Sony XTL-W7000 Service Manual

XTL-W7000

SERVICE MANUAL

Ver. 1.0 2004.12

• This set includes the TV antenna (VCA-119).

SPECIFICATIONS

Monitor section

Display type Wide LCD colour monitor

Picture size 7 in.; 154 × 87 mm, 180 mm

System TFT active matrix

Number of pixel

TV tuner section

Television system

Colour system

Channel converge

NTSC system only:

PAL system only:

CCIR VHF: 2 - 12 CH

CHINA VHF: 1 - 12 CH

UK/HKG (Hong Kong) VHF: –

ITALY VHF: A - H2 CH

NEWZEALAND VHF: 1 - 11 CH

AUSTRALIA VHF: 0 - 12 CH

(W × H, diagonally)

336,960 pixels

M system (NTSC)/

B, G, I, D, K system (PAL)

TV: NTSC (NTSC system)/PAL

(PAL system)

VIDEO: NTSC/PAL (Compatible)

VHF: 2 - 13 CH

UHF: 14 - 69 CH

UHF: 21 - 69 CH

UHF: 13 - 57 CH

UHF: 21 - 69 CH

UHF: 21 - 69 CH

UHF: 21 - 69 CH

UHF: 28 - 69 CH

E Model

Model Name Using Similar Mechanism NEW

Open/Close Mechanism Type DB-M01

General

Power requirements

12 V DC, from car battery (negative

ground)

Outputs Video/Audio (Sony BUS

compatible, 1)

Sony BUS (1)

Inputs Video/Audio (Sony BUS

compatible, 2)

Composite (either commercially

available navigation system or

back camera can be connected, 1)

Sony BUS (1)

TV antenna (1)

Speaker type 20 × 40 mm (monaural)

Dimensions with monitor retracted

Approx. 178 × 50 × 190.5 mm

(W × H × D)

Current drain Approx. 2 A

Mass Approx. 1.9 kg

Supplied accessories

Card remote commander RM-X701

(1) (incl. 1 lithium battery)

RCA interconnects (Audio L/R × 1,

Video × 1)

TV antenna VCA-119 (left/right) (1)

Parts for installation and

connections (1 set)

Installation/Connections manual (1)

Operating Instructions (1)

Design and specifications are subject to

change without notice.

9-879-218-01

2004L05-1

© 2004.12

MOBILE COLOR TV

Sony Corporation

e Vehicle Company

Published by Sony Engineering Corporation

XTL-W7000

TABLE OF CONTENTS

1. SERVICING NOTE.................................................. 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 11

3-2. Front Panel Assy.............................................................. 12

3-3. Case (Lower) Block......................................................... 12

3-4. Partition ........................................................................... 13

3-5. Bracket (Slider) ............................................................... 14

3-6. SLIDER Board ................................................................ 15

3-7. Bracket (Motor) Assy ...................................................... 15

3-8. Bracket (Motor S) Assy ................................................... 16

3-9. Monitor Block ................................................................. 16

3-10. Gear (1), Gear (4) ............................................................ 17

3-11. Mechanism Complete Assy (DB-M01)........................... 17

3-12. Liquid Crystal Display (LCD1)....................................... 18

3-13. MAIN Board.................................................................... 18

4. TEST MODE.............................................................. 19

5. ELECTRICAL ADJUSTMENTS......................... 22

6. DIAGRAMS

6-1. Block Diagram – VIDEO, AUDIO Section – .................. 24

6-2. Block Diagram – LCD, MOTOR Section – .................... 25

6-3. Block Diagram

– CONTROL, POWER SUPPLY Section – .................... 26

6-4. Printed Wiring Board – MAIN Section (1/2) – ............... 28

6-5. Printed Wiring Board – MAIN Section (2/2) – ............... 29

6-6. Schematic Diagram – MAIN Section (1/3) –.................. 30

6-7. Schematic Diagram – MAIN Section (2/3) –.................. 31

6-8. Schematic Diagram – MAIN Section (3/3) –.................. 32

6-9. Printed Wiring Boards – FRONT PANEL Section –....... 33

6-10. Schematic Diagram – FRONT PANEL Section – ........... 33

6-11. Printed Wiring Boards – SLIDER Section – ................... 34

6-12. Schematic Diagram – SLIDER Section – ....................... 35

6-13. Printed Wiring Board – MONITOR Section (1/2) – ....... 36

6-14. Printed Wiring Board – MONITOR Section (2/2) – ....... 37

6-15. Schematic Diagram – MONITOR Section (1/2) – .......... 38

6-16. Schematic Diagram – MONITOR Section (2/2) – .......... 39

6-17. Printed Wiring Board – KEY Section – .......................... 40

6-18. Schematic Diagram – KEY Section – ............................. 40

7. EXPLODED VIEWS

7-1. MAIN Board Section....................................................... 55

7-2. Front Panel Section ......................................................... 56

7-3. Chassis (Main) Section.................................................... 57

7-4. Monitor Section ............................................................... 58

7-5. Open/close Mechanism Deck Section ............................. 59

8. ELECTRICAL PARTS LIST................................ 60

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

2

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SECTION 1

7

gear(1 S)

6

stopper washer

(2.6 × 4.5)

1

two screws

(M2)

5

bracket (slider)

3

Rotate the worm gear in the direction of arrow B.

for pulling the monitor block.

8

Pull the monitor block.

Note: Don't touch except the gray portion of worm gear.

A

B

2

Open the bracket (slider)

in the direction of arrow A.

4

SERVICING NOTE

JIG ON REPAIRING

When repairing this set, etc., connect the extension cable as the figure shown below.

extension cable (32P) (J-2502-093-1)

(MONITOR board (CN101)-SLIDER board (CN2))

SLIDER board

(CN2)

MONITOR board

(CN101)

XTL-W7000

extension cable (50P) (J-2502-092-1)

(MAIN board (CN1851)-SLIDER board (CN1))

SLIDER board

(CN1)

HOW TO PULL OUT MONITOR BLOCK IN CASE ELECTRICITY DOES NOT CIRCULATE

When monitor block does not open by fault, pull out monitor block in the following procedures.

MAIN board

(CN1851)

3

XTL-W7000

Main unit

Monitor closed

SECTION 2

GENERAL

Location of Controls

1

This section is extracted from

instruction manual.

3

4

2

1 VIDEO 1 IN jacks (VIDEO, AUDIO (L/R))

2 CUSTOM button

3 TILT button

Monitor opened

5

4 OPEN/CLOSE button

5 Reset button

1

2

1 TV/VIDEO button

2 VOL +/– buttons

3

3 SEEK +/– buttons

4 ANGLE button

4

8

4

Card remote commander

The unit can be operated with the card remote commander.

MUTING

CH+

ENTER

CH–

TV/VIDEO

SEEK+

1

2

3

4

5

OFF

MENU

SEEK–

BACK

WIDE DSPL

PICTURE

XTL-W7000

8

9

q;

qa

qs

6

123

456

7

1 OFF button

2 MENU button

3 V/v CH +/– buttons

4 BACK button

5 WIDE button

6 PICTURE button

7 Number buttons

Tips

• See “Replacing the lithium battery” for details on how to replace the battery.

