MODE ............................................................... 11

5. ELECTRICAL ADJUSTMENTS

5-1. Equipment Used .............................................................. 12

5-2. Connection of Equipment ................................................ 12

5-3. Setup for Adjustment....................................................... 12

5-4. DC-DC Converter Adjustment ........................................ 12

5-4-1. Frequency Adjustment ............................................. 12

5-4-2. 5V Voltage Adjustment ............................................ 12

5-4-3. Other Voltage Checks ............................................... 12

5-5. PLL Adjustment .............................................................. 12

5-6. Inverter High Voltage Check ........................................... 13

5-6-1. Voltage Check .......................................................... 13

5-6-2. Frequency Check ..................................................... 13

5-7. OSD Dot Clock Check .................................................... 13

5-8. NTSC Subcarrier Check .................................................. 13

5-9. PAL Subcarrier Check ..................................................... 13

5-10. F0 Frequency Adjustment ............................................... 13

5-10-1. 3.2/3.8 MHz (CH2) Adjustment ............................ 13

5-10-2. 2.3/2.8 MHz (CH1) Check ..................................... 13

5-11. V COM Voltage/Position Adjustment ............................. 13

5-12. Video Adjustment ............................................................ 14

5-12-1. Brightness Signal Contrast Level (Y GAIN) ......... 14

5-12-2. Black Limiter Level Adjustment ............................ 14

5-12-3. White Limiter Level Adjustment ........................... 14

5-12-4. R Sub Brightness Adjustment ................................ 14

5-12-5. B Sub Brightness Adjustment ................................ 14

5-12-6. R Sub Contrast Adjustment ................................... 14

5-12-7. B Sub Contrast Adjustment ................................... 15

5-12-8. γ 1 Adjustment ....................................................... 15

5-12-9. γ 2 Adjustment ....................................................... 15

5-12-10. VCO Free Run Adjustment .................................... 15

5-12-11. V POS Adjustment ................................................. 15

5-12-12. H POS Adjustment................................................. 15

6. DIAGRAMS

6-1. Block Diagram –Connection Box Section– .................... 17

6-2. Block Diagram –Video Section– ..................................... 18

6-3. Block Diagram –Display Section– .................................. 19

6-4. Printed Wiring Board –Connection Box Section– .......... 22

6-5. Schematic Diagram –Connection Box Section (1/2)– .... 24

6-6. Schematic Diagram –Connection Box Section (2/2)– .... 25

6-7. Printed Wiring Boards –Monitor Section– ...................... 26

6-8. Schematic Diagram –Monitor Section (1/4)– ................. 28

6-9. Schematic Diagram –Monitor Section (2/4)– ................. 29

6-10. Schematic Diagram –Monitor Section (3/4)– ................. 30

6-11. Schematic Diagram –Monitor Section (4/4)– ................. 31

7. EXPLODED VIEWS

7-1. Cabinet (Rear) Section .................................................... 38

7-2. Cabinet (Front) Section ................................................... 39

7-3. Connection Box Unit ....................................................... 40

7-4. Cradle Section ................................................................. 41

8. ELECTRICAL PARTS LIST .................................. 42

2

Page 3

SECTION 1

SERVICE NOTES

NOTE FOR REPLACEMENT OF THE EEP ROM (IC403)

The EEP ROM (IC403) contains all data by which the LCD screen is defined.

When the EEP ROM is replaced, the normal LCD screen will not appear.

It is then necessary to write the data into the EEP ROM.

Writing Method:

1. Turn on power to the connection box XA-125/126.

2. Press the [POWER] key on the set to turn on the set.

(Normal LCD screen doesn’t appear because there is no data in EEP ROM.)

3. Press the [RESET] key while pressing the [INPUT] and [VOL--] keys on the set.

4. Press the [VOL--] key on the remote controller for more than 2 seconds.

5. The EEP ROM data will be written and the normal test mode screen will appear.

After this, perform V COM voltage/position adjustment as well as VIDEO adjustment.

NOTE FOR REPLACEMENT OF THE SYSTEM CONTROL (IC401)

When the IC401 is replaced, the video system should be set again according to the destinations.

XVM-F65WL

Ver. 1.1

Setting Method:

1. Enter the test mode. (See page 11).

2. Select NTSC/PAL SELECT from the test mode menu.

3. Set the video system to the appropriate mode for each destination by using the [MENU] key.

Video mode Destination

NTSC 2.4G PACK US, Canadian

PAL 2.4G PACK E, Chinese

PAL RGB 2.4G PACK AEP, UK

3

Page 4

XVM-F65WL

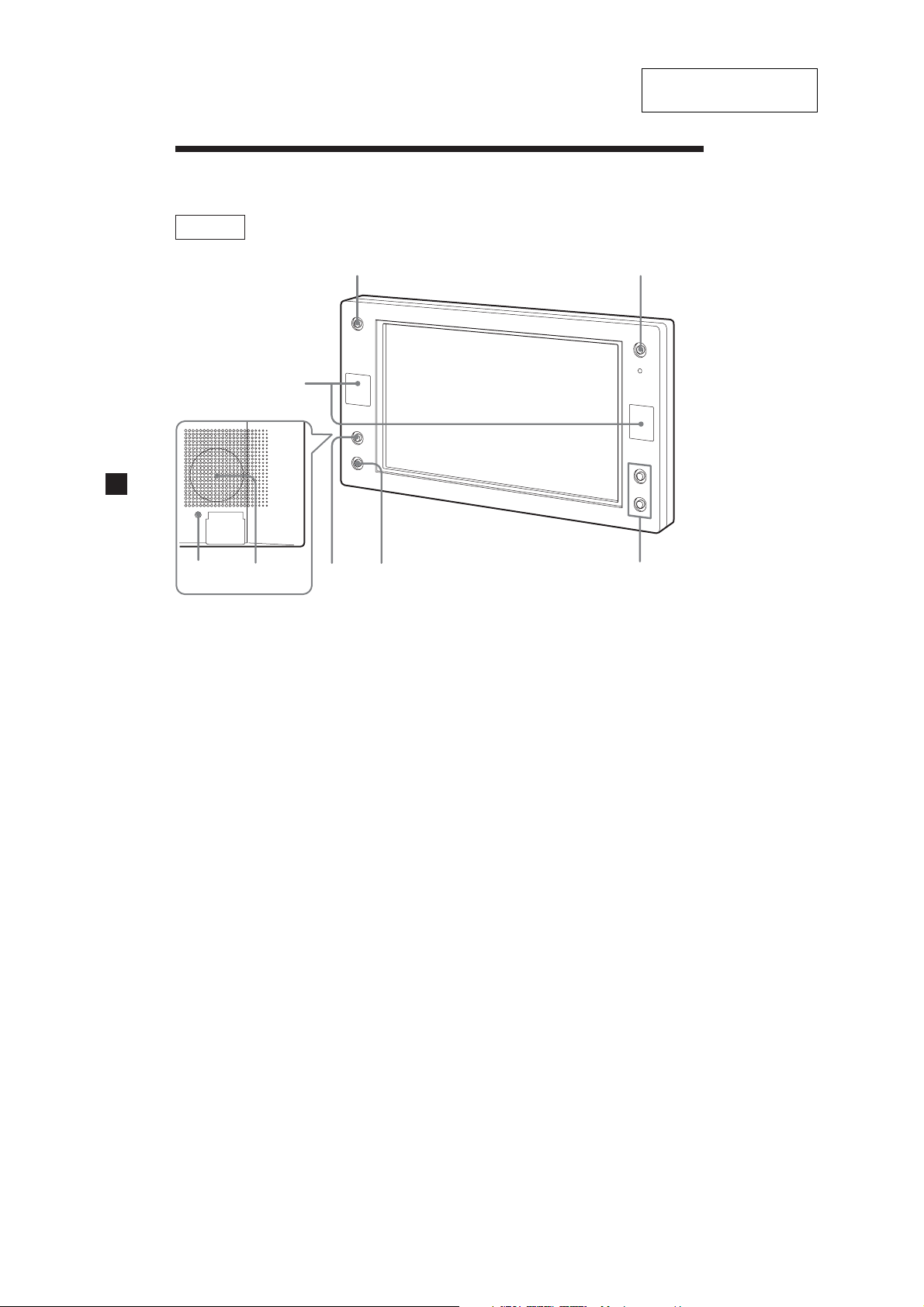

Location of controls

Monitor

15

2

SECTION 2

GENERAL

This section is extracted

from instruction manual.

7 8

1 INPUT button

Press to select the input source.

2 Receptor for the card remote

commander/Transmitter for the

cordless headphones*

3 MENU button

Press to make various settings.

4 DIMMER button

Press to switch the dimmer on/off.

(When it is set to On, the display

darkens.)

5 POWER (on/off) button

Press to turn on/off the monitor.

*

If interference occurs while using several cordless headphones

If several monitors are installed and used simultaneously, interference may occur.

6

43

6 VOLUME +/– buttons

Press to turn up or down the volume

(The default volume level is 25.) or

to select the item during menu

operation.

7

RESET button

8 Monaural speaker

6

4

Page 5

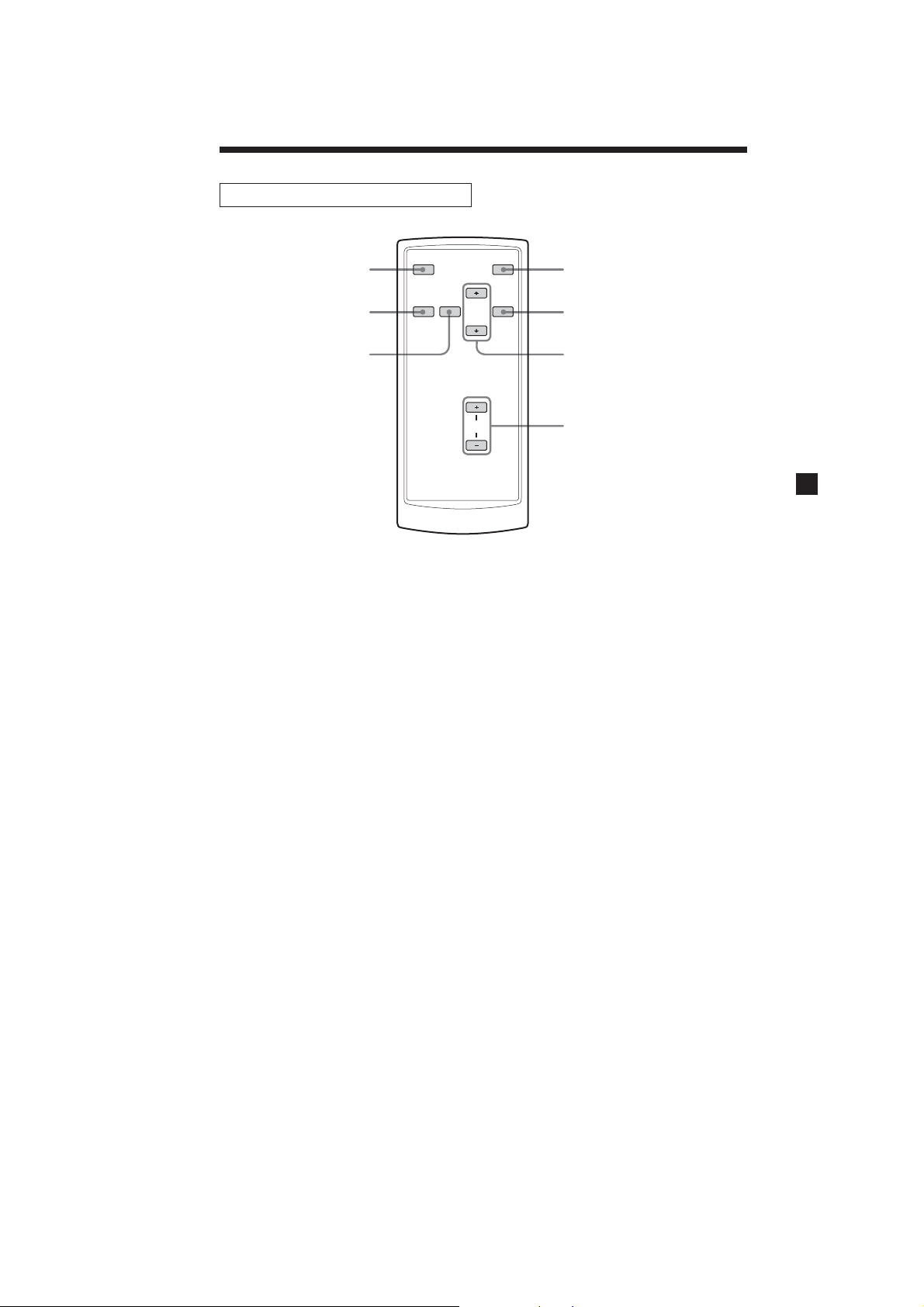

Card remote commander RM-X709

XVM-F65WL

1

2

3

1 ATT button

Press to quickly attenuate the

volume.

To restore the previous volume

level, press (ATT) again or (VOL)

+/–.

2 INPUT button

Press to select the input source.

3 MENU button

Press to select the menu settings.

4 |/1 (power) button

INPUT

AT T

`/1

4

MODEMENU

5

6

VOL

5 MODE button

6 M/m buttons

7 VOL (volume) +/– buttons

7

Press to change the screen mode.

Press to select the desired item.

Press to adjust the volume of the

monitor.

Tip

Refer to “Replacing the lithium battery” for details on how to replace the batteries (page 19).

