Sony XTL-6100MK2 Service manual

XTL-6100MK2

SERVICE MANUAL

VCA-114

RM-X86

XT-993V

This set consists of the following units.

•

MONITOR XVM-6100MK2

HIDEAWAY UNIT XT-993V

REMOTE COMMANDER RM-X86

ANTENNA VCA-114

AEP Model

UK Model

XVM-6100MK2

Monitor (XVM-6100MK2)

System Liquid crystal colour display

Display Transparent TN LCD panel

Drive system TFT active matrix system

Picture size 6 in.; 121.9 × 89.2 mm, 151 mm

(w × h, diagonally)

Picture segment

224,640 (w 960 × h 234)

Speaker type ø 5 cm dynamic speaker

Power requirements

12 V DC car battery

(negative earth)

Current drain

Approx. 0.7 A

Dimensions 162 × 129 × 31 mm (w × h × d)

Operating temperature

–10˚C ~ +60˚C

Mass Approx. 430 g

TV tuner unit (XT-993V)

Television system

CCIR B,G,I,D,K system

Colour system

TV: PAL

Video: PAL, NTSC

Channel converge

VHF: CCIR 2 CH ~ 12 CH

ITALY A CH ~ H2 CH

UHF: 21 CH ~ 69 CH (CCIR/ITALY/UK)

Power requirements

12 V DC car battery

(negative earth)

Current drain

Approx. 0.5 A

SPECIFICATIONS

Output terminals

Video output: RCA pin 1 Vp-p, 75 ohm

Audio output: RCA pin –10 dBs, 10 kohm

Monitor output: Square 16 -pin (exclusive)

Input terminals

Video input (2 system): RCA pin 1 Vp-p,

75 ohm

Audio input: RCA pin –10 dBs, 10 kohm

Aerial input (4 system): mini plug

Navigation input: Square 16 -pin (exclusive)

RCA pin:

Video 1 Vp-p, 75 ohm

Audio (monaural)

–10 dBs, 10 kohm

Dimensions 202 × 30 × 140 mm (w × h × d)

Mass Approx. 750 g

Wireless remote (RM-X86)

Power requirements

AA (R6) battery × 2

Operable range

Approx. 3 m

Dimensions 62 × 25 × 115 mm (w × h × d)

Mass Approx. 100 g

(including batteries)

– Continued on next page –

MOBILE COLOR TV

MICROFILM

1

TV aerial (VCA-114)

Cord 5 m, 75 ohm

Supplied accessories

Wireless remote RM-X86 (1)

Power input cord (1)

Monitor cable (1)

TV aerial VCA-114 (1)

Parts for installation and

connections (1 set)

Mounting kit (1 set)

Design and specifications are subject to change

without notice.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

TABLE OF CONTENTS

1. GENERAL

Location of Controls............................................................... 3

Getting Started........................................................................ 3

W a tching a TV Programme .................................................... 3

Watching a Video.................................................................... 4

Listening to the TV/video Sound

with the Picture Off ................................................................ 4

Adjusting the Picture .............................................................. 4

Adjusting the Screen Brightness ............................................ 5

Using the Navigation System ................................................. 5

Listening to the TV/video Sound while Using

the Navigation System............................................................ 5

Connections ............................................................................ 6

2. DISASSEMBLY

2-1. Rear Panel Assy ................................................................. 7

2-2. Main Board ........................................................................ 7

3. ELECTRICAL ADJUSTMENTS

Monitor Section ...................................................................... 8

Tuner Unit Section................................................................ 10

4. DIAGRAMS

4-1. Block Diagram

– Monitor Section (XVM-6100MK2) –........................... 13

4-2. Block Diagram

– Tuner Unit (Video) Section (XT-993V) – ..................... 14

4-3. Block Diagram

– Tuner Unit (Audio) Section (XT-993V) –..................... 15

4-4. Printed Wiring Board

– Monitor Section (XVM-6100MK2) –........................... 16

4-5. Schematic Diagram

– Monitor Section (1/2) (XVM-6100MK2) – .................. 18

4-6. Schematic Diagram

– Monitor Section (2/2) (XVM-6100MK2) – .................. 19

4-7. Printed Wiring Board

– Tuner Unit (XT-993V) – ............................................... 20

4-8. Schematic Diagram

– Tuner Unit (1/4) (XT-993V) –....................................... 22

4-9. Schematic Diagram

– Tuner Unit (2/4) (XT-993V) –....................................... 23

4-10. Schematic Diagram

– Tuner Unit (3/4) (XT-993V) –....................................... 24

4-11. Schematic Diagram

– Tuner Unit (4/4) (XT-993V) –....................................... 25

5. EXPLODED VIEW

5-1. Monitor Section (XVM-6100MK2)................................. 28

5-2. Tuner Unit Section (XT-993V) ........................................ 29

6. ELECTRICAL PARTS LIST ................................... 30

2

SECTION 1

GENERAL

This section is extracted

from instruction manual.