• If an optional Master-unit is connected using Sony BUS system, function of some of the buttons will change as

follows:

- The TV/VIDEO button will function as a NAVI button (when “NAVI/CAMERA” is set to “NAVI”).

- The OFF button will turn off the monitor.

- The SEEK –/+ and the Number buttons will be invalid.

789

10 11 12

8 MUTING button

Turning off the sound temporarily.

When you press the button, the sound is turned off

and “MUTING” appears in the display.

To restore the sound, press the button again

(or VOL +).

9 TV/VIDEO button

0 ENTER button

qa B/b SEEK –/+ buttons

qs DSPL button

qd VOL +/– buttons

VOL

qd

9

5

XTL-W7000

Connection Example

For details, see the section “1 Car Systems Connections” (pages 8 - 10). Be sure to refer also to the

documentation for all other components in the system.

System configuration

Mobile Colour TV XTL-W7000

Connection of separately available accessories

Items except the main unit and the connection box are optionally available.

Connecting without Sony BUS system

Car antenna for radio

Mobile Colour TV XTL-W7000

Video Camera (optional)

VIDEO1 IN

Sony BUS DVD Master-unit

*1

(optional)

Sony VCD Master-unit

(optional)

*1 Sony BUS DVD Master-unit will come in 2005.

*2 In case of other manufacture’s Master-units, audio signal is reproduced through FM modulator.

To output the audio of other manufacture’s Master-units using the RF modulator

If you connect a genuine car audio or a car audio without the TV control function to the TV unit, its audio

can be output through the TV unit’s built-in monaural speaker. You can also receive and hear the sound

from the FM tuner of the car audio by converting the audio signal to FM.

Preparations

•To use this function, connect the FM antenna of the car audio referring to page 9. Without a proper

connection, this function will not be effective.

•You may need to change the transmitted frequency or output level (see “Tips” below).

1 Press TV/VIDEO repeatedly to select the function of the connected device.

2 Press CUSTOM on the unit.

“RF OUTPUT ON” appears in the monitor.

If you have changed the function of the CUSTOM button, select RF OUTPUT ON or OFF from a Menu

screen.

3 Select the FM tuner from the car audio source, and tune in to “88.3 MHz”.

Once the audio is output, adjust the volume level with the car audio.

Tips

• If there is a broadcasting station of the same frequency as the transmitted frequency set on the TV unit, the sound of

TV or the connected device may be difficult to be heard, or noise may occur. In this case, change the transmitted

frequency on built-in RF modulator of the TV unit. For more information about how to change the frequency, see

“Changing the transmitted frequency on TV unit” on page 22. (The default setting is “88.3MHz”.)

•You can change the output level of the TV unit according to the input level of the FM tuner of a car audio. For more

information about how to change the setting, see “Changing the output level on the TV unit” on page 22. (The

default setting is “MID”.)

or or

or

The other Master-unit (optional)

CAMERA IN

VIDEO OUT

VIDEO2 INAUDIO OUT

*2

DVD Player (optional)

Rear Monitor

(optional)

Back Camera

(optional)

FM ANT OUT

Speakers

(optional)

Connecting with Sony BUS system

BUS CONTROL OUT

BUS CONTROL IN

* Sony BUS Master-unit (equipped with the TV control function) will come in 2005.

Tip

For connecting two or more CD/MD changers, the source selector is necessary.

5

6

VIDEO2 IN

FM ANT IN

Genuine Car audio

Mobile Colour TV XTL-W7000

VIDEO2 IN

VIDEO OUT

FRONT

Sony BUS Master-unit (equipped

with the TV control function)

VIDEO OUT

VIDEO OUT

BUS AUDIO IN

*

Rear passenger TV

or monitor etc.

DVD player etc.

Rear passenger TV or

monitor etc.

Connecting Information

For details, see the section “1 Car Systems Connections” (next page).

Connecting the cords

Notes

• Be sure to connect the power input

cord after all other cords are connected.

• If the parking brake switch cord is too

thin, connect the parking cord to the

parking brake switch cord directly

without using the tap.

Connect each cord using the taps. For the combination of each

cord, see the following table. Also, see the section “1 Car

Systems Connections” (next page).

TV unit side Car side

Orange/white Illumination signal cord

Purple/white Power terminal cord of the back lamp

Light green Paring brake switch cord

Using the tap

Tap 7

Connecting the parking cord

The mounting position of the parking brake switch cord depends

on your car. Refer to the system connection illustrations below

and consult your car dealer or your nearest Sony dealer for

further details.

Foot brake type

Hand brake type

The cord for utilizing the Navigation system

better

Purple/white cord (for the connection to the power terminal

cord of the back lamp)

If you connect the purple/white cord to the power terminal cord

of the back lamp, the image of back camera will be automatically

displayed on the monitor when a back lamp lights up. You can

adjust the parking location viewing the image of back camera

when you backup.

Parking brake switch cord

Parking cord

(Light green)

Parking brake switch cord

Parking brake switch cord

1 Car Systems Connections

Refer also to the documentation for all other components in the system.

Also see “Connecting Information” on page 7.

•Components listed here except for supplied accessories are available separately. When connecting such

components, be sure to also refer to their documentation.

For specifications and other information on separately available components, contact your dealer.

Prevention of accidents caused by short-circuits

To prevent the risk of accidents caused by short-circuits, connect the power supply leads (red and yellow)

only after all other wiring has been completed, and only with the ignition key in the OFF position.

Otherwise, accidental short-circuiting can lead to electric shock and to serious damage.

When a fuse has blown, check the wiring and locate the cause of the problem before replacing the fuse.

When replacing the fuse, be sure to use only a fuse of the same rating (ampere rating). Using a different

fuse or bridging the contacts with wire is highly dangerous and can lead to serious damage.

Make sure to connect all of the following leads.

Otherwise there is a risk of electric shock, damage to the equipment, or malfunction.

•Connect purple/white lead to back lamp lead of car.

•Connect orange/white lead to illumination signal lead of car.

•Connect light green lead to parking brake switch lead of car.

•Connect yellow lead to battery power supply of car.

•Connect red lead to accessory power supply of car.

•Connect black lead to metal point on car chassis.

* Do not mix up the yellow and red leads, as this will cause the memory contents to be lost.

Observe the following precautions.

Otherwise there is a risk of electric shock, damage to the equipment, or malfunction.

•Cover unused connectors with electrician’s tape to prevent accidental contact.

•Route FM/AM antenna cable, TV antenna cable, bus cable, RCA interconnects, and power supply leads

as far apart from each other as possible, to prevent noise interference.

•Always grasp the connector and do not pull the cable when disconnecting the bus cable or other cables.

Otherwise the cable may become detached.

Note

Install the TV antennas away from the FM/AM antenna.

Memory hold connection

When the yellow power input lead is connected, power will always be supplied to the memory circuit

even when the ignition key is turned off.