7

5

Page 6

XVM-F65WL

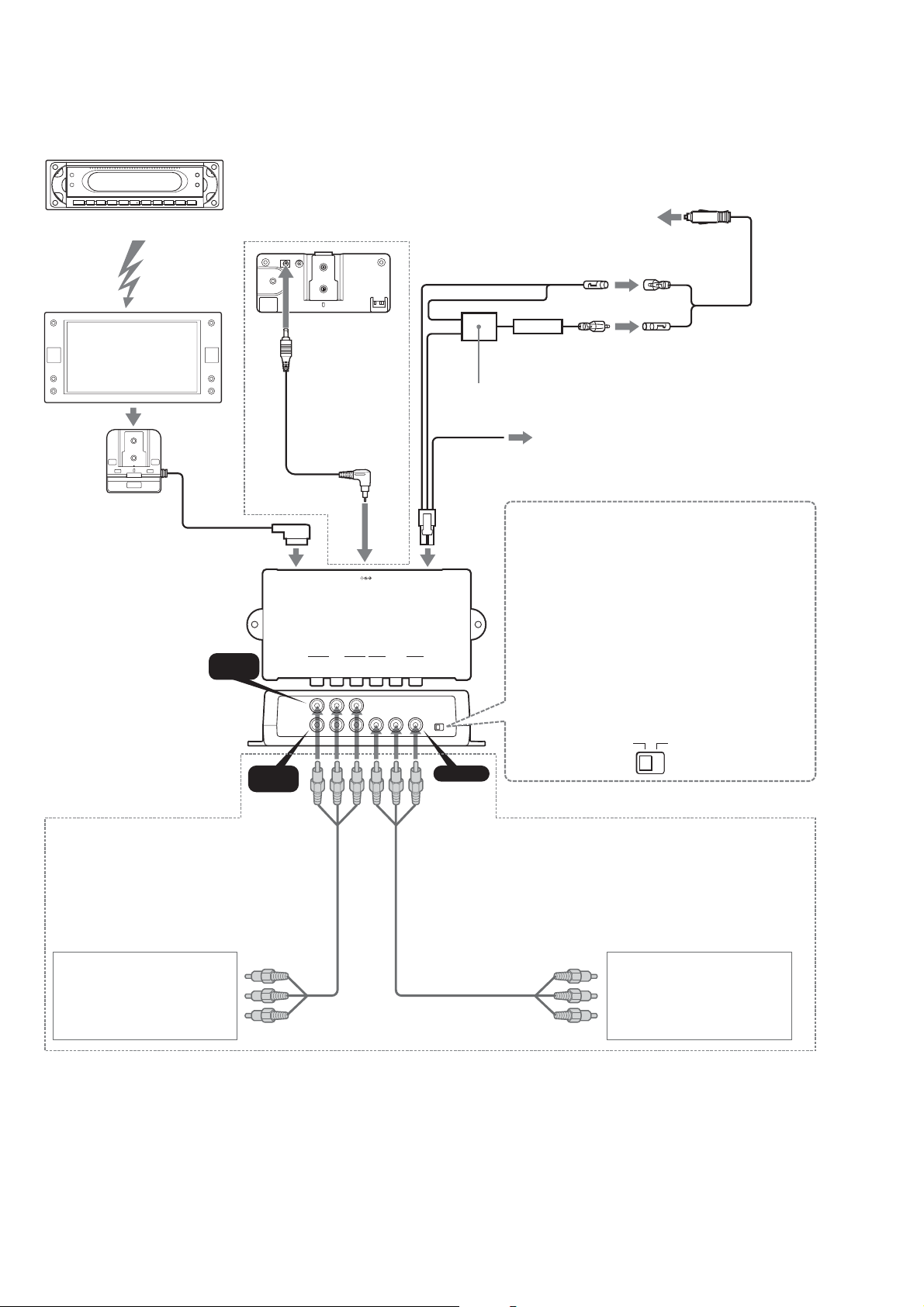

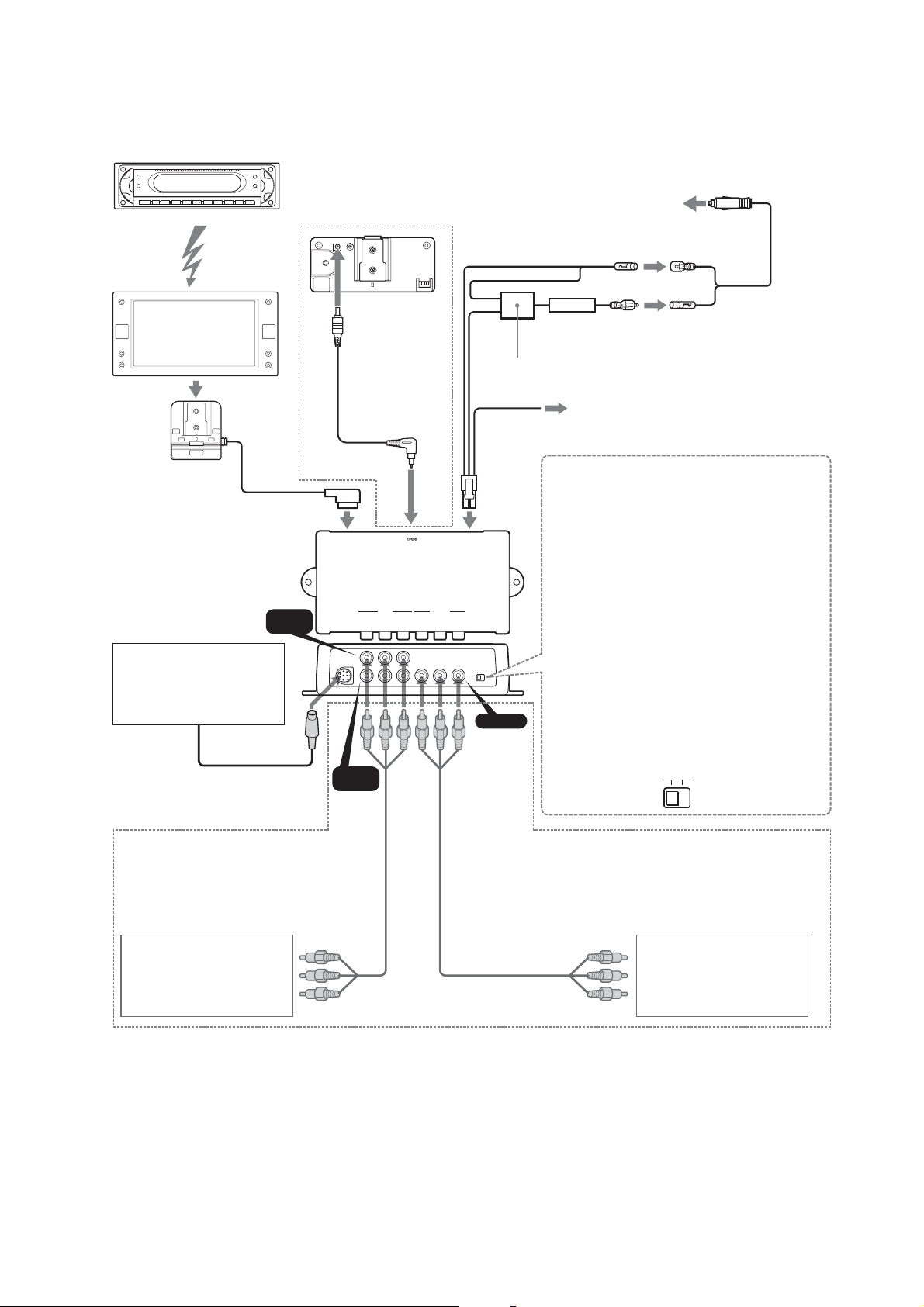

Connections

US, Canadian model

MEX-R5 (optional)

MEX-R5 (en option)

XVM-F65WL

2

Installation cradle

Berceau d’installation

INPUT

VIDEO 1

5

To charge the

rechargeable battery

Pour charger la pile

rechargeable

MV-100BAT

(optional)

MV-100BAT

(en option)

Battery

rechargeable

cable (Supplied)

Câble de pile

rechargeable

(en option)

3

MONITOR

(XVM)

INPUT

VIDEO 1

VIDEO 2

RGB

VLR VLR

DC OUT 9V

MAX 7A

OUTPUT

POWER

DC 12V 3A

REAR/FRONT

Black

Noir

Red

Rouge

LOCATION

1

Blue

Bleu

LC filter

Filtre LC

Cigar lighter adaptor (supplied)

Adaptateur d’allume-cigare (fourni)

To the cigar lighter socket

A la douille d’allume-cigare

Fuse (4 A)

Fusible (4 A)

To the parking brake switch cord

Au cordon du commutateur du frein de stationnement

Switch the location you mount the monitor

To use the monitor on dashboard:

Switch to “FRONT” and connect the blue cord to the parking

brake.

To use the monitor behind the headrest:

Switch to “REAR”.

Commutez l’emplacement de montage du moniteur

Pour utiliser le moniteur sur le tableau de bord:

Commutez à « FRONT » et connectez le cordon bleu au frein de

stationnement.

Pour utiliser le moniteur derrière le repose-tête:

Commutez à « REAR ».

4

RCA cable (not supplied)

Câble RCA (non fourni)

From DVD player

Du lecteur DVD

Notes

• Be sure to connect the power input cord after all

other cords have been connected.

• Be sure to insert each connector securely, as

vibration through driving may cause a poor

connection.

• When removing the cable, hold the connector to

avoid damages.

VIDEO 2

RCA cable (not supplied)

Câble RCA (non fourni)

Remarques

• Connectez bien le cordon d’entrée d’alimentation

après le raccordement de tous les autres cordons.

•Insérez fermement tous les connecteurs, car la

vibration due à la conduite peut provoquer une

mauvaise connexion.

•Au retrait du câble, saisissez le connecteur pour

éviter les dommages.

REAR FRONT

OUTPUTINPUT

To ot her monitor

A un autre moniteur

6

Page 7

Connections

AEP, UK model

MEX-R5 (optional)

MEX-R5 (en option)

MEX-R5 (optional)

To charge the rechargeable battery

Pour charger la pile rechargeable

Zum Aufladen des Akkus

Black

Noir

Schwarz

Cigar lighter adaptor (supplied)

Adaptateur d’allume-cigare (fourni)

Zigarettenanzünderadapter (mitgeliefert)

To the cigar lighter socket

A la douille d’allume-cigare

An Zigarettenanzünderbuchse

XVM-F65WL

XVM-F65WL

3

Installation cradle

Berceau d’installation

Einbauhalterung

Navigation system etc.

Système de navigation etc.

Navigationssystem usw.

INPUT

VIDEO 1

6

MV-100BAT

Battery rechargeable

cable (supplied)

Câble de pile

rechargeable (fourni)

Akkuladekabel

(mitgeliefert)

4

MONITOR

(XVM)

RGB

DC OUT 9V

MAX 7A

INPUT

VIDEO 1

VIDEO 2

VLR VLR

1

OUTPUT

POWER

DC 12V 3A

REAR/FRONT

Red

Rouge

Rot

LOCATION

Blue

Bleu

Blau

2

OUTPUT

LC filter

Filtre LC

LC-Filter

Fuse (4 A)

Fusible (4 A)

Sicherung (4 A)

To the parking brake switch cord

Au cordon du commutateur du frein de stationnement

An Feststellbremsen-Schalterkabel

Switch the location you mount the monitor

To use the monitor on dashboard:

Switch to “FRONT” and connect the blue cord to the parking

brake.

To use the monitor behind the headrest:

Switch to “REAR”.

Commutez l’emplacement de montage du moniteur

Pour utiliser le moniteur sur le tableau de bord:

Commutez à « FRONT » et connectez le cordon bleu au frein de

stationnement.

Pour utiliser le moniteur derrière le repose-tête:

Commutez à « REAR ».

Andere Einbaustelle für den Monitor wählen

Zur Verwendung des Monitors auf dem Armaturenbrett:

Schalten Sie auf „FRONT“ und schließen Sie das blaue Kabel an

die Feststellbremse an.

Zur Verwendung des Monitors hinter der Kopfstützt:

Schalten Sie auf „REAR“.

RGB cable (not supplied)

Câble RGB (non fourni)

RGB-Kabel (nicht mitgeliefert)

RCA cable (not supplied)

Câble RCA (non fourni)

RCA-Kabel (nicht mitgeliefert)

From DVD player

Du lecteur DVD

Von DVD-Player

Notes

• Be sure to connect the power input cord after all

other cords have been connected.

• Be sure to insert each connector securely, as

vibration through driving may cause a poor

connection.

•When removing the cable, hold the connector to

avoid damages.

•When connecting the additional monitor, even if

you select “NAVI” for the input source, the audio

of the additional monitor or the cordless

headphone will be “VIDEO 1”.

• Please use the commercially available RGB cable

with the connector that fits the RGB jack of the

connection box.

INPUT

VIDEO 2

RCA cable (not supplied)

Câble RCA (non fourni)

RCA-Kabel (nicht mitgeliefert)

Remarques

• Connectez bien le cordon d’entrée d’alimentation

après le raccordement de tous les autres cordons.

• Insérez fermement tous les connecteurs, car la

vibration due à la conduite peut provoquer une

mauvaise connexion.

•Au retrait du câble, saisissez le connecteur pour

éviter les dommages.

•Au raccordement d’un moniteur additionnel,

même si vous sélectionnez « NAVI » comme source

d’entrée, le son du moniteur additionnel ou du

casque sans fil sera « VIDEO 1 ».

• Utilisez un câble RGB disponible dans le commerce

avec connecteur adapté à la prise RGB de la boîte

de raccordement.

REAR FRONT

To o t her monitor

A un autre moniteur

An anderen Monitor

Hinweise

• Schließen Sie das Stromeingangskabel erst an,

nachdem alle anderen Kabel angeschlossen sind.

• Stellen Sie sicher, jeden Stecker fest anzuschließen,

da Fahrvibrationen die Verbindungen lockern

können.

• Beim Abnehmen des Kabels greifen Sie am Stecker,

um Schäden zu vermeiden.

• Beim Anschließen des zusätzlichen Monitors ist

das Tonsignal des zusätzlichen Monitors oder

schnurlosen Kopfhörers „VIDEO 1“, auch wenn Sie

„NAVI“ als Eingangsquelle wählen.

• Bitte verwenden Sie ein handelsübliches RGBKabel mit passendem Stecker für die RGB-Buchse

an der Anschlussbox.