3

456

3

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. REAR PANEL ASSY

2

screws (2.6x6)

3

screws (2.6x6)

5

screws (M2x5),

tapping, P3

6

screws (M2x5), tapping, P3

1

screws (2.6x6)

4

stand bracket

0

rear panel assy (6100)

2-2. MAIN BOARD

2

screws (M2x5),

tapping, P3

8

CN601

3

screws (M2x5), tapping, P3

9

CN8

7

screws, precision (P2x3), type

1

screw (M2x5),

tapping, P3

switch

4

ground terminal

5

CN3

MAIN board

7

SECTION 3

ELECTRICAL ADJUSTMENTS

MONITOR SECTION

Equipment

Use the following test equipment for alignment.

• Oscilloscope dual trace, 10 MHz band or above with delay mode

(use a 10 to 1 probe unless otherwise instructed.)

• PAL color bar generator

• DC power supply

• Digital voltmeter

• XT-993V (Hideaway unit)

• Frequency counter

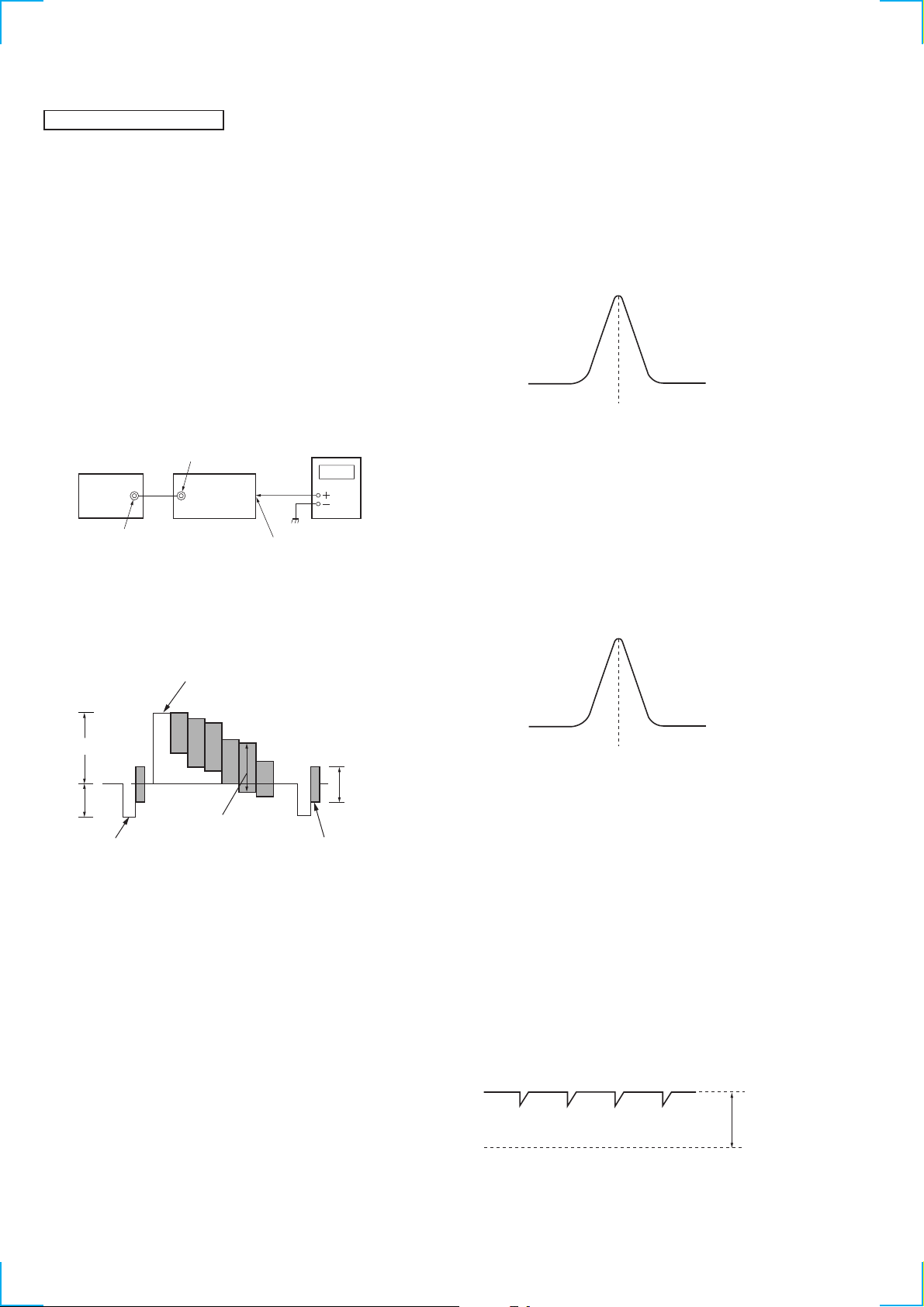

Equipment Connections

Make the test equipment connections as shown below (unless

instructed otherwise) and perform the alignment.

INPUT 1

color bar

generator

VIDEO output

(75 Ω)

VIDEO

XT-993V XVM-6100MK2

MONITOR OUT

V olta ge Adjustment

Setting :

DIMMER selector (S701) : HIGH

BRIGHT dial (RV702) : Max. (light)

VOL dial (RV301) : Max.

Procedure :

1. Input the color bar (chroma off) signal from P AL color bar generator and display on the monitor screen.

2. Connect the digital voltmeter to CL66 on the monitor main

board.

3. Adjust RV401 (+5V) so that the digital voltmeter reads 5 ± 0.1 V

DC.

4. Connect the digital voltmeter to CL86 on the monitor main

board.

5. Adjust RV601 (+9V) so that the digital voltmeter reads 8.5 ± 0.1 V

DC.

Connection points : Monitor main board

Alignment points : Monitor main board

RGB Adjustment

Procedure :

1. Input the color bar (chroma off) signal from P AL color bar generator and display on the monitor screen.

2. Connect the digital voltmeter to CL151 on the monitor main

board.

3. Adjust RV213 (OFFSET) so that the digital voltmeter r eads 2.3