7

8

6

Connecting without Sony BUS system

10

VIDEO2 IN

BUS AUDIO IN

VIDEO OUT FRONTCONTROL

VIDEO OUT

TV main unit

Film antenna qf

To the commercially available

Back Camera or Navigation

System

Antenna input

cable qg

TV

antenna

amplifier

unit qd

Black

To a metal point of the car

To the +12 V power terminal which

is energized at all times

Yellow

Fuse (5A)

Purple/white

To the +12 V power terminal of the

back lamp lead of car

Orange/white

To the +12 V power terminal which is

energized in the accessory position of the

ignition key switch.

Be sure to connect the black ground lead

first.

Light green

To a car’s illumination signal *

2

Parking brake switch lead of car

Red

This terminal is not used in this case.

Yellow

Red

White

Yellow

Red

White

2 RCA interconnects (0.5m)

3 RCA interconnects (0.5 m)

Rear passeger TV

or monitor etc.

Connecting with Sony BUS system

To a metal point of the car

To the +12 V power terminal

which is energized in the

accessory position of the

ignition key switch.

Be sure to connect the black

ground lead first.

Sony BUS Master-unit (equipped

with the TV control function) *

1

*1Sony BUS Master-unit (equipped with the TV control

function) will come in 2005.

*2First connect the black ground lead, then connect the

orange/white striped, yellow and red power input leads.

Tap 7

Tap 7

RCA interconnects (not supplied)

Black

Red

12

Removing the bracket

Before installing the unit, remove the bracket from the unit.

1

Insert two release keys qa together into the unit

and the bracket 8 until they click.

2

Pull down the bracket 8, then pull up the unit to

separate.

m

,

8

qa

Face the hook

inwards.

Film antenna qf

TV main unit

TV

antenna

amplifier

unit qd

Black

Red

VIDEO OUT

RCA interconnects (not supplied)

VIDEO2 IN

This terminal is not used in this case.

Black

Yellow Fuse (5A)

Purple/white

Orange/white

Light green

Red

*1 An adaptor (optional) may be necessary for your car and

car audio system. In such case, consult your dealer.

*2First connect the black ground lead, then connect the

orange/white striped, yellow and red power input leads.

Antenna connector *

Tap 7

Tap 7 Parking brake switch lead of car

To the commercially avilable

Back Camera or Navigation

System

Antenna input

cable qg

To a metal point of the car

To the +12 V power

terminal which is

energized in the

accessory position of the

ignition key switch.

Be sure to connect the

black ground lead first.

Car audio, rear

passenger TV or

monitor etc.

DVD player

etc.

Genuine Car

audio

1

2

from a car antenna *

1

To a metal point of the car

To the +12 V power terminal which

is energized at all times

To the +12 V power terminal of the

back lamp lead of car

To a car’s illumination signal *

To the +12 V power terminal which is

energized in the accessory position of the

ignition key switch.

Be sure to connect the black ground lead

first.

XTL-W7000

9

2 Installing the Main Unit

Installation angle

The unit should be installed within an

angle of 30 degrees from horizontal. If

this angle is exceeded, the monitor may

not open up or retract properly.

Note

Keep the units and connection cables

apart.

The TV main unit and the amplifier unit

qd should not be in close proximity.

After all connections are made, install the main unit to the

dashboard.

Before installation

This unit is designed to be completely safe, but if not installed

correctly, it can cause accidents. Be sure to verify the following

points before installation.

Install the main unit to the in-dash location, and the amplifier unit

under the navigator’s seat, etc.

• If the monitor in the opened position is close to a airconditioning outlet, the outlet should be closed.

• Install the unit so that the monitor when opened up will not

block access to the hazard switch or other important controls.

•Do not install the unit (monitor) in locations which may be

subject to excessively low or high temperatures. (Otherwise the

unit may be deformed and the LCD may be damaged.)

Exposure to direct sunlight can also lead to high temperatures

and should be avoided.

Selecting the installation location

Set the ignition key to OFF or remove it.

1

Place the units in their intended mounting

2

locations to check the cable length and monitor

installation conditions.

Installation procedure precautions

• Perform the installation carefully. Dropping the unit or

otherwise subjecting it to strong impact or force may deform

the chassis, resulting in failure of the monitor loading

mechanism or other defects.

•To allow for proper opening and closing of the monitor, there

must be a clearance of at least 167 mm between the closest

position of the shift lever and the mounting surface for the unit.

Shift lever

• In some cases, the shift lever may touch the monitor when

moved to a certain position. Make sure that there is no

obstruction to driving operations.

•When installing this unit together with other car audio

equipment (single DIN slot size) in a stacked configuration,

install the TV main unit on top.

NNTT

N T/N T/N T/NT

At least 167 mm

from mounting

surface

11

7

XTL-W7000

Installation procedure

Mounting example

When installing this unit, be sure to close the monitor of the unit.

If the monitor is opened while installing and given too much

force, it may cause a malfunction.

1

8

182

mm

53 m

m

2

Claws

3

Dashboard

8

9

Fire wall

q;

qs

Notes

• Do not press the front panel buttons of

the unit during installation and do not

apply strong force.

• Do not place any objects on top of the

unit.

• If a salient of the genuine bracket

touches the unit due to its figure, and

makes attachment hard, process the

bracket by scraping the salient off.

Toyota cars (illustration shows an example for a Toyota car)

Align the brackets of the factory-installed car stereo with the

mounting holes marked “T” on the side of the TV main unit, and

use the supplied screws to fasten the brackets. For Toyota cars,

the supplied screws 5 should be used.

Nissan cars

Align the brackets of the factory-installed car stereo with the

mounting holes marked “N” on the side of the TV main unit, and

use the supplied pan-head screws 5 to fasten the brackets.

* Be sure to use only the supplied pan-head screws 5 for

installation. If any other screws are used, make sure they

conform to the requirements shown below.

Using longer screws can cause internal damage to the unit.

Damage can also occur if the screws are used directly on the

unit without the brackets of the factory-installed car stereo.

Sony Bus DVD

Master unit

(optional)

Sony Bus DVD

Master unit

(optional)

6 mm

5

XTL-W7000

Screws of factoryinstalled car stereo

bracket

5

XTL-W7000

Screws of factoryinstalled car stereo

bracket

5 mm

Bracket of

factory-installed

car stereo

Bracket of

factory-installed

car stereo

3 Mounting the TV antenna

Mount the film antenna qf to the car and connect the TV main unit.

For directions on connecting the TV main unit, see also “1 Car Systems Connections (complete

connection diagram)” on pages 8-10.

Note

Once you have mounted the film

antenna, do not attempt to remove it and

attach it again, as the adhesive will be

considerably weakened. Be sure to

temporarily fasten the cable and antenna

in place and check that the cable has

sufficient play before permanently

attaching.

Note

• During the mounting procedure, it will

be necessary to remove the front pillar

molding to [attach a ground wire].

When performing the installation

yourself, if you decide it is too difficult

to remove the front pillar molding,

please contact your dealer for

assistance. (Note that your dealer may

charge a fee for their assistance.)

Note

Mount the film antennas to the inside of

the front window. Do not mount the

antennas anywhere other than the

location described here.

Before attaching

Using the supplied cleaning cloth w; to

wipe away any oil, wax, or dust tat may

be on the window.