7

Page 8

XVM-F65WL

SECTION 3

DISASSEMBLY

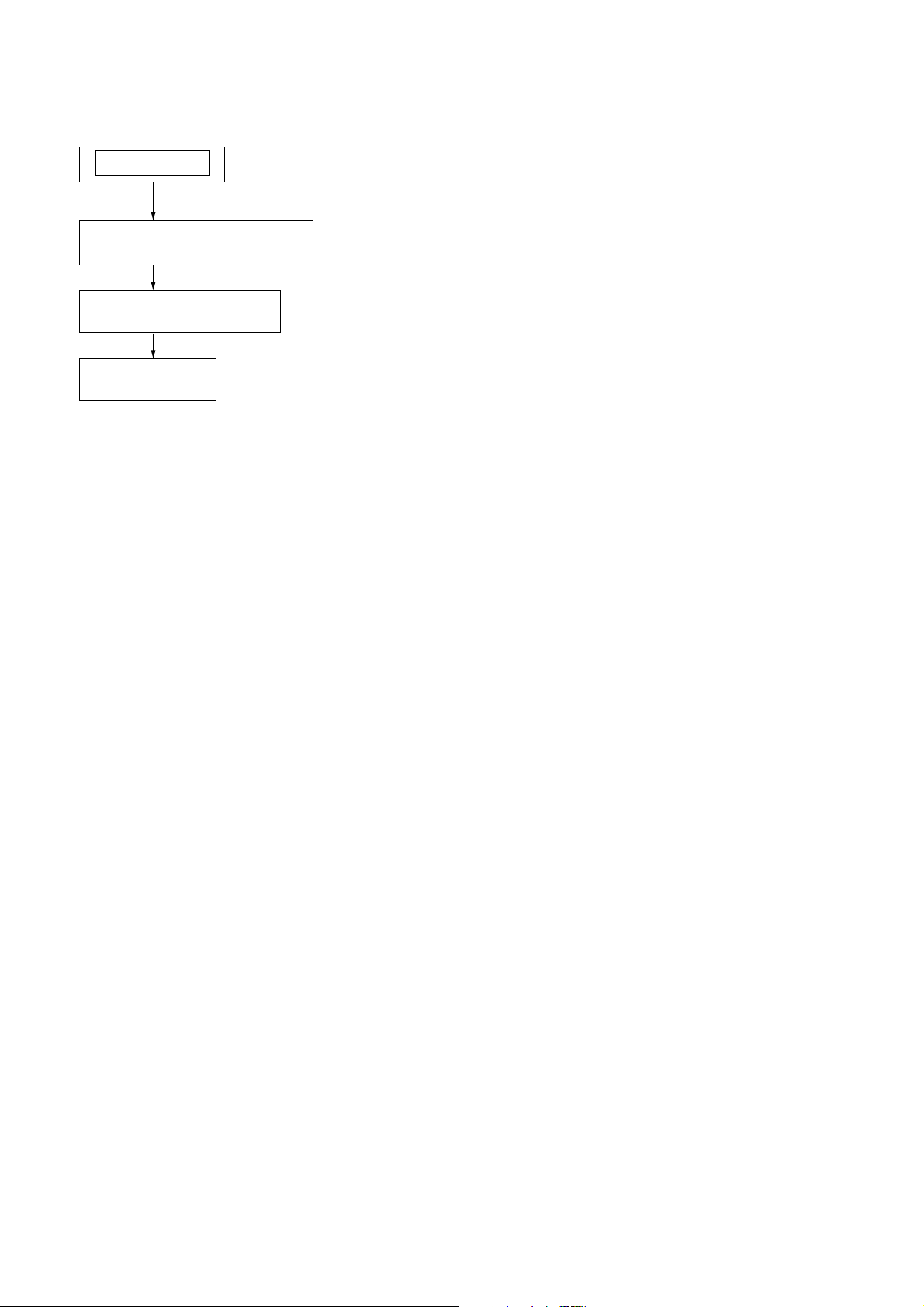

Note: This set can be disassemble according to the following sequence.

SET

3-1. CABINET (REAR) ASSY

(Page 9)

3-2. MONITOR BOARD

(Page 9)

3-3. LCD1

(Page 10)

8

Page 9

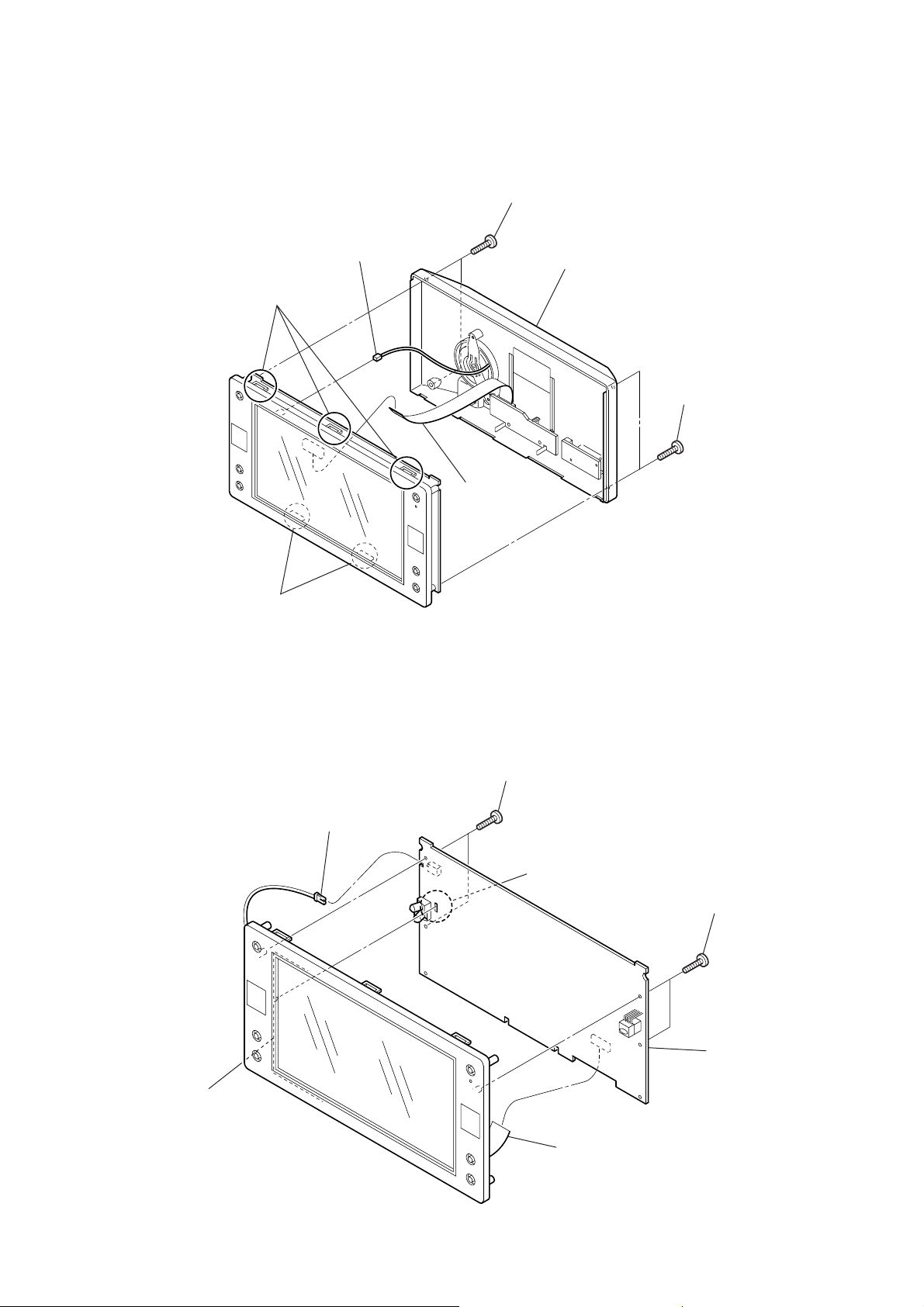

Note: Follow the disassembly procedure in the numerical order given.

s

3-1. CABINET (REAR) ASSY

6

CN252

3

three claws

2

two screws

(+P 2 × 8)

7

cabinet (rear) assy

1

two screw

(+P 2 × 8)

XVM-F65WL

3-2. MONITOR BOARD

4

two claws

2

CN801

5

CN904

4

two screws

(+BTP 2 × 6)

5

Remove the solder.

3

two screws

(+BTP 2 × 6)

bracket (LCD)

6

MONITOR board

1

CN701

9

Page 10

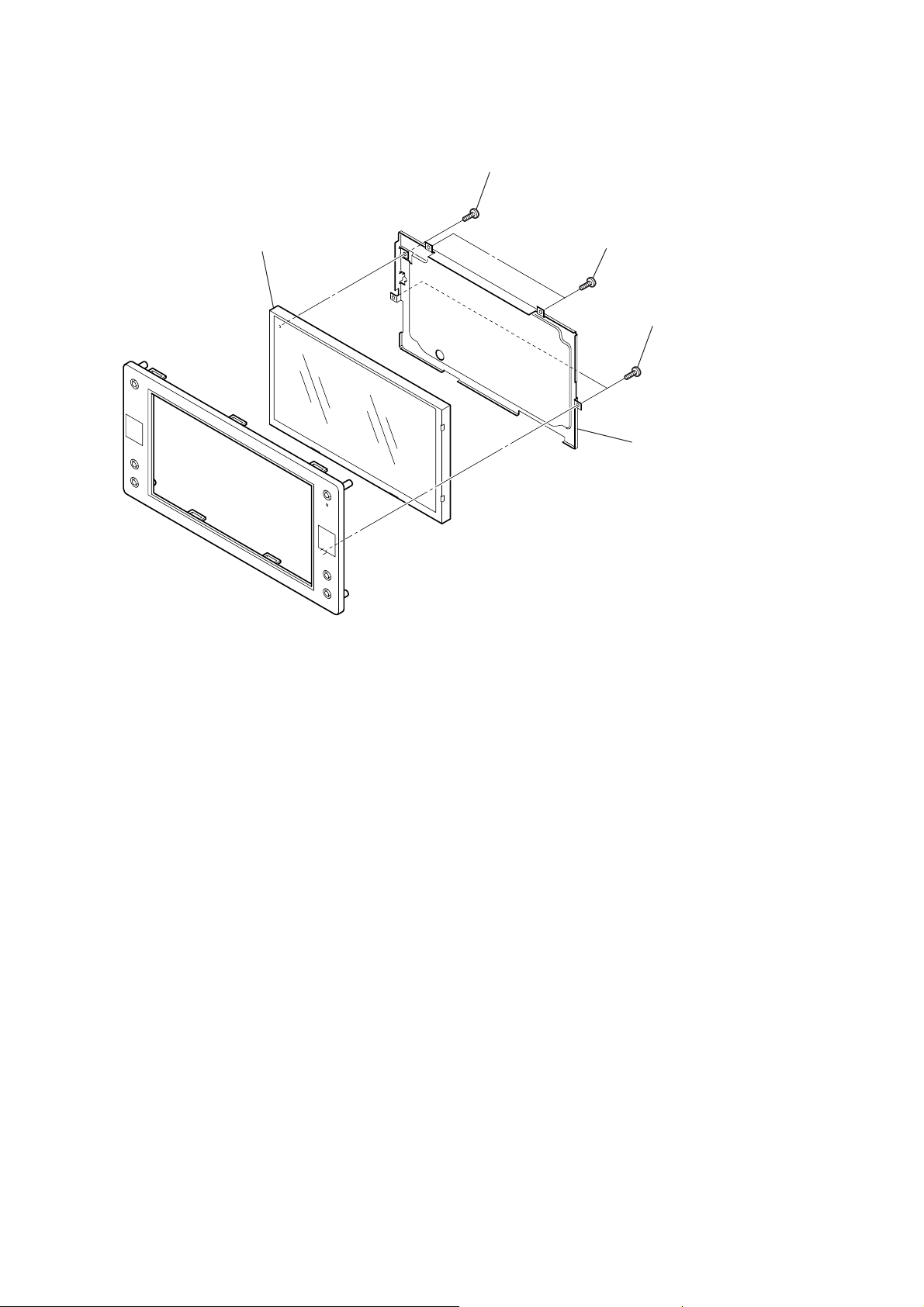

XVM-F65WL

3-3. LCD1

5

LCD1

3

precision screw

(+P 1.7 × 1.8)

1

two screws

(+BTP 2 × 6)

4

2

two screws

(+BTP 2 × 6)

bracket (LCD)

10

Page 11

SECTION 4

TEST MODE

Setting Method:

1. Turn on power to the connection box XA-125/126.

2. Press the [POWER] key on the set to turn on the set.

3. Press the [RESET] key while pressing the [INPUT] and [VOL--]

Keys on the set. Then TEST MODE MENU appears.

Terminating Method:

Select the MENU No. 5, SOFT RESET using the [MENU] key on

the remote controller and determine the selection using the [INPUT]

key.

The FOR FACTORY Mode:

The FOR FACTORY mode can be used to perform 13 different

adjustment items with the remote controller.

1. Select the MENU No. 2, FOR FACTORY using the [MENU] key

on the remote controller and determine the selection using the

[INPUT] key.

2. The FOR FACTORY mode is now entered. The following items

are selected in turn by pressing the [INPUT] key repeatedly.

XVM-F65WL

Com Gain

Y Gain

Black Limt

White Limt

R SUB BRT

B SUB BRT

R SUB CONT

B SUB CONT

Gamma1

Gamma2

VCO Free Run

PLL/V Pos

H Pos

3. For each item selected, adjust so that the adjustment value is

within the specified value range using the R and r keys on the

remote controller.

4. After adjustment, press the [INPUT] key on the remote controller

to determine the adjustment value. After that, it changes into the

following item.

5. After all necessary adjustments are completed, select EXIT

using the [MENU] key on the remote controller and press the

[INPUT] key to display the MENU screen. Then, select No.5,

SOFT RESET using the [MENU] key and determine the selection

using the [INPUT] key to terminate the TEST mode.