± 0.1 V DC.

4. Connect the oscilloscope to CL42 on the monitor main board.

5. Adjust RV212 (COM CUT) so that the lower b lack level is 6.2

± 0.05 V DC.

6. Adjust RV208 (COM DRIVE) so that the upper 100% white

level is 9.2 ± 0.05 V DC.

7. Repeat steps 5 & 6 until the items in the standards are satisfied.

8. Connect the oscilloscope to CL41 of the monitor main board.

9. Adjust RV207 (R DRIVE) so that the lo wer black lev el is 6.2 ±

0.05 V DC.

10. Adjust RV202 (R CUT) so that the upper 100% white level is

9.2 ± 0.05 V DC.

11. Repeat steps 9 & 10 until the items in the standards are satisfied.

12. Connect the oscilloscope to CL43 of the monitor main board.

13. Adjust RV209 (B DRIVE) so that the upper 100% white level

is 6.1 ± 0.05 V DC.

14. Adjust RV204 (B CUT) so that the upper 100% white level is

9.1 ± 0.05 V DC.

15. Repeat steps 13 & 14 until the items in the standards are satisfied.

1

2

3

4

5

6

7

8

white level (1st step)

black level (8th step)

0 V

Connection points : Monitor main board

Alignment points : Monitor main board

8

V COM Adjustment

Procedure :

1. Connect the oscilloscope to CL44 on the monitor main board.

2. Adjust RV210 (V COM AMP) & RV211 (V COM BIAS) so

that the output waveform is within the standards.

3. Repeat step 2 until the standards are satisfied.

Standard values :

A : Adjust RV210 so the value is 4.9 ± 0.1 Vp-p.

B : Adjust RV211 so the value is 5.1 ± 0.1 V.

A

Alignment points : Monitor main board

– MONITOR MAIN BOARD (SIDE A) –

RV207

R DRIVE

ADJ

RV208

COM DRIVE

ADJ

RV213

OFFSET

ADJ

RV212

COM CUT

ADJ

B

0 V

RV209

B DRIVE ADJ

RV204

B CUT ADJ

RV210

V COM AMP ADJ

RV211

V COM BIAS ADJ

RV401

+5V ADJ

RV601

+9V ADJ

RV202

R CUT

ADJ

Connection points : Monitor main board

– MONITOR MAIN BOARD (SIDE B) –

CL42

CL151

CL44 CL43 CL41 CL66

9

TUNER UNIT SECTION

• Use the following equipment for the electrical adjustment.