Before mounting

• It may not be possible to mount the antenna on some cars.

-In cars with glass that does not transmit radio waves

(infrared reflecting glass, insulated glass, glass that is opaque

to electromagnetic waves, etc.), the signal reception will be

extremely poor.

- The antenna cannot be mounted in cars which have airbags

in the front pillars.

• Mount the antenna to the front window, in the specified

location and according to the specified dimensions.

- The supplied film antenna is designed for attaching only to

the front window. If attached to the rear window or

elsewhere in the car, the signal reception may be extremely

poor.

Required items

Have the following items handy before beginning the mounting

procedure.

•Tools (Philips screwdriver, etc.)

• Cellophane tape

• Scissors

• Spray bottle (fill with 500 ml water and one or two drops of

detergent)

• Paper towels

Mounting position

Installation complete

Front pillar Front pillar

13

14

Film antenna mounting procedure

Check the film antenna qf mounting position.

1

1 Align the film antenna power supply point with the lower

edge of the window’s ceramic line and fasten temporarily

in place with cellophane tape.

Do not remove the adhesive backing from the antenna yet.

The figure below shows the results of this step, for the left

antenna. Temporarily position the right antenna in the

same manner.

About 120 mm

Align the

upper edge of

the antenna

with this line.

2 Mark the left and right sides of the film antenna, using

cellophane tape, etc.

Power supply point

Temporary fastener

(cellophane tape, etc.)

marking (cellophane tape, etc.)

Ceramic line

Antenna

input

cable qg

Film antenna

(left) qf

Notes

• The molding on the front pillar will be

Film antenna

TV

(right) qf

TV antenna

amplifier unit qd

Antenna

input cable

qg

15

fastened in place with clips or screws.

When removing it, take care not to

damage or deform it.

• When performing the installation

yourself, if you decide it is too difficult

to remove the front pillar molding,

please contact your dealer for

assistance. (Note that your dealer may

charge a fee for their assistance.)

16

Remove the inner molding from the front pillars on

2

both sides of the front window.

Front pillar

(The above figure shows an example of a car, such as a sedan

or SUV, which as a handle mounted on the front pillar.)

8

Before attaching

18

4 Use the supplied squeegee qj to make sure the film

antenna is well attached to the window.

•Hold the antenna so it does not move while using the

squeegee.

•Work from the center of the antenna outward.

•Work the squeegee along the length of the antenna,

pushing out air bubbles to obtain a good seal.

•Do not rub the antenna too hard.

5 Use paper towels to wipe away the excess detergent

solution and dry the antenna well.

We recommend you let the antenna dry for 3-4 hours.

Do not try to rush the drying process by using a hair dryer

or other heater. Doing so may damage the film antenna.

4

Attach the power supply terminal to the film

antenna qf.

1 Remove the power supply point protective sheet from the

film antenna.

2 Attach the antenna input cable qg to the film antenna

power supply terminals.

•The same type of cable is used for both the left and right

antennas.

•Temporarily fastening the cable near the ground

connection with cellophane tape will make the

procedure easier.

Note

Make sure that the film antenna is

completely dry before continuing with

the mounting procedure. Continuing

before the antenna is dry may cause it to

come off the window.

The color of the protective sheet is used

to distinguish the left and right

antennas.

The right antenna (as seen from inside

the car) has a blue protective sheet, and

the left antenna has a white protective

sheet. Take care to mount the antennas

on the proper side of the car.

Connecting to the power supply

terminals

Align the protrusions on the power

supply terminals with the arrows v on

the film antenna and fasten in place.

Squeegee qj

Protective sheet

Power supply point

Peel off the

protective sheet

Temporary fastening

(cellophane tape, etc.)

Power supply point

Peel off the

protective sheet

Temporary fastening

(cellophane tape, etc.)

Alignment marks

(protrusions)

Power supply

terminals

Alignment

marks (arrows

v)

20

3 Route the antenna input cable, using the supplied antenna

cord clamp ql to hold it in place.

Rout the cable so that it will be completely covered when

the front pillar molding is replaced.

6

Mount the TV antenna amplifier unit qd.

1 Mount the TV antenna amplifier unit.

Mount the unit near the floor in the foot area in front of

the passenger’s seat, in a location where the cables will

reach the expansion unit. (Be sure to wipe away any dirt

on the mounting surface.)

Important note

Use tape or other fasteners to route the

cables such that they cannot interfere

with vehicle operation. Do not wrap the

cables around the steering column, gear

shift lever, brake pedal, etc.

Important note

It would be extremely dangerous if the

TV antenna amplifier unit were to get

stuck underneath the brake pedal. Be

sure to mount the amplifier on the

passenger’s side.

Antenna cord clamp ql

Antenna cord clamp ql

Antenna input

cable (right) qg

Antenna input cable (left) qg

Antenna

cord clamp

ql

IMPORTANT CAUTION!

Do not route the cable

near the pedals!

TV antenna

amplifier unit qd

Peel off the

protective sheet

TV antenna

amplifier unit qd

Fold back

the floor

mat

• Remove the film antenna, which you

previously fastened temporarily in

place, before beginning these steps.

• Cover the dashboard with a cloth to

protect it from the water and detergent.

• Clean the front window well to remove

any dirt, oil, or anti-fogging agent

before beginning these steps.

When attaching the film antenna

• Position the antenna vertically by

aligning the upper edge of the antenna

with the lower edge of the ceramic line.

Position it horizontally by aligning the

edges with the marking (cellophane

tape, etc.) that you previously placed

on the window.

• Do not let the front window get dry as

you are working. Spray it again with

the detergent solution as needed.

• Until the front window dries, you can

slide the antenna to adjust its position.

• When you have the antenna positioned

where you want it, remove the

markings.

Attach film antenna qf.

3

1 Using a spray bottle, wet the inside of the front window

well with a mild detergent solution. The optimal solution

is 500 ml of water with one or two drops of detergent.

(Pure water will not work well for making fine

adjustments.)

spray bottle

marking (cellophane

tape, etc.)

2 Remove the clear backing from the film antenna. Using

the spray bottle, wet the exposed surface well with the

mild detergent solution.

•Grasp the peel-off tab and peel the clear backing off

slowly.

•Do not remove the protective sheet from the other side

(the side that faces the inside of the car) yet. You will

remove that sheet in step 4.

•Take care not to get dirt or fingerprints on the exposed

surface of the film antenna.

Peel-off tab

3 Stick the film antenna to the front window.

Align the upper edge of the

antenna with this line.

XTL-W7000

Notes

• Pull the roof lining down slightly and

thread the cable under it.

•Take care not to pull too hard on the

lining and bend it out of shape.

• Perform this step while holding on to

the power supply point to avoid

putting stress on that point.

• Route the antenna input cable carefully

to avoid pulling excessively on,

applying stress to, or kinking the cable.

Notes

• Carefully wipe away any dirt on the

attachment surface.

• Be sure to stick the grounding tape

completely to a flat, metal part of the

car body. Do not apply the grounding

tape to a place that is not flat, or over a

clip or screw hole. Do not scrape off

the finish on the car body.

3 Pass the antenna input cable qg through the roof lining

(inner roof panel).