11

Page 12

XVM-F65WL

y

SECTION 5

ELECTRICAL ADJUSTMENTS

5-1. EQUIPMENT USED

The following measuring equipment are used for these electrical

adjustments:

• Oscilloscope

• NTSC pattern generator

• Stabilized power supply

• Digital voltmeter

• Frequency counter

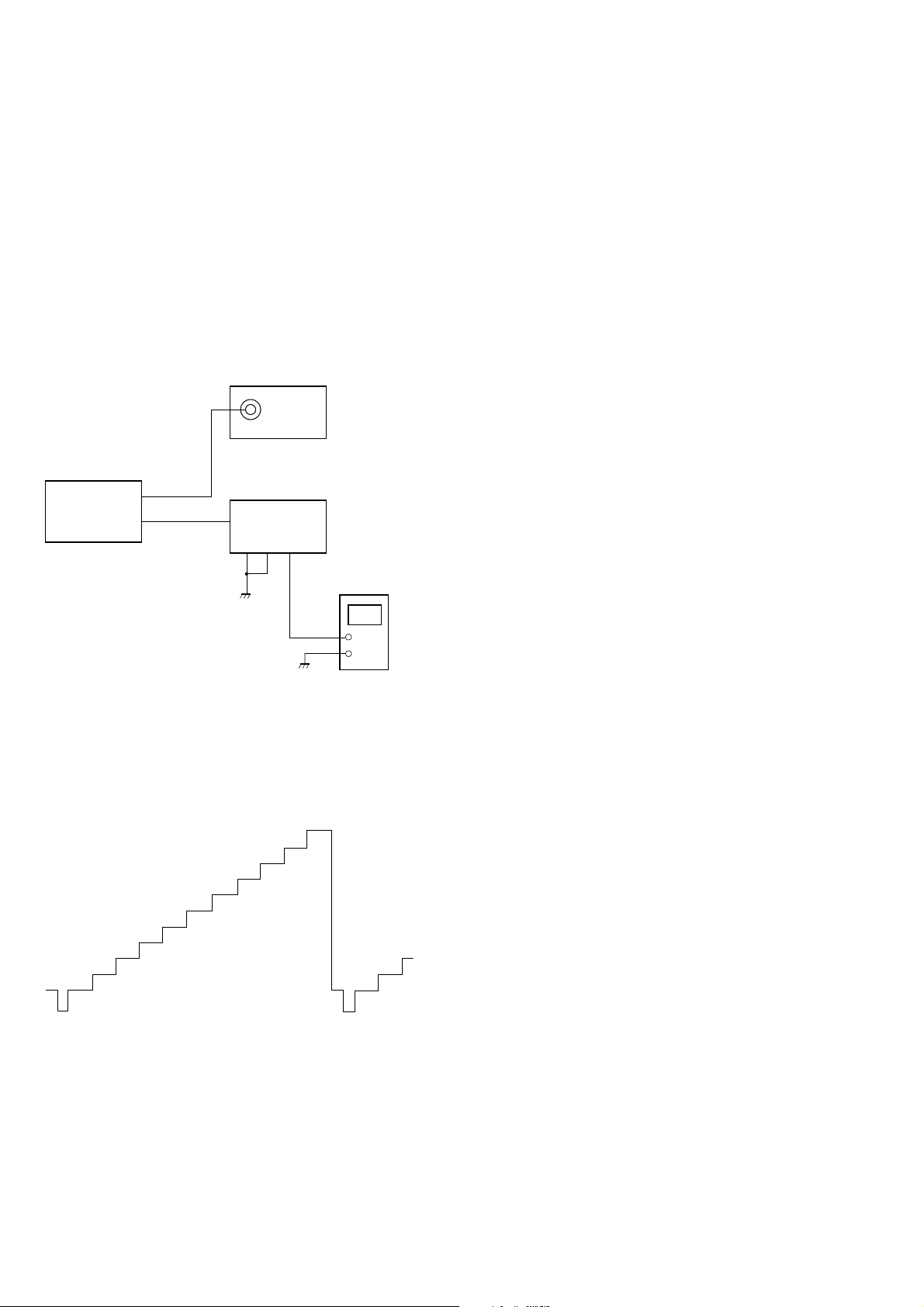

5-2. CONNECTION OF EQUIPMENT

Unless otherwise specified, the equipment should be connected as

shown below.

NTSC pattern

generator

VIDEO OUT

(75 Ω)

monitor

XVM-F65WL

MONITOR

board

TP501(+)

TP502(–)

connection box

XA-125/126

GND

PARK

BATT

stabilized

power suppl

14.4 V

5-3. SETUP FOR ADJUSTMENT

The 10-step gray scale signal from the NTSC pattern generator is

used as an adjustment signal for V COM voltage/position adjustment

as well as VIDEO adjustment.

5-4. DC-DC CONVERTER ADJUSTMENT

5-4-1. Frequency Adjustment

Adjustment Method:

1) Connect frequency counter between TP702 (+) and TP704 (–).

2) Adjust RV702 so that the reading on the counter stands at the

specified value.

Specified value: 243 ± 3 kHz

Adjustment location: Monitor board

5-4-2. 5V Voltage Adjustment

Adjustment Method:

1) Connect digital voltmeter between TP707 (+) and TP710 (–).

2) Adjust RV701 so that the reading on the voltmeter stands at the

specified value.

Specified value: 5.05 ± 0.03 V

Adjustment location: Monitor board

5-4-3. Other Voltage Checks

Checking Method:

1) Connect digital voltmeter between TP708 (+) (Vdd) and

TP710 (–).

2) Verify that the reading on the voltmeter is at 3.20 ± 0.2 V.

3) Connect digital voltmeter between TP706 (+) (Vgh) and

TP710 (–).

4) Verify that the reading on the voltmeter is at 7.3 ± 0.3 V.

5) Connect digital voltmeter between TP705 (+) (Vgh) and

TP710 (–).

6) Verify that the reading on the voltmeter is at 17.0 ± 1.5 V.

7) Connect digital voltmeter between TP709 (+) (Vss) and

TP710 (–).

8) Verify that the reading on the voltmeter is at –12.0 ± 1.5 V.

Checking location: Monitor board

5-5. PLL ADJUSTMENT

1. Frequency Adjustment

Adjustment Method:

1) Connect digital voltmeter between TP651 (+) and TP652 (–).

2) Adjust RV651 so that the reading on the voltmeter stands at the

specified value.

10-step gray scale signal (with burst), 1Vp-p, 75 Ω

12

Specified value: 2.2 ± 0.15 V

Adjustment location: Monitor board

Page 13

XVM-F65WL

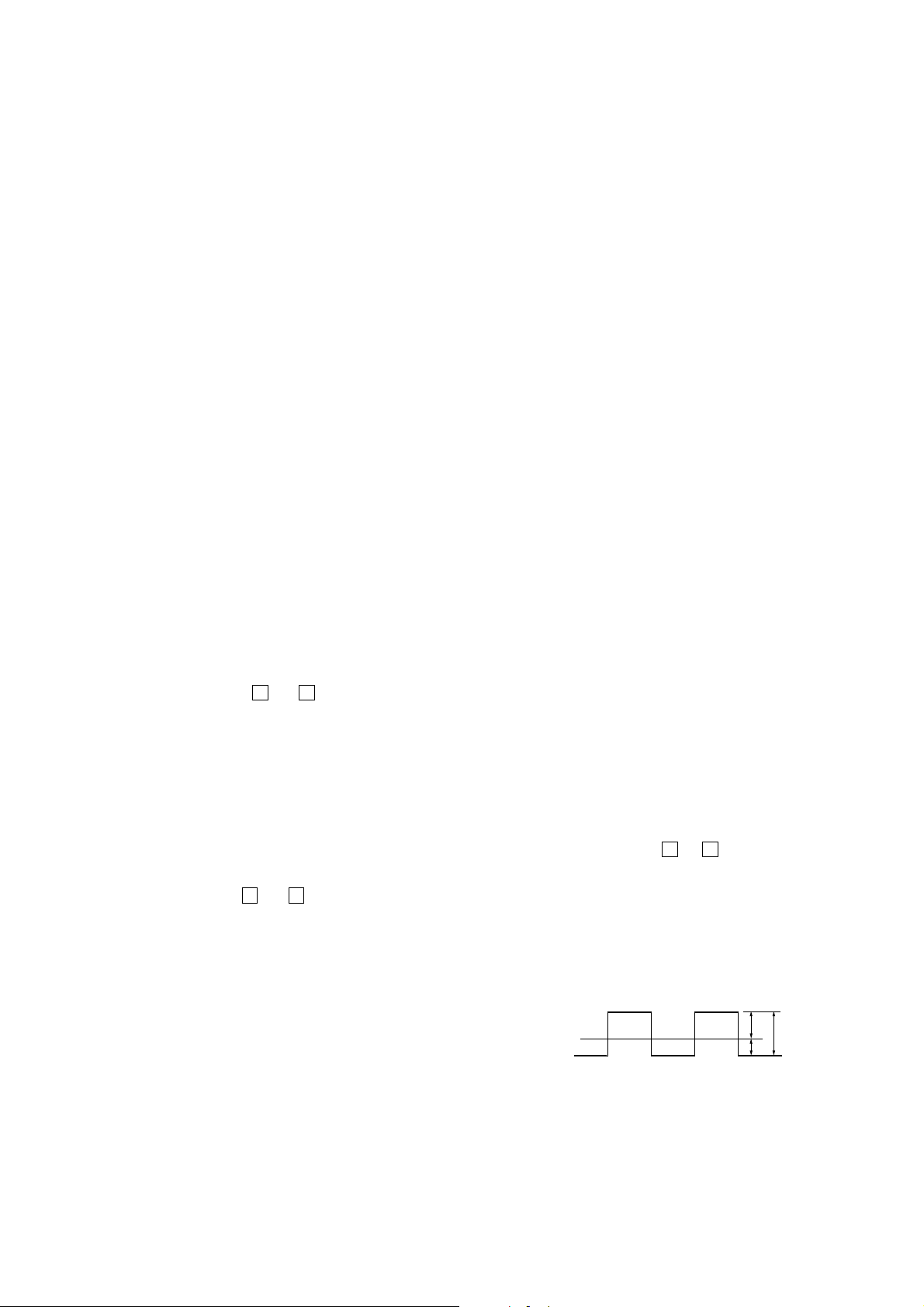

C

B

0V

A

5-6. INVERTER HIGH VOLTAGE CHECK

Condition: DIMMER switch OFF

5-6-1. Voltage Check

Checking Method:

1) Connect oscilloscope between TP809 (+) and TP804 (–) using

high voltage proof probes (100:1).

2) Verify that the reading on the oscilloscope is at 2.4 ± 0.15 Vpp.

Checking location: Monitor board

5-6-2. Frequency Check

Checking Method:

1) Connect oscilloscope between TP809 (+) and TP804 (–) using

high voltage proof probes.

2) Verify that the reading on the oscilloscope is at 50 ± 2.5 kHz.

Checking location: Monitor board

5-7. OSD DOT CLOCK CHECK

1. Dot Clock Check

Checking Method:

1) Connect frequency counter between TP555 (+) and TP554 (–).

2) Verify that the reading on the counter is at 6.5 ± 0.2 MHz.

Checking location: Monitor board

5-8. NTSC SUBCARRIER CHECK.

1. Subcarrier Check

Checking Method:

1) Press the [INPUT] key on the remote controller and enter the

NTSC mode using the R and r keys.

2) Connect frequency counter between TP503 (+) and TP504 (–).

3) Verify that the reading on the counter is at 3.579545 MHz ± 100

Hz.

Checking location: Monitor board

5-9. PAL SUBCARRIER CHECK

1. Subcarrier Check

Checking Method:

1) Press the [INPUT] key on the remote controller and enter the

PAL mode using the R and r keys.

2) Connect frequency counter between TP503 (+) and TP504 (–).

3) Verify that the reading on the counter is at 4.433619 MHz ± 100

Hz.

Checking location: Monitor board

5-10. F0 FREQUENCY ADJUSTMENT

5-10-1. 3.2/3.8MHz (CH2) Adjustment

Adjustment Method:

LCH (3.2 MHz)

1) TP356 is connected to GND.

2) Connect frequency counter between TP354 (+) and TP353 (–).

3) Adjust RV352 so that the reading on the counter stands at the

specified value.

Specified value: 3.2 MHz ± 3 kHz

RCH (3.8 MHz)

4) Connect frequency counter between TP352 (+) and TP353 (–).

5) Adjust RV351 so that the reading on the counter stands at the

specified value.

Specified value: 3.8 MHz ± 3 kHz

Adjustment location: Monitor board

5-10-2. 2.3/2.8MHz (CH1) Check

Checking Method:

LCH (2.3MHz)

1) TP365 is made open.

2) Connect frequency counter between TP354 (+) and TP353 (–).

3) Verify that the reading on the counter is at 2.3 MHz ± 30 kHz.

RCH (2.8MHz)

4) Connect frequency counter between TP352 (+) and TP353 (–).

5) Verify that the reading on the counter is at 2.8 MHz ± 30 kHz.

Checking location: Monitor board

5-11. V COM VOLTAGE/POSITION ADJUSTMENT

Condition: TEST MODE (See 11 page)

1. Voltage Setup Adjustment

Adjustment method:

1) Select Com Gain from the FOR FACTORY MODE.

2) Connect oscilloscope between TP724 (+) and TP710 (–).

3) Adjust so that the p-p value A of the waveform stands at the

specified value using the R and r keys on the remote controller.

4) Adjust so that the level B on the negative side stands at the

specified value using RV652.

5) Verify that the level C on the positive side stands at the specified

value.