Equipment

1 Monitor TV (XVM-6100MK2, etc.)

2 Spectrum analyzer

3 TV signal generator

4 Digital voltmeter

5 Oscilloscope

6 Audio analyzer

7 DC power supply

8 Frequency counter

Equipment Connections

Connect the test equipment as shown in the figure below (unless

otherwise instructed) and perform the adjustment.

TRAP Adjustment

Procedure:

1. With the Power off, input the output of TG to TP30 (with DC

cut by a capacitor (0.01 µF)).

2. Connect a spectrum analyzer to TP31 (with DC cut by a

capacitor (0.01 µF)).

3. Adjust T1 so that the waveform peak is 40.9 MHz ± 50 Hz.

4. Adjust T2 so that the waveform peak is 31.9 MHz ± 50 Hz.

5. After this adjustment, open TP30 and TP31. (Disconnect the

spectrum analyzer.)

DC

power supply

TV SG

RF out

ANT IN

set

POWER (CN4)

Setup during Adjustment

Use the video signal obtained from the TV signal generator as the

alignment signal, and check that this signal is within video output

signal standards.

white (approx. 100%)

0.7 V

0.3 V

red

horizontal sync. signal

Color bar signal from TV signal generator

burst signal (flat)

0.3 V

Connection points: Refer to page 12.

Adjustment points: Refer to page 12.

T1= 40.9 MHz

T2= 31.9 MHz

VCO Adjustment

Procedure:

1. No connection to ANT IN. (no signal state)

2. Connect a resistor (10 kΩ) between TP33 and +9 V (TP35).

3. Connect a spectrum analyzer to TP34 (with DC cut by a

capacitor (0.01 µF)).

4. Adjust T3 so that the waveform peak is 38.9 MHz ± 1 kHz.

5. After this adjustment, open TP34. (Disconnect the spectrum

analyzer.)

38.9 MHz

AGC Adjustment

Procedure:

1. Set the TV SYSTEM switch to 1.

2. Input a color bar signal of E8ch (196.25 MHz) and 66 dBµV

(75 Ω OPEN).

3. Connect the digital voltmeter to TP42.

4. Adjust VR1 so that reading on the digital voltmeter is

6.0 ± 0.1 V.

AFT Adjustment

Procedure:

1. Input a color bar signal of E8ch (196.25 MHz) and 74 dBµV

(75 Ω OPEN).

2. Connect the oscilloscope to TP102.

3. Adjust T3 untill the waveform on the oscilloscope is 2.5 Vp-p.

10

2.5 Vp-p

0 V

Note: Small peaks (dips) coming out from the top of the

waveform are unacceptable.

RGB Decoder FO Adjustment

Procedure:

1. Without INPUT1, INPUT2 inputs (no signal input mode), short

the jumper wire between TP100 and GND.

2. Connect a frequency counter to TP61.

3. Adjust VR6 so that reading on frequency counter is

4.433619 MHz ± 10 Hz.

4. Short the jumper wire between TP106 and GND.

5. Connect a frequency counter to TP61.

6. Confirm that reading on frequency counter is 3.579545 MHz ±

100 Hz.

7. After this adjustment, remove the jumper wires.

RGB Decoder Input Level Adjustment

Procedure:

1. Input signal : PAL EBU color bar (INPUT 1 VIDEO)

2. Adjust VR4 so that the white peak 1 (100% white) of

TP111 (B OUT) is at 1.0 Vp-p.

SYNC

124 3

TP111

white blue

DL AMP & DAT Adjustment

Procedure:

1. Adjust DAT so as to minimize the variation between the level

2 and the level 3 of TP111.

2. Adjust VR5 so that the blue level 4 is at 1.0 Vp-p.

3. Set the input to NTSC, and confirm that the blue level 4 is at

1.0 ± 0.1 Vp-p.

SYNC

124 3

TP111

white blue

11

Connection points and Adjustment points: Tuner main board

t

TP102

TP61

TP106

TP100

TP111

TP42

TP30

TP31

TP34

TP33

T1: TRAP Adjustment

T2: TRAP Adjustment

VR1: AGC Adjustmen

T3: VCO Adjustment

: AFT Adjustment

VR4: RGB Decoder

input Level Adjustment

VR5: DL AMP & DAT Adjustment

VR6: RGB Decoder FO Adjustment

12

Loading...

Loading...