Route the antenna input cable qg.

5

1 Apply the grounding tape qh to the car body.

Apply the grounding tape to the metal of the car body, in a

position where it can contact the ground contact on the

antenna input cable.

2 Affix the ground contact on the antenna input cable to the

grounding tape qh.

Peel off the protective sheet from the ground contact and

stick it completely to the grounding tape. Make sure that

no portion of the ground contact protrudes beyond the

grounding tape, and that there is no part of the ground

contact which is not firmly stuck to the grounding tape.

Ground contact

(peel off the

protective sheet)

Marking

(cellophane

tape, etc.)

roof lining

Grounding tape qh (peel off

the protective sheet)

17

19

9

XTL-W7000

2 Connect the grounding cable from the TV antenna

amplifier unit to a metal part of the car body where it can

make a good ground contact.

3 Connect the antenna input cables to the TV antenna

amplifier unit according to the markings on the amplifier

(1, 2, 3, 4, TV).

Connect the TV main unit and the car’s ACC power

7

supply.

1 Connect the antenna terminal (L-type) on the TV antenna

amplifier unit qd to the TV main unit.

2 Connect the accessory power supply terminal to the car’s

ACC power supply.

• Connect the ACC power supply cord from the TV main

unit to the spare contact.

• Do not connect directly to the battery.

Replace the front pillar molding.

8

Fasten cords out of the way.

9

Front pillar Front pillar

Antenna

input

cable

(left) qg

Vehicle ACC power supply

Film antenna

(left) qf

Antenna contacts

Ground contact

Film antenna

(right) qf

TV

Spare contact

TV antenna

amplifier unit qd

Antenna

input

cable

(right) qg

ENTER

MENU

BACK

MUTING

OFF

CH+

MENU

SEEK

–

ENTER

CH

–

BACK

WIDE DSPL

PICTURE

123

456

789

10 11 12

Changing the transmitted frequency on

TV/VIDEO

the TV unit

SEEK+

You can change the transmitted frequency on the built-in RF

V/v

modulator of the TV unit. The default setting is “88.3MHz”.

Press MENU.

1

Press V or v to select , then press ENTER.

2

VOL

Press V or v to select “RF FREQUENCY”, then press

3

ENTER.

Press V or v to adjust the transmitted frequency.

4

Adjust the frequency range from “88.3MHz” to “89.9MHz”.

Press ENTER.

5

Press MENU.

6

Changing the output level on the TV unit

You can change the output level of the TV unit according to the

input level of the FM tuner of a car audio. The default setting is

“MID”.

Press MENU.

1

Press V or v to select , then press ENTER.

2

Press V or v to select “RF LEVEL”, then press ENTER.

3

Press V or v to select the output level.

4

You can select from “HIGH”, “MID” or “LOW”.

Press ENTER.

5

Press MENU.

6

4 After Installation and Connections

Start the car’s engine.

1

Verify that the brake lights, other lights, horn, turn

2

indicators, and all other electrical parts operate

Note

To avoid the possibility of damage, you

should not use a needle or push the

button too strongly.

normally.

Use a ball-point pen or similar to push the Reset

3

button on the unit.

When you press the Reset button, the system becomes

operative.

Reset button

21

22

10

23

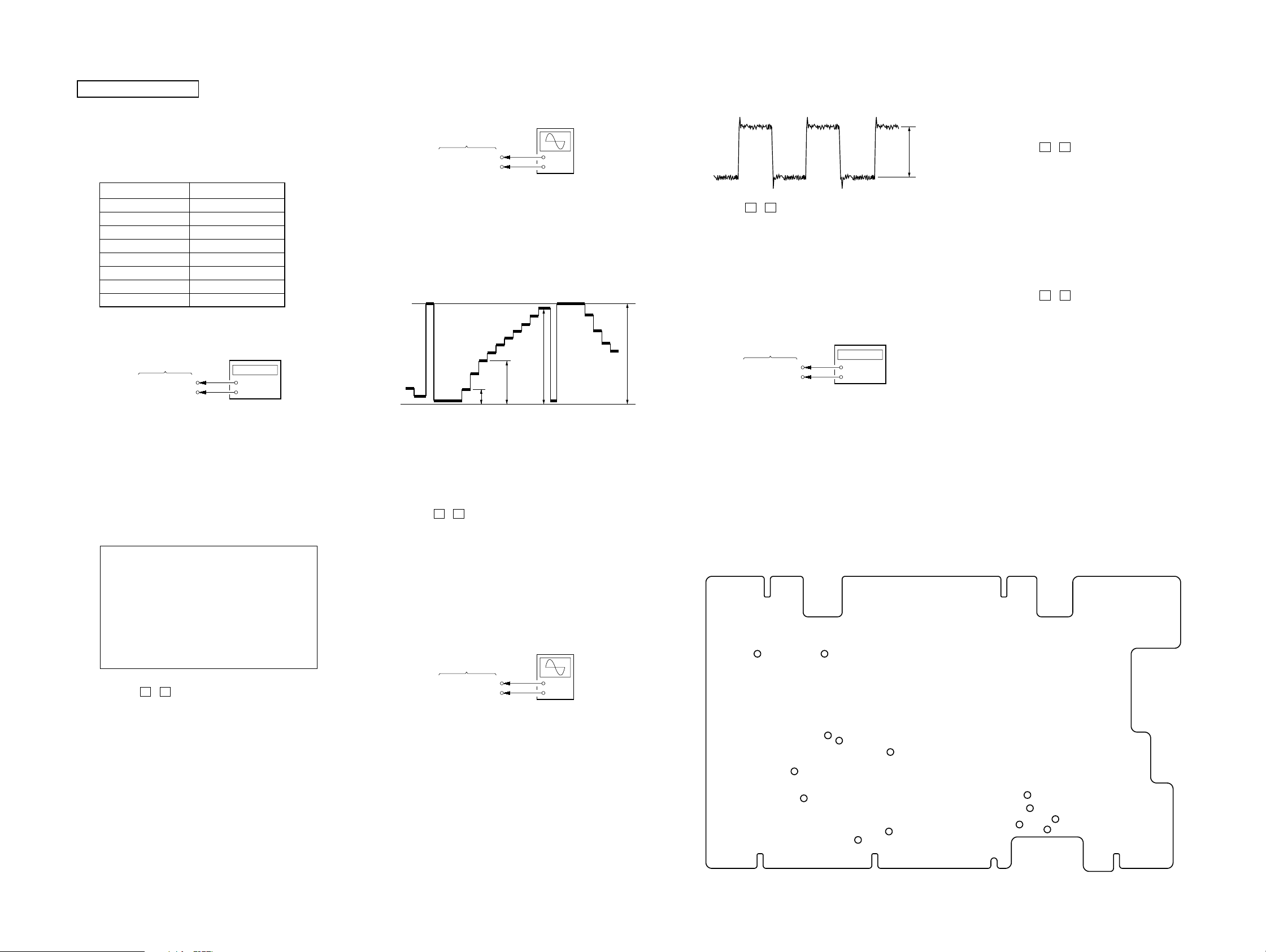

• This set can be disassembled in the order shown below.