Specified value A: 6.8 ± 0.1 Vp-p

Specified value B: –2.1 ± 0.1 V

Specified value C: 4.7 ± 0.1 V

Adjusting location: Monitor board

13

Page 14

XVM-F65WL

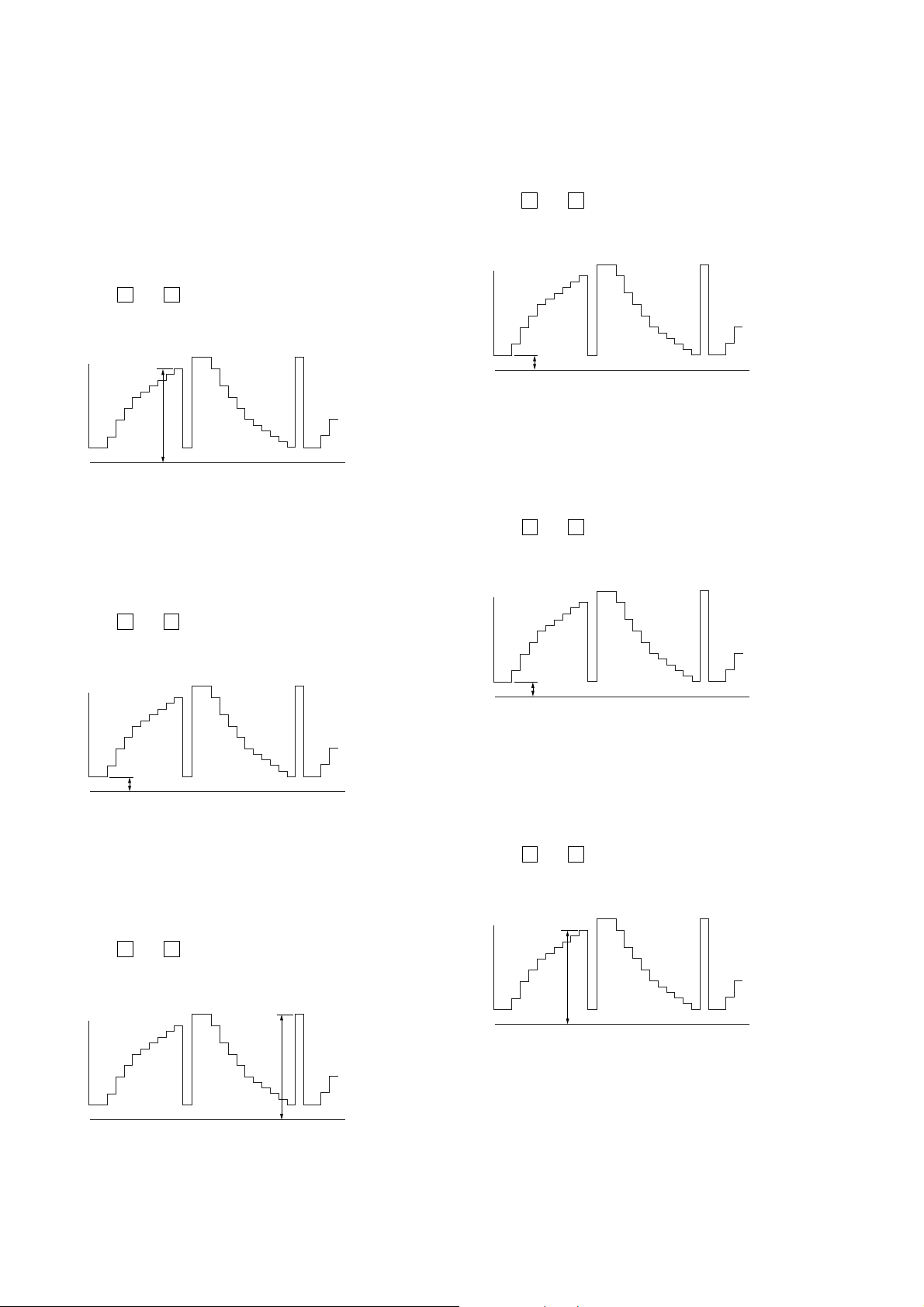

5-12. VIDEO ADJUSTMENT

Conditions: TEST MODE (See 11 page)

10-step gray scale signal input

NTSC mode

5-12-1. Brightness Signal Contrast Level (Y GAIN)

Adjustment Method:

1) Select Y Gain from the FOR FACTORY MODE.

2) Connect oscilloscope between TP714 (+) and TP710 (–).

3) Adjust so that the signal level A stands at the specified value

using the

Specified value: 3.8 ± 0.1 V

Adjustment location: Monitor board

5-12-2. Black Limiter Level Adjustment

Adjustment Method:

1) Select Black Limit from the FOR FACTORY MODE.

2) Connect oscilloscope between TP714 (+) and TP710 (–).

3) Adjust so that the signal level B stands at the specified value

using the

R

and r keys on the remote controller.

A

R

and r keys on the remote controller.

0V

5-12-4. R Sub Brightness Adjustment

Adjustment Method:

1) Select R SUS BRT from the FOR FACTORY MODE.

2) Connect oscilloscope between TP713 (+) and TP710 (–).

3) Adjust so that the signal level D stands at the specified value

R

using the

and r keys on the remote controller.

Specified value: 1.05 ± 0.15 V

D

0V

Adjustment location: Monitor board

5-12-5. B Sub Brightness Adjustment

Adjustment Method:

1) Select B SUS BRT from the FOR FACTORY MODE.

2) Connect oscilloscope between TP715 (+) and TP710 (–).

3) Adjust so that the signal level E stands at the specified value

R

using the

and r keys on the remote controller.

Specified value: 1.05 ± 0.15 V

Specified value: 1.05 ± 0.15 V

B

0V

Adjustment location: Monitor board

5-12-3. White Limiter Level Adjustment

Adjustment Method:

1) Select White Limit from the FOR FACTORY MODE.

2) Connect oscilloscope between TP714 (+) and TP710 (–).

3) Adjust so that the signal level C stands at the specified value

R

using the

and r keys on the remote controller.

Specified value: 3.95 ± 0.15 V

C

E

0V

Adjustment location: Monitor board

5-12-6. R Sub Contrast Adjustment

Adjustment Method:

1) Select R SUB CONT from the FOR FACTORY MODE.

2) Connect oscilloscope between TP713 (+) and TP710 (–).

3) Adjust so that the signal level F stands at the specified value

R

using the

and r keys on the remote controller.

Specified value: 3.8 ± 0.1 V

F

0V

Adjustment location: Monitor board

Adjustment location: Monitor board

14

0V

Page 15

XVM-F65WL

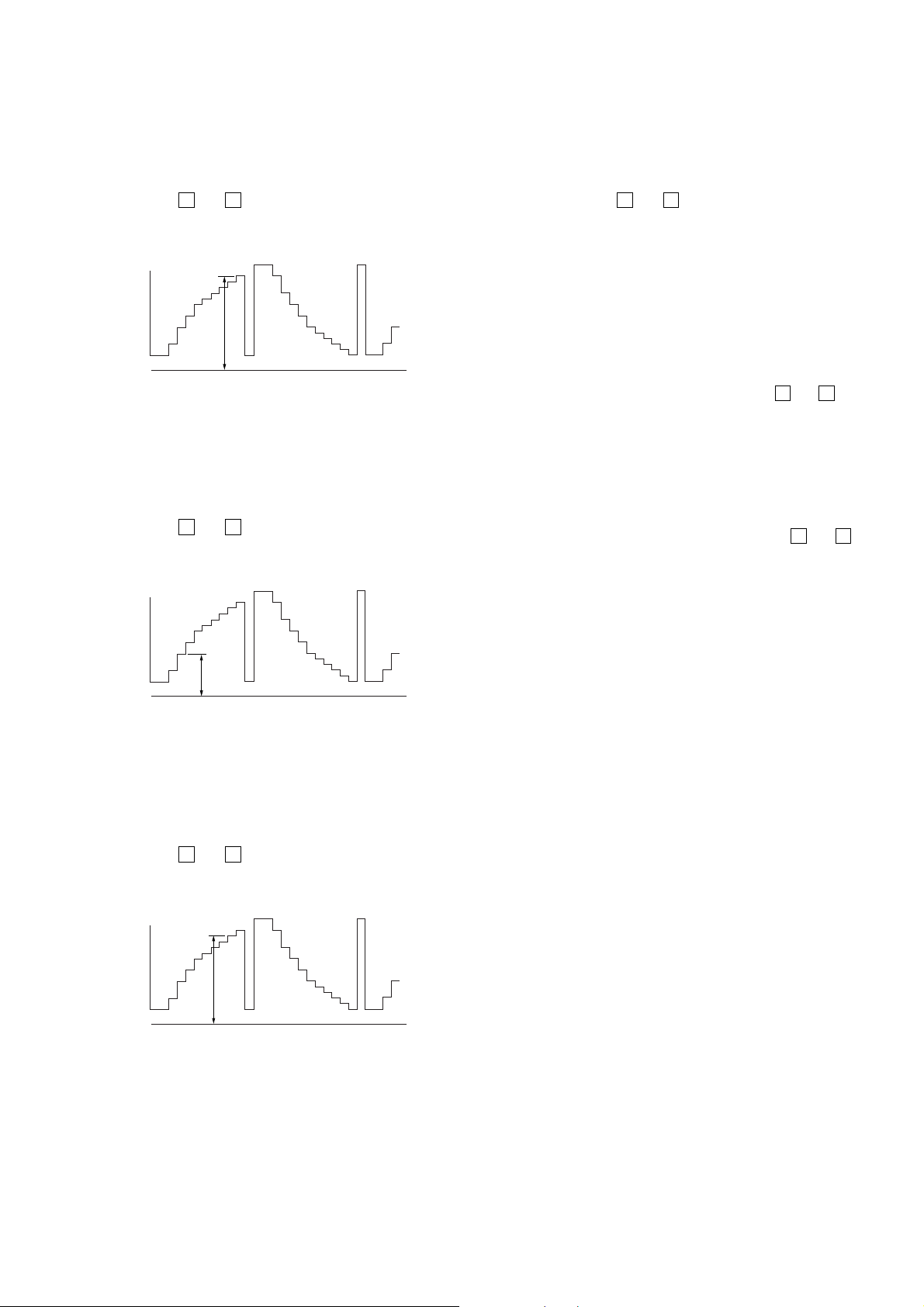

5-12-7. B Sub Contrast Adjustment

Adjustment Method:

1) Select B SUB CONT from the FOR FACTORY MODE.

2) Connect oscilloscope between TP715 (+) and TP710 (–).

3) Adjust so that the signal level G stands at the specified value

using the R and r keys on the remote controller.

Specified value: 3.8 ± 0.1 V

G

0V

Adjustment location: Monitor board

5-12-8. γ 1 Adjustment

Adjustment Method:

1) Select Gamma1 from the FOR FACTORY MODE.

2) Connect oscilloscope between TP714 (+) and TP710 (–).

3) Adjust so that the signal level H stands at the specified value

R

using the

and r keys on the remote controller.

Specified value: 2.1 ± 0.15 V

5-12-10. VCO Free Run Adjustment

Adjustment Method:

1) Select VCO Free Run from the FOR FACTOR MODE.

2) Connect frequency counter between TP508 (+) and TP504 (–).

3) Adjust so that the reading on the counter stands at the specified

R

value using the

and r keys on the remote controller.

Specified value: 15,734 ± 50 Hz

Adjustment location: Monitor board

5-12-11. V POS Adjustment

Adjustment Method:

1) Input mono scope signal from the NTSC pattern generator.

2) Select PLL/V POS from the FOR FACTORY MODE.

3) Observe the mono scope screen on the monitor and adjust so that

R

the screen is vertically symmetrical using the

and r keys on

the remote controller.

5-12-12. H POS Adjustment

Adjustment Method:

1) Input mono scope signal from the NTSC pattern generator.

2) Select H POS from the FOR FACTORY MODE.

3) Observe the mono scope screen on the monitor and adjust so that

R

the screen is horizontally symmetrical using the

and r keys

on the remote controller.

H

0V

Adjustment location: Monitor board

5-12-9. γ 2 Adjustment

Adjustment Method:

1) Select Gamma2 from the FOR FACTORY MODE.

2) Connect oscilloscope between TP714 (+) and TP710 (–).

3) Adjust so that the signal level I stands at the specified value

R

using the

and r keys on the remote controller.

Specified value: 3.6 ± 0.15 V

I

0V

Adjustment location: Monitor board

15

Page 16

XVM-F65WL

Adjustment Location:

– MONITOR BOARD – (SIDE A)

IC601

RV351

RV352

RV652

– MONITOR BOARD – (SIDE B)