SET

3-2. FRONT PANEL ASSY

(Page 12)

3-5. BRACKET (SLIDER)

(Page 14)

3-8. BRACKET (MOTOR S) ASSY

(Page 16)

3-9. MONITOR BLOCK

(Page 16)

3-7. BRACKET (MOTOR) ASSY

(Page 15)

3-10. GEAR (1), GEAR (4)

(Page 17)

3-11. MECHANICAL COMPLETE ASSY (DB-M01)

(Page 17)

3-12. LIQUID CRYSTAL DISPLAY (LCD1)

(Page 18)

3-6. SLIDER BOARD

(Page 15)

3-4. PARTITION

(Page 13)

3-13. MAIN BOARD

(Page 18)

3-3. CASE (LOWER) BLOCK

(Page 12)

3-1. DISASSEMBLY FLOW

XTL-W7000

SECTION 3

DISASSEMBLY

11

XTL-W7000

Note: Follow the disassembly procedure in the numerical order given.

3-2. FRONT PANEL ASSY

3

2

screw (EG grip)

5

connector

(CN1103)

1

4

claw

claw

screw

(PTT2.6

×

6)

6

connector

(CN1104)

3

claw

7

front panel assy

3-3. CASE (LOWER) BLOCK

4

flexible board (50P)

(CN1851)

2

1

4

claw

claw

screw

(PTT2.6

2

screw (EG grip)

4

claw

3

2

claw

×

6)

12

1

two screws

(PTT2.6

×

6)

1

screw

5

case (lower) block

1

two screws

(PTT2.6

(PTT2.6

×

6)

×

6)

3-4. PARTITION

)

1

screw (M1.7)

2

4

XTL-W7000

partition

NOTE WHEN INSTALLING THE FLEXIBLE (50P) BOARD

Note: Align the flexible (50P) board with the mark 1 on the partition,

and attach the sheet (FPC) to the location of 90 mm from the leading

end of flexible (50P) board, aligning with the mark 2 on the partition,

as shown in the following figure.

flexible (50P) board

sheet (FPC)

mark 2

3

sheet (FPC

90mm

partition

mark 2

mark 1

13

XTL-W7000

3-5. BRACKET (SLIDER)

B

monitor block

A

1

two screws

(M2)

2

Open the bracket (slider)

in the direction of arrow A.

3

Rotate the worm gear in the direction of arrow B.

for pulling the monitor block.

Note: Don't touch except the gray portion of worm gear.

5

bracket (slider)

4

two convex portions

14

RS board

Note: Never remove RS Board as the position of gear

has been adjusted in the production.

3-6. SLIDER BOARD

d

3

two connectors

(CN3, CN5)

4

screw (M2 × 3)

2

flexible (50P) board

(CN1)

3

connector

(CN6)

1

4

screw (M2 × 3)

5

SLIDER board

3

two connectors

(CN4, CN7)

XTL-W7000

flexible (32P) boar

(CN2)

3-7. BRACKET (MOTOR) ASSY

8

Rotate and remove the bracket (motor) assy block.

5

special head screw

(M2 )

qa

bracket (motor) assy

6

tapping screw

RS board

1

stopper washer (2.6 × 4.5)

3

stopper washer (2.6 × 4)

4

gear (worm wheel)

9

serration screw

×

3)

(M2

2

gear (1)

0

spacer (PWB)

RS board

7

Loosen the special head screw

(M2 ).

Note: Never remove RS Board

as the position of gear has been adjusted

in the production.

15

XTL-W7000

)

3-8. BRACKET (MOTOR S) ASSY

NOTE WHEN INST ALLING

THE BRACKET (R THRUST)

mark

bracket (motor S) assy

7

screw (M2)

9

screw

(M1.7

q;

bracket

(R thrust)

5

tension coil

spring (moniter)

×

2.5)

3

stopper washer (2.6 × 4)

4

gear (wheel S)

8

bracket (motor S) assy

1

stopper washer (2.6 × 4.5)

2

gear (1 S)

bracket (R thrust)

Note: When installing the bracket (R thrust),

no gap must be made at the

portion of the gear (worm).

3-9. MONITOR BLOCK

3

screw (M1.4 × 3.5)

gear (worm)

6

@

mark

5

stopper washer (2.6 × 4.5)

6

gear(1 S)

ring

(spring)

8

two tension coil springs (GT)

16

7

4

stopper (R)

9

monitor block

1

stopper (L)

2

screw (M1.4 × 3.5

y

3-10. GEAR (1), GEAR (4)

Note 1: For the gear (1) and gear (4), there is no problem whichever may be removed first.

3

stopper washer (2.6 × 4)

4

gear (4)

XTL-W7000

1

stopper washer (2.6 × 4.5)

2

gear (1)

Note 2: When the gear (1) or gear (4) is removed,

the monitor section will be folded abruptly

by a spring force, thus requiring care for handling.

3-11. MECHANICAL COMPLETE ASSY (DB-M01)

6

three screws

(EG grip)

3

4

two claws

three claws

7

monitor section

6

three screws

(EG grip)

1

flexible (32P) board

(CN2)

8

mechanical complete ass

(DB-M01)

2

two loose stopper screws

(M2)

4

three claws

5

cover (top) sub assy

17

XTL-W7000

)

)

s

e

3-12. LIQUID CRYSTAL DISPLAY (LCD1)

9

holder (upper)

q;

liquid crystal display panel

(LCD1)

4

connector

(CN601)

8

three screws

(P2.6 × 6)

3

7

holder (lower)

LCD flexible board

(CN901)

1

flexible (32P) board

(CN101)

2

flexible flat (10core) cabl

(CN821)

5

Remove three claw

from slits.

5

Remove two claws

from slits.

6

MONITOR board

3-13. MAIN BOARD

0

four ground point screws

(PTT2.6

×

6)

2

connection cord (camera)

(CN1101)

qa

qs

insulating sheet (main)

MAIN board

1

screw

(PTT2.6

5

screw

(PTT2.6 × 6)

claw

3

screw

(PTT2.6

×

6)

4

connection cord (RCA)

(CN1102, CN1501, CN1502)

6

connection cord (SONY bus

(CN1601)

8

connection cord (ANT-out

(CN1402)

×

6)

18

qd

case (lower)

9

two screws

(PTT2.6

7

screw

(PTT2.6

×

6)

×

6)

SECTION 4

TEST MODE

XTL-W7000

Note: To perform the Test Mode, remote commander (RM-X701) is

requisite.

1. ENTERING THE TEST MODE

Procedure:

1. Apply the voltage of 14.4 V to the ACC and BACKUP cord.

2. While pressing the [CUSTOM] button, press the [RESET]

button. (Hold the [CUSTOM] button press)

3. Release the [RESET] button and after tw o seconds, release the

[CUSTOM] button.

4. Press the [OPEN/CLOSE] button to open the monitor and

display as following figure (top menu).

TEST

1 ENGINEER

2 FACTORY MEASURE

3 FACTORY CHECK

SYS VERx.x.xx OSDVERx.x.xx

5. From the top menu screen, press the [1] button on the remote

commander to display as following figure (ENGINEER menu).

TEST

1 SYSTEM

2 TV

3 MECHA

4 MONITOR1

5 MONITOR2

6 MONITOR3

7 MONITOR INIT

8 DIMMER INIT

6. To back to the top menu screen, press the [BACK] button on

the remote commander.

Note: The items of “2. FACTORY MEASURE” and “3. FACTORY

CHECK” in the top menu are not used in servicing.

2. RELEASING THE TEST MODE

Procedure 1:

Press the [OFF] button on the remote commander to setting data is

saved.

Procedure 2:

Press the [RESET] button: Setting data is not saved.

3. OPERATION OF EACH ITEMS

This mode is used in order to perform adjustment in connection

with the whole set.

3-1. SYSTEM Mode

1. In the ENGINEER menu screen, press the [1] button on the

remote commander to enter the SYSTEM mode and display

as following figure.

TEST SYSTEM

SYSTEM INIT

PAR ON ATT *** DIML 61

REV OFF N/T 10V DIMM 51

ILL OFF DIMH 40

2. Press the V / v button on the remote commander to select

the item. And press the [VOL ---]/[VOL +] button to change

the value.

3. If initialize all values, select the “SYSTEM INIT” and press

the [ENTER] button on the remote commander.

4. To save the data and release the Test Mode, press the [BACK]

button and press the [OFF] button on the remote commander

Item in the SYSTEM Mode:

Item Contents

SYSTEM INT

PAR

REV

ILL

ATT Not used

N/P Judgment value setting of NTSC/PAL

DIML

DIMM

DIMH

Initialize the preset data, PAL system and security

code

PARKING terminal setting

ON : Parking position

OFF : Release the parking position

REVERSE terminal setting

ON : Reverse position

OFF : Release the reverse position

ILLUMINATION terminal setting

ON : Illumination on

OFF : Illumination off

DIMMER LOW level setting (000 to 255)

Initial value: 61 (no change)

DIMMER MID level setting (000 to 255)

Initial value: 51 (no change)

DIMMER HIGH level setting (000 to 255)

Initial value: 40 (no change)

3-2. TV Mode

Not used in servicing.

19

XTL-W7000

3-3. MECHA Mode

1. In the ENGINEER menu screen, press the [3] button on the

remote commander to enter the MECHA mode and display as

following figure (MECHA mode menu).

TEST MECHA

1 AGING ROOP

2 TILT AGING

3 FACTORY AGING

4 ERROR CHECK

5 ERROR INIT

2. To select the item in MECHA mode menu, press the

corresponding number button to menu item number.

3-3-1. AGING ROOP mode

In the MECHA mode menu screen, press the [1] button on the remote

commander to start the AGING ROOP mode.

Aging flow:

Start

Open (slide)

3-3-2. TILT AGING mode

In the MECHA mode menu screen, press the [2] button on the remote

commander to start the TILT AGING mode.

Aging flow:

Start

Angle=110

Angle=20

°

°

Operation:

[BACK] button : Stop aging.

Back to the menu screen, when this button is

pressed during the aging stop.

[ENTER] button : Restart aging.

Display:

TEST MECHA

TILT AGING

CYCLE *****

TEMP ##

ERROR $$

Angle=110

Angle=0

Close (slide)

°

°

Operation:

[BACK] button : Stop aging.

Back to the menu screen, when this button is

pressed during the aging stop.

[ENTER] button : Restart aging.

Display:

TEST MECHA

AGING ROOP

CYCLE *****

TEMP ##

ERROR $$

CYCLE : Aging number (00000 to 99999)

TEMP : Temperature of motor section (00h to FFh)

ERROR : Error code. It is displayed when error occurred. (Refer

to the “3-3-4. ERROR CHECK” for error code)

CYCLE : Aging number (00000 to 99999)

TEMP : Temperature of motor section (00h to FFh)

ERROR : Error code. It is displayed when error occurred. (Refer

to the “3-3-3. ERROR CHECK” for error code)

3-3-3. FACTORY AGING mode

Not used in servicing.

3-3-4. ERROR CODE display

In the MECHA mode menu screen, press the [4] button on the remote

commander to display ERROR CODE as following figure.

TEST MECHA

ERROR CODE

01:**02:**03:**04:**05:**

06:**07:**08:**09:**10:**

11:**12:**13:**14:**15:**

16:**17:**18:**19:**20:**

In this mode, It displays error cord or temperature until 20 counts

when error occurred. (No.1 is latest error)

These error history are not erased, if press the [RESET] button.

20

XTL-W7000

Operation:

[DSLP] button : Switch the displays to “ERROR CORD” and

“ERROR TEMP” (temperature when error

occurred (hexadecimal number)).

[BACK] button : Back to the menu screen.

Error cord:

Error code Detail of error

00 No error occur

01 Slide open error

02 Angle open error

03 Angle close error

04 Slide close error

05 Slide adjustment error

06 Angle adjustment error

07 Tilt operation error

08

09

Temperature error

(05h (–40°C) or less, FBh (+140°C) and over)

Time over of open/close operation

(over 30 seconds)

3-3-5. ERROR INIT mode

This mode is used to initialize the error history.

In the MECHA mode menu screen, press the [5] button on the remote

commander to start initialize the error history.

3-4. MONITOR1 Mode

Note 1:This mode is used to adjustment of the IC401 on MONITOR board.

(refer to “Section 4 ELECTRICAL ADJUSTMENTS” for details

of adjustments)

Note 2:No change input color system (NTSC/PAL) if press the [BACK] or

[OFF] button on the remote commander to data sav e and releasing

this mode. If color sysem is changed or no signal inputed, fault

data is written.

Factory default value of each items:

Display Setting Item Value

BRT Bright 90

CNT Contrast 154

COL Color gain 133

HUE Hue 125

G1 Gamma 1 117

G2 Gamma 2 80

WPL White peak limiter 125

BPL Black limiter 65

COM V COM AMP 71

VDN V COM DC (for NTSC) 83

SHP Sharpness 88

YGA Y gain 122

VCO VCO free run 128

CEN H. CENT 16

VDP V COM DC (for PAL) 103

3-5. MONITOR2 Mode

Note 1:This mode is used to adjustment of the IC401 on MONITOR board.

(refer to “Section 4 ELECTRICAL ADJUSTMENTS” for details

of adjustments)

Note 2:No change input color system (NTSC/PAL) if press the [BACK] or

[OFF] button on the remote commander to data sa ve and releasing

this mode. If color sysem is changed or no signal inputed, fault

data is written.

In the ENGINEER menu screen, press the [5] button on the remote

commander to enter the MONITOR2 mode and display as following

figure.

TEST MONITOR2

In the ENGINEER menu screen, press the [4] button on the remote

commander to enter the MONITOR1 mode and display as following

figure.

TEST MONITOR1

BRT*** G1 *** COM*** VCO***

CNT*** G2 *** VDN*** CEN***

COL*** WPL*** SHP*** VDP***

HUE*** BPL*** YGA***

When enter this mode, it set the signal format system to NTSC

mode and selects the “VIDEO2” mode automatically.