TP354

TP352

TP356

TP353

TP809

RV651

T701

RV701 RV702

TP502

IC102

TP503

IC501

TP501

TP508

TP504

16

TP804

IC401

TP555

TP704

TP554

TP702

IC701

TP710

TP652

TP705

TP707

TP708

TP706

TP709

TP651

TP714

TP713

TP715

TP724

Page 17

SECTION 6

DIAGRAMS

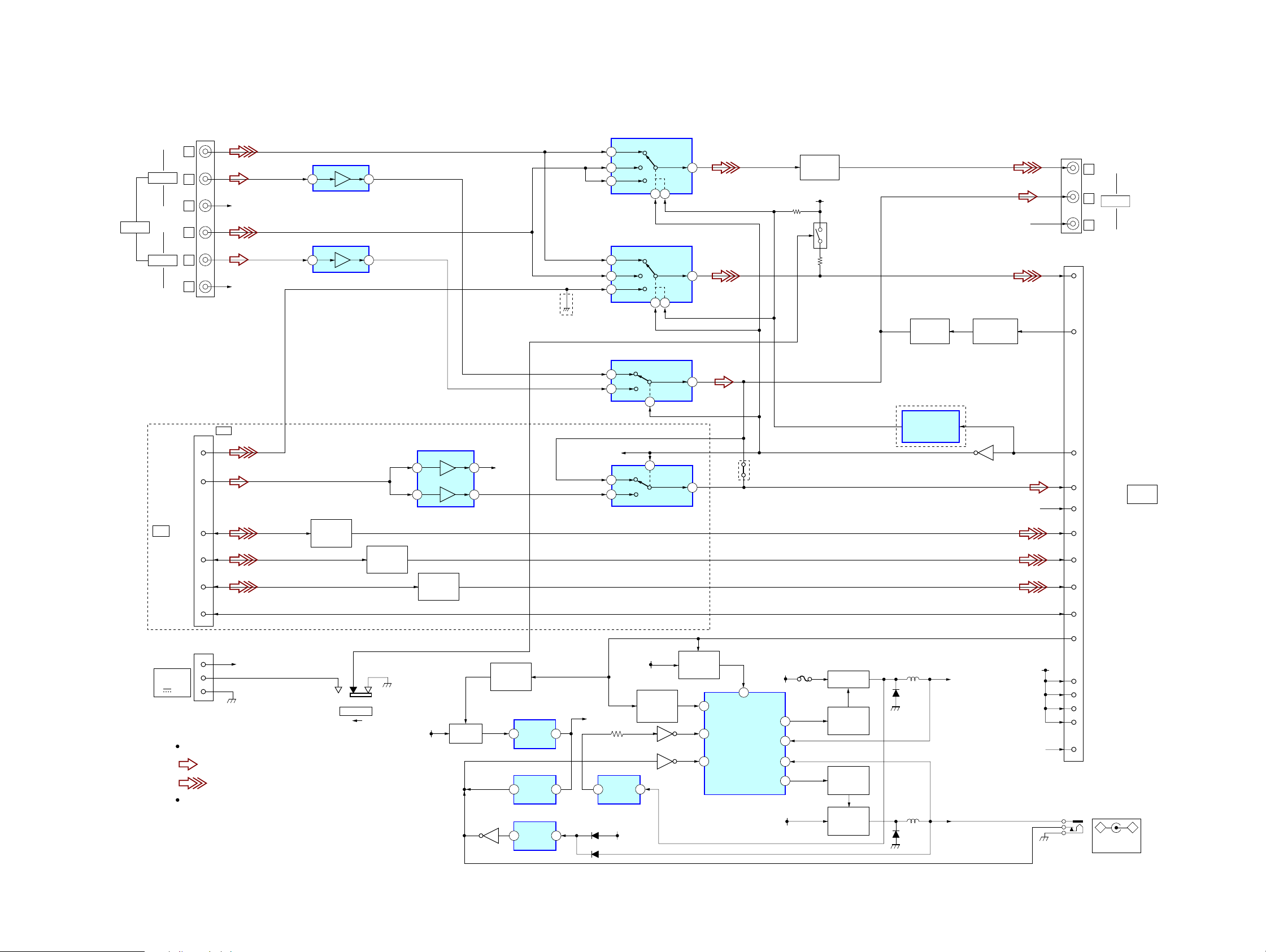

6-1. BLOCK DIAGRAM — CONNECTION BOX SECTION —

XA-126: AEP, UK model, XA-125: US, Canadian, E, Chinese model

XVM-F65WL

Ver. 1.1

JK1101

INPUT

JK1101

V

VIDEO 2

VIDEO 1

AEP,UK MODEL

J1501

RGB

POWER

DC IN 12V

3A

SYNC

AU-IN

EXT-R

EXT-G

EXT-B

NC

L

R

V

L

R

J1501

2

8

1

6

4

3

CN1851

4

2

1

Signal path

: AUDIO

: VIDEO

R-ch is omitted due to

same as L-ch

RGB

R-CH

R-CH

BATT

IC1201 AUDIO AMP

5 7

IC1101 AUDIO AMP

5 7

VIDEO RED

SIGNAL AMP

Q1501

S1431

LOCATION

FRONT REAR

VIDEO GREEN

SIGNAL AMP

Q1511

IC1541 AUDIO AMP

3

5

VIDEO BLUE

SIGNAL AMP

Q1521

BATT

+5V REG

Q1871

1

7

Q1951

R-CH

POWER

CONTROL

Q1872,1873

5 4

1 2

1 2

+3.3V REG

IC1871

VOLTAGE

DET

IC1941

VOLTAGE

DET

IC1951

US,CND,E

MODEL

IC1401 VIDEO SELECT

VIN2

3

VIN1

1

VIN3

5

IC1402 VIDEO SELECT

VIN2

3

VIN1

1 7

VIN3

5

IC1131 AUDIO SELECT

IN2

3

IN1

1

R-CH

IN1

1

IN3

3

IC1543 AUDIO SELECT

BATT

CONVERTER

+3.3V

VOLTAGE

DET

1 2

IC1841

8V

2 4

2 4

2

2

DC-DC

CONTROL

Q1822

VOUT

VOUT

OUT

OUT

Q1821

Q1921

7

7

7

POWER

CONTROL

Q1824,1825

15

11

6

SCP

DT2

DT1

9

VCC

DC-DC

CONVERTER

IC1801

US,CND,E,CH

MODEL

BATT

OUT2

NON2

NON1

OUT1

BATT

10

14

3

7

VIDEO AMP

F1801

Q1401

8V

Q1433,1434

LOCATION

SW CONTROL

Q1803

SWITCHING

SWITCHING

DRIVE

Q1801,1802

SWITCHING

DRIVE

Q1901,1902

SWITCHING

DRIVE

Q1903

MUTE

Q1301

AEP,UK MODEL

VIDEO SW

CONTROL

IC1421,Q1422,1423

D1801

D1901

+8V

MUTE DRIVE

Q1351-1353

Q1421

R-CH

R-CH

BATT

JK1401

V

JK1401

L

OUTPUT

R

CN1861

10

CVBS/SYNC

12

A-MUTE

14

V-SW

J1901

–

DC OUT 9V

MAX 1A

CN1861

MONITOR

(XVM)

+

5

AUDIO-L-CH

1

AUDIO-R-CH

7

EXT-R

8

EXT-G

3

EXT-B

15

NC

11

PW-ON

8V

13

8V

17

8V

18

8V

19

8V

16

+B-DET

XVM-F65WL

17 17

Page 18

XVM-F65WL

6-2. BLOCK DIAGRAM — VIDEO SECTION —

CN904

16

EXT-R

15

EXT-G

14

EXT-B

IC102

VIDEO SW

13

TO

CONNECTION

BOX

CN1861

CVBS/SYNC

1

2

3-6

22

POWER ON

24

SIRCS

21

A MUTE

23

V-SW

20

AU-L

18

AU-R

BATT

LITIUM

8V

D105

POWER

(Page 19)

4

PARKING DET

Q406,407

VIDEO

AUDIO-L

AUDIO-R

Q409

CONTROL

RECEIVER

V-SW

BUFFER

1

3

REMOTE

1

IC404

VD PULSE

SHAPE

Q505

34 35

R

8

G

9

B

2

1

L

R

OUTL

OUTR

10

CSYNCIN

46

C IN

57

Y IN

52

IC401 (1/2)

SYSTEM CONTOL

32

PW_DETLITIUM

48

2.4G-ON1

64

PARKING

PW_ON

2

44

HALT

47

REM_IN

S-SDA

7

S-SCL

6

AMUTE

53

63

SW1

SW2

62

+5V REG

1 8

IC201

SYNC

SEP

BPF/

ACC

SW

53

SYNC_DET

V-SDA

V-SCK

DATA

CLK

OSD

IR ON

P57

AMP ON

CS

VD

3

SYNC

SEP

Q501,502

7

2

BATT

Q405

10

9

6

5

8V 6V

+3.3V

1 3

REG

IC103

Q408

14 13

SW

SELECT

/VOL

IC301

AUDIO SELECT,

ELECTRONIC VOLUME

2 1

INITIAL

MUTE

IC252

3.3V

16

17

CSYNCOUT

HH

KILL

Q355

L

IN

16

R

IN

1

IC251

SPEAKER AMP

1

6

G-Y

GEN

DELAY/

SHARP

HSYNC LOCK

H PULSE

SHAPE

Q506,507

AUDIO IR

TRANSMITTER

AGC

AGC

5

8

MATRIX SW

SDATA

SCLK

48 14161517161817

IC351

PRE

EMPHASIS

PRE

EMPHASIS

R-Y/B-Y

DEMOD

SYNC

OUT

TRAP

21

17

16

19 3

20 1

22 2

43

49

8

5

VD IN

DATA

SCLK

CSN

VREF

FO SW

LEVEL

DETECT

VREF

SP251

SPEAKER

VCO I/N

OSD

SW

R_IN2

G_IN2

VRVGVB

OUTPUT

CONTROL

B_IN2

YS

VBLK

15

VIDEO RAM

610

VCO

VC0

11

V

COUNT

BRIGHT/

CONTRAST

VXO

CG

ROM

L-CH

VCO

R-CH

VCO

OUT

OUT

63 64473954

IC551

L

9

R

8

X501

3.585MHz

CHARACTER GENERATER

RV352

BUF

BUF

RV351

DATA

INVERT

SELECT

IC501

RGB DECODER

X502

4.43MHz

H

COUNT

V

COUNT

AUDIO IR

AMP

Q352,356,358

AUDIO IR

AMP

Q351,357,359

RGB

OUT

VCOMOUT

HD OUT

32

VD OUT

31

BLAK

18

R

26

G

21

B

19

POL

36

28

TRAP

CONTROL

Q503,504

H SYNC

OSC

V SYNC

D354 D352

Signal path

: AUDIO

: VIDEO

PCL

20

19

4

DRIVE

Q353,354

HD

(Page 19)

2

VD

BLK

R

G

B

POL

VCOM

PAL

HDOUT

Q551

REG

IR

8V

1

3

VDD3.3V

(Page 19)

(Page 19)

XVM-F65WL

1818

Page 19

6-3. BLOCK DIAGRAM — DISPLAY SECTION —

IC701

SWITCHING

REGULATOR

2

FREQUENCY

COMP

RV702

DC-DC

PWM

ERROR

OSC

Signal path

: VIDEO

BATT

AMP

(Page 18)

(Page 18)

(Page 18)

POWER

DET

Q402

PWM

COUT

SCP

LCD-VCC

DET

Q410

7

3

15

B+ SWITCH

ON/OFF

DRIVE

Q701,702

Q101,102

T701

8V

RF UNIT

8V

RF101

2

3

LED1+5V6V

LED2

LED3

LED4

Q403

D701

D702

D703

D704

D705

1

HD OUT

53

6

8

9

BLK

PAL

POL

VCOM

R

G

B

HD

VD

VGON 17V

9V

VDD3.3V

VSS-13V

EEPROM

IC403

LED

DRIVER

Q106-109

RV701

SW REG

X401

4.19MHz

5

6

VEE5V

23

N/P

45

PW IN

13

SDA

14

SCL

SYSTEM CONTROL

31

P12/ANI2

55

2.4G-ON2

40

X2

41

X1

50

CH1

CH2

51

52

CH3

CH4

54

IC401 (2/2)

SIED 1

SIDE 2

ZOOM

JUST

KEY1

KEY2

RESET

TFT_ON

DIMMER

59

58

57

61

30

29

36

56

60

RV651

NC

KEY MATRIX

S402-407

RESET

1 2

IC402

S401

(RESET)

IC651

VCO

3

4

H

COUNT

V

COUNT

FIELD DET

INT/EXT

SEL

5

7

DISPLAY CONTROL

3336

PDVCOI

PLL

DET

COM

OSC

IC652

8 13

PULSE

STEERING

F/F

BACK LIGHT CONTROL

OUT

OUT

16

PWM

COMP

IC601

H

V

RV652

VCOM

BIAS

IC801

ERROR

AMP

ERROR

Q652,654,655

AMP

1

VT

D601

OSC

HD OUT

6

HSYNC IN

2

VDBIN

5 16

NBLK

8 20

NP1

46 19

POL

14 17

VD OUT

7

4

QHSEL(SIDE1)

CPHSEL(SIDE2)

3

12

LTBOX(ZOOM)

3.3V

MASK

V

SEL

JUST

31

8V

29

27

25

23

24

26

18

21

VCOM

DRIVE

XVM-F65WL

RED

GREEN

BLUE

CPH1

CPH2

CPH3

STH1

STH2

CPV

STV1

STV2

OEV1

OEV2

OEV3

OEH

VCOM

T801

2

1

BACK LIGHT

DIMMER

CONTROL

Q802

LCD1

LCD

XVM-F65WL

VIDEO

AUDIO-L

AUDIO-R

10

1

2

BUFFER

Q104

BUFFER

Q105

VIDEO

AUDIO-L

AUDIO-R

4

(Page 18)

19 19

Page 20

XVM-F65WL

Ver. 1.1

• NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is

printed in each block.)

for schematic diagram:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

•%: indicates tolerance.

f

•

• C : panel designation.

Note: The components identified by mark 0 or dotted line

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

• CN901 of XVM-F65WL is connected to Connection Box

•Voltages are taken with a VOM (Input impedance 10 MΩ).

•Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

•Abbreviation

: internal component.

with mark 0 are critical for safety.

Replace only with part number specified.

with a monitor cable.

Power voltage is dc 14.4 V from BATT cord of the Connection Box and fed with regulated dc power supply.

Voltage and waveforms are measured at input the color

bar signal from the Connection Box.

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F : AUDIO

g : VIDEO

CND : Canadian model.

CH : Chinese model.

4

W or less unless otherwise

for printed wiring boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Par ts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

C

Q

B

E

Q

BCE

Q

B

C

•Abbreviation

CND : Canadian model.

CH : Chinese model.

These are omitted.

These are omitted.

E

XVM-F65WL

2020

Page 21

• Waveforms (MONITOR Board)

XVM-F65WL

1 IC501 eh (POL)

µ

sec

127

1 V/div, 50 µsec/div

2 IC501 rh (CSYNCIN)

H

0.5 V/div, 20 µsec/div

3 IC501 ts (YIN)

6 IC501 ql (B-OUT)

3.1 Vp-p 3.4 Vp-p

2H

1 V/div, 20 µsec/div

7 IC501 wa (G-OUT)

0.8 Vp-p

2H

1 V/div, 20 µsec/div

3.4 Vp-p

8 IC501 wh (R-OUT)

1 Vp-p

3.4 Vp-p

qa IC801 8 (OUTL)

µ

sec

20

2 V/div, 5 µsec/div

qs IC401 r; (X2)

4.19 MHz

1 V/div, 100 nsec/div

qd IC601 eh (VCO1)

8.0 Vp-p

3.6 Vp-p

3.0 Vp-p

qh IC601 6 (HOUT)

H

1 V/div, 20 µsec/div

qj IC652 1 (OUT1)

127

µ

sec

2 V/div, 20 µsec/div

qk CN701 1 (VCOM)

3.2 Vp-p

6.0 Vp-p

6.0 Vp-p

wa CN701 6 (BLUE)

2H

1 V/div, 20 µsec/div

ws Q702 C (TP703)

4.2

µ

sec

10 V/div, 2 µsec/div

wd IC102 1 (VIN1)

3.4 Vp-p

22 Vp-p

1.0 Vp-p

H

0.5 V/div, 20 µsec/div

4 IC501 tj (CIN)

H

0.5 V/div, 20 µsec/div

5 IC501 ys (SCOUT)

3.5795 MHz

0.2 V/div, 200 nsec/div

1 Vp-p

0.7 Vp-p

2H

1 V/div, 20 µsec/div

9 IC501 ea (VDOUT)

V

1 V/div, 2 msec/div

0 IC501 es (HDOUT)

H

1 V/div, 20 msec/div

3.2 Vp-p

3.2 Vp-p

41.7 nsec

0.5 V/div, 200 nsec/div

qf IC601 2 (HSYNCIN)

H

1 V/div, 20 µsec/div

qg IC601 5 (VDBIN)

V

1 V/div, 2 msec/div

3.2 Vp-p

3.2 Vp-p

127

µ

sec

2 V/div, 20 µsec/div

ql CN701 4 (RED)

2H

1 V/div, 20 µsec/div

w; CN701 5 (GREEN)

2H

1 V/div, 20 µsec/div

3.4 Vp-p

3.4 Vp-p

H

0.5 V/div, 20 µsec/div

wf IC102 7 (VO)