All operations in this mode are performed using remote control.

The operation of each button in this mode are as following table.

Button Function

V / v Select the item

VOL –/+ Change the adjustment value of selected item

DISPLAY On/off switching of the OSD

BACK

Save the adjusted data, and back to the

ENGINEER menu screen

VDN*** RB *** RC *** VDP***

COM*** BB *** BC***

When enter this mode, it set the signal format system to NTSC

mode and selects the “VIDEO2” mode automatically.

All operations in this mode are performed using remote control.

The operation of each button in this mode are as following table.

Button Function

V / v Select the item

VOL –/+ Change the adjustment value of selected item

DISPLAY On/off switching of the OSD

BACK

Save the adjusted data, and back to the

ENGINEER menu screen

Factory default value of each items:

Display Setting Item Value

VDN V COM DC (for NTSC) 83

COM V COM AMP 71

RB Sub bright red 135

BB Sub bright blue 140

RC Sub contrast red 100

BC Sub contrast blue 180

VDP V COM DC (for PAL) 103

21

XTL-W7000

r

SECTION 5

ELECTRICAL ADJUSTMENTS

MAIN SECTION

VCO CENTER FREQUENCY ADJUSTMENT

Setting:

frequency counte

MAIN board

TP1003

TP1001 (GND)

Adjustment Location:

– MAIN Board (Component Side) –

CT1001

+

–

Procedure:

1. Connect the TP1002 to ground and enter the VCO adjustments

mode.

2. Connect a frequency counter to the TP1003 and TP1001

(GND) on the MAIN board.

3. Adjust the CT1001 on MAIN board so that the value of

frequency counter becomes as following specified value.

Specified value:

NTSC model : 15.734 kHz ±0.02 kHz

PAL model : 15.625 kHz ±0.02 kHz

– MAIN Board (Conductor Side) –

TP1001

TP1003

TP1002

22

XTL-W7000

r

TEST MONITOR1

BRT*** G1 *** COM*** VCO***

CNT*** G2 *** VDN*** CEN***

COL*** WPL*** SHP*** VDP***

HUE*** BPL*** YGA***

e

L

e

r

MONITOR SECTION

PRECAUTION

1. Set the test mode when performing adjustments of monitor

section. (Refer to “Section 4 TEST MODE” for the test mode)

2. Before adjustments, confirm that the voltage of each point on

the MONITOR board as following table are specified value.

Measuring point Specified value

TP201 5.03 V± 0.05 V

TP202 15.2 V ± 0.5 V

TP203 –14.40 V ± 0.5 V

TP204 5.50 V ± 0.05 V

TP205 7.8 V ± 0.1 V

TP929 5.40 V ± 0.05 V

TP931 5.00 V ± 0.05 V

TP822 5.03 V ± 0.05 V

1. VCO ADJUSTMENT

Setting:

frequency counte

MONITOR board

TP121

TP122 (GND)

Procedure:

1. Input 10 steps signal (NTSC, gray scale) from VIDEO 2 input

jack.

2. Connect a frequency counter to the TP121 and TP122 (GND)

on the MONITOR board.

3. Enter the test mode.

4. Press the [1] button on the remote commander to display

ENGINEER menu screen, and press the [4] button on the

remote commander to enter the MONITOR1 mode. (refer to

following figure)

+

–

2. CONTRAST ADJUSTMENTS

Setting:

oscilloscop

(DC range)

MONITOR board

TP926

TP912 (GNG)

Procedure:

1. Input 10 steps signal (NTSC, gray scale) from VIDEO 2 input

jack.

2. Connect an oscilloscope to the TP926 and TP912 (GND) on

the MONITOR board.

3. Enter the MONITOR1 mode in the test mode.

4. Confirm that the waveform of oscilloscope is as following

figure.

GND

Specified value:

BPL : 5.00 V ±0.03 V

G1 : 2.13 V ±0.03 V

BRT : 0.68 V ±0.03 V

CNT : 4.83 V ±0.03 V

5. Press the V / v button on the remote commander to select

each item, and adjust the each item values by pressing

the [VOL ---]/[VOL +] button on the remote commander so

that the waveform of the oscilloscope becomes as above

specified values.

6. Repeat about each item until all specified value becomes

specified value.

7. Press the [BACK] button to save the adjusted data.

+

–

CNTG1BRT

BP

4. Confirm that the waveform of oscilloscope is as following

figure.

COM

5. Press the V / v button on the remote commander several

times to select the “COM”.

6. Adjust the “COM” value by pressing the [VOL ---] / [VOL

+] button on the remote commander so that the value of

frequency counter becomes 5.56 V ±0.05 V.

7. Press the [BACK] button to save the COM level on the

waveform adjusted data.

4. SUB CARRIER CONFIRMATION

Setting:

frequency counte

MONITOR board

TP462

TP122 (GND)

Procedure:

1. Input NTSC color bar signal from VIDEO 2 input jack.

2. Connect a frequency counter to the TP462 and TP122 (GND)

on the MONITOR board.

3. Confirm that the value of frequency counter is 3.579545 MHz

±100 Hz.

4. Change the input signal to PAL color bar.

5. Confirm that the value of frequency counter is 4.433619 MHz

±100 Hz.

Connecting Location:

– MONITOR Board (Conductor Side) –

+

–

5. NTSC FLICKER ADJUSTMENT

Procedure:

1. Input color bar signal (NTSC, all white, 40%) from the VIDEO

2 input jack.

2. Enter the MONITOR2 mode in the test mode.

3. Press the V / v button on the remote commander several

times to select the “VDN”.

4. Adjust the “VDN” value by pressing the [VOL ---] / [VOL

+] button on the remote commander so that the flicker

becomes optimally.

5. Press the [BACK] button to save the adjusted data.

6. PAL FLICKER ADJUSTMENT

Procedure:

1. Input color bar signal (P AL, all white, 40%) from the VIDEO

2 input jack.

2. Enter the MONITOR2 mode in the test mode.

3. Press the V / v button on the remote commander several

times to select the “VDP”.

4. Adjust the “VDP” value by pressing the [VOL ---] / [VOL

+] button on the remote commander so that the flicker

becomes optimally.

5. Change the input signal to NTSC color bar.

6. Press the [BACK] button to save the adjusted data.

5. Press the V / v button on the remote commander several

times to select the “VCO”.

6. Adjust the VCO value by pressing the [VOL ---] / [VOL +] button

on the remote commander so that the value of frequency counter

becomes 15.734 kHz ±0.05 kHz.

7. Press the [BACK] button to save the adjusted data.

XTL-W7000

3. V-COM ADJUSTMENT

Setting:

MONITOR board

TP916

TP912 (GNG)

Procedure:

1. Input 10 steps signal (NTSC, gray scale) from VIDEO 2 input

jack.

2. Connect an oscilloscope to the TP916 and TP912 (GND) on

the MONITOR board.

3. Enter the MONITOR1 mode in the test mode.

oscilloscop

(DC range)

+

–

TP204

TP121

TP205TP201

TP203

TP202

TP822

TP462

TP822

TP929

TP926

TP931

TP912

TP916

2323

Loading...

Loading...