1.0 Vp-p

H

0.5 V/div, 20 µsec/div

XVM-F65WL

21 21

Page 22

XVM-F65WL

Ver. 1.1

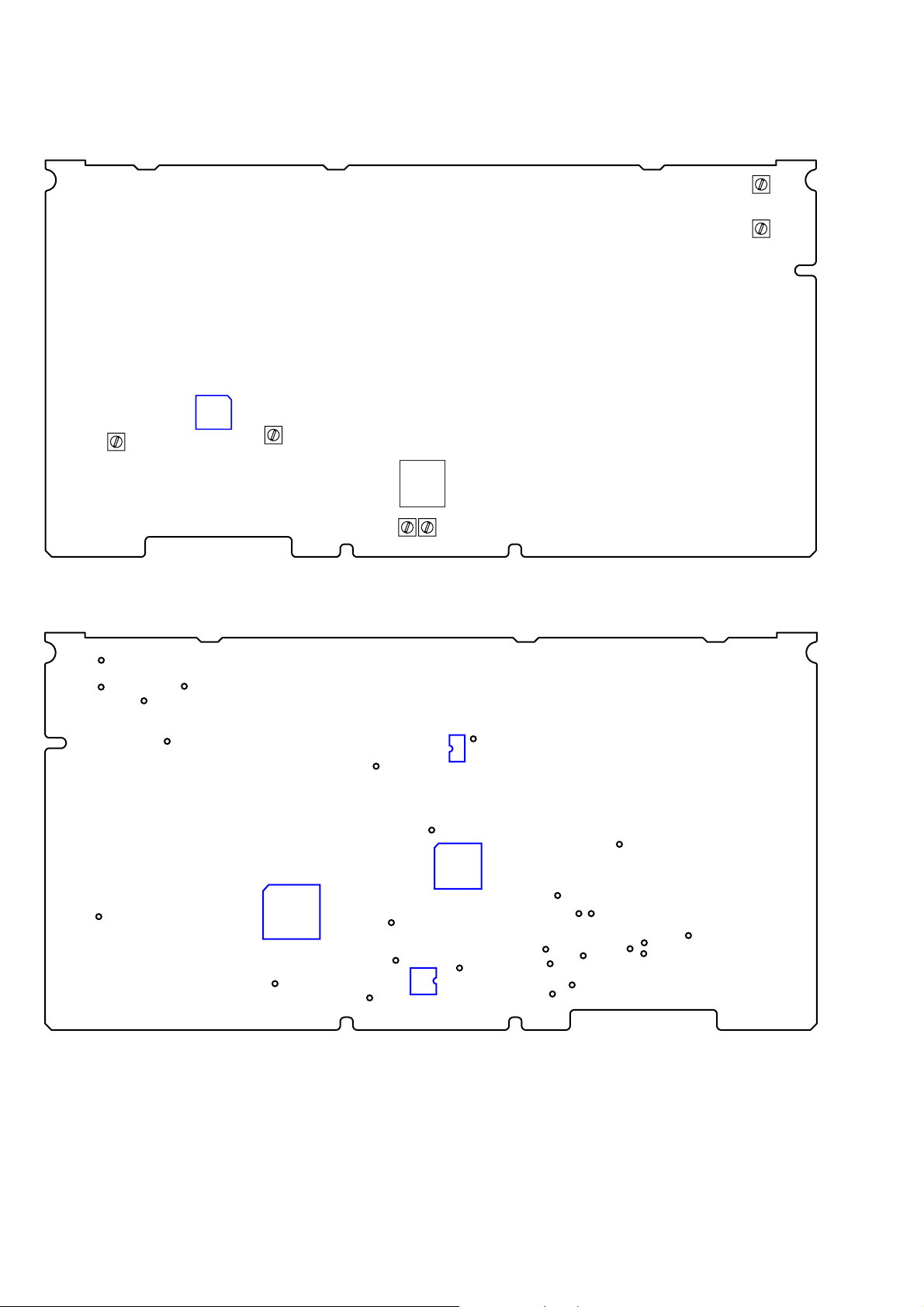

6-4. PRINTED WIRING BOARD — CONNECTION BOX SECTION —

XA-126: AEP, UK model, XA-125: US, Canadian, E, Chinese model

: Uses unleaded solder .

CON-BOX BOARD (SIDE A)

D1421

D1104

D1106

US,CND,E,CH MODEL

US,CND,E,CH MODEL

C1556

D1103

D1105

C1555

5

8

5

8

IC1543

IC1544

D1861

AEP,UK MODEL

4

1

R1541

4

1

R1542

C1551

C1552

L1803

TH1861

Q1825

ECB

C1831

R1832

R1831

ECB

Q1822

R1808R1806

234567891011121314

1

A

B

F1901

L1902L1903

L1901

C

R1835

R1836

Q1824

BCE

D

L1802

L1801

IC1421

• Semiconductor Location

Ref. No. Location

D1101 F-7

D1103 C-12

D1104 C-12

D1105 B-11

D1106 C-12

D1201 F-8

D1421 B-13

D1861 B-11

IC1131 F-6

IC1132 F-4

IC1421 F-12

Ref. No. Location

IC1543 C-11

IC1544 D-11

Q1301 F-5

Q1302 F-5

Q1421 F-12

Q1422 F-12

Q1423 F-12

Q1822 D-8

Q1824 D-4

Q1825 D-9

Q1421

R1424

R1422

54

81

AEP,UK MODEL

ECB

R1421

R1423

ECB

R1425R1426

Q1422

R1437

BCE

R1427

Q1423

C1421

R1413

L1402

L1401

R1404

R1402

R1403

R1401

R1201

C1201

R1202

C1213

L1201

C1203

R1229

C1202

D1201

C1204

R1101

C1101

R1102

R1129

C1103

C1102

C1104

D1101

C1105

C1205

C1113

L1131

L1101

1

IC1131 IC1132

4

R1130

8

5

Q1301

BCE BCE

R1303

Q1302

R1304

C1106

C1206

F1801

1

4

8

5

R1131

E

F

G

1-866-334-

21

H

XVM-F65WL

2222

Page 23

XVM-F65WL

Ver. 1.1

A

B

C

D

E

F

G

H

1

234567891011121314

CON-BOX BOARD (SIDE B)

VDR851

D1851

L1851

R1435

D1352

D1351

R1357

R1355

ECB

C1351

Q1353

S1431

S1431

LOATION

FRONT REAR

Q1352

C1352

BCE

R1354

R1352

BCE

Q1351

R1353

R1356

BP1851

R1351

FB1801

C1353

TP1853

C1853

C1894

DC IN 12V

C1852

C1801

CN1851

POWER

TP1852

CN1851

C1851

C1893

3A

TP1851

Q1802

C1802

FB1802

D1801

43

21

ECB

R1302

C1302

R1942

C1901

C1902

D1901

FB1902

R1903

C1905

R1801

R1803

ECB

Q1801

1

4

Q1803

85

R1842

TH1841

C1304

R1306

C1306

TP1152

TP1154

RL

R1802

FB1901

Q1902

BCE

R1902

C1805

R1804

R1308

TH1941

85

Q1903

14

Q1901

BCE

R1904

C1904

R1901

C1827

C1804

C1824

R1823

5

4

IC1841

13

C1303

R1305

TP1151

C1132

R1301

C1908

R1928

R1941

R1906

R1925

C1924

R1923

C1828

Q1821

R1825

BCE

C1826

C1841

R1843

R1828R1841

C1131

TP1112

R1307

C1301

TP1153

JK1401 JK1101

C1907

IC1941

45

312

R1943

R1908

R1907

C1923

R1922

18

IC1801

169

C1823

C1825

R1824

C1114 C1112 C1214

TP1111

C1305

D1411

D1412

R1935

R1931

BP1821

R1822

C1111

C1926

C1925

C1921

TP1451

R1934

TP1902

R1927

R1924

R1821

IC1101

V

TP1901

R1933

R1909

D1923

ECB

Q1921

D1921

R1921

C1821

R1827

58

41

TP1212

TP1452

VIDEO 1 VIDEO 2

TP1903

D1951

R1952

ECB

D1922

Q1951

R1951

C1211

TP1103

R1104

D1952

D1821

D1823

TP1104

J1901

–

DC OUT 9V

MAX 1A

R1953

IC1951

C1808

TP1211TP1113

IC1201

TP1204

R

+

C1911

R1955

R1956R1957

123

54

58

41

D1822

C1807

C1212

TP1203

R1204

Q1873

ECB

BCE

C1912

Q1872

R1871

D1871

C1872

C1871

IC1871

3

R1954

R1406

45

C1873

R1809

Q1401

BCE

R1405

C1406

C1401 C1402 C1415 C1407

TP1101

R1103

TP1102

VIDEO 1 VIDEO 2

Q1871

B C E

TP1861

1

TP1164

TP1202

L

INPUTOUTPUT

R1872

C1404

C1405

R1873

IC1401

C1812

R1433

AEP,UK MODEL

58

US,CND,E,

41

CH MODEL

AEP,UK MODEL

TP1201

R1203

TP1403

TP1863

C1811

C1545

R1541

Q1434

ECB

C1554

Q1433

ECB

R1434

TP1419

TP1418

C1410

R1410

R1415

C1412

C1403

TP1415

TP1401

D1401 D1403

D1402 D1404

VIDEO 1 VIDEO 2

V

TP1162

C1544

C1546

C1553

IC1541

US,CND,E,CH

MODEL

R1409

C1411

IC1402

TP1402

MONITOR

TP1864 TP1865

16 21

11 15

5

1

TP1161

C1542

58

41

C1541

C1414

58

41

C1408

TP1416

TP1509

TP1501

TP1163

R1545

D1543

C1547

R1543

R1544

TP1503

C1409

D1503

TP1417

D1505

TP1507

D1507

64 78

31 25

D1504

TP1505

TP1508

CN1861

(XVM)

CN1861

4

TP1462

AEP,UK MODEL

L1501

C1543

R1503

R1513

D1506

R1523

D1508

TP1502

D1509

J1501

J1501

RGB

10

TP1461

D1413

D1414

C1506

R1504

R1514

R1524

D1502

TP1504

TP1862

TP1463

C1505

C1501

C1511

C1521

D1501

TP1561

Q1501

BCE

R1505

R1506R1515

Q1511

BCE

R1516

BCE

R1525

Q1521

R1526

TP1563

TP1564TP1562

R1507

R1517

R1527

1-866-334-

C1512 C1502

C1522

21

XVM-F65WL

• Semiconductor Location

Ref. No. Location

D1351 F-3

D1352 F-2

D1401 G-10

D1402 G-10

D1403 G-11

D1404 G-11

D1411 G-7

D1412 G-7

D1413 C-13

D1414 C-13

D1501 G-13

Ref. No. Location

D1502 G-13

D1503 E-12

D1504 E-12

D1505 F-12

D1506 F-12

D1507 F-12

D1508 F-12

D1509 G-12

D1543 D-12

D1801 E-4

D1821 C-8

23 23

Ref. No. Location Ref. No. Location

D1822 C-9

D1823 D-8

D1851 C-2

D1871 B-9

D1901 B-5

D1921 C-8

D1922 C-8

D1923 C-7

D1951 B-8

D1952 B-8

IC1101 F-7

IC1201 F-8

IC1401 F-10

IC1402 F-11

IC1541 D-11

IC1801 D-6

IC1841 E-5

IC1871 C-9

IC1941 B-7

IC1951 C-8

Ref. No. Location Ref. No. Location

Q1351 F-2

Q1352 F-2

Q1353 G-3

Q1401 E-9

Q1433 D-11

Q1434 D-11

Q1501 E-13

Q1511 E-13

Q1521 F-13

Q1801 D-5

Q1803 E-5

Q1821 D-6

Q1871 B-9

Q1872 B-9

Q1873 B-9

Q1901 C-5

Q1902 C-5

Q1903 B-6

Q1921 C-7

Q1951 C-8

Q1802 D-4

Page 24

XVM-F65WL

Ver. 1.1

6-5. SCHEMATIC DIAGRAM — CONNECTION BOX SECTION (1/2) —

XA-126: AEP, UK model, XA-125: US, Canadian, E, Chinese model

• Refer to page 33 f or IC Block Dia grams.

J1501

D1403

D1404

JK1101(1/2)

TP1402

TP1201

TP1202

TP1203

TP1204

JK1101(2/2)

TP1401

TP1403

TP1101

TP1102

TP1103

TP1104

TP1503

TP1501

TP1509

TP1507

TP1502

TP1505

TP1508

TP1504

R1203

R1204

R1103

R1104

D1401

D1402

R1201

R1202

R1101

R1102

C1101

C1102

D1503

D1504

D1502

D1501

D1507

D1508

D1506

D1505

D1509

C1201

C1202

R1543

L1201

IC B/D

L1101

IC B/D

C1213

IC1201

C1113

IC1101

C1546

IC B/D

IC1541

C1203

C1204

C1103

C1104

C1542

C1541

C1214 C1212

C1211

D1201

C1114 C1112

C1111

D1101

C1545 C1544

TP1211

TP1212

R1229

TP1111

TP1112

R1129

L1541

TP1113

C1105

C1205

C1106

C1206

L1131

C1131

R1401

TP1415

TP1416

IC B/D

TP1417

TP1419

IC1131

IC1132

C1132

R1402

C1401

C1402

C1407

C1408

R1403

IC B/D

IC1401

R1404 C1415

R1437

IC1402

C1409 C1411

R1409

IC B/D

C1414

R1415

C1410

L1402

C1403

R1413

C1404

C1412

TP1418

R1410

R1434

R1130

R1131

C1405

Q1433

C1301

Q1301

R1303

R1304

Q1302

C1302

R1405 C1406

Q1401

R1436

Q1431

Q1434

R1301

R1305

R1306

R1302

R1406

Q1432

R1431

R1307

C1303

C1304

R1308

L1401

R1433

R1432

R1421

C1421

R1422

Q1421

C1305

C1306

D1411

D1412

R1424

R1425

R1426

C1894C1893

TP1451

TP1452

TP1151

TP1153

TP1152

TP1154

R1423

IC1421

R1427

Q1423

Q1422

JK1401

XVM-F65WL

R1544

C1501

R1503

R1506 R1507

R1504

C1511

R1513

R1516 R1517

R1514

C1521

R1523

R1526

R1524

R1505

R1515

R1525

C1547

Q1501

Q1511

Q1521

C1543

R1527

D1543

C1505

C1522

C1506

C1502

C1512

R1545

C1552

C1554

IC B/D

C1551

C1553

IC1544

IC1543

IC B/D

2424

R1541 R1542

(Page 25)

C1556L1501

C1555

D1413

D1104

D1106

D1414

D1861

D1421

D1103

D1105

TP1161

TP1163

TP1563

TP1462

TP1162

TP1564

TP1561

TP1562

TP1461

TP1861

TP1164

TP1463

TP1862

TP1863

TP1864

TP1865

CN1861

Page 25

6-6. SCHEMATIC DIAGRAM — CONNECTION BOX SECTION (2/2) —

XA-126: AEP, UK model, XA-125: US, Canadian, E, Chinese model

XVM-F65WL

Ver. 1.1

• Refer to page 33 f or IC Block Dia grams.

(Page 24)

C1812

L1803

R1809

R1806

C1808C1811

R1808

IC B/D

L1802

D1801

C1807

FB1801

IC1871

R1841

TH1841

R1842

C1841

R1843

Q1803

C1871

Q1871

D1871

R1871

C1872

IC1841

R1804

Q1802

Q1801

R1872

R1873

Q1872

Q1873

C1804

R1802

C1805

FB1802

R1803

R1801

F1801

C1802

C1353

L1801

Q1353

D1352

C1801

C1352

R1357

R1355

R1356

C1821

C1351

Q1352C1873

D1351

R1821

R1822

C1925

R1924

R1922

R1354

C1921

R1353

R1921

Q1822

R1823

C1823

R1923

Q1351

C1924

R1351

R1352

R1831

C1824

R1925

R1832

C1831

R1825

R1824 C1825

C1923

C1828

C1827

IC B/D

IC1801

C1851

R1836

Q1921

Q1824

TH1861

C1852

Q1825

C1826

R1927

R1835

Q1821

R1827

C1926

D1851C1853

VDR851

D1823

D1923

R1828

S1431

L1851

D1821

D1822

R1435

TP1851

BP1851

TP1853

TP1852

CN1851

XVM-F65WL

J1901

TP1901

TP1902

TP1903

D1951

D1952

R1955

R1956

R1957

L1903 L1902

C1912

C1911

R1906

R1907

R1909

R1908

C1908

D1901

C1907

FB1901

IC1951

Q1903

TH1941

R1942

R1943

R1941

IC1941

FB1902

Q1901

R1904

Q1902

R1901

C1904

R1902

C1905

R1903

25 25

F1901

C1902

R1934

R1933

R1928

C1901

R1954

R1935

R1931

R1953

R1952

R1951

D1921

D1922

Q1951

Page 26

XVM-F65WL

6-7. PRINTED WIRING BOARDS — MONITOR SECTION —

MONITOR BOARD (SIDE A)

IC404

13

C412

D406

L402

RB602 RB601

R622

R638

R670

Q654

FB603

FB604

FB605

R664

FB609

R669

R661R662

RV652

R672

R666

C657

L653

C659

R663R665

5

IC652

8

Q655

R673

ECB ECB

Q652

C658

C660

R674

4

1

R671

L654

C661

• Semiconductor Location (MONITOR Board)

Ref. No. Location

D201 B-6

D352 D-1

D354 D-1

D402 F-6

D404 E-5

D405 E-6

D406 D-14

D601 F-10

D602 F-10

D701 F-8

D702 G-8

Ref. No. Location

D703 G-8

D704 G-8

D705 H-8

D801 G-2

IC103 D-4

IC201 B-6

IC301 B-8

IC351 B-3

IC403 G-5

IC404 C-14

Ref. No. Location Ref. No. Location

IC551 G-5

IC601 E-11

IC652 F-13

IC801 G-2

Q351 B-2

Q352 B-2

Q402 E-6

Q403 F-6

Q409 D-5

Q410 E-6

R619

R621

13

RB603RB604

24

R634

FB610

FB611

C610

CN701

LCD1

LIQUID CRYSTAL

DISPLAY PANEL

12

IC601

25 36

C611

C612

1

L602

C608

C613

48

C606

37

C605

R603

R602

C729

130

: Uses unleaded solder.

R608

R607

R604

L604

R722

D601

R653

L652

L712C728

D602

L603

C607

L601

C601

RV651

C651

L651

L711

L710

L708

L709

FB602

R605

C603

C604

R723

C727

C726

C724

C725

Q501 D-8

Q502 E-8

Q505 F-9

Q512 F-9

Q513 F-9

Q652 G-13

Q654 F-13

Q655 F-13

Q702 G-7

Q802 G-2

R652

R651

L504

C312

C322

C302

C301

C323

C546

C723

R566

C720

C730

C722

R563 R534

ECB ECB

Q505Q512

R565

R564

C719

L705

L706

L707

L704

C714

L703

R306

C324

R526

C538

Q513

ECB

R305

C566

R533

R302

R505

C567

C545

R532

C715

C716

C717

C718

R567

R301

R501

R525

A K

C313

C314

C317

C318

R304C304

D701

D702

D703

D705

L503

A K A K A K A K

R303

C303

C501

C503

C504

VR301

VR302

Q501

D704

R307

R308

R504

R502

Q502

C536

1

12

ECBECB

RV701

C535

C534

C502

IC301

C320

L501

R503

C564

C533

T701

BATT PLUG BOARD (SIDE A)

R904

C307

C321

C531

C532

RV702

R711R702R701

F902

C306

C308

24

R311

C309

C310

R312

C311

13

L301

X501

X502

C528

C529

C530

1-866-332-

C

R315

R314

R316

R313

C710

R309

R310

C712

R719

C525

C526

C527

Q702

21

18

L702

R516

R517

R518

C713

L201

C201

C515 C514

E

B

C203

IC201

45

C202

24 1

CN904

R405

D405

C418

F701

EBC

EBC

Q403

R433

R434

C409

Q402

BCE

R422

R423

R551

R404

Q410

D402

R401

R552

R432

D201

C562

C411

R430

R431

C410

C408

C404

11

20 1

C561

L551

L202

C210

R415

R403

R491

IC551

D404

C407

R490

C552

MONITOR SUB BOARD (SIDE A)

R901

C902

GSD

C901

R902

Q903

BCE

Q902

D903

D901

R903

C903

9

81

R454

C421

R455

C416

R429

R468

X401

R469

R473

R476

R477

R479

C414

R480

18

IC403

45

C554

C553

C555

10

L552

R558

16

CN901

ECB

Q409

L252 L253

C258

C257

CN252

12

WHT

C114

C113

1

IC103

3

C112

L401

C402

CN903

24 1

BLK

C401

L801

F901

F903

1-866-333-

R259

2

F801

D902

SP251

SPEAKER

C351

R353

R351

R352

R354

C352

R819

R818

21

C353

C806

C805

C804

C803

C356

16

1

IC351

C816

R815

R804

R802

R360

9

8

C355

C821

C808

112010

C807

C810

234567891011121314

RV351

C358

B

Q352

R366

R367

C815

IC801

C

E

B

C

Q351

E

RV352

CN801

1

2

T801

C818

R816

C814

R814

C813

C812

C811

1

R806

R812

BCE

R809

R811

R810

R805

R820

Q802

R808

• Semiconductor

Location

(MONITOR SUB

Board)

Ref. No. Location

D901 I-6

D902 I-4

D903 I-6

Q902 I-6

Q903 I-6

R378

R379

R813

D801

JC354

1-866-331-

WHT

PNK

D354

D352

1

A

B

LCD

C

BACK

LIGHT

D

E

F

G

21

H

I

XVM-F65WL

2626

Page 27

XVM-F65WL

A

B

C

D

E

F

G

H

I

XVM-F65WL

1

234567891011 12 13 14

MONITOR BOARD (SIDE B)

Q358

C362R370C363

D409

C361

R371

C364

TP808

R374R380

Q359

R375

R381

R817

C817

BCE

BCE

F351

TP356

S407

INPUT

JC353

TP408

S405

DIMMER

JC351

TP409

S406

MENU

R443

TP354

R496

TP804

TP405

TP352

R368

R369

R372

ECB

Q356

R373

ECB

Q357

TP807

R376

R377

BCE

TP802

TP801

C359

Q355

C4

C819

Q354

TP805

C357

C354

BCE

R364

TP809

R365

Q353

TP353

BCE

TP351

TP355

L351

C801

C360

TP252

IC251

R260

TP806

C255

R256

TP251

R261

C254

R255

41

58

C256

IC252

135

4

TP934

TP407

S401

(RESET)

R406

R257

C403

R407

R258

D202

TP935

TP410

TP406

C413

R474

R475

R478

R253 C253

C259

R254

C260

R464

D408

R460

R466

RB401

RB402 RB403

R424

R408

R409

R410

Q407

ECB ECB

Q406

R463

R465

C420

C419

RB408

64

1

16

17 32

TP555

R555

R553

C560

C559

MONITOR SUB BOARD (SIDE B)

TP901

TP902

TP916

TP906

TP904

TP915

TP917

TP940

TP952

TP913

TP912

TP907

TP906

TP201

R462

R554

R251

TP932

RB407

R561

C565

BCE

C558

TP909

C108

TP933

R461

IC401

R557

TP910

C415

Q551

R556

R562

C556

D912

D913

RB406 RB405

R451

R489

R492

TP908

TP911

R203

C209 R206 R202

D107

R118

TP922

49

48

33

R493

R494

R440

R495

TP903

R444

R436

Q405

BCE

R439

D106

R414

C406

R413

C405

R412

R411

R204

R205

R453

RB404

C208

TP925 TP924

TP930

TP921

R452

ECB

13

IC402

54

TP919

R437

R438

R435

TP914

TP926

TP920

TP928

D505

D504

Q408

TP554

1-866-333-

TP502

TP929

C206

C207

TP923

L701

R543

TP927

D506

TP552

TP704

R718

TP702

13

64

Q701

TP703

21

C315

C316

C319

TP501

C105

C110

R101

C513

C512

R507

TP505

64

1

16

17 32

C732

R709

R710

C705

TP701

C704

16

R708

R704

R703

C701

C511

R522

R705

85

IC102

14

C509

C510

IC501

R523

TP710

C508

R524

TP509

C107

C507

R506

49

C537

R103

L505

C506

48

33

R532

C118

R716

R717

R715

C709

R714

L101

R102

D108

TP503

C520

C521

C522

TP506

C524

TP553

R512

R513

R514 R515

TP551

C706

R712

C707

R713

C708

81

IC701

9

C733

C702

R707

R706

C703

BATT PLUG BOARD (SIDE B)

CN902

27 27

Q102

123

BCE

C505

R535

C109

R104

R106

C121

C517

R527

R528

C539

R529

C544

R539

R540

C548

1-866-332-

Q101

Q503

C540

R531

BCE

BCE

R509

R536

R537

C542

R530

R538

BCE

Q507

C101

C541

R508

C653

C663

TP508

R655

C654

TP108

R656

R657

R659

TP712

C609

FB601

C615

C602

C614

TP714

RF101

(RF UNIT)

TP109

Q106

R658

C655

R660

TP110

R636

TP713

TP715

TP723

R637

TP507

C618

TP718

R635

R620

C617

TP720

TP719

TP711

TP717

R721

C616

TP716

D706

TP725

R633

TP722

D707

TP653

TP726

FB608

TP724

FB607

C117

L102

R113

R116

Q104 Q105

BCE

BCE

R111 R114

TP105

C116

TP103

TP510

TP709

R105

TP104

TP652

C115

TP101

TP102

110

Q504

BCE

C519

C543

D501

C518

Q506

ECB

L502

R541

TP511

TP504

TP705

TP707

TP708

TP107

TP106

BCE BCE ECB ECB

Q109 Q108 Q107

R610

C652

R654

54

13

IC651

TP651

R601

C656

TP706

TP734

TP732

TP730

• Semiconductor Location

Ref. No. Location

D105 B-14

21

D106 C-6

D107 C-6

D108 C-7

D202 B-4

D407 H-13

D408 D-5

D409 H-2

D501 E-9

D504 E-6

D505 D-6

D506 E-7

D706 G-12

Ref. No. Location

D707 G-12

D912 D-6

D913 D-6

IC102 C-8

IC251 B-4

IC252 C-4

IC401 F-5

IC402 G-6

IC501 E-8

IC651 F-11

IC701 G-7

S402

POWER

D105

POWER

R117

TP401

TP729

TP654

TP727

FB606

TP731

TP721

TP726

TP402

D407

TP404

R441

TP403

S403

VOLUME

R442

S404

1-866-331-

Ref. No. Location Ref. No. Location

Q101 C-9

Q102 C-9

Q104 C-9

Q105 C-10

Q106 D-11

Q107 D-11

Q108 D-10

Q109 D-10

Q353 B-3

Q354 B-3

Q355 B-3

Q356 B-2

Q358 A-2

Q359 B-3

Q405 G-6

Q406 D-5

Q407 D-5

Q408 E-6

Q503 D-9

Q504 D-9

Q506 E-9

Q507 F-9

Q551 G-5

Q701 G-7

Q357 B-2

21

Page 28

XVM-F65WL

6-8. SCHEMATIC DIAGRAM — MONITOR SECTION (1/4) —

Q501

R502

R508

R509

C501

L501

Q504

C502

R501

C517

Q503

TP504

C503

R503

L505

C516

C513

C514

C515

TP501

TP502

• Refer to page 21 for Waveforms. • Refer to page 32 for IC Block Diagram.

TP511

Q507

C545

R532

TP510

TP508

TP507

L503

R541

C536

R524

C535

C534

C533

R523

C532

R522

C546

C537

C531

R504

C506

C511

R507

C512

C505

R506

C507

C508

C509

C510

X501

L502

R505

X502

C518

TP503

IC B/D

Q502

C504

C519

C564

C567

R525

TP509

C520

R536 R538

R537

C539

R528

C540

R527

R526

TP505

C538

TP506

C521

C522

R529

C542

R530

C524

C541

IC501

C525

C543

C526

C527

R531

C528

D501

C529

C544

C530

R539

Q506

R540

C548

R535

L504

R533

R564

Q505

R534

C566 R563

R565

R566

Q513

Q512

R567